Abstract

The frequency of work accidents in construction projects is relatively high. One contributing factor to work accidents is unsafe behavior by workers at construction sites. In Indonesia, this is the first study to investigate 2503 instances of unsafe behavior that occurred across Indonesian construction projects in relation to their attributes to obtain insightful knowledge by using the association rule mining (ARM) method. Association rule mining was used to explore the database. As a result, two consolidated rules were obtained. The most frequent unsafe behaviors were workers putting tools and materials in random places, workers not attaching safety lines at provided places, and workers moving work tools and materials in ways that were not in accordance with procedures. These unsafe behaviors were associated with accident types of falling, and being struck or cut by items, as well as violations of Manpower and Transmigration Ministerial Regulation 01/1980, and Manpower Ministerial Regulation 09/2016. The ARM results were evaluated with a reliability evaluation method before being validated by construction safety experts. Hence, the findings are reliable to be used as guideline information for safety trainers to prioritize related safety trainings and for safety inspectors when carrying out inspections on construction sites. As a result, safety management and safety performance can increase significantly.

1. Introduction

Construction is one of the most dangerous industries and accounts for a significant number of occupational accidents around the world [1]. According to US Department of Labor (2021), there are 1008 fatal accident cases related to construction every year [2]. In Indonesia, this sector contributed to 32% of all work-related injury records [3]. Accidents yield disadvantages to construction projects, including, among others, delays, cost increase, damage to the company’s reputation, and decreasing confidence among the workforce [4]. Accidents also cause financial losses due to property damages and penalties from authorities [5].

Construction accidents are highly correlated with unsafe behavior at construction sites, resulting in low safety performance [6]. Therefore, it is important to investigate unsafe behavior to improve the policies regarding safety management systems. In every project, various types of unsafe behaviors can occur. The characteristics and frequency of unsafe behavior may vary depending on type, contract value, construction period, and other project characteristics. Therefore, it is important to analyze unsafe behavior not only based on the unsafe behavior itself, but also from other project attributes. By using data mining, meaningful patterns and trends can be extracted from vast volumes of data [7]. Many data-mining methods, including association rule mining (ARM), Bayesian networks (BNs), and decision trees (DT), have been employed to find hidden patterns in enormous amounts of data [8]. Additionally, several additional techniques, including the manifold learning technique (i.e., Laplacian Eigenmaps) [9] and the autoencoder (i.e., NVAE) were also employed [10].

ARM is efficient for identifying significant relationships between pertinent features in a sea of complex databases [7]. In Taiwan, ARM was used to analyze the data of 2027 instances of unsafe behavior [11]. Liao and Perng uncovered the features of fatal injuries according to mining association guidelines from 309 accident reports of fatal injuries in the construction business [12]. Shin et al. investigated 98,189 serious injury and mortality accidents that occurred at Korean construction sites between 2006 and 2010 in order to identify intuitive knowledge defined as association rules among multiple features of construction accidents [13].

To date, there have been no studies investigating unsafe behavior related to multiple attributes using data-mining methods in the Indonesian construction industry. Therefore, this study aims to investigate unsafe behaviors in construction projects in relation to other attributes. This study can obtain results that provide insightful knowledge and propose ways to improve the effectiveness of behavioral safety management at construction sites.

2. Literature Review

According to the Global Competitiveness Index (2011), Indonesia is one of the ASEAN countries with the highest number of work accidents, with a fatal working accident index of 40 per 100.000 workers [14]. Generally, the high number of occupational accidents in Indonesia has been perceived to be caused by the unsafe behavior of workers, unsafe conditions, or both [15]. According to Yang et al., 80–90% of all accidents are caused by unsafe behavior [16]. Unsafe behavior of construction workers refers to unsafe behavior that violates operating policies, organizational rules, and methodologies in professional operations [17]. These unsafe worker behaviors have the potential to cause a variety of accidents, including (1) falls, (2) being hit or cut by objects, (3) becoming caught in or between objects, (4) electrocution, (5) being run over or struck by moving traffic objects, and (6) fires and explosions [18]. The Government of Indonesia (GoI) has stipulated several laws, regulations, and standards regarding construction employees’ rights and responsibilities for occupational safety and health (OHS), as summarized in Table 1. The policies have been established by the state government and various ministries with the general aim of protecting worker safety while ensuring increased productivity and worker welfare. However, the implementation of OHS regulations and standards in the Indonesian construction industry is not adequate and is still far from ideal standards [19]. Many mistakes made during the construction process as a result of violations of existing laws and regulations are directly related to the increase in the occurrence of work accidents [20].

Table 1.

GoI’s regulations regarding OHS.

Numerous studies on construction safety have been conducted in Indonesia to date. Some of these studies have been conducted to identify variables that affect the likelihood of accidents in the construction industry, as well as solutions and innovations that have impacts on improving safety standards in the Indonesian construction sector. However, data-mining techniques are still infrequently used for construction safety investigations in Indonesia. In fact, if applied correctly, this method has the potential to address Indonesia’s issues with construction accidents. Given that identical factors consistently lead to construction accident occurrences, historical accident data may be helpful in predicting the occurrence of similar incidents in the future [13]. As a result, it is essential to examine an enormous amount of construction data and to process it using data mining. One of the data-mining methods is ARM, which can provide significant relationships. This research introduces the ARM method for analyzing worker’s unsafe behavior patterns in Indonesia. ARM results can serve as a guide for practitioners in the construction industry to lower the number of construction accidents in Indonesia.

3. Methodology

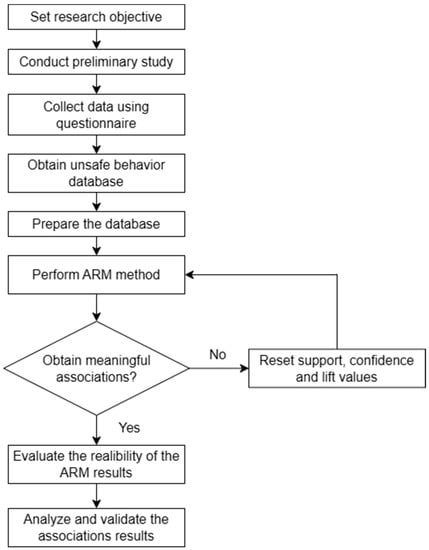

This study analyzed unsafe behavior data in accordance with the process of ARM, as shown in Figure 1. The objective of this study was to investigate unsafe behavior at construction projects in relation to other attributes (step 1). The unsafe behavior list and the attributes were identified through a literature review and validated by the construction safety experts (step 2). The data used for this study were collected by conducting a questionnaire survey (step 3). As a result, the database was populated with information about a total of 4134 unsafe behavior cases (step 4). Before being entered into the ARM algorithm, the database was cleaned from outliers, resulting in 2503 unsafe behavior cases, and the database format was changed to fit the format of the ARM algorithm (step 5). The database was analyzed using the ARM method (step 6), and the mined rules were evaluated using support, confidence, and lift parameters (step 7). When a mined rule did not have a meaningful association, an additional iteration of the association analysis was performed by resetting the parameters. To establish the dependability of the dataset used, the reliability evaluation method is conducted to gain a comprehensive understanding of the ARM results, which can then be used to determine whether the ARM results are suitable as a reference for decision making during the analysis process (step 8). Finally, the results were validated by construction safety experts (step 9).

Figure 1.

Methodology.

3.1. Questionnaire Design and Data Collection

Several survey data, mainly related to the number of cases of unsafe worker behavior at construction projects, along with other attributes such as construction type, construction sector, and construction contract amount, were needed as input for this study. For this regard, a questionnaire survey was conducted with respondents consisting of construction workers.

The first part of the questionnaire contained instructions, research objectives, and questions regarding respondents’ demographical features. The questionnaire’s second part consisted of several questions related to general project attributes, including the name, type, and sector of the construction project. The last component of the questionnaire was a question list regarding how many unsafe behavior cases respondents observed during a specific time period. The unsafe behaviors listed in the questionnaires were formed based on the literature and validated by the experts. The list of attributes and the categories of each attribute used in this study are shown in Table 2.

Table 2.

Attribute list.

3.2. Database Preparation

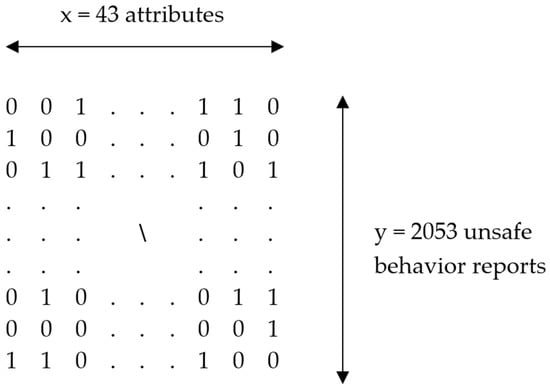

Database preparation was performed to clean and transform raw database obtained from the questionnaires into a database that can be analyzed efficiently and adequately. In the cleaning stage, Z-score method was performed to identify outliers from the database by calculating mean and standard deviation of the dataset. Once the outliers had been detected using the Z-score method, the outliers were removed from the dataset. In transformation stage, the database was transformed into “Boolean”, as shown in Figure 2. The value “1” represented that attribute has been detected in the unsafe behavior reports, and the value “0” that it has not [29].

Figure 2.

Boolean dataset.

3.3. Association Rule Mining (ARM)

Association rule mining (ARM) is a procedure that aims to seek associations, causal structures, frequent patterns, or correlations from datasets found in various kinds of databases and repositories [30]. It has been used to characterize and evaluate hidden associations in enormous datasets of safety issue evaluations for detecting frequent item sets between ambiguous parameters and producing robust association rules from enormous datasets [11]. The Apriori, FP-growth, and DIC algorithms are currently the three most frequently used correlation algorithms [31,32,33]. The Apriori algorithm was applied in this research to mine large amounts of information and generate frequent data item sets in order to determine the degrees of correlation between attributes of unsafe behavior [34].

Generally, a standard association rule is expressed in A→B form, where A is the antecedent and B is the consequent, which signifies that A occurs with B for the same instance in a database with a minimum level of significance [35]. The main measurements of rule effectiveness are support, confidence, and lift [36]. Support (S) is the measurement of the proportional occurrence of any item set or combination of item sets. The support (S) formula can be calculated as follows:

Confidence (C) is defined as the conditional probability (P) of the occurrence of the consequent of an item set given that the antecedent of that itemset has already occurred. Confidence (C) is calculated as follows:

Lift (L) is the measurement of the correlation between A and B. Lift is expressed as follows:

A lift value equal to 1 indicates independence, and a value greater than 1 indicates positive interdependence [37]. The higher the lift, the greater the strength of the rule.

3.4. Reliability Evaluation Method of Association Rules

The dependability of an association rule is described as the reliability attained by the rule under a certain situation, which indicates the correlation between the data in the database [38]. The reliability evaluation method consists of three degrees of measurement: accuracy, completeness, and consistency. Accuracy refers to how accurately an association rule describes the data, while completeness and consistency refer to how consistent the association rule is distributed throughout the data.

3.4.1. Accuracy

Support, confidence, and lift are three values that are used to define the accuracy of rules. These three parameters can avoid the effect of false opinion because they are derived using the precise principles of statistical methods, and they can be used to gauge how accurate the association rules are [38]. The association rule accuracy function is the geometrically weighted average value of the three indicators as follows:

where .

3.4.2. Completeness

Completeness of the association rules is the integrity value measured by the association rules from the research dataset, which expresses the correlation in the database [38]. The method is carried out by dividing the research dataset into a study dataset and a verification dataset. The composition of each dataset can be varied, such as 50–50, 70–30, or 80–20. To differentiate, the study dataset is a dataset that generates fewer rules than the verification dataset. The key to measuring completeness is by identifying any missing rules between the study dataset and the verification dataset. The completeness formula is the ratio of the number of association rules (K) in the study dataset divided by the sum of the number of output rules from both datasets as follows:

where : the number of rules in the study dataset, : the number of rules in the verification dataset.

3.4.3. Consistency

The consistency of association rules is determined by examining common rules that appear in the mining results of the study dataset and verification dataset [38]. A rule is considered to have good consistency if it appears in the mining results of the study dataset as well as all on the verification dataset, and if the frequency distribution of the rule is consistent across these datasets. Conversely, if the rule’s distribution in the datasets is uneven, indicating poor consistency of the rule set, then the datasets should be divided appropriately in order to obtain more reliable and complete association rules. The assessment of consistency involves two components, referred to as result consistency (RC) and data consistency (DC).

RC is the ratio of the number of common rules (C) that arise from the study dataset and the other dataset with the rules from the study dataset (K) as follows:

where : the number of common rules in the two different datasets.

DC is a statistic that measures how consistently a general rule applies across different datasets [38]. It is calculated by considering the standard deviation value of the support (S) parameter of the common rules in study dataset and verification dataset. The following steps are involved in DC calculation:

- (1)

- Compute :

- (2)

- Calculate :

- (3)

- Define DC:where : deviation value of the support, : standardizing value of , S: support.

Based on the definition of RC and DC, the consistency of rules is determined by combining these two results. The formula for calculating the rule consistency is as follows:

where .

4. Results and Discussion

4.1. Demographic Profile of Respondents

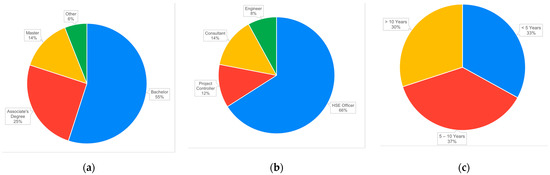

A total of 49 respondents were obtained in the data collection process. Most of the respondents were HSE officers who were primarily responsible for ensuring that work was performed in a safe and healthy environment, with most respondents having worked for more than five years and holding a bachelor’s degree. The data acquired were ensured to come from individuals who had substantial experience in construction activities. A summary of the sample demographics is shown in Figure 3.

Figure 3.

Respondent profile summary: (a) educational background; (b) job title; (c) work experience.

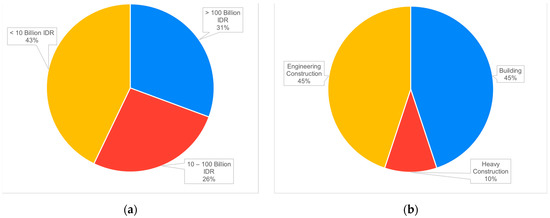

Participants in this study came from a variety of construction projects, with the attributes of contract value and construction sector being shown in Figure 4. According to the classification of construction safety risk levels in PUPR ministerial regulation 10/2021, projects with a contract value of less than IDR 10 billion had a small safety risk level, those between IDR 10 and 100 billion had a moderate safety risk level, and those of more than IDR 100 billion had a large safety risk level. The construction industry was broken down into three categories in this study: building, which included residential and commercial projects; engineering, which included power generation, smelter projects, gas pipeline installation, and the construction of rigs; and heavy construction, which included toll road construction projects, reservoir dams, and other projects.

Figure 4.

Construction attributes: (a) contract amount; (b) construction sectors.

4.2. Data Exploration

In a survey of 49 respondents from various construction projects, 4134 cases of unsafe behavior were discovered. After database cleaning was performed, 1631 outliers were identified, resulting in 2503 cases. The outliers were deleted to ensure data quality using the Z-score method. The information that was gathered was then elaborated on with the attributes of the type of accident and the law that the unsafe behavior violated. Types of accidents were categorized based on the potentials for accidents with the greatest likelihood of occurrence when workers engaged in these unsafe behaviors. Regarding the attribute of law violation, it was determined based on which law was violated by an unsafe behavior. Information about the frequency and categorization of unsafe behaviors is provided in Table 3.

Table 3.

Cases of unsafe behavior in the database.

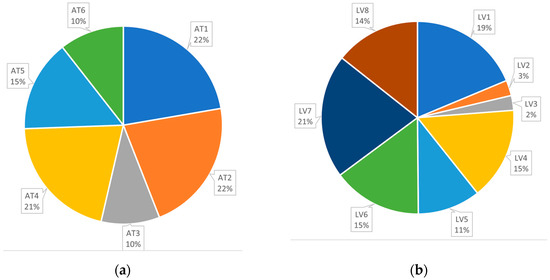

From Table 3, the first three most frequent unsafe behaviors at construction sites were UB7 (workers put tools and materials in random places) with 155 incidents, UB2 (workers do not attach safety lines to the provided places) with 140 incidents, and UB8 (workers move work tools and materials in ways that are not in accordance with procedures) with 137 incidents. Furthermore, the data showed that the majority of unsafe behaviors were related to the type of accident, especially AT1 (falls) with 558 incidents and AT2 (being hit or cut by objects) with 545 incidents. Lastly, violations of laws occurred evenly, with LV7 (Manpower Ministerial Regulation 12/2015) being the most frequently violated with 521 incidents, as shown in Figure 5.

Figure 5.

Categorization of (a) accident type and (b) law violation.

4.3. Association Rules Result

The ARM approach was applied to the database, which was input into Jupyter notebook and processed with Python programming language. In the database, six attributes of the data were formatted as a Boolean dataset. The lower threshold for each parameter was set at 5% for support to obtain selective and insightful associations; 50% for confidence because the probability of occurrence used was greater than 50% of the events; 1 for lift because the selected rules in this study were only dependent on each other; and 3 for the maximum number of attributes because a rule’s intuitiveness decreased with the number of attributes. Five legitimate rules were obtained that met the thresholds among the produced output rules, as shown in Table 4.

Table 4.

Association rules for unsafe behaviors.

As shown in Table 4, out of 26 unsafe behaviors, UB1, UB2, UB3, UB7, and UB8 had greater chances of occurring. Furthermore, these unsafe behaviors were associated with the accident types of AT1 (falling), and AT2 (being hit or cut by objects), as well as violations of laws LV4 (Manpower and Transmigration Ministerial Regulation 01/1980), and LV6 (Manpower Ministerial Regulation 09/2016). The five legitimated rules were combined into two consolidated rules, which were obtained by combining the related consequents.

4.4. Reliability Evaluation Result

4.4.1. Accuracy

As shown in Table 5, 174 rules were obtained from the study dataset. Then, using Formula (4), the accuracy value for each rule was evaluated and the overall average accuracy of all ARM data processing outputs is 0.665. This score suggests that the studied rule has a high rate, depth, and significance in the database and provides a good representation of the correlation between the data.

Table 5.

Accuracy evaluation.

4.4.2. Completeness

The research dataset was divided into two parts, namely the study dataset and the verification dataset. The composition of each dataset was 50–50. A total of 174 rules (K) were obtained from the study dataset. In the subsequent processing of the verification dataset, 232 rules (N) were obtained. Using Formula (5), the completeness value of the ARM processing in this study was 0.43. Based on the completeness evaluation, it was found that the completeness of the association rules derived from the data is 43%, which suggests that the rule generated does not comprehensively capture the correlations within the dataset.

4.4.3. Consistency

The first step in calculating the consistency parameter is to determine the RC value. It was discovered that there were 91 common rules (C) in both datasets. Using Formula (6), the RC value was 0.52 for the dataset used in this study. After determining the RC value, the next step was to calculate the DC value by comparing the support values of the common rules from the study dataset and the other dataset. Using Formulas (7) to (9), the DC value with value 0.68 was obtained. The final consistency value was calculated using Formula (10). By assigning a coefficient of 0.5 to both RC and DC, the consistency value was 0.60.

The results of the consistency evaluation of the data indicate that 52% of the association rules remain consistent across multiple data sets, demonstrating a high level of reliability in the ARM outcomes. Moreover, the data consistency of the distribution of these common rules in different data sets is 68%, further substantiating their validity. As a result, the rule set for the construction safety is deemed to be consistent, and the unsafe behavior pattern illustrated in Table 4 should be given full consideration in safety management.

4.5. Experts’ Judgement Result

As mentioned in Section 4.3, several patterns of unsafe behaviors at construction sites are obtained. These results were validated by interviewing construction safety experts. Below are experts’ analyses that are developed from the ARM output results to serve as a guideline in implementing the construction safety program.

- Safety inspectors should devote more attention to these particular unsafe behaviors (UB1, UB2, UB3, UB7, and UB8) and prioritize safety training to avoid these particular accident types (AT1 and AT2).

- It is important to implement safety training for workers to minimize the frequency of unsafe behavior and work-related accidents, resulting in the enhancement of construction safety performance [39]. A good safety training program can develop a person’s awareness of safety risks, comprehension of risks, and comprehension of safety responses, which ultimately enables them to decide on safe actions and execute these safe actions in behavior throughout the work process [40]. However, safety training is not implemented consistently and is often neglected [41,42]. As a result, lack of appropriate training causes workers to lose the information necessary to engage in safe work practices. Hence, this study suggests that, through the Manpower Ministry, the GoI should supervise the implementation of laws regarding safe working procedures at construction sites to decrease the probability of law violations.

- It is important for safety trainers to implement safety trainings, giving priority to the most likely unsafe behaviors and accident types that can occur, as well as the laws that are most likely to be violated. This study contributed to this matter so that safety trainers can arrange safety trainings and safety tools accordingly. For example, during safety training about Manpower Ministerial Regulation 12/2015, which is a regulation explaining the safe working procedures for heights, safety trainers could provide real body harnesses to emphasize their importance for avoiding accidents.

- Construction workers tend to engage in unsafe behaviors because of the projects’ time constraints. Therefore, it is advised that the project management generates a more precise project target plan based on the qualities and number of workers. Hence, the workers can work without additional pressure and finally carry work out more carefully in accordance with applicable safety standards and procedures.

Nevertheless, this study has several limitations. First, the database was dominated by building and engineering construction projects. Therefore, the amount of data should be increased, with more variety in construction type. Second, the attributes are limited and should be enriched with more attributes, such as degree of injury, worker tenure, worker age, worker occupation, and accident time. Nevertheless, this study introduced how unsafe behavior in addition to other attributes could be explored using ARM as a data-mining method to obtain insightful results. These results could serve as primary data to improve safety management in the construction industry of Indonesia. Currently, the GoI does not have a comprehensive database regarding construction accidents related to unsafe behavior that is updated regularly. The GoI usually only documents construction accidents for special projects performed either by the Ministry of Public Works or the Ministry of Manpower. Thus, there is a need to develop a standard for recording work accident data in the Indonesian construction industry to facilitate further research to obtain a more reliable database.

5. Conclusions

This study aimed to discover insightful associations among unsafe behaviors and other construction attributes by evaluating the pattern of unsafe behaviors. A total of 4134 cases of unsafe behavior were recorded based on the questionnaire. After database cleaning to identify the outliers, a total of 2503 unsafe behavior cases were finalized. Using the Apriori algorithm, the rules of association among the attributes of unsafe behaviors were discovered. After conducting ARM, two final consolidated rules were obtained, which provided insightful associations. Prior to receiving validation from construction safety experts, the ARM results underwent a reliability evaluation review. Of the 26 identified unsafe behaviors, workers putting tools and materials in random places, workers not attaching safety lines to provided places, and workers moving work tools and materials in ways that were not in accordance with procedures had higher probabilities of occurring. Additionally, these unsafe behaviors were in violation of Manpower and Transmigration Ministerial Regulation 01/1980, and Manpower Ministerial Regulation 09/2016 and caused the accident types of falling, and being struck or cut by items. The construction industry in Indonesia can benefit from these findings by using them as a basis for improving safety management and organizing safety training. For example, to prevent these specific sorts of accidents, safety inspectors should pay closer attention to these specific unsafe behaviors and provided related safety trainings as a top priority. For future study, the current database should be upgraded by increasing the amount of data and adding new attributes, such as degree of injury, worker tenure, worker age, worker occupation, and accident time. Other data-mining methods should be used to explore the database to obtain insightful information from different perspectives.

Author Contributions

Conceptualization, Y.L. and R.A.M.; methodology, R.A.M., T.S.N.R. and N.F.; software, N.F.; validation, Y.L., J.-H.C. and A.M.A.; resources, R.A.M., T.S.N.R. and N.F.; writing—original draft preparation, N.F. and T.S.N.R.; writing—review and editing, N.F., T.S.N.R. and R.A.M.; project administration, R.A.M.; funding acquisition, R.A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Directorate of Research and Development, Universitas Indonesia, under Hibah PUTI Q2 (Grant No. NKB-1349/UN2.RST/HKP.05.00/2022).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| ASEAN | Association of Southeast Asian Nations |

| ARM | Association Rule Mining |

| BNs | Bayesian Networks |

| DC | Data Consistency |

| DIC | Dynamic Itemset Counting |

| DT | Decision Tree |

| FP | Frequent Pattern |

| GoI | Government of Indonesia |

| HSE | Health, Safety and Environment |

| IDR | Indonesian Rupiah |

| NVAE | Nouveau Variational Autoencoders |

| OHS | Occupational Health and Safety |

| RC | Result Consistency |

References

- Berglund, L.; Johansson, M.; Nygren, M.; Samuelson, B.; Stenberg, M.; Johansson, J. Occupational accidents in Swedish construction trades. Int. J. Occup. Saf. Ergon. 2019, 27, 552–561. [Google Scholar] [CrossRef]

- U.S. Department of Labour. National Census of Fatal Occupational Injuries. 2020. Available online: https://www.bls.gov/iif/oshwc/cfoi/cfoi_rates_2020hb.xlsx (accessed on 17 November 2022).

- Machfudiyanto, R.A.; Latief, Y.; Sagita, L.; Suraji, A. Identification of institutional safety factors affecting safety culture in construction sector in Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2020, 426. [Google Scholar] [CrossRef]

- Arachchige, W.; Ranasinghe, M.; Asanka, W.A.; Ranasinghe, M. Study on the Impact of Accidents on Construction Projects Municipal Solid Waste Management in Local Authorities in Sri Lanka View Project Microtunnel View Project Study on the Impact of Accidents on Construction Projects. 2015. Available online: https://www.researchgate.net/publication/288022884 (accessed on 17 November 2022).

- Wang, W.C.; Liu, J.J.; Chou, S.C. Simulation-based safety evaluation model integrated with network schedule. Autom. Constr. 2006, 15, 341–354. [Google Scholar] [CrossRef]

- Hamid, A.R.A.; Zaimi, M.; Majid, A.; Singh, B. Causes of Accidents at Construction Sites. Malays. J. Civ. Eng. 2008, 20, 242–259. [Google Scholar]

- Cheng, W.; Lin, C.C.; Leu, S.S. Use of association rules to explore cause–effect relationships in occupational accidents in the Taiwan construction industry. Saf. Sci. 2010, 48, 436–444. [Google Scholar] [CrossRef]

- Poh, Q.X.; Ubeynarayana, C.U.; Goh, Y.M. Safety leading indicators for construction sites: A machine learning approach. Autom. Constr. 2018, 93, 375–386. [Google Scholar] [CrossRef]

- Li, B.; Li, Y.R.; Zhang, X.L. A survey on Laplacian eigenmaps based manifold learning methods. Neurocomputing 2019, 335, 336–351. [Google Scholar] [CrossRef]

- Vahdat, A.; Kautz, J. NVAE: A Deep Hierarchical Variational Autoencoder. 2020. Available online: https://proceedings.neurips.cc/paper/2020/file/e3b21256183cf7c2c7a66be163579d37-Paper.pdf (accessed on 4 February 2023).

- Wang, H.H.; Chen, J.H.; Arifai, A.M.; Gheisari, M. Exploring Empirical Rules for Construction Accident Prevention Based on Unsafe Behaviors. Sustainability 2022, 14, 4058. [Google Scholar] [CrossRef]

- Liao, C.W.; Perng, Y.H. Data mining for occupational injuries in the Taiwan construction industry. Saf. Sci. 2008, 46, 1091–1102. [Google Scholar] [CrossRef]

- Shin, D.P.; Park, Y.J.; Seo, J.; Lee, D.E. Association Rules Mined from Construction Accident Data. KSCE J. Civ. Eng. 2018, 22, 1027–1039. [Google Scholar] [CrossRef]

- Machfudiyanto, R.A.; Latief, Y.; Arifuddin, R.; Yogiswara, Y. Identification of Safety Culture Dimensions Based on the Implementation of OSH Management System in Construction Company. Procedia Eng. 2017, 171, 405–412. [Google Scholar] [CrossRef]

- Primadianto, D.; Putri, S.K.; Alifen, R.S. The Effect of Unsafe Acts and Unsafe Conditions on Construction Work Accidents. J. Dimens. Pratama Tek. Sipil 2018, 7, 77–84. Available online: https://publication.petra.ac.id/index.php/teknik-sipil/article/view/7036 (accessed on 28 December 2022).

- Yang, J.; Ye, G.; Xiang, Q.; Kim, M.; Liu, Q.; Yue, H. Insights into the mechanism of construction workers’ unsafe behaviors from an individual perspective. Saf. Sci. 2021, 133, 105004. [Google Scholar] [CrossRef]

- Liu, W.; Meng, Q.; Li, Z.; Hu, X. Applications of Computer Vision in Monitoring the Unsafe Behavior of Construction Workers: Current Status and Challenges. Buildings 2021, 11, 409. [Google Scholar] [CrossRef]

- Pan, X.; Zhong, B.; Wang, Y.; Shen, L. Identification of accident-injury type and bodypart factors from construction accident reports: A graph-based deep learning framework. Adv. Eng. Inform. 2022, 54. [Google Scholar] [CrossRef]

- Machfudiyanto, R.A.; Latief, Y.; Yogiswara, Y.; Setiawan, R.M.F. Structural equation model to investigate the dimensions influencing safety culture improvement in construction sector: A case in Indonesia. AIP Conf. Proc. 2017, 1855. [Google Scholar] [CrossRef]

- Uddin, S.M.J.; Ganapati, N.E.; Pradhananga, N.; Prajapati, J.; Albert, A. Is the Workers’ Health and Safety Scenario Different in Post-Disaster Reconstruction from Conventional Construction? A Case Study in Bhaktapur, Nepal. Int. J. Disaster Risk Reduct. 2021, 64, 102529. [Google Scholar] [CrossRef]

- Government of Indonesia. Law Number 1 of 1970 on Occupational Safety; Jakarta, Indonesia, 1970. Available online: https://temank3.kemnaker.go.id/public/media/files/Undang-Undang_No_1_Tahun_1970_tentang_Keselamatan_Kerja.pdf (accessed on 11 November 2022).

- Government of Indonesia. Law Number 36 of 2009 on Health; Jakarta, Indonesia, 2009. Available online: https://peraturan.bpk.go.id/Home/Details/38778/uu-no-36-tahun-2009 (accessed on 11 November 2022).

- Government of Indonesia. Law Number 2 of 2017 on Construction Service; Jakarta, Indonesia, 2017. Available online: https://jdih.pu.go.id/internal/assets/assets/produk/UU/2017/01/UU02-2017.pdf (accessed on 11 November 2022).

- Ministry of Manpower and Transmigration. Manpower and Transmigration Ministerial Regulation 01/1980 on Occupational Health and Safety in Building Construction; Jakarta, Indonesia, 1980. Available online: https://temank3.id/public/media/files/20210725204520.pdf (accessed on 11 November 2022).

- Ministry of Manpower and Ministry of Public Works. Manpower Ministerial and Public Works Ministerial Joint Decree 174/186 and 104/1986 on Occupational Health and Safety at Construction Activities; Jakarta, Indonesia, 1986. Available online: https://temank3.id/public/media/files/20210725205052.pdf (accessed on 11 November 2022).

- Ministry of Manpower. Manpower Ministerial Regulation 12/2015 on Electrical Occupational Safety and Health in the Workplace; Jakarta, Indonesia, 2015. Available online: https://jdih.kemnaker.go.id/katalog-610-Peraturan%20Menteri.html (accessed on 11 November 2022).

- Ministry of Manpower. Manpower Ministerial Regulation 09/2016 on Occupational Safety and Health in Work at Height; Jakarta, Indonesia, 2016. Available online: https://jdih.kemnaker.go.id/katalog-1210-Peraturan%20Menteri.html (accessed on 11 November 2022).

- Ministry of Manpower. Manpower Ministerial Regulation 08/2020 Occupational Safety and Health of Lifting and Transport Equipment; Jakarta, Indonesia, 2020. Available online: https://jdih.kemnaker.go.id/katalog-1668-Peraturan%20Menteri.html (accessed on 11 November 2022).

- Tixier, J.P.; Hallowell, M.R.; Rajagopalan, B.; Bowman, D. Construction Safety Clash Detection: Identifying Safety Incompatibilities among Fundamental Attributes using Data Mining. Autom. Constr. 2017, 74, 39–54. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, C.; Ding, L.; Sekula, P.; Love, P.E.D.; Zhou, C. Combining association rules mining with complex networks to monitor coupled risks. Reliab. Eng. Syst. Saf. 2019, 186, 194–208. [Google Scholar] [CrossRef]

- Agrawal, R.; Imieliński, T.; Swami, A. Mining association rules between sets of items in large databases. In Proceedings of the 1993 ACM SIGMOD International Conference on Management of Data, Washington, DC, USA, 25–28 May 1993; pp. 207–216. [Google Scholar] [CrossRef]

- Han, J.; Fu, Y. Discovery of multiple-level association rules from large databases. VLDB 1995, 21, 420–431. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=6bbc138445ea5507717d528b0cdd5dd68b476cb1 (accessed on 16 January 2023).

- Toivonen, H. Sampling large databases for association rules. VLDB 1996, 22, 134–145. Available online: https://www.cin.ufpe.br/~jtalr/Mestrado/toiSample.pdf (accessed on 16 January 2023).

- Qiao, W.; Liu, Q.; Li, X.; Luo, X.; Wan, Y.L. Using data mining techniques to analyze the influencing factor of unsafe behaviors in Chinese underground coal mines. Resour. Policy 2018, 59, 210–216. [Google Scholar] [CrossRef]

- Verma, A.; Khan, S.D.; Maiti, J.; Krishna, O.B. Identifying patterns of safety related incidents in a steel plant using association rule mining of incident investigation reports. Saf. Sci. 2014, 70, 89–98. [Google Scholar] [CrossRef]

- Montella, A.; Aria, M.; D’Ambrosio, A.; Mauriello, F. Analysis of powered two-wheeler crashes in Italy by classification trees and rules discovery. Accid. Anal. Prev. 2012, 49, 58–72. [Google Scholar] [CrossRef]

- Lee, C.; Song, B.; Park, Y. Design of convergent product concepts based on functionality: An association rule mining and decision tree approach. Expert Syst. Appl. 2012, 39, 9534–9542. [Google Scholar] [CrossRef]

- Chen, J.; Feng, W.; Luo, M. A Reliability Evaluation System of Association Rules. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, III–2, 53–60. [Google Scholar] [CrossRef]

- Mahendra, R.; Yakin, K.; Bustamin, M.O. Study of Knowledge and Attitudes of Workers on Occupational Safety and Health (Case Study on the Avian Tower Surabaya Project). Ge-STRAM J. Perenc. Dan Rekayasa Sipil 2019, 2, 74. [Google Scholar] [CrossRef]

- Liang, Q.; Zhou, Z.; Ye, G.; Shen, L. Unveiling the mechanism of construction workers’ unsafe behaviors from an occupational stress perspective: A qualitative and quantitative examination of a stress–cognition–safety model. Saf. Sci. 2022, 145, 105486. [Google Scholar] [CrossRef]

- Manurung, E.H. OHS Planning for Construction Work. J. Civ. Mech. Constr. Eng. 2020, 3, 49–54. Available online: https://core.ac.uk/download/pdf/335282677.pdf (accessed on 3 January 2023).

- Chan, P.C.; Wong, F.K.W.; Hon, C.K.H.; Javed, A.A.; Lyu, S. Construction safety and health problems of ethnic minority workers in Hong Kong. Eng. Constr. Archit. Manag. 2017, 24, 901–919. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).