Embodied Energy Coefficient Quantification and Implementation for an Energy-Conservative House in Thailand

Abstract

1. Introduction

- Develop a Thailand-specific embodied energy database for 36 key building materials using the IO-based method within a cradle-to-gate scope.

- Quantify the total energy consumption of a single-family detached house using the LCEA framework within a cradle-to-grave scope, encompassing six stages, i.e., initial, transportation, construction, operational, recurrent, and demolition. The Thailand-specific embodied energy database was applied to quantify both initial and recurrent embodied energy.

2. Methods and Data

2.1. Quantifying the Embodied Energy Coefficients of Thailand’s Building Materials

2.1.1. IO-Based Method for Quantifying Embodied Energy Coefficient

2.1.2. Establishment of Hybrid Embodied Energy Coefficients

2.2. Life-Cycle Energy Analysis of a Single-Family Detached House in Thailand

2.2.1. Single-Family Detached House: The Case Study

2.2.2. Initial Embodied Energy

2.2.3. Transportation Energy

2.2.4. Construction Energy

2.2.5. Recurrent Embodied Energy

2.2.6. Operational Energy

2.2.7. Demolition Energy

2.2.8. Total Energy Consumption

3. Results

3.1. Embodied Energy Coefficient Quantification

3.2. Life-Cycle Energy Analysis of the Case-Study House

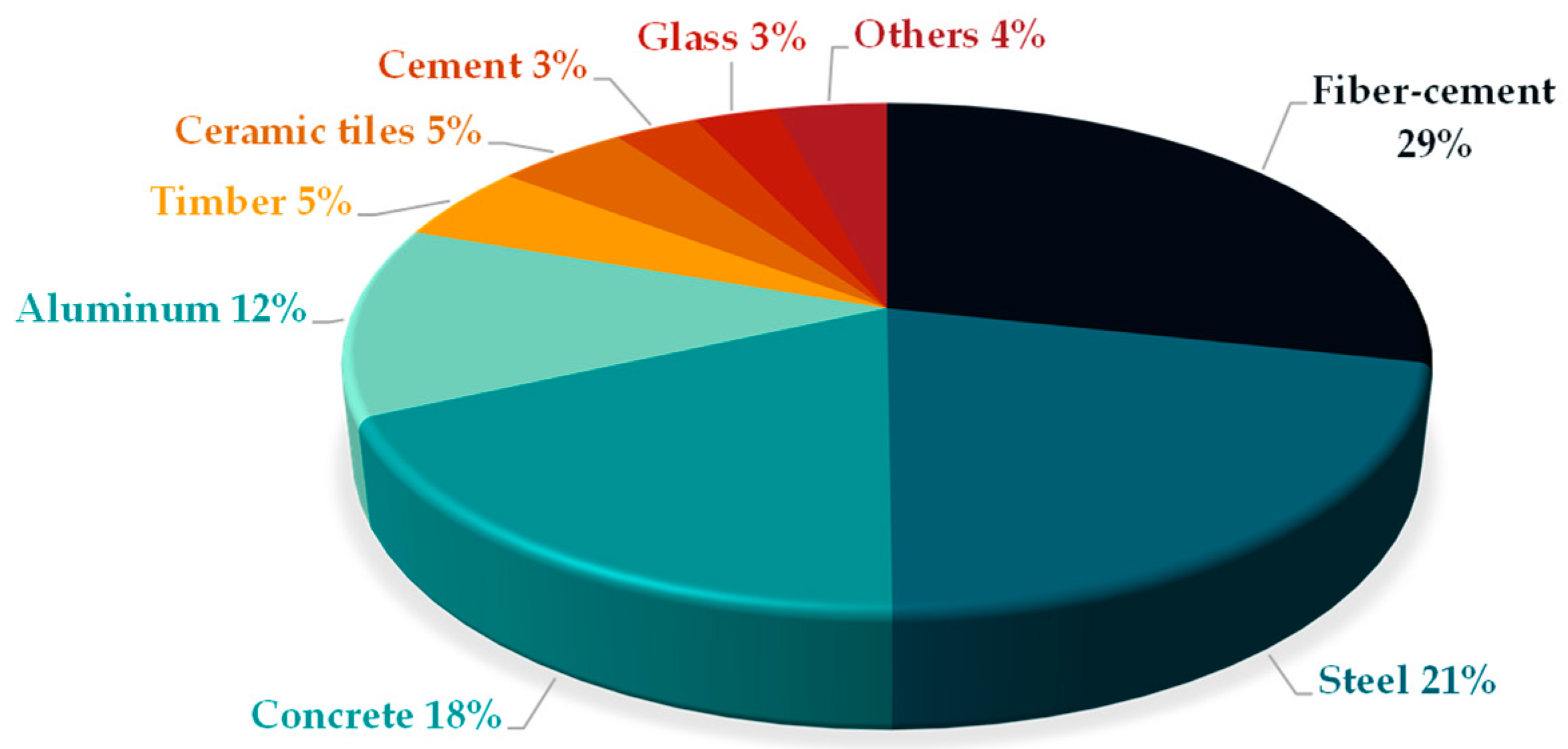

3.2.1. Embodied Energy of Building Materials

- High quantity, low embodied energy coefficient: Concrete can be classified in this category. While concrete has a relatively low embodied energy coefficient, its large quantity consumption can lead to a high embodied energy impact.

- High quantity, high embodied energy coefficient: Steel and fiber–cement can be categorized in this group. These materials are consumed in large quantities and provide high embodied energy coefficients.

- Low quantity, high embodied energy coefficient: This group includes materials such as aluminum; while consumed in smaller quantities, their high embodied energy coefficient can still affect the total embodied energy.

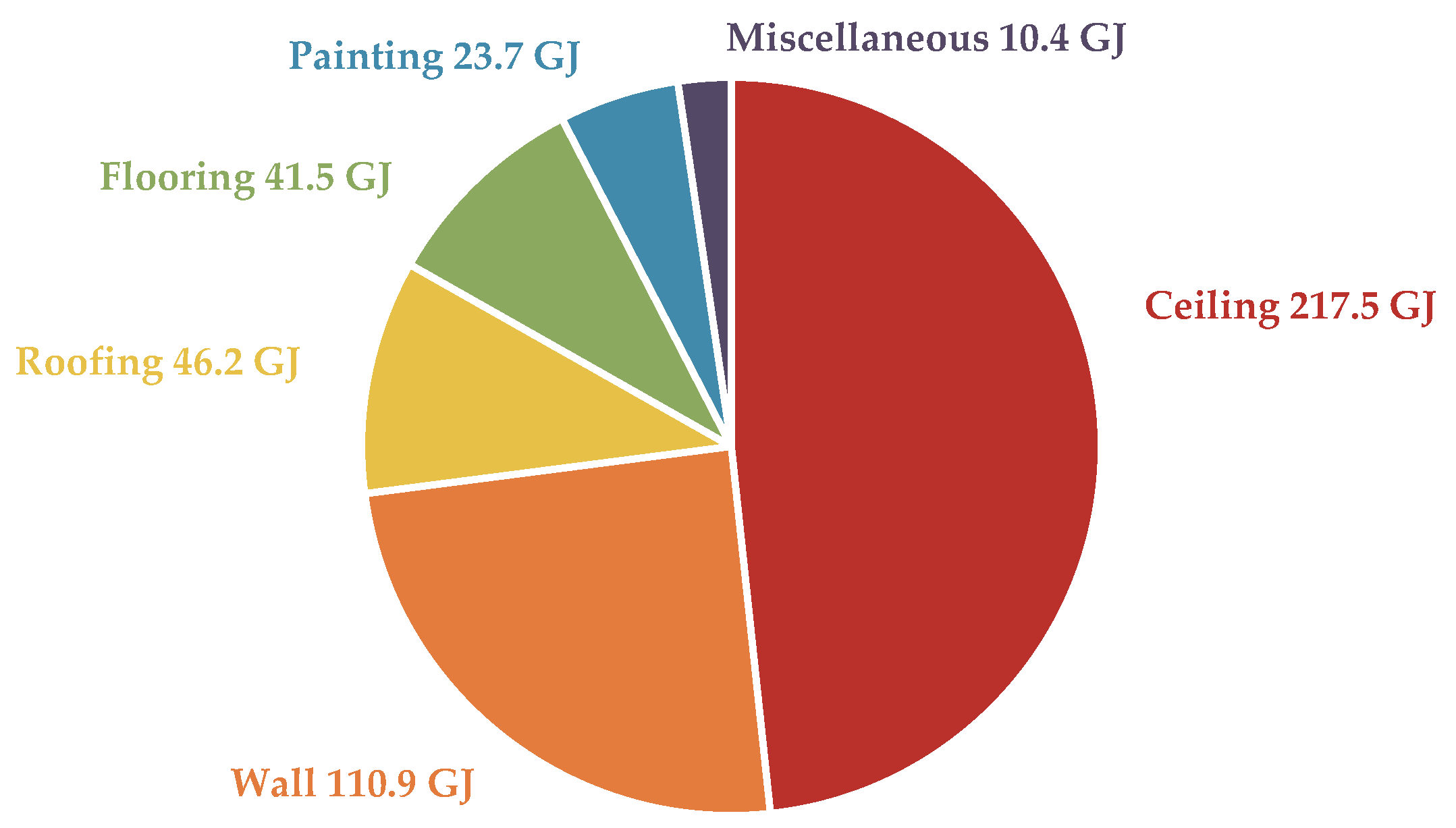

3.2.2. Effect of Recurrent Embodied Energy

3.2.3. Total Life-Cycle Energy Consumption of the Case-Study House

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DEC | Direct embodied energy coefficient |

| EE | Embodied energy |

| HEC | Hybrid embodied energy coefficient |

| IEE | Initial embodied energy |

| IO | Input–Output |

| LCA | Life cycle assessment |

| LCEA | Life cycle energy analysis |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| OE | Operational energy |

| PEC | Process-embodied energy coefficient |

| PEF | Primary energy factor |

| REE | Recurrent embodied energy |

| TEC | Total embodied energy coefficient |

References

- Schenk, D.; Amiri, A. Life Cycle Energy Analysis of Residential Wooden Buildings versus Concrete and Steel Buildings: A Review. Frontiers in Built Environment. Front. Media 2022, 8, 975071. [Google Scholar] [CrossRef]

- Huang, Z.; Zhou, H.; Miao, Z.; Tang, H.; Lin, B.; Zhuang, W. Life-Cycle Carbon Emissions (LCCE) of Buildings: Implications, Calculations, and Reductions. Engineering 2024, in press. [Google Scholar] [CrossRef]

- Hu, F.; Zheng, X. Carbon Emission of Energy Efficient Residential Building. Procedia Eng. 2015, 121, 1096–1102. [Google Scholar] [CrossRef]

- Information and Communication Technology Center. Energy Situation 2022; Information and Communication Technology Center: Bangkok, Thailand, 2022. [Google Scholar]

- Research Institute and Consultancy; Thammasat University. The Forecasting Housing Needs and Affordability for Thailand 2017–2037; Thammasat University: Bangkok, Thailand, 2017. [Google Scholar]

- Crowther, P. Design for Disassembly to Recover Embodied Energy. In The 16th Annual Conference on Passsive and Low Energy Architecture; Australian University: Brisbane, Australia, 1999. [Google Scholar]

- Monteiro, H.; Fernández, J.E.; Freire, F. Comparative Life-Cycle Energy Analysis of a New and an Existing House: The Significance of Occupant’s Habits, Building Systems and Embodied Energy. Sustain. Cities Soc. 2016, 26, 507–518. [Google Scholar] [CrossRef]

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, C.H. Identification of Parameters for Embodied Energy Measurement: A Literature Review. Energy Build 2010, 42, 1238–1247. [Google Scholar] [CrossRef]

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, C.H. Need for an Embodied Energy Measurement Protocol for Buildings: A Review Paper. Renew. Sustain. Energy Rev. 2012, 16, 3730–3743. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life Cycle Assessment (LCA) and Life Cycle Energy Analysis (LCEA) of Buildings and the Building Sector: A Review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Plank, R. The Principles of Sustainable Construction. IES J. Part A Civ. Struct. Eng. 2008, 1, 301–307. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A. Life Cycle Primary Energy Analysis of Residential Buildings. Energy Build 2010, 42, 210–220. [Google Scholar] [CrossRef]

- Davies, P.J.; Emmitt, S.; Firth, S.K. Challenges for Capturing and Assessing Initial Embodied Energy: A Contractor’s Perspective. Constr. Manag. Econ. 2014, 32, 290–308. [Google Scholar] [CrossRef]

- Copiello, S. Economic Implications of the Energy Issue: Evidence for a Positive Non-Linear Relation between Embodied Energy and Construction Cost. Energy Build 2016, 123, 59–70. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy Use in the Life Cycle of Conventional and Low-Energy Buildings: A Review Article. Energy Build 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Su, X.; Tian, S.; Shao, X.; Zhao, X. Embodied and Operational Energy and Carbon Emissions of Passive Building in HSCW Zone in China: A Case Study. Energy Build 2020, 222, 110090. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life Cycle Energy Analysis of Buildings: An Overview. Energy Build 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Shadram, F.; Johansson, T.D.; Lu, W.; Schade, J.; Olofsson, T. An Integrated BIM-Based Framework for Minimizing Embodied Energy during Building Design. Energy Build 2016, 128, 592–604. [Google Scholar] [CrossRef]

- Crawford, R.H.; Treloar, G.J. Validation of the Use of Australian Input-Output Data for Building Embodied Energy Simulation. In Proceedings of the 8th International Building Performance Simulation Association Conference, Eindhoven, The Netherlands, 1 January 2003. [Google Scholar]

- Thormark, C. Energy and Resources, Material Choice and Recycling Potential in Low Energy Buildings. In Proceedings of the CIB Conference SB07 Sustainable Construction, Materials and Practices, Lisbon, Portugal, 12–14 September 2007. [Google Scholar]

- Department of Alternative Energy Development and Efficiency. Study on Energy Efficiency Criteria and Prototype Development for Residential Buildings. Available online: https://www.aad.kmitl.ac.th/dede/ (accessed on 1 March 2024).

- Department of Alternative Energy Development and Efficiency. A Study of Energy Efficiency Criteria in Residential Buildings and the Development of an Energy-Efficient House Prototype; Department of Alternative Energy Development and Efficiency: Bangkok, Thailand, 2015. [Google Scholar]

- Joshi, S. Product Environmental Life—Cycle Assessment Using Input—Output Techniques. J. Ind. Ecol. 1999, 3, 95–120. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the Construction Industry: A Review of Recent Developments Based on LCA. Constr. Build Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Zabalza Bribián, I.; Aranda Usón, A.; Scarpellini, S. Life Cycle Assessment in Buildings: State-of-the-Art and Simplified LCA Methodology as a Complement for Building Certification. Build Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Life Cycle Assessment of Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A Review of Life Cycle Assessment of Buildings Using a Systematic Approach. Build Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- Fay, R.; Treloar, G.; Iyer-Raniga, U. Life-Cycle Energy Analysis of Buildings: A Case Study. Build. Res. Inf. 2000, 28, 31–41. [Google Scholar] [CrossRef]

- Huberman, N.; Pearlmutter, D. A Life-Cycle Energy Analysis of Building Materials in the Negev Desert. Energy Build 2008, 40, 837–848. [Google Scholar] [CrossRef]

- BS EN 15978:2011; Sustainability of Construction Works. Assessment of Environmental Performance of Buildings. Calculation Method. British Standards Institution: London, UK, 2011. Available online: https://www.en-standard.eu/bs-en-15978-2011 (accessed on 1 April 2024).

- Adalberth, K. Energy Use during the Life Cycle of Single-Unit Dwellings: Examples. Build Environ. 1997, 32, 321–329. [Google Scholar] [CrossRef]

- Pinky Devi, L.; Palaniappan, S. A Case Study on Life Cycle Energy Use of Residential Building in Southern India. Energy Build 2014, 80, 247–259. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; de Myttenaere, K. A Comprehensive Assessment of the Life Cycle Energy Demand of Passive Houses. Appl. Energy 2013, 112, 23–34. [Google Scholar] [CrossRef]

- Chen, T.Y.; Burnett, J.; Chau, C.K. Analysis of Embodied Energy Use in the Residential Building of Hong Kong. Energy 2001, 26, 323–340. [Google Scholar] [CrossRef]

- Nässén, J.; Holmberg, J.; Wadeskog, A.; Nyman, M. Direct and Indirect Energy Use and Carbon Emissions in the Production Phase of Buildings: An Input-Output Analysis. Energy 2007, 32, 1593–1602. [Google Scholar] [CrossRef]

- Treloar, G.J. A Comprehensive Embodied Energy Analysis Framework. Ph.D. Thesis, Deakin University, Melbourne, Australia, 1998. [Google Scholar]

- Crawford, R.H. Using Input-Output in Life Cycle Inventory Analysis. Ph.D. Thesis, Daekin University., Melbourne, Australia, 2004. [Google Scholar]

- Dixit, M.K. Embodied Energy Calculation: Method and Guidelines for a Building and Its Constituent Materials. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2013. [Google Scholar]

- Kofoworola, O.F.; Gheewala, S.H. Life Cycle Energy Assessment of a Typical Office Building in Thailand. Energy Build 2009, 41, 1076–1083. [Google Scholar] [CrossRef]

- Dixit, M.K. Embodied Energy Analysis of Building Materials: An Improved IO-Based Hybrid Method Using Sectoral Disaggregation. Energy 2017, 124, 46–58. [Google Scholar] [CrossRef]

- Mithraratne, N.; Vale, B. Life Cycle Analysis Model for New Zealand Houses. Build Environ. 2004, 39, 483–492. [Google Scholar] [CrossRef]

- Circular Ecology. Embodied Carbon—The ICE Database. Available online: https://circularecology.com/ (accessed on 5 April 2024).

- Baird, G.; Alcorn, A.; Haslam, P. The Energy Embodied in Building Materials—Updated New Zealand Coefficients and Their Significance. IPENZ Trans. 1997, 24, 46–54. [Google Scholar]

- Treloar, G.J. Extracting Embodied Energy Paths from Input–Output Tables: Towards an Input–Output-Based Hybrid Energy Analysis Method. Econ. Syst. Res. 1997, 9, 375–391. [Google Scholar] [CrossRef]

- Treloar, G.J.; Love, P.E.D.; Faniran, O.O.; Iyer-Raniga, U. A Hybrid Life Cycle Assessment Method for Construction. Constr. Manag. Econ. 2000, 18, 5–9. [Google Scholar] [CrossRef]

- Treloar, G.J.; Love, P.E.D.; Holt, G.D. Using National Input/Output Data for Embodied Energy Analysis of Individual Residential Buildings. Constr. Manag. Econ. 2001, 19, 49–61. [Google Scholar] [CrossRef]

- Sangngamratsakul, N.; Kubaha, K. Embodied Energy Analysis of Building Materials in Thailand: The Quantification and Guideline Using Input-Output Analysis Method. In Proceedings of the 6th International Conference on Business and Industrial Research, ICBIR 2021—Proceedings, Bangkok, Thailand, 20–21 May 2021. [Google Scholar] [CrossRef]

- Office of the National Economic and Social Development Council. Input-Output Tables (I-O Tables). Available online: https://www.nesdc.go.th/ (accessed on 1 March 2024).

- Miller, R.E.; Blair, P.D. Input-Output Analysis: Foundations and Extensions, 2nd ed.; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar] [CrossRef]

- Department of Alternative Energy Development and Efficiency; Ministry of Energy. Thailand Energy Balance 2015. Available online: https://oldwww.dede.go.th/ewt_news.php?nid=47341 (accessed on 1 March 2024).

- Ministry of Commerce. Bureau of Trade and Economic Indices. Available online: http://www.indexpr.moc.go.th/PRICE_PRESENT/ (accessed on 1 March 2024).

- Thailand Institute of Scientific and Technological Research. Final Report on the Project for the Development of Energy Efficiency in the Ceramics and Brick Industry; Thailand Institute of Scientific and Technological Research: Bangkok, Thailand, 2003. [Google Scholar]

- Department of Alternative Energy Development and Efficiency. Energy Conservation for the Plastics Industry; Department of Alternative Energy Development and Efficiency: Bangkok, Thailand, 2006. [Google Scholar]

- Department of Alternative Energy Development and Efficiency. A Study on Energy Consumption Criteria in the Non-Metallic Industry; Department of Alternative Energy Development and Efficiency: Bangkok Thailand, 2007. [Google Scholar]

- Juntueng, S.; Towprayoon, S.; Chiarakorn, S. Energy and Carbon Dioxide Intensity of Thailand’s Steel Industry and Greenhouse Gas Emission Projection toward the Year 2050. Resour. Conserv. Recycl. 2014, 87, 46–56. [Google Scholar] [CrossRef]

- Department of Industrial Works. Guidelines for Preparing Product Life Cycle Data: Lightweight Concrete Products Industry; Department of Industrial Works: Bangkok, Thailand, 2017. [Google Scholar]

- Crawford, R.H. Validation of the Use of Input-Output Data for Embodied Energy Analysis of the Australian Construction Industry. J. Constr. Res. 2005, 6, 71–90. [Google Scholar] [CrossRef]

- The Comptroller General’s Department. Guidelines, Practices, and Details for Estimating Construction Cost; The Comptroller General’s Department: Bangkok, Thailand, 2017. [Google Scholar]

- Treloar, G.; Fay, R.; Love, P.E.D.; Iyer-Raniga, U. Analysing the Life-Cycle Energy of an Australian Residential Building and Its Householders. Build. Res. Inf. 2000, 28, 184–195. [Google Scholar] [CrossRef]

- Crawford, R.H.; Czerniakowski, I.; Fuller, R.J. A Comprehensive Framework for Assessing the Life-Cycle Energy of Building Construction Assemblies. Archit. Sci. Rev. 2010, 53, 288–296. [Google Scholar] [CrossRef]

- Nitsunkit, S. Embodied Energy of Energy-Efficient Houses in Thailand. Master’s Thesis, King Mongkut’s University of Technology Thonburi, Bangkok, Thailand, 2018. [Google Scholar]

- Guan, L.; Walmsely, M.; Chen, G. Life Cycle Energy Analysis of Eight Residential Houses in Brisbane, Australia. Procedia Eng. 2015, 121, 653–661. [Google Scholar] [CrossRef]

- Crawford, R.; Stephen, A.; Prideaux, F. Environmental Performance in Construction (EPiC) Database. Available online: https://melbourne.figshare.com/projects/Environmental_Performance_in_Construction_EPiC_Database/68177 (accessed on 1 March 2024).

- Peng, J.; Aziz, T.I.S.T.; Leng, P.C. The Exploration of Energy Efficient Material for Shading Devices in Tropical Climates. Chem. Eng. Trans. 2023, 106, 301–306. [Google Scholar] [CrossRef]

- Campiotti, C.A.; Gatti, L.; Campiotti, A.; Consorti, L.; De Rossi, P.; Bibbiani, C.; Muleo, R.; Latini, A. Vertical Greenery as Natural Tool for Improving Energy Efficiency of Buildings. Horticulturae 2022, 8, 526. [Google Scholar] [CrossRef]

- The Aluminum Association. Aluminum’s Sustainability Infinitely Recyclable. Uniquely Sustainable. Available online: https://www.aluminum.org/sustainability (accessed on 1 April 2024).

- Kvande, H. The Aluminum Smelting Process. J. Occup. Environ. Med. 2014, 56, S2–S4. [Google Scholar] [CrossRef] [PubMed]

- Brough, D.; Jouhara, H. The Aluminium Industry: A Review on State-of-the-Art Technologies, Environmental Impacts and Possibilities for Waste Heat Recovery. Int. J. Thermofluids 2020, 1–2, 100007. [Google Scholar] [CrossRef]

| Characteristics | Description |

|---|---|

| Building lifetime | 50 years |

| Gross floor area | 215 m2 |

| Internal floor area | 127 m2 |

| Number of occupants | 4 |

| Structure | Reinforced concrete structure |

| Envelop | 30 mm autoclaved aerated blocks plastered with cement and painted (interior wall) 30 mm autoclaved aerated blocks cladded with fiber–cement board (exterior wall) |

| Window | 6 mm tinted float glass and white aluminum frames |

| Ceiling | 9 mm gypsum board suspended on a galvanized steel frame with a 76 mm fiberglass insulation covered with reinforced aluminum foil (insulation used for the 2nd floor) |

| Roof | Fiber–cement roof tiles |

| Material Name | Useful Life * (Year) | Number of Replacements | Description of Materials Used |

|---|---|---|---|

| Paint | 10 | 4 | External walls and internal walls |

| Fiberglass (aluminum foil) | 15 | 3 | Insulation |

| Ceramic tiles | 25 | 1 | Flooring and internal walls |

| Roof tiles | 25 | 1 | Roofs |

| Plywood (MDF) | 25 | 1 | Flooring, doors, and stairs |

| Timber | 25 | 1 | Flooring, doors, and stairs |

| Plastics | 25 | 1 | Doors |

| Fiber–cement panel | 30 | 1 | External walls and ceilings |

| Gypsum board | 30 | 1 | Ceilings |

| Energy Supply Sector | Inverse Energy Tariffs (MJ/THB) | PEF |

|---|---|---|

| Coal and lignite | 8.02 | 1.0 |

| Petroleum and natural gas | 3.29 | 1.0 |

| Petroleum refineries | 1.81 | 1.2 |

| Electricity | 0.80 | 2.4 |

| No. | Building Material | This Study | Previous Studies 1,2,3,4,5 |

|---|---|---|---|

| 1 | Aluminum | 156.61 | 67.9–295 |

| 2 | Brick | 1.78 * | 1.86–4.8 |

| 3 | Cement | 4.34 * | 3.6–7.8 |

| 4 | Fiber–cement panels | 16.33 | 9.5–18.30 |

| 5 | Fiber–cement (roof tiles) | 11.47 | 9.5–18.30 |

| 6 | Ceramic tiles | 11.04 * | 2.2–18.9 |

| 7 | Concrete (general) | 0.60 | 0.75–1.1 |

| 8 | Concrete blocks | 0.64 | 0.59–2.6 |

| 9 | Autoclaved aerated block | 4.11 * | 3.50 3, 8.5 5 |

| 10 | Concrete 180 ksc (cylinder) | 0.57 | 0.70–1.3 |

| 11 | Concrete 210 ksc (cylinder) | 0.58 | 0.74 3 |

| 12 | Concrete (roof tiles) | 1.96 | 0.81 4, 4.3 5 |

| 13 | Concrete slab (hollow core) | 1.10 | 1.50 3, 2.0 4 |

| 14 | Granite | 12.68 | 0.70 1, 11.00 3 |

| 15 | Glass (general) | 14.19 | 15.00–28.5 |

| 16 | Glass (toughened) | 23.46 | 23.50–29.8 |

| 17 | Fiberglass | 63.14 * | 30.3–57.5 |

| 18 | Fiberglass (aluminum foil) | 79.98 | NA |

| 19 | Gypsum board | 6.64 | 3.31–21.1 |

| 20 | Gypsum board (moisture resistance) | 9.57 | NA |

| 21 | Nails | 15.86 | NA |

| 22 | Paints (general) | 70.82 | 67.4–90.4 |

| 23 | Waterborne paint | 54.46 | 59.00–111 |

| 24 | Solventborne paint | 87.19 | 81.5–124 |

| 25 | Plastic pipe (general) | 63.88 * | 98.2 (general) 2 80.50 (general) 3 70.0 (PVC) 4 76.3 (PVC) 5 |

| 26 | Plywood (general) | 12.74 | 7.0–15.00 |

| 27 | Plywood (medium-density fiberboard; MDF) | 16.80 | 7.0–11.9 |

| 28 | Rock (crushed) | 0.18 | 0.08–3.0 |

| 29 | Rubber floor tiles | 15.22 | NA |

| 30 | Sand | 0.14 | 0.08–0.34 |

| 31 | Soil | 0.10 | 0.45 3 |

| 32 | Steel (reinforcement) | 12.81 * | 11.1–32.0 |

| 33 | Steel (section) | 18.09 | 21.50–38.8 |

| 34 | Steel binding wires | 15.90 | NA |

| 35 | Timber (hardwood) | 7.16 | 2.0–10.00 |

| 36 | Timber (medium hardwood) | 5.02 | 1.6–10.00 |

| Building Material | Embodied Energy Coefficients (MJ/kg) | %GAP | |

|---|---|---|---|

| Process-Based | Hybrid | ||

| Brick | 0.032 1 | 1.78 | 98 |

| Plastic pipe | 1.65 2 | 63.88 | 97 |

| Steel reinforcement | 2.10 4 | 12.18 | 83 |

| Fiberglass | 22.15 3 | 63.14 | 65 |

| Autoclaved aerated block | 1.98 5 | 4.11 | 52 |

| Ceramic tiles | 5.31 1 | 11.04 | 52 |

| Glass | 8.78 3 | 14.19 | 38 |

| Cement | 3.54 3 | 4.34 | 18 |

| Case Studies | Life Cycle Energy Consumption | Country | ||

|---|---|---|---|---|

| Initial Embodied Energy | Operational Energy | LCEA | ||

| (GJ/m2) | (GJ/m2/year) | (GJ/m2/year) | ||

| This study | 7.99 | 0.42 | 0.66 | Thailand |

| Fay R. [29] | 14.1 | 0.30 | 1.52 | Australia |

| Stephen A. [34] | 19.17 | 0.40 | 0.88 | Belgium |

| Adalberth K. [32] | 2.92–3.67 | 0.46–0.53 | 0.55–0.63 | Sweden |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sangngamratsakul, N.; Kubaha, K.; Chiarakorn, S. Embodied Energy Coefficient Quantification and Implementation for an Energy-Conservative House in Thailand. Sustainability 2024, 16, 4045. https://doi.org/10.3390/su16104045

Sangngamratsakul N, Kubaha K, Chiarakorn S. Embodied Energy Coefficient Quantification and Implementation for an Energy-Conservative House in Thailand. Sustainability. 2024; 16(10):4045. https://doi.org/10.3390/su16104045

Chicago/Turabian StyleSangngamratsakul, Nattaya, Kuskana Kubaha, and Siriluk Chiarakorn. 2024. "Embodied Energy Coefficient Quantification and Implementation for an Energy-Conservative House in Thailand" Sustainability 16, no. 10: 4045. https://doi.org/10.3390/su16104045

APA StyleSangngamratsakul, N., Kubaha, K., & Chiarakorn, S. (2024). Embodied Energy Coefficient Quantification and Implementation for an Energy-Conservative House in Thailand. Sustainability, 16(10), 4045. https://doi.org/10.3390/su16104045