Field Test Study on the Bearing Capacity of Extra-Long PHC Pipe Piles under Dynamic and Static Loads

Abstract

1. Introduction

| Year | Research Content | Researcher |

|---|---|---|

| 2018 | static capacity obtained from static and dynamic load tests | Noor, S. T. et al. [14] |

| 2018 | the stress performance of the mixed reinforced PHC pipe piles | Zhang et al. [29] |

| 2019 | time effect of large diameter steel pipe piles | Hu et al. [30] |

| 2019 | the uplift bearing capacity of a PHC pile | Zhou, J. J. et al. [18] |

| 2020 | interpretation of dynamic pile load testing for open-ended tubular piles | Mehdi et al. [16] |

| 2020 | bearing characteristics of prestressed high strength concrete (PHC) piles | Cao, X. L. et al. [10] |

| 2020 | evaluation of ultimate bearing capacity (UBC) of PHC pipe pile | Wei, Y. J. et al. [31] |

| 2020 | excess pore water pressure caused by PHC pipe pile penetration | Wang et al. [32] |

| 2021 | analysis of influencing factors of the bearing capacity of PHC pipe piles | Li, X. S. et al. [21] |

| 2021 | penetration characteristics of open and closed PHC pipe piles | Wang, Y. H. et al. [1] |

| 2021 | pretensioned centrifugal spun concrete piles with steel strands alone | Ren, J. W. et al. [33] |

| 2022 | a method to estimate bearing capacity of bored PHC nodular piles | Huynh et al. [20] |

| 2022 | the difference between the dynamic and static method for the PHC pile | Liu, C. L. et al. [34] |

| 2022 | shear performance evaluation of PHC piles | Oktiovan, et al. [7] |

| 2022 | the construction effect of PHC based on visual digital photography | Zhang, G. J. et al. [3] |

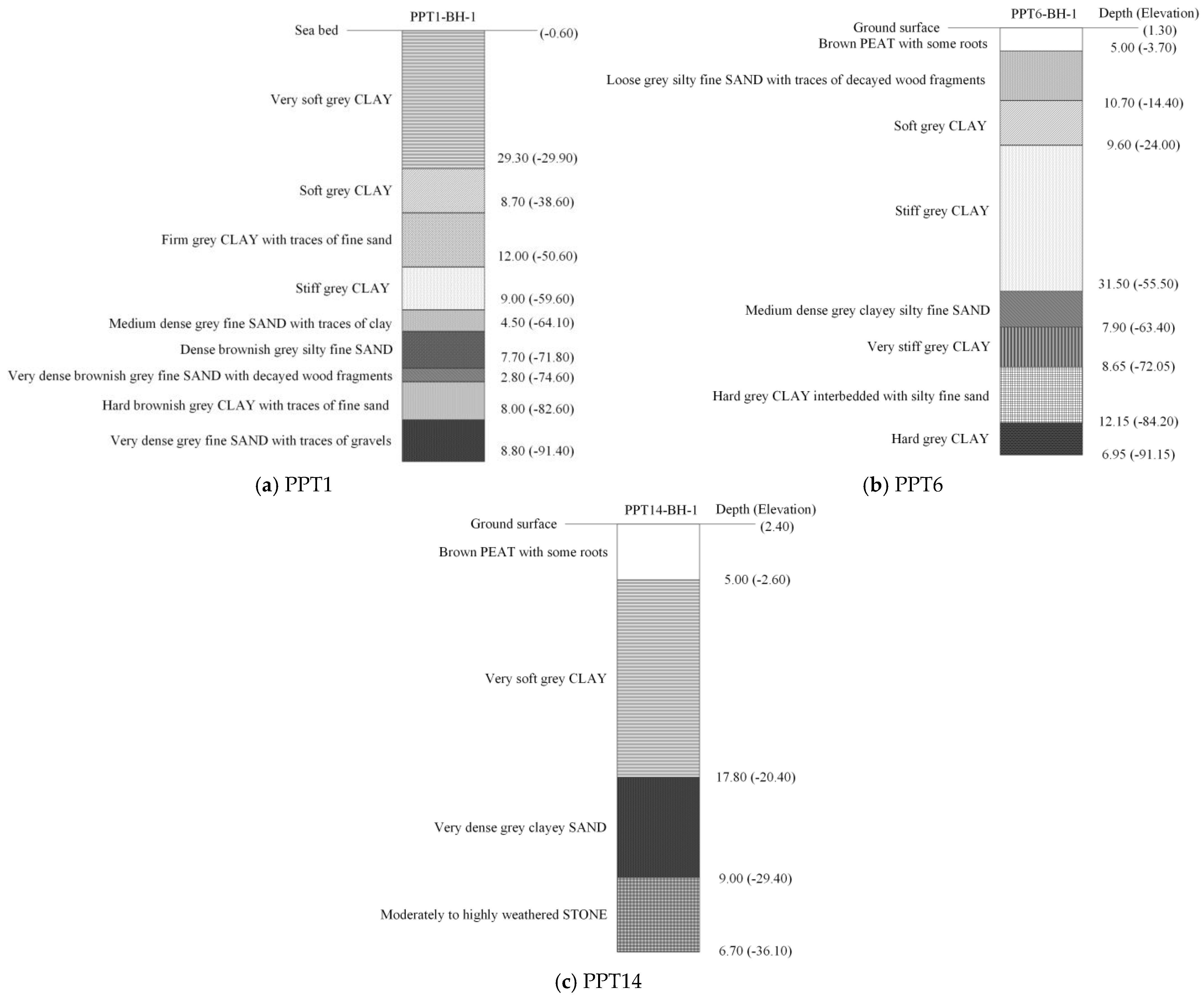

2. Materials and Methods

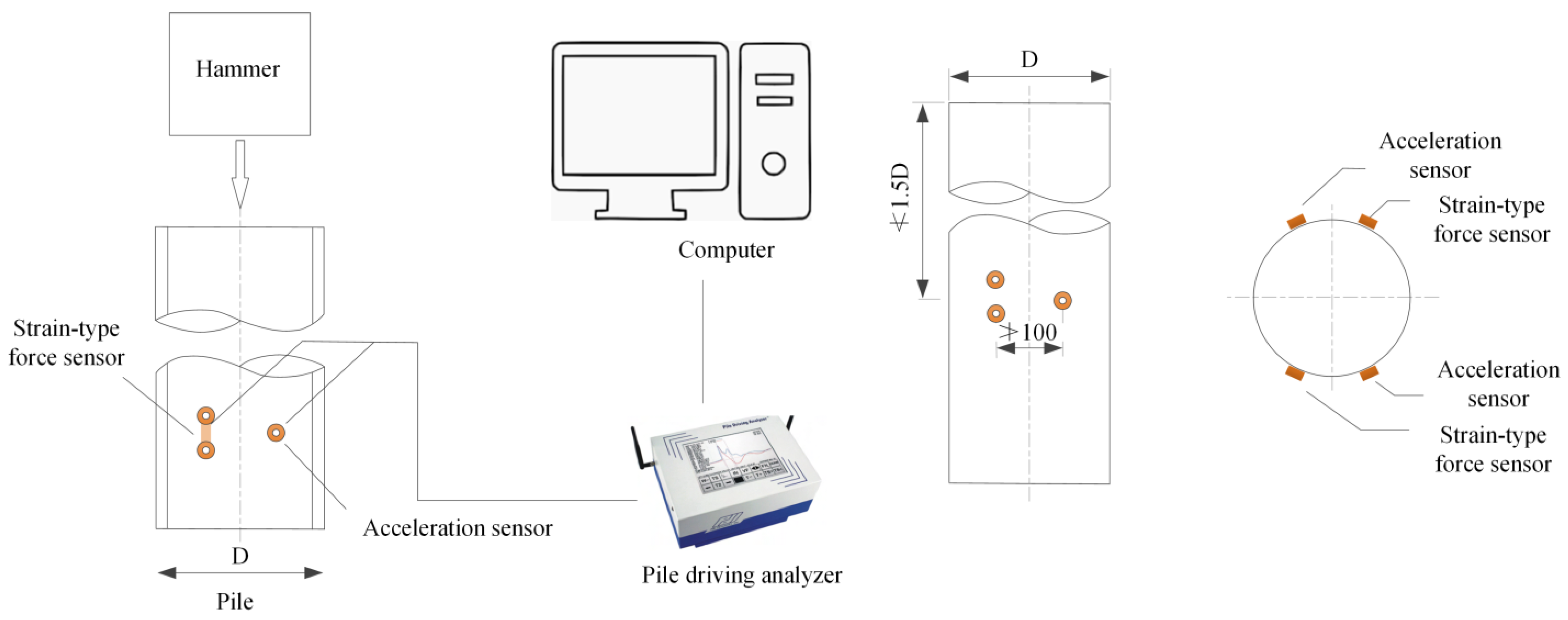

2.1. Piling Dynamic Load Tests

2.2. Static Load Tests

- (i)

- To determine/confirm the bearing capacity of foundation piles and their apportionment into shaft friction for various soil/rock strata and end bearing;

- (ii)

- To evaluate the design parameters in relation to the ultimate shaft friction and end bearing;

- (iii)

- To study the behavior of pile settlement and structural shortening under the applied loads.

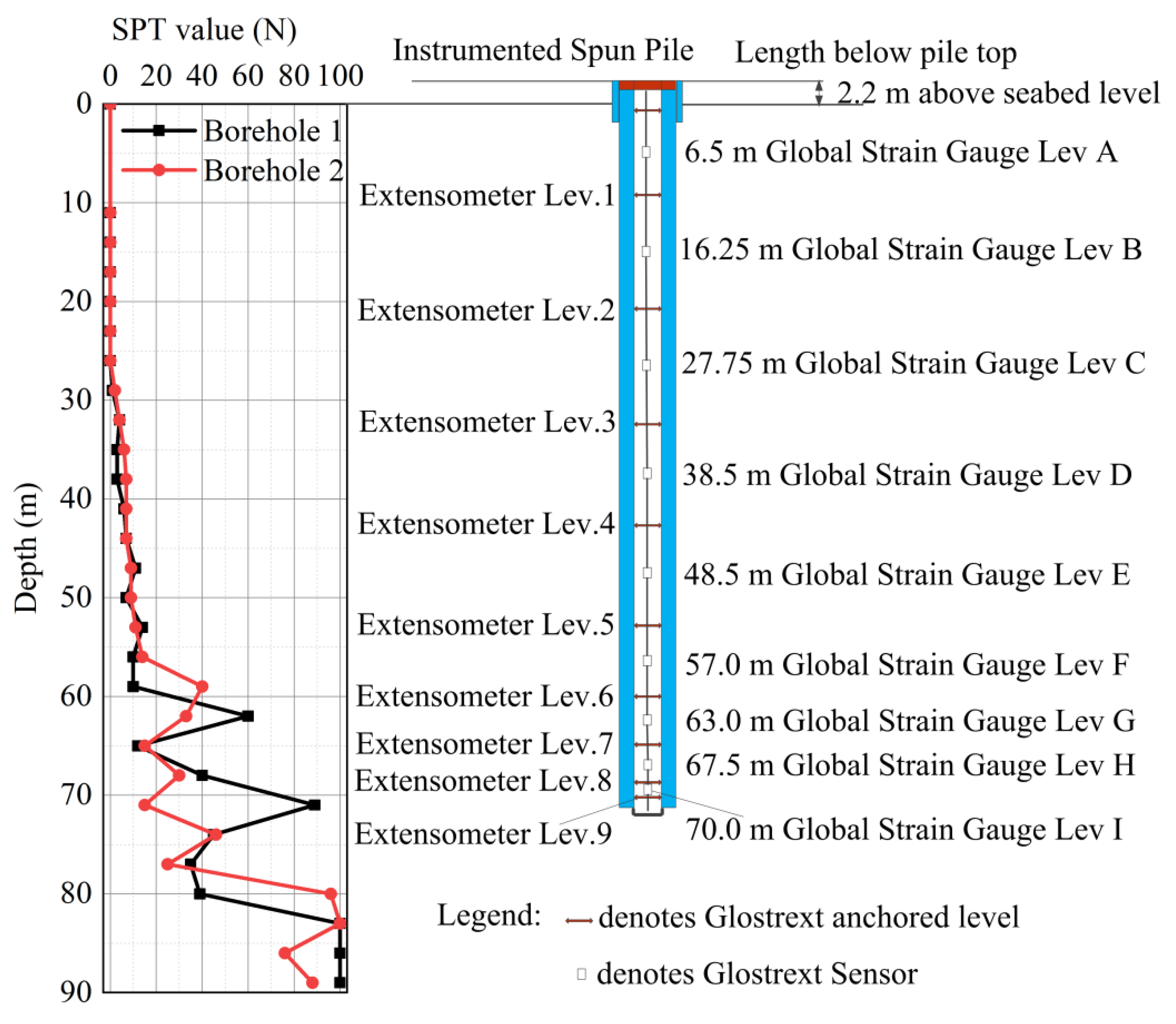

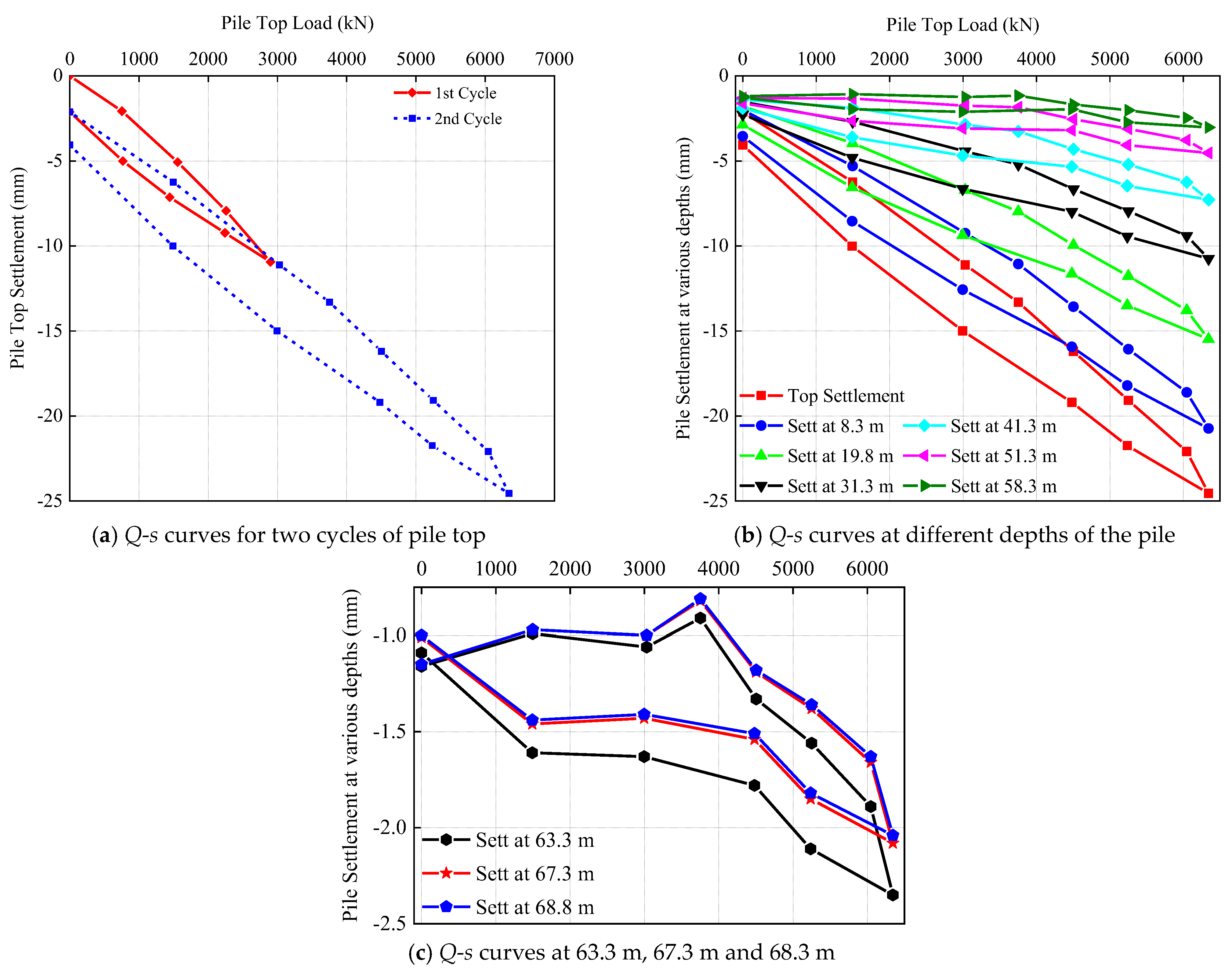

2.2.1. Pile Instrumentation

- (i)

- VW Global Strain Gauges:

- Global Strain Gauges Level A was aimed at 4.3 m below ground (seabed) level (bgl);

- Level B was aimed at 14.05 m bgl; Level C was aimed at 25.55 m bgl;

- Level D was aimed at 36.3 m bgl; Level E was aimed at 46.3 m bgl;

- Level F was aimed at 54.8 m bgl; Level G was aimed at 60.8 m bgl;

- Level H was aimed at 65.3 m bgl; Level I was aimed at 67.8 m bgl accordingly.

- (ii)

- Vibrating Wire (VW) Extensometers:

- Ext. Lev 1 at interval from 0.3 m to 8.3 m depth;

- Ext. Lev 2 at interval from 8.3 m to 19.8 m depth;

- Ext. Lev 3 at interval from 19.8 m to 31.3 m depth;

- Ext. Lev 4 at interval from 31.3 m to 41.3 m depth;

- Ext. Lev 5 at interval from 41.3 m to 51.3 m depth;

- Ext. Lev 6 at interval from 51.3 m to 58.3 m depth;

- Ext. Lev 7 at interval from 58.3 m to 63.3 m depth;

- Ext. Lev 8 at interval from 63.3 m to 67.3 m depth;

- Ext. Lev 9 at interval from 67.3 m to 68.3 m depth accordingly.

2.2.2. Pile Movement Monitoring System

3. Results and Discussion

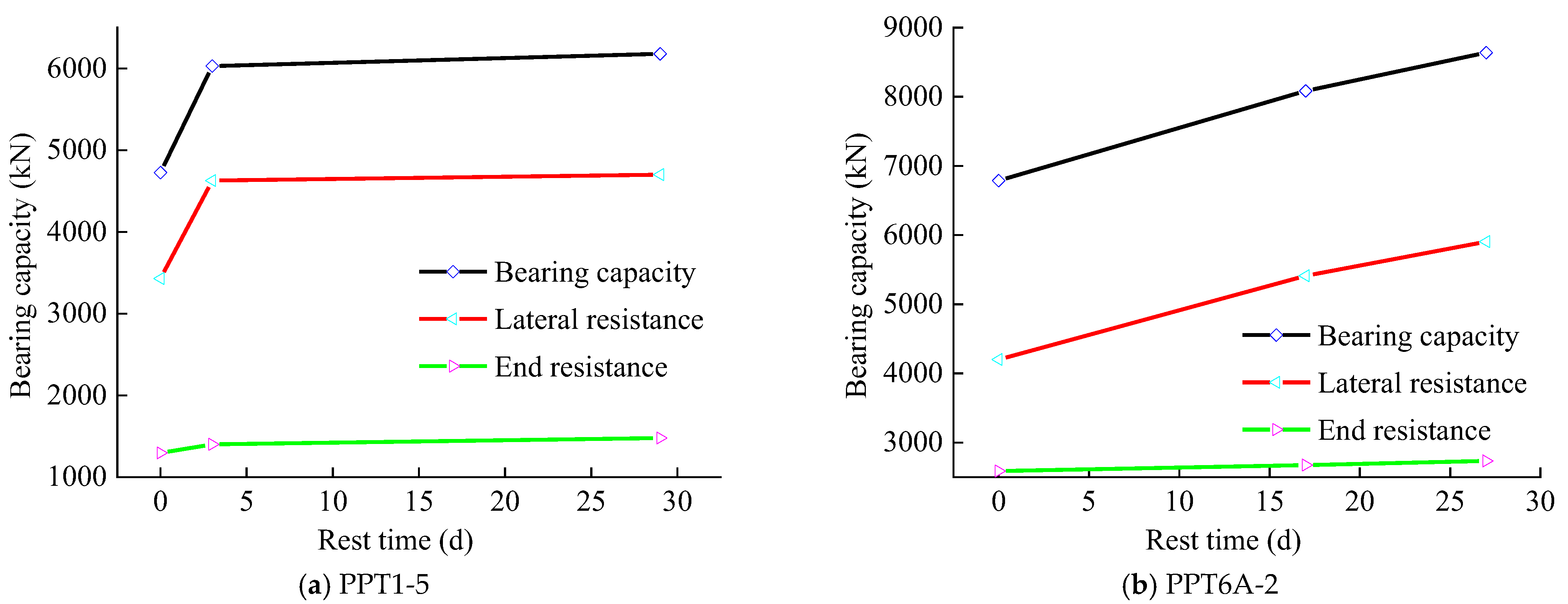

3.1. Results and Analysis of Dynamic Load Pile Driving Tests

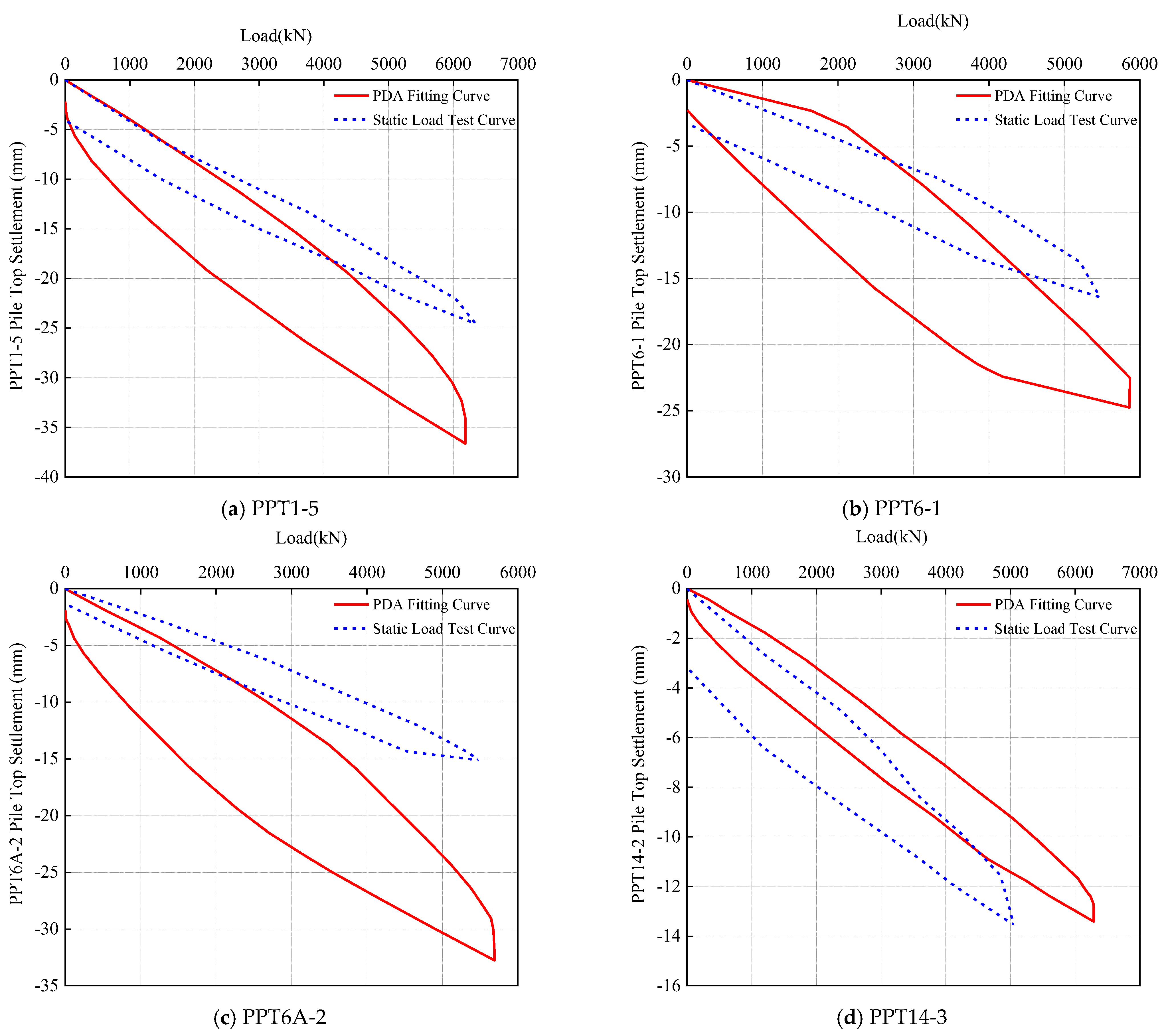

3.2. Static Load Test Verification Analysis

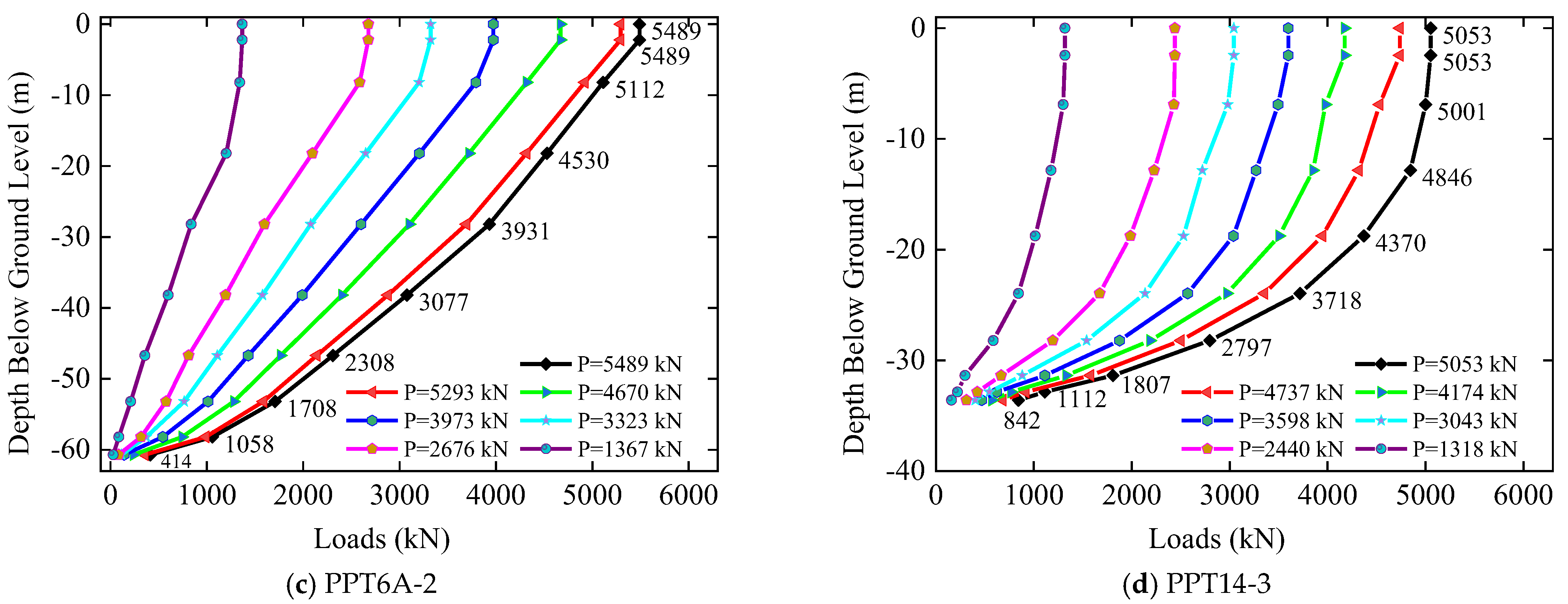

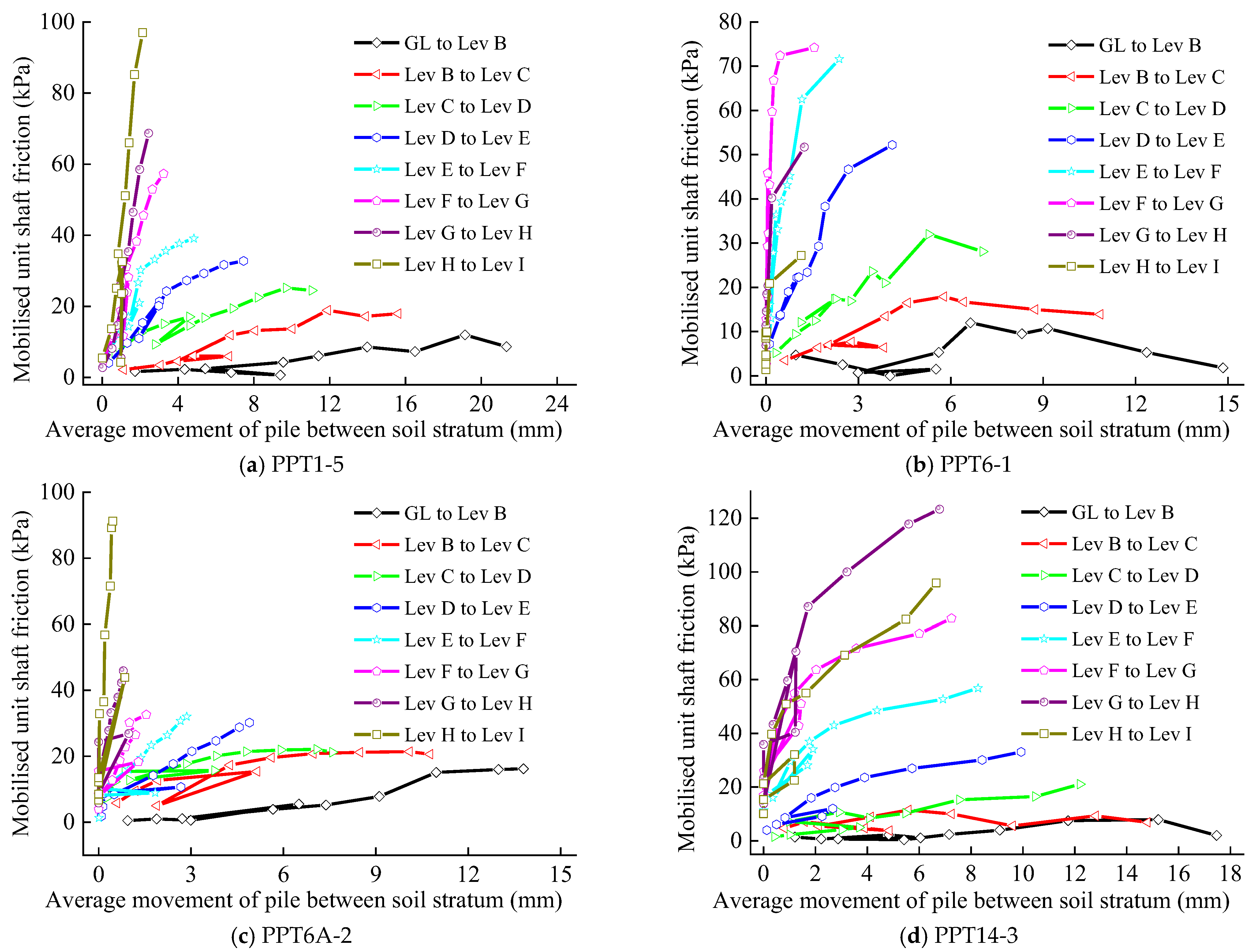

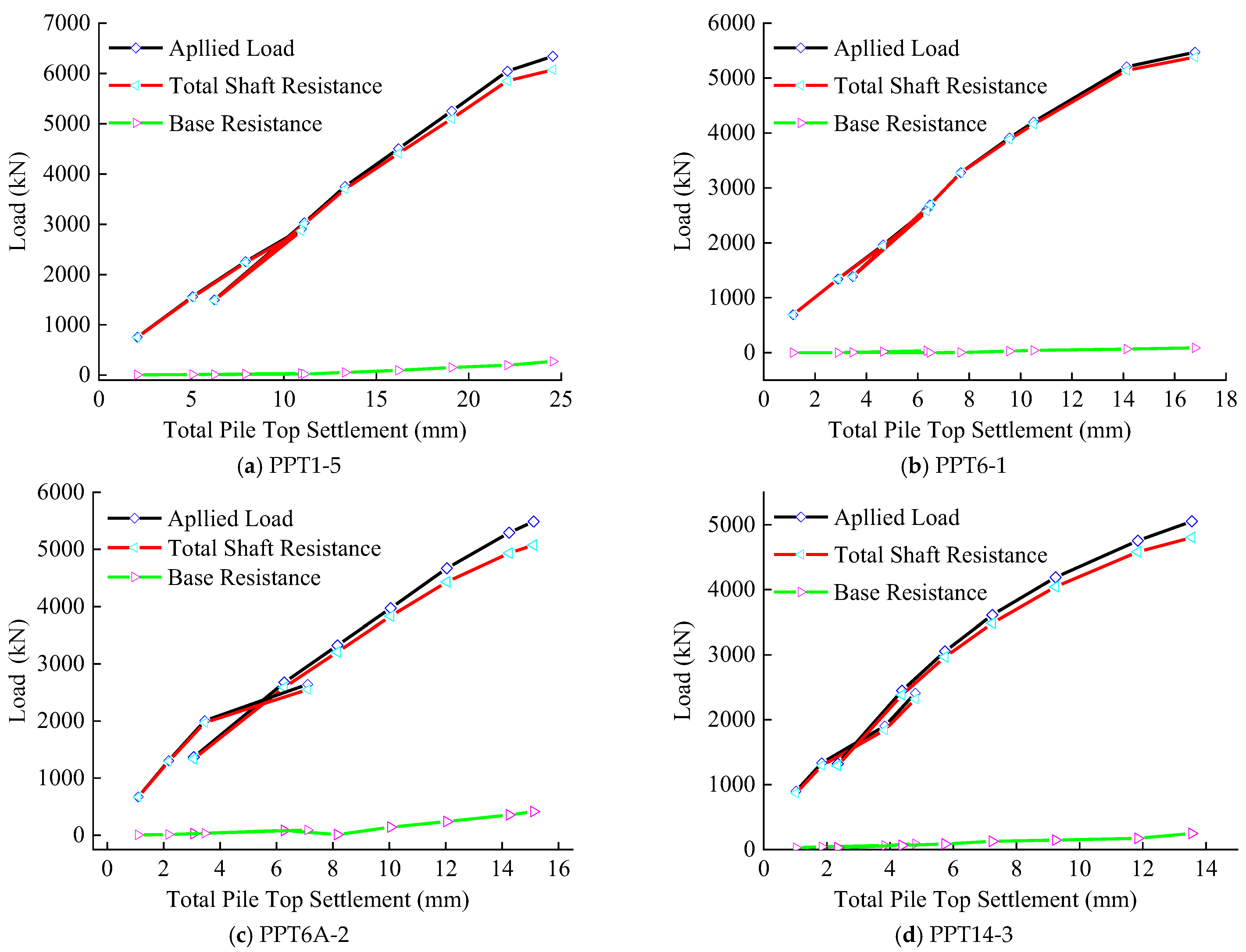

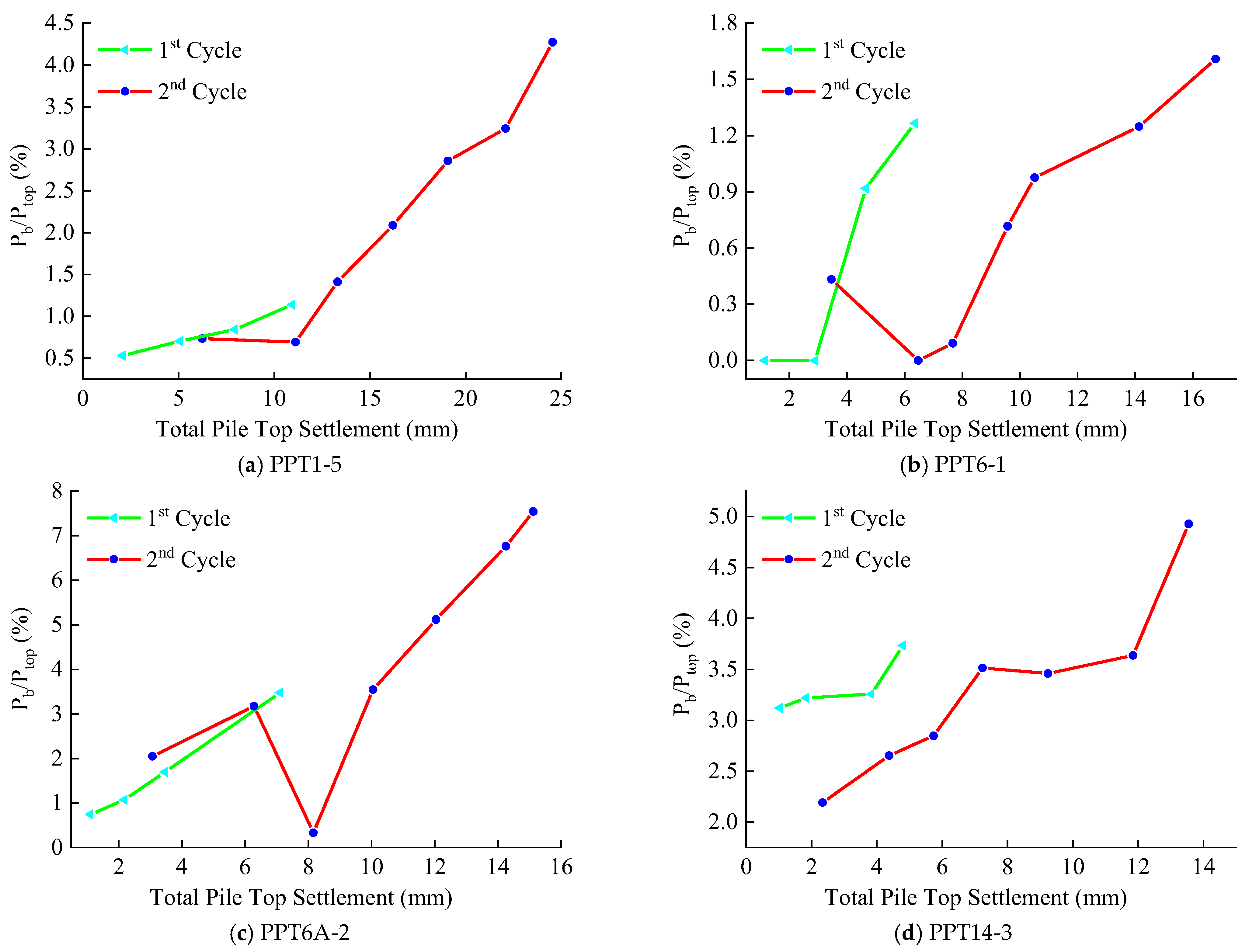

3.3. Results and Analysis of Static Load Tests

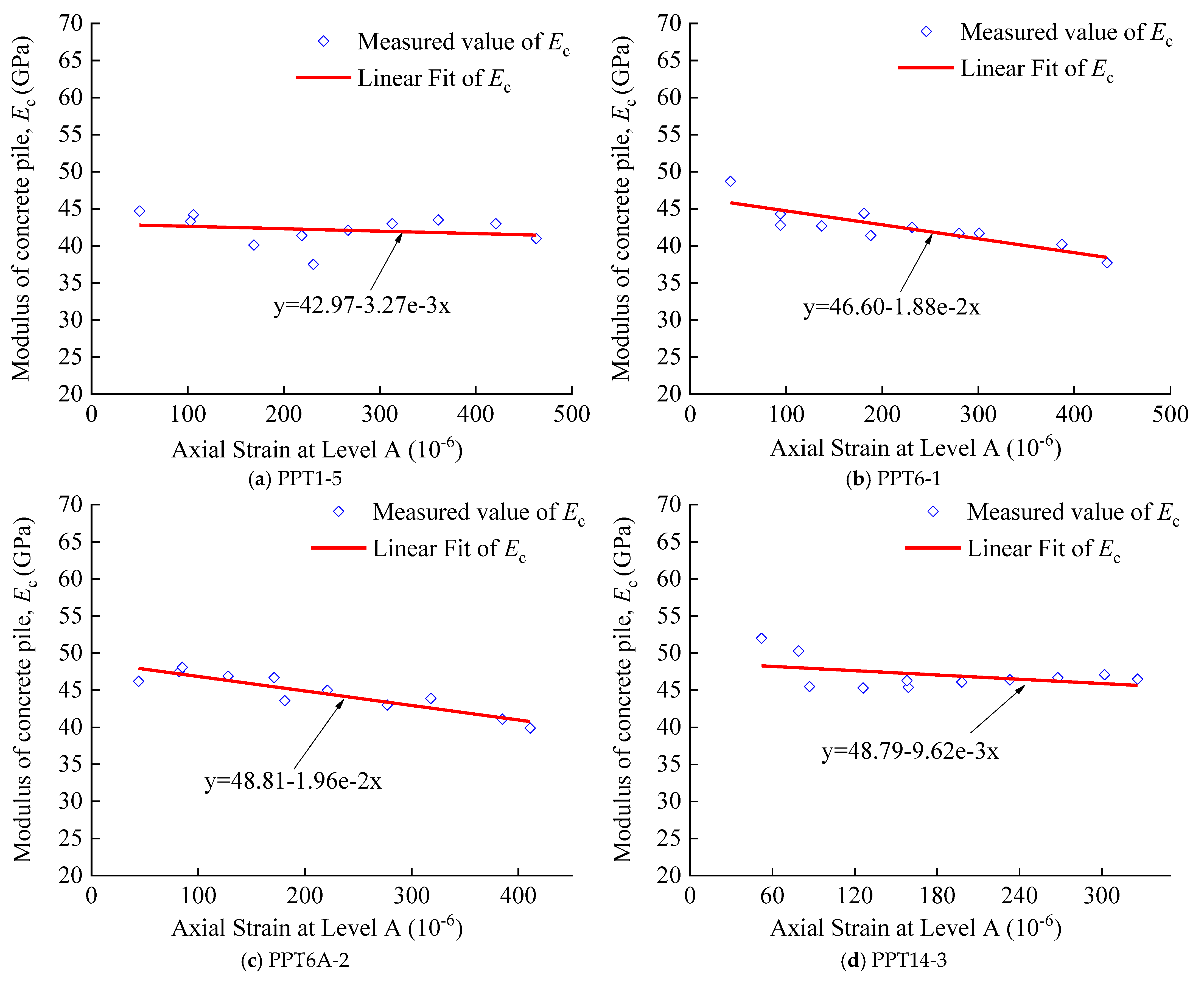

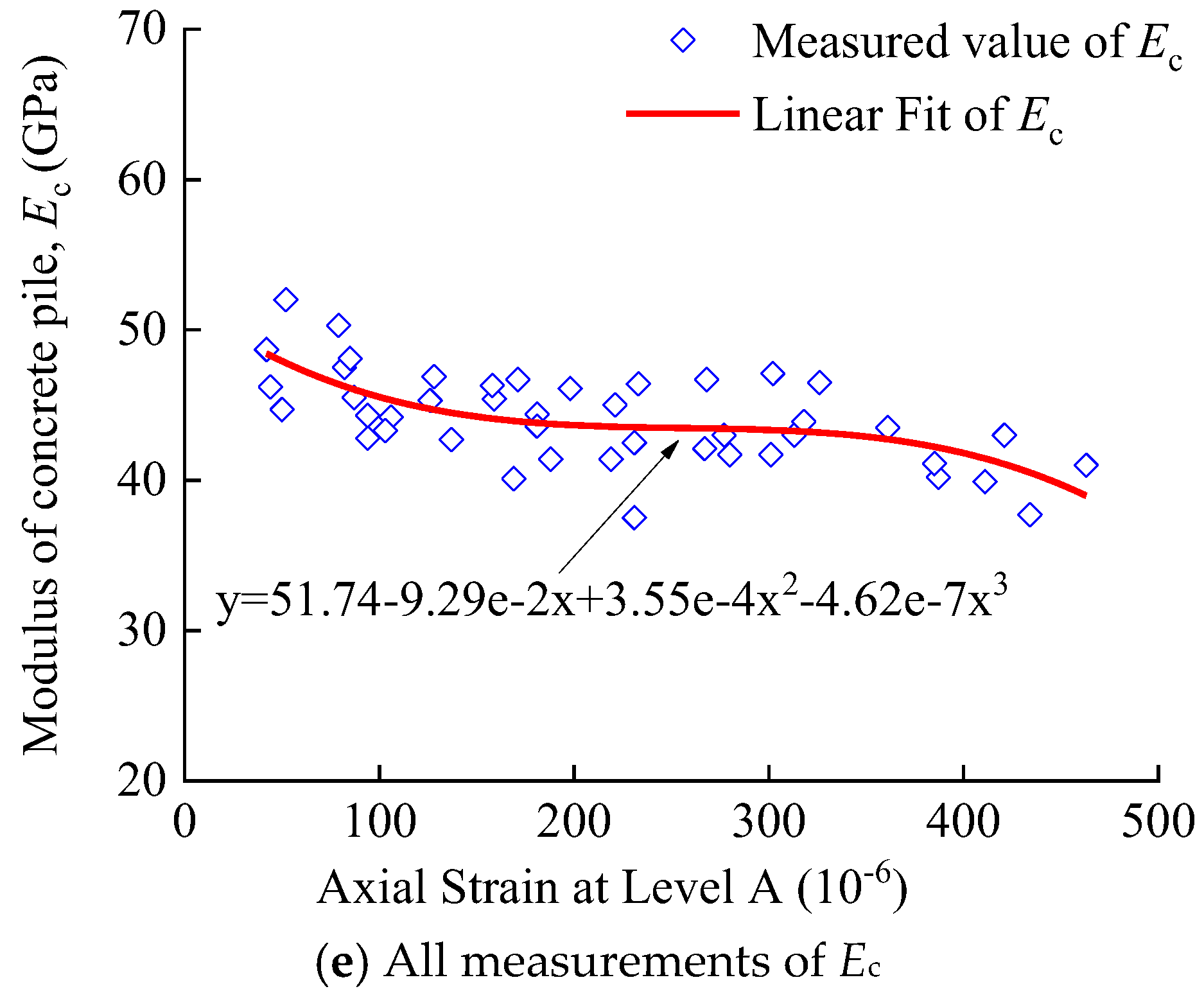

- ε = average change in global strain gauge readings.

- Ac = cross-sectional area of spun pile section.

- Ec = concrete modulus of pile section.

4. Conclusions

- The time-dependent behavior of the bearing capacity of prefabricated pipe piles was obvious. By the end of the dynamic test, the bearing capacity of each test pile increased by 27% to 66%. The final bearing capacity of the pile foundation can be roughly predicted by using the high strain initial driving results and restitution coefficient.

- The bearing capacity of the PHC pipe piles increased rapidly within three days after driving, and then entered a slow growth stage. The increase of pile lateral resistance with time was much larger than that of end resistance.

- The fitting Q-s curve of the high strain test was not in good agreement with the Q-s curve of the static load test. Taking the results of the static load method bearing capacity as the verification standard, the errors of the four piles’ high strain method bearing capacity are −2.4%, 7.2%, 3.6% and 24.4%, respectively.

- Under 2.1 times the design load, the change range of the pile concrete modulus was from 37.5 GPa to 52 GPa, the change range of the pile side friction resistance was from 0 kPa to 97 kPa and the change range of the pile end to pile bottom load ratio was from 0% to 7.54%.

- The relative displacement of the pile and soil required to give full play to the pile side friction resistance in clay soil was greater than 10 mm. The softening of pile-soil relative displacement was more significant in shallow buried cohesive soil. During the test, the shaft friction and end bearing of the lower part of the piles were not fully mobilized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.H.; Sang, S.K.; Zhang, M.Y.; Bai, X.Y.; Su, L. Investigation on in-situ test of penetration characteristics of open and closed PHC pipe piles. Soils Found. 2021, 61, 960–973. [Google Scholar] [CrossRef]

- Nguyen, T.; Ly, K.D.; Nguyen-Thoi, T.; Nguyen, B.P.; Doan, N.P. Prediction of axial load bearing capacity of PHC nodular pile using Bayesian regularization artificial neural network. Soils Found. 2022, 62, 101203. [Google Scholar] [CrossRef]

- Zhang, G.J.; Liu, Z.Y.; Xiong, W.; Zhang, S.F.; Liu, S.Z.; Wang, Z.W.; Wang, Y.S. Dynamic Monitoring of the Standard Penetration of PHC Tubular Piles and Analysis of the Construction Effect Based on Monocular Visual Digital Photography. Appl. Sci. 2022, 12, 11468. [Google Scholar] [CrossRef]

- Kou, H.L.; Diao, W.Z.; Liu, T.; Yang, D.L.; Horpibulsuk, S. Field Performance of Open-Ended Prestressed High-Strength Concrete Pipe Piles Jacked into Clay. Sensors 2018, 18, 4216. [Google Scholar] [CrossRef]

- Wang, Y.H.; Sang, S.K.; Zhang, M.Y.; Liu, X.Y.; Yang, S.C. Field test of earth pressure at pile-soil interface by single pile penetration in silty soil and silty clay. Soil Dyn. Earthq. Eng. 2021, 145, 106666. [Google Scholar] [CrossRef]

- Hwang, T.; Cho, J.; Lee, Y.S. Calculation method for settlement of micropile installed in rock layers through field tests. Geomech. Eng. 2022, 31, 197–208. [Google Scholar] [CrossRef]

- Oktiovan, Y.P.; Otaki, T.; Obara, T.; Kono, S.; Asai, Y.; Kobayashi, K.; Watanabe, H.; Mukai, D. Shear performance evaluation of PHC piles under different levels of axial load ratio. Earthq. Eng. Struct. Dyn. 2022, 51, 2091–2112. [Google Scholar] [CrossRef]

- Wang, B.; Qi, L.; Yang, Y.D. Experimental Study on Bending Resistance of New Type Joint of Prestressed Concrete Pipe Pile. Symmetry 2022, 14, 1920. [Google Scholar] [CrossRef]

- Zhang, X.W.; Gong, S.F.; Xu, Q.B.; Gan, G.; Yu, X.D.; Lu, Y. Flexural performance of pretensioned spun concrete piles reinforced with steel strands. Mag. Concr. Res. 2022, 74, 757–777. [Google Scholar] [CrossRef]

- Cao, X.L.; Dai, G.L.; Gong, W.M.; Zhu, M.X.; Tang, J.A. Experimental study on the seismic behavior of new PHC piles. Arab. J. Geosci. 2020, 13, 1–8. [Google Scholar] [CrossRef]

- Huang, F.Y.; Shan, Y.L.; Javanmardi, A.; Luo, X.Y.; Chen, B.C. Seismic Performance of Various Piles Considering Soil-Pile Interaction under Lateral Cycle Loads for Integral Abutment Jointless Bridges (IAJBs). Appl. Sci. 2020, 10, 3406. [Google Scholar] [CrossRef]

- Yang, Z.J.; Li, G.C.; Nan, B. Study on Seismic Performance of Improved High-Strength Concrete Pipe-Pile Cap Connection. Adv. Mater. Sci. Eng. 2020, 2020, 4326208. [Google Scholar] [CrossRef]

- Kou, H.; Xing, D.; Zhang, M. Experimental study on influence of residual stress of jacked pile on bearing behavior of piles. Build. Struct. 2017, 47, 94–97. [Google Scholar]

- Noor, S.T.; Islam, M.S.; Mumtarin, M.; Chakraborty, N. Dynamic load test of full-scale pile for the construction and rehabilitation of bridges. In Proceedings of the 10th Asia Pacific Structural Engineering and Construction Conference, Langkawi, Malaysia, 13–15 November 2019; Volume 513. [Google Scholar] [CrossRef]

- Salgado, R.; Zhang, Y.; Abou-Jaoude, G.; Loukidis, D.; Bisht, V. Pile driving formulas based on pile wave equation analyses. Comput. Geotech. 2017, 81, 307–321. [Google Scholar] [CrossRef]

- Aghayarzadeh, M.; Khabbaz, H.; Fatahi, B.; Terzaghi, S. Interpretation of Dynamic Pile Load Testing for Open-Ended Tubular Piles Using Finite-Element Method. Int. J. Geomech. 2020, 20, 04019169. [Google Scholar] [CrossRef]

- Kou, H.L.; Chu, J.; Guo, W.; Zhang, M.Y. Field study of residual forces developed in pre-stressed high-strength concrete (PHC) pipe piles. Can. Geotech. J. 2016, 53, 696–707. [Google Scholar] [CrossRef]

- Zhou, J.J.; Yu, J.L.; Gong, X.N.; Zhang, R.H.; Yan, T.L. Influence of soil reinforcement on the uplift bearing capacity of a pre-stressed high-strength concrete pile embedded in clayey soil. Soils Found. 2019, 59, 2367–2375. [Google Scholar] [CrossRef]

- Kim, S.; Whang, S.W.; Kim, S. Pile Foundation Design Through the Increased Bearing Capacity of Extended End Pile. J. Asian Archit. Build. Eng. 2017, 16, 395–402. [Google Scholar] [CrossRef]

- Huynh, V.H.; Nguyen, T.; Nguyen, D.P.; Nguyen, T.S.; Huynh, T.M.D.; Nguyen, T.C. A novel direct SPT method to accurately estimate ultimate axial bearing capacity of bored PHC nodular piles with 81 case studies in Vietnam. Soils Found. 2022, 62, 101163. [Google Scholar] [CrossRef]

- Li, X.S.; Zhang, J.Q.; Xu, H.; Shi, Z.W.; Gao, Q.F. Static Load Test and Numerical Analysis of Influencing Factors of the Ultimate Bearing Capacity of PHC Pipe Piles in Multilayer Soil. Sustainability 2021, 13, 13166. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, D.C.; Kim, T.H. Field Evaluation of the Vertical Bearing Capacity of a Screw Pretensioned Spun High-Strength Concrete Pile. Mar. Georesources Geotechnol. 2016, 34, 474–485. [Google Scholar] [CrossRef]

- Lehane, B.M.; Li, L.; Bittar, E.J. Cone penetration test-based load-transfer formulations for driven piles in sand. Geotech. Lett. 2020, 10, 568–574. [Google Scholar] [CrossRef]

- Li, L.; Li, J.-P.; Sun, D.-A.; Fang, R. Time-dependence of bearing capacity of jacked piles in natural saturated clay. Rock Soil Mech. 2017, 38, 2515–2522. [Google Scholar] [CrossRef]

- Yang, Y.; Kong, M.; Cui, X. Study on the Time of Negative Skin Friction of Single Pile in Collapsible Loess. Chin. Q. Mech. 2019, 40, 384–391. [Google Scholar]

- Ye, X.; Wu, J.T.; Li, G.W. Time-dependent field performance of PHC pile-cap-beam-supported embankment over soft marine clay. Transp. Geotech. 2021, 26, 100435. [Google Scholar] [CrossRef]

- Sakr, M. Comparison between high strain dynamic and static load tests of helical piles in cohesive soils. Soil Dyn. Earthq. Eng. 2013, 54, 20–30. [Google Scholar] [CrossRef]

- Dudek, N. Pile group settlement analysis on the basis of Static Load Test. In Proceedings of the 22nd International Scientific Conference on Construction—The Formation of Living Environment (FORM), Tashkent Inst Irrigat & Agr Mechanizat Engineers, Tashkent, Uzbekistan, 18–21 April 2019; Volume 97. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, G. Finite element analysis of mechanical behavior of PHC pipe piles with mixed reinforcement in pressurized situations. Build. Sci. 2018, 34, 54–60. [Google Scholar]

- Hu, X.; Wang, X.; Lou, X.; Chen, M. Experimental study on time effect of large diameter steel pipe piles under complex geological conditions at sea. Ocean. Eng. 2019, 37, 93–100. [Google Scholar]

- Wei, Y.J.; Wang, D.L.; Li, J.W.; Jie, Y.X.; Ke, Z.D.; Li, J.U.; Wong, T.M. Evaluation of Ultimate Bearing Capacity of Pre-Stressed High-Strength Concrete Pipe Pile Embedded in Saturated Sandy Soil Based on In-Situ Test. Appl. Sci. 2020, 10, 6269. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Zhang, M.; Yang, S.; Sang, S. Field Test of Excess Pore Water Pressure at Pile-Soil Interface Caused by PHC Pipe Pile Penetration Based on Silicon Piezoresistive Sensor. Sensors 2020, 20, 2829. [Google Scholar] [CrossRef]

- Ren, J.W.; Xu, Q.B.; Chen, G.; Liu, C.B.; Gong, S.F.; Lu, Y. Flexural performance of pretensioned centrifugal spun concrete piles with combined steel strands and reinforcing bars. Structures 2021, 34, 4467–4485. [Google Scholar] [CrossRef]

- Liu, C.; Tang, M.; Hu, H.; Chen, H.; Liu, C.; Hou, Z. Comparative study on vertical compressive bearing behavior of PHC pipe piles based on high strain method and static load method. Build. Struct. 2022, 52, 136–140. [Google Scholar]

- Lam, C. Discussion of “Comprehensive Load Test on Prestressed Concrete Piles in Alluvial Clays and Marl in Savannah, Georgia” by Yong Tan and Guoming Lin. J. Perform. Constr. Facil. 2015, 29, 178–190. [Google Scholar] [CrossRef]

- Zhao, C.; Lu, J.; Sun, Q.; Zhu, T.; Li, S. Experimental Study of Load Transmission Property of Large-Diameter Bored Cast-In-Situ Deep and Long Pile in Different Soil Layers. Chin. J. Rock Mech. Eng. 2009, 28, 1020–1026. [Google Scholar]

| Pile Number | Diameter (mm) | Pile Length (m) | Length Under Sensor (m) | Mud Entry Depth (m) | Hammer Weight (tons) | Drop Height (m) |

|---|---|---|---|---|---|---|

| PPT1-5 | 900 | 78 | 75.5 | 69.5 | 20 | 0.7 |

| PPT6-1 | 900 | 78 | 72.7 | 70.6 | 20 | 1.2 |

| PPT6A-2 | 900 | 65 | 63 | 60.15 | 20 | 1.2 |

| PPT14-3 | 900 | 37 | 35 | 34 | 20 | 1.0 |

| Pile Number | Rest Time (d) | Bearing Capacity (kN) | Lateral Resistance (kN) | End Resistance (kN) | K of Bearing Capacity | K of Lateral Resistance | K of End Resistance |

|---|---|---|---|---|---|---|---|

| PPT1-5 | 0 | 4725.6 | 3429.8 | 1295.8 | 1.00 | 1.00 | 1.00 |

| 3 | 6030.3 | 4628.9 | 1401.4 | 1.28 | 1.35 | 1.08 | |

| 29 | 6179.2 | 4701.0 | 1478.2 | 1.31 | 1.37 | 1.14 | |

| PPT6-1 | 0 | 6689.6 | 2353.2 | 4336.4 | 1.00 | 1.00 | 1.00 |

| 17 | 9540.4 | 5104.3 | 4436.1 | 1.43 | 2.17 | 1.02 | |

| PPT6A-2 | 0 | 6788.3 | 4199.7 | 2588.6 | 1.00 | 1.00 | 1.00 |

| 17 | 8084.6 | 5410.6 | 2674.0 | 1.19 | 1.29 | 1.03 | |

| 27 | 8638.9 | 5905.3 | 2733.6 | 1.27 | 1.41 | 1.06 | |

| PPT14-3 | 0 | 4760.9 | 1347.4 | 3413.5 | 1.00 | 1.00 | 1.00 |

| 21 | 7936.9 | 4397.1 | 3539.8 | 1.67 | 3.26 | 1.04 |

| Pile Number | Maximum Loading (kN) | High Strain Load (kN) | Maximum Settlement (mm) | Residual Settlement (mm) |

|---|---|---|---|---|

| PPT1-5 | 6344 | 6187 | 24.55 | 4.06 |

| PPT6-1 | 5471 | 5867 | 16.42 | 3.3 |

| PPT6A-2 | 5489 | 5689 | 15.12 | 1.33 |

| PPT14-3 | 5053 | 6286 | 13.55 | 3.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Liu, X.; Zhou, J.; Song, L. Field Test Study on the Bearing Capacity of Extra-Long PHC Pipe Piles under Dynamic and Static Loads. Sustainability 2023, 15, 5161. https://doi.org/10.3390/su15065161

Xiao Y, Liu X, Zhou J, Song L. Field Test Study on the Bearing Capacity of Extra-Long PHC Pipe Piles under Dynamic and Static Loads. Sustainability. 2023; 15(6):5161. https://doi.org/10.3390/su15065161

Chicago/Turabian StyleXiao, Yonggang, Xiaomin Liu, Junlong Zhou, and Liwei Song. 2023. "Field Test Study on the Bearing Capacity of Extra-Long PHC Pipe Piles under Dynamic and Static Loads" Sustainability 15, no. 6: 5161. https://doi.org/10.3390/su15065161

APA StyleXiao, Y., Liu, X., Zhou, J., & Song, L. (2023). Field Test Study on the Bearing Capacity of Extra-Long PHC Pipe Piles under Dynamic and Static Loads. Sustainability, 15(6), 5161. https://doi.org/10.3390/su15065161