Feature Selection and Damage Identification for Urban Railway Track Using Bayesian Globally Sparse Principal Component Analysis

Abstract

1. Introduction

2. Bayesian Globally Sparse PCA for Feature Selection and Damage Identification

2.1. Bayesian PCA Model

2.2. Bayesian Inference for Globally Sparse PCA

2.3. Feature Selection and Damage Identification Procedure for Urban Railway Track

- (1)

- Based on the inputs of the data matrix of track monitoring and dimension of the latent space in , the EM algorithm is performed iteratively from the initially selected values to infer the most probable values of the uncertain parameter using Equations (17)–(20).

- (2)

- The most probable values of continuous vector v are transformed into a binary vector , and the selected relevant variables (data columns) in the data matrix correspond to the nonzero entries in vector .

- (3)

- The binary elements (0 and 1) of the inferred vector are employed to distinguish whether each monitoring data piece is associated with an abnormal (element value is 0, indicating there is damage occurring in the areas near the sensor) or normal (element value is 1, indicating there is no damage occurring in the areas near the sensor) condition.

- (4)

- Inspection of the track is performed in the areas near the sensor for precise localization of damage.

3. Engineering Verification

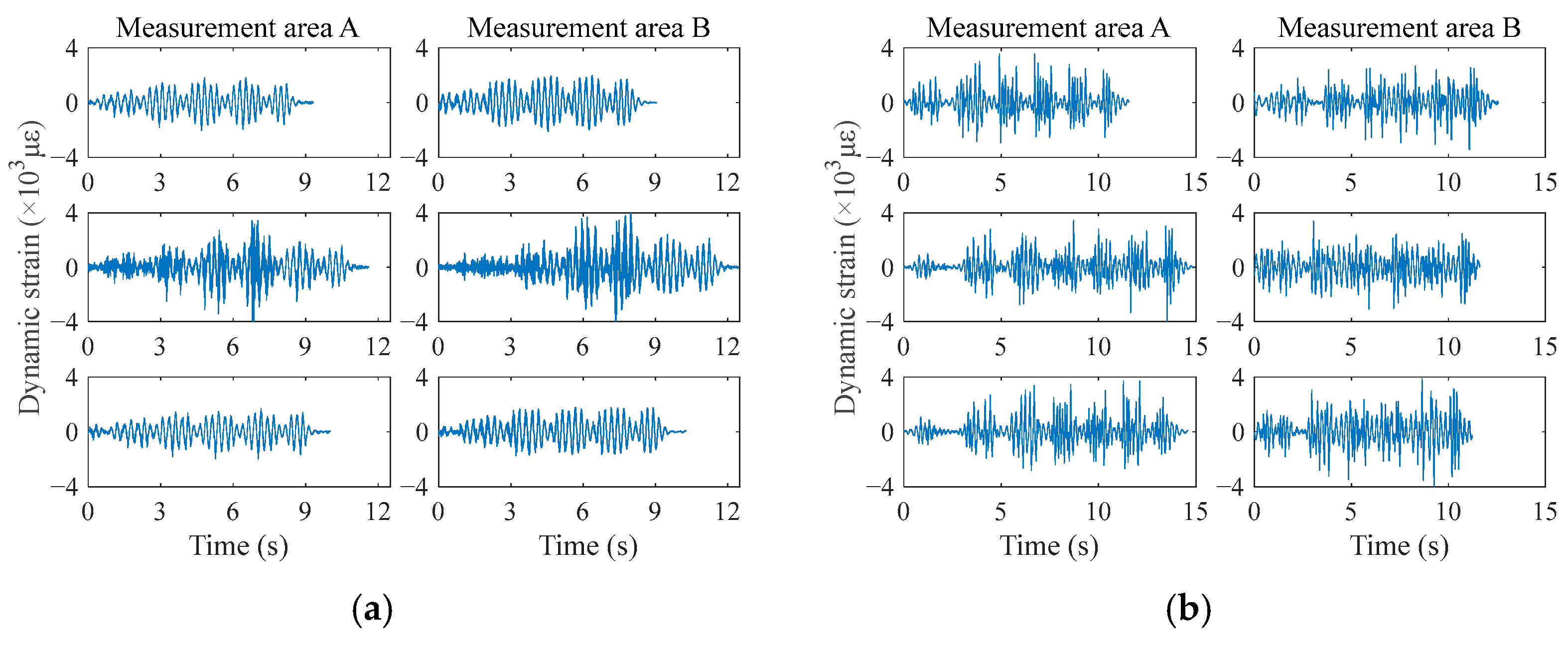

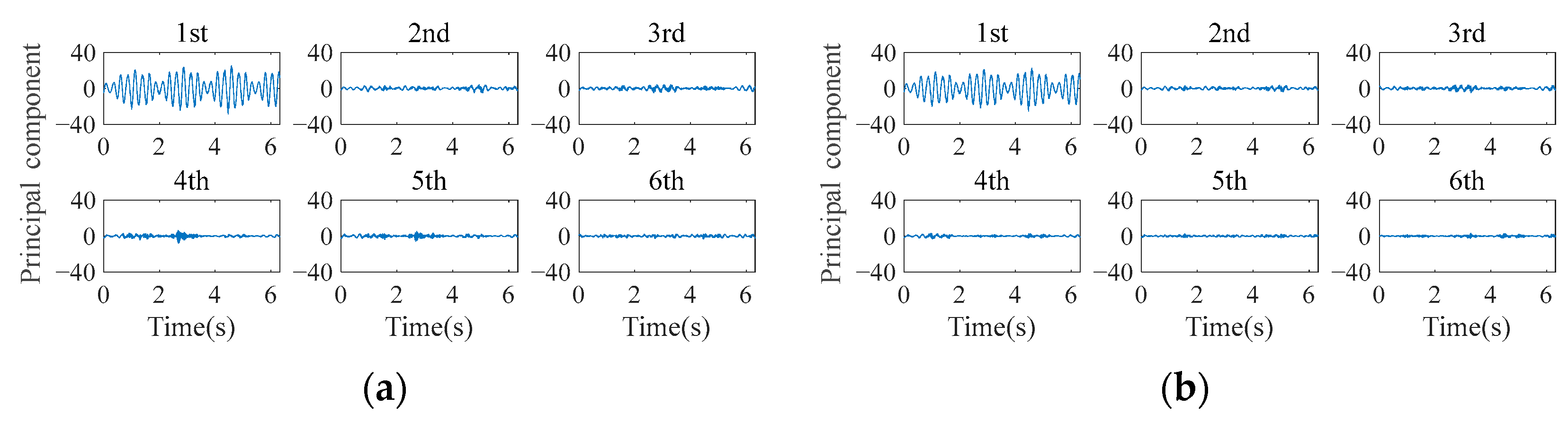

3.1. Urban Railway Track Monitoring Data

3.2. Urban Railway Track Damage Identification Performance

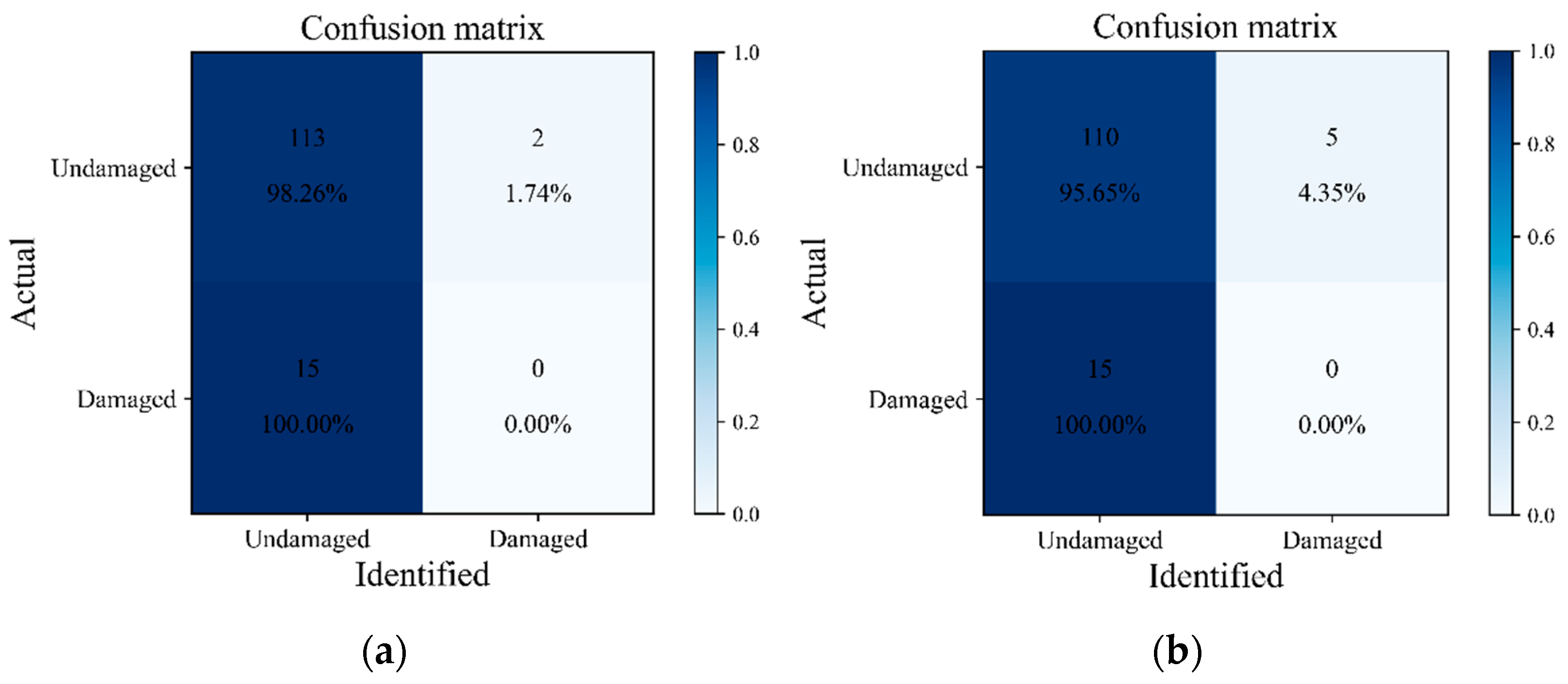

3.2.1. Scenario 1: Verification in Single Monitoring Area

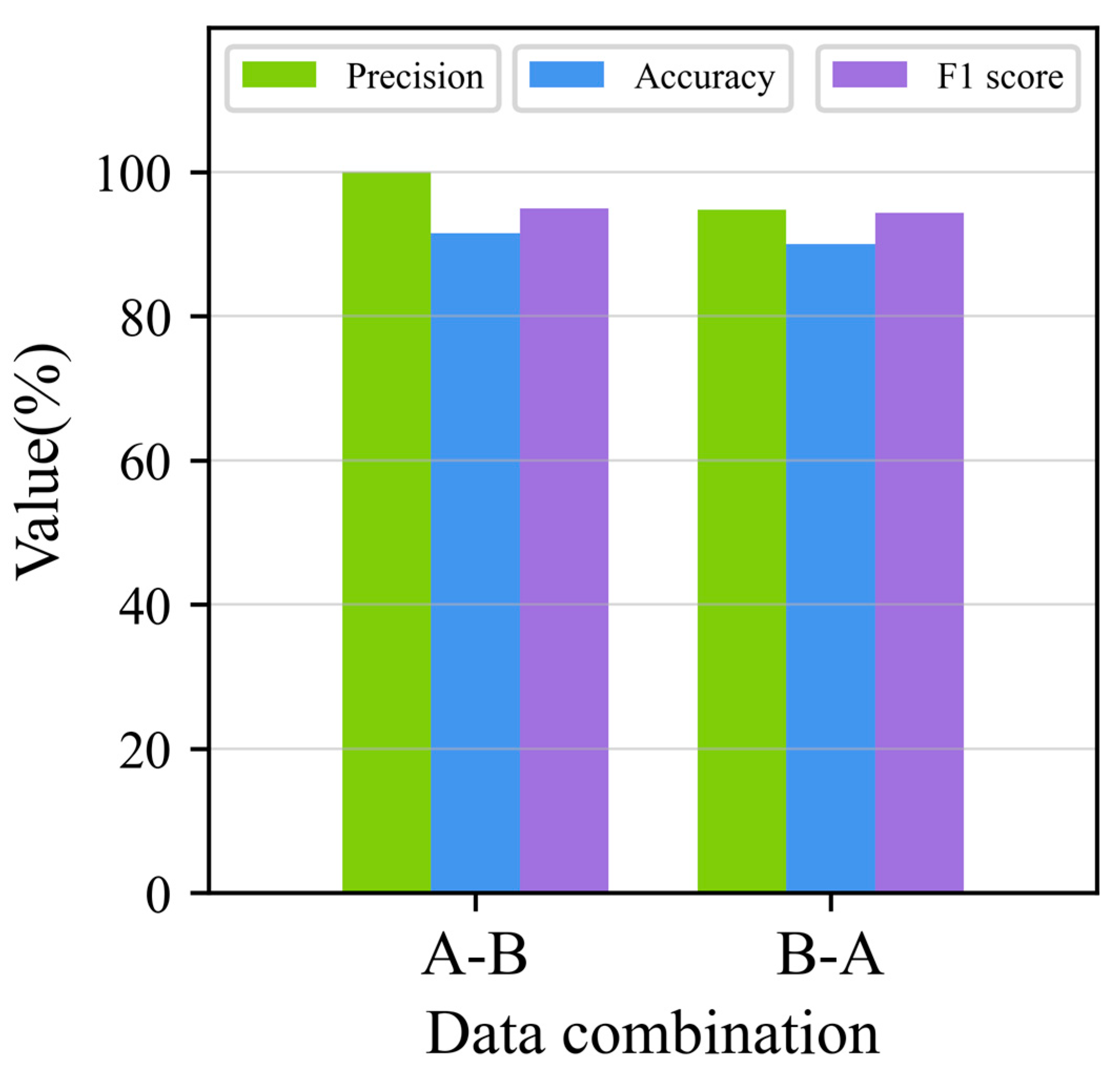

3.2.2. Scenario 2: Verification across Monitoring Areas

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thomas, B.; DeRobertis, M. The safety of urban cycle tracks: A review of the literature. Accid. Anal. Prev. 2013, 52, 219–227. [Google Scholar] [CrossRef] [PubMed]

- FRA (Federal Railroad Administration). Track Inspector Rail Defect Reference Manual. 2015. Available online: https://railroads.dot.gov/elibrary/track-inspector-rail-defect-reference-manual (accessed on 25 January 2023).

- Karakose, M.; Yaman, O.; Baygin, M.; Akin, E. A new computer vision based method for rail track detection and fault diagnosis in railways. Int. J. Mech. Eng. Robot. Res. 2017, 6, 22-17. [Google Scholar] [CrossRef]

- Xiang, C.; Li, Z.; Qi, X.; Cao, S.; Liu, H. Research on track damage identification based on the response of vehicle-rail contact point. Transp. Eng. 2022, 10, 100149. [Google Scholar] [CrossRef]

- Alves, V.N.; de Oliveira, M.M.; Ribeiro, D.; Calcada, R.; Cury, A. Model-based damage identification of railway bridges using genetic algorithms. Eng. Fail. Anal. 2020, 118, 104845. [Google Scholar] [CrossRef]

- Xie, J.; Huang, J.; Zeng, C.; Jiang, S.; Podlich, N. Systematic literature review on data-driven models for predictive maintenance of railway track: Implications in geotechnical engineering. Geosciences 2020, 10, 425. [Google Scholar] [CrossRef]

- Wang, S.; Gao, J.; Lin, C.; Li, H.; Huang, Y. Condition assessment of high-speed railway track structure based on sparse Bayesian extreme learning machine and Bayesian hypothesis testing. Int. J. Rail Transp. 2022, 1–25. [Google Scholar] [CrossRef]

- Li, S.; Wei, S.; Bao, Y.; Li, H. Condition assessment of cables by pattern recognition of vehicle-induced cable tension ratio, Eng. Struct. 2018, 155, 1–15. [Google Scholar]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Chan, T.H.; Jia, K.; Gao, S.; Lu, J. PCANet: A simple deep learning baseline for image classification? IEEE Trans. Image Process. 2015, 24, 5017–5032. [Google Scholar] [CrossRef]

- W, J.; H, Y.; Z, G.; W, C. Offline handwritten numeral recognition based on principal component analysis. In Proceedings of the 2007 8th International Conference on Electronic Measurement and Instruments, Xian, China, 16–18 August 2007. [Google Scholar]

- Almotiri, J.; Elleithy, K.; Elleithy, A. Comparison of autoencoder and Principal Component Analysis followed by neural network for e-learning using handwritten recognition. In Proceedings of the 2017 IEEE Long Island Systems, Applications and Technology Conference (LISAT), Farmingdale, NY, USA, 5 May 2017. [Google Scholar]

- Bahurupi, S.P.; Chaudhari, D.S. Principal component analysis for face recognition. Int. J. Eng. Adv. Technol. 2012, 1, 91–94. [Google Scholar]

- Abdullah, N.A.; Saidi, M.J.; Rahman, N.H.A.; Wen, C.C.; Hamid, I.R.A. Face recognition for criminal identification: An implementation of principal component analysis for face recognition. In AIP Conference Proceedings; AIP Publishing LLC.: Melville, NY, USA, 2017; Volume 1891, p. 020002. [Google Scholar]

- Lu, Y.; Cohen, I.; Zhou, X.S.; Tian, Q. Feature selection using principal feature analysis. In Proceedings of the 15th ACM international conference on Multimedia, New York, NY, USA, 25–29 September 2007; pp. 301–304. [Google Scholar]

- Ren, Y.; Koops, H.V.; Bountouridis, D.; Volk, A.; Swierstra, W.S.; Veltkamp, R.C.; Holzapfel, A.; Pikrakis, A. Feature analysis of repeated patterns in dutch folk songs using principal component analysis. In Proceedings of the 8th International Workshop on Folk Music Analysis (FMA2018), Aristotle University of Thessaloniki, Thessaloniki, Greece, 26–29 June 2018; pp. 86–88. [Google Scholar]

- Gadekallu, T.R.; Rajput, D.S.; Reddy, M.P.K.; Lakshmanna, K.; Bhattacharya, S.; Singh, S.; Alazab, M. A novel PCA–whale optimization-based deep neural network model for classification of tomato plant diseases using GPU. J. Real-Time Image Process. 2021, 18, 1383–1396. [Google Scholar] [CrossRef]

- Reddy, G.T.; Reddy, M.P.K.; Lakshmanna, K.; Kaluri, R.; Rajput, D.S.; Srivastava, G.; Baker, T. Analysis of dimensionality reduction techniques on big data. Ieee Access 2020, 8, 54776–54788. [Google Scholar] [CrossRef]

- Zou, H.; Hastie, T.; Tibshirani, R. Sparse principal component analysis. J. Comput. Graph. Stat. 2006, 15, 265–286. [Google Scholar] [CrossRef]

- Zou, H.; Xue, L. A selective overview of sparse principal component analysis. Proc. IEEE 2018, 106, 1311–1320. [Google Scholar] [CrossRef]

- Ning, B. Spike and slab Bayesian sparse principal component analysis. arXiv 2021, arXiv:2102.00305. [Google Scholar]

- Zeng, J.; Liu, K.; Huang, W.; Liang, J. Sparse probabilistic principal component analysis model for plant-wide process monitoring. Korean J. Chem. Eng. 2017, 34, 2135–2146. [Google Scholar] [CrossRef]

- Bouveyron, C.; Latouche, P.; Mattei, P.A. Bayesian variable selection for globally sparse probabilistic PCA. Electron. J. Stat. 2018, 12, 3036–3070. [Google Scholar] [CrossRef]

- Tipping, M.E.; Bishop, C.M. Probabilistic principal component analysis. J. R. Stat. Soc. Ser. B (Stat. Methodol.) 1999, 61, 611–622. [Google Scholar] [CrossRef]

- Christopher, M.B. Bayesian PCA. In Proceedings of the 1998 Conference on Advances in Neural Information Processing Systems II, July 1999; pp. 382–388. [Google Scholar]

- Bouveyron, C.; Latouche, P.; Mattei, P.A. Exact dimensionality selection for Bayesian PCA. Scand. J. Stat. 2020, 47, 196–211. [Google Scholar] [CrossRef]

- Cai, M.; Shi, Y.; Liu, J.; Niyoyita, J.P.; Jahanshahi, H.; Aly, A.A. DRKPCA-VBGMM: Fault monitoring via dynamically-recursive kernel principal component analysis with variational Bayesian Gaussian mixture model. J. Intell. Manuf. 2022, 1–29. [Google Scholar] [CrossRef]

- Jaynes, E.T. Probability Theory: The Logic of Science; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Beck, J.L. Bayesian system identification based on probability logic. Struct. Control Health Monit. 2010, 17, 825–847. [Google Scholar] [CrossRef]

- MacKay, D.J.C. Bayesian methods for backpropagation networks. In Models of Neural Networks III; Springer: New York, NY, USA, 1996; pp. 211–254. [Google Scholar]

- Tipping, M.E. Sparse Bayesian learning and the relevance vector machine. J. Mach. Learn. Res. 2001, 1, 211–244. [Google Scholar]

- Huang, Y.; Beck, J.L.; Li, H. Bayesian system identification based on hierarchical sparse Bayesian learning and Gibbs sampling with application to structural damage assessment. Comput. Methods Appl. Mech. Eng. 2017, 318, 382–411. [Google Scholar] [CrossRef]

- Huang, Y.; Shao, C.; Wu, B.; Beck, J.L.; Li, H. State-of-the-art review on Bayesian inference in structural system identification and damage assessment. Adv. Struct. Eng. 2019, 22, 1329–1351. [Google Scholar] [CrossRef]

- Bishop, C.M.; Nasrabadi, N.M. Pattern Recognition and Machine Learning; Springer: New York, NY, USA, 2006. [Google Scholar]

- Murphy, K.P. Machine Learning: A Probabilistic Perspective; MIT Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Murugesan, V.; Selvaraj, M.S.; Yang, M.H. HPSIPT: A high-precision single-packet IP traceback scheme. Comput. Netw. 2018, 143, 275–288. [Google Scholar] [CrossRef]

| Methods | Identification Means | Drawbacks |

|---|---|---|

| Manual inspection [2] | Visual observation and simple instrumentation measurement | Inability to detect damage in time, difficulty in detection of inconspicuous damage |

| Model-based method [4,5] | Constructing an accurate structural model | Requires large amounts of high-quality data for model calibration and updating |

| Data-driven method [6,7,8] | Extract damage-sensitive signal features | No physical information about the structure is incorporated |

| Metrics (%) | Measurement Area A | Measurement Area B |

|---|---|---|

| Precision | 100.00 | 100.00 |

| Accuracy | 83.07 | 89.23 |

| 89.42 | 93.51 |

| Metrics (%) | Measurement Area A | Measurement Area B |

|---|---|---|

| Precision | 100.00 | 94.74 |

| Accuracy | 91.54 | 90.00 |

| 94.98 | 94.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Huang, Y.; Chen, J.; Liu, X.; Meng, X.; Lin, C. Feature Selection and Damage Identification for Urban Railway Track Using Bayesian Globally Sparse Principal Component Analysis. Sustainability 2023, 15, 5391. https://doi.org/10.3390/su15065391

Li Q, Huang Y, Chen J, Liu X, Meng X, Lin C. Feature Selection and Damage Identification for Urban Railway Track Using Bayesian Globally Sparse Principal Component Analysis. Sustainability. 2023; 15(6):5391. https://doi.org/10.3390/su15065391

Chicago/Turabian StyleLi, Qi, Yong Huang, Jiahui Chen, Xiaohui Liu, Xianghao Meng, and Chao Lin. 2023. "Feature Selection and Damage Identification for Urban Railway Track Using Bayesian Globally Sparse Principal Component Analysis" Sustainability 15, no. 6: 5391. https://doi.org/10.3390/su15065391

APA StyleLi, Q., Huang, Y., Chen, J., Liu, X., Meng, X., & Lin, C. (2023). Feature Selection and Damage Identification for Urban Railway Track Using Bayesian Globally Sparse Principal Component Analysis. Sustainability, 15(6), 5391. https://doi.org/10.3390/su15065391