Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques

Abstract

:1. Introduction

2. Current State in PV Recycling

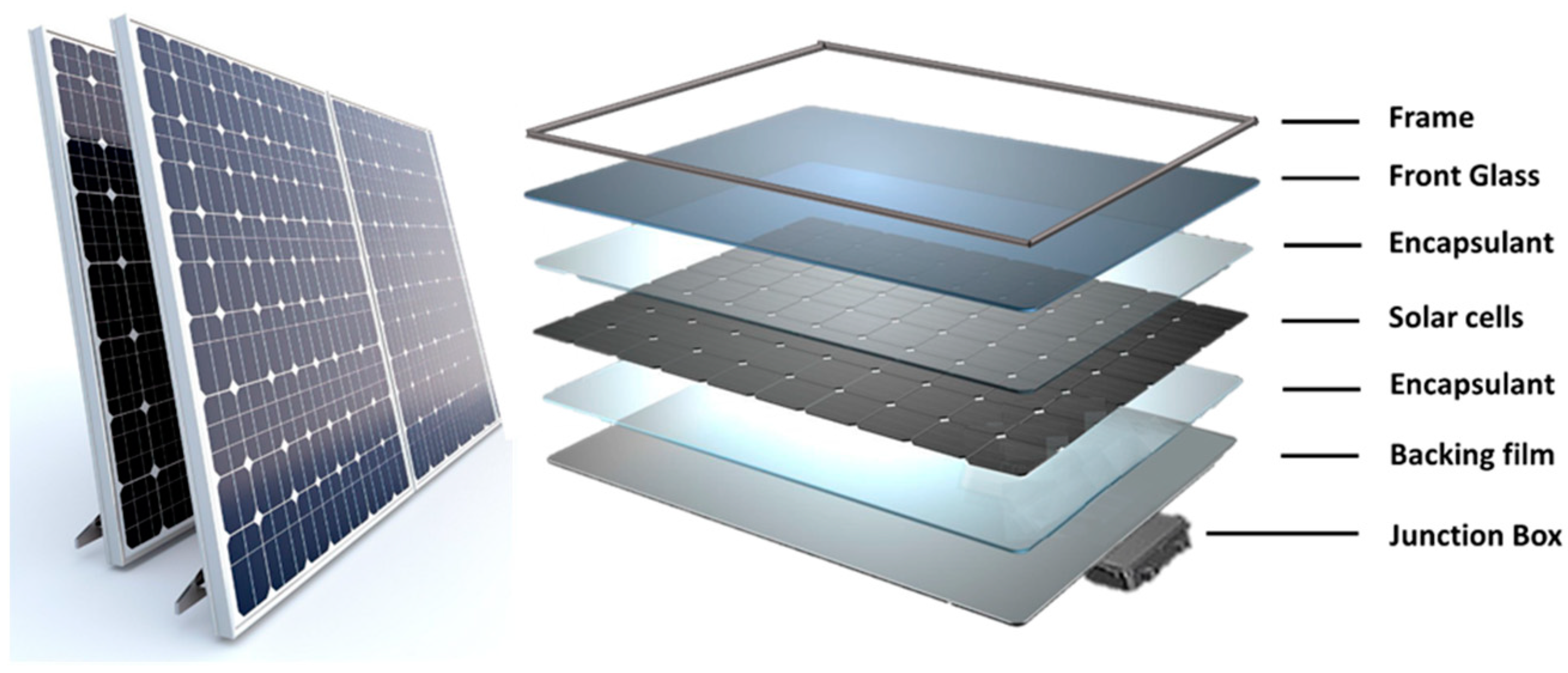

3. Crystalline Silicon Solar Panel Composition

3.1. Front Glass (or Cover)

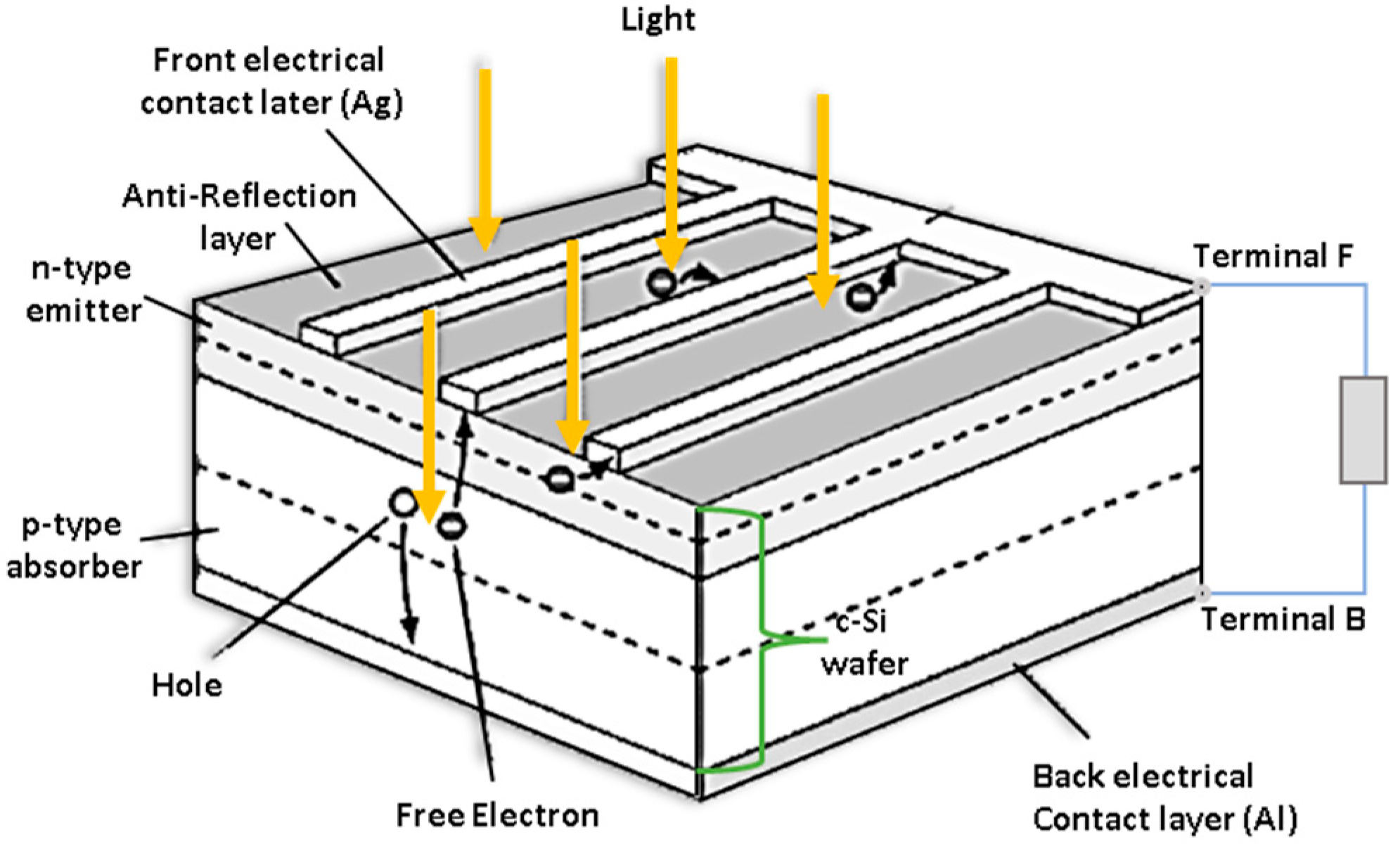

3.2. Silicon Solar Cells

3.3. Anti-Reflective Coating

3.4. Backing Film

3.5. Junction Box and Electrical Connections

3.6. Frame

3.7. Encapsulants

3.8. Composition and Recyclability

4. Mechanical Processes in PV Recycling

5. Thermal Processes in PV Recycling

6. Chemical Processes in PV Recycling

7. Current Challenges in Solar Panel Recycling

7.1. Volume Concern

7.2. Material Recovery

7.3. Environmental Impact

7.4. Economic Viability

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Franco, M.A.; Groesser, S.N. A Systematic Literature Review of the Solar Photovoltaic Value Chain for a Circular Economy. Sustainability 2021, 13, 9615. [Google Scholar] [CrossRef]

- Heath, G.A.; Silverman, T.J.; Kempe, M.; Deceglie, M.; Ravikumar, D.; Remo, T.; Cui, H.; Sinha, P.; Libby, C.; Shaw, S. Research and development priorities for silicon photovoltaic module recycling to support a circular economy. Nat. Energy 2020, 5, 502–510. [Google Scholar] [CrossRef]

- IRENA. Renewable Energy Statistics; IRENA: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Tan, J.; Jia, S.; Ramakrishna, S. End-of-Life Photovoltaic Modules. Energies 2022, 15, 5113. [Google Scholar] [CrossRef]

- IRENA. End of Life Management. Solar Photovoltaic Panels; IRENA: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- Domínguez, A.; Geyer, R. Photovoltaic waste assessment of major photovoltaic installations in the United States of America. Renew. Energy 2019, 133, 1188–1200. [Google Scholar] [CrossRef]

- Gielen, D.; Gorini, R.; Wagner, N.; Leme, R.; Gutierrez, L.; Prakash, G.; Asmelash, E.; Janeiro, L.; Gallina, G.; Vale, G. Global Energy Transformation: A Roadmap to 2050; IRENA: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Weckend, S.; Wade, A.; Heath, G.A. End of Life Management: Solar Photovoltaic Panels; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016. [Google Scholar]

- Domínguez, A.; Geyer, R. Photovoltaic waste assessment in Mexico. Resour. Conserv. Recycl. 2017, 127, 29–41. [Google Scholar] [CrossRef]

- Jamali, M.Y.; Aslani, A.; Moghadam, B.F.; Naaranoja, M.; Madvar, M.D. Analysis of photovoltaic technology development based on technology life cycle approach. J. Renew. Sustain. Energy 2016, 8, 035905. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.; Espinosa, D.C.R. E-waste: An overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef]

- Corcelli, F.; Ripa, M.; Leccisi, E.; Cigolotti, V.; Fiandra, V.; Graditi, G.; Sannino, L.; Tammaro, M.; Ulgiati, S. Sustainable urban electricity supply chain—Indicators of material recovery and energy savings from crystalline silicon photovoltaic panels end-of-life. Ecol. Indic. 2018, 94, 37–51. [Google Scholar] [CrossRef]

- D’Adamo, I.; Miliacca, M.; Rosa, P. Economic feasibility for recycling of waste crystalline silicon photovoltaic modules. Int. J. Photoenergy 2017, 2017, 4184676. [Google Scholar] [CrossRef]

- Majewski, P.; Al-Shammari, W.; Dudley, M.; Jit, J.; Lee, S.-H.; Myoung-Kug, K.; Sung-Jim, K. Recycling of solar PV panels—product stewardship and regulatory approaches. Energy Policy 2021, 149, 112062. [Google Scholar] [CrossRef]

- Tan, J.; Tan, F.J.; Ramakrishna, S. Transitioning to a circular economy: A systematic review of its drivers and barriers. Sustainability 2022, 14, 1757. [Google Scholar] [CrossRef]

- Sica, D.; Malandrino, O.; Supino, S.; Testa, M.; Lucchetti, M.C. Management of end-of-life photovoltaic panels as a step towards a circular economy. Renew. Sustain. Energy Rev. 2018, 82, 2934–2945. [Google Scholar] [CrossRef]

- Luo, W.; Khoo, Y.S.; Kumar, A.; Low, J.S.C.; Li, Y.; Tan, Y.S.; Wang, Y.; Aberle, A.G.; Ramakrishna, S. A comparative life-cycle assessment of photovoltaic electricity generation in Singapore by multicrystalline silicon technologies. Sol. Energy Mater. Sol. Cells 2018, 174, 157–162. [Google Scholar] [CrossRef]

- Kim, S.; Jeong, B. Closed-loop supply chain planning model for a photovoltaic system manufacturer with internal and external recycling. Sustainability 2016, 8, 596. [Google Scholar] [CrossRef]

- Farrell, C.; Osman, A.I.; Harrison, J.; Vennard, A.; Murphy, A.; Doherty, R.; Russell, M.; Kumaravel, V.; Al-Muhtaseb, A.a.H.; Zhang, X.; et al. Pyrolysis Kinetic Modeling of a Poly(ethylene-co-vinyl acetate) Encapsulant Found in Waste Photovoltaic Modules. Ind. Eng. Chem. Res. 2021, 60, 13492–13504. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Peeters, J.R.; Altamirano, D.; Dewulf, W.; Duflou, J.R. Forecasting the composition of emerging waste streams with sensitivity analysis: A case study for photovoltaic (PV) panels in Flanders. Resour. Conserv. Recycl. 2017, 120, 14–26. [Google Scholar] [CrossRef]

- Tao, M.; Fthenakis, V.; Ebin, B.; Steenari, B.M.; Butler, E.; Sinha, P.; Corkish, R.; Wambach, K.; Simon, E.S. Major challenges and opportunities in silicon solar module recycling. Prog. Photovolt. Res. Appl. 2020, 28, 1077–1088. [Google Scholar] [CrossRef]

- Komoto, K.; Lee, J.-S.; Zhang, J.; Ravikumar, D.; Sinha, P.; Wade, A.; Heath, G.A. End-of-Life Management of Photovoltaic Panels: Trends in PV Module Recycling Technologies; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2018. [Google Scholar]

- Klugmann-Radziemska, E.; Ostrowski, P. Chemical treatment of crystalline silicon solar cells as a method of recovering pure silicon from photovoltaic modules. Renew. Energy 2010, 35, 1751–1759. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Ostrowski, P.; Cenian, A.; Sawczak, M. Chemical, thermal and laser processes in recycling of photovoltaic silicon solar cells and modules. Ecol. Chem. Eng. S 2010, 17, 384–391. [Google Scholar]

- Latunussa, C.E.L.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. Cells 2016, 156, 101–111. [Google Scholar] [CrossRef]

- Jung, B.; Park, J.; Seo, D.; Park, N. Sustainable system for raw-metal recovery from crystalline silicon solar panels: From noble-metal extraction to lead removal. ACS Sustain. Chem. Eng. 2016, 4, 4079–4083. [Google Scholar] [CrossRef]

- Ilias, A.V.; Meletios, R.G.; Yiannis, K.A.; Nikolaos, B. Integration & assessment of recycling into c-Si photovoltaic module’s life cycle. Int. J. Sustain. Eng. 2018, 11, 186–195. [Google Scholar]

- Mohammed Niyaz, H.; Meena, R.; Gupta, R. Impact of cracks on crystalline silicon photovoltaic modules temperature distribution. Sol. Energy 2021, 225, 148–161. [Google Scholar] [CrossRef]

- Tune, D.D.; Flavel, B.S. Advances in carbon nanotube–silicon heterojunction solar cells. Adv. Energy Mater. 2018, 8, 1703241. [Google Scholar] [CrossRef]

- Yu, H.F.; Hasanuzzaman, M.; Rahim, N.A.; Amin, N.; Nor Adzman, N. Global Challenges and Prospects of Photovoltaic Materials Disposal and Recycling: A Comprehensive Review. Sustainability 2022, 14, 8567. [Google Scholar] [CrossRef]

- Shahsavari, A.; Yazdi, F.; Yazdi, H. Potential of solar energy in Iran for carbon dioxide mitigation. Int. J. Environ. Sci. Technol. 2019, 16, 507–524. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental impacts of solar photovoltaic systems: A critical review of recent progress and future outlook. Sci. Total Environ. 2021, 759, 143528. [Google Scholar] [CrossRef]

- Walker, G.R.; Sernia, P.C. Cascaded DC-DC converter connection of photovoltaic modules. IEEE Trans. Power Electron. 2004, 19, 1130–1139. [Google Scholar] [CrossRef]

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on Life Cycle Assessment of Solar Photovoltaic Panels. Energies 2020, 13, 252. [Google Scholar] [CrossRef]

- De Oliveira, M.C.C.; Cardoso, A.S.A.D.; Viana, M.M.; Lins, V.d.F.C. The causes and effects of degradation of encapsulant ethylene vinyl acetate copolymer (EVA) in crystalline silicon photovoltaic modules: A review. Renew. Sustain. Energy Rev. 2018, 81, 2299–2317. [Google Scholar] [CrossRef]

- Kahoul, N.; Chenni, R.; Cheghib, H.; Mekhilef, S. Evaluating the reliability of crystalline silicon photovoltaic modules in harsh environment. Renew. Energy 2017, 109, 66–72. [Google Scholar] [CrossRef]

- Han, H.; Dong, X.; Li, B.; Yan, H.; Verlinden, P.J.; Liu, J.; Huang, J.; Liang, Z.; Shen, H. Degradation analysis of crystalline silicon photovoltaic modules exposed over 30 years in hot-humid climate in China. Sol. Energy 2018, 170, 510–519. [Google Scholar] [CrossRef]

- Herceg, S.; Pinto Bautista, S.; Weiß, K.-A. Influence of Waste Management on the Environmental Footprint of Electricity Produced by Photovoltaic Systems. Energies 2020, 13, 2146. [Google Scholar] [CrossRef]

- Sander, K.; SchillingJan, S.; Reinschmidt; Wambach, K.; Schlenker, S. Study on the Development of a Takeback and Recovery System for Photovoltaic Modules; Ökopol: Hamburg, Germany, 2007. [Google Scholar]

- Savvilotidou, V.; Antoniou, A.; Gidarakos, E. Toxicity assessment and feasible recycling process for amorphous silicon and CIS waste photovoltaic panels. Waste Manag. 2017, 59, 394–402. [Google Scholar] [CrossRef] [PubMed]

- Dias, P.; Javimczik, S.; Benevit, M.; Veit, H.; Bernardes, A.M. Recycling WEEE: Extraction and concentration of silver from waste crystalline silicon photovoltaic modules. Waste Manag. 2016, 57, 220–225. [Google Scholar] [CrossRef]

- Shin, J.; Park, J.; Park, N. A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers. Sol. Energy Mater. Sol. Cells 2017, 162, 38. [Google Scholar] [CrossRef]

- Granata, G.; Pagnanelli, F.; Moscardini, E.; Havlik, T.; Toro, L. Recycling of photovoltaic panels by physical operations. Sol. Energy Mater. Sol. Cells 2014, 123, 239–248. [Google Scholar] [CrossRef]

- Wang, T.-Y.; Hsiao, J.-C.; Du, C.-H. Recycling of materials from silicon base solar cell module. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012. [Google Scholar]

- Kim, Y.; Lee, J. Dissolution of ethylene vinyl acetate in crystalline silicon PV modules using ultrasonic irradiation and organic solvent. Sol. Energy Mater. Sol. Cells 2012, 98, 317–322. [Google Scholar] [CrossRef]

- Tammaro, M.; Rimauro, J.; Fiandra, V.; Salluzzo, A. Thermal treatment of waste photovoltaic module for recovery and recycling: Experimental assessment of the presence of metals in the gas emissions and in the ashes. Renew. Energy 2015, 81, 103–112. [Google Scholar] [CrossRef]

- Chitra; Sah, D.; Lodhi, K.; Kant, C.; Saini, P.; Kumar, S. Structural composition and thermal stability of extracted EVA from silicon solar modules waste. Sol. Energy 2020, 211, 74–81. [Google Scholar] [CrossRef]

- Dias, P.; Schmidt, L.; Gomes, L.B.; Bettanin, A.; Veit, H.; Bernardes, A.M. Recycling waste crystalline silicon photovoltaic modules by electrostatic separation. J. Sustain. Metall. 2018, 4, 176–186. [Google Scholar] [CrossRef]

- Bombach, E.; Röver, I.; Müller, A.; Schlenker, S.; Wambach, K.; Kopecek, R.; Wefringhaus, E. Technical experience during thermal and chemical recycling of a 23 year old PV generator formerly installed on Pellworm island. In Proceedings of the 21st European Photovoltaic Solar Energy Conference, Dresden, Germany, 4–8 September 2006. [Google Scholar]

- Zeng, D.-w.; Born, M.; Wambach, K. Pyrolysis of EVA and its application in recycling of photovoltaic modules. J. Environ. Sci. 2004, 16, 889–893. [Google Scholar]

- Mapari, R.; Narkhede, S.; Navale, A.; Babrah, J. Automatic waste segregator and monitoring system. Int. J. Adv. Comput. Res. 2020, 10, 171. [Google Scholar] [CrossRef]

- Pagnanelli, F.; Moscardini, E.; Granata, G.; Atia, T.A.; Altimari, P.; Havlik, T.; Toro, L. Physical and chemical treatment of end of life panels: An integrated automatic approach viable for different photovoltaic technologies. Waste Manag. 2017, 59, 422–431. [Google Scholar] [CrossRef] [PubMed]

- Dias, P.; Dias, P.; Veit, H. Recycling crystalline silicon photovoltaic modules. In Emerging Photovoltaic Materials: Silicon & Beyond; John Wiley & Sons: Hoboken, NJ, USA, 2018; pp. 61–102. [Google Scholar]

- Salama, A.; Richard, G.; Medles, K.; Zeghloul, T.; Dascalescu, L. Distinct recovery of copper and aluminum from waste electric wires using a roll-type electrostatic separator. Waste Manag. 2018, 76, 207–216. [Google Scholar] [CrossRef]

- Akimoto, Y.; Iizuka, A.; Shibata, E. High-voltage pulse crushing and physical separation of polycrystalline silicon photovoltaic panels. Miner. Eng. 2018, 125, 1–9. [Google Scholar] [CrossRef]

- Fernández, L.J.; Ferrer, R.; Aponte, D.; Fernandez, P. Recycling silicon solar cell waste in cement-based systems. Sol. Energy Mater. Sol. Cells 2011, 95, 1701–1706. [Google Scholar] [CrossRef]

- Directive, E.C. Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE). Off. J. Eur. Union Eur. Parliam. Counc. Eur. Union 2012, 197, 38–71. [Google Scholar]

- Lovato, E.S.; Donato, L.M.; Lopes, P.P.; Tanabe, E.H.; Bertuol, D.A. Application of supercritical CO2 for delaminating photovoltaic panels to recover valuable materials. J. CO2 Util. 2021, 46, 101477. [Google Scholar] [CrossRef]

- Andres, U. Development and prospects of mineral liberation by electrical pulses. Int. J. Miner. Process. 2010, 97, 31–38. [Google Scholar] [CrossRef]

- Wang, E.; Shi, F.; Manlapig, E. Pre-weakening of mineral ores by high voltage pulses. Miner. Eng. 2011, 24, 455–462. [Google Scholar] [CrossRef]

- Yan, G.; Zhang, B.; Lv, B.; Zhu, G.; Zhu, X.; Zhao, Y. Enrichment of chalcopyrite using high-voltage pulse discharge. Powder Technol. 2018, 340, 420–427. [Google Scholar] [CrossRef]

- Zuo, W.; Shi, F. A t10-based method for evaluation of ore pre-weakening and energy reduction. Miner. Eng. 2015, 79, 212–219. [Google Scholar] [CrossRef]

- Song, B.P.; Zhang, M.Y.; Fan, Y.; Jiang, L.; Kang, J.; Gou, T.T.; Zhang, C.L.; Yang, N.; Zhang, G.J.; Zhou, X. Recycling experimental investigation on end of life photovoltaic panels by application of high voltage fragmentation. Waste Manag. 2020, 101, 180–187. [Google Scholar] [CrossRef] [PubMed]

- Nevala, S.-M.; Hamuyuni, J.; Junnila, T.; Sirviö, T.; Eisert, S.; Wilson, B.P.; Serna-Guerrero, R.; Lundström, M. Electro-hydraulic fragmentation vs conventional crushing of photovoltaic panels–Impact on recycling. Waste Manag. 2019, 87, 43–50. [Google Scholar] [CrossRef]

- Dias; Benevit, P.R.; Veit, M.G.; Marcelo, H. Photovoltaic solar panels of crystalline silicon: Characterization and separation. Waste Manag. Res. 2016, 34, 235–245. [Google Scholar] [CrossRef]

- Dias, P.; Javimczik, S.; Benevit, M.; Veit, H. Recycling WEEE: Polymer characterization and pyrolysis study for waste of crystalline silicon photovoltaic modules. Waste Manag. 2017, 60, 716–722. [Google Scholar] [CrossRef]

- Deng, R.; Chang, N.L.; Ouyang, Z.; Chong, C.M. A techno-economic review of silicon photovoltaic module recycling. Renew. Sustain. Energy Rev. 2019, 109, 532–550. [Google Scholar] [CrossRef]

- Wang, R.; Song, E.; Zhang, C.; Zhuang, X.; Ma, E.; Bai, J.; Yuan, W.; Wang, J. Pyrolysis-based separation mechanism for waste crystalline silicon photovoltaic modules by a two-stage heating treatment. RSC Adv. 2019, 9, 18115–18123. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Buekens, A.; Li, X. Brominated flame retardants and the formation of dioxins and furans in fires and combustion. J. Hazard. Mater. 2016, 304, 26–39. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Yoo, S.; Lee, J.; Boo, B.; Ryu, H. Experimental investigations for recycling of silicon and glass from waste photovoltaic modules. Renew. Energy 2012, 47, 152–159. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Ostrowski, P.; Drabczyk, K.; Panek, P.; Szkodo, M. Experimental validation of crystalline silicon solar cells recycling by thermal and chemical methods. Sol. Energy Mater. Sol. Cells 2010, 94, 2275–2282. [Google Scholar] [CrossRef]

- McDonald, N.C.; Pearce, J.M. Producer responsibility and recycling solar photovoltaic modules. Energy Policy 2010, 38, 7041–7047. [Google Scholar] [CrossRef]

- Yang, E.-H.; Lee, J.-K.; Lee, J.-S.; Ahn, Y.-S.; Kang, G.-H.; Cho, C.-H. Environmentally friendly recovery of Ag from end-of-life c-Si solar cell using organic acid and its electrochemical purification. Hydrometallurgy 2017, 167, 129–133. [Google Scholar] [CrossRef]

- Padoan, F.C.S.M.; Altimari, P.; Pagnanelli, F. Recycling of end of life photovoltaic panels: A chemical prospective on process development. Sol. Energy 2019, 177, 746–761. [Google Scholar] [CrossRef]

- Doi, T.; Tsuda, I.; Unagida, H.; Murata, A.; Sakuta, K.; Kurokawa, K. Experimental study on PV module recycling with organic solvent method. Sol. Energy Mater. Sol. Cells 2001, 67, 397–403. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E. Recycling of Photovoltaic Solar Cells and Modules-The State-of-Art; Lambert Academic Publishing: Saarbrücken, Germany, 2014. [Google Scholar]

- Tao, J.; Yu, S. Review on feasible recycling pathways and technologies of solar photovoltaic modules. Sol. Energy Mater. Sol. Cells 2015, 141, 108–124. [Google Scholar] [CrossRef]

- Palitzsch, W.; Loser, U. A new and intelligent de-metalization step of broken silicon cells and silicon cell production waste in the recycling procedure of crystalline Si modules. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011. [Google Scholar]

- Nieland, S.; Neuhaus, U.; Pfaff, T.; Rädlein, E. New approaches for component recycling of crystalline solar modules. In Proceedings of the 2012 Electronics Goes Green 2012+, Berlin, Germany, 9–12 September 2012. [Google Scholar]

- Lee, C.-H.; Hung, C.-E.; Tsai, S.-L.; Popuri, S.R.; Liao, C.-H. Resource recovery of scrap silicon solar battery cell. Waste Manag. Res. 2013, 31, 518–524. [Google Scholar] [CrossRef]

- Hiskey, J.; Sanchez, V. Mechanistic and kinetic aspects of silver dissolution in cyanide solutions. J. Appl. Electrochem. 1990, 20, 479–487. [Google Scholar] [CrossRef]

- Gernon, M. Environmental benefits of methanesulfonic acid. Comparative properties and advantages. Green Chem. 1999, 1, 127–140. [Google Scholar] [CrossRef]

- Lee, J.-K.; Lee, J.-S.; Ahn, Y.-S.; Kang, G.-H.; Song, H.-E.; Lee, J.-I.; Kang, M.-G.; Cho, C.-H. Photovoltaic performance of c-Si wafer reclaimed from end-of-life solar cell using various mixing ratios of HF and HNO3. Sol. Energy Mater. Sol. Cells 2017, 160, 301–306. [Google Scholar] [CrossRef]

- Nain, P.; Kumar, A. Ecological and human health risk assessment of metals leached from end-of-life solar photovoltaics. Environ. Pollut. 2020, 267, 115393. [Google Scholar] [CrossRef]

- Verma, S.; Lee, T.; Sahle-Demessie, E.; Ateia, M.; Nadagouda, M.N. Recent advances on PFAS degradation via thermal and nonthermal methods. Chem. Eng. J. Adv. 2022, 100421. [Google Scholar] [CrossRef] [PubMed]

- Zachmann, N. Separation of Organic Components from Crystalline Silicon Solar Cells by Supercritical Fluid Technology. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2020. [Google Scholar]

- Granata, G.; Altimari, P.; Pagnanelli, F.; De Greef, J. Recycling of solar photovoltaic panels: Techno-economic assessment in waste management perspective. J. Clean. Prod. 2022, 363. [Google Scholar] [CrossRef]

- Zeng, X.; Mathews, J.A.; Li, J. Urban Mining of E-Waste is Becoming More Cost-Effective Than Virgin Mining. Env. Sci Technol 2018, 52, 4835–4841. [Google Scholar] [CrossRef]

- Li, J.; Shao, J.; Yao, X.; Li, J. Life cycle analysis of the economic costs and environmental benefits of photovoltaic module waste recycling in China. Resour. Conserv. Recycl. 2023, 196, 10727. [Google Scholar] [CrossRef]

- Dias, P.R.; Schmidt, L.; Chang, N.L.; Lunardi, M.M.; Deng, R.; Trigger, B.; Gomes, L.B.; Egan, R.; Veit, H. High yield, low cost, environmentally friendly process to recycle silicon solar panels: Technical, economic and environmental feasibility assessment. Renew. Sustain. Energy Rev. 2022, 169, 112900. [Google Scholar] [CrossRef]

| Characteristic | Double Fluoropolymer | Single Fluoropolymer | Non-Fluoropolymer |

|---|---|---|---|

| Composition | A Polyethylene Terephthalate (PET) core layer is encased by two external layers of fluoropolymer material, potentially Tedlar (Polyvinyl Fluoride, PVF) or Kynar (Polyvinylidene Fluoride, PVDF) | Tedlar or Kynar on the outer side; PET and primer or EVA layers on the inner side | Two PET layers and one primer or EVA layer |

| Protection Level | Superior | Satisfactory | Basic, but improving with advancements |

| Price | Most expensive | Moderate | Cheapest |

| UV Durability | High | Satisfactory | High (with recent advancements) |

| Historical Context | Preferred for high protection | Developed to balance cost and performance | Initially avoided due to degradation risks |

| Advancements | N/A | N/A | Significant, leading to highly UV-durable films |

| Unit | Main Component | [4] | [40] | [41] | [12] |

|---|---|---|---|---|---|

| Front Glass | Glass | 70% | 70% | 63% | 54.721% |

| Silicon solar cells | Silicon | 3.56% | 3.65% | 4% | 3.101% |

| Silver | 0.05% | 0.05% | <0.01% | 0.03% | |

| Copper | 1.14% | 0.11% | Not Available | 0.451% | |

| Tin | 0.053% | 0.05% | <0.1% | Not Available | |

| Lead | <0.1% | ||||

| Aluminum | 0.53% | 0.53% | 19% | ||

| Frame | Aluminum | 18% | 18% | 12% | |

| Junction Box and Electrical Connections | Box body (including copper or plastic terminal), lid, diode, cables, connectors | 1% | Copper: 0.33% Plastic: 0.67% | Copper: 0.6% Others: Not available | Not Available |

| Encapsulants | EVA | 5.1% | 5.1% | Organic:11% | 10% |

| Backing film | PVF, PVDF, PET, etc. | 1.5% | 1.5% | 17.091% |

| Method | High Voltage Fragmentation, Sieving, and Dense Medium Separation | Incorporation in Cement Matrices | Crushing and Thermal treatment | Electro-Hydraulic Fragmentation (EHF) |

|---|---|---|---|---|

| Primary Use | Selective separation and recovery of PV panel materials | Recycling in construction materials | Glass recovery | Recovery of valuable metals from PV modules |

| Recovery Rate | Not specified | Not specified | Approx. 85% (by weight) | 99% Cu, 60% Ag, 80% Pb/Sn/Al |

| Materials Recovered | Glass, Cu, Sn, Pb, Ag | Not specified | Glass, potential for various metals | Si (0.5–2 mm), Ag, Cu, Sn, Pb, Al |

| Challenges | Improving Ag recovery ratio | Decreased mechanical strength, increased porosity, durability confirmation needed | Emissions management, ensuring clean recovered glass | Not specified |

| Environmental and Economic Impact | 0.21 JPY/W processing costs, potential commercial viability | Not detailed | Reduces energy and chemical consumption | Economically attractive |

| Advantages | Effective separation and recovery of various materials, economically viable | Utilization of PV waste, potential for creating insulation and soundproofing materials | Applicable to various PV types, high glass recovery rate | Selective concentration of metals, straightforward metal recovery |

| Disadvantages | Additional methods needed for higher Ag recovery | Does not recover materials for direct reuse in PV manufacturing | Emission management, further processing for metal recovery | Not specified |

| Ref. | [57] | [58] | [45] | [66] |

| Method | Triple Crushing along with Thermal or Chemical Treatment for Selected Fractions | Electrostatic Separation | High Voltage Fragmentation | Supercritical CO2 |

| Primary Use | Recycling of PV panels | Separation of Cu and Al from waste wires | Recovery of valuable metals from PV modules | Separation of solar cell from encapsulation and glass layer |

| Recovery Rate | 91% | 68.6% Cu (99% purity) | 95% Cu, 96% Ag | Over 96% (glass, Pb filaments, back sheet) |

| Materials Recovered | Glass, Al, Cu, (Ag) | Cu, Al | Cu, Al, Pb, Ag (<1 mm), Sn | Glass, Pb filaments, back sheet |

| Challenges | Not specified | Not specified | Not specified | Not specified |

| Environmental and Economic Impact | Economically feasible (PBT < 6 years for 75,000 ton/y) | Not specified | Not specified | Use of toluene |

| Advantages | Single scheme for different PV types, reduced thermal waste, single equipment uses | High purity in recovered metals, adaptable to industrial scale | Specific size crushing, concentration of select materials in size fractions | High recovery rate, reduced solvent usage, and delamination time shortened to one-third compared to atmospheric pressure |

| Disadvantages | Not specified | Model improvement for Al particles needed and further development for industrial application | Not specified | Not specified |

| Ref. | [54] | [56] | [65] | [60] |

| Method | Thermal Treatment at 170 °C and Mechanical Force | 500 °C Pyrolysis for 30 min to 1 h | Organic Solvents, Thermal Treatment (600 °C for 1 h), and Chemical Etching | |

|---|---|---|---|---|

| Significant Findings | EVA extracted with similar properties to commercial EVA; thermally stable until 215 °C | A > 99% polymer removal; 75% of polymers degrade between 400 °C and 500 °C | An 86% silicon recovery yield; a purity of 99.999% | |

| Advantages | Eco-friendly, no material degradation or gas emission | Significant removal of polymers | Efficient silicon recovery | |

| Challenges and Limitations | Not specified | Mass loss rate decreases significantly above 500 °C | Not specified | |

| Potential Applications | Reuse of extracted EVA in solar modules and possibly in packaging and textile industries | Not specified | Solves issues related to silicon supply, manufacturing costs, and PV module end-of-life management | |

| Ref. | [49] | [68] | [72] | |

| Method | Thermal Treatment up to 600 °C | Two-Stage Heating (150 °C and 500 °C) | ||

| Significant Findings | Detection of metals (including hazardous ones) in gas emissions and solid residues | Integral recovery of TPT backing materials; EVA binder removed | ||

| Advantages | Highlights the emission of hazardous metals for management | Detailed analysis of EVA pyrolysis; potential for environmental friendliness | ||

| Challenges & Limitations | Emissions need to be adequately managed to prevent environmental impact | Management/treatment of pyrolysis products | ||

| Potential Applications | Not specified | Environmentally friendly and efficient recycling of waste crystalline silicon solar panels | ||

| Ref. | [48] | [70] | ||

| Method | Mechanical and Nitric Acid Leaching | Nitric Acid Leaching | Organic Solvent | Organic Solvent |

|---|---|---|---|---|

| Target Material | Ag | Si, Cu, Ag, Pb | Si | Si |

| Key Process /Agent | Milling, Sieving, Leaching in HNO3, Precipitating with NaCl | 5M Nitric Acid, Agitation at 200 rpm | Trichloroethylene at 80 °C with mechanical pressure | o-Dichlorobenzene at 120 °C |

| Efficiency /Outcome | 94% silver concentration yield | Si: 80%, Cu: 79%, Ag: 90%, Pb: 93% removal | Successfully recovered without damage after 7–10 days | Successfully recovered without damage after 1 week |

| Concerns /Issues | Energy consumption | Handling of acids and heavy metal disposal | Swelling and cracking of PV cells if pressure not applied | Swelling of EVA, potential for cracking |

| Ref. | [68] | [28] | [77] | [77] |

| Method | Solvent Extraction and Electrowinning | Acid Precipitation | Sulfurization and Neutralization Treatment | Chemical Etching |

| Target Material | Cu | Ag | Pb | Si |

| Key Process /Agent | LIX84-I extraction, H2SO4 Stripping, Electrowinning | HCl Precipitation, NaOH, Hydrazine Hydrate Reduction, Electrolytic Refining | NaOH Neutralization, Na2S Sulfurization | HF, HNO3, H2SO4, CH3COOH, surfactant |

| Efficiency /Outcome | Not specified | 99.99% purity after refining | 93% removal | 86% yield, 99.999% purity |

| Concerns /Issues | Handling of chemicals | Handling of chemicals, high-temperature processes | Handling of toxic Pb compounds | Handling of strong acids |

| Ref. | [28] | [28] | [28] | [72] |

| Method | Ultrasonic Irradiation | Chemical Refinement | Chemical Refabrication | Chemical Recovery and Electrorefining |

| Target Material | EVA | Si | Si | Ag |

| Key Process /Agent | O-DCB, TCE, Benzene, Toluene, Ultrasonic Power | Thermal or Chemical Separation, followed by Chemical Refinement | Wet chemical process using a mixture of HNO3 and HF | Methanesulfonic acid (MSA) mixed with H2O2. Purification by Electrorefining |

| Efficiency /Outcome | Complete dissolution in 3 M O-DCB at 70 °C, 900 W, 30 min | Silicon recovery with resultant new cells achieving 13–15% efficiency | Re-fabrication achieved a high efficiency of 17.6%, an 18.9% rise compared to the original efficiency | Optimal Ag extraction was achieved with a 90:10 MSA:H2O2 ratio. Initial purity of Ag powder was around 99% (2N), improved to 99.995% (4N5) after electrorefining. |

| Concerns /Issues | PV cell damage in other solvents | Absence of SiNx antireflective coating on resultant cells | Determining the optimal ratio of HNO3 to HF to avoid incomplete etching or deposition of Ag particles | Managing the balance between MSA and H2O2 to avoid excessive H2O2 decomposition and ensuing H2O generation which dilutes the solution. |

| Ref. | [47] | [25] | [85] | [75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.-H.; Chen, W.-S.; Lee, C.-H.; Wu, J.-Y. Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques. Sustainability 2024, 16, 60. https://doi.org/10.3390/su16010060

Chen P-H, Chen W-S, Lee C-H, Wu J-Y. Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques. Sustainability. 2024; 16(1):60. https://doi.org/10.3390/su16010060

Chicago/Turabian StyleChen, Pin-Han, Wei-Sheng Chen, Cheng-Han Lee, and Jun-Yi Wu. 2024. "Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques" Sustainability 16, no. 1: 60. https://doi.org/10.3390/su16010060

APA StyleChen, P.-H., Chen, W.-S., Lee, C.-H., & Wu, J.-Y. (2024). Comprehensive Review of Crystalline Silicon Solar Panel Recycling: From Historical Context to Advanced Techniques. Sustainability, 16(1), 60. https://doi.org/10.3390/su16010060