Environmental Sustainability of Bricks in an Emerging Economy: Current Environmental Hotspots and Mitigation Potentials for the Future

Abstract

1. Introduction

2. Materials and Methods

2.1. Effects of Carbon Emissions, Water Consumption, and Land Use

2.2. Comparative Assessment of the Effects of Carbon Emissions, Water Consumption, and Land Use

2.3. Future Scenario Analysis

| Input | CF Intensity | Unit | Reference |

|---|---|---|---|

| Coal | 1.94 Note | kg CO2 eq./kg | [28,29] |

| Fuelwood | 0.22 Note | kg CO2 eq./kg | [30,31] |

| Electricity | 0.65 | kg CO2 eq./kWh | [32] |

| Diesel | 0.55 | kg CO2 eq./L | [20] |

| Machinery oil | 1.07 | kg CO2 eq./kg | [33] |

| Hydraulic oil | 1.07 | kg CO2 eq./kg | [33] |

| Kerosene | 0.55 | kg CO2 eq./L | [20] |

| Input | WF Intensity | Unit | Reference |

|---|---|---|---|

| Coal | 0.36 | m3/ton | [35,36] |

| Fuelwood | 0.01 Note | m3/kg | [13] |

| Water | 0.0001 | m3/nos. | Survey |

| Electricity | 0.0164 | m3/kWh | [36] |

| Diesel | 0.0003 | m3/L | [37] |

| Machinery oil | 0.0014 | m3/L | [20] |

| Hydraulic oil | 0.0014 | m3/L | [20] |

| Kerosene | 0.0003 | m3/L | [37] |

3. Results

3.1. Carbon Emissions, Water Consumption, and Land Use of the Brick Sector in Bangladesh

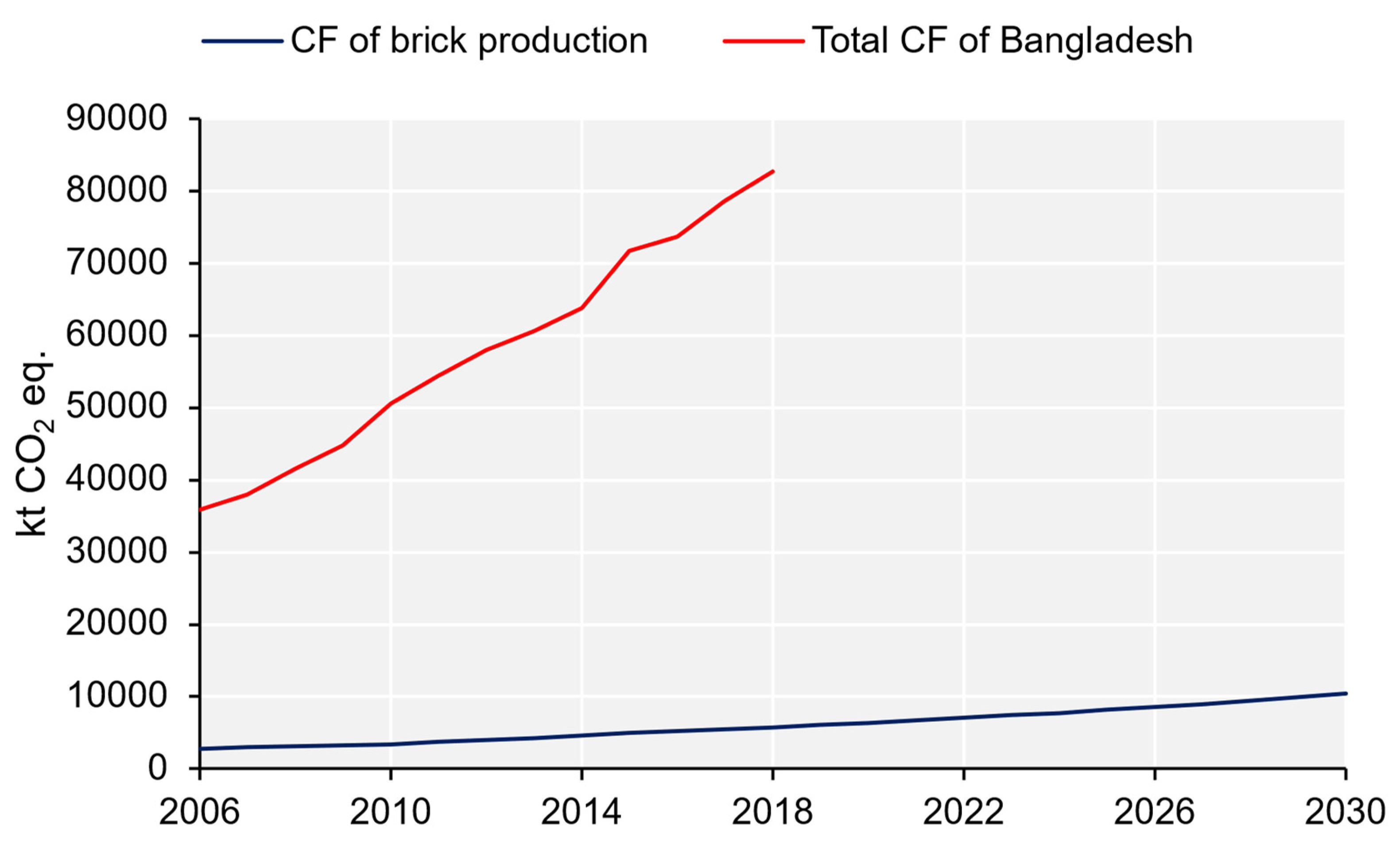

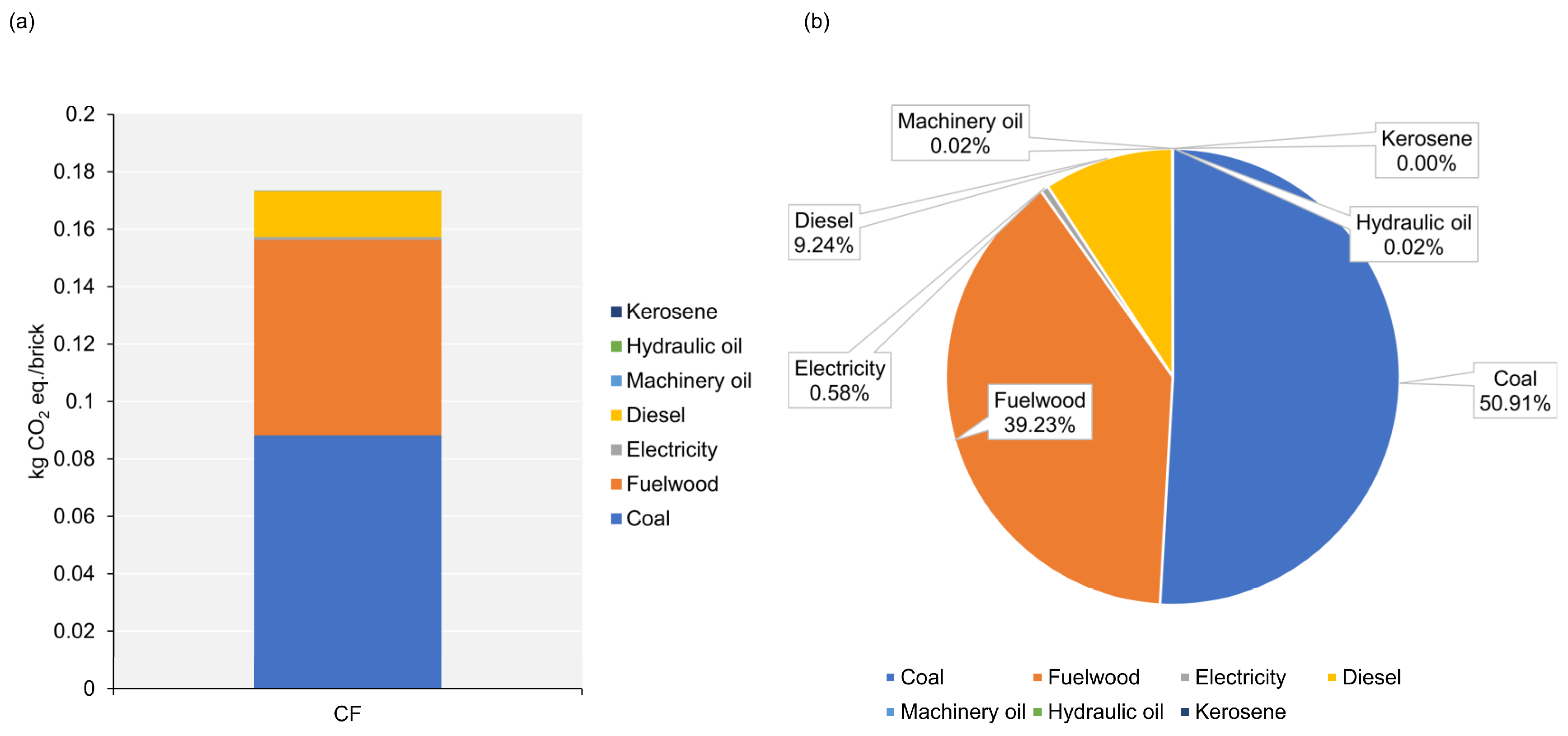

3.1.1. CF Accounting

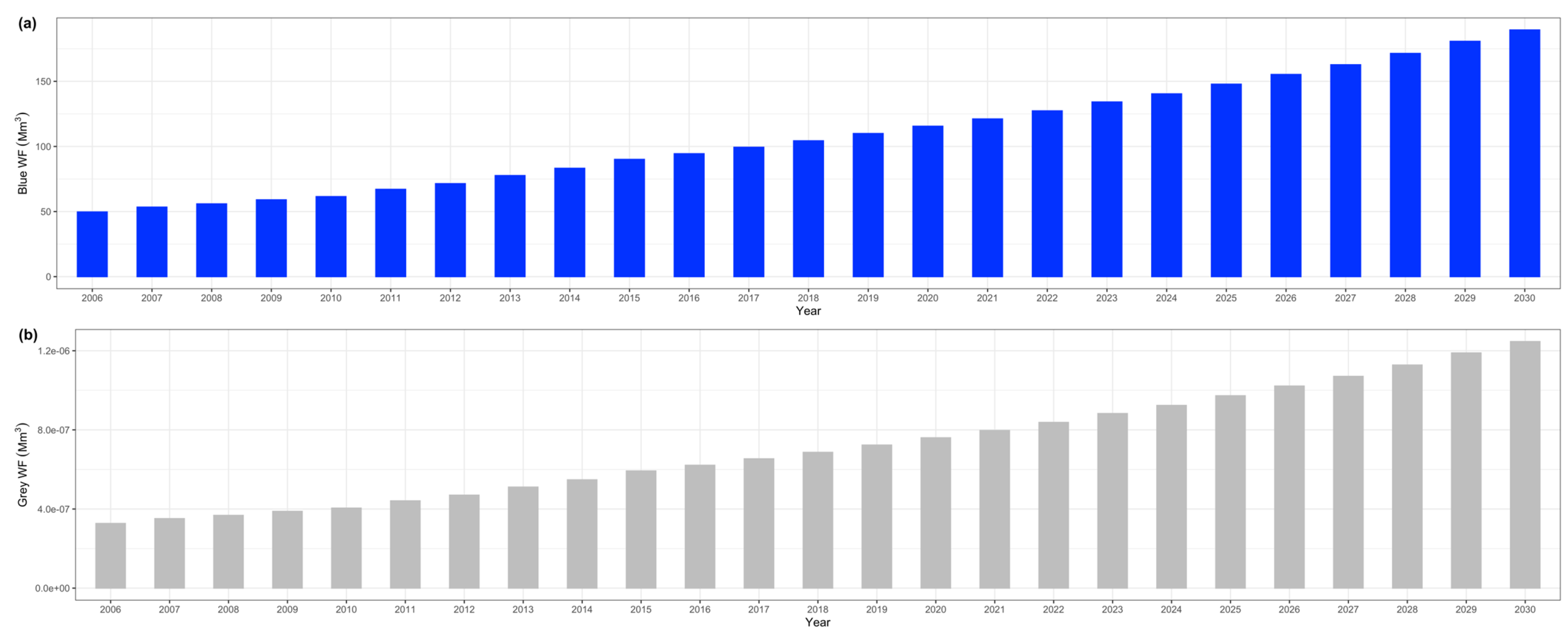

3.1.2. WF Accounting

3.1.3. Land Use

3.2. Comparative Assessment of Different Environmental Dimensions

3.2.1. Carbon Emissions: Land Required for Carbon Absorption

3.2.2. Water Consumption: Land Required for Water Catchment

3.2.3. Comparison of Different Environmental Dimensions

3.3. How to Reduce the Carbon, Water, and EF of Brick Production in Bangladesh

4. Discussion, Limitations, and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Rahman, A.M. CO2 Emission from Brickfields in Bangladesh: Can Ethical Responsibility by Doing Reduce Level of Emission? Athens J. Soc. Sci. 2022, 9, 255–272. [Google Scholar] [CrossRef]

- Darain, K.M.; Jumaat, M.Z.; Islam, A.B.M.S.; Obaydullah, M.; Iqbal, A.; Adham, M.I.; Rahman, M.M. Energy Efficient Brick Kilns for Sustainable Environment. Desalination Water Treat. 2016, 57, 105–114. [Google Scholar] [CrossRef]

- Saha, C.K.; Hosain, J. Impact of Brick Kilning Industry in Peri-Urban Bangladesh. Int. J. Environ. Stud. 2016, 73, 491–501. [Google Scholar] [CrossRef]

- Department of Environment. National Strategy for Sustainable Brick Production in Bangladesh; Department of Environment: Dhaka, Bangladesh, 2017.

- Alam, M.N.; Barman, S. Climate and Clean Air Coalition to Reduce Short-Lived Climate Pollutants Bangladesh Brick Sector Roadmap 2019–2030; Climate and Clean Air Coalition: Dhaka, Bangladesh, 2019. [Google Scholar]

- Van Hemelrijck, A. Resilience in Bangladesh: Impact Evaluation of the Promoting Sustainable Building in Bangladesh (PSBiB) Project; Oxfam GB: Nairobi, Kenya, 2020. [Google Scholar]

- Weyant, C.; Athalye, V.; Ragavan, S.; Rajarathnam, U.; Lalchandani, D.; Maithel, S.; Baum, E.; Bond, T.C. Emissions from South Asian Brick Production. Environ. Sci. Technol. 2014, 48, 6477–6483. [Google Scholar] [CrossRef]

- Haque, M.I.; Nahar, K.; Kabir, M.H.; Salam, A. Particulate Black Carbon and Gaseous Emission from Brick Kilns in Greater Dhaka Region, Bangladesh. Air Qual. Atmos. Health 2018, 11, 925–935. [Google Scholar] [CrossRef]

- Biswas, D.; Gurley, E.S.; Rutherford, S.; Luby, S.P. The Drivers and Impacts of Selling Soil for Brick Making in Bangladesh. Environ. Manag. 2018, 62, 792–802. [Google Scholar] [CrossRef]

- Guttikunda, S.K.; Begum, B.A.; Wadud, Z. Particulate Pollution from Brick Kiln Clusters in the Greater Dhaka Region, Bangladesh. Air Qual. Atmos. Health 2013, 6, 357–365. [Google Scholar] [CrossRef]

- Skouteris, G.; Ouki, S.; Foo, D.; Saroj, D.; Altini, M.; Melidis, P.; Cowley, B.; Ells, G.; Palmer, S.; O’Dell, S. Water Footprint and Water Pinch Analysis Techniques for Sustainable Water Management in the Brick-Manufacturing Industry. J. Clean. Prod. 2018, 172, 786–794. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. Global Gray Water Footprint and Water Pollution Levels Related to Anthropogenic Nitrogen Loads to Fresh Water. Environ. Sci. Technol. 2015, 49, 12860–12868. [Google Scholar] [CrossRef]

- Schyns, J.F.; Booij, M.J.; Hoekstra, A.Y. The Water Footprint of Wood for Lumber, Pulp, Paper, Fuel and Firewood. Adv. Water Resour. 2017, 107, 490–501. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Wiedmann, T.O. Humanity’s Unsustainable Environmental Footprint. Science 2014, 344, 1114–1118. [Google Scholar] [CrossRef]

- Wright, L.A.; Kemp, S.; Williams, I. “Carbon Footprinting”: Towards a Universally Accepted Definition. Carbon Manag. 2011, 2, 61–72. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard; Water Footprint Network: Enschede, The Netherlands, 2011. [Google Scholar]

- ISO 14046:2014; Environmental Management—Water Footprint—Principles, Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2014.

- Wiedmann, T.O.; Schandl, H.; Lenzen, M.; Moran, D.; Suh, S.; West, J.; Kanemoto, K. The Material Footprint of Nations. Proc. Natl. Acad. Sci. USA 2015, 112, 6271–6276. [Google Scholar] [CrossRef]

- Rees, W.E. Ecological Footprints and Appropriated Carrying Capacity: What Urban Economics Leaves Out. Environ. Urban. 1992, 4, 121–130. [Google Scholar] [CrossRef]

- Islam, K.; Murakami, S. Accounting for Water Footprint of an Open-Pit Copper Mine. Sustainability 2020, 12, 9660. [Google Scholar] [CrossRef]

- Hossain, M.S. Social Life Cycle Assessment (SLCA) of Clay Brick Manufacturing Process in Bangladesh. Master’s Thesis, Institute of Forestry and Environmental Science, University of Chittagong, Chittagong, Bangladesh, 2019. [Google Scholar]

- Murakami, S.; Takasu, T.; Islam, K.; Yamasue, E.; Adachi, T. Ecological Footprint and Total Material Requirement as Environmental Indicators of Mining Activities: Case Studies of Copper Mines. Environ. Sustain. Indic. 2020, 8, 100082. [Google Scholar] [CrossRef]

- Islam, K.; Yokoi, R.; Motoshita, M.; Murakami, S. Ecological Footprint Accounting of Mining Areas and Metal Production of the World. Resour. Conserv. Recycl. 2022, 183, 106384. [Google Scholar] [CrossRef]

- Boulay, A.-M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA Consensus Characterization Model for Water Scarcity Footprints: Assessing Impacts of Water Consumption Based on Available Water Remaining (AWARE). Int. J. Life Cycle Assess. 2018, 23, 368–378. [Google Scholar] [CrossRef]

- Motoshita, M.; Ono, Y.; Finkbeiner, M.; Inaba, A. The Effect of Land Use on Availability of Japanese Freshwater Resources and Its Significance for Water Footprinting. Sustainability 2016, 8, 86. [Google Scholar] [CrossRef]

- Yano, S.; Hanasaki, N.; Itsubo, N.; Oki, T. Water Scarcity Footprints by Considering the Differences in Water Sources. Sustainability 2015, 7, 9753–9772. [Google Scholar] [CrossRef]

- Müller Schmied, H.; Cáceres, D.; Eisner, S.; Flörke, M.; Herbert, C.; Niemann, C.; Peiris, T.A.; Popat, E.; Portmann, F.T.; Reinecke, R.; et al. The Global Water Resources and Use Model WaterGAP v2.2d: Model Description and Evaluation. Geosci. Model Dev. 2021, 14, 1037–1079. [Google Scholar] [CrossRef]

- Roy, P.; Hossain, M.N.; Hossain, M.M. Estimation of greenhouse gas emission from coal mining in bangladesh through life cycle assessment (lca). In Proceedings of the International Conference on Mechanical Engineering and Renewable Energy 2019, Chittagong, Bangladesh, 11–13 December 2019. [Google Scholar]

- U.S. EIA. Carbon Dioxide Emission Factors for Coal; U.S. Energy Information Administration: Washington, DC, USA, 2022.

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 Emissions from Biomass Combustion for Bioenergy: Atmospheric Decay and Contribution to Global Warming. GCB Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef]

- Ullah, S.A.; Tani, M. Fuelwood Consumption and Its Impact on Forests in the Teknaf Peninsula on the Southern Coast of Bangladesh. Am. J. Environ. Sci. 2017, 13, 225–232. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Cuevas, P. Comparative Life Cycle Assessment of Biolubricants and Mineral Based Lubricants. Master’s Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2010. [Google Scholar]

- Smith, K.R.; Uma, R.; Kishore, V.V.N.; Zhang, J.; Joshi, V.; Khalil, M.A.K. Greenhouse Implications of Household Stoves: An Analysis for India. Annu. Rev. Energy Environ. 2000, 25, 741–763. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Gerbens-Leenes, P.W.; Hoekstra, A.Y. The Consumptive Water Footprint of Electricity and Heat: A Global Assessment. Environ. Sci. Water Res. Technol. 2015, 1, 285–297. [Google Scholar] [CrossRef]

- Chini, C.M.; Peer, R.A.M. The Traded Water Footprint of Global Energy from 2010 to 2018. Sci. Data 2021, 8, 7. [Google Scholar] [CrossRef]

- Wu, M.; Mintz, M.; Wang, M.; Arora, S. Consumptive Water Use in the Production of Ethanol and Petroleum Gasoline; U.S. Department of Energy, Argonne: Lemont, IL, USA, 2009.

- PCA. Carbon Footprint; PCA: Washington, DC, USA, 2021. [Google Scholar]

- Eil, A.; Li, J.; Baral, P.; Saikawa, E. Dirty Stacks, High Stakes: An Overview of Brick Sector in South Asia; The World Bank: Washington, DC, USA, 2020. [Google Scholar]

- Gomes, E.; Hossain, I. Transition from Traditional Brick Manufacturing to More Sustainable Practices. Energy Sustain. Dev. 2003, 7, 66–76. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental Sustainability of Biofuels: A Review. Proc. R. Soc. Math. Phys. Eng. Sci. 2020, 476, 20200351. [Google Scholar] [CrossRef]

| Input | Per FU | Unit |

|---|---|---|

| Coal | 4.55 × 10−05 | ton |

| Fuelwood | 3.09 × 10−01 | kg |

| Water | 1.45 × 10−04 | m3 |

| Discharge | 4.55 × 10−06 | m3 |

| Electricity | 1.54 × 10−03 | kWh |

| Diesel | 2.91 × 10−02 | L |

| Machinery oil | 3.94 × 10−05 | L |

| Hydraulic oil | 3.52 × 10−05 | L |

| Kerosene | 1.61 × 10−06 | L |

| Soil/clay | 2.23 × 10−01 | cft |

| Sand | 4.78 × 10−03 | cft |

| Feature | Occupied Land (ha) | EF_Built-Up Land (gha) | Share |

|---|---|---|---|

| Kiln | 0.44 | 0.62 | 16.30% |

| Labor accommodation | 0.27 | 0.38 | 10.00% |

| Soil storage | 0.10 | 0.13 | 3.50% |

| Fuel storage | 0.00 | 0.00 | 0.10% |

| Water storage | 0.26 | 0.36 | 9.50% |

| Brick drying | 1.93 | 2.29 | 60.50% |

| Total | 3.00 | 3.78 | 100.00% |

| Year | Carbon-Absorption Land (1000 gha) | Water Catchment (1000 gha) | Built-Up Land (1000 gha) |

|---|---|---|---|

| 2006 | 2601.67 | 8.12 | 15.68 |

| 2007 | 2796.79 | 8.73 | 16.85 |

| 2008 | 2926.87 | 9.13 | 17.64 |

| 2009 | 3089.48 | 9.64 | 18.62 |

| 2010 | 3219.56 | 10.05 | 19.40 |

| 2011 | 3512.25 | 10.96 | 21.16 |

| 2012 | 3739.90 | 11.67 | 22.54 |

| 2013 | 4065.10 | 12.68 | 24.50 |

| 2014 | 4357.79 | 13.60 | 26.26 |

| 2015 | 4715.52 | 14.71 | 28.42 |

| 2016 | 4943.17 | 15.42 | 29.79 |

| 2017 | 5203.33 | 16.23 | 31.36 |

| 2018 | 5463.50 | 17.05 | 32.92 |

| 2019 | 5756.19 | 17.96 | 34.69 |

| 2020 | 6048.87 | 18.87 | 36.45 |

| 2021 | 6341.56 | 19.79 | 38.22 |

| 2022 | 6666.77 | 20.80 | 40.17 |

| 2023 | 7024.50 | 21.92 | 42.33 |

| 2024 | 7349.71 | 22.93 | 44.29 |

| 2025 | 7739.96 | 24.15 | 46.64 |

| 2026 | 8130.21 | 25.37 | 49.00 |

| 2027 | 8520.46 | 26.58 | 51.35 |

| 2028 | 8975.75 | 28.00 | 54.09 |

| 2029 | 9463.56 | 29.53 | 57.03 |

| 2030 | 9918.85 | 30.95 | 59.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, K.; Motoshita, M.; Murakami, S. Environmental Sustainability of Bricks in an Emerging Economy: Current Environmental Hotspots and Mitigation Potentials for the Future. Sustainability 2023, 15, 5228. https://doi.org/10.3390/su15065228

Islam K, Motoshita M, Murakami S. Environmental Sustainability of Bricks in an Emerging Economy: Current Environmental Hotspots and Mitigation Potentials for the Future. Sustainability. 2023; 15(6):5228. https://doi.org/10.3390/su15065228

Chicago/Turabian StyleIslam, Kamrul, Masaharu Motoshita, and Shinsuke Murakami. 2023. "Environmental Sustainability of Bricks in an Emerging Economy: Current Environmental Hotspots and Mitigation Potentials for the Future" Sustainability 15, no. 6: 5228. https://doi.org/10.3390/su15065228

APA StyleIslam, K., Motoshita, M., & Murakami, S. (2023). Environmental Sustainability of Bricks in an Emerging Economy: Current Environmental Hotspots and Mitigation Potentials for the Future. Sustainability, 15(6), 5228. https://doi.org/10.3390/su15065228