The Effect of Green Purchasing Practices on Financial Performance under the Mediating Role of Environmental Performance: Evidence from Türkiye

Abstract

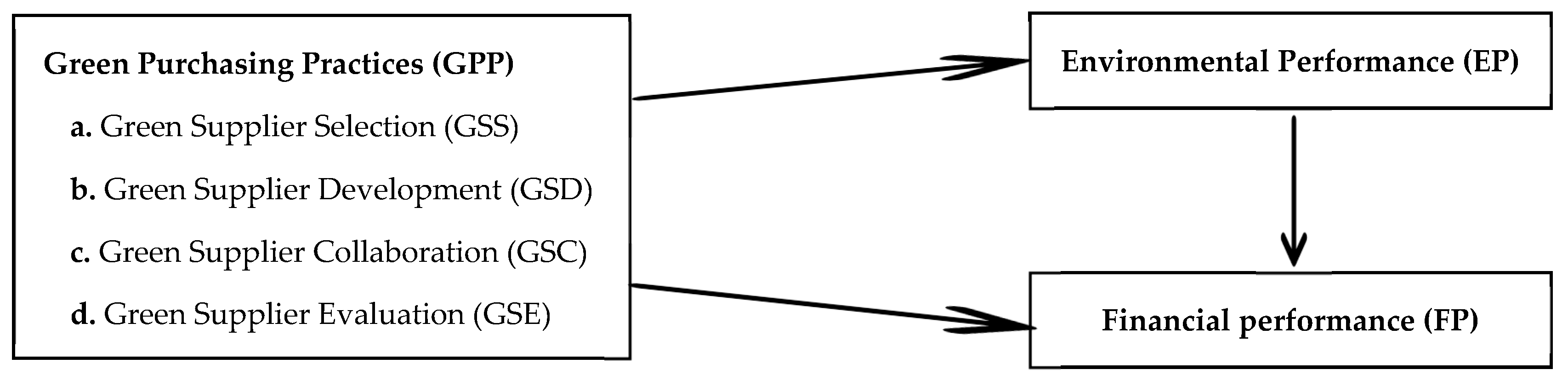

1. Introduction

2. Theoretical Background

2.1. Green Purchasing Practices (GPP)

2.2. Company Performance

2.3. Hypothesis Development and Conceptual Model

3. Research Method

3.1. Method and Tool of Data Collection

3.2. Pilot Study

3.3. Reliability and Validity Analyses

3.4. Exploratory (EFA) and Confirmatory Factor Analyses (CFA)

4. Data Analysis and Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Green Supplier Selection (GSS) | Source | |

| GSS1 | Suppliers with capabilities of eco-friendly technology and eco-design. | [22,50,53,82,83,84,85] |

| GSS3 | Suppliers with Green Image/Appearance. | |

| GSS4 | Suppliers with environmental management system certification (e.g., ISO 14001). | |

| GSS9 | Suppliers’ ability to use environmental packaging materials (lighter, biodegradable, and non-hazardous) for their products. | |

| GSS12 | Suppliers with pollution control activities. | |

| GSS13 | Suppliers with waste management systems. | |

| Green Supplier Development (GSD) | Source | |

| GSD1 | To provide suppliers with design features/specifications including environmental requirements for purchased products. | [33,59,76,84,86,87] |

| GSD2 | To put pressure on suppliers for taking environmental measures. | |

| GSD3 | To transfer employees with expertise on environmental issues to suppliers. | |

| GSD6 | To train suppliers to reduce non-recyclable packaging. | |

| GSD7 | To make field visits to supplier facilities to support their environmental performance development. | |

| GSD8 | To provide advice to suppliers on eco-design product development. | |

| GSD10 | To support suppliers in achieving their environmental targets. | |

| GSD11 | To bring suppliers from the same industry together and allow them to learn about each other’s environmental problems. | |

| Green Supplier Collaboration (GSC) | Source | |

| GSC1 | To cooperate with suppliers to achieve environmental objectives. | [36,39,50,56,76,88,89,90] |

| GSC5 | To collaborate with suppliers during product design stage to minimize damages caused to the environment. | |

| GSC11 | To cooperate with suppliers to minimize or eliminate packaging/wrapping materials along with their respective processes. | |

| GSC12 | To build a return system with suppliers for recycling and reuse of used and defective products. | |

| GSC14 | To cooperate with suppliers for investment recovery through resale of scrap and used materials. | |

| Green Supplier Evaluation (GSE) | Source | |

| GSE1 | To control possible negative environmental effects by suppliers through monitoring with evaluation programs. | [33,36,76,84,86,91,92] |

| GSE3 | To make surveys with suppliers to evaluate their environmental compliance and performance. | |

| GSE7 | To evaluate eco-friendly practices by secondary suppliers (suppliers of suppliers). | |

| Environmental Performance (EP) | Source | |

| EP1 | Reduction in air emission. | [36,37,38] |

| EP2 | Reduction in wastewater. | |

| EP3 | Reduction in solid wastes. | |

| EP4 | Decrease in consumption for hazardous/harmful/toxic materials. | |

| EP5 | Improve an enterprise’s environmental situation. | |

| EP6 | Decrease in frequency for environmental accident. | |

| Financial Performance (FP) | ||

| FP1 | Decrease in cost for materials purchasing. | |

| FP2 | Decrease in cost for energy consumption. | |

| FP3 | Decrease in fee for waste treatment. | |

| FP4 | Decrease in fee for waste discharge. | |

| FP5 | Decrease in fine for environmental accidents. | |

References

- Sari, K. A novel multi-criteria decision framework for evaluating green supply chain management practices. Comput. Ind. Eng. 2017, 105, 338–347. [Google Scholar] [CrossRef]

- Huang, Y.-C.; Borazon, E.Q.; Liu, J.-M. Antecedents and consequences of green supply chain management in Taiwan’s electric and electronic industry. J. Manuf. Technol. Manag. 2021, 32, 1066–1093. [Google Scholar] [CrossRef]

- Sari, K.; Suslu, M. A modeling approach for evaluating green performance of a hotel supply chain. Technol. Forecast. Soc. Chang. 2018, 137, 53–60. [Google Scholar] [CrossRef]

- Zhu, Q.; Feng, Y.; Choi, S.-B. The role of customer relational governance in environmental and economic performance improvement through green supply chain management. J. Clean. Prod. 2017, 155, 46–53. [Google Scholar] [CrossRef]

- Gupta, S.; Vijayvargy, L. Selection of Green Supplier in Automotive Industry: An Expert Choice Methodology. IOP Conf. Ser. Earth Environ. Sci. 2021, 795, 12036. [Google Scholar] [CrossRef]

- AlNuaimi, B.K.; Khan, M. Public-sector green procurement in the United Arab Emirates: Innovation capability and commitment to change. J. Clean. Prod. 2019, 233, 482–489. [Google Scholar] [CrossRef]

- Fajriani, M.; Ridwan, A.Y.; Saputra, M. Designing Green Procurement based on ERP for Leather Tanning Industry. In Proceedings of the 2020 8th International Conference on Information and Communication Technology (ICoICT), Yogyakarta, Indonesia, 24–26 June 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Yee, F.M.; Shaharudin, M.R.; Ma, G.; Zailani, S.H.M.; Kanapathy, K. Green purchasing capabilities and practices towards Firm’s triple bottom line in Malaysia. J. Clean. Prod. 2021, 307, 127268. [Google Scholar] [CrossRef]

- Finger, G.S.W.; Lima-Junior, F.R. A hesitant fuzzy linguistic QFD approach for formulating sustainable supplier development programs. Int. J. Prod. Econ. 2022, 247, 108428. [Google Scholar] [CrossRef]

- Hąbek, P.; Villahoz, J.J.L. Socially Responsible Supplier Development. Practices of Automotive Industry. Multidiscip. Asp. Prod. Eng. 2020, 3, 707–719. [Google Scholar] [CrossRef]

- Quyen, T. The Relationship between Green Procurement Practices and Organizational Performance in the Manufacturing Industry of Vietnam. Arthatama 2020, 4, 1–16. [Google Scholar]

- Chatzoudes, D.; Chatzoglou, P. Antecedents and effects of green supply chain management (GSCM) practices. Benchmarking Int. J. 2022. ahead of print. [Google Scholar] [CrossRef]

- Namagembe, S.; Ryan, S.; Sridharan, R. Green supply chain practice adoption and firm performance: Manufacturing SMEs in Uganda. Manag. Environ. Qual. Int. J. 2019, 30, 5–35. [Google Scholar] [CrossRef]

- Alzubi, E.; Akkerman, R. Sustainable supply chain management practices in developing countries: An empirical study of Jordanian manufacturing companies. Clean. Prod. Lett. 2022, 2, 100005. [Google Scholar] [CrossRef]

- Ghosh, S.; Mandal, M.C.; Ray, A. Exploring the influence of critical parameters on green supply chain management performance of small and medium-sized enterprise: An integrated multivariate analysis-robust design approach. Clean. Logist. Supply Chain. 2022, 4, 100057. [Google Scholar] [CrossRef]

- Dalay, M.; Sari, K. Exploring the importance of green criteria in supplier selection: The case of the Turkish food industry. J. Ind. Eng. 2022, 33, 500–5013. [Google Scholar] [CrossRef]

- Alghababsheh, M.; Abu Khader, D.E.; Butt, A.S.; Moktadir, A. Business strategy, green supply chain management practices, and financial performance: A nuanced empirical examination. J. Clean. Prod. 2022, 380, 134865. [Google Scholar] [CrossRef]

- Asif, M.S.; Lau, H.; Nakandala, D.; Fan, Y.; Hurriyet, H. Adoption of green supply chain management practices through collaboration approach in developing countries—From literature review to conceptual framework. J. Clean. Prod. 2020, 276, 124191. [Google Scholar] [CrossRef]

- Galeazzo, A.; Ortiz-De-Mandojana, N.; Delgado-Ceballos, J. Green procurement and financial performance in the tourism industry: The moderating role of tourists’ green purchasing behaviour. Curr. Issues Tour. 2021, 24, 700–716. [Google Scholar] [CrossRef]

- Dubey, R.; Bag, S.; Ali, S.S.; Venkatesh, V. Green purchasing is key to superior performance: An empirical study. Int. J. Procure. Manag. 2013, 6, 187. [Google Scholar] [CrossRef]

- Hazaea, S.A.; Al-Matari, E.M.; Zedan, K.; Khatib, S.F.A.; Zhu, J.; Al Amosh, H. Green Purchasing: Past, Present and Future. Sustainability 2022, 14, 5008. [Google Scholar] [CrossRef]

- Farizal; Dewi, R.M.; Gabriel, D.S. Supplier evaluation and order allocation using fuzzy analytical hierarchy process and augmented epsilon constraint methods. IOP Conf. Ser. Mater. Sci. Eng. 2019, 567, 12035. [Google Scholar] [CrossRef]

- Gu, V.C.; Zhou, B.; Cao, Q.; Adams, J. Exploring the relationship between supplier development, big data analytics capability, and firm performance. Ann. Oper. Res. 2021, 302, 151–172. [Google Scholar] [CrossRef]

- Dutta, P.; Jaikumar, B.; Arora, M.S. Applications of data envelopment analysis in supplier selection between 2000 and 2020: A literature review. Ann. Oper. Res. 2021, 315, 1399–1454. [Google Scholar] [CrossRef]

- Sosnowski, P. Green concepts in the supply chain. Logforum 2015, 18, 15–25. [Google Scholar] [CrossRef]

- Norheim-Hansen, A. Green supplier development: What’s in it for you, the buyer? Bus. Horizons 2023, 66, 101–107. [Google Scholar] [CrossRef]

- Hu, S.; Dong, Z.S.; Lev, B. Supplier selection in disaster operations management: Review and research gap identification. Socio-Econ. Plan. Sci. 2022, 82, 101302. [Google Scholar] [CrossRef]

- Cai, J.; Cheng, J.; Shi, H.; Feng, T. The impact of organisational conflict on green supplier integration: The moderating role of governance mechanism. Int. J. Logist. Res. Appl. 2022, 25, 143–160. [Google Scholar] [CrossRef]

- Haeri, S.A.S.; Rezaei, J. A grey-based green supplier selection model for uncertain environments. J. Clean. Prod. 2019, 221, 768–784. [Google Scholar] [CrossRef]

- Govindan, K.; Aditi; Darbari, J.D.; Kaul, A.; Jha, P. Structural model for analysis of key performance indicators for sustainable manufacturer–supplier collaboration: A grey-decision-making trial and evaluation laboratory-based approach. Bus. Strat. Environ. 2021, 30, 1702–1722. [Google Scholar] [CrossRef]

- Foo, M.; Kanapathy, K.; Zailani, S.; Shaharudin, M.R. Green Purchasing: Capabilities, Practices and Effects on Firms’ Triple Bottom Line Performance. Stud. Appl. Econ. 2021, 39, 6. [Google Scholar] [CrossRef]

- Fianko, S.K.; Amoah, N.; Jnr, S.A.; Dzogbewu, T.C. Green Supply Chain Management and Environmental Performance: The moderating role of Firm Size. Int. J. Ind. Eng. Manag. 2021, 12, 154–164. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S.; Jayaraman, K. The examination on the drivers for green purchasing adoption among EMS 14001 certified companies in Malaysia. J. Manuf. Technol. Manag. 2010, 21, 206–225. [Google Scholar] [CrossRef]

- Awaliyah, H.; Haryanto, B. The Influence of Green Organizational Culture, Green Innovation, and Environmental Performance on Competitive Advantage Moderated by Green Supply Chain Management (Case Study on SME in Solo Raya). Int. J. Innov. Sci. Res. Technol. 2022, 7, 191–199. [Google Scholar]

- Pakurár, M.; Khan, M.A.; Benedek, A.; Oláh, J. The impact of green practices, cooperation and innovation on the performance of supply chains using statistical method of meta-analysis. J. Int. Stud. 2020, 13, 111–128. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Fujita, T.; Hashimoto, S. Green supply chain management in leading manufacturers: Case studies in Japanese large companies. Manag. Res. Rev. 2010, 33, 380–392. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Examining the effects of green supply chain management practices and their mediations on performance improvements. Int. J. Prod. Res. 2012, 50, 1377–1394. [Google Scholar] [CrossRef]

- Petljak, K.; Zulauf, K.; Štulec, I.; Seuring, S.; Wagner, R. Green supply chain management in food retailing: Survey-based evidence in Croatia. Supply Chain Manag. Int. J. 2018, 23, 1–15. [Google Scholar] [CrossRef]

- Khodaparasti, R.B.; Garabollagh, H.B.; Mohammadpour, R. Engagement in green procurement: Antecedents and outcomes on manufacturing small and medium-sized enterprises from Iran. Amfiteatru Econ. 2020, 22, 102–120. [Google Scholar] [CrossRef]

- Ajayi, E.O.; Onikoyi, I.A.; Babalola, H.B.; Lateef, S.A. Green Supply Chain Management: An Empirical Study of Green Distribution and Procurement and Operational Performance within Nigerian SMEs. Appl. Econ. Bus. 2021, 5, 62. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Y.; Gu, Q.; Xie, H. The antecedents and consequences of green purchasing: An empirical investigation. Benchmarking: Int. J. 2021, 29, 1–21. [Google Scholar] [CrossRef]

- Bu, X.; Dang, W.V.; Wang, J.; Liu, Q. Environmental Orientation, Green Supply Chain Management, and Firm Performance: Empirical Evidence from Chinese Small and Medium-Sized Enterprises. Int. J. Environ. Res. Public Health 2020, 17, 1199. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Zhang, M.; Huo, B. The impact of supply chain quality integration on green supply chain management and environmental performance. Total Qual. Manag. Bus. Excel. 2019, 30, 1110–1125. [Google Scholar] [CrossRef]

- Li, S.; Qiao, J.; Cui, H.; Wang, S. Realizing the Environmental Benefits of Proactive Environmental Strategy: The Roles of Green Supply Chain Integration and Relational Capability. Sustainability 2020, 12, 2907. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Tanuwijaya, N.C.; Siagian, H. Does Top Management Attentiveness Affect Green Performance through Green Purchasing and Supplier Collaboration. Ph.D. Thesis, Petra Christian University, Jawa Timur, Indonesia, 2020. Available online: http://repository.petra.ac.id/18929/ (accessed on 6 February 2021).

- Jabbour, A.B.L.; Jabbour, C.J. Are supplier selection criteria going green? Case studies of companies in Brazil. Ind. Manag. Data Syst. 2009, 109, 477–495. [Google Scholar] [CrossRef]

- Shah, N.; Soomro, B.A. Internal green integration and environmental performance: The predictive power of proactive environmental strategy, greening the supplier, and environmental collaboration with the supplier. Bus. Strat. Environ. 2021, 30, 1333–1344. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lawson, B.; Petersen, K.J.; Fugate, B. Investigating green supply chain management practices and performance. Int. J. Oper. Prod. Manag. 2019, 39, 767–786. [Google Scholar] [CrossRef]

- Choudhary, K.; Sangwan, K.S. Adoption of green practices throughout the supply chain: An empirical investigation. Benchmarking Int. J. 2019, 26, 1650–1675. [Google Scholar] [CrossRef]

- Altaf, B.; Ali, S.S.; Weber, G.-W. Modeling the relationship between organizational performance and green supply chain practices using canonical correlation analysis. Wirel. Netw. 2020, 26, 5835–5853. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Yu, Z.; Farooq, K. Green capabilities, green purchasing, and triple bottom line performance: Leading toward environmental sustainability. Bus. Strat. Environ. 2022, 1–13. [Google Scholar] [CrossRef]

- Gupta, S.; Soni, U.; Kumar, G. Green supplier selection using multi-criterion decision making under fuzzy environment: A case study in automotive industry. Comput. Ind. Eng. 2019, 136, 663–680. [Google Scholar] [CrossRef]

- Javad, M.O.M.; Darvishi, M.; Javad, A.O.M. Green supplier selection for the steel industry using BWM and fuzzy TOPSIS: A case study of Khouzestan steel company. Sustain. Futures 2020, 2, 100012. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. Evaluation of the green supply chain management practices: A fuzzy ANP approach. Prod. Plan. Control 2012, 23, 405–418. [Google Scholar] [CrossRef]

- Zhang, Q.; Pan, J.; Jiang, Y.; Feng, T. The impact of green supplier integration on firm performance: The mediating role of social capital accumulation. J. Purch. Supply Manag. 2020, 26, 100579. [Google Scholar] [CrossRef]

- Khoo, B.M.; Ahmad, W.N.K.W.; Shamsuddin, A. The Relationship between Green Supplier Development Strategies and Firm Performance. Res. Manag. Technol. Bus. 2021, 2, 229–240. [Google Scholar] [CrossRef]

- Klassen, R.D.; McLaughlin, C.P. The Impact of Environmental Management on Firm Performance. Manag. Sci. 1996, 42, 1199–1214. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Hendrick, T.E. Purchasing’s involvement in environmental issues: A multi-country perspective. Ind. Manag. Data Syst. 1998, 98, 313–320. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Vanalle, R.M.; Ganga, G.M.D.; Filho, M.G.; Lucato, W.C. Green supply chain management: An investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 2017, 151, 250–259. [Google Scholar] [CrossRef]

- Yook, K.H.; Choi, J.H.; Suresh, N.C. Linking green purchasing capabilities to environmental and economic performance: The moderating role of firm size. J. Purch. Supply Manag. 2018, 24, 326–337. [Google Scholar] [CrossRef]

- Rosiana, N.; Surjandari, D.A. The Effect of Hidden Value of Intangible Assets, Investment Opportunity Set, and Environmental Performance on Economic Performance. J. Econ. Finance Account. Stud. 2022, 4, 115–125. [Google Scholar] [CrossRef]

- Shetty, S.K.; Bhat, K.S. Green supply chain management practices implementation and sustainability—A review. Mater. Today Proc. 2022, 52, 735–740. [Google Scholar] [CrossRef]

- Yang, C.-S.; Lu, C.-S.; Haider, J.J.; Marlow, P.B. The effect of green supply chain management on green performance and firm competitiveness in the context of container shipping in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2013, 55, 55–73. [Google Scholar] [CrossRef]

- Bassetti, T.; Blasi, S.; Sedita, S.R. The management of sustainable development: A longitudinal analysis of the effects of environmental performance on economic performance. Bus. Strat. Environ. 2021, 30, 21–37. [Google Scholar] [CrossRef]

- Taherdoost, H. Determining sample size; how to calculate survey sample size. Int. J. Econ. Manag. Syst. 2017, 2, 237–239. [Google Scholar]

- Tabachnick, B.G.; Fidell, L.S. Using Multivariate Statistics, 6th ed.; Baloğlu, M., Translator; Original work published; Nobel Yayınevi: Çankaya/Ankara, Turkey, 2015. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis: Global Edition, 7th ed.; Pearson Education: London, UK, 2014. [Google Scholar]

- Brown, S. Measures of Shape: Skewness and Kurtosis. Available online: https://web.ipac.caltech.edu/staff/fmasci/home/astro_refs/SkewStatSignif.pdf (accessed on 29 June 2011).

- Firuzan, A.R. The Effects of Hospital Quality Of Care on Patient Belonging: Structural Equality Model and Mediation. Bus. Manag. Stud. Int. J. 2017, 5, 462. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); SAGE Publications: Southend Oaks, CA, USA, 2014. [Google Scholar]

- Aydoğan, D.; Özbay, Y.; Büyüköztürk, Ş. Özgünlük Ölçeği’nin uyarlanması ve özgünlük ile mutluluk arasındaki ilişkide maneviyatın aracı rolü. J. Happiness Well-Being 2017, 5, 38–59. [Google Scholar]

- Yüksek, S.; Ölmez, C. Ölmez & Yüksek Taekwondo’da Kyorugi Performans Değerlendirme Ölçeğinin Geliştirilmesi “Development of Ölmez & Yüksek Taekwondo Kyorugi Performance Evaluation Scale”. Res. Sport. Sci. 2020, 10, 1–6. [Google Scholar] [CrossRef]

- Nam, S.-T.; Kim, D.-G.; Jin, C.-Y. A Comparison Analysis among Structural Equation Modeling (AMOS, LISREL and PLS) Using the Same Data. J. Korea Inst. Inf. Commun. Eng. 2018, 22, 978–984. [Google Scholar] [CrossRef]

- Paulraj, A. Understanding the relationships between internal resources and capabilities, sustainable supply management and organizational sustainability. J. Supply Chain Manag. 2011, 47, 19–37. [Google Scholar] [CrossRef]

- Ab Hamid, M.; Sami, W.; Sidek, M.M. Discriminant validity assessment: Use of Fornell & Larcker criterion versus HTMT criterion. J. Phys. Conf. Ser. 2017, 890, 012163. [Google Scholar]

- Fritz, M.S.; MacKinnon, D.P. Required Sample Size to Detect the Mediated Effect. Psychol. Sci. 2007, 18, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain Manag. Int. J. 2012, 17, 202–216. [Google Scholar] [CrossRef]

- Gualandris, J.; Kalchschmidt, M. Developing environmental and social performance: The role of suppliers’ sustainability and buyer–supplier trust. Int. J. Prod. Res. 2016, 54, 2470–2486. [Google Scholar] [CrossRef]

- Younis, H.; Sundarakani, B.; Vel, P. The impact of implementing green supply chain management practices on corporate performance. Compet. Rev. Int. Bus. J. 2016, 26, 216–245. [Google Scholar] [CrossRef]

- Min, H.; Galle, W.P. Green Purchasing Strategies: Trends and Implications. Int. J. Purch. Mater. Manag. 1997, 33, 10–17. [Google Scholar] [CrossRef]

- Handfield, R.; Walton, S.V.; Sroufe, R.; Melnyk, S.A. Applying environmental criteria to supplier assessment: A study in the application of the Analytical Hierarchy Process. Eur. J. Oper. Res. 2002, 141, 70–87. [Google Scholar] [CrossRef]

- Rao, P. Greening the supply chain: A new initiative in South East Asia. Int. J. Oper. Prod. Manag. 2002, 22, 632–655. [Google Scholar] [CrossRef]

- Davoudabadi, R.; Mousavi, S.M.; Sharifi, E. An integrated weighting and ranking model based on entropy, DEA and PCA considering two aggregation approaches for resilient supplier selection problem. J. Comput. Sci. 2020, 40, 101074. [Google Scholar] [CrossRef]

- Sarkis, J. Green Supply Chain Management; Momentum Press: New York, NY, USA, 2014; ISBN 9781606506431. [Google Scholar]

- Sharma, V.K.; Chandna, P.; Bhardwaj, A. Green supply chain management related performance indicators in agro industry: A review. J. Clean. Prod. 2017, 141, 1194–1208. [Google Scholar] [CrossRef]

- Carter, C.R.; Carter, J.R. Interorganizational Determinants of Environmental Purchasing: Initial Evidence from the Consumer Products Industries. Decis. Sci. 1998, 29, 659–684. [Google Scholar] [CrossRef]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farukt, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Atrek, B.; Özdağoğlu, A. Yeşil Tedarik Zinciri Uygulamaları: Alüminyum Doğrama Sektörü İzmir Örneği. Anadolu Üniversitesi Sos. Bilim. Derg. 2014, 14, 13–25. [Google Scholar] [CrossRef]

- Roman, A.V. Institutionalizing sustainability: A structural equation model of sustainable procurement in US public agencies. J. Clean. Prod. 2017, 143, 1048–1059. [Google Scholar] [CrossRef]

- Islam, M.S.; Tseng, M.-L.; Karia, N.; Lee, C.-H. Assessing green supply chain practices in Bangladesh using fuzzy importance and performance approach. Resour. Conserv. Recycl. 2018, 131, 134–145. [Google Scholar] [CrossRef]

| Number | % | ||

|---|---|---|---|

| Gender | Female | 121 | 26.59 |

| Male | 334 | 73.41 | |

| Work Period | 0–4 years | 22 | 4.84 |

| 5–9 years | 59 | 12.97 | |

| 10–14 years | 173 | 38.02 | |

| 15–19 years | 167 | 36.7 | |

| 20 years and above | 34 | 7.47 | |

| Job Level | Expert | 41 | 9.01 |

| Chief | 113 | 24.84 | |

| Mid-Level Manager | 222 | 48.79 | |

| Senior Manager | 79 | 17.36 | |

| Number of Employees | 1–49 persons | 220 | 48.35 |

| 50–249 persons | 163 | 35.82 | |

| 250–499 persons | 48 | 10.55 | |

| 500–999 persons | 13 | 2.86 | |

| 1000 and above | 11 | 2.42 | |

| Supplied | Goods/Materials | 331 | 72.75 |

| Service | 61 | 13.41 | |

| Both | 63 | 13.85 | |

| Environmental Management System Certification (ISO 14001 etc.) | No | 389 | 85.49 |

| Yes | 66 | 14.51 | |

| Industry | Textile, Ready-to-Wear, Leather | 92 | 20.22 |

| Food | 87 | 19.12 | |

| Chemistry, Petroleum, Rubber, and Plastics | 64 | 14.07 | |

| Tourism, Accommodation, Catering Services | 43 | 9.45 | |

| Woodwork, Paper, and Paper Products | 32 | 7.03 | |

| Other | 137 | 30.11 | |

| In-Country Multiple Branches | No | 384 | 84.4 |

| Yes | 71 | 15.6 | |

| Abroad Affiliates | No | 422 | 92.75 |

| Yes | 33 | 7.25 |

| Factors | EFA | CFA | |||||

|---|---|---|---|---|---|---|---|

| Item | Std. Loads | AV | α | CR | AVE | ||

| Green Purchasing Practices (GPP) | 0.93 | 0.91 | 0.54 | ||||

| Green Supplier Selection (GSS) | GSS1 | 0.69 | 20.28% | 0.88 | 0.88 | 0.55 | |

| GSS3 | 0.66 | ||||||

| GSS4 | 0.76 | ||||||

| GSS9 | 0.67 | ||||||

| GSS12 | 0.60 | ||||||

| GSS13 | 0.61 | ||||||

| Green Supplier Development (GSD) | GSD1 | 0.59 | 17.51% | 0.90 | 0.90 | 0.53 | |

| GSD2 | 0.80 | ||||||

| GSD3 | 0.76 | ||||||

| GSD6 | 0.52 | ||||||

| GSD7 | 0.73 | ||||||

| GSD8 | 0.53 | ||||||

| GSD10 | 0.63 | ||||||

| GSD11 | 0.76 | ||||||

| Green Supplier Collaboration (GSC) | GSC1 | 0.72 | 14.43% | 0.80 | 0.81 | 0.46 | |

| GSC5 | 0.74 | ||||||

| GSC11 | 0.55 | ||||||

| GSC12 | 0.68 | ||||||

| GSC14 | 0.60 | ||||||

| Green Supplier Evaluation (GSE) | GSE1 | 0.93 | 11.24% | 0.87 | 0.89 | 0.73 | |

| GSE3 | 0.94 | ||||||

| GSE7 | 0.72 | ||||||

| Total AV | 63.46% | Goodness of Fit Index | |||||

| KMO | 0.94 | CMIN | 492.830 | CFI | 0.95 | ||

| Bartlett’s Test of Sphericity | DF | 203 | GFI | 0.91 | |||

| Chi-square | 5638.863 | CMIN/DF | 2.428 | AGFI | 0.89 | ||

| Degrees of Freedom (df) | 231 | P | 0.000 * | NFI | 0.91 | ||

| Significance (Sig.) | 0.000 * | RMSEA | 0.056 | ||||

| Factors | EFA | CFA | |||||

|---|---|---|---|---|---|---|---|

| Item | Std. Loads | AV | α | CR | AVE | ||

| Company Performance | 0.93 | 0.94 | 0.60 | ||||

| Environmental Performance (EP) | EP1 | 0.73 | 37.33% | 0.90 | 0.90 | 0.60 | |

| EP2 | 0.74 | ||||||

| EP3 | 0.81 | ||||||

| EP4 | 0.79 | ||||||

| EP5 | 0.74 | ||||||

| EP6 | 0.70 | ||||||

| Financial Performance (FP) | FP1 | 0.81 | 30.79% | 0.88 | 0.89 | 0.61 | |

| FP2 | 0.84 | ||||||

| FP3 | 0.79 | ||||||

| FP4 | 0.67 | ||||||

| FP5 | 0.57 | ||||||

| Total AV | 68.12% | Goodness of Fit Index | |||||

| KMO | 0.93 | CMIN | 158.520 | CFI | 0.96 | ||

| Bartlett’s Test of Sphericity | DF | 41 | GFI | 0.94 | |||

| Chi-square | 3236.520 | CMIN/DF | 3.866 | AGFI | 0.90 | ||

| Degrees of Freedom (df) | 55 | P | 0.000 * | NFI | 0.95 | ||

| Significance (Sig.) | 0.000 * | RMSEA | 0.079 | ||||

| Factors | GSS | GSD | GSC | GSE | EP | FP | Mean | SD |

|---|---|---|---|---|---|---|---|---|

| GSS | 0.74 | 3.97 | 0.69330 | |||||

| GSD | 0.73 * | 0.73 | 3.83 | 0.72375 | ||||

| GSC | 0.67 * | 0.61 * | 0.68 | 3.96 | 0.63460 | |||

| GSE | 0.24 * | 0.22 * | 0.34 * | 0.85 | 4.06 | 0.75599 | ||

| EP | 0.68 * | 0.52 * | 0.66 * | 0.28 * | 0.77 | 3.85 | 0.89972 | |

| FP | 0.68 * | 0.59 * | 0.60 * | 0.31 * | 0.75 * | 0.78 | 3.82 | 0.92415 |

| GPP | 0.68 * | 0.70 * | 3.96 | 0.54074 | ||||

| Hypotheses | Model Summary | ANOVA | Coefficients | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R2 | Sig. | F | B | Std. Error | β | T | p | Tolerance | VIF | |

| H1 | 0.464 | 0.000 * | 392.258 | 1.133 | 0.06 | 0.68 | 19.805 | 0.000 * | 1.000 | 1.000 |

| H1a | 0.542 | 0.000 * | 133.164 | 0.62 | 0.07 | 0.48 | 9.262 | 0.000 * | 0.39 | 2.582 |

| H1b | −0.07 | 0.06 | −0.06 | −1.242 | 0.215 | 0.44 | 2.283 | |||

| H1c | 0.51 | 0.07 | 0.36 | 7.809 | 0.000 * | 0.49 | 2.044 | |||

| H1d | 0.07 | 0.04 | 0.06 | 1.626 | 0.105 | 0.89 | 1.129 | |||

| H2 | 0.495 | 0.000 * | 444.374 | 1.203 | 0.06 | 0.70 | 21.080 | 0.000 * | 1.000 | 1.000 |

| H2a | 0.523 | 0.000 * | 123.404 | 0.56 | 0.07 | 0.42 | 7.981 | 0.000 * | 0.39 | 2.582 |

| H2b | 0.18 | 0.06 | 0.14 | 2.825 | 0.005 * | 0.44 | 2.283 | |||

| H2c | 0.29 | 0.07 | 0.20 | 4.231 | 0.000 * | 0.49 | 2.044 | |||

| H2d | 0.15 | 0.04 | 0.12 | 3.499 | 0.000 * | 0.89 | 1.129 | |||

| H3 | 0.556 | 0.000 * | 568.216 | 0.77 | 0.03 | 0.75 | 23.837 | 0.000 * | 1.000 | 1.000 |

| Hypotheses | Results |

|---|---|

| H1, GPP→EP, β = 0.68, p < 0.01 | Partially Supported |

| Supported |

| Not Supported |

| Supported |

| Not Supported |

| H2, GPP→FP, β = 0.70, p < 0.01 | Supported |

| Supported |

| Supported |

| Supported |

| Supported |

| H3, EP→FP, β = 0.75, p < 0.01 | Supported |

| H4, GPP→EP→FP | Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balin, A.I.; Sari, K. The Effect of Green Purchasing Practices on Financial Performance under the Mediating Role of Environmental Performance: Evidence from Türkiye. Sustainability 2023, 15, 3617. https://doi.org/10.3390/su15043617

Balin AI, Sari K. The Effect of Green Purchasing Practices on Financial Performance under the Mediating Role of Environmental Performance: Evidence from Türkiye. Sustainability. 2023; 15(4):3617. https://doi.org/10.3390/su15043617

Chicago/Turabian StyleBalin, Ali Ibrahim, and Kazim Sari. 2023. "The Effect of Green Purchasing Practices on Financial Performance under the Mediating Role of Environmental Performance: Evidence from Türkiye" Sustainability 15, no. 4: 3617. https://doi.org/10.3390/su15043617

APA StyleBalin, A. I., & Sari, K. (2023). The Effect of Green Purchasing Practices on Financial Performance under the Mediating Role of Environmental Performance: Evidence from Türkiye. Sustainability, 15(4), 3617. https://doi.org/10.3390/su15043617