1. Introduction

Greenhouse gas (GHG) emissions pose a real threat to the environment, causing global warming and climate change. According to the US Environmental Protection Agency [

1], GHGs comprise 79.4% CO

2, 11.5% CH

4 (methane), 6.2% N

2O (nitrous oxide), and 3% fluorinated gases. The construction industry is a major contributor to GHG emissions, with excessive steel reinforcement bar (rebar) usage and cutting waste generating significant carbon emissions globally [

2]. In 2019, global rebar-cutting waste reached 47.3 million tons, equivalent to 16.2 million tons of CO

2 emissions [

3], wasting a tremendous amount of energy for nothing. High amounts of rebar-cutting waste can end up in landfills if not properly managed and disposed of. When rebar pieces end up in landfills, they can indirectly contribute to the production of landfill gas (LFG). Improperly disposed of cutting waste can end up in landfills, where it may be mixed with other types of waste, such as general waste. The presence of rebar-cutting waste within the landfill can exacerbate the generation of LFG by entrapping moisture and increasing the temperature of the surrounding waste, consequently accelerating the decomposition process [

4]. LFG is mainly composed of 40–50% CO

2 and 50–60% CH

4 [

5,

6], with trace amounts of H

2S (hydrogen sulfide) [

7]. CH

4 is a powerful greenhouse gas (GHG) with a global warming potential 28 times greater than CO

2 [

7]. The production of each metric ton of rebar requires 304–525 kWh of electricity and 54–96 m

3 of fresh water [

8] and is further burdened by potential carbon emissions associated with inefficient, non-renewable thermal power plants. Therefore, rebar-cutting waste and rebar usage is a serious threat to the environment. From a construction field viewpoint, employing a rebar unit price of USD 900/ton-rebar [

9] and a carbon price of USD 75/ton-CO

2 [

10], global financial losses resulting from rebar-cutting waste could reach a notable USD 43.8 billion. This figure arises from the substantial production of rebar-cutting waste, estimated at 47.3 million tons, which contributes to approximately 16.2 million tons of CO

2 emissions. Thus, minimizing rebar-cutting waste and rebar usage is essential to prevent further financial losses in construction projects and foster sustainable construction practices.

Previous studies predominantly utilized stock-length rebar to create cutting patterns to minimize cutting waste [

11,

12,

13,

14,

15,

16]. Subsequently, with the introduction of special-length (SpL) rebar, some researchers have successfully integrated stock-length and special-length rebars, leading to an even greater reduction in cutting waste [

17,

18]. However, certain conditions, such as a minimum order quantity, pre-order time, minimum length, and maximum length associated with acquiring SpL rebar, might differ between steel mills [

18]. Regarding the lap splice position, most studies examined the lap splice position to optimize rebar-cutting patterns [

13,

14,

15,

16,

17]. Building codes stipulate lapping zone regulations that govern the position of lap splices during rebar design and arrangement. These regulations are intended to ensure the effective distribution of moment forces within the structure. Researchers [

11,

12,

19] attempted to optimize the lap splice position to reduce rebar-cutting waste in the beam, column, and shear wall. However, despite the adherence, significant cutting waste was still generated (7.2–10.8%). These results imply that the adoption of the lapping zone regulation provided by building codes restricts the effort to reduce the cutting waste. Moreover, construction sites do not strictly adhere to rebar lapping zones in practice due to time-consuming construction procedures, reducing constructability and productivity [

20]. Lap splice design in concrete relies on factors like bond strength, cover, confinement, and rebar tensile capacity [

21]. Consequently, the lap position within the member is flexible if designed per these factors. Placed beyond the mandated zone, lap splices can still achieve equivalent strength and stability to those placed within [

20].

The previous optimization studies [

11,

12,

13,

14,

15,

16,

17] limited their study, as they primarily focused on minimizing cutting waste, ignoring the potential for reducing rebar usage through the reduction of the number of splices. In support of this viewpoint, Chen and Yang asserted that the RC design should consider as few splices as possible [

19]. Considering the limitations of the previous studies and the potential of placing lap splices beyond the lapping zone, this study proposed a novel algorithm that aimed to minimize rebar usage and obtain near-zero rebar-cutting waste (N0RCW) by reducing the number of splices, allowing flexibility in the positioning of lap splices, and using SpL rebars. The proposed algorithm was verified using longitudinal rebar of continuous columns. This type of column was selected due to its significance as a key structural member in reinforced concrete buildings and its high rebar requirements. In addition, the algorithm’s objective aligns with the Sustainable Development Goals (SDGs) [

22] adopted by the United Nations in 2015, particularly SDGs 9, 12, 13, and 15. These goals have a direct or indirect connection with the construction sector [

23]. SDG 9 aims to build resilient infrastructure, promote inclusive and sustainable industrialization, and foster innovation; SDG 12 aims to ensure sustainable consumption and production patterns; SDG 13 aims to take serious action to combat climate change and its impacts; and SDG 15 aims to protect and restore land, as well as halt land degradation. Therefore, the application of the proposed algorithm is expected to contribute to the advancement of sustainable, green construction practices and the achievement of the SDGs.

This paper is systematically organized into distinct phases: (1) definition of problems and introduction of novelty; (2) thorough review of existing studies focusing on optimizing rebar-cutting waste and understanding column characteristics; (3) development of the proposed algorithm with detailed methods and procedural steps; (4) comprehensive analysis of rebar-cutting waste, rebar usage, CO2 emissions, and related costs in a case study that applied the proposed algorithm; and (5) in-depth discussion, presentation of findings, results, and insights into future research avenues.

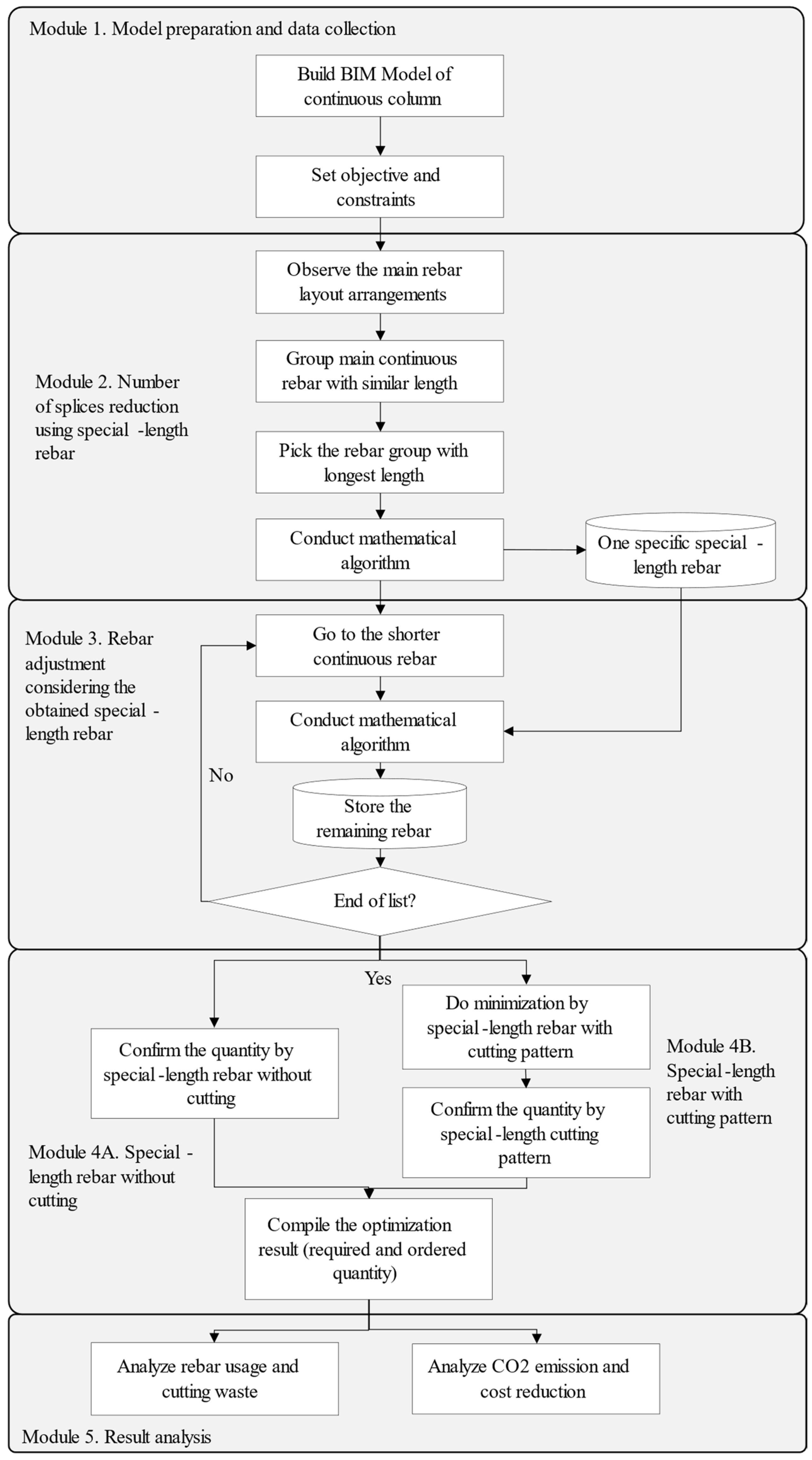

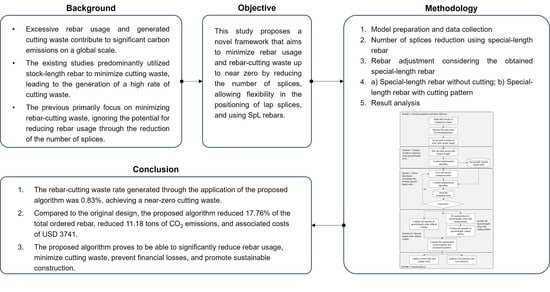

3. Algorithm for the N0RCW and Rebar Usage Minimization

Figure 2 shows the framework of this study. The framework consisted of five modules: (1) model preparation and data collection; (2) the number of splices reduction using SpL rebar; (3) rebar adjustment considering the obtained special SpL rebar; (4) generation of SpL rebar without cutting and SpL rebar with cutting patterns; and (5) results analysis regarding cutting waste, rebar usage, CO

2 emission, and cost reduction. The primary focus of the proposed algorithm was minimizing rebar usage and cutting waste, aiming for near-zero by reducing splices, introducing flexibility in the lap splice positions, and employing SpL rebar. This paper presents an algorithm to generate a single SpL rebar that meets steel mills’ minimum quantity and preorder time requirements for SpL rebar procurement. Lee et al. [

18] defined the minimum ordered quantity as 50 tons and a two-month lead time for preorders.

3.1. Model Preparation and Data Collection

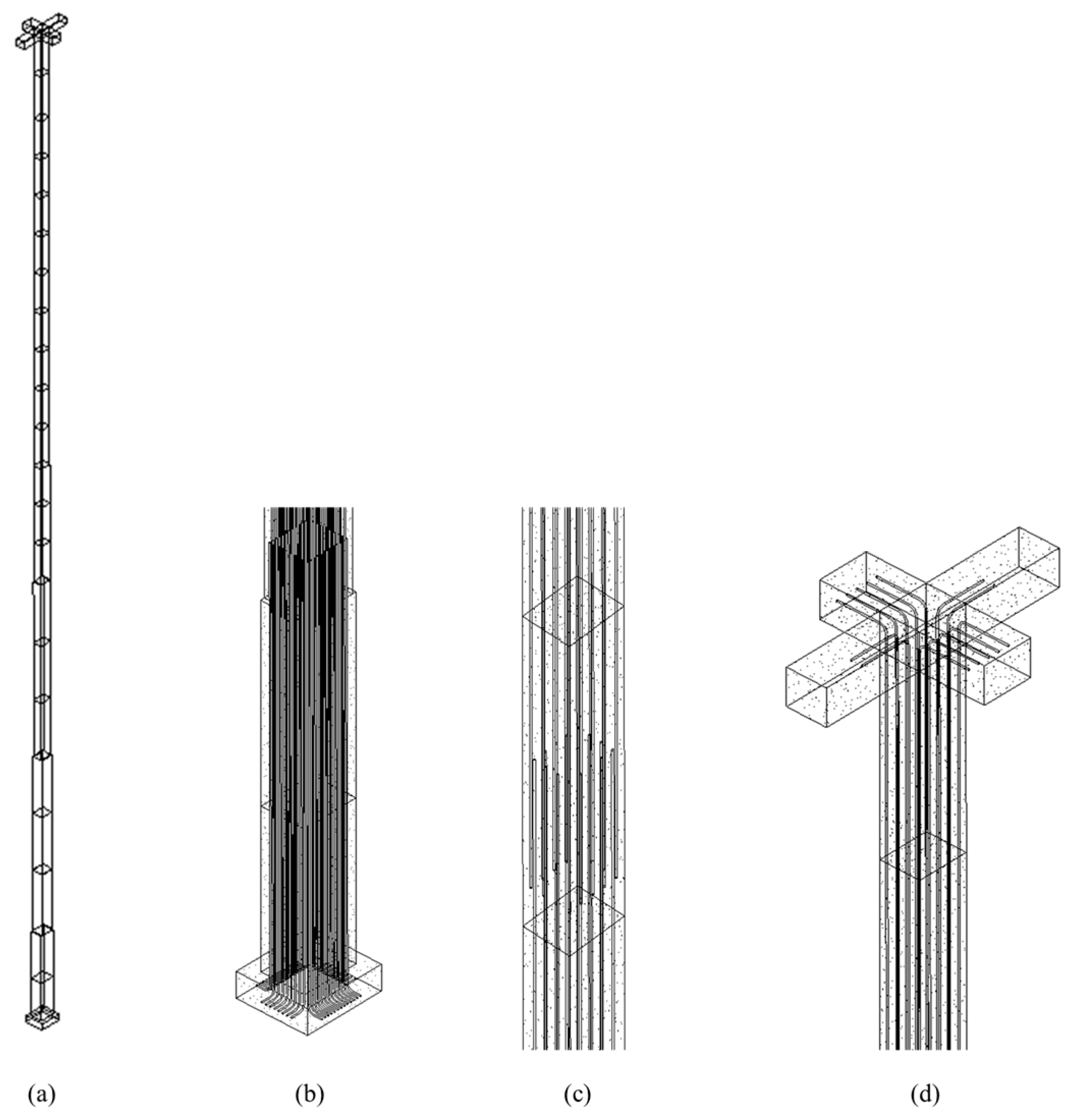

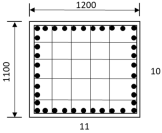

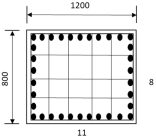

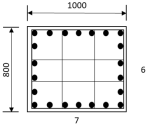

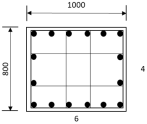

In the first module, the column was built as a structural BIM model in Autodesk Revit following the original structural design. A 3D model was created with the length, width, and depth of concrete columns from the foundation to the roof floor. The reinforcements, which consisted of the main rebar and hoops, were added to the column. From the BIM model, it can be observed that the column exhibited various rebar layout configurations as it extended from the basement floor (B2) to the roof floor, as shown in

Table 1. This variation occurred because the column dimensions and the number of rebars decreased on the upper floors. For instance, there were 42 rebars from B2 to B1, whereas there were only 14 rebars from the 13th floor (F13) to the 20th floor (F20).

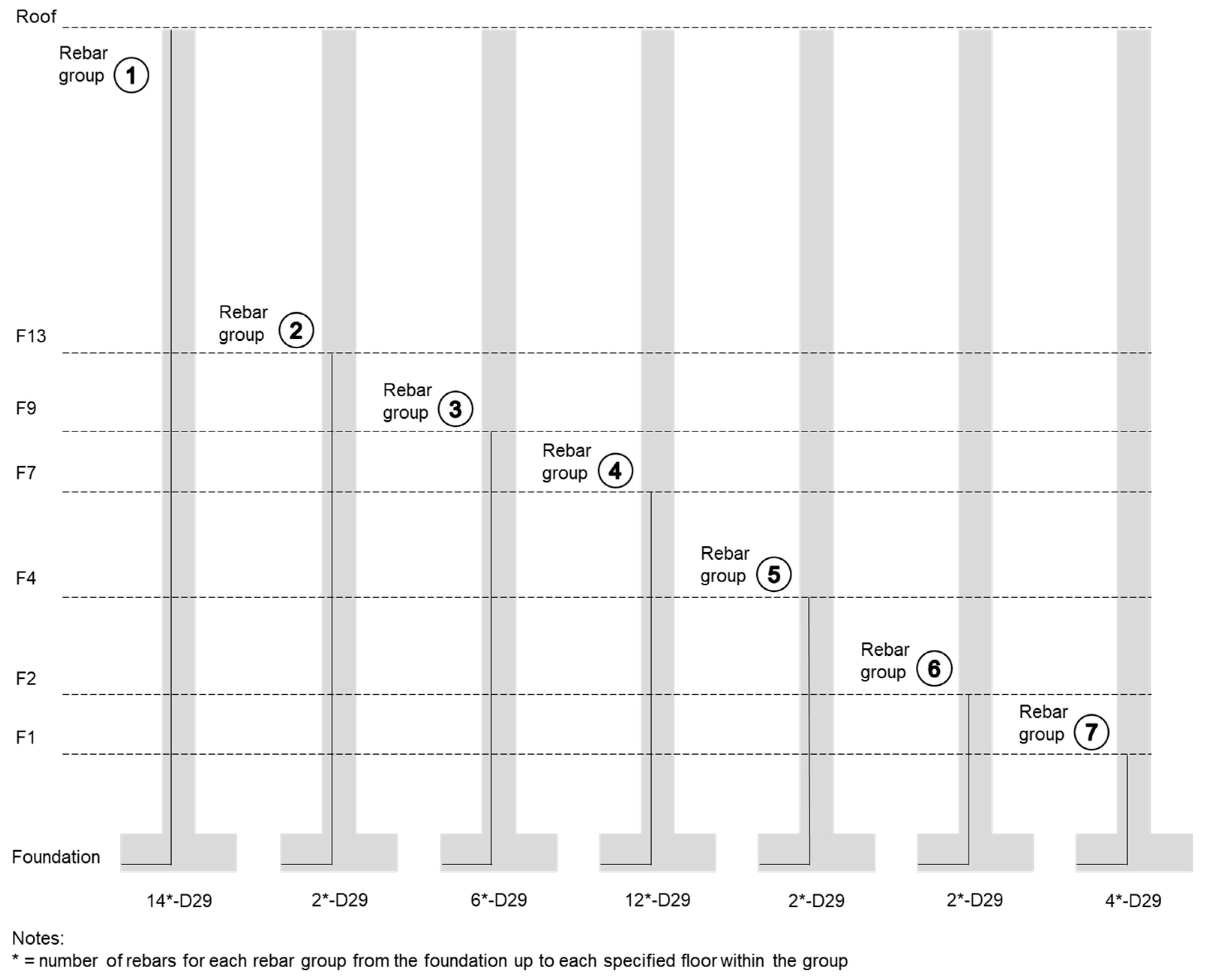

Based on the observed layout configuration, it can be deduced that certain rebars spanned from the foundation to the roof floor, while others extended only up to a specific point in the column. The proposed algorithm took advantage of this rebar layout by grouping rebars with similar lengths. Consequently, column rebars were classified based on their shared length. For instance, 14 rebars that spanned from the foundation to the roof floor were grouped and labeled as the first rebar group. Similarly, two rebars that spanned from the foundation to the 13th floor (F13) were grouped and referred to as the second rebar group. In this case study, the grouping process was repeated until a total of seven rebar groups were obtained, as shown in

Figure 3.

3.2. Number of Splices Reduction Prioritizing SpL Rebar

The second module dealt with the first rebar group, which had the longest length. A series of mathematical algorithms were implemented to reduce the number of splices from the original design. By the end of this module, one specific SpL rebar was obtained.

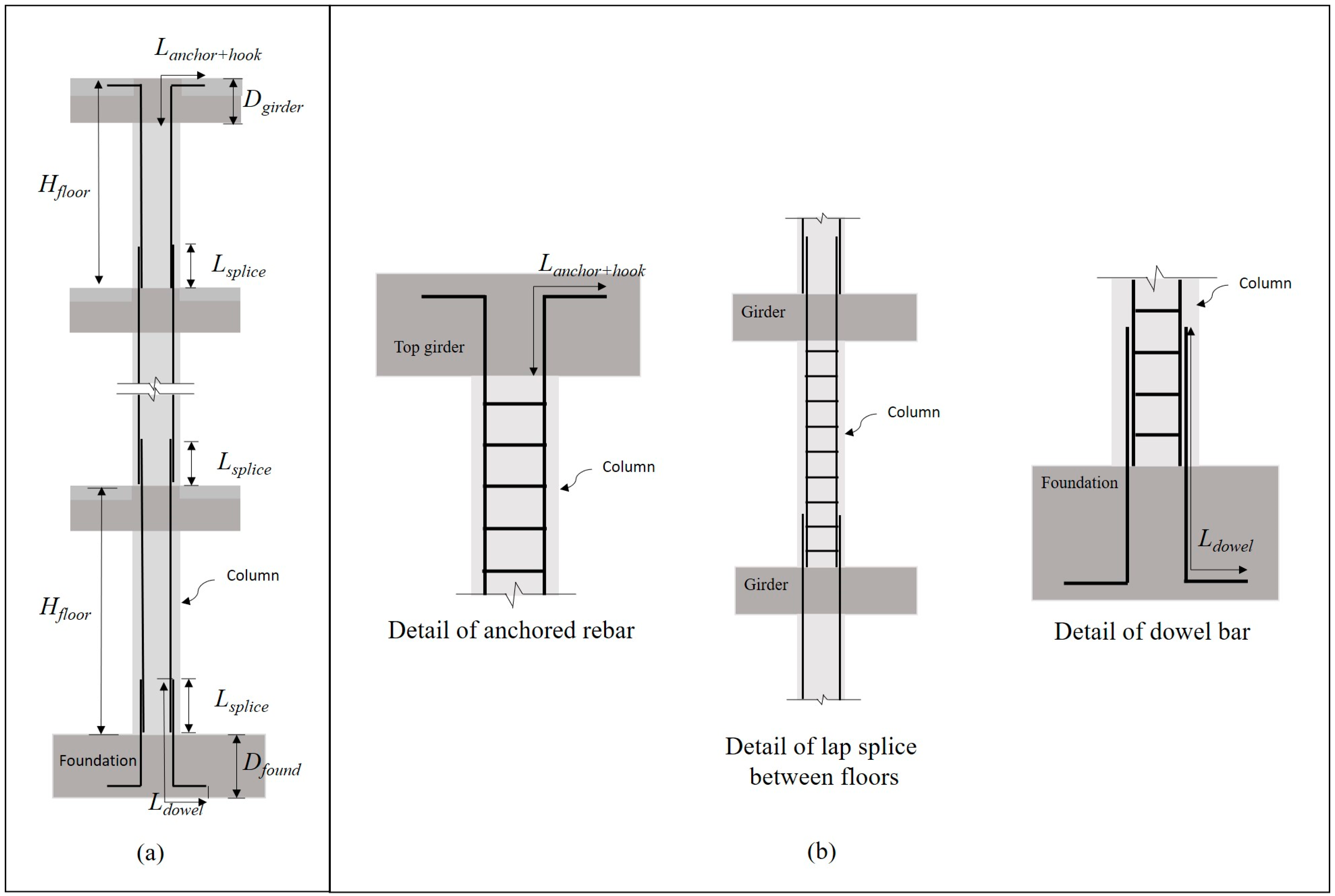

First, rebar information regarding splices (

), spans (

), rebars (

), and the length of lapping (

) of the original design needed to be obtained, as it is necessary for the algorithm. Second, the total length (

) of continuous rebar in the first rebar group was calculated. The total length equation of the column main rebar that stretched from the foundation to the top girder is shown in Equation (1), as proposed in previous research [

24]. Equation (1) incorporates the height of the floor, number of floors, depth of girder, length of dowel, length of anchorage, lap length, and number of lap splices.

where

is the total length of continuous main rebar (mm),

is the height of each floor (mm),

is the number of floors for each rebar group,

is the depth of the girder (mm),

is the length of the dowel bar (mm),

is the hook anchorage length (mm),

is the lap splice length (mm),

is the number of splices, and

is the bending deduction.

Third, the number of SpL rebar was calculated by dividing the total length (

) by the maximum purchase length (

). The number of SpL rebars (

) was calculated using the ceiling function to obtain an integer number, as shown in Equation (2).

It can be observed that the number of SpL rebars was less than the original number of rebars (

), which means that the number of splices for an SpL rebar (

) was less than the original number of splices (

). Calculation of the number of splices of an SpL rebar (

) was undertaken by reducing the number of SpL rebars by 1, as shown in Equation (3). For example, if the previous equation yielded five SpL rebars, then there would be four splices when considering the SpL rebars (5 − 1 = 4).

The difference between the number of splices in the original design and with using SpL rebar led to the reduction in lap splice

), which was calculated as shown in Equation (4).

The new total rebar length (

) should be calculated due to the reduction in the number of splices, as described in Equation (5).

The new total rebar length (

) was then divided by the number of SpL rebar (

) to acquire the calculated length of the rebar (

), as shown in Equation (6). Then, the calculated length acquired was rounded up to obtain the special-length rebar (

), as shown in Equation (7). The roundup function was used so that the calculation result was rounded up to one decimal place, as SpL rebar can only be ordered in 0.1 m intervals.

Finally, the lapping length was adjusted by using Equation (8).

3.3. Rebar Adjustment Considering the Obtained SpL Rebar

This third module attempted to utilize the SpL rebar obtained from the previous module to accommodate other rebar groups. As dividing the total length of each rebar group by the obtained SpL rebars did not yield an integer value, this step generated a remaining rebar. By the end of the third module, the remaining rebars were collected.

Utilizing Equation (1), the total rebar length (

) for each rebar group was obtained. The number of rebars (

) could be calculated by dividing the total rebar length (

) by the length of the SpL rebar (

), as described in Equation (9). The ceiling function was used to obtain an integer number. Subsequently, Equation (10) could be employed to calculate the number of SpL rebars for each rebar group.

However, not all rebars could be installed with the obtained SpL rebar. Thus, the remaining rebar (

) could be calculated by subtracting the total rebar length (

) by the total length of SpL rebar that could be installed, as shown in Equation (11). It should be emphasized that the number of remaining rebars will consistently remain at one.

3.4. Quantity Calculation

As shown in

Figure 2, the fourth module was about quantity calculation and was divided into two parts. Module 4A was developed to calculate the rebar quantity (

) by multiplying the SpL rebar length (

), number of SpL rebars (

), and unit weight of the rebar (

), as shown in Equation (12). The number of SpL rebars without cutting could be collected from the second and third modules.

Meanwhile, for module 4B, the number of SpL rebars with cutting patterns (

) for the remaining rebars needed to be processed using Equation (13) through Equation (18). These equations were derived from a prior study by Lee et al. [

18]. Equation (13) served as the objective function, aiming to reduce the proportion of cutting waste produced by the cutting patterns of SpL rebar.

where

is special length

(mm),

is the length of cutting pattern

obtained by combining multiple demand lengths (mm), and

is the number of rebar combinations with the same cutting pattern.

Equations (14)–(18) show the constraints necessary for fulfilling the objective function. In Equation (14), it is required that the length (

) of cutting pattern

gained from the multiple required rebars combination (

) should not exceed or equal to the designated special length

). Equation (15) stipulates that the number of rebar combinations sharing the same cutting pattern

(

) must be greater than zero, with

being a positive natural number. Equation (16) specifies that the special length (

) must fall within the range of minimum (

) to maximum (

) of the special length that can be ordered. Equation (17) dictates that the total combined rebar quantity (

) must be greater than or equal to the minimum rebar quantity required by the steel mills (

). Finally, Equation (18) establishes that the rebar-cutting waste (

) should be less than or equal to the target rebar-cutting waste (

).

From this module, the required quantity

() and ordered quantity (

) were obtained based on Equation (12). The required quantity was the actual quantity that was used in the construction, while the ordered quantity was the quantity ordered by the contractors from the steel mills; they were calculated by multiplying the quantity, length, and unit weight of rebar (

). The required quantity for continuous rebars

() could be calculated by considering the calculated rebar length

() described in Equation (6), as shown in Equation (19), while for the remaining rebars

(), the quantity could be calculated by considering the total length of the cutting pattern

i (), as described in Equation (20). Equation (21) could be utilized to calculate the ordered quantity for both the continuous and remaining rebars, taking into account the identified SpL rebar (

). The RCW rate was calculated by dividing the difference between the ordered and required quantities by the ordered quantity, as described in Equation (22).

3.5. Result Analysis

In the fifth module, the rebar database from the second and third modules, as well as the required and ordered quantities from the fourth module, were compiled. Then, the rebar usage and RCW from the developed algorithm were analyzed and compared with the original design. Finally, the advantages of reducing the number of splices and using SpL rebar were confirmed by comparing the produced CO2 emission and the CO2-associated saving cost with the original design.

5. Discussion

Sustainable and green construction practices have placed significant emphasis on reducing rebar-cutting waste, as investigated by previous studies [

11,

12,

13,

14,

15,

16,

17,

18]. Nevertheless, there has been an insufficient focus on reducing rebar consumption. Unnecessary rebar usage commonly occurs when contractors place the lap splice on every floor of the continuous column when the rebar can be continued to the next floor. This practice does not conform to Chen and Yang’s statement. Chen and Yang [

19] affirmed that there should be as few splices as possible in designing continuous reinforcements. Therefore, the proposed algorithm of this study emphasizes a number of splices reduction, which can significantly reduce rebar usage. Compared with the original design with a lap splice on every floor, the proposed algorithm used one specific length of SpL rebar, where the lap splice can be placed anywhere along the column. As a result, there was a notable decrease of 17.76% in the total amount of ordered rebar, emphasizing a substantial reduction in rebar consumption.

Regarding cutting waste, the algorithm successfully achieved N0RCW with 0.83% RCW, compared with the 12.93% RCW of the original design, representing a 94.72% reduction. N0RCW is possible due to SpL rebar utilization for rebar with and without cutting patterns. Even after achieving less rebar usage and N0RCW, the algorithm has a limitation. The algorithm is conducted by obtaining predetermined SpL rebar from the rebar group with the longest length and using that SpL rebar in other rebar groups. Hence, for future studies, an algorithm should be developed to be able to obtain one specific SpL rebar without a predetermined SpL rebar. Additionally, the installation of continuous SpL rebar may present certain challenges. To address these challenges, the development of a specialized device to facilitate the installation process, particularly in column–beam or column–girder joints, will be explored in future research.

While reliable and cost-effective, conventional lap splices become longer with increasing rebar diameter. To ensure a good bond, lap splices must be long enough, which can make them costly and impractical. Certain building codes, like the ACI [

33], prohibit splicing rebar with a diameter exceeding 36 mm. Couplers of mechanical splices offer an alternative to lap splicing, allowing for connecting these rebar sizes with shorter lap splicing [

39], reducing the number of rebars required and rebar waste. Future research could explore the use of couplers to further reduce rebar usage.

Given the immense worldwide demand for steel and rebar, the reduction in rebar usage and cutting waste would result in a reduction in carbon emissions, as well as GHG and cost throughout the entire production and installation process. This study showed that the proposed algorithm was able to reduce CO2 emissions by up to 11.18 tons and the cost by up to USD 3741. This was only for one column, namely, C14. Hence, when the algorithm is applied to a construction project with many columns, the advantages of the algorithm will also be multiplied. Additionally, the reduction of rebar waste conforms with the Sustainable Development Goals (SDGs) adopted by the United Nations in 2015, particularly SDGs 9, 12, 13, and 15. This ensures sustainable rebar usage and helps to tackle the adverse impacts of rebar waste on the environment.

Nevertheless, SpL rebar usage is not yet commonly adopted by the construction industry. One challenge is that steel mills often set difficult requirements, such as a minimum order quantity for a specific SpL rebar. This study demonstrated that obtaining a specific SpL rebar for a single continuous column is possible, requiring 14.939 tons for one column. This was sufficient to meet the minimum order quantity of 50 tons, as the building was constructed of multiple columns. As the authors expect that SpL rebar usage will become more prevalent in the future, it would be advantageous for steel mills to apply more flexible SpL rebar procurement options to make it more accessible to small and medium construction projects. Furthermore, manufacturers of construction materials and products play a critical role in attaining several Sustainable Development Goals (SDGs) targets [

40].