Using Electric Field to Improve the Effect of Microbial-Induced Carbonate Precipitation

Abstract

1. Introduction

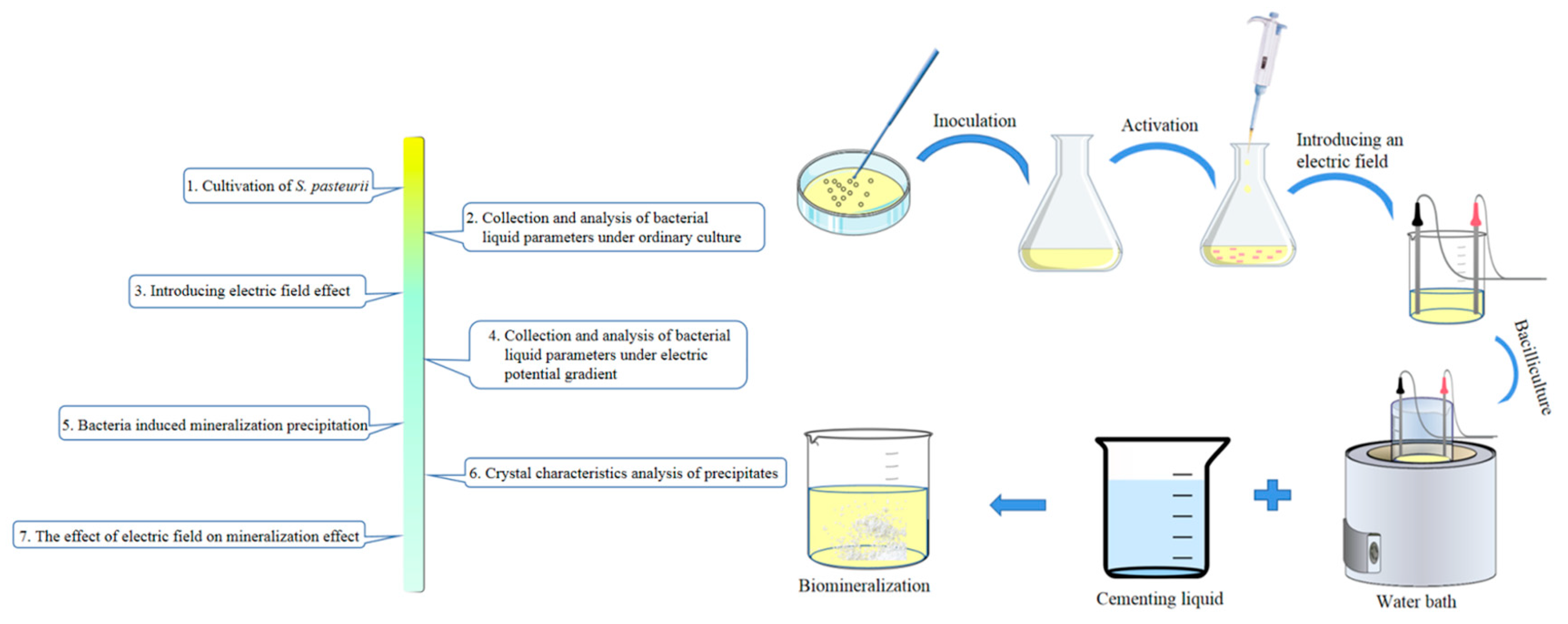

2. Materials and Methods

2.1. Test Bacteria

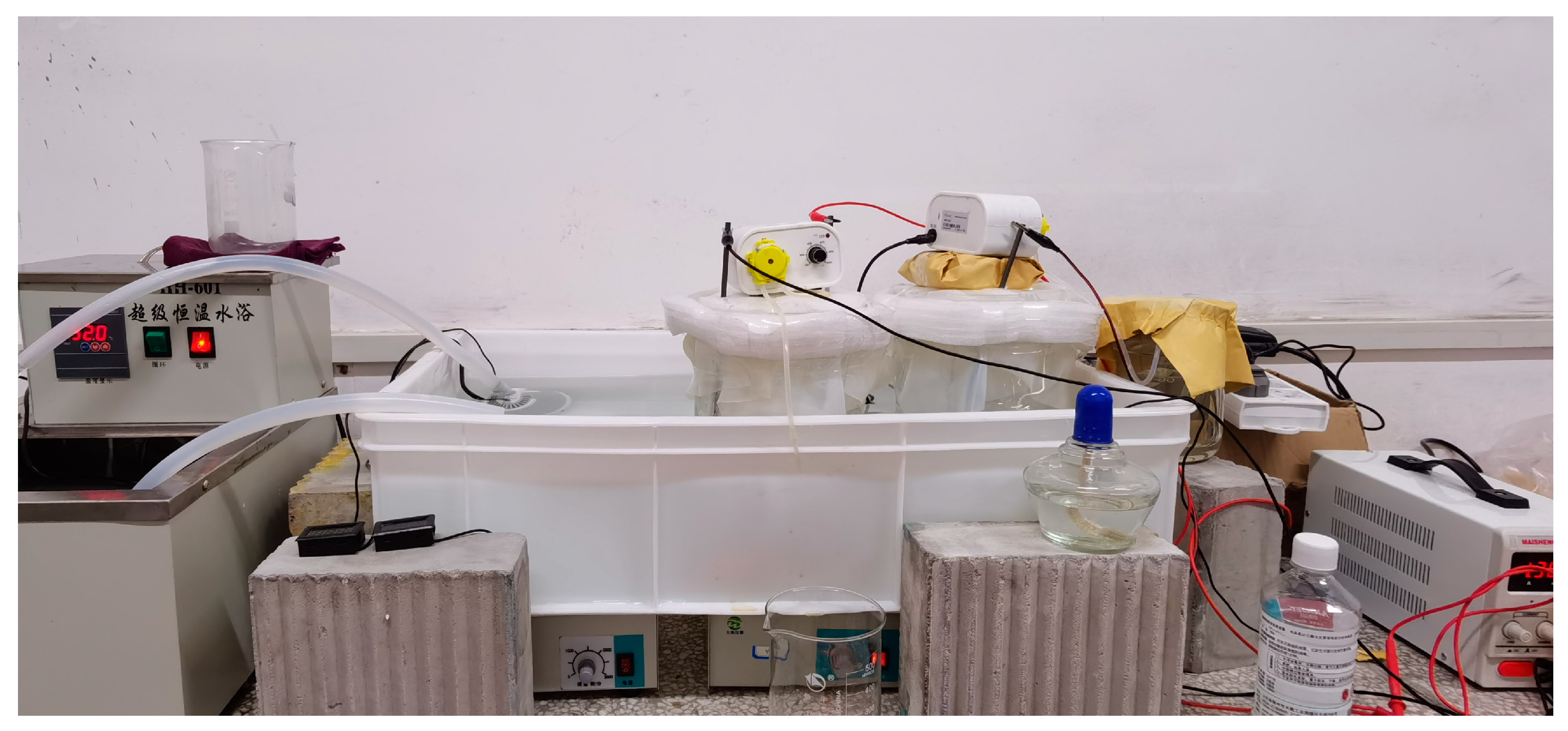

2.2. Equipment and Materials

2.3. Experiment Method

3. Results and Discussion

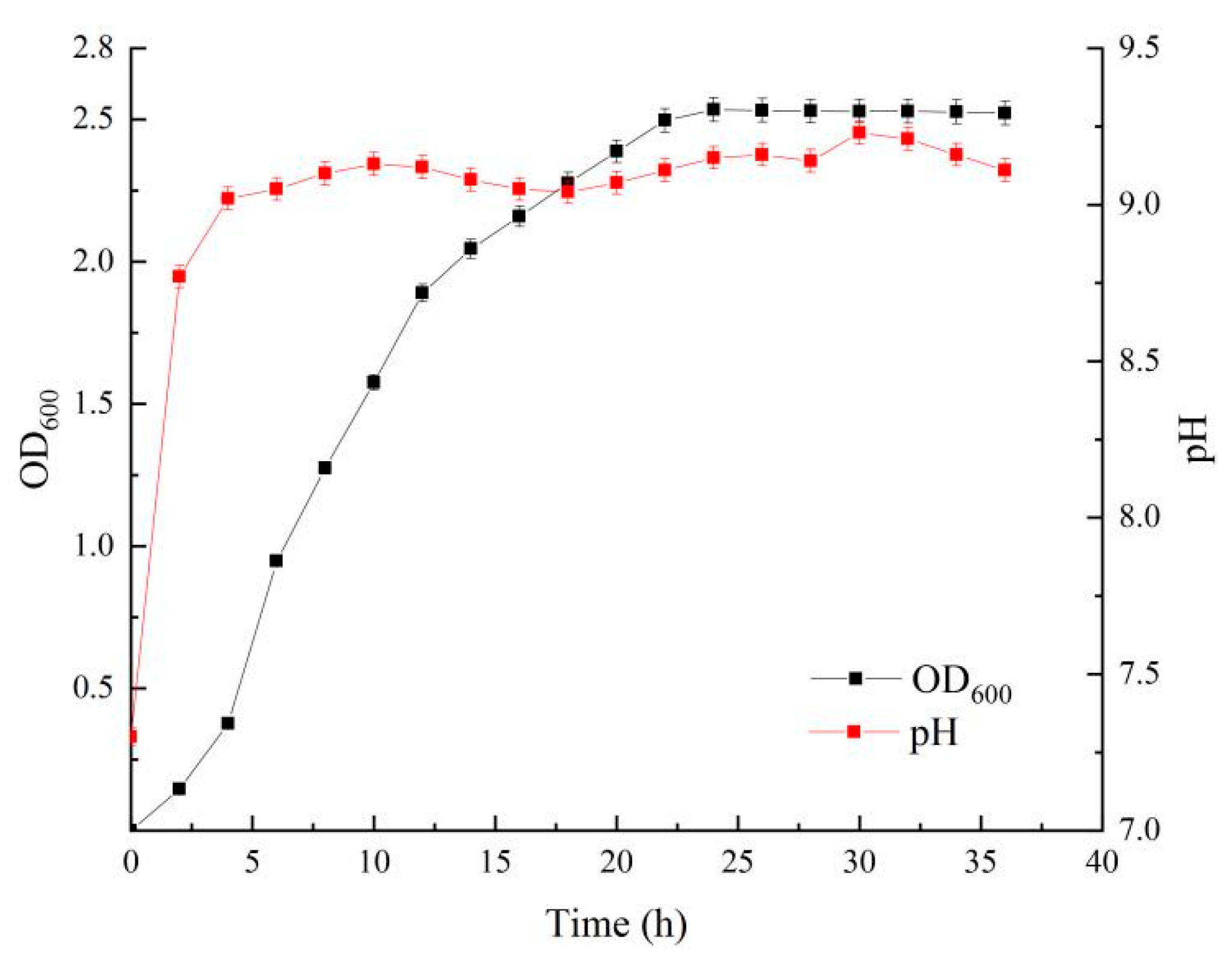

3.1. Cultivation of S. pasteurii

3.1.1. Bacterial Growth

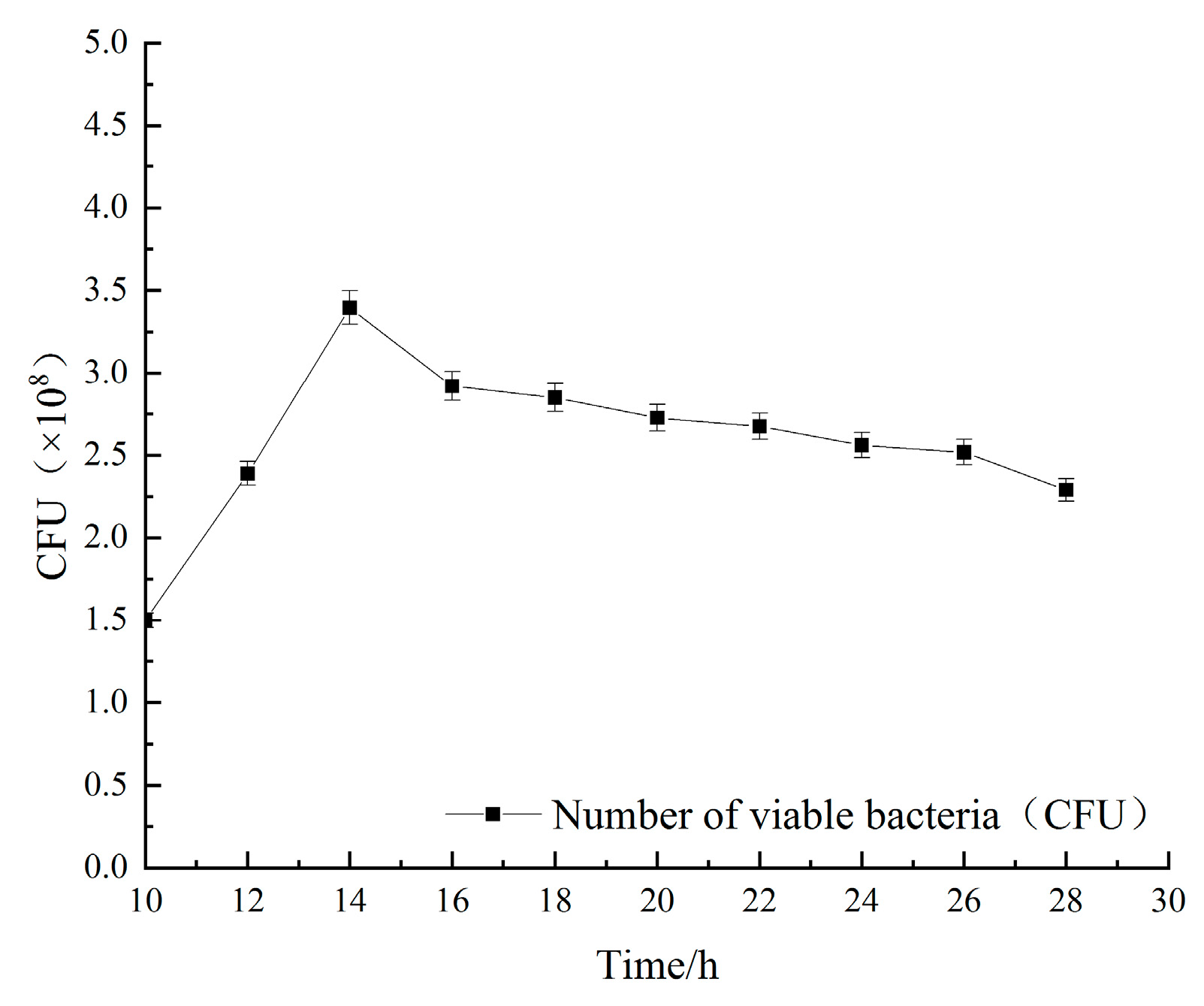

3.1.2. Viability and Bacterial Count

3.2. The Effect of External Electric Field on Bacteria

3.2.1. Bacteria Growing in the Electric Field

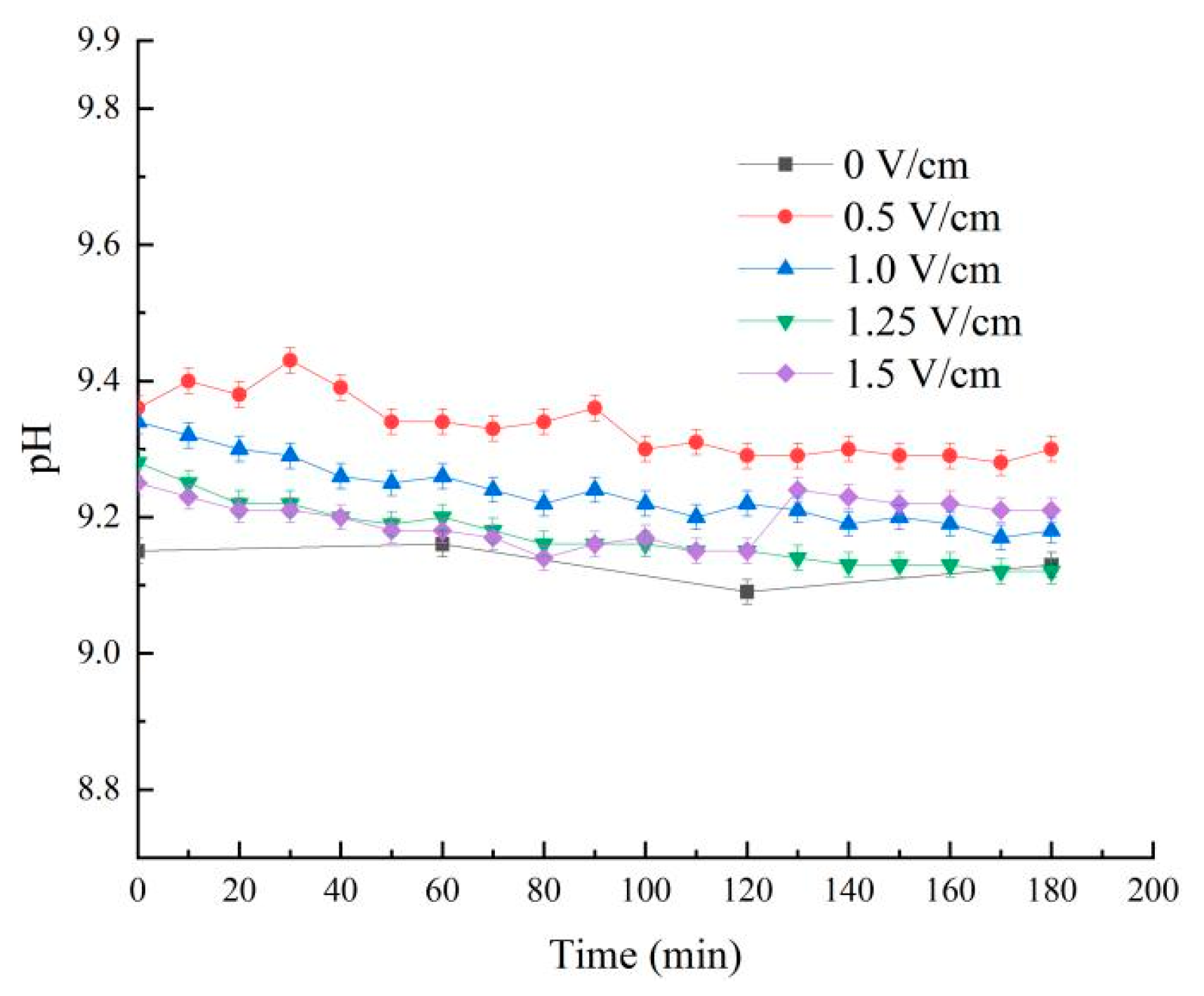

3.2.2. The Influence of Applied Electric Potential on the pH and Viability of Bacterial Liquid

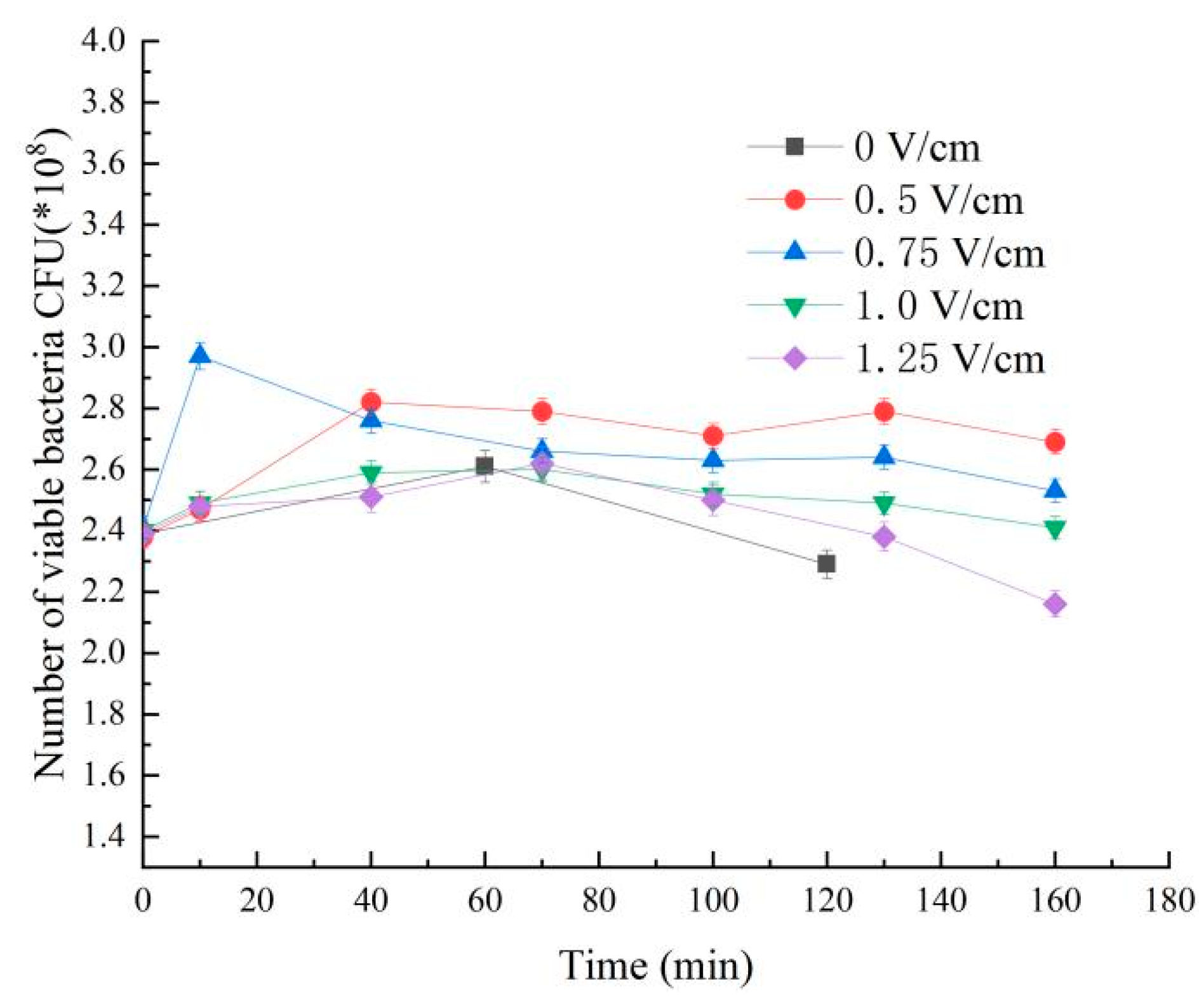

3.2.3. Effect of Applied Electric Potential on the Survivability of S. pasteurii

4. Effect of Electric Field on the Process of Bacteria-Induced Calcium Carbonate Mineralization

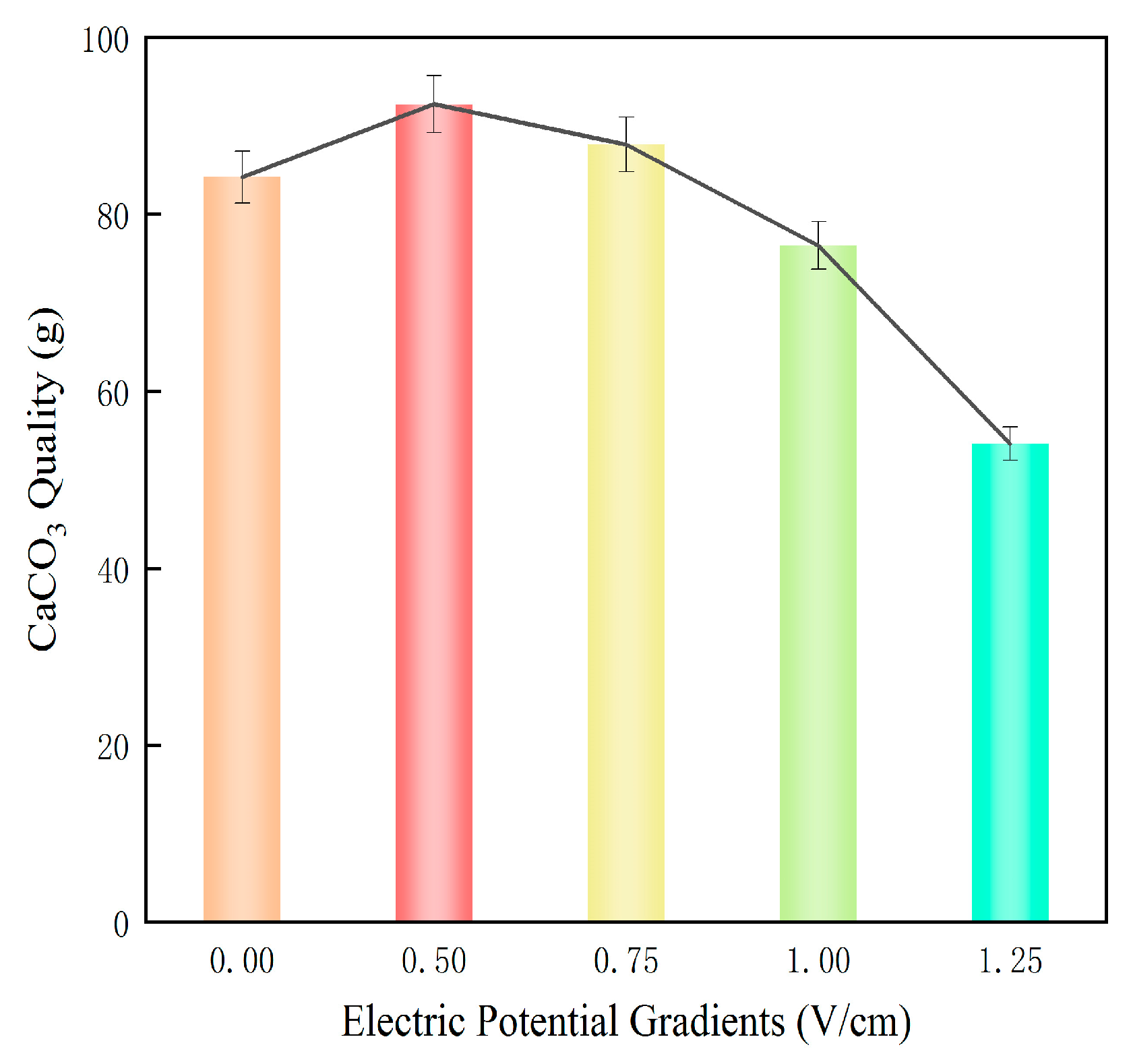

4.1. The Amount of Calcium Carbonate Produced

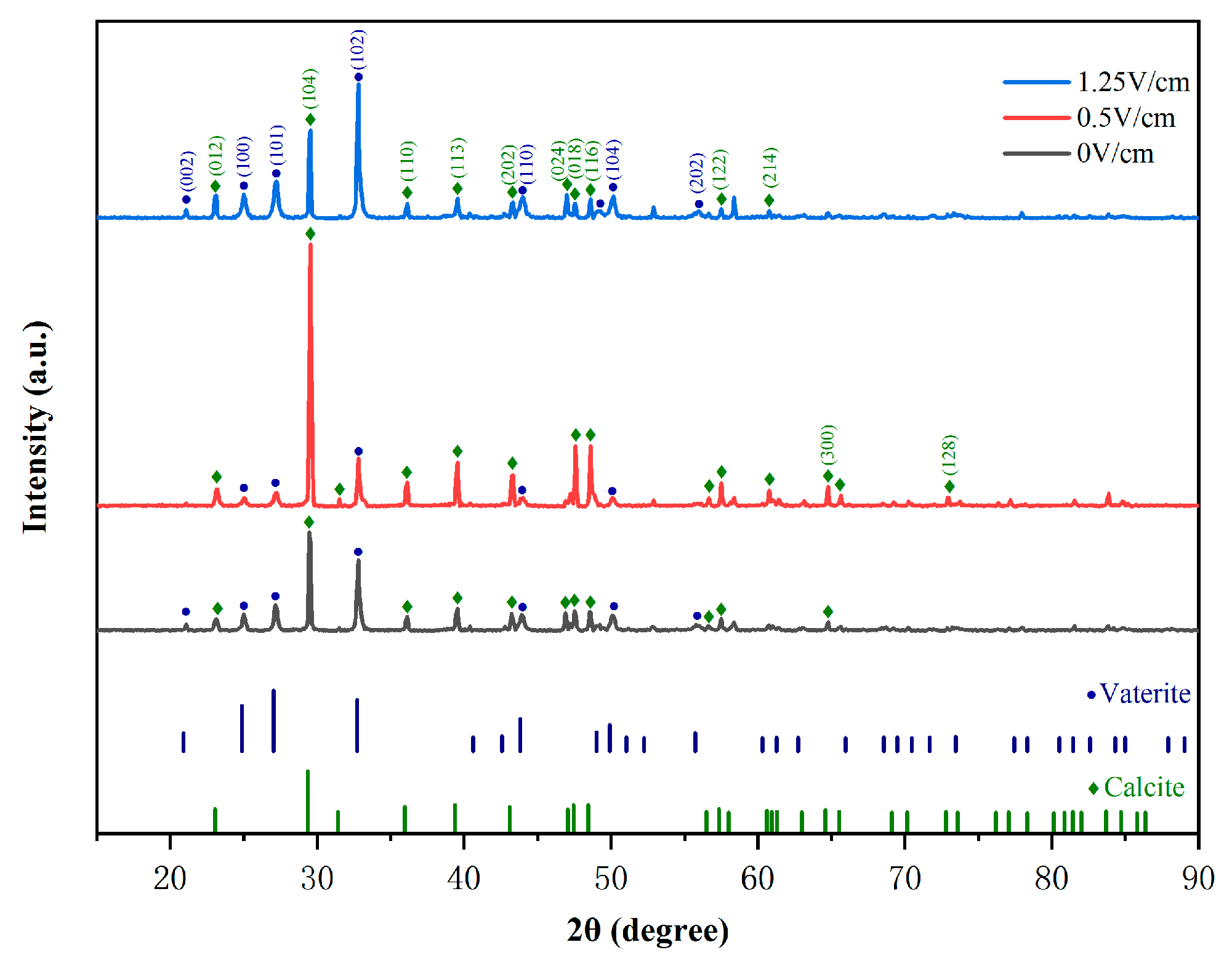

4.2. Changes in Crystal Form

4.2.1. Micro-Morphology and Infrared Analysis

4.2.2. Sediment Composition

5. Discussion

6. Conclusions

7. Significance and Suggestions of Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miller, S.A. The role of cement service-life on the efficient use of resources. Environ. Res. Lett. 2020, 15, 024004. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable Cement Production—Present and Future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Feng, J.; Chen, B.; Sun, W.; Wang, Y. Microbial induced calcium carbonate precipitation study using Bacillus subtilis with application to self-healing concrete preparation and characterization. Constr. Build. Mater. 2021, 280, 122460. [Google Scholar] [CrossRef]

- Sj, A.; Sg, B.; Msr, A. Influence of biogenic treatment in improving the durability properties of waste amended concrete: A review. Constr. Build. Mater. 2020, 263, 120170. [Google Scholar]

- Yu, X.; Jiang, J.; Liu, J.; Li, W. Review on potential uses, cementing process, mechanism and syntheses of phosphate cementitious materials by the microbial mineralization method. Constr. Build. Mater. 2020, 273, 121113. [Google Scholar] [CrossRef]

- Zheng, T.; Qian, C. Self-Healing of Later-Age Cracks in Cement-Based Materials by Encapsulation-Based Bacteria. J. Mater. Civ. Eng. 2020, 32, 04020341. [Google Scholar] [CrossRef]

- Almajed, A.; Lateef, M.A.; Moghal, A.A.B.; Lemboye, K. State-of-the-art review of the applicability and challenges of microbial-induced calcite precipitation (MICP) and enzyme-induced calcite precipitation (EICP) techniques for geotechnical and geoenvironmental applications. Crystals 2021, 11, 370. [Google Scholar] [CrossRef]

- Feng, C.; Cui, B.; Ge, H.; Huang, Y.; Zhang, W.; Zhu, J. Reinforcement of recycled aggregate by Microbial-Induced mineralization and deposition of calcium carbonate—Influencing factors, mechanism and effect of reinforcement. Crystals 2021, 11, 887. [Google Scholar] [CrossRef]

- Gao, H.; Dai, S. Influence of Culture Medium on Cementation of Coarse Grains Based on Microbially Induced Carbonate Precipitation. Crystals 2022, 12, 188. [Google Scholar] [CrossRef]

- Lin, H.; Suleiman, M.T.; Brown, D.G. Investigation of pore-scale CaCO3 distributions and their effects on stiffness and permeability of sands treated by microbially induced carbonate precipitation (MICP). Soils Found. 2020, 60, 944–961. [Google Scholar] [CrossRef]

- Zhang, Z.-J.; Li, B.; Hu, L.; Zheng, H.-M.; He, G.-C.; Yu, Q.; Wu, L.-L. Experimental study on MICP technology for strengthening tail sand under a seepage field. Geofluids 2020, 2020, 8819326. [Google Scholar] [CrossRef]

- Hoang, T.; Alleman, J.; Cetin, B.; Ikuma, K.; Choi, S.G. Sand and Silty-Sand Soil Stabilization Using Bacterial Enzyme Induced Calcite Precipitation (BEICP). Can. Geotech. J. 2019, 56, 808–822. [Google Scholar] [CrossRef]

- Chek, A.; Crowley, R.; Ellis, T.N.; Durnin, M.; Wingender, B. Evaluation of Factors Affecting Erodibility Improvement for MICP-Treated Beach Sand. J. Geotech. Geoenviron. Eng. 2021, 147, 4021001. [Google Scholar] [CrossRef]

- Chuo, S.C.; Mohamed, S.F.; Setapar, S.; Ahmad, A.; Ibrahim, M. Insights into the Current Trends in the Utilization of Bacteria for Microbially Induced Calcium Carbonate Precipitation. Materials 2020, 13, 4993. [Google Scholar] [CrossRef]

- Lai, Y.; Yu, J.; Liu, S.; Liu, J.; Dong, B. Experimental study to improve the mechanical properties of iron tailings sand by using MICP at low pH. Constr. Build. Mater. 2020, 273, 121729. [Google Scholar] [CrossRef]

- Liu, B.; Zhu, C.; Tang, C.S.; Xie, Y.H.; Shi, B. Bio-remediation of desiccation cracking in clayey soils through microbially induced calcite precipitation (MICP). Eng. Geol. 2019, 264, 105389. [Google Scholar] [CrossRef]

- Xu, X.; Guo, H.; Cheng, X.; Li, M. The promotion of magnesium ions on aragonite precipitation in MICP process. Constr. Build. Mater. 2020, 263, 120057. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Tong, K.W.; Hu, L.; Yu, Q.; Wu, L.L. Experimental study on solidification of tailings by MICP under the regulation of organic matrix. Constr. Build. Mater. 2020, 265, 120303. [Google Scholar] [CrossRef]

- Okwadha, G.D.O.; Li, J. Optimum conditions for microbial carbonate precipitation. Chemosphere 2010, 81, 1143–1148. [Google Scholar] [CrossRef]

- Yu, T.; Souli, H.; Péchaud, Y.; Fleureau, J.M. Optimizing protocols for microbial induced calcite precipitation (MICP) for soil improvement—A review. Eur. J. Environ. Civ. Eng. 2022, 26, 2218–2233. [Google Scholar] [CrossRef]

- Kitamura, M.; Konno, H.; Yasui, A.; Masuoka, H. Controlling factors and mechanism of reactive crystallization of calcium carbonate polymorphs from calcium hydroxide suspensions. J. Cryst. Growth 2002, 236, 323–332. [Google Scholar] [CrossRef]

- Wei, S.P.; Cui, H.P.; Jiang, Z.L.; Liu, H.; He, H.; Fang, N.Q. Biomineralization processes of calcite induced by bacteria isolated from marine sediments. Braz. J. Microbiol. 2015, 46, 455–464. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Zheng, J.; Chu, J.; Zhang, R.; Cui, M.; Lai, H.; Zeng, C. New method for using N-(N-butyl)-thiophosphoric triamide to improve the effect of microbial induced carbonate precipitation. Constr. Build. Mater. 2021, 313, 125490. [Google Scholar] [CrossRef]

- Nemati, M.; Greene, E.A.; Voordouw, G. Permeability profile modification using bacterially formed calcium carbonate: Comparison with enzymic option. Process Biochem. 2005, 40, 925–933. [Google Scholar] [CrossRef]

- Gidudu, B.; Chirwa, E.M.N. The combined application of a high voltage, low electrode spacing, and biosurfactants enhances the bio-electrokinetic remediation of petroleum contaminated soil. J. Clean. Prod. 2020, 276, 122745. [Google Scholar] [CrossRef]

- Ossai, I.C.; Ahmed, A.; Hassan, A.; Hamid, F.S. Remediation of soil and water contaminated with petroleum hydrocarbon: A review. Environ. Technol. Innov. 2019, 17, 100526. [Google Scholar] [CrossRef]

- Mena, E.; Villasenor, J.; Canizares, P.; Rodrigo, M.A. Effect of a direct electric current on the activity of a hydrocarbon-degrading microorganism culture used as the flushing liquid in soil remediation processes. Sep. Purif. Technol. 2014, 124, 217–223. [Google Scholar] [CrossRef]

- Cheng, F.L.; Guo, S.H.; Wang, S.; Guo, P.H.; Lu, W.J. Transportation and augmentation of the deposited soil bacteria in the electrokinetic process: Interactions between soil particles and bacteria. Geoderma 2021, 404, 115260. [Google Scholar] [CrossRef]

- Martin, D.; Dodds, K.; Ngwenya, B.T.; Butler, I.B.; Elphick, S.C. Inhibition of Sporosarcina pasteurii under Anoxic Conditions: Implications for Subsurface Carbonate Precipitation and Remediation via Ureolysis. Environ. Sci. Technol. 2012, 46, 8351–8355. [Google Scholar] [CrossRef]

- Kang, B.; Zha, F.; Li, H.; Xu, L.; Sun, X.; Lu, Z. Bio-Mediated Method for Immobilizing Copper Tailings Sand Contaminated with Multiple Heavy Metals. Crystals 2022, 12, 522. [Google Scholar] [CrossRef]

- Ramachandran, S.K.; Ramakrishnan, V.; Bang, S.S. Remediation of Concrete Using Microorganisms. ACI Mater. J. 2001, 98, 3–9. [Google Scholar]

- Zhao, Q.; Li, L.; Li, C.; Li, M.; Amini, F.; Zhang, H. Factors affecting improvement of engineering properties of MICP-treated soil catalyzed by bacteria and urease. J. Mater. Civ. Eng. 2014, 26, 04014094. [Google Scholar] [CrossRef]

- Cuzman, O.A.; Richter, K.; Wittig, L.; Tiano, P. Alternative nutrient sources for biotechnological use of Sporosarcina pasteurii. World J. Microbiol. Biotechnol. 2015, 31, 897–906. [Google Scholar] [CrossRef] [PubMed]

- Di, P.; Zhi-Ming, L.; Bi-Ru, H.; Wen-Jian, W. Progress on mineralization mechanism and application research of Sporosarcina pasteurii. Prog. Biochem. Biophys. 2020, 47, 467–482. [Google Scholar]

- Whiffin, V.S.; Van Paassen, L.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Sun, X.-T.; Ma, J.; Sun, X.-Y.; Liu, B. Electrolytic Stimulation of Escherichia coli by a Direct Current. Microbiol./Weishengwuxue Tongbao 2010, 37, 1440–1446. [Google Scholar]

- Zhang, B.; Liu, Y.; Tong, S.; Zheng, M.; Zhao, Y.; Tian, C.; Liu, H.; Feng, C. Enhancement of bacterial denitrification for nitrate removal in groundwater with electrical stimulation from microbial fuel cells. J. Power Sources 2014, 268, 423–429. [Google Scholar] [CrossRef]

- Liu, H.; Ouyang, F.; Chen, Z.; Chen, Z.; Lichtfouse, E. Weak electricity stimulates biological nitrate removal of wastewater: Hypothesis and first evidences. Sci. Total Environ. 2021, 757, 143764. [Google Scholar] [CrossRef]

- Rabbi, M.F.; Clark, B.; Gale, R.J. In situ TCE bioremediation study using electrokinetic cometabolite injection. Waste Manag. 2000, 20, 279–286. [Google Scholar] [CrossRef]

- Yi, H.; Zheng, T.; Jia, Z.; Su, T.; Wang, C. Study on the influencing factors and mechanism of calcium carbonate precipitation induced by urease bacteria. J. Cryst. Growth 2021, 564, 126113. [Google Scholar] [CrossRef]

- Ferris, F.G.; Phoenix, V.; Fujita, Y.; Smith, R. Kinetics of calcite precipitation induced by ureolytic bacteria at 10 to 20 C in artificial groundwater. Geochim. Cosmochim. Acta 2004, 68, 1701–1710. [Google Scholar] [CrossRef]

- Ng, W.-S.; Lee, M.-L.; Hii, S.-L. An overview of the factors affecting microbial-induced calcite precipitation and its potential application in soil improvement. Int. J. Civ. Environ. Eng. 2012, 6, 188–194. [Google Scholar]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Wick, L.Y.; Shi, L.; Harms, H. Electro-bioremediation of hydrophobic organic soil-contaminants: A review of fundamental interactions. Electrochim. Acta 2007, 52, 3441–3448. [Google Scholar] [CrossRef]

- Cheng, L.; Qian, C.; Wang, R.; Wang, J. Study on the mechanism of calcium carbonate formation induced by carbonate-mineralization microbe. Acta Chim. Sin. 2007, 65, 2133–2138. [Google Scholar]

- Rong, H.; Qian, C.-X.; Li, L.-Z. Study on microstructure and properties of sandstone cemented by microbe cement. Constr. Build. Mater. 2012, 36, 687–694. [Google Scholar] [CrossRef]

- Gebauer, D.; Volkel, A.; Colfen, H. Stable prenucleation calcium carbonate clusters. Science 2008, 322, 1819–1822. [Google Scholar] [CrossRef]

- Zheng, H.-M.; Wu, L.-L.; Tong, K.-W.; Ding, D.-X.; Zhang, Z.-J.; Yu, Q.; He, G.-C. Experiment on microbial grouting reinforcement of tailings under the regulation of egg white. Soils Found. 2020, 60, 962–977. [Google Scholar] [CrossRef]

- Muynck, W.D.; Belie, N.D.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Stocks-Fischer, S.; Galinat, J.K.; Bang, S.S. Microbiological precipitation of CaCO3. Soil Biol. Biochem. 1999, 31, 1563–1571. [Google Scholar] [CrossRef]

- Naveed, M.; Duan, J.; Uddin, S.; Suleman, M.; Hui, Y.; Li, H. Application of microbially induced calcium carbonate precipitation with urea hydrolysis to improve the mechanical properties of soil. Ecol. Eng. 2020, 153, 105885. [Google Scholar] [CrossRef]

- Li, M.; Cheng, X.; Guo, H. Heavy metal removal by biomineralization of urease producing bacteria isolated from soil. Int. Biodeterior. Biodegrad. 2013, 76, 81–85. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hora, R.N.; Ahenkorah, I.; Beecham, S.; Karim, M.R.; Iqbal, A. State-of-the-art review of microbial-induced calcite precipitation and its sustainability in engineering applications. Sustainability 2020, 12, 6281. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, J.; Li, M.; Tian, Y.; Zhang, Z.; Wu, L.; Hu, L. Using Electric Field to Improve the Effect of Microbial-Induced Carbonate Precipitation. Sustainability 2023, 15, 5901. https://doi.org/10.3390/su15075901

Deng J, Li M, Tian Y, Zhang Z, Wu L, Hu L. Using Electric Field to Improve the Effect of Microbial-Induced Carbonate Precipitation. Sustainability. 2023; 15(7):5901. https://doi.org/10.3390/su15075901

Chicago/Turabian StyleDeng, Jinxiang, Mengjie Li, Yakun Tian, Zhijun Zhang, Lingling Wu, and Lin Hu. 2023. "Using Electric Field to Improve the Effect of Microbial-Induced Carbonate Precipitation" Sustainability 15, no. 7: 5901. https://doi.org/10.3390/su15075901

APA StyleDeng, J., Li, M., Tian, Y., Zhang, Z., Wu, L., & Hu, L. (2023). Using Electric Field to Improve the Effect of Microbial-Induced Carbonate Precipitation. Sustainability, 15(7), 5901. https://doi.org/10.3390/su15075901