A Study of the Physical and Mechanical Properties of Yellow River Sediments and Their Impact on the Reclamation of Coal-Mined Subsided Land

Abstract

1. Introduction

2. Materials and Methods

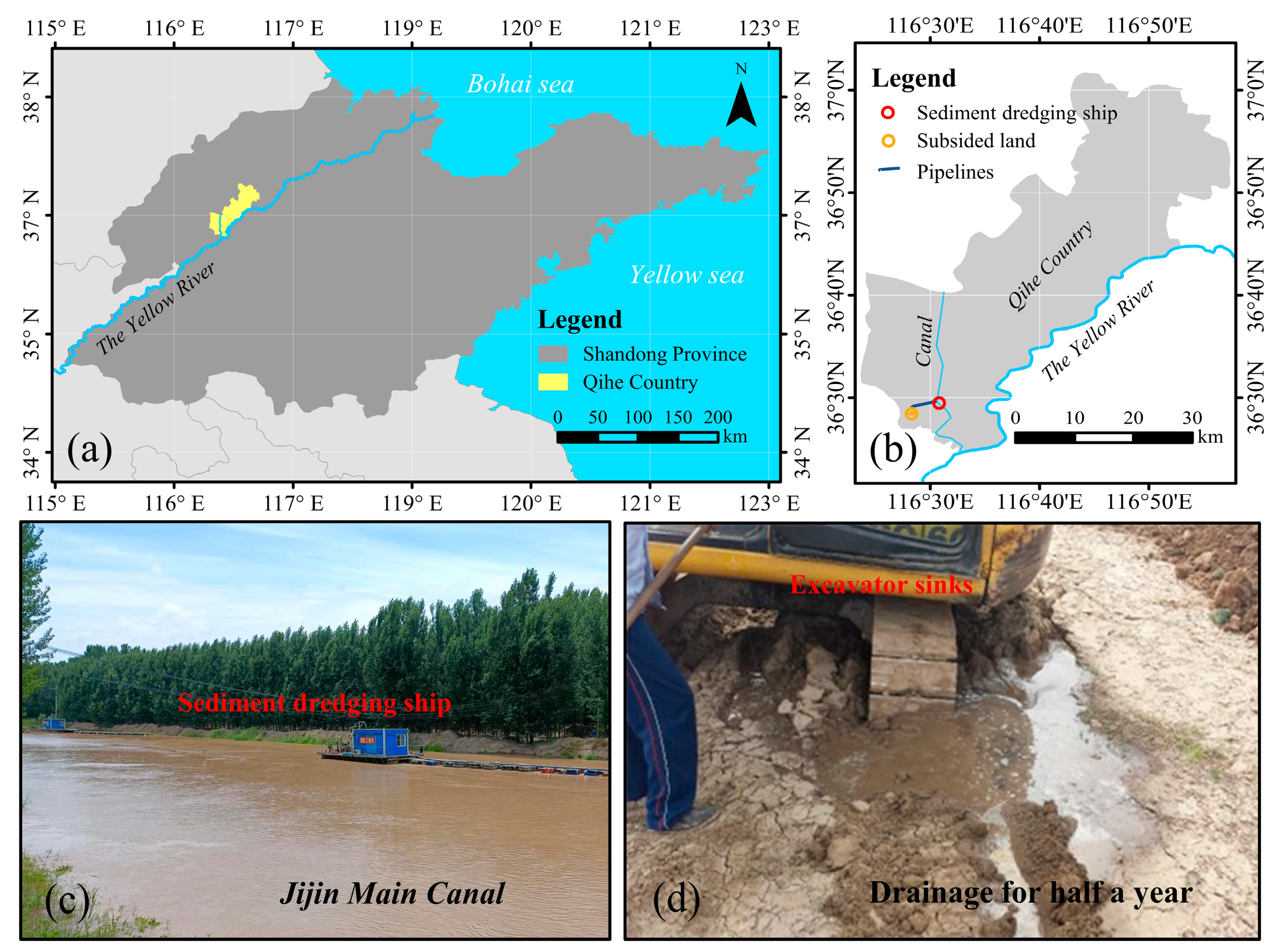

2.1. Experimental Materials

2.2. Physical and Mechanical Properties Determination Method

- (1)

- Relative density

- (2)

- Porosity and water content

- (3)

- Water permeability and plasticity

- (4)

- Mechanical properties

2.3. Data Processing and Analasis

3. Results

3.1. Physical Properties

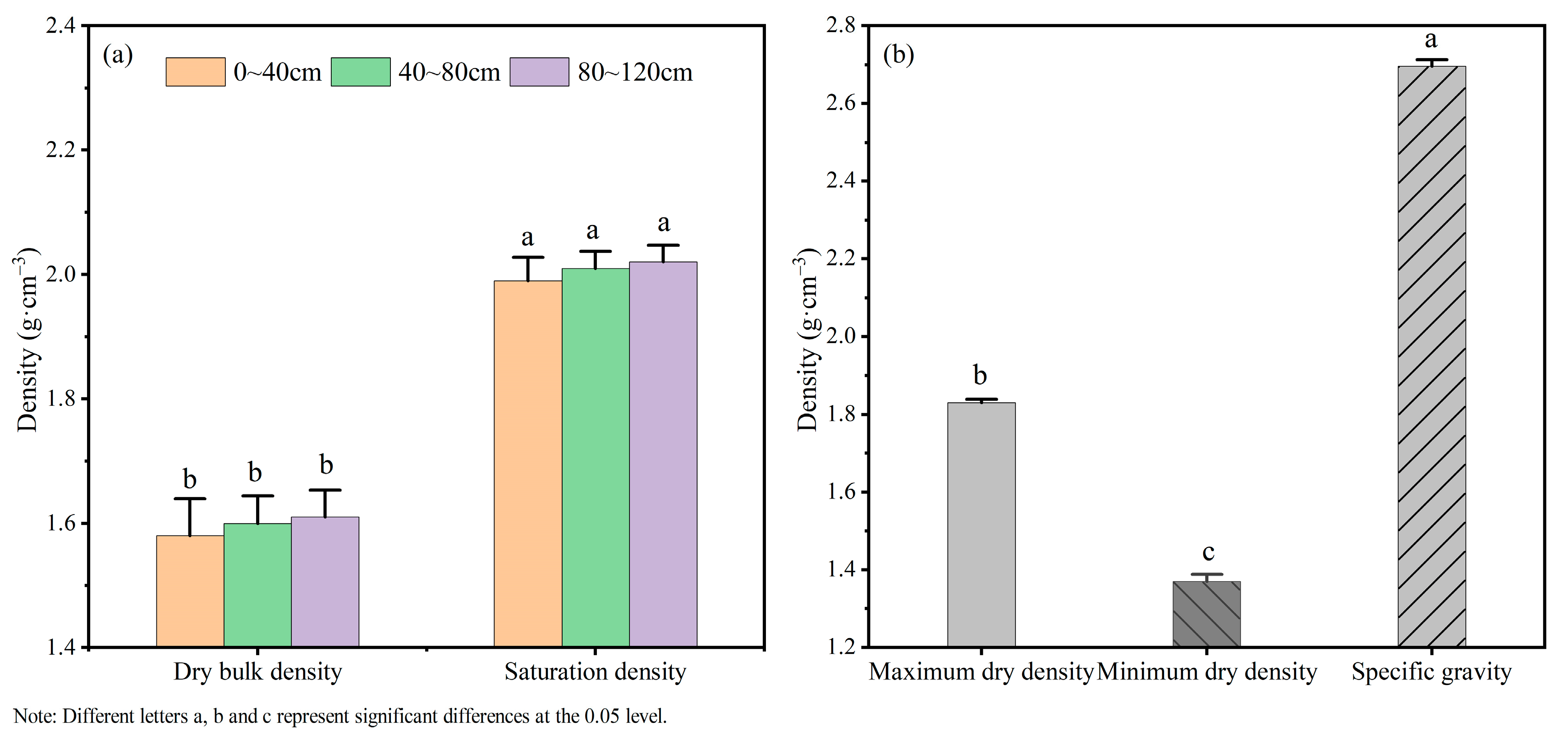

3.1.1. Basic Physical Properties

3.1.2. Porosity and Water Content

3.1.3. Water Permeability and Plasticity

3.2. Mechanical Properties

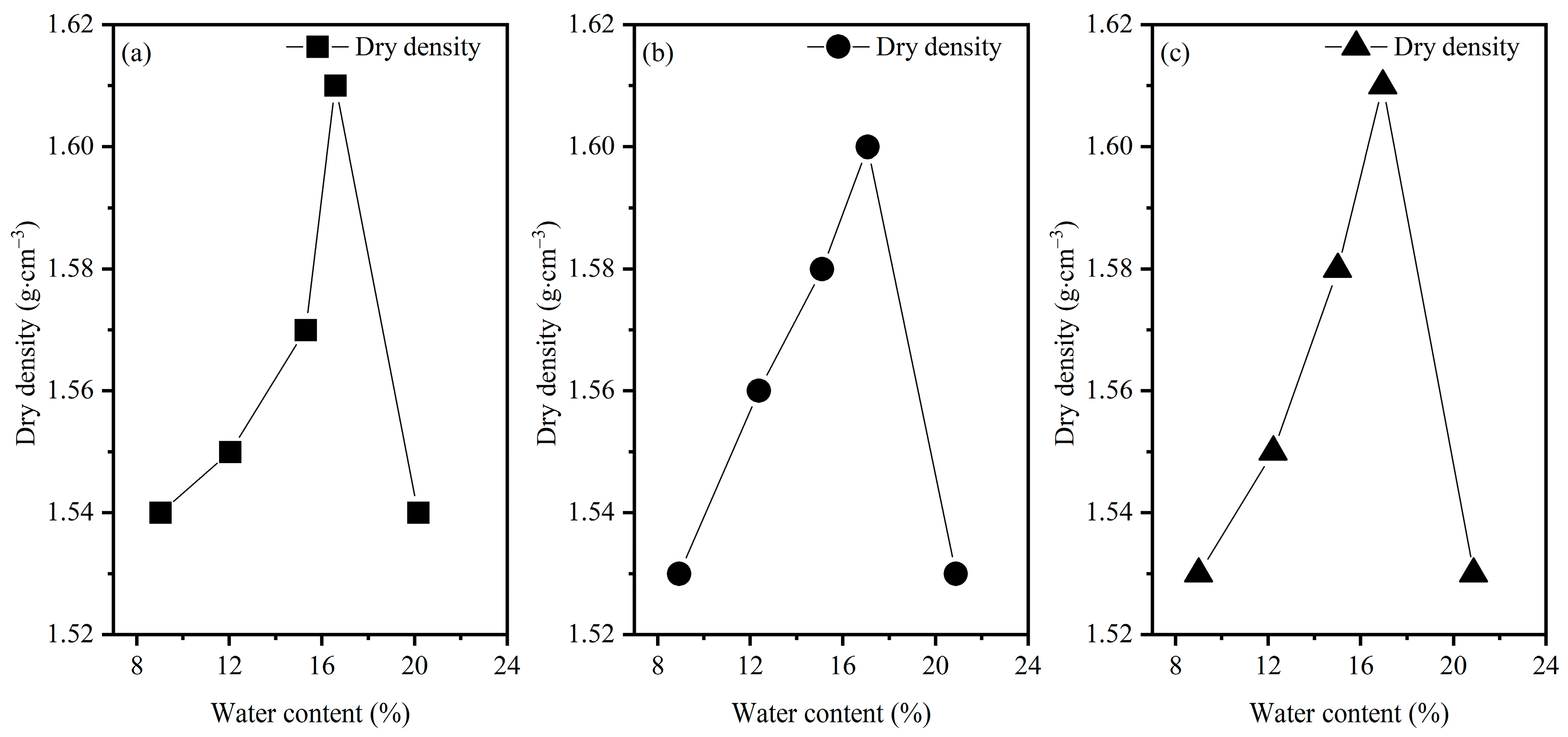

3.2.1. Compaction Property

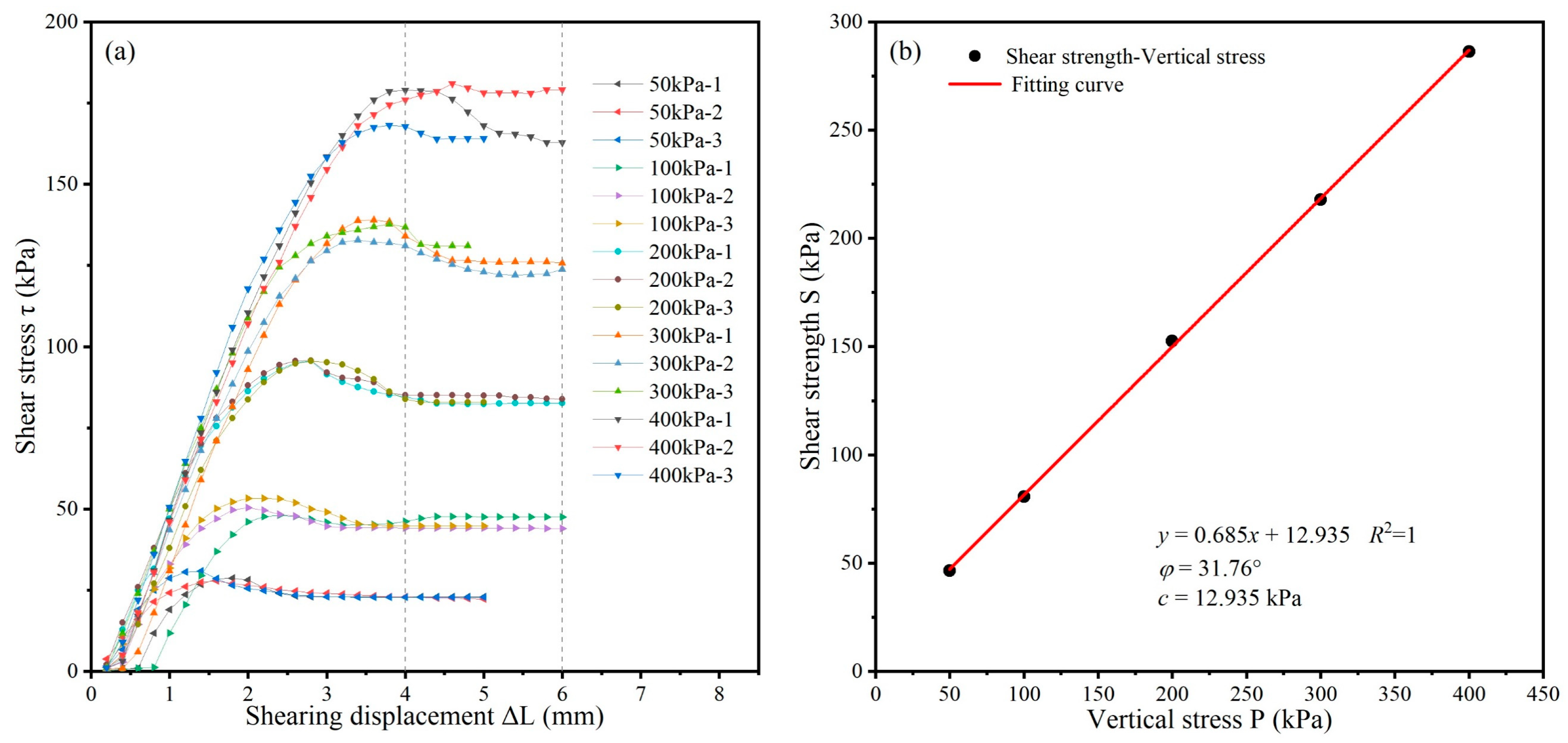

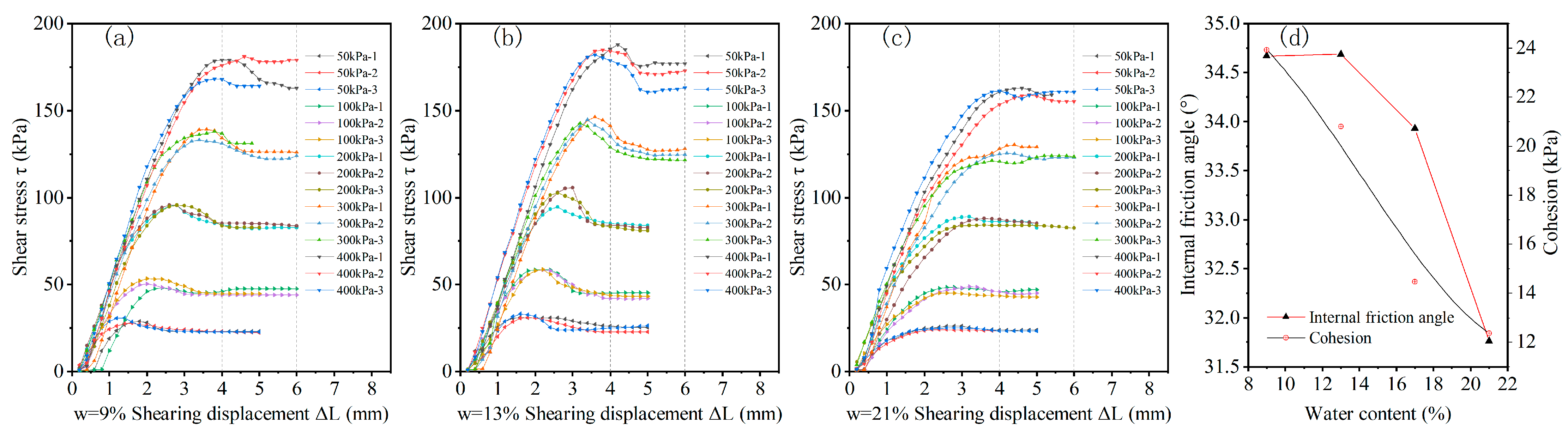

3.2.2. Shear Strength

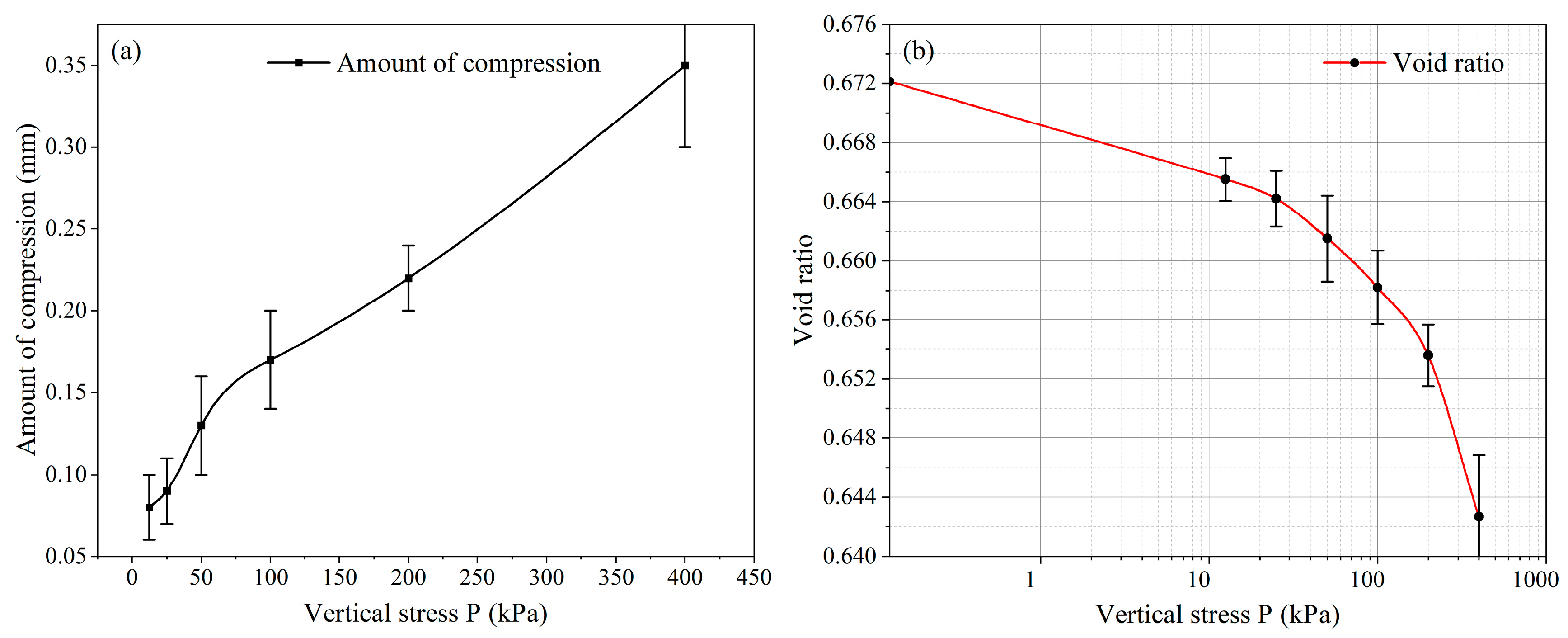

3.2.3. Compressibility

4. Discussion

4.1. Causes of Productivity Barriers and Soil Reconstruction in Yellow River Sediment Reclamation

4.2. Causes and Criteria of Drainage Problems in Yellow River Sediment Reclamation

4.3. Design Filled Ground Level for Reclamation: The Key to Controlling Subsidence

4.4. Ensuring Construction Safety: Key Measures and Reference Standards

4.5. Limitations and Future Works

5. Conclusions

- (1)

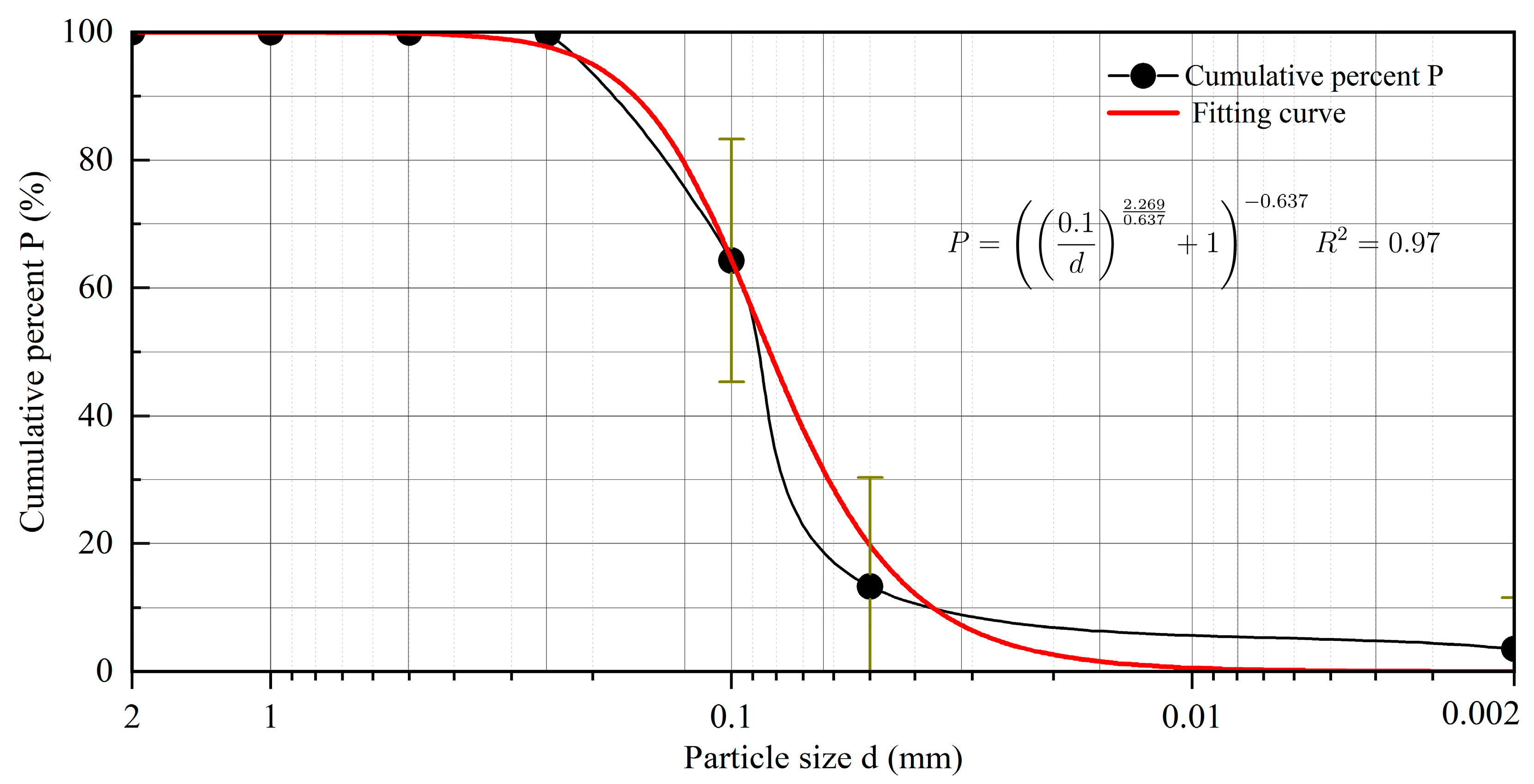

- The average particle size () of Yellow River sediment in coal-mined subsided land filling reclamation is 0.08 mm, which belongs to fine-grained sandy soil with a relatively uniform particle size and poor grading. After laboratory remolding and filling drainage, the dry capacity of Yellow River sediment is approximately 1.60 g·cm−3. The minimum dry density is 1.37 g·cm−3, and the maximum dry density is 1.83 g·cm−3. The void ratio is 0.68, the porosity is 40.64%, the minimum water holding capacity is 13.02%, the saturation capacity is 40.64%, and the degree of saturation is 51.24%. The liquid limit () is , the plastic limit () is , and the plasticity index () is .

- (2)

- The permeability of the Yellow River sediment used for reclaimed coal-mined subsided land is 2.91 × 10−3 cm·s−1, which is similar to that of silt. Although this generally makes it suitable as a filling material for land reclamation purposes, its low permeability during drainage can create drainage obstacles during backfilling. In practical engineering projects, it is necessary to improve drainage measures to increase the construction rates. The permeability of the sediments similar to silt may cause drainage barriers during backfilling processes, which highlights the need for improving drainage systems and techniques to optimize filling and drainage efficiency.

- (3)

- The Yellow River sediment used for reclaimed coal-mined subsided land exhibits internal friction angles that range from 34.67° to 31.76° and cohesions from 23.92 to 20.79 kPa. To ensure the safe levelling of the sediment during construction without submerging machinery, it is recommended that draining should achieve around 13% water content. At this level of water content, drainage can proceed swiftly while providing adequate stability for construction equipment operations. Achieving the appropriate water content allows maximum filling efficiency while simultaneously minimizing the risks of machinery immobilization during the levelling and compaction of the sediment. Further drainage might increase stability but could also extend the project schedule.

- (4)

- The Yellow River sediment used for reclaimed coal-mined subsided land has a low compressibility compression coefficient of 0.05 MPa−1. During reclamation construction, it would be uneconomical to undergo mechanical compression and compaction. With the increase in the depth of the backfill, the sediment experiences a change in overburden stress, which causes consecutive subsidence deformations over time because of wetting and drying cycles. Consider accounting for the cumulative subsidence by designing the final elevation (H) and initial backfill elevation (h) to comply with the equation: .

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, Y.; Gao, X.; Zhou, D.; Zhou, R. Changes in Soil Physical and Chemical Properties after a Coal Mine Subsidence Event in a Semi-Arid Climate Region. Pol. J. Environ. Stud. 2022, 31, 2329–2340. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Wang, C.; Pang, L. Overburden and Surface Subsidence with Slicing Paste Filling Mining in Thick Coal Seams. Front. Earth Sci. 2023, 10, 1027816. [Google Scholar] [CrossRef]

- Han, C.; Gao, Z.; Wu, Z.; Huang, J.; Liu, Z.; Zhang, L.; Zhang, G. Restoration of Damaged Ecosystems in Desert Steppe Open-Pit Coal Mines: Effects on Soil Nematode Communities and Functions. Land Degrad. Dev. 2021, 32, 4402–4416. [Google Scholar] [CrossRef]

- Zeng, Y.; Pang, Z.; Wu, Q.; Hua, Z.; Lv, Y.; Wang, L.; Zhang, Y.; Du, X.; Liu, S. Study of Water-Controlled and Environmentally Friendly Coal Mining Models in an Ecologically Fragile Area of Northwest China. Mine Water Environ. 2022, 41, 802–816. [Google Scholar] [CrossRef]

- Shang, H.; Zhan, H.-Z.; Ni, W.-K.; Liu, Y.; Gan, Z.-H.; Liu, S.-H. Surface Environmental Evolution Monitoring in Coal Mining Subsidence Area Based on Multi-Source Remote Sensing Data. Front. Earth Sci. 2022, 10, 790737. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, B. The Use of Coal Fly Ash in Sodic Soil Reclamation. Land Degrad. Dev. 2003, 14, 285–299. [Google Scholar] [CrossRef]

- Wang, J.; Qin, Q.; Hu, S.; Wu, K. A Concrete Material with Waste Coal Gangue and Fly Ash Used for Farmland Drainage in High Groundwater Level Areas. J. Clean. Prod. 2016, 112, 631–638. [Google Scholar] [CrossRef]

- Bai, D.-S.; Yang, X.; Lai, J.-L.; Wang, Y.-W.; Zhang, Y.; Luo, X.-G. In situ restoration of soil ecological function in a coal gangue reclamation area after 10 years of elm/poplar phytoremediation. J. Environ. Manag. 2022, 305, 114400. [Google Scholar] [CrossRef]

- Xu, L.; Xu, S.; Yang, X.; Yan, J.; Meuser, H.; Makowsky, L. Study on Distribution Character of Physical and Chemical Properties and Heavy Metals in Reclaimed Land Filled with Fly Ash:A Case Study of Reclaimed Land of Luohe Power Plant in Huainan City. J. Agro-Environ. Sci. 2012, 31, 2352–2360. [Google Scholar]

- Wang, P.; Shao, F.; Liu, J.; Li, X.; Hu, Z.S.; Yost, R. Simulated Experiment on Drainage and Fine Sediment Retention Effects of Geotextiles in Land Reclamation with Yellow River Sediments. Trans. Chin. Soc. Agric. Eng. 2015, 31, 72–80. [Google Scholar] [CrossRef]

- Weber, J.; Straczynska, S.; Kocowicz, A.; Gilewska, M.; Bogacz, A.; Gwizdz, M.; Debicka, M. Properties of Soil Materials Derived from Fly Ash 11 Years after Revegetation of Post-Mining Excavation. Catena 2015, 133, 250–254. [Google Scholar] [CrossRef]

- Wang, H.; Han, B.; Bian, Z. Simulation Research on Water Upright Movement in Reclaimed Soil by Filling. J. China Univ. Min. Technol. 2007, 36, 690–695. [Google Scholar]

- Fu, J.; Lu, J.; Wu, M.; Ma, L.; An, C. Medium-Sized Channel Shaping in the Lower Yellow River Due to Water-Sediment Regulation. Water Supply 2023, 23, 192–205. [Google Scholar] [CrossRef]

- Zhang, J.; Shang, Y.; Cui, M.; Luo, Q.; Zhang, R. Successful and Sustainable Governance of the Lower Yellow River, China: A Floodplain Utilization Approach for Balancing Ecological Conservation and Development. Environ. Dev. Sustain. 2022, 24, 3014–3038. [Google Scholar] [CrossRef]

- Wang, P.; Hu, Z.; Shao, F.; Jiang, Z.; Qiao, Z.; Liu, D.; Chen, Y. Feasibility Analysis of Yellow River Sediment Used as the Filling Reclamation Material of Mining Subsidence Land. J. China Coal Soc. 2014, 39, 1133–1139. [Google Scholar] [CrossRef]

- Hu, Z.; Shao, F.; Duo, L.; Wu, S.; Li, X.; McSweeney, K. Technique of Reclaiming Subsided Land with Yellow River Sediments in the Form of Spaced Strips. J. China Coal Soc. 2017, 42, 557–566. [Google Scholar] [CrossRef]

- Wang, P. Technique of Filling and Drainage of Water-Sediment Mixture Used to Reclaim Mining Subsidence Land in Eastern China. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2016. [Google Scholar]

- Li, X.; Niu, W.; Zhang, W.; Wang, Y.; Wen, S.; Yang, X. Effect of Potassium Sulfate Fertilizer on Flocculation and Sedimentation of Static Yellow River Water. J. Soil Water Conserv. 2019, 33, 140–146+227. [Google Scholar] [CrossRef]

- Zhao, R.; Hua, L.; Liu, H.; Yu, Y.; Song, Q.; Wu, S.; Yin, Y. Feasibility Study on Yellow River Sediment Used in Subgrade Filling of Expressway. Yellow River 2021, 43, 122–126. [Google Scholar] [CrossRef]

- Yong-Gang, J.; Xiao-Lei, L.; Hong-Xian, S.; Jie-Wen, Z.; Su-Xia, H. The Effects of Hydrodynamic Conditions on Geotechnical Strength of the Sediment in Yellow River Delta. Int. J. Sediment. Res. 2011, 26, 318–330. [Google Scholar] [CrossRef]

- Jing, X.; Li, G.; Zhang, Y.; Han, J.; Wang, B. Experimental Research on the Modification of the Yellow River Sediment. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 1031–1037. [Google Scholar] [CrossRef]

- Jiang, S.; Xu, J.; Song, Y.; Xu, Y. Alkali-Activated Fly Ash Foam Concrete with Yellow River Silt: Physico-Mechanical and Structural Properties. Constr. Build. Mater. 2023, 373, 130879. [Google Scholar] [CrossRef]

- Fang, L.; Li, C.; Chen, C.; Yan, G.; Zhang, Y.; Chai, X.; Zhang, Y. Research on Mechanical Performance of Yellow River Sediment Concrete in Kaifeng Section. Yellow River 2022, 44, 141–144+162. [Google Scholar] [CrossRef]

- Mao, W.; Kang, S.; Wan, Y.; Sun, Y.; Li, X.; Wang, Y. Yellow River Sediment as a Soil Amendment for Amelioration of Saline Land in the Yellow River Delta. Land Degrad. Dev. 2016, 27, 1595–1602. [Google Scholar] [CrossRef]

- Wang, P.; Hua, B.; Sun, H.; Fan, S.; Yang, Y.; Hu, Z. Investigation and Analysis of Obstacle Factors on Productivity of the Reclaimed Farmland Filled with Yellow River Sediment. J. China Agric. Univ. 2020, 25, 139–147. [Google Scholar] [CrossRef]

- Hu, Z.; Duo, L.; Wang, X. Principle and Method of Reclaiming Subsidence Land with Inter-Layers of Filling Materals. J. China Coal Soc. 2018, 43, 198–206. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, X.; McSweeney, K.; Li, Y. Restoring Subsided Coal Mined Land to Farmland Using Optimized Placement of Yellow River Sediment to Amend Soil. Land Degrad. Dev. 2022, 33, 1029–1042. [Google Scholar] [CrossRef]

- GB-T50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- NY-T 1121.4-2006; Soil Testing—Part 4: Method for Determination of Soil Bulk Density. China Agriculture Press: Beijing, China, 2006.

- SL 42-2010; Technical Standard for Determination of Sediment Particle Size in Open Channels. Ministry of Water Resources of the People’s Republic of China: Beijing, China, 2010.

- NY-T 1121.22-2010; Soil Testing—Part 22: Cutting Ring Method for Determination of Field Water-Holding Capacity in Soil. China Agriculture Press: Beijing, China, 2010.

- Swamee, P.K.; Ojha, C.S.P. Bed-Load and Suspended-Load Transport of Nonuniform Sediments. J. Hydraul. Eng. 1991, 117, 774–787. [Google Scholar] [CrossRef]

- Mao, C. Dikes Engineering Mannual; China Water&Power Press: Beijing, China, 2009; ISBN 978-7-5084-6875-4. [Google Scholar]

- Das, B.M. Advanced Soil Mechanics, 5th ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2019; ISBN 978-1-351-21516-9. [Google Scholar]

- Wang, X. Mechanism of Action of Interlayers in Reconstructed Soil Filled with Yellow River Sediments and Its Simulation. Ph.D. Dissertation, China University of Mining and Technology, Beijing, China, 2020. [Google Scholar]

- Van Maren, D.S.; Winterwerp, J.C.; Wang, Z.Y.; Pu, Q. Suspended Sediment Dynamics and Morphodynamics in the Yellow River, China. Sedimentology 2009, 56, 785–806. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, M. Coarse Sediment and Lower Yellow River Siltation. J. Hydro-Environ. Res. 2012, 6, 267–273. [Google Scholar] [CrossRef]

- Bednik, M.; Medyńska-Juraszek, A.; Dudek, M.; Kloc, S.; Kręt, A.; Łabaz, B.; Waroszewski, J. Wheat Straw Biochar and NPK Fertilization Efficiency in Sandy Soil Reclamation. Agronomy 2020, 10, 496. [Google Scholar] [CrossRef]

- Shao, F.; Wang, P.; Li, E.; Jiang, Z.; Qiao, Z.; Liu, D.; Chen, Y. The Feasibility of Application of Desilting and Drainage Engineering Measures in the Process of Filling Reclamation with Yellow River Sediment. Energy Environ. Prot. 2013, 27, 1–5. [Google Scholar]

- Wang, Q.; Xie, J.; Yang, J.; Liu, P.; Chang, D.; Xu, W. Research on Permeability Coefficient of Fine Sediments in Debris-Flow Gullies, Southwestern China. Soil Syst. 2022, 6, 29. [Google Scholar] [CrossRef]

- He, T.; Xiao, W.; Zhao, Y.; Chen, W.; Deng, X.; Zhang, J. Continues Monitoring of Subsidence Water in Mining Area from the Eastern Plain in China from 1986 to 2018 Using Landsat Imagery and Google Earth Engine. J. Clean. Prod. 2021, 279, 123610. [Google Scholar] [CrossRef]

- Lehmann, P.; Merlin, O.; Gentine, P.; Or, D. Soil Texture Effects on Surface Resistance to Bare-Soil Evaporation. Geophys. Res. Lett. 2018, 45, 10398–10405. [Google Scholar] [CrossRef]

- Jie, L.; Ping, L.; Xiao, L.; Yuanqin, X.; Wei, G. The Characteristics of Consolidation Settlement and Its Contribution to the Topographical Change in the Northern Modern Huanghe River Subaqueous Delta in China. Acta Oceanol. Sin. 2015, 34, 136–142. [Google Scholar] [CrossRef]

- Yang, X.; Jia, Y.; Liu, H.; Shan, H. Research on consolidation characteristics and origin of the yellow river estuary sediments. Mar. Geol. Quat. Geol. 2009, 29, 29–34. [Google Scholar]

- Hu, Z.; Duo, L.; Shao, F. Optimal Thickness of Soil Cover for Reclaiming Subsided Land with Yellow River Sediments. Sustainability 2018, 10, 3853. [Google Scholar] [CrossRef]

- Alias, R.; Kasa, A.; Taha, M.R. Particle Size Effect on Shear Strength of Granular Materials in Direct Shear Test. Int. J. Civ. Environ. Eng. 2014, 8, 1144–1147. [Google Scholar]

- Fan, Z.; Qu, J.; Zhou, H. The Relationship between Sand Particle Internal Friction Angle and Particle Size, Water Content and Slope Angle. J. Desert Res. 2015, 35, 301–305. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, X.; Su, X.; Guo, L.; Cui, Y.; Jia, C.; Ling, X. CPT-Based Evaluation of Sediment Characteristics and Effective Internal Friction Angle in the Yellow River Estuary. Mar. Georesour. Geotechnol. 2022, 40, 1108–1118. [Google Scholar] [CrossRef]

- Gu, T.; Wang, J.; Wang, C.; Bi, Y.; Guo, Q.; Liu, Y. Experimental Study of the Shear Strength of Soil from the Heifangtai Platform of the Loess Plateau of China. J. Soils Sediments 2019, 19, 3463–3475. [Google Scholar] [CrossRef]

- Canakci, H.; Hamed, M.; Celik, F.; Sidik, W.; Eviz, F. Friction Characteristics of Organic Soil with Construction Materials. Soils Found. 2016, 56, 965–972. [Google Scholar] [CrossRef]

- Xing, H.; Liu, J.; Wang, L.; Yao, X.; Wang, C.; Zhang, Y.; Zhou, D. Friction Characteristics of Soil-Soil Interface and Root-Soil Interface of Caragana Intermedia and Salix Psammophila. Tribology 2010, 30, 87–91. [Google Scholar] [CrossRef]

- Duo, L. Key Technologies of Subsidence Land Reclamation Filled with Yellow River Sediments by Alternating Mutli-Times and Multilayers. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2019. [Google Scholar]

| Dry Bulk Density (g·cm−3) | Saturation Capacity (%) | Minimum Water Holding Capacity (%) | Degree of Saturation (%) | Void Ratio | Porosity (%) | Permeability Coefficient (cm·s−1) |

|---|---|---|---|---|---|---|

| 1.60 | 40.64% | 13.02% | 51.24% | 0.68 | 40.64% | 2.91 × 10−3 |

| Soil Type | Thickness (cm) | Dry Bulk Density (g·cm−3) | Weight Density (KN·m−3) | Self-Weight Stress (kPa) | Settlement Deformation Amount (cm) |

|---|---|---|---|---|---|

| Topsoil | 30 | 1.35 | 18.3 | 5.49 | - |

| Subsoil | 40 | 1.43 | 19.1 | 7.64 | - |

| Yellow River sediment | 100 | 1.60 | 20.8 | 20.8 | 0.87 |

| Excavator Model | Tonnage (t) | Ground Specific Pressure (kPa) | Radius of Gyration (m) | Safe Load (kPa) |

|---|---|---|---|---|

| SY375H-S | big 30–50 t | 68.8 | 10.875 m | 82.56 |

| SY205C | medium 13–30 t | 47.4 | 10.28 m | 56.88 |

| SY75C | small 5–13 t | 33 | 6.24 m | 39.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Hu, Z.; Wang, S. A Study of the Physical and Mechanical Properties of Yellow River Sediments and Their Impact on the Reclamation of Coal-Mined Subsided Land. Sustainability 2024, 16, 439. https://doi.org/10.3390/su16010439

Sun H, Hu Z, Wang S. A Study of the Physical and Mechanical Properties of Yellow River Sediments and Their Impact on the Reclamation of Coal-Mined Subsided Land. Sustainability. 2024; 16(1):439. https://doi.org/10.3390/su16010439

Chicago/Turabian StyleSun, Huang, Zhenqi Hu, and Shuai Wang. 2024. "A Study of the Physical and Mechanical Properties of Yellow River Sediments and Their Impact on the Reclamation of Coal-Mined Subsided Land" Sustainability 16, no. 1: 439. https://doi.org/10.3390/su16010439

APA StyleSun, H., Hu, Z., & Wang, S. (2024). A Study of the Physical and Mechanical Properties of Yellow River Sediments and Their Impact on the Reclamation of Coal-Mined Subsided Land. Sustainability, 16(1), 439. https://doi.org/10.3390/su16010439