The global warming profile for each rotation system was evaluated from an ALCA and a CLCA approach. Thus, the crop rotation systems with the best and the worst global warming impact were identified, and a detailed assessment was conducted with the aim of identifying the activities or processes more responsible for those GHG emissions. As justified above, the profiles were reported per kg of WW grain to identify the rotation system preferred from a climate change perspective; that is, the one that produces WW grain with the least GW score.

Table 5 shows the characterized results in terms of GW to produce one kg of WW grain under different rotation systems and considering ALCA and CLCA approaches. According to this table, the climate change impacts considerably change with the LCA perspective considered, as does the order of preferred production systems.

It is important to note that the goal of ALCA differs from that of CLCA; while the former is to assess the environmental burden of a product, assuming a status-quo situation, the latter is to assess the environmental consequences of a change in demand.

3.1. Outcomes from ALCA

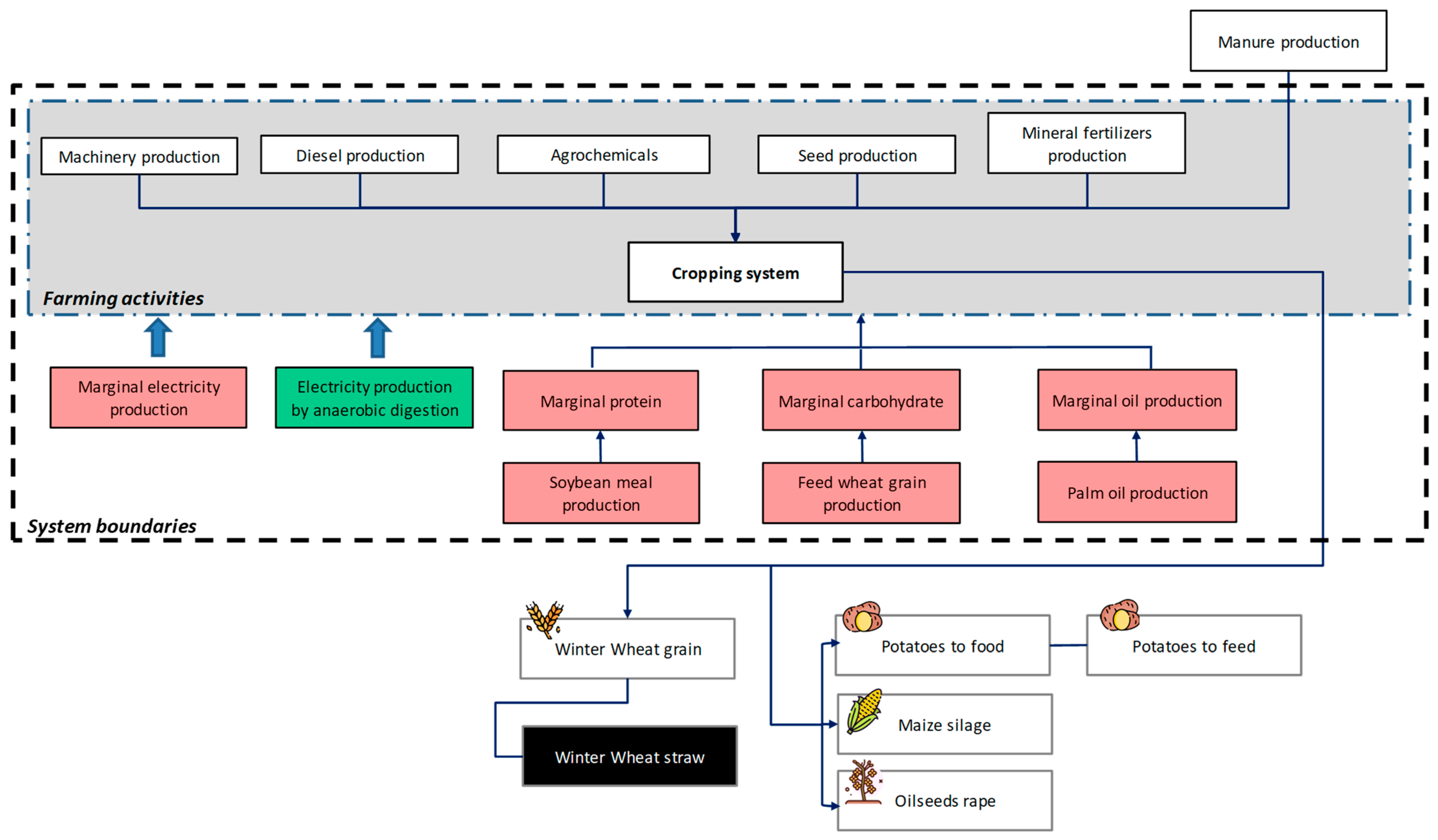

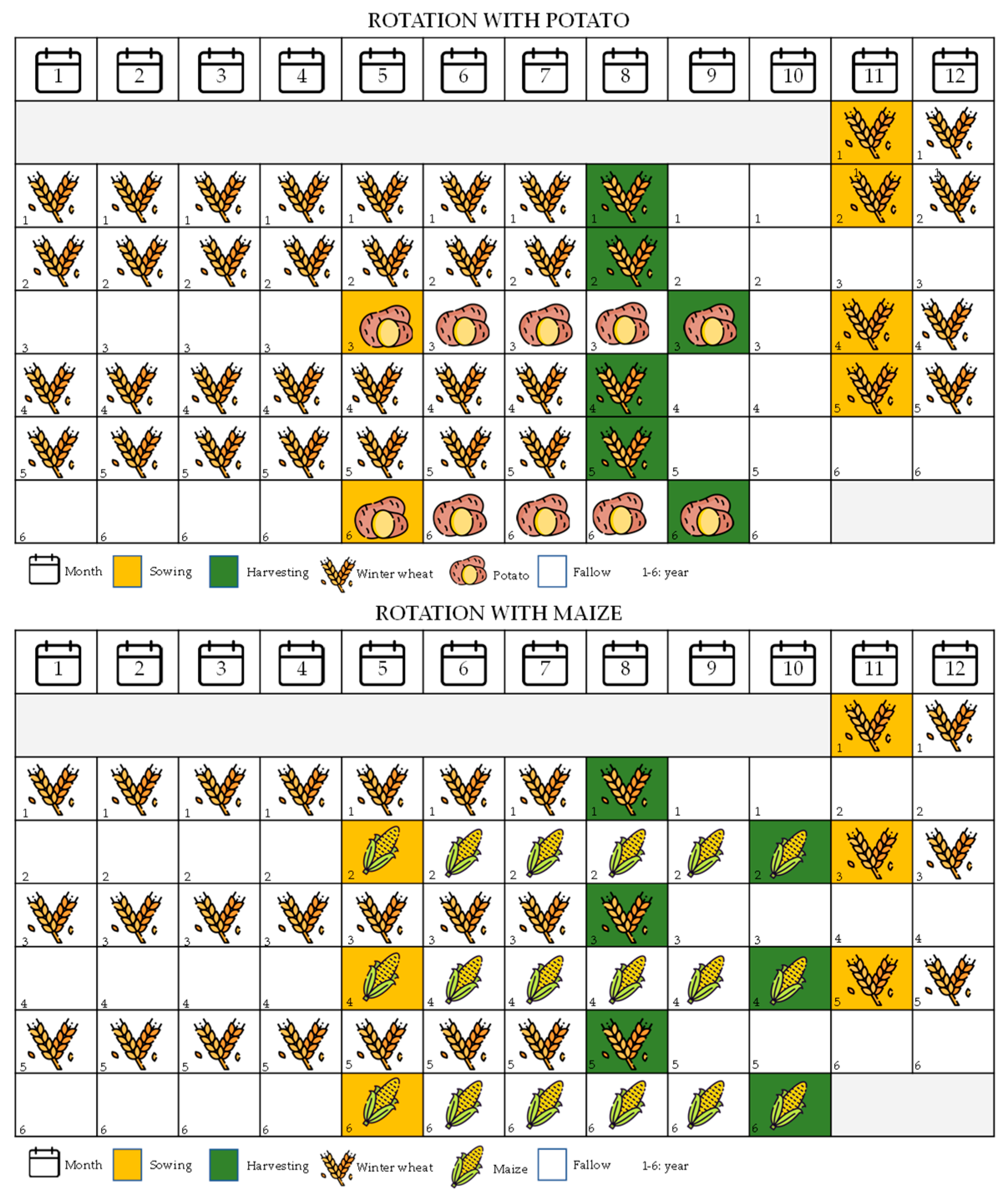

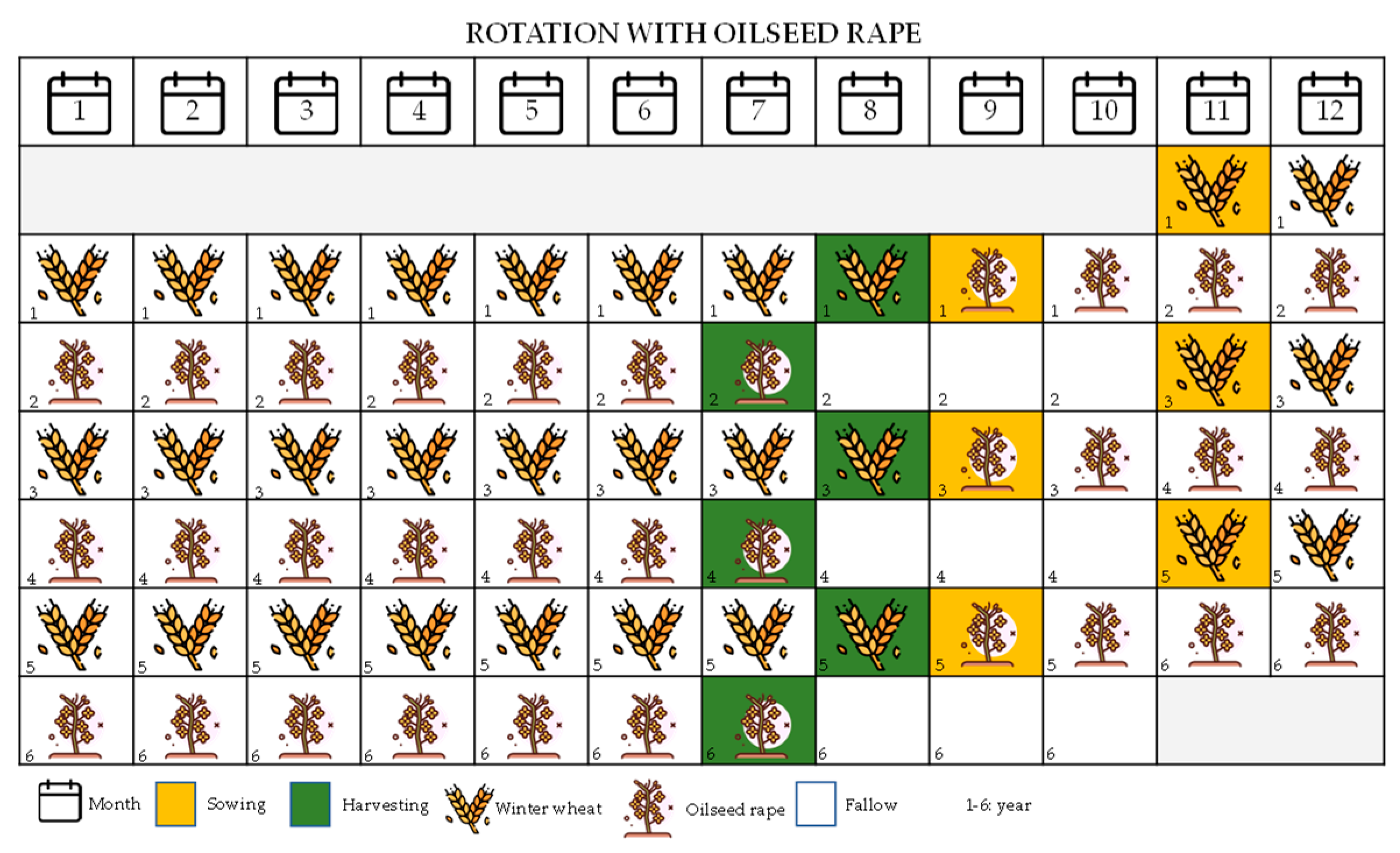

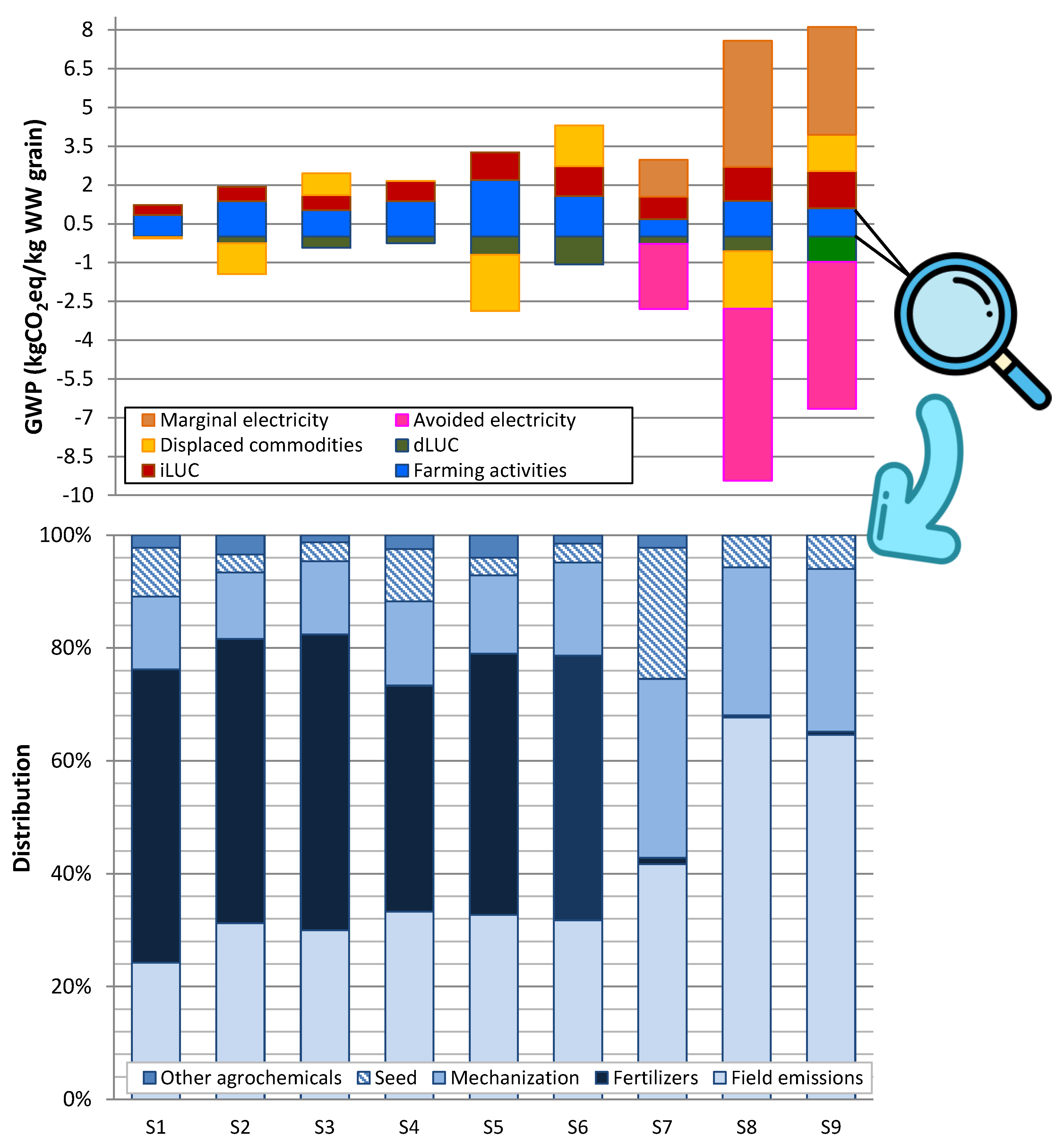

Figure 2 shows the contribution of different parameters involved in the global warming impact of the different scenarios estimated via an ALCA approach. The environmental hotspots are associated with the farming activities developed in the field that require specific inputs such as agrochemicals (mainly mineral fertilizers) and diesel. This parameter is clearly the main contributor to GHG emissions, regardless of the scenario.

Figure 2 shows that there are two farming activities with the highest GHG emission levels: field emissions (26–45% of total depending on the scenario) and fertilizer production (23–49%). Field emissions include on-site emissions derived from the application of fertilizers, N2O being the main responsible gas. There are other emissions into the environment resulting from the application of agrochemicals but not contributing to GW, such as nitrogen oxides and ammonia into air and nitrate and phosphate into water. Concerning fertilizer production, it includes the production of mineral and organic fertilizer (the latter only in ecological scenarios, i.e., S6–S9). It is important to highlight that the organic fertilizers (poultry and cow manure) have been assumed to be partly responsible for the environmental burdens derived from their background production systems (see the adopted economic allocation procedure in

Section 2.3.1). The contribution to GHG emission from organic fertilizers in S8 and S9 is extensive mainly because of the large amount of manure used.

Regarding mechanized activities, this contributing factor includes all agricultural operations performed on the field from field establishment to crop harvesting and thus the corresponding diesel requirements and tail-pipe emissions. This factor is responsible for 13–29% of GW, mainly due to the production of diesel, and harvesting is the main hotspot in all scenarios (moldboard ploughing and ground milling are also relevant in those scenarios where they are performed because of the large demand of diesel due to extensive operation hours). The effect on GW from seed production is relevant in the scenarios including potato as alternate crop (i.e., S1, S4 and S7) because a large amount of seeds is required per ha, as well as potato being a highly mechanized crop. Finally, the effect of the production of other required agrochemicals (i.e., pesticides, insecticides and fungicides) is insignificant or even negligible in the ecological scenarios, where they are only required in the cultivation of potato and maize (see

Figure A3 in the

Appendix A) but in lower amounts than in their conventional counterparts.

The effect over the GW from iLUC is negligible in all scenarios. The iLUC score was estimated as 289 kgCO

2·ha

−1 for a period of 6 years in an ALCA approach. After the application of the allocation factors corresponding to the WW grain per scenario (see

Table A2 in the

Appendix A), the iLUC effect is insignificant.

dLUC includes the increment on the soil organic content (environmental credit) because of returning straw into the field after harvesting. After applying the economic allocation factor, S1 is the scenario with the lowest biomass return rate (1.16 t straw DM per ha) and thus, the effect of dLUC in GW is negligible. Conversely, S6 with 27.9 t straw DM per ha returned into field, presents the largest environmental credit counteracting the effect of the mentioned contributing parameters.

3.2. Outcomes from CLCA

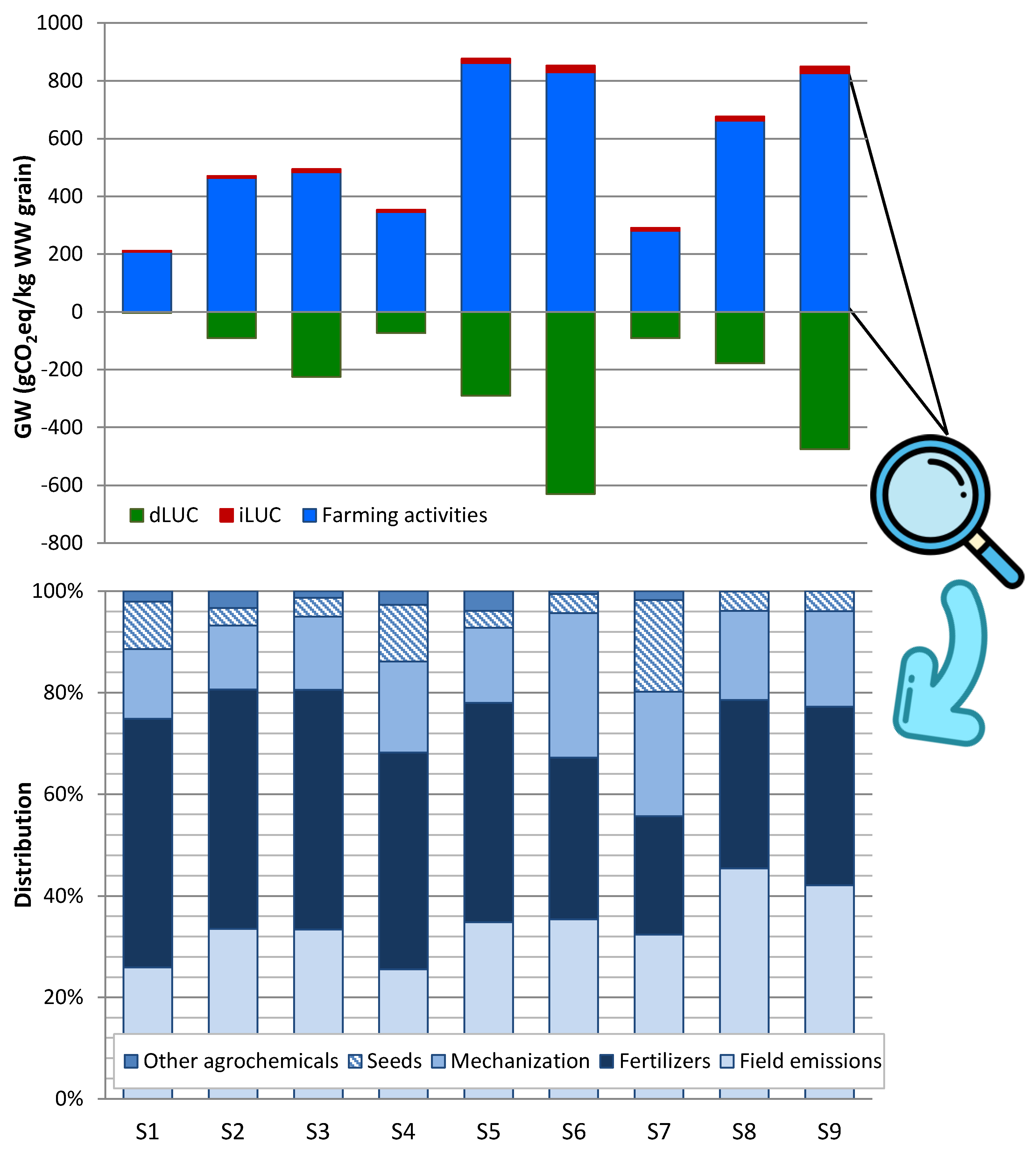

The global warming profile entirely changes between the ALCA and the CLCA approach.

Figure 3 depicts the distribution of GHG emissions per scenario between the involved parameters. The effect of the farming activities is also relevant but to a lesser extent than in ALCA, since their effect is in some scenarios surpassed by other parameters, such as those related to the marginal processes (mostly in ecological scenarios, S7–S9), the avoided conventional manure management (in S7–S9) and iLUC. Therefore, the importance of the displaced processes (marginal electricity and commodities) and avoided burdens is shown to be significant in this approach, which is often higher than the impact from the agricultural activities themselves. Thus, the results in CLCA considerably depend on the contribution from the marginal products, which in some cases are the most important contributing factor (e.g., in ecological scenarios).

In assessing, in more detail, the distribution of impacts from farming activities, two factors are identified as environmental hotspots: field emissions (i.e., N2O) and production of mineral fertilizers, mostly in ecological scenarios and conventional scenarios, respectively. The ecological scenarios (S7–S9) do not show a direct effect from organic fertilizer production (since they are free from upstream environmental burdens when estimated with the CLCA approach but in consideration of the avoided burdens from conventional manure management, i.e., avoided electricity production from biogas obtained by anaerobic digestion of manure), but the mechanized activities play a key role (and as detailed above, harvesting is the main responsible process regardless of the scenario).

In ecological scenarios, the production of marginal electricity is the environmental hotspot, which is required to compensate the manure that is partially destined for fertilizing activities.

Regarding the displaced commodities (feed carbohydrate, feed protein and vegetable oil), their effect over the profile varies with the scenarios. In some cropping systems, they constitute an environmental credit (S2, S5 and S8) mainly due to the avoided production of feed wheat (23.5 t DM, 22.5 t DM and 18.7 t DM, respectively) and to a lesser extent the avoided production of palm oil (0.90 t, 0.94 t and 0.79 t, respectively). Nevertheless, in other scenarios, such as S3, S6 and S9, they constitute an environmental hotspot. The reason behind these results is linked to the displacement of marginal fodder because of the co-production of potatoes, maize silage and rapeseed oil as detailed in

Table 4.

Conversely, dLUC and iLUC must be analyzed in detail. As in the ALCA approach, dLUC is an environmental credit in most scenarios, due to the large amounts of WW straw returned into field. For that reason, the effect is negligible in S1. Concerning iLUC, this parameter plays a key role over the profile, as opposed to that estimated via ALCA. In the CLCA approach, iLUC was estimated as 8,661 kgCO2·ha−1 for a period of 6 years. Bearing in mind the WW grain yields per rotation system, iLUC ranges from 0.394 kgCO2·kgWW grain−1 in S1 to 1.44 kgCO2·kgWW grain−1 in S9; these values are considerably higher than those estimated via the ALCA approach (ranging from 3.5 to 23.6 gCO2·kgWW grain−1, depending on the scenario).

3.3. Selection of the Best Cropping System from a Climate Change Perspective

This study demonstrates how the conclusions, hotspots and decision-support to farmer and consumers can vary depending on the LCA approach adopted. According to our results, and as expected, there are discrepancies in the GW scores between both methodological approaches (ALCA and CLCA) and thus in the choice of the best cropping system from a climate change perspective, i.e., the one that produces WW grain with the lowest GW impact.

The GW scores are generally higher in CLCA: from 1.3 to 14.5 times higher in S2 and S6, respectively, for CLCA relative to ALCA, except in S5 and S7 where the score is slightly lower and in S8, where the global warming value is even negative for CLCA in comparison with ALCA (−1.86 and 0.498 kgCO2eq·kg−1 WW grain, for CLCA and ALCA, respectively, in the latter). Regarding the hotspots, although farming activities occupy a leading position in terms of GHG emission, their effect is more significant over the global profile in ALCA than in CLCA (although in terms of GHG emission per kg of WW grain, farming activities are from 2 to 4 times higher in CLCA than in ALCA, depending on the scenario). The allocation of environmental burdens from contributing parameters in ALCA and the system expansion approach in CLCA are the factors explaining the differences in the results.

Concerning the selection of the cropping system that produces WW grain with the lowest associated GHG emission level, S7, which involves the production of the Galician WW variety in combination with potato under ecological management, is the preferred scenario when an ALCA approach is considered (0.200 kgCO

2eq·kg

−1 WW grain), followed by S1 (0.208 kgCO

2eq·kg

−1 WW grain), where a commercial wheat variety is combined with potato under conventional management. Conversely, S5, where the Galician variety is cultivated under rotation with maize and conventional management, is the worst choice (0.586 kgCO

2eq·kg

−1 WW grain), followed by S8 (crop rotation of Galician variety with maize under ecological management, 0.498 kgCO

2eq·kg

−1 WW grain) (see

Table 5).

The selection ranking notoriously changes (and even reverts) when the CLCA approach is considered. In this case, S8 is the preferred scenario (−1.86 kgCO2eq·kg−1 WW grain), followed by S7 (native wheat variety with potato under ecological management, 0.175 kgCO2eq·kg−1 WW grain), while S6 (native variety combined with oilseed rape under conventional management, 3.24 kgCO2eq·kg−1 WW grain) is the worst choice. The reason behind these results is mainly the different delimitation of system boundaries, among other methodological factors. Ecological scenarios, such as S7, S8 and S9, report a climate change profile that is penalized by the marginal electricity production. Moreover, indirect LUC effect is also penalized by the CLCA approach. In addition, ecological scenarios report the lowest crop yields, which directly involve highest impacts when the results are quantified per kg of product. Nevertheless, on the contrary, these scenarios involve environmental credits because of the avoided burdens of conventional manure management because of its use as fertilizer.

If an average value between the results of the two approaches was used to rank the crop rotations, the best and the worst crop rotations would be in line with those identified in the CLCA approach. Thus, S8 would be the best crop rotation (−0.681 kgCO2eq·kg−1 WW grain) to produce WW grain from a climate change perspective, and S6 the worst (1.73 kgCO2eq·kg−1 WW grain).

Considering that CLCA models the changes that are induced by a decision in a consequential manner and that ALCA models the share of global impacts that is attributed to the product under analysis [

36,

38,

60], the delimitation of system boundaries is different in both approaches. In CLCA, the system boundaries are extended to include those processes that are affected by the decision in question, while in ALCA, the overall environmental impact of a specific product system is included in the system boundary [

36]. Accordingly, differences in the results between both modelling approaches are expected. In our case study, these differences are due to the recovery of nutrients from manure in ecological systems (S7–S9), thereby avoiding the burdens of conventional manure management, as well as the inclusion of marginal feedstocks and electricity in CLCA and the use of average data and the partition of burdens between co-products in ALCA.

It can be concluded that the choice of the modelling framework leads to very different outcomes and conclusions, which is especially relevant for informing policy makers and other decision makers. It is therefore important to interpret the environmental results carefully—in our case, the carbon footprint of the farming systems under analysis—in line with the choices made.

Further research would be welcomed on (i) identifying the modelling parameters of the LCA approaches that better explain differences in results, (ii) further exploring their salient features and (iii) providing advances from current LCA practice that would support the reach of a much-needed consensus for identifying robust decision-support strategies.

However, despite their discrepancies and the fact that the modeled impacts are very sensitive to the approach taken, the importance of LCA and carbon footprinting for agricultural policy support is growing [

60,

61]. Therefore, the lack of scientific consensus on the treatment of critical methodological choices highlights the need for increased harmonization in LCA to improve the robustness and reproducibility of the results generated. In this regard, LCA practitioners, scientists and decision-makers need to address this issue urgently so that actions aimed at real climate change mitigation can be identified and implemented.