Comparative Environmental Evaluation of Sewage Sludge Treatment and Aggregate Production Process by Life Cycle Assessment

Abstract

1. Introduction

2. Materials and Methods

2.1. Manufacturing Lightweight Aggregate Using Sewage Sludge

2.2. Life Cycle Assessment Method

- Define the purpose and scope: In this, the goal and boundaries of the work must be defined. In this study, a comparison of the environmental impact and aspects of the various methods of sludge treatment (landfill, incineration, and aggregate production) were analyzed.

- Analyze the lifecycle inventory (LCI): This includes emission data for each unit process related to the inputs and outputs of energy and mass flow of the sludge treatment process. This step involves calculating both material and energy inputs and outputs to create a numerical representation.

- Life cycle impact assessment (LCIA): this step assesses potential environmental impacts and estimates resources, which includes the LCI results and manufacturing/process characterization of sludge treatment methods.

- Interpret the entire lifecycle: This step provides the overall conclusion through the interpretation of important environmental issues arising during the LCA of the sludge management techniques. In this study, the total environmental impact of the treatment of 1 ton of anaerobic digestion sludge was quantified without estimating the entire life cycle effect within the time span.

2.3. Goal and Scope Definition

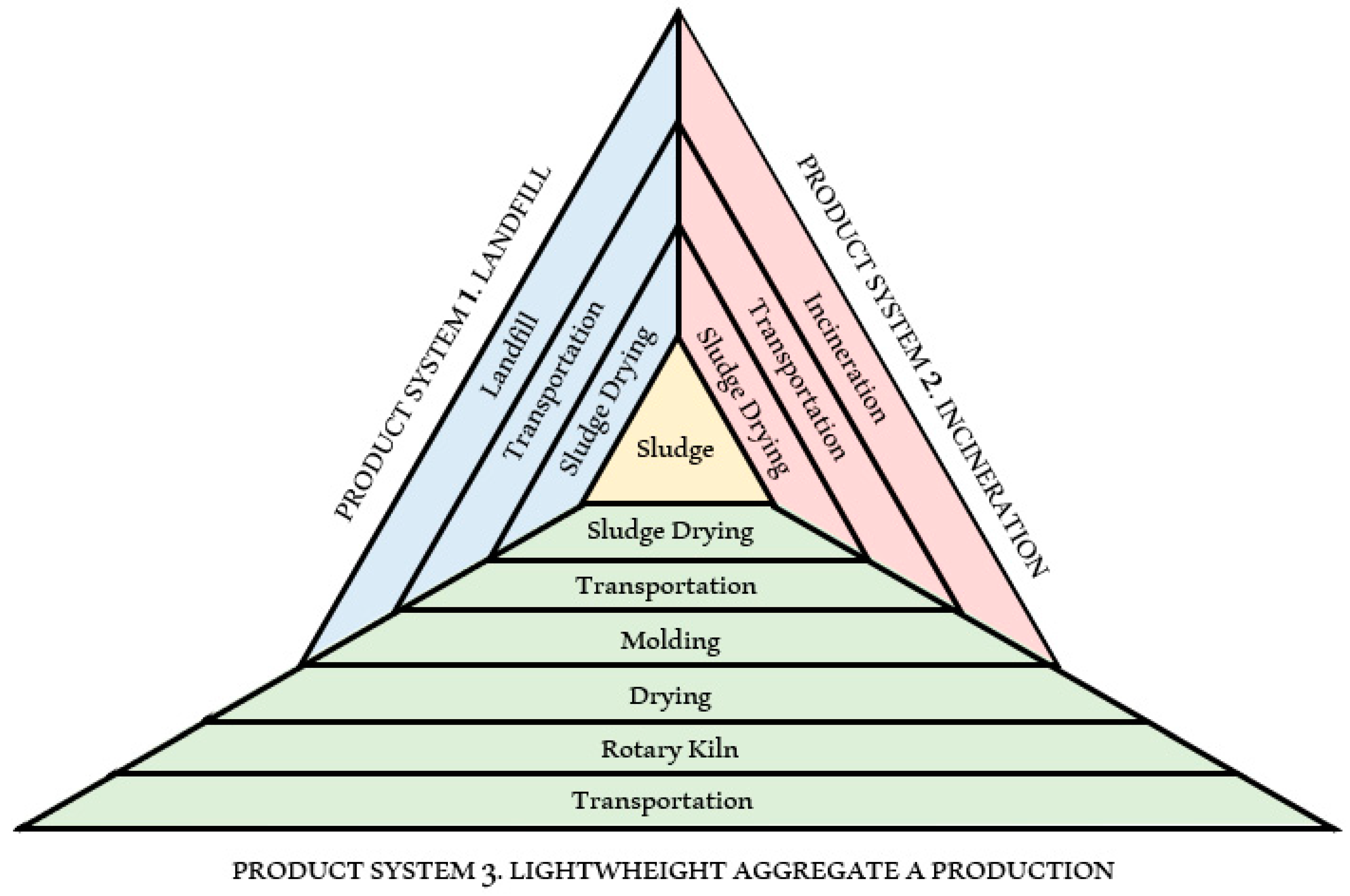

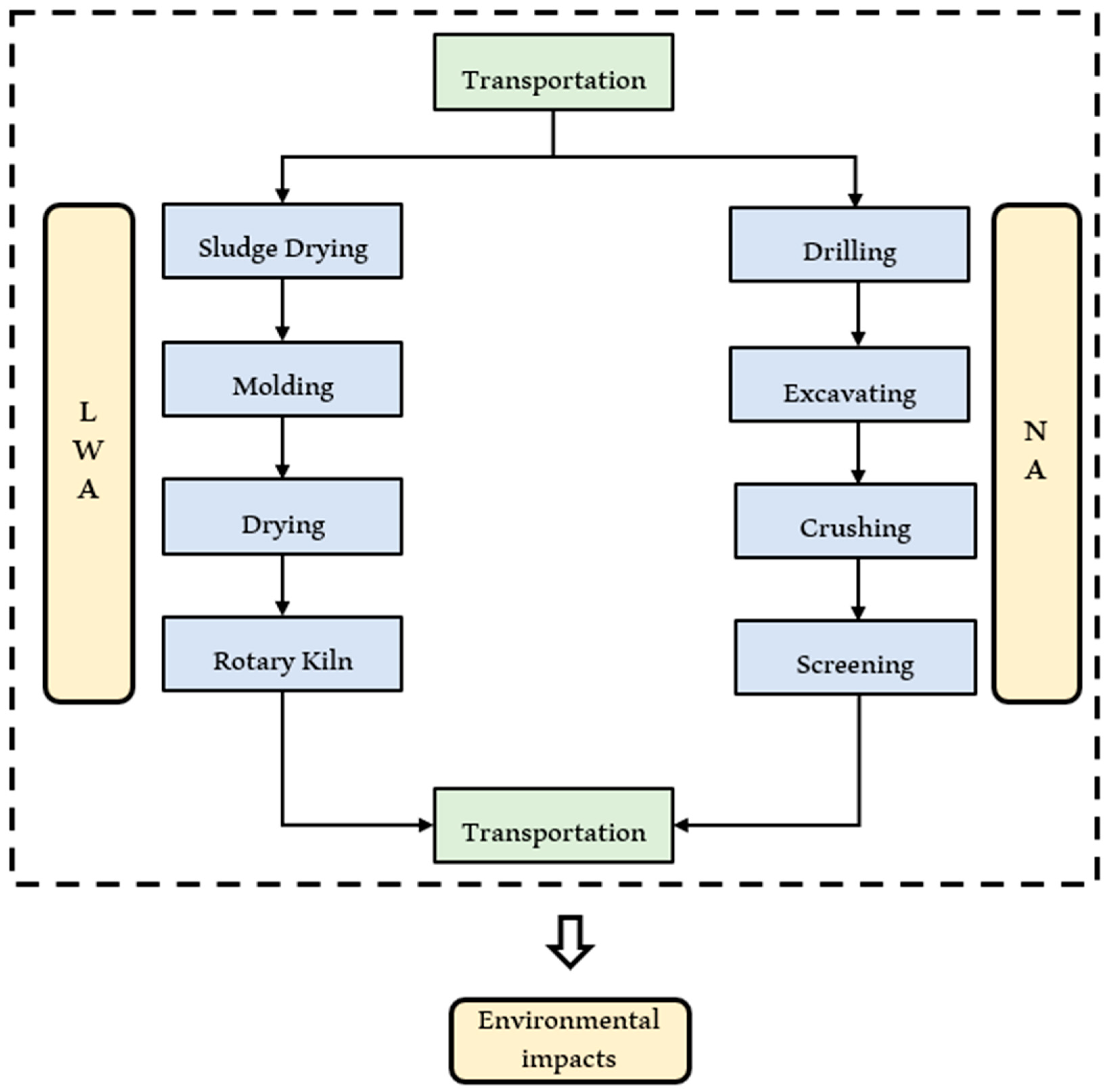

2.4. Description of System Boundaries

2.5. Life Cycle Inventory (LCI) Analysis

2.5.1. Drying Sludge

2.5.2. Transportation

2.5.3. Landfill

2.5.4. Incineration

2.5.5. Lightweight Aggregate (LWA)

2.5.6. Natural Aggregate (NA)

2.6. Life Cycle Impact Assessment

3. Result and Discussion

3.1. Assessment of Input and Output Parameters Used for Different Sludge Treatment Methods

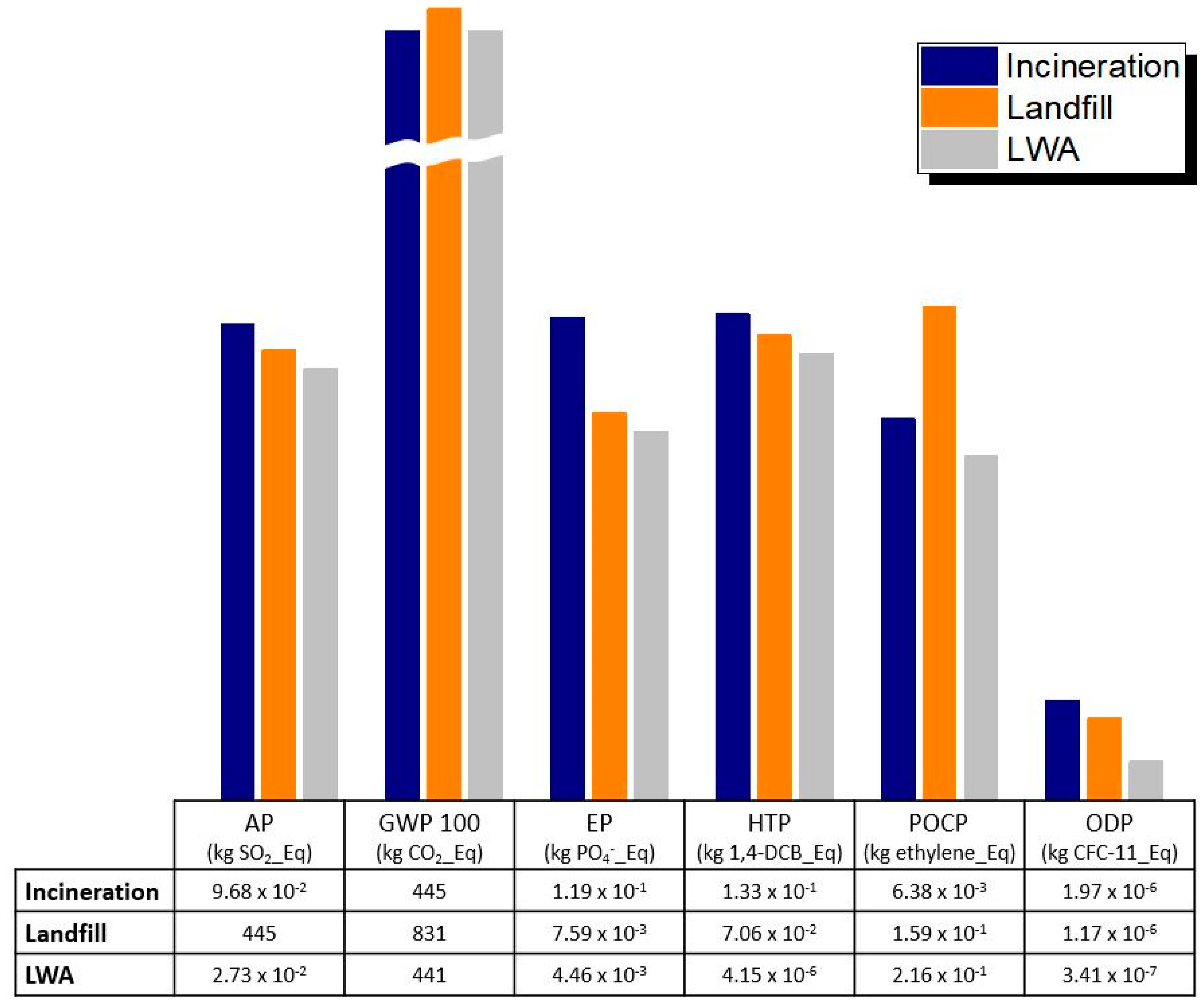

3.2. Assessment of Environmental Impact Parameters Used for LCA of Sludge Treatment Methods

3.3. Limitation/Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LWA | Lightweight Aggregate |

| NA | Natural Aggregate |

| GHG | Green House Gas |

| ISO | International Standardization Organization |

| AP | Acidification Potential |

| GWP 100 | Global Warming Potential |

| EP | Eutrophication Potential |

| HTP | Human Toxicity Potential |

| POCP | Photochemical Ozone Creation Potentials |

| ODP | Ozone Depletion Potential |

| D. Sludge | Dried (25% TS -> 83% TS) Sludge |

| M. Sludge | Molded Sludge |

| NMVOC | Non-Methane Volatile Organic Compound |

Appendix A

References

- Young-moo, C.; Hong, L.S. A Study on the Reduction and Disposal Treatment of Sewage Sludge in Gyeonggi-Do. 2012. Available online: http://www.dbpia.co.kr/journal/articleDetail?nodeId=NODE02171845 (accessed on 20 December 2023).

- Werther, J.; Ogada, T. Sewage sludge combustion. Prog. Energy Combust. Sci. 1999, 25, 55–116. [Google Scholar] [CrossRef]

- Kasina, M.; Kajdas, B.; Michalik, M. The leaching potential of sewage sludge and municipal waste incineration ashes in terms of landfill safety and potential reuse. Sci. Total Environ. 2021, 791, 148313. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Pawłowski, A. Sewage sludge-to-energy approaches based on anaerobic digestion and pyrolysis: Brief overview and energy efficiency assessment. Renew. Sustain. Energy Rev. 2012, 16, 1657–1665. [Google Scholar] [CrossRef]

- Kheradmand, S.; Karimi-Jashni, A.; Sartaj, M. Treatment of municipal landfill leachate using a combined anaerobic digester and activated sludge system. Waste Manag. 2010, 30, 1025–1031. [Google Scholar] [CrossRef] [PubMed]

- Suh, Y.-J.; Rousseaux, P. An LCA of alternative wastewater sludge treatment scenarios. Resour. Conserv. Recycl. 2002, 35, 191–200. [Google Scholar] [CrossRef]

- Ding, A.; Zhang, R.; Ngo, H.H.; He, X.; Ma, J.; Nan, J.; Li, G. Life cycle assessment of sewage sludge treatment and disposal based on nutrient and energy recovery: A review. Sci. Total Environ. 2021, 769, 144451. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Sun, Z.; Piao, W. Research on the environment-economy-technical comprehensive benefit evaluation method of typical sludge treatment technology. In Proceedings of the 2021 International Conference on E-Commerce and E-Management (ICECEM), Dalian, China, 24–26 September 2021. [Google Scholar]

- Teoh, S.K.; Li, L.Y. Feasibility of alternative sewage sludge treatment methods from a lifecycle assessment (LCA) perspective. J. Clean. Prod. 2020, 247, 119495. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Yoshida, H.; ten Hoeve, M.; Christensen, T.H.; Bruun, S.; Jensen, L.S.; Scheutz, C. Life cycle assessment of sewage sludge management options including long-term impacts after land application. J. Clean. Prod. 2018, 174, 538–547. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, C.; Liang, Y.; Gan, W.; Ho, J. Pumping lightweight aggregate concrete into high-rise buildings. J. Build. Eng. 2023, 80, 108069. [Google Scholar] [CrossRef]

- Grand View Research. Aggregates Market Size, Share & Trends Analysis Report by Type (Gravel, Crushed Stone, Sand), by Application (Concrete, Road Base & Coverings), by Region (APAC, MEA), and Segment Forecasts, 2020–2027; Markets Publishers: Birmingham, UK, 2020. [Google Scholar]

- Ausland, G.; Stevik, T.K.; Hanssen, J.F.; Køhler, J.C.; Jenssen, P.D. Intermittent filtration of wastewater—Removal of fecal coliforms and fecal streptococci. Water Res. 2002, 36, 3507–3516. [Google Scholar] [CrossRef] [PubMed]

- Nkansah, M.A.; Christy, A.A.; Barth, T.; Francis, G.W. The use of lightweight expanded clay aggregate (LECA) as sorbent for PAHs removal from water. J. Hazard. Mater. 2012, 217–218, 360–365. [Google Scholar] [CrossRef] [PubMed]

- Øiseth, E.; Refsdal, G. Lightweight Aggregates as Frost Insulation in Roads—Design Chart. In Cold Regions Engineering 2006; ASCE Press: Reston, VA, USA, 2006; pp. 1–11. [Google Scholar] [CrossRef]

- Bernhardt, M.; Tellesbø, H.; Justnes, H.; Wiik, K. Mechanical properties of lightweight aggregates. J. Eur. Ceram. Soc. 2013, 33, 2731–2743. [Google Scholar] [CrossRef]

- Sarabèr, A.; Overhof, R.; Green, T.; Pels, J. Artificial lightweight aggregates as utilization for future ashes—A case study. Waste Manag. 2012, 32, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-C.; Kuo, J. Potential of greenhouse gas emissions from sewage sludge management: A case study of Taiwan. J. Clean. Prod. 2016, 129, 196–201. [Google Scholar] [CrossRef]

- Lombardi, L.; Nocita, C.; Bettazzi, E.; Fibbi, D.; Carnevale, E. Environmental comparison of alternative treatments for sewage sludge: An Italian case study. Waste Manag. 2017, 69, 365–376. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Chen, W.; Hong, J. Life-cycle environmental and economic assessment of sewage sludge treatment in China. J. Clean. Prod. 2014, 67, 79–87. [Google Scholar] [CrossRef]

- Park, K.H.; Kim, Y.M.; Jang, H.W.; Kim, O.J.; Park, B.J. Current Status and Preferred Model of Clinical Trial Education and Certification Program for Clinical Trial Pharmacists: A Questionnaire Survey. J. Korean Soc. Clin. Pharmacol. Ther. 2005, 13, 208–220. [Google Scholar] [CrossRef][Green Version]

- Riley, C.M. Relation of Chemical Properties to the Bloating of Clays. J. Am. Ceram. Soc. 1951, 34, 121–128. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, K.G.; Lee, Y.S.; Wie, Y.M. Manufacturing and application of artificial lightweight aggregate from water treatment sludge. J. Clean. Prod. 2021, 307, 127260. [Google Scholar] [CrossRef]

- Lee, K.H.; Qasim, M.; Lee, K.G.; Inam, M.A.; Khan, I.A.; Khan, R.; Wie, Y.M. Use of ballasted flocculation (BF) sludge for the manufacturing of lightweight aggregates. J. Environ. Manag. 2022, 305, 114379. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.; Liu, Y.; Sun, S.; Gao, Y. Estimating life-cycle CO2 emissions of urban road corridor construction: A case study in Xi’an, China. J. Clean. Prod. 2020, 255, 120033. [Google Scholar] [CrossRef]

- Piippo, S.; Lauronen, M.; Postila, H. Greenhouse gas emissions from different sewage sludge treatment methods in north. J. Clean. Prod. 2018, 177, 483–492. [Google Scholar] [CrossRef]

- Moreno-Gutiérrez, J.; Durán-Grados, V. Calculating ships’ real emissions of pollutants and greenhouse gases: Towards zero uncertainties. Sci. Total Environ. 2021, 750, 141471. [Google Scholar] [CrossRef]

- Chua, C.B.H.; Lee, H.M.; Low, J.S.C. Life cycle emissions and energy study of biodiesel derived from waste cooking oil and diesel in Singapore. Int. J. Life Cycle Assess. 2010, 15, 417–423. [Google Scholar] [CrossRef]

- Hu, G.; Feng, H.; He, P.; Li, J.; Hewage, K.; Sadiq, R. Comparative life-cycle assessment of traditional and emerging oily sludge treatment approaches. J. Clean. Prod. 2020, 251, 119594. [Google Scholar] [CrossRef]

- Eggleston, S. IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies (IGES): Kanagawa, Japan, 2006. [Google Scholar]

- Liu, S.; Fan, W.; Guo, H.; Wu, X.; Chen, J.; Liu, Z.; Wang, X. Relationship between the N2O decomposition and NO formation in H2O/CO2/NH3/NO atmosphere under the conditions of simulated air-staged combustion in the temperature interval of 900–1600 °C. Energy 2020, 211, 118647. [Google Scholar] [CrossRef]

- Dongkeun, L.E.E.; Youngsang, K.I.M.; Kookyoung, A.H.N. Analysis of Methane Conversion Rate and Selectivity of Methane Pyrolysis Reaction in Ceramic Tube According to Temperature and Reaction Time. Trans. Korean Hydrogen. New Energy Soc. 2022, 33, 1–7. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- Martínez, E.; Blanco, J.; Jiménez, E.; Saenz-Díez, J.; Sanz, F. Comparative evaluation of life cycle impact assessment software tools through a wind turbine case study. Renew. Energy 2015, 74, 237–246. [Google Scholar] [CrossRef]

- Xiao, H.; Li, K.; Zhang, D.; Tang, Z.; Niu, X.; Yi, L.; Lin, Z.; Fu, M. Environmental, energy, and economic impact assessment of sludge management alternatives based on incineration. J. Environ. Manag. 2022, 321, 115848. [Google Scholar] [CrossRef] [PubMed]

- Deviatkin, I.; Kapustina, V.; Vasilieva, E.; Isyanov, L.; Horttanainen, M. Comparative life cycle assessment of deinking sludge utilization alternatives. J. Clean. Prod. 2016, 112, 3232–3243. [Google Scholar] [CrossRef]

- Liang, Y.; Xu, D.; Feng, P.; Hao, B.; Guo, Y.; Wang, S. Municipal sewage sludge incineration and its air pollution control. J. Clean. Prod. 2021, 295, 126456. [Google Scholar] [CrossRef]

- Sohail, M.; Eqani, S.; Shah, M.A.; Hashmi, M.Z. Chapter 14—Occurrence and fate of micropollutants in soils. In Environmental Micropollutants; Hashmi, M.Z., Wang, S., Ahmed, Z., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 295–304. [Google Scholar] [CrossRef]

- Nowak, B.; Perutka, L.; Aschenbrenner, P.; Kraus, P.; Rechberger, H.; Winter, F. Limitations for heavy metal release during thermo-chemical treatment of sewage sludge ash. Waste Manag. 2011, 31, 1285–1291. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Kalamdhad, A.S. Reduction of heavy metals during composting. Int. J. Environ. Prot. 2012, 2, 36–43. [Google Scholar]

- Björklund, A.E. Survey of approaches to improve reliability in LCA. Int. J. Life Cycle Assess. 2002, 7, 64–72. [Google Scholar] [CrossRef]

- Huijbregts, M.A.; Norris, G.; Bretz, R.; Ciroth, A.; Maurice, B.; von Bahr, B.; Weidema, B.; de Beaufort, A.S. Framework for modelling data uncertainty in life cycle inventories. Int. J. Life Cycle Assess. 2001, 6, 127–132. [Google Scholar] [CrossRef]

- Ross, S.; Evans, D.; Webber, M. How LCA studies deal with uncertainty. Int. J. Life Cycle Assess. 2002, 7, 47–52. [Google Scholar] [CrossRef]

- Shang, X.; Chang, J.; Yang, J.; Ke, X.; Duan, Z. Life cycle sustainable assessment of natural vs artificial lightweight aggregates. J. Clean. Prod. 2022, 367, 133064. [Google Scholar] [CrossRef]

- Todde, G.; Carboni, G.; Marras, S.; Caria, M.; Sirca, C. Industrial hemp (Cannabis sativa L.) for phytoremediation: Energy and environmental life cycle assessment of using contaminated biomass as an energy resource. Sustain. Energy Technol. Assess. 2022, 52, 102081. [Google Scholar] [CrossRef]

| Name | Fuel Type | CO2 Emission Coefficient | Energy Consumption | Reference | |

|---|---|---|---|---|---|

| Transport | Heavy-duty truck (Loaded) | Diesel | 0.1052 kg CO2/t·km | - | [28] |

| Heavy-duty truck (Empty) | Diesel | 0.0488 kg CO2/t·km | - | [28] | |

| Ship | Crude oil | 1.2682 kg CO2/t·km | - | - | |

| LWA | Rotary kiln | LNG | 2.17 kg CO2/m3 | 350 m3/h | Environmental Labeling |

| Dehydrator | Electricity | 4.95 × 10−1 kg CO2/kWh | 3.1 kW | Environmental Labeling | |

| Molding machine | Electricity | 4.95 × 10−1 kg CO2/kWh | 14.92 kW | Environmental Labeling |

| Process | Input | Quantity | Unit | Output | Quantity | Unit | Impact Potential |

|---|---|---|---|---|---|---|---|

| Landfill process | |||||||

| Drying | Sludge | 1.00 | Ton | ||||

| Diesel | 51.5 | Kg | CO2 | 162 | Kg | GWP | |

| Transportation | Diesel | 54.4 | Kg | CO2 | 16.6 | Kg | GWP |

| SO2 | 5.61 × 10−3 | Kg | AP, HTP | ||||

| NOx | 5.84 × 10−2 | Kg | AP, EP, HTP | ||||

| CO | 8.82 × 10−2 | Kg | GWP, POCP | ||||

| PM | 6.02 × 10−3 | Kg | - | ||||

| NMVOC | 4.72 × 10−2 | Kg | - | ||||

| CH4 | 2.33 × 10−2 | Kg | GWP, POCP | ||||

| CFC-11 | 1.17 × 10−6 | Kg | GWP, ODP | ||||

| Landfill | D. Sludge | 430 | Kg | 26.1 | Kg | GWP, POCP | |

| Incineration process | |||||||

| Drying | Sludge | 1.00 | Ton | ||||

| Diesel | 51.5 | Kg | CO2 | 162 | Kg | GWP | |

| Transportation | Diesel | 91.4 | Kg | CO2 | 27.8 | Kg | GWP |

| SO2 | 9.42 × 10−3 | Kg | AP, HTP | ||||

| NOx | 9.82 × 10−2 | Kg | AP, EP, HTP | ||||

| CO | 1.48 × 10−1 | Kg | GWP, POCP | ||||

| PM | 1.01 × 10−2 | Kg | - | ||||

| NMVOC | 7.93 × 10−2 | Kg | - | ||||

| CH4 | 3.92 × 10−2 | Kg | GWP, POCP | ||||

| CFC-11 | 1.97 × 10−6 | Kg | GWP, ODP | ||||

| Incineration | D. Sludge | 430 | Kg | CO2 | 188 | Kg | GWP |

| CH4 | 4.17 × 10−3 | Kg | GWP, POCP | ||||

| N2O | 3.87 × 10−1 | Kg | GWP, EP | ||||

| SOx | 1.00 × 10−2 | Kg | - | ||||

| PM | 2.00 × 10−4 | Kg | - | ||||

| NOx | 1.00 × 10−2 | Kg | EP, HTP | ||||

| CO | 4.00 × 10−3 | Kg | POCP | ||||

| HCl | 1.90 × 10−3 | Kg | HTP | ||||

| Coal | 1.40 × 103 | MJ | CO2 | 138 | Kg | GWP | |

| LWA | |||||||

| Drying | Sludge | 1.00 | Ton | D. Sludge | 430 | Kg | - |

| Diesel | 51.5 | Kg | CO2 | 162 | Kg | GWP | |

| Transportation | Diesel | 12.0 | Kg | CO2 | 3.64 | Kg | GWP |

| SO2 | 1.23 × 10−3 | Kg | AP, HTP | ||||

| NOx | 1.29 × 10−2 | Kg | AP, EP, HTP | ||||

| CO | 1.94 × 10−2 | Kg | GWP, POCP | ||||

| PM | 1.32 × 10−3 | Kg | - | ||||

| NMVOC | 1.04 × 10−2 | Kg | - | ||||

| CH4 | 5.13 × 10−3 | Kg | GWP, POCP | ||||

| CFC-11 | 2.57 × 10−7 | Kg | GWP, ODP | ||||

| Molding | Electricity | 14.9 | kWh | CO2 | 7.39 | Kg | GWP |

| D. Sludge | 430 | Kg | M. Sludge | 7.16 × 102 | Kg | - | |

| Clay | 286 | Kg | - | ||||

| Drying | Electricity | 74.4 | kWh | CO2 | 36.9 | Kg | GWP |

| M. Sludge | 716 | Kg | M. Sludge (Dried) | 716 | Kg | - | |

| Calcination | LNG | 4.64 × 103 | MJ | CO2 | 228 | Kg | GWP |

| M. Sludge (Dried) | 716 | kg | LWA | 716 | kg | - | |

| Natural aggregates (NA) | |||||||

| Transportation (Ship) | Crude Oil | 104 | Kg | CO2 | 334 | Kg | GWP |

| CO | 2.89 × 10−1 | Kg | GWP, POCP | ||||

| N2O | 1.57 × 10−2 | Kg | GWP, EP | ||||

| CH4 | 6.27 × 10−3 | Kg | GWP, POCP | ||||

| NOx | 9.11 | Kg | AP, EP, HTP | ||||

| NMVOC | 3.22 × 10−1 | Kg | - | ||||

| SOx | 2.76 | Kg | |||||

| Drilling | Electricity | 75.6 | kWh | CO2 | 37.4 | Kg | GWP |

| Excavating | Electricity | 75.6 | kWh | CO2 | 37.4 | Kg | GWP |

| NA | 716 | Kg | - | ||||

| Crushing | Electricity | 75.0 | kWh | CO2 | 37.1 | Kg | GWP |

| NA | 716 | Kg | NA | 716 | Kg | - | |

| Screening | Electricity | 22.0 | kWh | CO2 | 10.9 | Kg | GWP |

| NA | 716 | Kg | NA | 716 | Kg | - | |

| Transportation (Truck) | Diesel | 2.76 × 103 | MJ | CO2 | 36.9 | Kg | GWP |

| NA | 716 | Kg | CO | 1.97 × 10−1 | Kg | GWP, POCP | |

| CH4 | 5.20 × 10−2 | Kg | GWP, POCP | ||||

| CFC-11 | 1.57 × 10−6 | Kg | GWP, ODP | ||||

| NOx | 1.3 × 10−1 | Kg | AP, EP, HTP | ||||

| NMVOC | 1.05 × 10−1 | Kg | - | ||||

| SOx | 1.23 × 10−2 | Kg | - | ||||

| NA | 716 | Kg | - | ||||

| LWA vs. Landfill vs. Incineration | ||||

|---|---|---|---|---|

| Indicator | LWA | Landfill | Incineration | Unit |

| acidification potential (AP) | 2.73 × 10−2 | 4.65 × 10−2 | 9.68 × 10−2 | kg SO2_Eq |

| climate change (GWP 100) | 441 | 831 | 445 | kg CO2_Eq |

| eutrophication potential (EP) | 4.46 × 10−3 | 7.59 × 10−3 | 1.19 × 10−1 | kg PO4−_Eq |

| human toxicity (HTP) | 4.15 × 10−2 | 7.06 × 10−2 | 1.33 × 10−1 | kg 1,4-DCB_Eq |

| photochemical oxidation (summer smog) (POCP) | 1.64 × 10−3 | 1.59 × 10−1 | 5.30 × 10−3 | kg CH4_Eq |

| stratospheric ozone depletion (ODP) | 3.41 × 10−7 | 1.17 × 10−6 | 1.97 × 10−6 | kg CFC-11_Eq |

| LWA vs. NA | |||

|---|---|---|---|

| Indicator | LWA | NA | Unit |

| acidification potential (AP) | 2.73 × 10−2 | 8.40 | kg SO2_Eq |

| climate change (GWP 100) | 441 | 604 | kg CO2_Eq |

| eutrophication potential (EP) | 4.46 × 10−3 | 1.56 | kg PO4−_Eq |

| human toxicity (HTP) | 4.15 × 10−2 | 14.4 | kg 1,4-DCB_Eq |

| photochemical oxidation (summer smog) (POCP) | 1.64 × 10−3 | 1.64 × 10−2 | kg ethylene_Eq |

| stratospheric ozone depletion (ODP) | 3.41 × 10−7 | 1.57 × 10−6 | kg CFC-11_Eq |

| Landfill | Incineration | LWA | NA | ||

|---|---|---|---|---|---|

| CO2 | mean | 179.15 | 516.55 | 440.34 | 576.94 |

| Standard deviation | 2.36 | 3.91 | 0.59 | 42.97 | |

| SO2 | mean | 5.60 × 10−3 | 1.94 × 10−2 | 3.29 × 10−3 | 6.47 × 10−3 |

| Standard deviation | 8.00 × 10−4 | 1.32 × 10−3 | 4.07 × 10−4 | 9.16 × 10−4 | |

| NOx | mean | 5.83 × 10−2 | 1.08 × 10−1 | 3.43 × 10−2 | 11.9 |

| Standard deviation | 8.33 × 10−3 | 1.38 × 10−2 | 4.24 × 10−3 | 1.17 | |

| CO | mean | 8.81 × 10−2 | 1.52 × 10−1 | 5.18 × 10−2 | 4.78 × 10−1 |

| Standard deviation | 1.26 × 10−2 | 2.08 × 10−2 | 6.41 × 10−3 | 3.98 × 10−2 | |

| PM | mean | 6.01 × 10−3 | 1.03 × 10−2 | 3.53 × 10−3 | 1.39 |

| Standard deviation | 8.59 × 10−4 | 1.42 × 10−3 | 4.37 × 10−4 | 1.36 × 10−1 | |

| NMVOC | mean | 4.71 × 10−2 | 7.93 × 10−2 | 2.77 × 10−2 | 4.72 × 10−1 |

| Standard deviation | 6.73 × 10−3 | 1.12 × 10−2 | 3.43 × 10−3 | 4.19 × 10−2 | |

| CH4 | mean | 26.1 | 4.33 × 10−2 | 1.37 × 10−2 | 3.5 × 10−2 |

| Standard deviation | 3.33 × 10−3 | 5.51 × 10−3 | 1.69 × 10−3 | 3.90 × 10−3 | |

| CFC-11 | mean | 1.17 × 10−6 | 1.96 × 10−6 | 3.42 × 10−7 | 8.09 × 10−7 |

| Standard deviation | 1.17 × 10−7 | 1.96 × 10−7 | 2.70 × 10−8 | 8.14 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.-J.; Eom, J.-Y.; Lee, M.-J.; Hwang, D.-H.; Park, W.-B.; Wie, Y.-M.; Lee, K.-G.; Lee, K.-H. Comparative Environmental Evaluation of Sewage Sludge Treatment and Aggregate Production Process by Life Cycle Assessment. Sustainability 2024, 16, 226. https://doi.org/10.3390/su16010226

Yang S-J, Eom J-Y, Lee M-J, Hwang D-H, Park W-B, Wie Y-M, Lee K-G, Lee K-H. Comparative Environmental Evaluation of Sewage Sludge Treatment and Aggregate Production Process by Life Cycle Assessment. Sustainability. 2024; 16(1):226. https://doi.org/10.3390/su16010226

Chicago/Turabian StyleYang, Seong-Jun, Ji-Young Eom, Myung-Jin Lee, Dae-Hwan Hwang, Won-Bin Park, Young-Min Wie, Ki-Gang Lee, and Kang-Hoon Lee. 2024. "Comparative Environmental Evaluation of Sewage Sludge Treatment and Aggregate Production Process by Life Cycle Assessment" Sustainability 16, no. 1: 226. https://doi.org/10.3390/su16010226

APA StyleYang, S.-J., Eom, J.-Y., Lee, M.-J., Hwang, D.-H., Park, W.-B., Wie, Y.-M., Lee, K.-G., & Lee, K.-H. (2024). Comparative Environmental Evaluation of Sewage Sludge Treatment and Aggregate Production Process by Life Cycle Assessment. Sustainability, 16(1), 226. https://doi.org/10.3390/su16010226