Circular Economy Approaches for Electrical and Conventional Vehicles

Abstract

1. Introduction

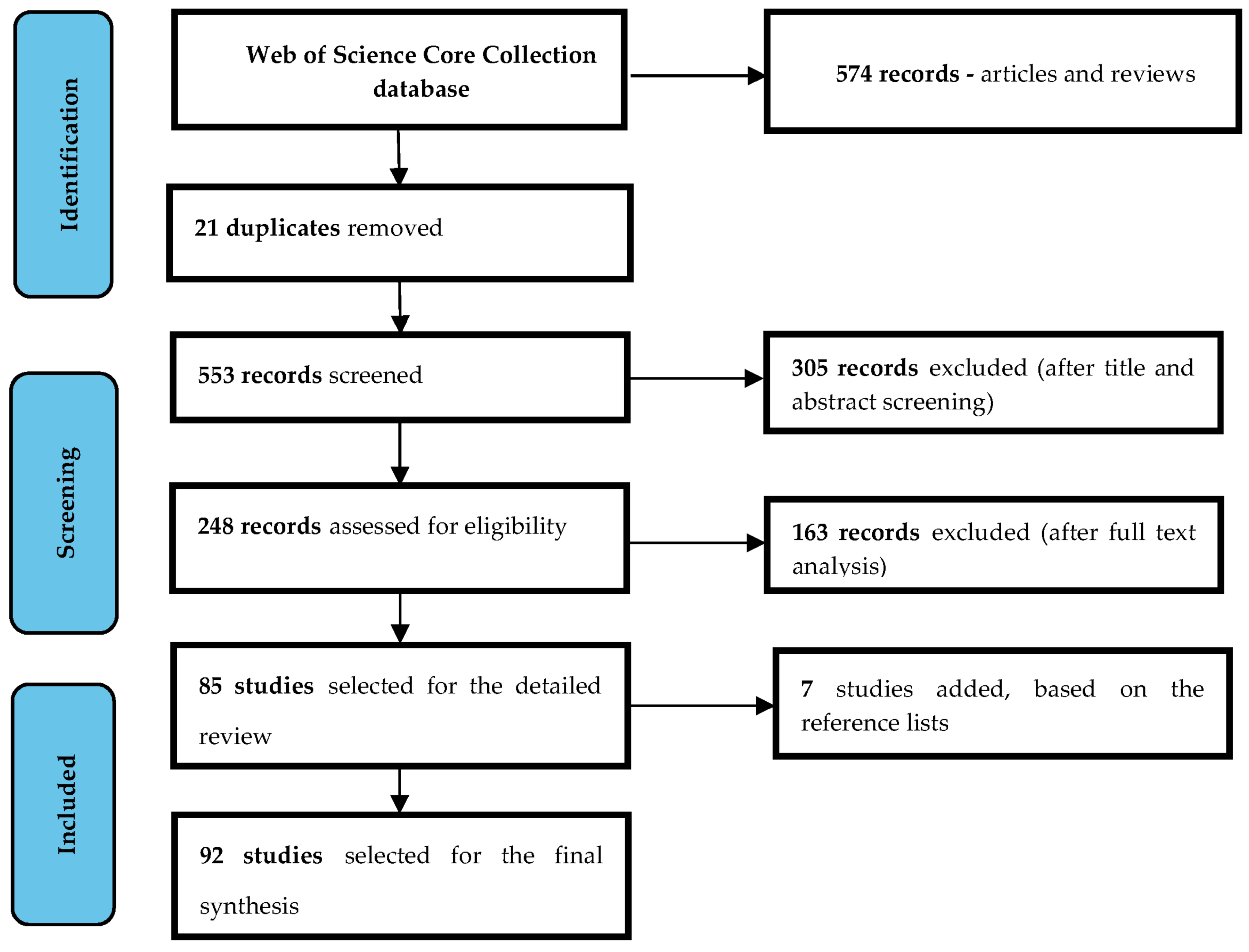

2. Materials and Methods

2.1. EVs and CE–Bibliometric Analysis

2.2. Conventional Vehicles and CE–Bibliometric Analysis

3. Literature Review

3.1. The Electrical Vehicle and Circular Economy

- Battery management:

- Vehicle management:

- Implement government incentives to reduce environmental impact.

- Public awareness to increase environmental protection.

- Better relationship between consumers and car manufacturers [63].

- Digital twin technologies for smart EVs [64].

- Sustainability optimization framework to supply chain for the automotive industry [67].

- Life cycle sustainable assessment:

- Transport management:

- Consumer behavior:

- Electricity renewable sources and charging infrastructure:

- Raw materials:

- Air pollution reduction strategies:

- Eco-design (Technical design changes):

3.2. The Conventional Vehicle and Circular Economy

- CE strategies:

- Develop strategies from a holistic life cycle approach, particularly through more scrap utilization, higher intensity of vehicle uses, and design for reuse/remanufacturing [12].

- Complete update of strategies such as raw material recycling, resource reconstruction, extending product life, product services, and transformation from ownership to sharing [100].

- Evaluate and discover the correlation in terms of a freight transport system [101].

- Identify the parameters used for material efficiency potential [102].

- Recycling management:

- Raw materials:

- Studies for different products, components, and materials for reuse (non-destructive) and recycle (destructive) strategies [107].

- Policies and regulations are needed to change business models and consumer behavior in order to implement product longevity strategies [8].

- Evaluation of the metals in the vehicle, including downcycling [110].

- EOL management:

- Develop components that can be remanufactured or repaired, and collect sorted components for dedicated and functional recycling [111].

- Intensify further case studies for specific cities or companies in the automotive industry, as well as waste chain research to stimulate a higher recycling process [112].

- Better solutions and support tools for EoL, material waste reductions, recyclability of materials, and innovative forming processes for recycling [113].

- EoL alternative(s) for the used heavy vehicles collected and the components recovered after dismantling operations [114].

- Recyclability and recoverability at the EoL of the material used [115].

- Identify and apply improvement in the EoL management of heavy vehicles, from the dismantling to the economic recovery [114].

4. Results and Discussions

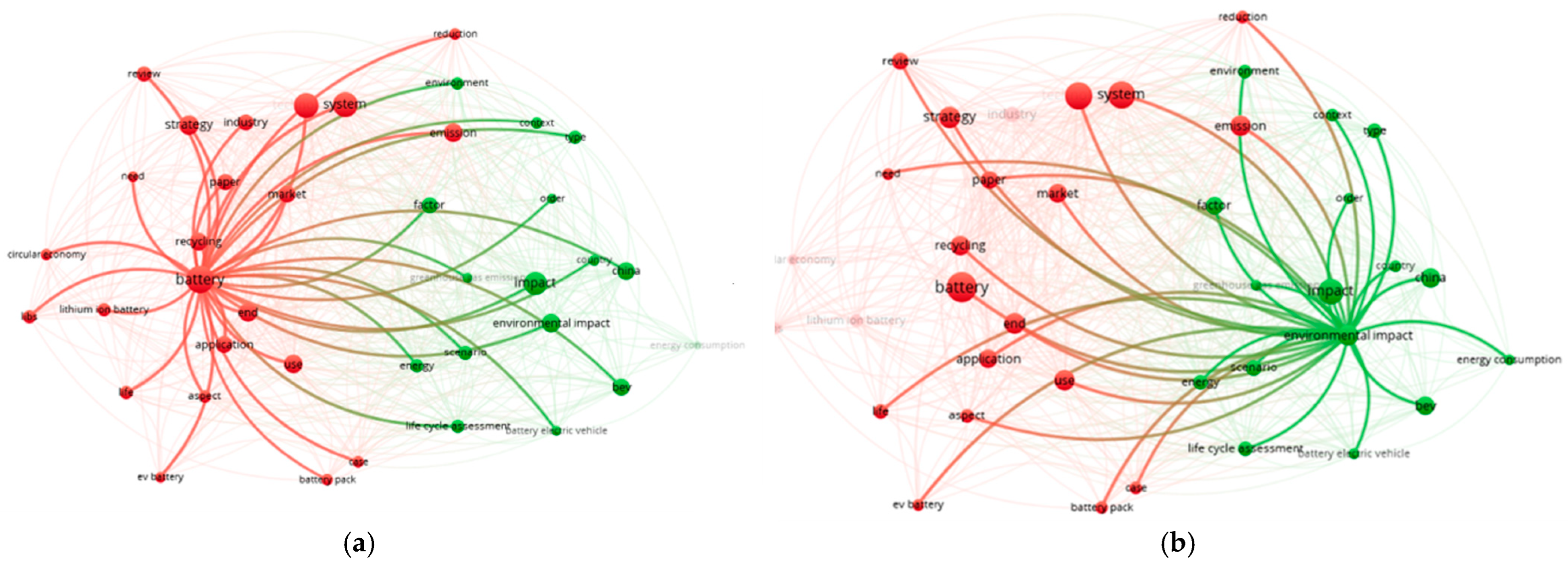

4.1. Electric Vehicle and CE: The VOSViewer Representation

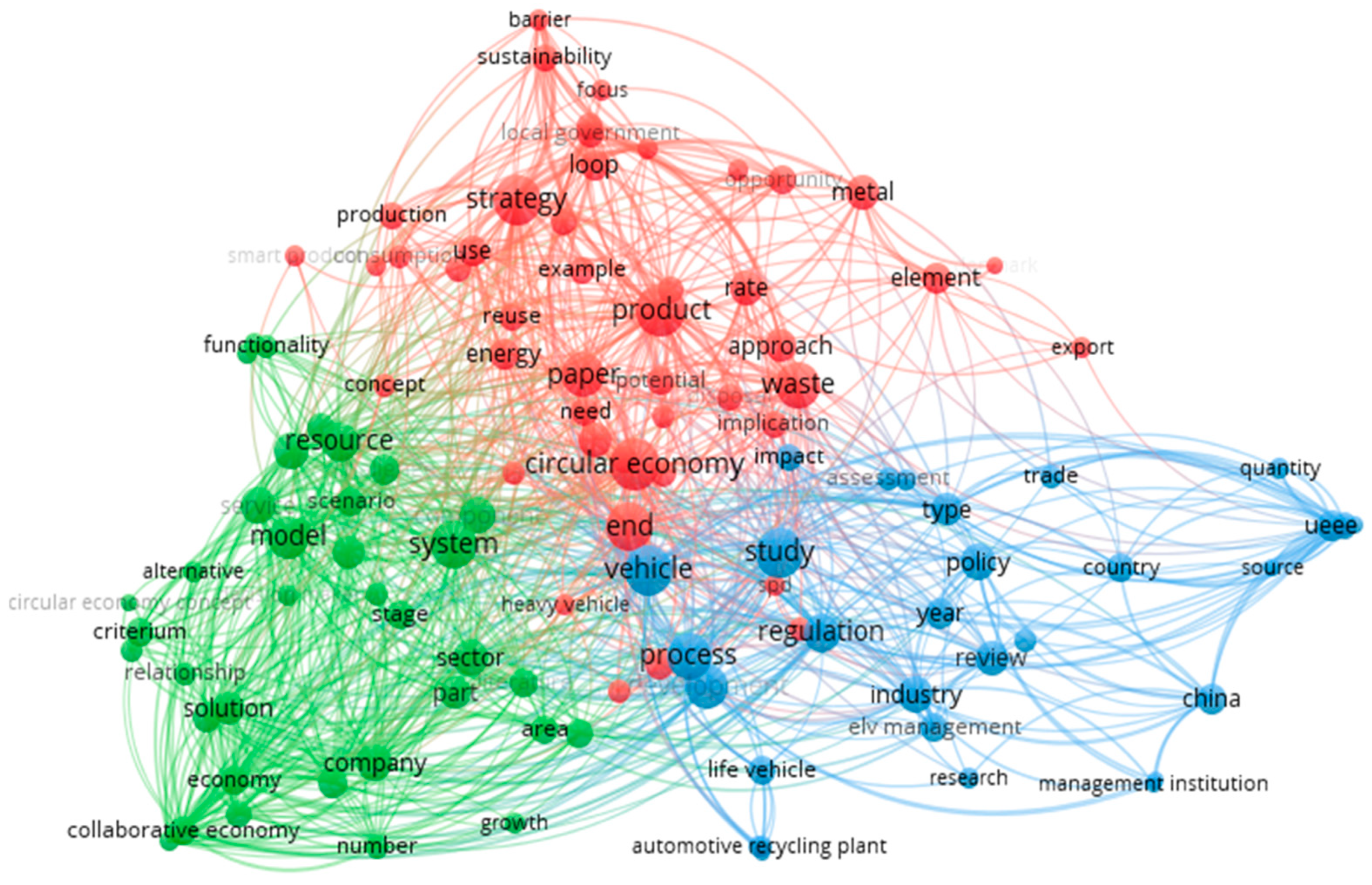

4.2. Conventional Vehicle and CE; the VOSViewer Representation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Main Findings—CE Approaches for EVs

| Study Objective | Findings | Limitations | Proposals | Reference |

| A. BATTERY MANAGEMENT | ||||

| Overview of the LIB recycling technologies. | Hydrometallurgical regeneration of cathode and direct regeneration can be used for recycling the huge number of LIBs. | There are many challenges, such as cost, safety, environmental friendliness, and energy consumption. | Further studies should focus on the repeatability of the regeneration process to see the quality of cathodes. | [31] |

| Heterogeneous EVs fleet routing problem with time windows. | The number of small EVs will affect the optimal recycling plan. | The charging problem of EVs is not considered. | The impact of EV charging time should be considered. | [45] |

| Batteries for electric logistics vehicles (BELVs) are analyzed. | It is necessary to improve vehicle parameters such as the curb mass, all-electric range, energy efficiency, and charging efficiency, and to develop the technology of power exchange and charging. | No complete data on the electricity consumption rates of the various models on the market. | Improve the vehicle performance, reliability, and market penetration of BELVs, and propose new incentive policies. | [46] |

| The social-economic-environmental impact of recycling retired EV batteries. | Subsidy and reward-penalty policies can help to improve the recycling of retired EV batteries. | China case-study. | More comprehensive environmental assessments may be integrated, especially the local pollutants such as PM10 and PM 2.5. | [51] |

| A deep review of LIBs and other types of batteries. | Safety concerns and negative environmental impacts of LIBs. | Only LIB type BEV was analyzed in the study. | Issues and challenges about environmental impact, performance, and applications, are highlighted as a basis for further research. | [29] |

| Sustainable Recycling Technology for LIBs. | Due to the complexity of the battery, secondary pollution such as wastewater, gas, and waste, can occur during the recovery process. | Complex recycling process. | Studies are needed to focus on the environmental impact of batteries, secondary users, and the recycling stage. | [49] |

| Strategy optimization for recycling batteries. | New EV manufacturers can promote the construction and cooperation of battery recycling sites. | China case-study. | Governments are encouraged to create combined battery recycling strategies, to promote sustainable development. | [36] |

| Review for electronic waste and EV battery waste. | Bibliometric analysis of research of electronic waste environmental impact. | Limitations regarding keywords selected and databases. | Research in the area of environmental impact of LIBs. | [26] |

| Environmental footprint for BEV. | The sustainability of the battery pack during production phase is more efficient than other parts with the same weight, if green materials are adopted. | No consideration for energy consumption in the use phase, and also LCA in production and use phase. | More practical perspectives. | [50] |

| Develop a model for EoL management of BEV based on activity theory. | A source for strategies for sustainable management of EoL batteries. | China case study. | A quantitative analysis of the ecological impact of the LIB EV system. | [27] |

| Model of battery recycling networks. | Optimization of the design of recycling networks. | Only CO2 emissions considered in the model. | Other pollutants need to be taken into consideration in the model. | [32] |

| LIBs circularity and the UK transition to EVs. | Circularity is the way for low carbon technologies. | UK case study. | Integrate ‘circular novel thinking’ | [42] |

| Use of several methodologies for environmental impact assessment of LIBs. | Multi-criteria analysis is beneficial for complex systems. | It does not include some aspects, such as different deployment scenarios, or improved EoL practices. | More research needed due to lack of information for LIBs. | [43] |

| A review of LIB manufacturing. | Explain the complexity, challenges, and opportunities for LIBs. | Complexity of the subject. | The need for more detailed data on environmental impacts. | [54] |

| Lifecycle environmental impact assessment for battery system life cycle stages. | A set of 10 principles is proposed for increasing environmental impact of battery application. | LCA models depend on policy and market drivers. | Develop new solution for environmental sustainability. | [52] |

| Evaluate a LABs recycling firm in Yunnan to quantify the emissions impact. | Recycling system could not achieve sustainable development goals because of the dependence on non-renewable resources. | A company case study. | Policies to improve these types of systems. | [30] |

| Investigate a closed loop system for the rare elements in electric batteries for Europe. | A CE model for earth elements is beneficial in terms of resource depletion, and it reduces supply risk. | It is limited to the rare elements, without taking into account the other components of the battery (e.g., metals), or the uncertainty of new future recycling methods. | Future business models for used batteries focusing more on second use than recycling. | [21] |

| Investigate recycling and reuse of batteries from EVs. | A strategy for the CE could be to adapt facilities for both recycling, and testing batteries for second life. | Theoretical investigation of EV battery recycle and reuse. | Detailed studies for each of the battery reuse applications. | [7] |

| A review to investigate the recycling of LIBs. | Green aspects of the recovery process of LIBs, and the importance of cell design to a more efficient recycling process. | Study specific to a single product type—LIB recycling. | Extending this type of review to other products. | [33] |

| Demonstration and evaluation of CE strategy for LIBs. | Circular resource planning and distribution model developed. | The case study is for Berlin, Germany. | Extended for other areas. | [47] |

| A review that demonstrates the need for government policies to manage LIBs at the end of the life cycle. | It offers potential solutions through CE models that are based on property models (LIB to be owned by producers even during consumer use). | The data are based on currently uncertain assumptions about market evolution and battery life. | Further studies on the topic and future data are needed in order to decide on the benefits of the CE through direct recycling of LIBs. | [48] |

| Analyses of processes for the treatment of post-use LIBs by approaching the CE. | There are great challenges, both economically and environmentally, that will appear in the future, with the increase in the number of batteries. | Precarious legislative framework regarding spent batteries. | For a CE model, it is necessary to design products that are easily reused and recycled. | [25] |

| Development of a sustainable business model for second use battery for EVs. | In the emerging B2U (Battery Second Use) market, stakeholders integrate sustainable value creation activities into sustainable business processes. | Was applied only for second use battery case for EVs. | Development of sustainable business model. | [38] |

| Reusing used batteries from EVs in buildings as stationary storage systems. | Old batteries from EVs can be used for the building sector. | Limited data are available about the parameters of the energy model e.g., charge/discharge efficiency, battery capacity degradation, and battery lifetime. | More studies on sustainability of the second life of used batteries. | [40] |

| CE perspective on the reuse and recycling of LIBs. | Reuse and recycling of LIBs is a necessity. | The review is limited to reuse and recycling of the LIBs. | The study is helpful for policy makers to use in updating policies for energy transition. | [44] |

| Second life applications for EV batteries. | There are organizational and cognitive barriers for second life applications for BEVs. | Several unexplored aspects during the interviews with stakeholders. | Further research from the technical, economic, and organizational perspectives, regarding the stage of production and use of the battery, in order to identify strategies with added value. | [39] |

| LCA for BEVs in second use applications. | There are environmental benefits to extending an EV battery’s lifetime. | Lack of data regarding the repurposing stage. | Environmental assessments should be considered, in order to provide a complete overview of the sustainability of reuse. | [41] |

| Improvements to EoL management of LIBs in the US. | Provides a set of EoL management recommendations for the US on policy, infrastructure, and technology. | US case-study. | Determine urgent aspects regarding policy, infrastructure, and technology. | [28] |

| Recycling methods for LIBs. | Many papers are focusing on recycling and recovery-related issues. | Most of the studies were experimental. | Further techno-economic assessment of the recycling process, safe reverse logistics, and a global EV assessment, thus revealing material recovery potential. | [34] |

| Adapt manufacturing processes for the coming cell chemistries and components regarding BEVs. | Current practices in material collection, sorting, transportation, handling, and recycling. | One limitation is represented by constantly changing the composition. | For Li–metal and Li–S batteries, the reactivity of the materials will bring up safety concerns during recycling. | [55] |

| A perspective regarding the LIB recycling process. | Synthesis of challenges associated with LIBs recycling. | Technical, policy and economic and ecological considerations. | Practical suggestion for a CE for LIBs. | [37] |

| Battery recycling network perspective. | Remanufacturing, reuse and recycling strategies for LIBs. | Chinese company case-study. | A recycling network model is developed in order to minimize the total cost and carbon emissions. | [35] |

| Evaluation of LIBs’ environmental impact. | Renewable energy for electricity maximizes environmental benefits. | LIB industry is very complex. | Electricity generation source determine EV emissions. | [53] |

| B. VEHICLE MANAGEMENT | ||||

| Changes after replacing the cars with 100% EVs. | Electric mobility and renewable energies as possible approaches for “zero emissions” concept. | A case study on a Portuguese business campus. | Extend application to other areas. | [58] |

| Analysis of vehicle emissions correlated with energy use and climate change. | The impact of vehicle emissions, energy use, and climate change, on the environment and human health. | Ghana case-study. | It is necessary to create and apply policies in sectors such as transport, environment, and energy. | [59] |

| Digital twin technology review. | Digital twin technologies adapted for smart electric vehicle use cases are described. | Modeling complex systems is a limitation. | Further work can begin with the identified technologies for sustainable development. | [64] |

| Apply the sustainability optimization framework to the supply chain for the automotive industry in Europe. | The automotive industry has the potential to improve sustainability, considering that labor costs and emissions achieve a major impact in the manufacturing stage | The study is conducted on the European car industry. | Detailed model for electric vehicle components and determination of emission factors specific to various European countries. | [67] |

| Analyzing if strategy adopted in the city of Dundee regarding EVs, is beneficial for reducing carbon emissions. | An ecological plan of the local authorities leads in the direction of meeting the objectives of Agenda 30 SDG. | Applied to one city. | Forthcoming studies on how DGS objectives are implemented. | [60] |

| Develop an emission index. | An electric light truck emissions index that measure greenhouse gas (GHG) emissions, was established. | China case study. | Different perspectives based on the created index can offer suggestions regarding GHG emissions research. | [18] |

| Analyzing the EV recycling process. | Preparation of materials for recycling is conducted in a small number of companies, mostly using metals. | Some limitations include disassembling, and the structure of the vehicle. | Improvement of the EV recycling and energy recovery sustainability model. Greater inclusion of leadership factors in the model of sustainable EV recycling. | [65] |

| SWOT and PESTL methodologies for strategies for five countries regarding e-mobility in European regions. | Positive changes in EVs. | Limitations regarding the number of countries analyzed. | Optimize strategies for e-mobility. | [61] |

| Investigation regarding optimal decisions from EV manufacturing, and government subsidies, from social point of view. | Environmental impact performance is not necessarily increasing after introducing EVs. | Considered only manufacturers for EVs and also conventional vehicles. | Discrepancy between manufacturers and governments; different rules from government regarding reward and punishment. | [63] |

| Evaluation of sustainability for EVs. | Sustainability is considered an end indicator. | Research review methodology. | A better approach to the interaction between sustainability and EV systems. | [56] |

| Highlighting how CE strategies can reduce the extraction of raw materials (e.g., cobalt). | The best CE strategies are the new substitution technologies. | The scope is limited to the European Union. | Development of new strategies, both at government and business level. | [57] |

| Attempt to identify the trends and factors that affect the performance of the 3R system for the BEV. | Highlight factors that affect 3R system design and performance. | Empirical sources from the study were mainly Swedish and European. | 3R system modeling for BEV considers factors that may affect the system over time. | [66] |

| A review of ways to recycle EVs. | that the battery is the element of the recycling process that is worth the most. | Limited future estimates of EV flows and limited assessment of stakeholder relationships in the reverse supply chain. | Focus on other components of worth that can be recycled from EV components. | [13] |

| A review of business models for battery second use. | The necessity of a multi-stakeholder network-centric business model. | Most BEVs will be retired after several years. | Development of a business model that highlights the relationships between stakeholders, especially OEM (Original Equipment Manufacturer) and battery second use service providers. | [22] |

| Ways to adopt an integrated life cycle approach. | Gaps identified in socio-economic assessment, macro-level assessment, and CE applications. | Only the Scopus database was considered. | State-of-the-art and practice of emerging technologies and EVs in the field of LCA. | [62] |

| C. LIFE CYCLE SUSTAINABLE ASSESSMENT | ||||

| A comparison between CVs and EVs. | The environmental benefits of EVs are higher than the environmental benefits of CVs. | Vehicles from China are selected for the model. | Future work should be focused on different types of vehicles. | [78] |

| Macro-sustainability assessment for alternative vehicles in the US. | EVs have less air pollution compared to others vehicles. | Applications of the life cycle sustainable assessment method are limited in a real case study. | Models that include temporal and spatial variations should be integrated. | [68] |

| Comparison of environmental impacts of EVs vs. CVs. | The developed method is used for analysis of environmental effects of new technologies. | Considered only a few pollutants, and just two types of vehicles. | Waste collection to be investigated. | [69] |

| Model to quantify sustainability indicators using LCSA and multi-criteria decision- making. | Using solar energy for BEVs reduces environmental impacts. | Vehicle manufacturing and disposal phases are not considered. | The Qatar case study to be extended for other countries. | [108] |

| Assessment of life cycle sustainability in China. | According to LCA, the comprehensive impact value of the resource environment of the life cycle of the BEVs is higher than in the case of ICEVs (Internal Combustion Engine Vehicle). | China case study and some assumptions that may vary from reality. | Expanding the scope. | [70] |

| Multi-regional input-output based Life Cycle Sustainability Assessment framework model. | BEVs have a lower impact, in terms of global warming potential, particle formation, and photochemistry oxidant formation. | Vehicle manufacturing and EoL are not analyzed. | The model can be developed by making a connection between the three sustainability pillars (not only separately analyzing the indicators). | [109] |

| Proposed a model for evaluating environmental, social, and economic impacts of EV. | The importance of the three pillars model. | The simulation did not take into account the upward trend of acquisitions; the market share was considered constant over time. | New studies regarding the increased trend of sales markets for EVs, and relation to pollutants. | [73] |

| Environmental impact evaluation for EVs. | BEVs have the smallest environmental impacts. | Brasilia case study. | Extend to other areas. | [74] |

| Comparison between EVs and ICEVs. | The manufacturing and disposal of electronics and batteries, and also energy consumption and rare earth elements used in those processes, are detrimental to the environment. | Some assumptions and delimitations on life cycle stages. | It is necessary to close the loop, in terms of raw materials and rare earth elements. | [75] |

| Investigation of whether nonmaterial brings a positive environmental impact for EVs. | It was found that using environmentally friendly materials in the extraction and production phase, brings disadvantages to the environment in the use phase, and vice versa. | Data’s limitations in LCA. | Collaboration between nanotechnology, nanotoxicology, eco-design, and green chemistry, for the transport sector. | [76] |

| LCA comparison between EVs and ICEVs from an environmental perspective. | The BEV manufacturing stage still has a major impact on the environment. | Dates used are taken from literature, studies, and existing dates. | BEV improvement of technological efficiency. | [77] |

| Assessment of EV sustainability, from the design stage. | Cobalt is an important element in the manufacturing of batteries, and great care is needed to avoid its depletion. | There is limited knowledge in the design stage. | The assessment can also be used for other types of products. | [71] |

| Developing an integrated and dynamic life cycle sustainability assessment framework for EVs. | Environmental impacts of BEVs are highest in the manufacturing phase, compared to manufacturing phase impacts of ICEVs. | Estimation of the sustainability impact of vehicle options are limited by narrow system boundaries. | Exploratory modeling and analysis should be integrated in the model. | [72] |

| Identify the most used CE strategies. | LCA-supported CE has not been sufficiently explored. | Standardized CE and LCA tools and indicators need to be developed. | Create circular models to improve the overall resource efficiency of electromobility. | [79] |

| D. TRANSPORT MANAGEMENT | ||||

| Highlight policies for EVs. | Environmental and industrial goals: a decrease in GHG emissions. | Study focused on Germany and the UK. | Additional research on more precise pathways, as well as the quantification of further aspects, could lead to a more extensive analysis. | [80] |

| Identify the best alternatives for sustainable transport. | The connected electric vehicle is considered to be the most sustainable option for public transport. | Others factors should be considered aside from those mentioned in the study. | Review the multi-criteria decision model proposed in this analysis, considering limitation, changes in the automotive industry, and fuel alternatives. | [81] |

| The scope is to develop public transport using electric buses. | It is considered that the lack of funds for the maintenance of BEVs could affect public transport with EVs. | Poland case-study. | Differences compared to other countries. | [82] |

| Create a model for green public procurement. | Biomethane solutions may be linked to positive environmental effects. | Sweden case-study. | Apply to another context. | [83] |

| Develop charging strategies. | Renewable power consumption, netload valley filling, and minimizing charging costs, can reduce emissions. | A perfect collaboration between EV owners. | Identify how limitations can impact results. | [84] |

| E. CONSUMER BEHAVIOR | ||||

| Investigate the factors affecting consumers’ intentions to adopt EVs. | Results show the factors which affect consumers’ intentions to buy EVs. | Limitations may be represented by the need to use other theories, such as the model of technological acceptance, in order to see the impact of other factors. | Other methods of data analysis, such as machine learning and multi-criteria decision-making, should be used. | [86] |

| The need to understand the gap in green purchasing behavior. | Proposes using the model of Motivation—Intention—Context–Behavior, to explain the driving factors behind green purchases. | Applied to China. | Finding out and simulating various policies for green procurement. | [85] |

| Determine the factors that influence the purchase of EVs. | Manufacturers should take steps to better promote EVs. | The case study refers to consumers in China. | Connect industry with consumers, from the industrial and technological perspectives of EVs. | [87] |

| Survey to analyze consumer interests in a CE for the automotive industry, especially durable tires | The results of the study show that perceptions of climate change, using test reports or assessment portals, are variable, and related to the configuration preferences of software for sustainable automotive products. | The limits are represented by an online survey applied in Germany before the onset of the COVID-19 crisis. | Future studies to assess consumer preferences following incentives for new car purchases, and to evaluate target groups interested in purchasing sustainable cars. | [4] |

| F. ELECTRICITY RENEWABLE SOURCES AND CHARGING INFRASTRUCTURE | ||||

| Propose a methodology for sustainability. | Development of a methodology to demonstrate sustainability for EVs regarding CO2 emissions. | It is limited to Spain, and only to CO2 emissions. | Extension for possible electrification in transport. | [117] |

| Highlight the environmental impact of electric power production for BEVs, five countries being compared | GHG quantity for a BEV is dependent on the power generation technology. | The study is based on data for five European countries. | Extend to other countries. | [88] |

| Estimation of environmental impact for four types of chargers. | Quantity of chargers is mainly affected by the electricity mix, types, and quantities of chargers. | Many factors affect the increase of chargers. | Combine the LCA of charging infrastructure, with management and economics methodology (organizational strategies and reward-driven systems). | [89] |

| Develop a model regarding external costs, including emissions and time losses, with societal and consumer life cycle costs. | The EV has the lowest life cycle cost, due to the low cost of electricity. | Estimation of data from different models. | Include some other criteria. | [90] |

| G. RAW MATERIALS | ||||

| Impact of the EV on the lithium market. | Uncertainties related to the environmental impact of lithium production. | The model does not consider recycling and remanufacturing. | The model should consider remanufacturing and recycling infrastructures, and the model can be used for other materials (non-ferrous and rare-earth metals). | [91] |

| Develop a Multi-Regional Input-Output, based on LCA approach. | Manufacturing phase dominates the life-cycle material footprints of vehicles. | Predefined data used. | System dynamic approach. | [92] |

| Eco-efficiency analysis for LIB waste. | LCA and eco-efficiency are important for determining the greatest environmental benefits under a CE-inspired waste management hierarchy for EoL LIBs. | It is a case study applied to a theoretical stream of 1000 LIBs. | Industry will still require technology development, to create collection programs and improve metal recovery. | [93] |

| Material flow analysis for lithium. | In 2015, China’s lithium consumption was 50% of the total amount. | China case-study. | Big quantities of lithium stocked in LIBs, brings an opportunity for lithium recycling, from a circularity perspective. | [94] |

| H. AIR POLLUTION REDUCTION STRATEGIES | ||||

| An evaluation of EV air pollution in India. | In order to increase the purchase of EVs, different government policies are recommended, depending on the social class. | A review for India. | Extend the review for other areas. | [95] |

| Strategies to reduce carbon emissions by using the CE. | The increased demand for lithium will generate an imbalance by 2050, which will affect the BEV market and will also increase CO2 emissions. | Social-environmental consequences for critical material supply should be included in the model. | Creating a model to increase recycling rates that probably require energy consumption, which leads to increased emissions. | [96] |

| I. ECO-DESIGN (TECHNICAL DESIGN CHANGES) | ||||

| Predictions regarding HEV/EV. | Predictions regarding HEV/EV stock evolution to reduce GHG emissions. | Technical aspects of EVs, such as efficiency, reliability, autonomy, and cost, must be improved. | Alternative cooling architectures, (spray cooling, jet impingement cooling, heat pipes, etc.) should be investigated for implementation in real EVs. | [97] |

| Components modification for EVs, in order to increase environmental sustainability. | For eco-design, choice of material is important. Use of lighter materials, reduces fuel consumption. | Limitations of the study consist of the various estimates and assumptions contained therein. | The development of a product configurator, to support design. | [98] |

Appendix B. Main Findings—CE Approaches for CVs

| Study Objective | Findings | Limitations | Proposals | Reference |

| A. CE STRATEGIES | ||||

| Evaluate and discover a correlation, in terms of a freight transport system. | Prioritization list of CE concepts. | Complexity of the model and complex mathematical apparatus for calculating relational relationships between criteria. | Development of an adaptive decision-making tool based on the fuzzy DIBR-D’CoCoSo methodology. | [101] |

| CE strategy implications for sustainable development of products. | Greater emphasis on addressing the CE during strategic product planning and task clarification activities. | Lack of information concerning products’ EOL. | It is recommended in existing decision-making support, for example, by adding circularity indicators in product evaluation comparison tables. | [6] |

| An example of planning the supply of spare parts. | Model of the reverse logistic chain. | Some limitations on model indicators (weight of spare parts, physical volume spare parts, etc.). | Reverse logistics for a CE system. | [2] |

| CE strategies. | ICEVs use ∼6% renewable life cycle primary energy, and 27% recycled materials. | Consider material efficiency, reusing and recycling parts, vehicle design, shared mobility, and low-carbon technologies for CE strategies. | Further studies for developing targeted CE strategies. | [116] |

| Analysis of 20 crucial roadblocks hindering CE implementation in Indian automobile companies. | The top roadblocks analyzed are ‘lacking ability to deliver high quality remanufactured products’, ‘maintaining the design of reuse product’, ‘lack of awareness in society’ and ‘lack of consumer knowledge about refurbished products’. | Case-study on Indian automobile companies. | Extend to other countries. | [5] |

| Structured group multi-criteria decision-making methods MCDM) for evaluation of stakeholders’ cooperation. | MCDM methods and the CE combined together for new results. | Small sample of two empirical group MCDM exercises. | New studies bringing together several actors from a supply chain, necessary for information exchange. | [10] |

| Effectiveness of product-based circularity, using the Material Circularity Indicator and Product Circularity Indicator. | Regulation has limited effects on realizing material circularity in the automotive industry. | Study is using only 2 indicators. | Develop effective CE strategies from a holistic life cycle approach, particularly through more scrap utilization, higher intensity of vehicle uses, and design for reuse/remanufacturing. | [12] |

| Identify the parameters used for material efficiency potentials and pathways of socio-economic development, and also to improve existing methods and processes. | Different scenarios for the potential greenhouse gas abatement that could be achieved by 2050, through the deployment of different combinations of ten strategies in several counties. | Limit the scope of assessment to large, regional, resolutions. | Extend the presented scenarios. | [102] |

| Find technical solution for non-metallic parts to maximize recyclability and recoverability. | A CE-updated strategy is necessary, including raw material recycling, resource reconstruction, extended product life, product service, and transformation from individual ownership to multi-person sharing. | Metallic parts are not included. | New studies regarding the strategies for CE. | [100] |

| Maximal potential recycling of EV steel, by exploring the utilization methods of scrap, sorted by parts, to produce crude alloy steel, with minimal losses of alloying elements. | Parts-based scrap sorting could bring a recovery of 94−98% of the alloying elements from parts scrap. | Japan case-study. | Redefining CE policies so as to engage industries that use recycled materials, as well as recyclers and manufacturers of products subject to recycling. | [99] |

| B. RECYCLING MANAGEMENT | ||||

| Study the innovation of vehicle recycling in Italy. | Facilities for automotive recycling necessity. | Italy case-study. | Automotive recycling center could be an instrument and operational source for environment protection. | [103] |

| Study that focuses on the separation of recycling rates into the following categories: closed-loop collection rate, open-loop collection rate, and recycling rate. | Collection rates represent collected material that enters the recycling process, and recycle rates measure the available secondary resources produced from recycling processes. | Switzerland case-study. | Currently used rates are not suitable as a performance indicator for a CE. | [106] |

| Remanufacturing for CE. | Remanufacturing is an important sector for green development, with cost reduction, energy and material savings. | China case-study. | Define responsibility of management institutions, modify the legal and standards system, launch tax incentives for remanufactured products, and standardized reverse logistics system. | [24] |

| Database for scrap of three bulk metals (iron and steel, aluminum and copper). | Quantities of alloying elements can be considerable. Alloying elements such as Cr, Zn, Mn, Cu, Sn, Ni, and Pb, have an aggregated weight in the three scrap metals that was higher than 2 kt in the year 2017. | Denmark case study. | Identify how trade of scrap metals affects recycling and efficiency pathways. | [104] |

| Identify critical components of recycling business model. | Recycling process reduces carbon footprint. | Web of Science and ScienceDirect databases. | Practical solutions for new business models. | [105] |

| C. RAW MATERIALS | ||||

| Hierarchical level description—substance level (elements and compound)—circularity reference level method. | Multilevel Statistical Entropy Analysis allows the degree of circularity of material flow systems to be evaluated in the context of combinations of different CE strategies. | The mixing component between substances and raw material extraction is not considered. | Further studies should focus on different levels of products, components, and materials, in order to be applicable for reuse (non-destructive) and recycle (destructive) strategies. | [107] |

| The Statistical Entropy Analysis (SEA) method is used to evaluate the use of resources and the functionality of the product over time, and also to indicate which of the EC strategies keeps the functionality at the maximum level, with minimum effort. | SEA has the role of quantifying the effects of CE strategies. | The case study employed vehicles with a simplified vehicle composition, and only proposed basic CE strategies. | Include export and import of vehicles, also raw material processing. | [11] |

| Evaluation of the metals included in the vehicle, including downcycling. | Even if quantity of downcycled metals represents 4.5% of the total metal weight of the vehicle, in rarity terms, this figure increases to approximately 27%. | Macro assessment done for the evaluation of the metals. | Changing the eco-design to favor the easier disassembly required at the end of life. | [110] |

| D. EOL MANAGEMENT | ||||

| Improvement in the EoL of heavy vehicles, from the dismantling to the economic recovery. | EoL alternative(s) for the used heavy vehicles collected and for the components recovered after the dismantling operations. | Industrial pilot study case. | Improvement solutions and support tools for EoL. | [114] |

| Identify gaps and further research for EoL vehicle management systems. | Literature review of the EoL management system. | Limitation regarding method review criteria: period 2000–2019. | To document industry practices in case studies or surveys and identify environmental consequences regarding extending the EV logistics network. | [113] |

| The aim is to quantify recyclability and recoverability at the EoL of the material used. | It has been found that better recycling and recovery processes are needed for better recycling and recovery. | South Korea case-study. | a collaboration between the manufacturer and the recycler is recommended, in order to take into account the feedback of the recycler regarding the separation of the material and the incompatibility of mixing the materials. | [115] |

| The aim is to determine how many components can be hypothetically manufactured, and whether a dedicated recycling program for the components of interest, is feasible. | Some opportunities include: develop components that can be remanufactured or repaired, and collect sorted components for dedicated and functional recycling. | Only two components of the vehicle included in the case study (wheel component and gearbox component). | In order to increase recycling programs and the implementation of CE policies, it is necessary for there to be collaboration between stakeholders. | [111] |

| Policies for recycled EoL vehicles. | Value added tax and a deposit-refund system would stimulate a higher recycle process, at 80% until 2050. | China case-study. | New studies should include case studies for specific cities or companies in the automotive industry, as well as waste chain research. | [112] |

References

- Capgemini Research Institute. The Automotive Industry in the Era of Sustainability Executive Summary; Capgemini Research Institute: Paris, France, 2020. [Google Scholar]

- Makarova, I.; Shubenkova, K.; Buyvol, P.; Shepelev, V.; Gritsenko, A. The role of reverse logistics in the transition to a circular economy: Case study of automotive spare parts logistics. FME Trans. 2021, 49, 173–185. [Google Scholar] [CrossRef]

- Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Vazquez-Brust, D.; Yakovleva, N. Circular economy, degrowth and green growth as pathways for research on sustainable development goals: A global analysis and future agenda. Ecol. Econ. 2021, 185, 107050. [Google Scholar] [CrossRef]

- Wurster, S.; Heß, P.; Nauruschat, M.; Jütting, M. Sustainable Circular Mobility: User-Integrated Innovation and Specifics of Electric Vehicle Owners. Sustainability 2020, 12, 7900. [Google Scholar] [CrossRef]

- Agrawal, R.; Wankhede, V.A.; Kumar, A.; Luthra, S. Analysing the roadblocks of circular economy adoption in the automobile sector: Reducing waste and environmental perspectives. Bus. Strat. Environ. 2020, 30, 1051–1066. [Google Scholar] [CrossRef]

- Diaz, A.; Schöggl, J.-P.; Reyes, T.; Baumgartner, R.J. Sustainable product development in a circular economy: Implications for products, actors, decision-making support and lifecycle information management. Sustain. Prod. Consum. 2021, 26, 1031–1045. [Google Scholar] [CrossRef]

- Kotak, Y.; Fernández, C.M.; Casals, L.C.; Kotak, B.; Koch, D.; Geisbauer, C.; Trilla, L.; Gómez-Núñez, A.; Schweiger, H.-G. End of Electric Vehicle Batteries: Reuse vs. Recycle. Energies 2021, 14, 2217. [Google Scholar] [CrossRef]

- Dominish, E.; Retamal, M.; Sharpe, S.; Lane, R.; Rhamdhani, M.A.; Corder, G.; Giurco, D.; Florin, N. “Slowing” and “Narrowing” the Flow of Metals for Consumer Goods: Evaluating Opportunities and Barriers. Sustainability 2018, 10, 1096. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Bachér, J.; Pihkola, H.; Kujanpää, L.; Mroueh, U.-M. Advancing the circular economy through group decision-making and stakeholder involvement. Detritus 2018, 4, 22–35. [Google Scholar] [CrossRef]

- Parchomenko, A.; Nelen, D.; Gillabel, J.; Vrancken, K.C.; Rechberger, H. Resource effectiveness of the European automotive sector—a statistical entropy analysis over time. Resour. Conserv. Recycl. 2021, 169, 105558. [Google Scholar] [CrossRef]

- Soo, V.K.; Doolan, M.; Compston, P.; Duflou, J.R.; Peeters, J.; Umeda, Y. The influence of end-of-life regulation on vehicle material circularity: A comparison of Europe, Japan, Australia and the US. Resour. Conserv. Recycl. 2020, 168, 105294. [Google Scholar] [CrossRef]

- D’Adamo, I.; Rosa, P. A Structured Literature Review on Obsolete Electric Vehicles Management Practices. Sustainability 2019, 11, 6876. [Google Scholar] [CrossRef]

- Sadik-Zada, E.R.; Gonzalez, E.D.S.; Gatto, A.; Althaus, T.; Quliyev, F. Pathways to the hydrogen mobility futures in German public transportation: A scenario analysis. Renew. Energy 2023, 205, 384–392. [Google Scholar] [CrossRef]

- Golinska, P.; Kosacka, M. Environmental Friendly Practices in the Automotive Industry. Environ. Issues Automot. Ind. 2013, 3–22. [Google Scholar] [CrossRef]

- Grigore, N.A.; Kifor, C.V. Are electric vehicles eco-friendly products? A review from life cycle and sustainability perspective. MATEC Web Conf. 2021, 343, 07002. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Zhang, T.; Yin, H.; Zhang, H.; Huo, W.; Zhang, Y.; Li, Y. Research on integration simulation and balance control of a novel load isolated pure electric driving system. Energy 2019, 189, 116220. [Google Scholar] [CrossRef]

- Li, J.; Yang, B. Quantifying the effects of vehicle technical performance and electricity carbon intensity on greenhouse gas emissions from electric light truck: A case study of China. Atmos. Pollut. Res. 2020, 11, 1290–1302. [Google Scholar] [CrossRef]

- Gosens, J. The greening of South-South trade: Levels, growth, and specialization of trade in clean energy technologies between countries in the global South. Renew. Energy 2020, 160, 931–943. [Google Scholar] [CrossRef]

- Sadik-Zada, E.R.; Gatto, A.; Scharfenstein, M. Sustainable management of lithium and green hydrogen and long-run perspectives of electromobility. Technol. Forecast. Soc. Chang. 2023, 186, 121992. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Silvestri, C.; Traverso, M. Circularity potential of rare earths for sustainable mobility: Recent developments, challenges and future prospects. J. Clean. Prod. 2021, 292, 126089. [Google Scholar] [CrossRef]

- Reinhardt, R.; Christodoulou, I.; Gassó-Domingo, S.; García, B.A. Towards sustainable business models for electric vehicle battery second use: A critical review. J. Environ. Manag. 2019, 245, 432–446. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, M.; Yuan, Q.; Fan, X.; Teng, Y.; Fu, J.; Ma, Q.; Wang, Q.; Zuo, J. Transitioning China to a circular economy through remanufacturing: A comprehensive review of the management institutions and policy system. Resour. Conserv. Recycl. 2020, 161, 104920. [Google Scholar] [CrossRef]

- Mossali, E.; Picone, N.; Gentilini, L.; Rodrìguez, O.; Pérez, J.M.; Colledani, M. Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. J. Environ. Manag. 2020, 264, 110500. [Google Scholar] [CrossRef]

- Preeti, M.; Sayali, A. Scientometric Analysis of Research on End-oflife Electronic Waste and Electric Vehicle Battery Waste. J. Sci. Res. 2021, 10, 37–46. [Google Scholar] [CrossRef]

- Li, J.; Qiao, Z.; Simeone, A.; Bao, J.; Zhang, Y. An activity theory-based analysis approach for end-of-life management of electric vehicle batteries. Resour. Conserv. Recycl. 2020, 162, 105040. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Malladi, S.; Zayas, I.C. End-of-Life Management of Electric Vehicle Lithium-Ion Batteries in the United States. Clean Technol. 2022, 4, 1162–1174. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.D.M.; Hussain, A.; Yusof, Y.; Ker, A.P.J. State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications: Issues and Recommendations. IEEE Access Spec. Sect. Adv. Energy Storage Technol. Appl. 2018, 6, 19362–19378. [Google Scholar] [CrossRef]

- Pan, H.; Geng, Y.; Dong, H.; Ali, M.; Xiao, S. Sustainability evaluation of secondary lead production from spent lead acid batteries recycling. Resour. Conserv. Recycl. 2018, 140, 13–22. [Google Scholar] [CrossRef]

- Wang, Y.; An, N.; Wen, L.; Wang, L.; Jiang, X.; Hou, F.; Yin, Y.; Liang, J. Recent progress on the recycling technology of Li-ion batteries. J. Energy Chem. 2020, 55, 391–419. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Yang, W. Optimal design of electric vehicle battery recycling network—From the perspective of electric vehicle manufacturers. Appl. Energy 2020, 275, 115328. [Google Scholar] [CrossRef]

- Thompson, D.L.; Hartley, J.M.; Lambert, S.M.; Shiref, M.; Harper, G.D.J.; Kendrick, E.; Anderson, P.; Ryder, K.S.; Gaines, L.; Abbott, A.P. The importance of design in lithium ion battery recycling—A critical review. Green Chem. 2020, 22, 7585–7603. [Google Scholar] [CrossRef]

- Islam, T.; Iyer-Raniga, U. Lithium-Ion Battery Recycling in the Circular Economy: A Review. Recycling 2022, 7, 33. [Google Scholar] [CrossRef]

- Hu, X.; Yan, W.; Zhang, X.; Feng, Z.; Wang, Y.; Ying, B.; Zhang, H. LRP-Based Design of Sustainable Recycling Network for Electric Vehicle Batteries. Processes 2022, 10, 273. [Google Scholar] [CrossRef]

- Lyu, X.; Xu, Y.; Sun, D. An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide. Sustainability 2021, 13, 4165. [Google Scholar] [CrossRef]

- Yu, X.; Li, W.; Gupta, V.; Gao, H.; Tran, D.; Sarwar, S.; Chen, Z. Current Challenges in Efficient Lithium-Ion Batteries’ Recycling: A Perspective. Glob. Chall. 2022, 6, 2200099. [Google Scholar] [CrossRef]

- Reinhardt, R.; Christodoulou, I.; García, B.A.; Gassó-Domingo, S. Sustainable business model archetypes for the electric vehicle battery second use industry: Towards a conceptual framework. J. Clean. Prod. 2020, 254, 119994. [Google Scholar] [CrossRef]

- Olsson, L.; Fallahi, S.; Schnurr, M.; Diener, D.; van Loon, P. Circular Business Models for Extended EV Battery Life. Batteries 2018, 4, 57. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Ferraro, M.; Cellura, M. Energy and environmental benefits of circular economy strategies: The case study of reusing used batteries from electric vehicles. J. Energy Storage 2019, 25, 100845. [Google Scholar] [CrossRef]

- Bobba, S.; Mathieux, F.; Ardente, F.; Blengini, G.A.; Cusenza, M.A.; Podias, A.; Pfrang, A. Life Cycle Assessment of repurposed electric vehicle batteries: An adapted method based on modelling energy flows. J. Energy Storage 2018, 19, 213–225. [Google Scholar] [CrossRef]

- Bonsu, N.O. Towards a circular and low-carbon economy: Insights from the transitioning to electric vehicles and net zero economy. J. Clean. Prod. 2020, 256, 120659. [Google Scholar] [CrossRef]

- Bobba, S.; Bianco, I.; Eynard, U.; Carrara, S.; Mathieux, F.; Blengini, G.A. Bridging Tools to Better Understand Environmental Performances and Raw Materials Supply of Traction Batteries in the Future EU Fleet. Energies 2020, 13, 2513. [Google Scholar] [CrossRef]

- Pagliaro, M.; Meneguzzo, F. Lithium battery reusing and recycling: A circular economy insight. Heliyon 2019, 5, e01866. [Google Scholar] [CrossRef]

- Cao, S.; Liao, W.; Huang, Y. Heterogeneous fleet recyclables collection routing optimization in a two-echelon collaborative reverse logistics network from circular economic and environmental perspective. Sci. Total. Environ. 2021, 758, 144062. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Guo, X. Evaluation of Performance and Technological Characteristics of Battery Electric Logistics Vehicles: China as a Case Study. Energies 2020, 13, 2455. [Google Scholar] [CrossRef]

- Moore, E.A.; Russell, J.D.; Babbitt, C.W.; Tomaszewski, B.; Clark, S.S. Spatial modeling of a second-use strategy for electric vehicle batteries to improve disaster resilience and circular economy. Resour. Conserv. Recycl. 2020, 160, 104889. [Google Scholar] [CrossRef]

- Ahuja, J.; Dawson, L.; Lee, R. A circular economy for electric vehicle batteries: Driving the change. J. Prop. Plan. Environ. Law 2020, 12, 235–250. [Google Scholar] [CrossRef]

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects. Chem. Rev. 2020, 120, 7020–7063. [Google Scholar] [CrossRef]

- Wu, H.; Hu, Y.; Yu, Y.; Huang, K.; Wang, L. The environmental footprint of electric vehicle battery packs during the production and use phases with different functional units. Int. J. Life Cycle Assess. 2020, 26, 97–113. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Li, Y.; Li, H.; Pan, X.; McLellan, B. The social-economic-environmental impacts of recycling retired EV batteries under reward-penalty mechanism. Appl. Energy 2019, 251, 113313. [Google Scholar] [CrossRef]

- Arbabzadeh, M.; Lewis, G.M.; Keoleian, G.A. Green principles for responsible battery management in mobile applications. J. Energy Storage 2019, 24, 100779. [Google Scholar] [CrossRef]

- Yang, Z.; Huang, H.; Lin, F. Sustainable Electric Vehicle Batteries for a Sustainable World: Perspectives on Battery Cathodes, Environment, Supply Chain, Manufacturing, Life Cycle, and Policy. Adv. Energy Mater. 2022, 12, 2200383. [Google Scholar] [CrossRef]

- Stampatori, D.; Raimondi, P.P.; Noussan, M. Li-Ion Batteries: A Review of a Key Technology for Transport Decarbonization. Energies 2020, 13, 2638. [Google Scholar] [CrossRef]

- Neumann, J.; Petranikova, M.; Meeus, M.; Gamarra, J.D.; Younesi, R.; Winter, M.; Nowak, S. Recycling of Lithium-Ion Batteries—Current State of the Art, Circular Economy, and Next Generation Recycling. Adv. Energy Mater. 2022, 12, 2102917. [Google Scholar] [CrossRef]

- Lopez-Arboleda, E.; Sarmiento, A.T.; Cardenas, L.M. Systematic Review of Integrated Sustainable Transportation Models for Electric Passenger Vehicle Diffusion. Sustainability 2019, 11, 2513. [Google Scholar] [CrossRef]

- Baars, J.; Domenech, T.; Bleischwitz, R.; Melin, H.E.; Heidrich, O. Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nat. Sustain. 2020, 4, 71–79. [Google Scholar] [CrossRef]

- Pinto, B.; Barata, F.; Soares, C.; Viveiros, C. Fleet Transition from Combustion to Electric Vehicles: A Case Study in a Portuguese Business Campus. Energies 2020, 13, 1267. [Google Scholar] [CrossRef]

- Angnunavuri, P.N.; Kuranchie, F.A.; Attiogbe, F.; Nerquaye-Tetteh, E.N. The potential of integrating vehicular emissions policy into Ghana’s transport policy for sustainable urban mobility. SN Appl. Sci. 2019, 1, 1201. [Google Scholar] [CrossRef]

- Asekomeh, A.; Gershon, O.; Azubuike, S. Optimally Clocking the Low Carbon Energy Mile to Achieve the Sustainable Development Goals: Evidence from Dundee’s Electric Vehicle Strategy. Energies 2021, 14, 842. [Google Scholar] [CrossRef]

- Petrauskiene, K.; Dvarioniene, J.; Kaveckis, G.; Kliaugaite, D.; Chenadec, J.; Hehn, L.; Pérez, B.; Bordi, C.; Scavino, G.; Vignoli, A.; et al. Situation Analysis of Policies for Electric Mobility Development: Experience from Five European Regions. Sustainability 2020, 12, 2935. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M. A systematic review on sustainability assessment of electric vehicles: Knowledge gaps and future perspectives. Environ. Impact Assess. Rev. 2022, 97, 106867. [Google Scholar] [CrossRef]

- Zheng, X.; Lin, H.; Liu, Z.; Li, D.; Llopis-Albert, C.; Zeng, S. Manufacturing Decisions and Government Subsidies for Electric Vehicles in China: A Maximal Social Welfare Perspective. Sustainability 2018, 10, 672. [Google Scholar] [CrossRef]

- Bhatti, G.; Mohan, H.; Singh, R.R. Towards the future of smart electric vehicles: Digital twin technology. Renew. Sustain. Energy Rev. 2021, 141, 110801. [Google Scholar] [CrossRef]

- Petronijević, V.; Đorđević, A.; Stefanović, M.; Arsovski, S.; Krivokapić, Z.; Mišić, M. Energy Recovery through End-of-Life Vehicles Recycling in Developing Countries. Sustainability 2020, 12, 8764. [Google Scholar] [CrossRef]

- Kurdve, M.; Zackrisson, M.; Johansson, M.I.; Ebin, B.; Harlin, U. Considerations when Modelling EV Battery Circularity Systems. Batteries 2019, 5, 40. [Google Scholar] [CrossRef]

- Kannegiesser, M.; Günther, H.-O.; Gylfason, Ó. Sustainable development of global supply chains—Part 2: Investigation of the European automotive industry. Flex. Serv. Manuf. J. 2014, 26, 48–68. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Towards Life Cycle Sustainability Assessment of Alternative Passenger Vehicles. Sustainability 2014, 6, 9305–9342. [Google Scholar] [CrossRef]

- Syré, A.; Heining, F.; Göhlich, D. Method for a Multi-Vehicle, Simulation-Based Life Cycle Assessment and Application to Berlin’s Motorized Individual Transport. Sustainability 2020, 12, 7302. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, G.; Li, T.; Wei, X. Comprehensive Evaluation of the Sustainable Development of Battery Electric Vehicles in China. Sustainability 2019, 11, 5635. [Google Scholar] [CrossRef]

- Reuter, B. Assessment of sustainability issues for the selection of materials and technologies during product design: A case study of lithium-ion batteries for electric vehicles. Int. J. Interact. Des. Manuf. (IJIDeM) 2016, 10, 217–227. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O.; Egilmez, G. Integration of system dynamics approach toward deepening and broadening the life cycle sustainability assessment framework: A case for electric vehicles. Int. J. Life Cycle Assess. 2016, 21, 1009–1034. [Google Scholar] [CrossRef]

- Pautasso, E.; Osella, M.; Caroleo, B. Addressing the Sustainability Issue in Smart Cities: A Comprehensive Model for Evaluating the Impacts of Electric Vehicle Diffusion. Systems 2019, 7, 29. [Google Scholar] [CrossRef]

- Souza, L.L.P.D.; Lora, E.E.S.; Palacio, J.C.E.; Rocha, M.H.; Renó, M.L.G.; Venturini, O.J. Comparative environmental life cycle assessment of conventional vehicles with different fuel options, plug-in hybrid and electric vehicles for a sustainable transportation system in Brazil. J. Clean. Prod. 2018, 203, 444–468. [Google Scholar] [CrossRef]

- Gradin, K.T.; Poulikidou, S.; Björklund, A.; Luttropp, C. Scrutinising the electric vehicle material backpack. J. Clean. Prod. 2018, 172, 1699–1710. [Google Scholar] [CrossRef]

- Ellingsen, L.A.-W.; Hung, C.R.; Majeau-Bettez, G.; Singh, B.; Chen, Z.; Whittingham, M.S.; Strømman, A.H. Nanotechnology for environmentally sustainable electromobility. Nat. Nanotechnol. 2016, 11, 1039–1051. [Google Scholar] [CrossRef] [PubMed]

- Tagliaferri, C.; Evangelisti, S.; Acconcia, F.; Domenech, T.; Ekins, P.; Barletta, D.; Lettieri, P. Life cycle assessment of future electric and hybrid vehicles: A cradle-to-grave systems engineering approach. Chem. Eng. Res. Des. 2016, 112, 298–309. [Google Scholar] [CrossRef]

- Zeng, D.; Dong, Y.; Cao, H.; Li, Y.; Wang, J.; Li, Z.; Hauschild, M.Z. Are the electric vehicles more sustainable than the conventional ones? Influences of the assumptions and modeling approaches in the case of typical cars in China. Resour. Conserv. Recycl. 2020, 167, 105210. [Google Scholar] [CrossRef]

- Picatoste, A.; Justel, D.; Mendoza, J.M.F. Circularity and life cycle environmental impact assessment of batteries for electric vehicles: Industrial challenges, best practices and research guidelines. Renew. Sustain. Energy Rev. 2022, 169, 112941. [Google Scholar] [CrossRef]

- Mazur, C.; Contestabile, M.; Offer, G.J.; Brandon, N. Assessing and comparing German and UK transition policies for electric mobility. Environ. Innov. Soc. Transit. 2015, 14, 84–100. [Google Scholar] [CrossRef]

- Gutiérrez, L.R.; Oliva, M.D.V.; Romero-Ania, A. Managing Sustainable Urban Public Transport Systems: An AHP Multicriteria Decision Model. Sustainability 2021, 13, 4614. [Google Scholar] [CrossRef]

- Połom, M.; Wiśniewski, P. Implementing Electromobility in Public Transport in Poland in 1990–2020. A Review of Experiences and Evaluation of the Current Development Directions. Sustainability 2021, 13, 4009. [Google Scholar] [CrossRef]

- Lindfors, A.; Ammenberg, J. Using national environmental objectives in green public procurement: Method development and application on transport procurement in Sweden. J. Clean. Prod. 2020, 280, 124821. [Google Scholar] [CrossRef]

- Chen, J.; Wang, F.; He, X.; Liang, X.; Huang, J.; Zhang, S.; Wu, Y. Emission mitigation potential from coordinated charging schemes for future private electric vehicles. Appl. Energy 2021, 308, 118385. [Google Scholar] [CrossRef]

- He, Z.; Zhou, Y.; Wang, J.; Li, C.; Wang, M.; Li, W. The impact of motivation, intention, and contextual factors on green purchasing behavior: New energy vehicles as an example. Bus. Strat. Environ. 2020, 30, 1249–1269. [Google Scholar] [CrossRef]

- Asadi, S.; Nilashi, M.; Samad, S.; Abdullah, R.; Mahmoud, M.; Alkinani, M.H.; Yadegaridehkordi, E. Factors impacting consumers’ intention toward adoption of electric vehicles in Malaysia. J. Clean. Prod. 2020, 282, 124474. [Google Scholar] [CrossRef]

- Tu, J.-C.; Yang, C. Key Factors Influencing Consumers’ Purchase of Electric Vehicles. Sustainability 2019, 11, 3863. [Google Scholar] [CrossRef]

- Skrúcaný, T.; Kendra, M.; Stopka, O.; Milojević, S.; Figlus, T.; Csiszár, C. Impact of the Electric Mobility Implementation on the Greenhouse Gases Production in Central European Countries. Sustainability 2019, 11, 4948. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, X.; Ding, N.; Yang, J. Life cycle environmental assessment of charging infrastructure for electric vehicles in China. J. Clean. Prod. 2019, 227, 932–941. [Google Scholar] [CrossRef]

- Mitropoulos, L.K.; Prevedouros, P.D. Life cycle emissions and cost model for urban light duty vehicles. Transp. Res. Part D Transp. Environ. 2015, 41, 147–159. [Google Scholar] [CrossRef]

- Hache, E.; Seck, G.S.; Simoen, M.; Bonnet, C.; Carcanague, S. Critical raw materials and transportation sector electrification: A detailed bottom-up analysis in world transport. Appl. Energy 2019, 240, 6–25. [Google Scholar] [CrossRef]

- Sen, B.; Onat, N.C.; Kucukvar, M.; Tatari, O. Material footprint of electric vehicles: A multiregional life cycle assessment. J. Clean. Prod. 2018, 209, 1033–1043. [Google Scholar] [CrossRef]

- Richa, K.; Babbitt, C.W.; Gaustad, G. Eco-Efficiency Analysis of a Lithium-Ion Battery Waste Hierarchy Inspired by Circular Economy. J. Ind. Ecol. 2017, 21, 715–730. [Google Scholar] [CrossRef]

- Hao, H.; Liu, Z.; Zhao, F.; Geng, Y.; Sarkis, J. Material flow analysis of lithium in China. Resour. Policy 2016, 51, 100–106. [Google Scholar] [CrossRef]

- Vidhi, R.; Shrivastava, P. A Review of Electric Vehicle Lifecycle Emissions and Policy Recommendations to Increase EV Penetration in India. Energies 2018, 11, 483. [Google Scholar] [CrossRef]

- Watari, T.; Nansai, K.; Nakajima, K.; McLellan, B.C.; Dominish, E.; Giurco, D. Integrating Circular Economy Strategies with Low-Carbon Scenarios: Lithium Use in Electric Vehicles. Environ. Sci. Technol. 2019, 53, 11657–11665. [Google Scholar] [CrossRef] [PubMed]

- López, I.; Ibarra, E.; Matallana, A.; Andreu, J.; Kortabarria, I. Next generation electric drives for HEV/EV propulsion systems: Technology, trends and challenges. Renew. Sustain. Energy Rev. 2019, 114, 109336. [Google Scholar] [CrossRef]

- Spreafico, C. Can modified components make cars greener? A life cycle assessment. J. Clean. Prod. 2021, 307, 127190. [Google Scholar] [CrossRef]

- Ohno, H.; Matsubae, K.; Nakajima, K.; Kondo, Y.; Nakamura, S.; Fukushima, Y.; Nagasaka, T. Optimal Recycling of Steel Scrap and Alloying Elements: Input-Output based Linear Programming Method with Its Application to End-of-Life Vehicles in Japan. Environ. Sci. Technol. 2017, 51, 13086–13094. [Google Scholar] [CrossRef]

- He, X.; Su, D.; Cai, W.; Pehlken, A.; Zhang, G.; Wang, A.; Xiao, J. Influence of Material Selection and Product Design on Automotive Vehicle Recyclability. Sustainability 2021, 13, 3407. [Google Scholar] [CrossRef]

- Pamucar, D.; Deveci, M.; Gokasar, I.; Işık, M.; Zizovic, M. Circular economy concepts in urban mobility alternatives using integrated DIBR method and fuzzy Dombi CoCoSo model. J. Clean. Prod. 2021, 323, 129096. [Google Scholar] [CrossRef]

- Fishman, T.; Heeren, N.; Pauliuk, S.; Berrill, P.; Tu, Q.; Wolfram, P.; Hertwich, E.G. A comprehensive set of global scenarios of housing, mobility, and material efficiency for material cycles and energy systems modeling. J. Ind. Ecol. 2021, 25, 305–320. [Google Scholar] [CrossRef]

- Pomili, L.; Fabrizi, A. automotive recycling: A circular economy centre. Environ. Eng. Manag. J. 2020, 19, 1747–1753. [Google Scholar] [CrossRef]

- Tan, J.; Wehde, M.V.; Brønd, F.; Kalvig, P. Traded metal scrap, traded alloying elements: A case study of Denmark and implications for circular economy. Resour. Conserv. Recycl. 2020, 168, 105242. [Google Scholar] [CrossRef]

- Islam, T.; Iyer-Raniga, U.; Trewick, S. Recycling Perspectives of Circular Business Models: A Review. Recycling 2022, 7, 79. [Google Scholar] [CrossRef]

- Haupt, M.; Vadenbo, C.; Hellweg, S. Do We Have the Right Performance Indicators for the Circular Economy?: Insight into the Swiss Waste Management System. J. Ind. Ecol. 2016, 21, 615–627. [Google Scholar] [CrossRef]

- Parchomenko, A.; Nelen, D.; Gillabel, J.; Vrancken, K.C.; Rechberger, H. Evaluation of the resource effectiveness of circular economy strategies through multilevel Statistical Entropy Analysis. Resour. Conserv. Recycl. 2020, 161, 104925. [Google Scholar] [CrossRef]

- Onat, N.C.; Aboushaqrah, N.N.; Kucukvar, M.; Tarlochan, F.; Hamouda, A.M. From sustainability assessment to sustainability management for policy development: The case for electric vehicles. Energy Convers. Manag. 2020, 216, 112937. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Aboushaqrah, N.N.; Jabbar, R. How sustainable is electric mobility? A comprehensive sustainability assessment approach for the case of Qatar. Appl. Energy 2019, 250, 461–477. [Google Scholar] [CrossRef]

- Ortego, A.; Valero, A.; Valero, A.; Iglesias, M. Downcycling in automobile recycling process: A thermodynamic assessment. Resour. Conserv. Recycl. 2018, 136, 24–32. [Google Scholar] [CrossRef]

- Diener, D.L.; Tillman, A.-M. Scrapping steel components for recycling—Isn’t that good enough? Seeking improvements in automotive component end-of-life. Resour. Conserv. Recycl. 2016, 110, 48–60. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, D.; Wang, T.; Hu, S. Policies on end-of-life passenger cars in China: Dynamic modeling and cost-benefit analysis. J. Clean. Prod. 2015, 108, 1140–1148. [Google Scholar] [CrossRef]

- Karagoz, S.; Aydin, N.; Simic, V. End-of-life vehicle management: A comprehensive review. J. Mater. Cycles Waste Manag. 2019, 22, 416–442. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. Dismantling, remanufacturing and recovering heavy vehicles in a circular economy—Technico-economic and organisational lessons learnt from an industrial pilot study. Resour. Conserv. Recycl. 2020, 156, 104684. [Google Scholar] [CrossRef]

- Lee, C.-K.; Lee, J.-Y.; Kim, J. Recyclability and Recoverability of Rolling Stock with Recycling Efficiency Factors. Resour. Conserv. Recycl. 2020, 155, 104620. [Google Scholar] [CrossRef]

- Esteva, L.C.A.; Kasliwal, A.; Kinzler, M.S.; Kim, H.C.; Keoleian, G.A. Circular economy framework for automobiles: Closing energy and material loops. J. Ind. Ecol. 2020, 25, 877–889. [Google Scholar] [CrossRef]

- Bastida-Molina, P.; Hurtado-Pérez, E.; Peñalvo-López, E.; Gómez, M.C.M. Assessing transport emissions reduction while increasing electric vehicles and renewable generation levels. Transp. Res. Part D Transp. Environ. 2020, 88, 102560. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kifor, C.V.; Grigore, N.A. Circular Economy Approaches for Electrical and Conventional Vehicles. Sustainability 2023, 15, 6140. https://doi.org/10.3390/su15076140

Kifor CV, Grigore NA. Circular Economy Approaches for Electrical and Conventional Vehicles. Sustainability. 2023; 15(7):6140. https://doi.org/10.3390/su15076140

Chicago/Turabian StyleKifor, Claudiu Vasile, and Niculina Alexandra Grigore. 2023. "Circular Economy Approaches for Electrical and Conventional Vehicles" Sustainability 15, no. 7: 6140. https://doi.org/10.3390/su15076140

APA StyleKifor, C. V., & Grigore, N. A. (2023). Circular Economy Approaches for Electrical and Conventional Vehicles. Sustainability, 15(7), 6140. https://doi.org/10.3390/su15076140