Abstract

All university departments must maximize their use of time and resources in order to meet their goal with the least amount of waste. The existing system in a local university does not implement the time equation and so the processing time determined is not in accordance with the actual processing time of every activity. Thus, the present implementation in the organization does not illustrate the correlation between the supplied resources and the practical capacity. The purpose of this study was to build a new costing structure using time-driven activity-based costing for academic staff. This work considered annual Key Performance Indicator Analysis data for the year 2020 with 53 sub parameters; this was from an engineering faculty for lecturers in two different grades with 12 and 27 samples, respectively. Eventually, there were 3 and 16 samples in grade DS45 and DS51/52, respectively, that have an insufficient time capacity. The remaining samples in both grades then had an unused time capacity, which ultimately resulted in unused cost capacity, also known as waste cost. This work was able to discover the total amount of used time that results in used, unused, or otherwise insufficient capacity, after analyzing the capacity cost using Time-Driven Activity-Based Costing.

1. Introduction

Higher education is a place in which people aim to improve themselves [1]. More than 20,000 academic institutions spread across 196 countries and regions are profiled in the World Higher Education Database [2]. In addition to other things, the government aims to see the nation focus less on foreign companies and more on establishing its own capabilities in early research. To fulfil this objective, the Malaysian government has been generous in funding graduate education. The Ministry of Higher Education (MoHE) designated five universities as research universities in 2008. MoHE also provided special funding to assist those institutions in developing graduate-level research and teaching infrastructure. The government raised financing to these five research universities by almost 71% in 2008 and 2009. The government has also allocated an incremental RM 500 million (approximately USD 117.19 million) to support graduate students [3].

Government officials and university academicians in Malaysia place a strong focus on making significant investments in education as a way to develop a workforce that is educated, which will then draw in outside investment. The nation’s economic growth would thereafter be fueled by this foreign investment. The higher education system must not only be excellent, but also widely regarded as outstanding by the global world in order to accomplish these aims. The advantages of enhancing the higher education system will only be realized when prospective students decide to attend school in Malaysia, when business and industry choose to relocate here, and when foreign investors recognize Malaysia as a top-notch location for their venture. For this purpose, the government places a great value on the reputation and credibility of Malaysian higher education abroad. The most straightforward path to obtaining the required level of international recognition was to encourage scholars to boost their publications in prestigious international journals; this is because publication rates are a crucial component of all international ranking systems [3]. When the cost of unused capacity is considered in capacity planning, the idle time of valuable resources can be exploited more efficiently [4]. The current approach of the researched university apparently does not implement a time equation, so the processing time that is determined is not in accordance with the actual processing time of every activity. Thus, the present implementation in the organization does not illustrate the correlation between the supplied resources and the practical capacity.

2. Literature Reviews

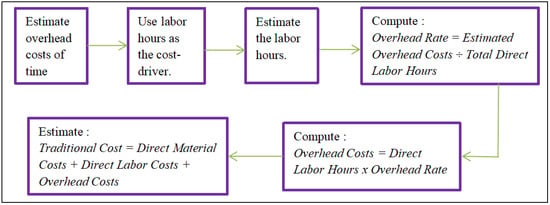

According to Amiri and Khmidi (2019) [5], direct and indirect costs must both be considered when calculating the costs of a product or service. Direct costs are defined as “expenditures exclusively associated to a single product, operation, or cost department” in the business terminology. These costs, also known as variable costs, include labor, material, and fuel costs. They are predetermined for each manufacturing unit but vary in response to adjustments in the total output. Indirect costs, on the other hand, are defined as costs that cannot be associated with a specific expense, activity, or item. These expenses are also known as fixed costs or overhead expenses, and include monthly or annual rents, as well as charges for maintenance, security, and supervision [5]. The majority of businesses often evaluate their overhead costs for their products or services based on the number of units sold, direct labor costs, direct working hours, or machine production hours [6]. Figure 1 illustrates Wilkinson’s explanation of common costing techniques.

Figure 1.

Traditional costing accounting (TCA). Source: Wilkinson (2013) [6].

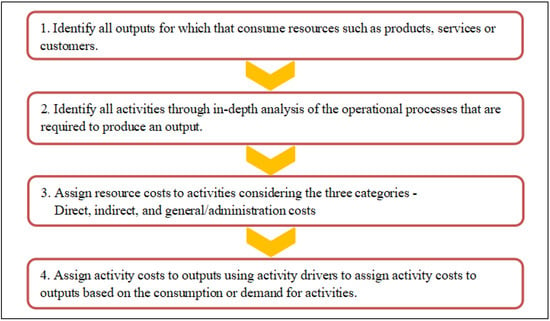

Despite the fact that traditional costing methods are simple to use, they are nonetheless thought to have a few drawbacks. The primary drawback is that it can only allocate costs based on a single volumetric measure, such as direct working hours and machine hours, and it is inaccurate when the overhead is high in comparison to the variable costs [7]. An alternative to the traditional costing approach is known as Activity-Based Costing (ABC). According to Kaplan and Burns (1987) [8], the original purpose of ABC was to improve managers’ activities, which are clearly relevant to profits and have a significant impact on company net incomes. In contrast to a conventional costing method, ABC identifies indirect expenses and assigns them based on the drivers of the activities to reduce costs and increase the usage of assets. ABC offers managers the option to distinguish between activities at the unit, batch, product, and facility levels. As shown in Figure 2, Edwards (2008) [7] described four methods for adopting ABC into practice.

Figure 2.

Implementation of ABC. Source: Edwards (2008) [7].

The ABC implementation comes with its own problems as a result of how individuals create their ABC models. These difficulties arise when larger businesses, which require more resources to complete this task, seek to continually use ABC. As a result, the expected ABC cost driver rates are typically higher than the actual capacity utilization. The Time-Driven Activity-Based Costing (TDABC) model, which was later proposed by Kaplan and Anderson (2004) [9], helps companies estimate the costs of each operation, product, or consumer by using time as an activity cost driver and the frequency of an activity to allocate resources to various cost centers. The TDABC is applied to evaluate the resource needs for various programs for radiation fractionation treatment, as shown by the analysis of Dziemianowicz et al. (2021) [10]. When health care is switched to value-added care, TDABC can help uncover methods to reduce costs and increase clinical efficiency. The TDABC approach builds on the conventional ABC while lowering application, development, and execution costs and improving accessibility. Additionally, analytical data from Mohsin et al. (2021) show that the combination of TDABC and lean management principles has a considerable and substantial impact on choices about the product mix [11].

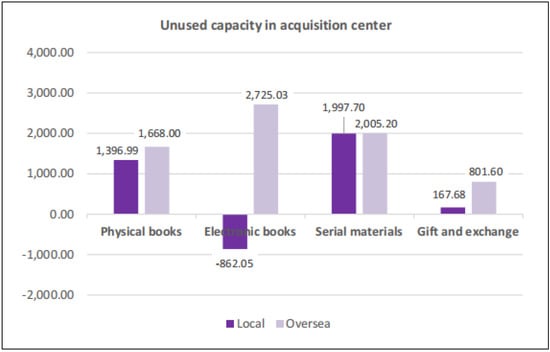

When determining overall cost, TDABC was found to comply with the research institution’s real resource utilization in the library sector [12]. The research aimed to develop a new costing system that would maximize the use of the capacity of the library system. Thus, in this study, time-driven activity-based costing (TDABC) was applied in the library of a local university. The TDABC was implemented across a number of phases. By utilizing process mapping and the recorded resources, all the activities and sub-activities were specified. The time equation was then developed by first determining the cost driver in relation to the operational costs. The total amount of time spent on the activity was then determined. The total used capacity for each activity was determined by multiplying its volume in a month by the amount of time it took to complete it. By evaluating the overall cost of all the supplied capacities, as well as the capacity presently being utilized in the production process, the capacity cost rate (CCR) was determined. In order to construct the projection, unused capacity was assessed in terms of time and cost. Figure 3 shows that only the electronic book in the local material had an insufficient capacity of 862.05 min, whereas the other activities had unused capacity. With a total of 2725.03 min, overseas material had the most underutilized capacity. This study identified which operations provide value and which may be scaled back to meet the capacity at hand.

Figure 3.

Unused capacity in acquisition center. Source: Zaini (2021) [12].

3. Materials and Methods

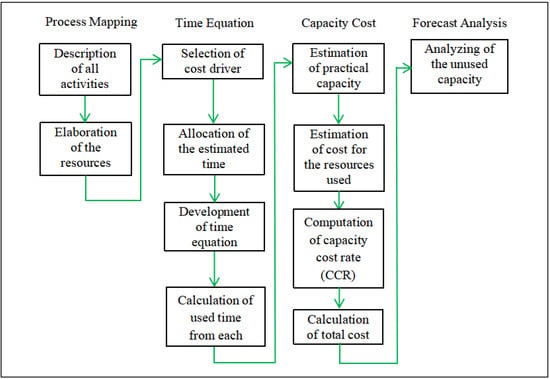

The TDABC incorporates a set of stages as shown in Figure 4. First of all, through process mapping, all the parameters are described. The cost driver that is related to the amount of time spent is then identified and the time equation is established. Then, by analyzing the current costs and capacities in the service operation, the capacity cost rate is determined. Finally, the forecast is constructed by estimating the unused capacity in terms of time and cost.

Figure 4.

Data analysis of TDABC. Source: Zaini (2021) [12].

3.1. Process Mapping

To develop a proper sequence of process mapping, all the activity centers, main activities, and sub-activities are first defined. A process map is a strategy and management tool that illustrates the flow of work from the broadest viewpoint to the degree of specificity needed to find possibilities for improved performance. Process mapping prioritizes the task over hierarchies or job titles.

3.2. Time Equation

Once a thorough process map has been created, time equations should be generated using the estimated time and cost driver volume for each sub-activity. The total time required to complete each task may be determined using the time equations. These data can be gathered through academician interviews. The TDABC time equation is capable of combining all the times required to complete all the sub-activities in each sample into a single Equation (1), and the mathematical model that was involved in creating the TDABC time equation is depicted below.

where

the time needed to perform an activity (minute);

the standard time to perform the basic activity (minute);

the estimated time to perform the incremental activity (minute);

the quantity of the incremental activity (time).

3.3. Capacity Cost Rate

To begin calculating the cost of capacity, all expenses related to providing this resource are included. Additionally, the working hours of personnel and any expenses associated with providing the resources must be listed in order to compute the CCR. The costs of labor and overheads are resources that are essential. The CCR is determined by dividing the costs associated with it by the practical capacity it provides, which is often expressed as an hourly or minutely cost. The following Equation (2) may be used to calculate the capacity cost rate (RM per minute).

3.4. Forecasting

The analysis of capacity utilization involves used and unused capacity, which are associated with utilization costs and waste costs accordingly. When the total capacities are multiplied with the CCR, the costs of utilization and waste may both be calculated. The final phase in the TDABC approach is forecasting analysis, which is crucial as it determines the optimum use of resources. It also plays a significant part in decision-making actions, such as expanding the source of labor and removing unnecessary processes.

4. Results

This section discussed the analysis of TDABC in two different grades of lecturers, which are DS45 and DS51/52.

4.1. Process Mapping

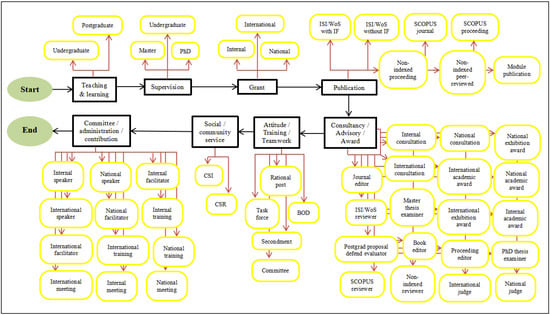

This analysis’s data are based on the evaluation of parameter KPIs, which are then verified against the Human Resource Department of the university’s previously recorded data. The particular KPI is used to categorize all activities, and both grades employ a similar process mapping. There are 53 sub-activities in addition to the 8 main ones. Figure 5 details the entire procedure.

Figure 5.

Process mapping.

4.2. Time Equation

4.2.1. In DS45

To determine the estimated used time, a time equation must be created. Based on the concepts of the Motion and Time principle, the estimated amount of time spent for each parameter is calculated. The TDABC time equation can incorporate all of the time required to complete each sub-parameter in a given sample in a single equation. The time equation used to determine the overall amount of time spent in DS45 is displayed in Table 1.

Table 1.

Time equations for DS45.

After the time equations are created, the actual used time for each sample is obtained by multiplying the quantity of the round spent for each activity per year by the total time taken for every round. As an example, Table 2 shows the total used time for sample 2 and 5 from the 12 overall samples, as they have the lowest and highest used times, respectively.

Table 2.

Total used time for sample 5 and 10 of DS45.

4.2.2. In DS51/52

The time equations to calculate the total used time in DS51/52 are presented in Table 3, as shown below.

Table 3.

Time equations for DS51/52.

After the time equations are created, the actual used time for each sample is obtained by multiplying the quantity of the round spent for each activity per year by the total time taken for every round. As an example, Table 4 shows the total used time for sample 7 and 14 from the 27 overall samples, as they have the highest and lowest used times, respectively.

Table 4.

Total used time for samples 7 and 14 of DS51/52.

The total used time can be determined by substituting the value of the cost drivers, which is hours/quantity, from Table 4 into time equations from Table 3. As an example, the total used time from sample 7 and 14 are, accordingly, shown below.

4.3. Capacity Cost Rate

Furthermore, in order to calculate the total cost utilized, the capacity cost rate (CCR) is multiplied by the total used time for each activity. In order to determine the CCR, the practical capacity and all the costs involved in supplying the resources need to be identified. The CCR is calculated by dividing its involved costs by the practical capacity it supplies, usually as an hourly or a minutely cost. The CCR (RM per minute) can be obtained using the previously shown Equation (2).

In the meantime, based on employee work hours, estimates of the practical capacity have also been made. The general working hours of lecturers are subject to the government’s service circular, which is issued by the public service department (JPA). The official working times are 8 a.m. to 5 p.m., on average, from Monday to Friday, on a 22-day basis. There are 10% deductions for breaks or leave and another 10% for training and workshops from these working hours, meaning that employees have an acceptable capacity of 1920 h each per year. In this study, samples from 12 academic staff of grade DS45 and 27 academic staff of grade DS 51/52 are discussed.

Based on the types of resources required for each activity, the costs are distributed. These are split into two categories: labor costs and overhead expenses, such as office supplies and material expenditures. Costs for the studied year are those that are included in this research. The labor costs are determined by the public service department’s (JPA) salary chart, which is based on the staff’s present grades. The costs are gathered from the recorded data in the HR Department. However, describing the actual overhead expenses in the academic profession is quite obscure. The other costs, which are not included in this sub-chapter, are based on the supposition that they will not change in either the present or the future. Therefore, in this research, the cost of the resources provided is limited to labor expenses.

Malaysian government personnel are all entitled to a basic salary of RM 1200, with different minimum salaries and annual increments according to their grade. According to the Minimum-Maximum Wage Table (JGMM) for management and professional educational services updated in 2016 by the JPA, grade DS45 shall receive RM 3,070, while grade DS51/52 will receive RM 5,855 as their salary.

4.3.1. In DS45

For all 12 samples in DS45, the cost of all the resources (labor cost) and the practical capacity are same. By using Equation (2), the labor cost of RM 36,840 was divided by the practical capacity of 1920 h. Therefore, the CCR for all 12 samples is also similar, which is RM 19.19 per hour. Table 5 explains the total costs for DS45. The total cost can be calculated when the used time is multiplied by the CCR.

Table 5.

Total costs for DS45.

For example, in sample 5, the total used time can be represented by 1098 h per year. When multiplied by the CCR of RM 19.19 per hour, it can be determined that the total cost of this sample comes out as RM 21,067.88 per year. Sample 5 has the lowest total cost because it has the lowest used time. By adding all the total costs from each sample together, the total cost for DS45 is RM 387,222.96.

4.3.2. In DS51/52

The cost of resources (labor cost) and the practical capacity are the same for all 27 samples in DS51/52. By using Equation (2), the labor cost of RM 70,260 was divided by the practical capacity of 1920 h. Therefore, the CCR for all 27 samples is RM 36.59 per hour. The entire expenditures for DS51/52 are shown in Table 6. When the time consumed is multiplied by the CCR, the total used cost may be determined.

Table 6.

Total used costs for DS51/52.

The total time used in sample 7 can be represented by 5243 h per year. The total cost of this sample equals RM 191,861.03 per year when multiplied by the CCR of RM 36.59 per hour. Due to possessing the highest usage of time, sample 7 had the highest total cost. The overall cost for DS51/52 is RM 2,498,108.94 when the all the costs for each sample are added together.

4.4. Forecast Analysis

This approach to planning capacity subsequently breaks down into three stages. These are the identification of the service-level demands, the assessment of the capacity at the moment, and the forecast for the future. There are three processes in this early phase: defining workloads, figuring out the unit of work and establishing the service standards. In order to assess the capacity and thus examine every workload and system as a whole, the present production schedule has been analyzed.

4.4.1. In DS45

The forecasting plan is developed as the last stage, in order to determine the amount of incoming work anticipated during the upcoming year. Table 7 displays the capacity utilization analysis for grade DS45.

Table 7.

Analysis of capacity utilization for DS45.

This work was able to discover the unused time that results in unused costs or otherwise insufficient costs after analyzing the capacity cost using TDABC. Due to the identical CCR values in each sample, the insufficient cost was reflected in parallel with the insufficient time. Three of the samples, sample 1, 2 and 9, had no unused capacity, but had an insufficient capacity of time. The remaining nine samples, sample 3, 4, 5, 6, 7, 8, 10, 11 and 12, then had wasted time capacity; this ultimately resulted in the unused capacity of cost, commonly known as waste capacity.

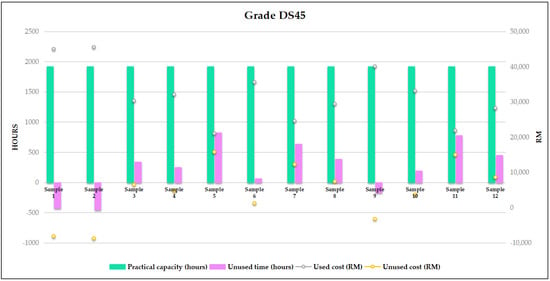

For 12 samples of DS45, Figure 6 compares the practical capacity of time with used cost, and unused time with unused cost. First of all, sample 5 has the least amount of time used (1.098 h) compared to its 822 h of unused time. Low capacity utilization rates lead to low capacity expenditures. Due to its large unused time capacity, this sample has the highest unused cost, which is RM 15,772.13. It is possible to conclude that sample 5’s performance was poor because it did not make full use of the available practical capacity.

Figure 6.

Capacity utilization in DS45.

Next, sample 6 has the closest quantity of used time (1857 h) to the practical capacity of 1920 h. It has an unused time of 63 h. This sample has an unused capacity of cost of RM 1,208.81. As it did fully utilize the provided practical capacity of 1920 h, the quality of the performance of sample 6 can be regarded as moderate.

Then, sample 2 has the highest used time (2376 h) among the other 11 samples. It has no unused time but has an insufficient capacity of time (456 h). The present, which has an insufficient capacity of time, will result in the existence of an insufficient capacity of cost. This sample has an insufficient capacity of cost of RM 8749.50. As this sample did fully utilize and exceed the provided practical capacity of 1920 h, the quality of the performance of sample 2 can be regarded as good.

4.4.2. In DS51/52

The analysis of capacity utilization for DS51/52 is shown in Table 8.

Table 8.

Analysis of capacity utilization for DS51/52.

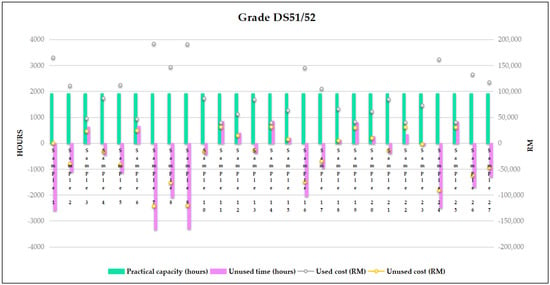

Similar to the forecast analysis of the DS45, the insufficient capacity that is reflected in parallel with the insufficient time, due to there being no difference, varies the CCR of each sample. Samples 3, 6, 11, 12, 14, 15, 18, 19, 20, 22 and 25 are the only eleven samples that have unused time capacity; this ultimately results in unused cost capacity, also known as waste cost. Then, the remaining 16 samples have an insufficient capacity of time.

For 27 samples of DS51/52, Figure 7 compares practical capacity with used time, and unused time with unused capacity of cost. Firstly, sample 14 has the smallest amount of used time (1072 h) compared to its 848 h of unused time. Low capacity utilization rates correspond to a low capacity of cost. Due to its high unused time capacity, this sample has the highest unused cost (RM31,031.50). Given that the practical capacity was not completely utilized, sample 14’s performance can be considered as being of poor quality.

Figure 7.

Capacity utilization in DS51/52.

In addition, sample 23 has the closest quantity of used time (1981 h) to its practical capacity of 1920 h. It has 61 h of insufficient time, which results in a small amount of insufficient capacity of cost, with RM 2232.22. As it has a small amount of extra used time compared to the provided 1920 h, sample 23’s performance quality may be regarded as moderate.

Then, sample 7 has the highest used time (5243 h) among the other 26 samples. There is no unused time, yet there is insufficient time available (3323 h). The current insufficient time capacity will lead to the presence of a lack of cost capacity. This sample has an insufficient capacity of cost of RM 121,601.03. Given that this sample did fully utilize and exceed the 1920 h practical capacity that was provided, sample 7’s performance quality may be regarded as being good.

5. Discussion

The TDABC approach is crucial to this exhaustive analysis since it involves two essential components of data in order to determine whether there is any unused capacity: time and cost. First and foremost, it takes time to determine the ideal staff ratio for each activity and organization. Furthermore, it is crucial to identify unwanted waste costs and develop strategies to reduce or eliminate them [9].

For each new member of academic staff, the candidate will need to undergo a series of interviews according to their possible grade. After managing to obtain the position, they must accomplish the related tasks to the minimum standard according to the annual work target for academic staff. The current practice used to measure the existing unused capacity, specifically in the mentioned engineering faculty, refers to the evaluation of the KPIs. For parameter 1, which is teaching and learning, both DS45 and DS51/52 need to accomplish more than or equal to five credit hours per year. Next, for parameter 2, which signifies supervision, DS45 staff need to have more than or equal to two undergraduate students, while DS51/52 staff need two undergraduate students and more than or equal to two postgraduate students. Then, in parameter 3, both grades need to have one research grant; however, DS51/52 staff need to also apply for a new grant within that year. In addition, for parameter 4, which indicates publication, both grades need to have at least two SCOPUS or ISI indexed for journal publication. As another option, if they do not fulfill the journal publication requirement, DS45 staff may opt to publish one module and DS51/52 staff may opt for two modules. Afterwards, parameter 5, 6, 7 and 8 express consultancy or advisory or award, attitude or training or teamwork, social or community service, and committee or administration or contribution, respectively. These four parameters require all academic staffs to attend at least one program throughout the year.

TDABC is a relevant method for enumerating the existing unused capacity in the academic sector. In this work, the final outcomes of unused capacity are in the form of quantity and the activities the academic staff perform that do not fulfil their minimum requirements of work. As all academic staff receive same salary according to their grade, it is unequal and unethical for academic staff who show unused capacity to acquire similar benefits to others. Academic integrity is a combination of intrinsic values that are necessary to build and foster an attitude of respect and responsibility towards the exploration of knowledge and academic excellence. Intrinsic values include aspects of qualifications, skills, experience, expertise and academic principles that are believed and practiced. In other words, the culture of an excellent academic community should be based on academic integrity [13].

So far, the conventional method has relied on an important simplifying assumption, which is that all orders or transactions of a particular type are the same and require the same amount of time to process. However, TDABC does not demand this simplification. It can accommodate the complexity of real-world operations by incorporating time equations, a new feature that enables the model to reflect how order and activity characteristics cause processing times to vary. Time equations greatly simplify the estimating process and produce a far more accurate cost model than would be possible using traditional ABC techniques [9].

It is important to note that the cost accounting system should support the university’s mission and vision by identifying any capacity that is unutilized, offering pertinent data for rational decision-making; this enhances the quality of services offered to students, and manages resources effectively and efficiently. By presuming that time is the primary cost driver of overhead expenses and concentrating activities within resource centers rather than in separate activity centers as in ABC, TDABC has been designed to alleviate the drawbacks of ABC. TDABC is useful for discovering any idle capacity in each resource center [14].

Author Contributions

Writing—original draft preparation, S.N.A.M.Z.; funding acquisition, M.Y.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Ministry of Higher Education under Fundamental Research Grant Scheme FRGS/1/2022/TK0/UMP/02/8.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lee, N.N.M. Higher Education in Southeast Asia in the Era of Globalization. In International Handbook of Higher Education; Springer: Berlin/Heidelberg, Germany, 2006; pp. 539–555. [Google Scholar] [CrossRef]

- World Higher Education Database. Available online: https://whed.net/home.php (accessed on 18 November 2022).

- UNESCO Institute for Statistics. Higher Education in Asia, Expanding Out, Expanding Up: The Rise of Graduate Education and University Research; UNESCO Institute for Statistics: Montreal, QC, Canada, 2014; pp. 1–163. [Google Scholar]

- Sebestyen, Z. The impact of the cost of unused capacity on production planning of flexible manufacturing systems. Period. Polytech. Soc. Manag. Sci. 2003, 11, 185–200. [Google Scholar]

- Amiri, N.A.; Khmidi, S.E. Implementing time-driven activity-based costing (TDABC) in out-patient nursing department: A case from UAE. Manag. Sci. Lett. 2019, 9, 365–380. [Google Scholar] [CrossRef]

- Activity-Based Costing (ABC) vs. Traditional Costing. Available online: https://strategiccfo.com/activity-based-costing-abc-vs-traditional-costing/ (accessed on 18 November 2022).

- Activity Based Costing: Topic Gateway Series No. 1. Available online: https://www.cimaglobal.com/Documents/ImportedDocuments/cid_tg_activity_based_costing_nov08.pdf.pdf (accessed on 18 November 2022).

- Kaplan, R.S.; Burns, W.J. Accounting and Management: Field Study Perspectives; Harvard Business School Press: Boston, MA, USA, 1987. [Google Scholar]

- Kaplan, R.S.; Anderson, S.R. Time-Driven Activity Based Costing. Harv. Bus. Rev. 2004, 82, 131–138. [Google Scholar] [CrossRef] [PubMed]

- Dziemianowicz, M.; Burmeister, J.; Dominello, M. Examining the Financial Impact of Altered Fractionation in Breast Cancer: An Analysis Using Time-Driven Activity-Based Costing. Pract. Radiat. Oncol. 2021, 11, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Mohsin, N.M.R.; Al-Bayati, H.A.M.; Oleiwi, Z.H. Product-Mix Decision Using Lean Production and Activity-Based Costing: An Integrated Model. J. Asian Financ. Econ. Bus. 2021, 8, 517–527. [Google Scholar] [CrossRef]

- Zaini, S.N.A.M.; Abu, M.Y. Optimization of capacity utilization using time-driven activity-based costing for library system. IOP Conference Series: Mate-rials Science and Engineering, Volume 1092, The 2nd International Conference on Innovative Technology, Engineering and Sciences (iCITES 2020), Pekan Pahang, Malaysia, (22–23/12/2020). IOP Conf. Ser. Mater. Sci. Eng. 2021, 1092, 012016. [Google Scholar] [CrossRef]

- Kementerian Pengajian Tinggi Malaysia. Garis Panduan Integriti Akademik; Institutusi Pengajian Tinggi Malaysia: Putrajaya, Malaysia, 2010. [Google Scholar]

- Oraby, S. A Guide to Implementation of Time- Driven Activity -Based Costing in Saudi Electronic University. Int. J. Bus. Manag. 2020, 16, 68–78. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).