A Novel Integrated q-Rung Fuzzy Framework for Biomass Location Selection with No Apriori Weight Choices

Abstract

1. Introduction

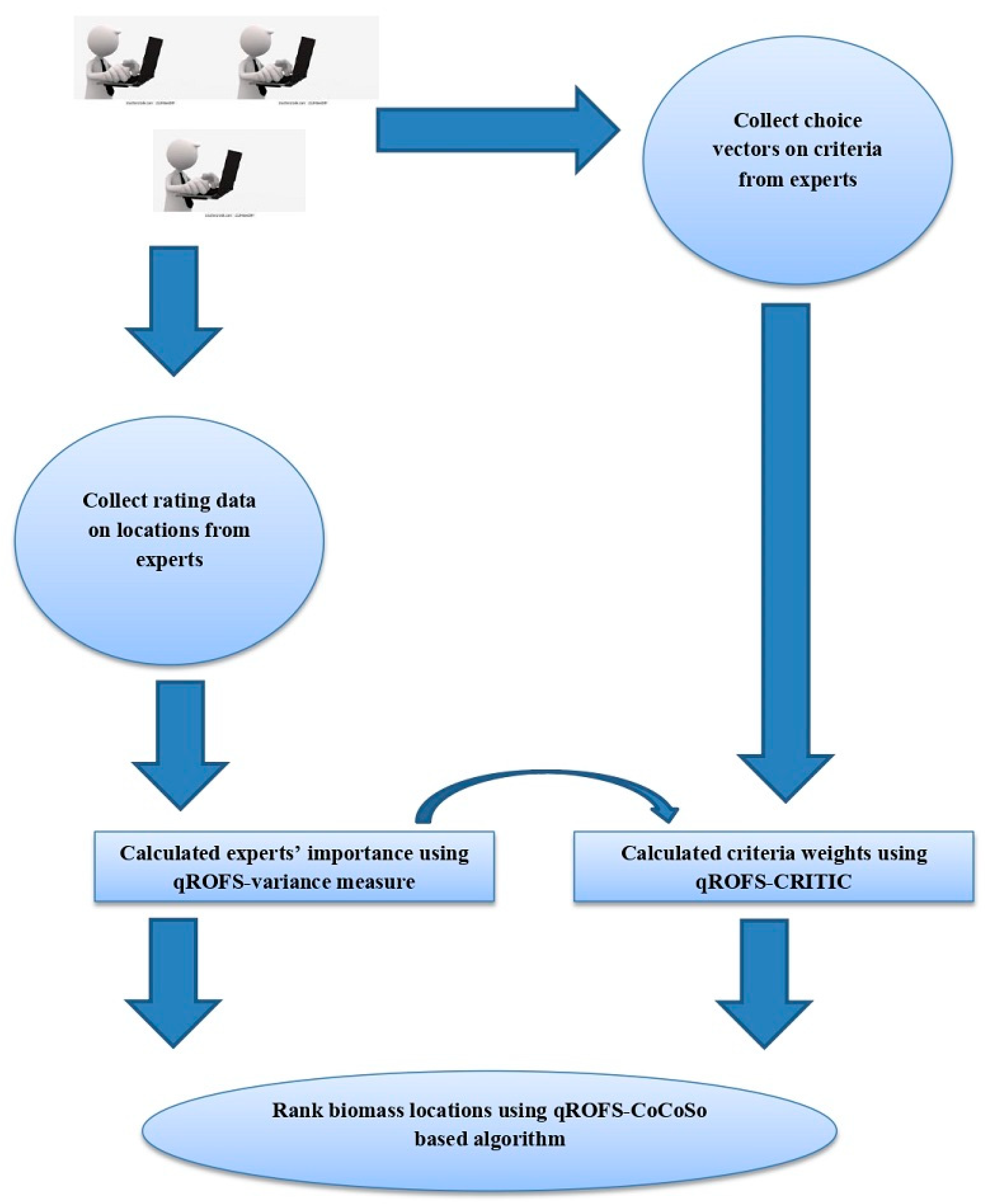

- The q-Rung fuzzy data method is considered for rating locations and criteria, which offers experts a flexible window for expressing their opinions in terms of membership, nonmembership, and hesitancy. By adjusting the factor , the opinion window can be expanded or shrunk.

- Importance of experts is methodically determined via a variance approach that not only considers variability distribution in preferences but also captures the hesitation of experts during the rating process.

- Furthermore, weights of criteria are calculated based on a procedure devised with criteria importance through intercriteria correlation (CRITIC) formulation so that the interaction of criteria and the importance of experts are considered effective.

- Finally, a ranking procedure is developed based on the combined compromise solution (CoCoSo) approach that considers multiple compromise solutions forms and criteria types during the rank assessment.

2. Literature Review

2.1. Biomass Location Selection

2.2. q-Rung Orthopair Fuzzy Models for MCDM

2.3. Insights

3. Methodology

3.1. Preliminaries

3.2. Weights of Experts and Criteria

3.3. Ranking Algorithm

4. Case Example

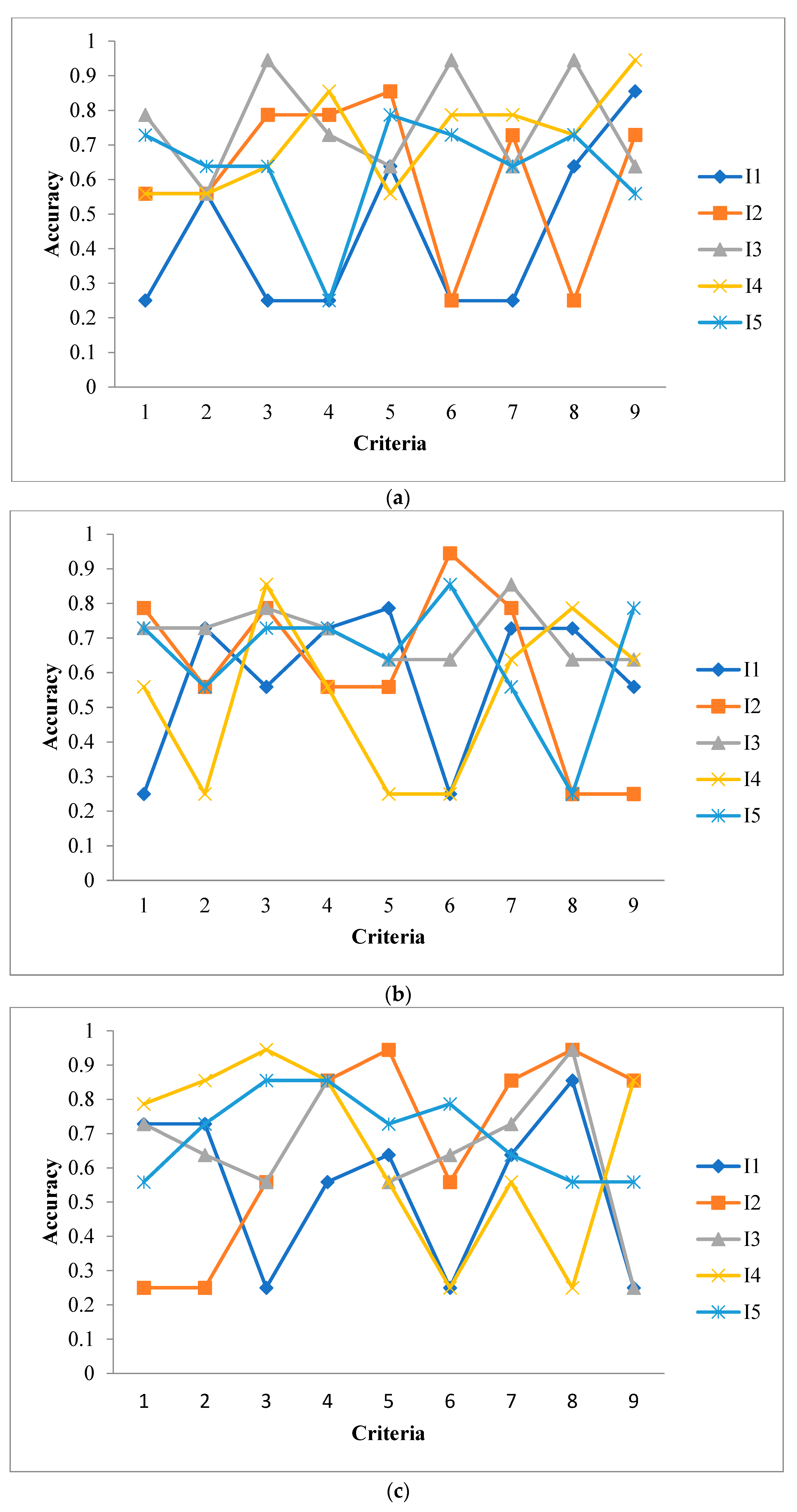

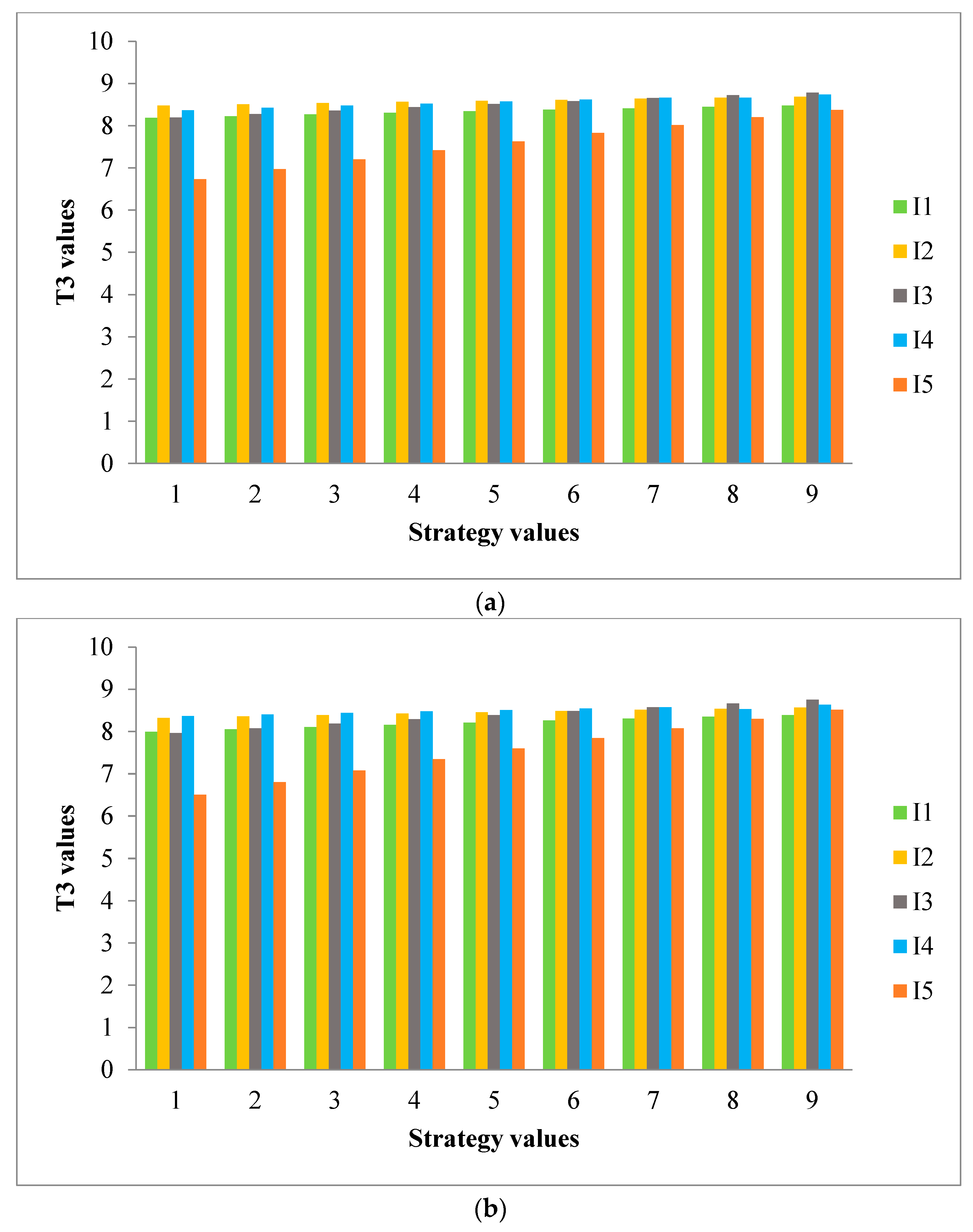

5. Sensitivity Analysis and Comparative Discussion

- q-ROFN is the preferred style utilized by the framework to ease the process of preference elicitation and offer flexibility to experts to express their opinions in three degrees viz. membership, hesitancy, and nonmembership. Initially, a qualitative Likert scale rating is obtained from the expert team, which is later converted to the respective q-ROFNs with the view of mitigating subjective randomness. Unlike the other models, the proposed model could handle uncertainty effectively with the help of the factor , which enables the broadening and shrinking of the preference window as required, and also model uncertainty from three dimensions, which is lacking in other extant models.

- Further, the developed model reduces human intervention by methodically calculating parameters such as weights of experts, weights of criteria, and rank values of alternative locations, which minimizes the inaccuracies, subjectivity, and biases in the decision process.

- Additionally, compared to the extant models, in the proposed model, criteria interactions are captured effectively along with the variability in the distribution of preferences, which mimics the hesitancy behavior of experts in the decision process. Such features enable the rational selection of locations for biomass production compared to the counter models.

- The developed ranking algorithm considers both experts’ and criteria’s weights in its formulation, which is lacking in earlier models. Additionally, the formulation determines multiple compromise solutions via the sum, minimum, and maximum operation forms, which are combined to obtain the net rank values of alternative locations. The formulation is simple and elegant, with a close resemblance to human-driven decision-making that tries to identify solutions with the maximum gain in the solution space by considering alternatives with the maximum utility value that are determined from the scalar multiplied form and the power functions of the rating information.

- Unlike the extant biomass location selection models, the current model reduces human intervention by calculating decision parameters methodically, which supports a reduction in inaccuracies, biases, and subjectivity.

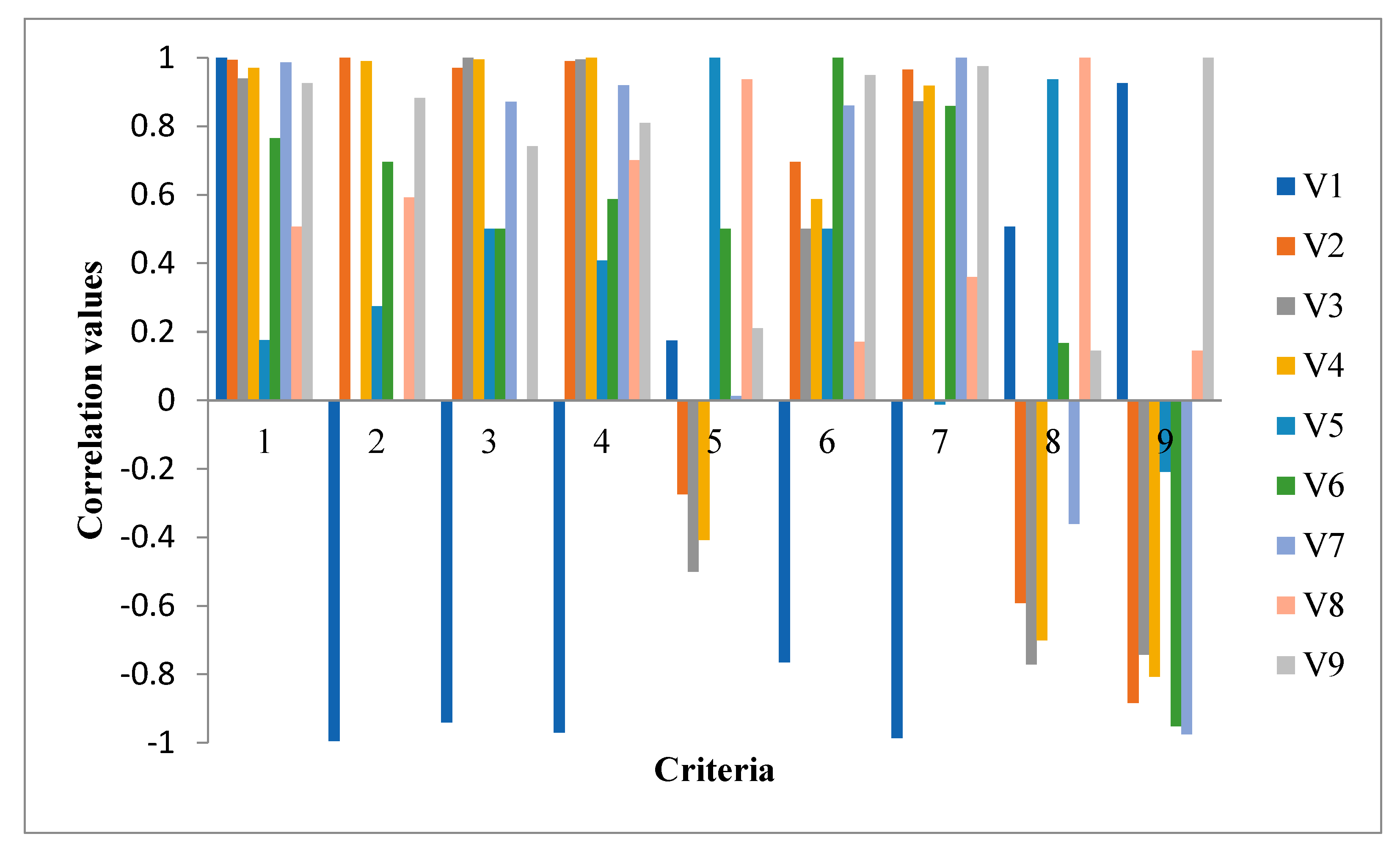

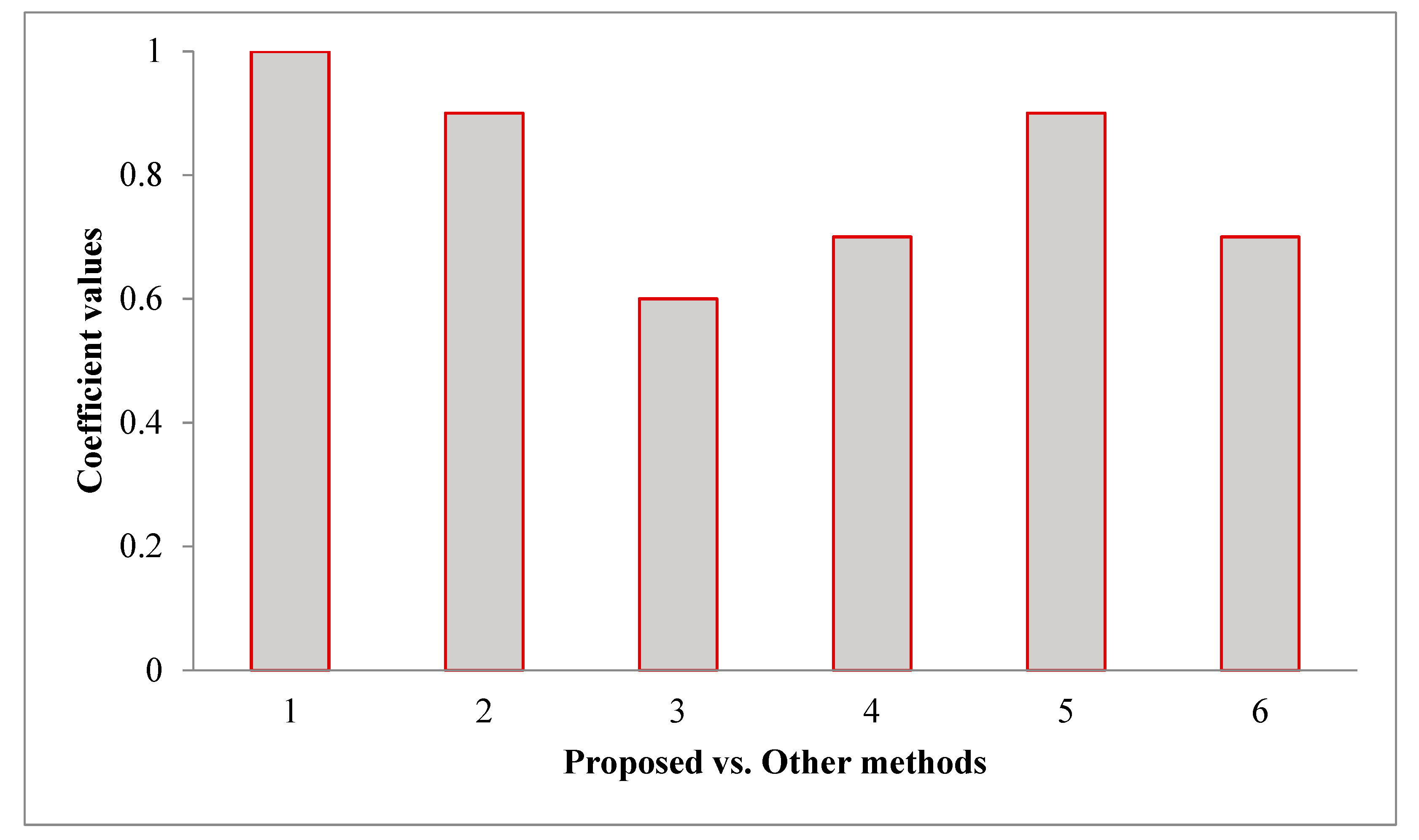

- Along with the efficacy from the application aspect, we would like to extend the experiment to the methodical aspect as well. For this purpose, recent and relevant q-ROFN-based decision models such as those by Peng et al. [34], Wang et al. [22], Xin et al. [39], Zolfani et al. [35], and Mishra and Rani [33] are compared with the proposed model to realize the consistency effect of the proposed work with other methods. Rank vectors from each method are given to the Spearman correlation method to determine the correlation coefficient, and based on the experiment, we obtained values as 1.0, 0.90, 0.60, 0.70, 0.90, and 0.70, respectively (refer to Figure 5). Hence, it is observed that the proposed model is fairly consistent with the existing models and can rationally order alternative locations.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Meaning |

| Membership grade | |

| Nonmembership grade | |

| Window parameter | |

| Indeterminacy degree | |

| Scalar factor | |

| Number of experts | |

| Number of locations for biomass | |

| Number of criteria | |

| Index for locations | |

| Index for criteria | |

| Index for experts | |

| Variance value | |

| q-Rung orthopair fuzzy number | |

| Expert weight | |

| Correlation measure between and | |

| Weight of criteria | |

| Sum operation | |

| Minimum operation | |

| Maximum operation | |

| Net rank value |

References

- Owen, G. What makes climate change adaptation effective? A systematic review of the literature. Glob. Environ. Chang. 2020, 62, 102071. [Google Scholar] [CrossRef]

- Pandve, H. Global initiatives to prevent climate change. Indian J. Occup. Environ. Med. 2008, 12, 96–97. [Google Scholar] [CrossRef] [PubMed]

- Poizot, P.; Dolhem, F. Clean energy new deal for a sustainable world: From non-CO2 generating energy sources to greener electrochemical storage devices. Energy Environ. Sci. 2011, 4, 2003–2019. [Google Scholar] [CrossRef]

- Behera, B.; Jeetendra, A.; Ali, A. Household collection and use of biomass energy sources in South Asia. Energy 2015, 85, 468–480. [Google Scholar] [CrossRef]

- Nansaior, A.; Patanothai, A.; Rambo, A.T.; Simaraks, S. Climbing the energy ladder or diversifying energy sources? The continuing importance of household use of biomass energy in urbanizing communities in Northeast Thailand. Biomass Bioenergy 2011, 35, 4180–4418. [Google Scholar] [CrossRef]

- Kim, K.H.; Jahan, S.A.; Kabir, E. A review of diseases associated with household air pollution due to the use of biomass fuels. J. Hazard. Mater. 2011, 192, 425–431. [Google Scholar] [CrossRef]

- Jeong, J.S.; Ramírez-Gómez, A. Optimizing the location of a biomass plant with a fuzzy-DEcision-MAking Trial and Evaluation Laboratory (F-DEMATEL) and multi-criteria spatial decision assessment for renewable energy management and long-term sustainability. J. Clean. Prod. 2018, 182, 509–520. [Google Scholar] [CrossRef]

- Hamdy, A.; Abd Elhafez, S.; Hamad, H.; Ali, R. The interplay of autoclaving with oxalate as pretreatment technique in the view of bioethanol production based on corn stover. Polymers 2021, 13, 3762. [Google Scholar] [CrossRef] [PubMed]

- Morales, J.Y.R.; López, G.L.; Martínez, V.M.A.; Vázquez, F.D.J.S.; Mendoza, J.A.B.; García, M.M. Parametric study and control of a pressure swing adsorption process to separate the water-ethanol mixture under disturbances. Sep. Purif. Technol. 2020, 236, 116214. [Google Scholar] [CrossRef]

- Torres Cantero, C.A.; Lopez Lopez, G.; Alvarado, V.M.; Escobar Jimenez, R.F.; Rumbo Morales, J.Y.; Sanchez Coronado, E.M. Control structures evaluation for a salt extractive distillation pilot plant: Application to bio-ethanol dehydration. Energies 2017, 10, 1276. [Google Scholar] [CrossRef]

- Rumbo Morales, J.Y.; Perez Vidal, A.F.; Ortiz Torres, G.; Salas Villalobo, A.U.; Sorcia Vázquez, F.D.J.; Brizuela Mendoza, J.A.; Torres, G.O.; Sorcia Vázquez, F.d.J.; Rojas, A.C.; Valdez Martínez, J.S. Adsorption and Separation of the H2O/H2SO4 and H2O/C2H5 OH Mixtures: A Simulated and Experimental Study. Processes 2020, 8, 290. [Google Scholar] [CrossRef]

- Bojić, S.; Đatkov, Đ.; Brcanov, D.; Georgijević, M.; Martinov, M. Location allocation of solid biomass power plants: Case study of Vojvodina. Renew. Sustain. Energy Rev. 2013, 26, 769–775. [Google Scholar] [CrossRef]

- Zhao, X.; Li, A. A multi-objective sustainable location model for biomass power plants: Case of China. Energy 2016, 112, 1184–1193. [Google Scholar] [CrossRef]

- Cebi, S.; Ilbahar, E.; Atasoy, A. A fuzzy information axiom based method to determine the optimal location for a biomass power plant: A case study in Aegean Region of Turkey. Energy 2016, 116, 894–907. [Google Scholar] [CrossRef]

- Jayarathna, L.; Kent, G.; O’Hara, I.; Hobson, P. A Geographical Information System based framework to identify optimal location and size of biomass energy plants using single or multiple biomass types. Appl. Energy 2020, 275, 115398. [Google Scholar] [CrossRef]

- Guler, D.; Charisoulis, G.; Buttenfield, B.P.; Yomralioglu, T. Suitability modeling and sensitivity analysis for biomass energy facilities in Turkey. Clean Technol. Environ. Policy 2021, 23, 2183–2199. [Google Scholar] [CrossRef]

- Middelhoff, E.; Madden, B.; Ximenes, F.; Carney, C.; Florin, N. Assessing electricity generation potential and identifying possible locations for siting hybrid concentrated solar biomass (HCSB) plants in New South Wales (NSW), Australia. Appl. Energy 2022, 305, 117942. [Google Scholar] [CrossRef]

- Atici, U.; Gürcan, Ö.F.; Güldeş, M.; Şahin, C. A Fuzzy Multi-Criteria Decision-Making Method for Selection of Biomass Power Plant Location. In Optimization and Decision-Making in the Renewable Energy Industry; IGI Global: Hershey, PA, USA, 2022; pp. 1–30. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, H.; Huang, Z.; Sun, Q. Location mapping for constructing biomass power plant using multi-criteria decision-making method. Sustain. Energy Technol. Assess. 2022, 49, 101707. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Z.; Wang, Z.; Wang, C.; Zhang, R.; Xu, G.; Wu, X. Macro-site selection and obstacle factor extraction of biomass cogeneration based on comprehensive weight method of Game theory. Energy Rep. 2022, 8, 14416–14427. [Google Scholar] [CrossRef]

- Afkhami, P.; Zarrinpoor, N. Location Assessment of Jatropha Cultivation for Biofuel Production in Fars Province, Iran: A Hybrid GIS-Based Fuzzy Multi-criteria Framework. Waste Biomass Valorization 2022, 13, 4511–4532. [Google Scholar] [CrossRef]

- Kengpol, A.; Rontlaong, P.; Elfvengren, K. Sustainable Assessment for Biomass Power Plant Location during the COVID-19 Pandemic. Ind. Eng. Manag. Syst. 2022, 21, 20–42. [Google Scholar] [CrossRef]

- Da Silva Romero, C.W.; Miyazaki, M.R.; Berni, M.D.; Figueiredo, G.K.D.A.; Lamparelli, R.A.C. A spatial approach for integrating GIS and fuzzy logic in multicriteria problem solving to support the definition of ideal areas for biorefinery deployment. J. Clean. Prod. 2023, 390, 135886. [Google Scholar] [CrossRef]

- Atanassov, K.T. Intuitionistic fuzzy sets. Fuzzy Sets Syst. 1986, 20, 87–96. [Google Scholar] [CrossRef]

- Yager, R.R. Pythagorean membership grades in multicriteria decision making. IEEE Trans. Fuzzy Syst. 2014, 22, 958–965. [Google Scholar] [CrossRef]

- Alipour, M.; Hafezi, R.; Rani, P.; Hafezi, M.; Mardani, A. A new Pythagorean fuzzy-based decision-making method through entropy measure for fuel cell and hydrogen components supplier selection. Energy 2021, 234, 121208. [Google Scholar] [CrossRef]

- Yager, R.R. Generalized Orthopair Fuzzy Sets. IEEE Trans. Fuzzy Syst. 2017, 25, 1222–1230. [Google Scholar] [CrossRef]

- Garg, H.; Chen, S.-M. Multiattribute group decision making based on neutrality aggregation operators of q-rung orthopair fuzzy sets. Inf. Sci. 2022, 517, 427–447. [Google Scholar] [CrossRef]

- Seikh, M.R.; Mandal, U. q-rung orthopair fuzzy Frank aggregation operators and its application in multiple attribute decision-making with unknown attribute weights. Granul. Comput. 2021, 7, 709–730. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, R.; Zhu, X.; Zhou, Z.; Shang, X.; Li, W. Some q-rung orthopair fuzzy Muirhead means with their application to multi-attribute group decision making. J. Intell. Fuzzy Syst. 2019, 36, 1599–1614. [Google Scholar] [CrossRef]

- Kumar, K.; Chen, S.-M. Group decision making based on q-rung orthopair fuzzy weighted averaging aggregation operator of q-rung orthopair fuzzy numbers. Inf. Sci. 2022, 598, 1–18. [Google Scholar] [CrossRef]

- Kakati, P.; Rahman, S. The q-rung orthopair fuzzy hamacher generalized shapley choquet integral operator and its application to multiattribute decision making. EURO J. Decis. Process. 2022, 10, 100012. [Google Scholar] [CrossRef]

- Peng, X.; Krishankumar, R.; Ravichandran, K.S. Generalized orthopair fuzzy weighted distance-based approximation (WDBA) algorithm in emergency decision-making. Int. J. Intell. Syst. 2019, 34, 2364–2402. [Google Scholar] [CrossRef]

- Yin, S.; Wang, Y.; Shafiee, S. Ranking products through online reviews considering the mass assignment of features based on BERT and q-rung orthopair fuzzy set theory. Expert Syst. Appl. 2023, 213, 119142. [Google Scholar] [CrossRef]

- Krishankumar, R.; Gowtham, Y.; Ahmed, I.; Ravichandran, K.S.; Kar, S. Solving green supplier selection problem using q-rung orthopair fuzzy-based decision framework with unknown weight information. Appl. Soft Comput. 2020, 94, 106431. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P.; Saha, A.; Pamucar, D.; Hezam, I.M. A q-rung orthopair fuzzy combined compromise solution approach for selecting sustainable third-party reverse logistics provider. Manag. Decis. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Krishankumar, R.; Nimmagadda, S.S.; Rani, P.; Mishra, A.R.; Ravichandran, K.S.; Gandomi, A.H. Solving renewable energy source selection problems using a q-rung orthopair fuzzy-based integrated decision-making approach. J. Clean. Prod. 2021, 279, 123329. [Google Scholar] [CrossRef]

- Tang, G.; Yang, Y.; Gu, X.; Chiclana, F.; Liu, P.; Wang, F. A new integrated multi-attribute decision-making approach for mobile medical app evaluation under q-rung orthopair fuzzy environment. Expert Syst. Appl. 2022, 200, 117034. [Google Scholar] [CrossRef]

- Yang, Z.; Shang, W.-L.; Zhang, H.; Garg, H.; Han, C. Assessing the green distribution transformer manufacturing process using a cloud-based q-rung orthopair fuzzy multi-criteria framework. Appl. Energy 2022, 311, 118687. [Google Scholar] [CrossRef]

- Fetanat, A.; Tayebi, M. Industrial filtration technologies selection for contamination control in natural gas processing plants: A sustainability and maintainability-based decision support system under q-rung orthopair fuzzy set. Process Saf. Environ. Prot. 2023, 170, 310–327. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P. A q-rung orthopair fuzzy ARAS method based on entropy and discrimination measures: An application of sustainable recycling partner selection. J. Ambient. Intell. Humaniz. Comput. 2021, 1–22. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P.; Pamucar, D.; Hezam, I.M.; Saha, A. Entropy and discrimination measures based q-rung orthopair fuzzy MULTIMOORA framework for selecting solid waste disposal method. Environ. Sci. Pollut. Res. 2022, 30, 12988–13011. [Google Scholar] [CrossRef] [PubMed]

- Zolfani, S.H.; Krishankumar, R.; Pamucar, D.; Görçün, Ö.F. The potentials of the Southern & Eastern European countries in the process of the regionalization of the global supply chains using a q-rung orthopair fuzzy-based integrated decision-making approach. Comput. Ind. Eng. 2022, 171, 108405. [Google Scholar]

- Deveci, M.; Pamucar, D.; Gokasar, I.; Köppen, M.; Gupta, B.B. Personal mobility in metaverse with autonomous vehicles using Q-rung orthopair fuzzy sets based OPA-RAFSI model. IEEE Trans. Intell. Transp. Syst. 2022, 1–10. [Google Scholar] [CrossRef]

- Krishankumar, R.; Mishra, A.R.; Rani, P.; Zavadskas, E.K.; Ravichandran, K.S.; Kar, S. A new decision model with integrated approach for healthcare waste treatment technology selection with generalized orthopair fuzzy information. Inf. Sci. 2022, 610, 1010–1028. [Google Scholar] [CrossRef]

- Zhang, C.; Bai, W.; Li, D.; Zhan, J. Multiple attribute group decision making based on multigranulation probabilistic models, MULTIMOORA and TPOP in incomplete q-rung orthopair fuzzy information systems. Int. J. Approx. Reason. 2022, 143, 102–120. [Google Scholar] [CrossRef]

- Xin, L.; Lang, S.; Mishra, A.R. Evaluate the challenges of sustainable supply chain 4.0 implementation under the circular economy concept using new decision making approach. Oper. Manag. Res. 2022, 15, 773–792. [Google Scholar] [CrossRef]

- Krishankumar, R.; Ecer, F.; Mishra, A.R.; Ravichandran, K.S.; Gandomi, A.H.; Kar, S. A SWOT-based framework for personalized ranking of IoT service providers with generalized fuzzy data for sustainable transport in urban regions. IEEE Trans. Eng. Manag. 2022, 1–14. [Google Scholar] [CrossRef]

- Bai, L.; Garcia, F.J.S.; Mishra, A.R. Adoption of the sustainable circular supply chain under disruptions risk in manufacturing industry using an integrated fuzzy decision-making approach. Oper. Manag. Res. 2022, 15, 743–759. [Google Scholar] [CrossRef]

- Hu, Y.; Al-Barakati, A.; Rani, P. Investigating the Internet-of-Things (IoT) risks for supply chain management using q-rung orthopair fuzzy-SWARA-ARAS framework. Technol. Econ. Dev. Econ. 2022, 1–26. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Liu, W.; Ji, M.; Mishra, A.R. Critical success factors of blockchain technology to implement the sustainable supply chain using an extended decision-making approach. Technol. Forecast. Soc. Chang. 2022, 182, 121881. [Google Scholar] [CrossRef]

- Zhu, D.; Li, Z.; Mishra, A.R. Evaluation of the critical success factors of dynamic enterprise risk management in manufacturing SMEs using an integrated fuzzy decision-making model. Technol. Forecast. Soc. Chang. 2022, 186, 122137. [Google Scholar] [CrossRef]

- Yang, Z.; Ahmad, S.; Bernardi, A.; Shang, W.L.; Xuan, J.; Xu, B. Evaluating alternative low carbon fuel technologies using a stakeholder participation-based q-rung orthopair linguistic multi-criteria framework. Appl. Energy 2023, 332, 120492. [Google Scholar] [CrossRef]

- Kausar, R.; Farid, H.M.A.; Riaz, M.; Gonul Bilgin, N. Innovative CODAS Algorithm for q-Rung Orthopair Fuzzy Information and Cancer Risk Assessment. Symmetry 2023, 15, 205. [Google Scholar] [CrossRef]

- Krishankumar, R.; Ecer, F. Selection of IoT service provider for sustainable transport using q-rung orthopair fuzzy CRADIS and unknown weights. Appl. Soft Comput. 2023, 132, 109870. [Google Scholar] [CrossRef]

- Seker, S.; Bağlan, F.B.; Aydin, N.; Deveci, M.; Ding, W. Risk assessment approach for analyzing risk factors to overcome pandemic using interval-valued q-rung orthopair fuzzy decision making method. Appl. Soft Comput. 2023, 132, 109891. [Google Scholar] [CrossRef]

- Qiyas, M.; Abdullah, S.; Khan, N.; Naeem, M.; Khan, F.; Liu, Y. Case study for hospital-based Post-Acute Care-Cerebrovascular Disease using Sine Hyperbolic q-rung orthopair fuzzy Dombi aggregation operators. Expert Syst. Appl. 2023, 215, 119224. [Google Scholar] [CrossRef]

- Xu, Y. A two-stage multi-criteria decision-making method with interval-valued q-Rung Orthopair fuzzy technology for selecting bike-sharing recycling supplier. Eng. Appl. Artif. Intell. 2023, 119, 105827. [Google Scholar] [CrossRef]

- Kao, C. Weight determination for consistently ranking alternatives in multiple criteria decision analysis. Appl. Math. Model. 2010, 34, 1779–1787. [Google Scholar] [CrossRef]

- Koksalmis, E.; Kabak, Ö. Deriving decision makers’ weights in group decision making: An overview of objective methods. Inf. Fusion 2019, 49, 146–160. [Google Scholar] [CrossRef]

- Sivagami, R.; Krishankumar, R.; Sangeetha, V.; Ravichandran, K.S.; Kar, S.; Gandomi, A.H. Assessment of cloud vendors using interval-valued probabilistic linguistic information and unknown weights. Int. J. Intell. Syst. 2021, 36, 3813–3851. [Google Scholar] [CrossRef]

- Anbuudayasankar, S.P.; Srikanthan, R.; Karthik, M.; Nair, P.R.; Sivakarthik, N.; Indukumar, P. Cloud-based technology for small and medium scale enterprises: A decision-making paradigm using IPA, AHP and fuzzy-AHP techniques. Int. J. Integr. Supply Manag. 2020, 13, 335–352. [Google Scholar] [CrossRef]

- Gül, S. Fermatean fuzzy set extensions of SAW, ARAS, and VIKOR with applications in COVID-19 testing laboratory selection problem. Expert Syst. 2021, 38, e12769. [Google Scholar] [CrossRef]

- Omar, Y.M.; Plapper, P. A survey of information entropy metrics for complex networks. Entropy 2020, 22, 1417. [Google Scholar] [CrossRef]

- Rani, P.; Ali, J.; Krishankumar, R.; Mishra, A.R.; Cavallaro, F.; Ravichandran, K.S. An integrated single-valued neutrosophic combined compromise solution methodology for renewable energy resource selection problem. Energies 2021, 14, 4594. [Google Scholar] [CrossRef]

- Yazdani, M.; Zarate, P.; Zavadskas, E.K.; Turskis, Z. A Combined Compromise Solution (CoCoSo) method for multi-criteria decision-making problems. Manag. Decis. 2019, 57, 2501–2519. [Google Scholar] [CrossRef]

- Zeleny, M. A concept of compromise solutions and the method of the displaced ideal. Comput. Oper. Res. 1974, 1, 479–496. [Google Scholar] [CrossRef]

- Natarajan, K.; Latva-Käyrä, P.; Zyadin, A.; Chauhan, S.; Singh, H.; Pappinen, A.; Pelkonen, P. Biomass resource assessment and existing biomass use in the Madhya Pradesh, Maharashtra, and Tamil Nadu States of India. Challenges 2015, 6, 158–172. [Google Scholar] [CrossRef]

- Jayarathna, L.; Kent, G.; O’Hara, I.; Hobson, P. Geographical information system based fuzzy multi criteria analysis for sustainability assessment of biomass energy plant siting: A case study in Queensland, Australia. Land Use Policy 2022, 114, 105986. [Google Scholar] [CrossRef]

| Linguistic Variable | q-ROFN | Linguistic Variable | q-ROFN |

|---|---|---|---|

| Absolutely high (AH) | (0.9, 0.65) | Absolutely preferred (AP) | (0.9, 0.65) |

| Very high (VH) | (0.9, 0.6) | Very highly preferred (VMP) | (0.9, 0.6) |

| Moderately high (MH) | (0.8, 0.65) | Highly preferred (HP) | (0.8, 0.6) |

| High (H) | (0.75, 0.6) | Moderately preferred (MP) | (0.75, 0.6) |

| Moderate (M) | (0.5, 0.5) | Neutral (N) | (0.5, 0.5) |

| Low (L) | (0.6, 0.7) | Moderately less preferred (MLP) | (0.6, 0.7) |

| Moderately low (ML) | (0.7, 0.8) | Less preferred (LP) | (0.7, 0.8) |

| Very low | Very less preferred (VLP) | (0.65, 0.9) | |

| Absolutely low (AL) | (0.6, 0.9) | Extremely less preferred (ELP) | (0.6, 0.9) |

| M | L | M | M | H | M | M | H | ML | |

| L | L | MH | MH | ML | M | VH | M | AH | |

| MH | L | VL | AH | H | VL | H | VL | H | |

| L | L | H | ML | L | MH | MH | AH | VL | |

| VH | H | H | M | MH | AH | H | AH | L | |

| M | AH | L | VH | MH | M | VH | VH | L | |

| MH | L | MH | L | L | VL | MH | M | M | |

| AH | AH | MH | VH | H | H | ML | H | H | |

| L | M | ML | L | M | M | H | MH | H | |

| AH | L | AH | AH | H | ML | L | M | MH | |

| VH | VH | M | L | H | M | H | ML | M | |

| M | M | L | ML | VL | L | ML | VL | ML | |

| VH | H | L | ML | L | H | VH | VL | M | |

| MH | ML | VL | ML | L | M | L | M | ML | |

| L | VH | ML | ML | VH | MH | H | L | L | |

| HP | MLP | N | N | LP | LP | N | VMP | LP | |

| MP | AP | MP | HP | VMP | LP | MLP | N | HP | |

| MLP | HP | MP | LP | LP | VLP | LP | MLP | MP | |

| 1.806 | 26.018 | 8.343 | 19.375 | |

| 1.862 | 27.839 | 8.589 | 20.399 | |

| 1.845 | 28.004 | 8.513 | 20.389 | |

| 1.634 | 26.917 | 8.571 | 19.381 | |

| 18.814 | 7.628 | 15.526 |

| Context | Proposed | Jayarathna et al. [69] | Atici et al. [18] | Guler et al. [16] | Zhao et al. [19] | Jeong and Rameriz-Gomes [7] |

|---|---|---|---|---|---|---|

| Input | q-ROFN | Fuzzy | Fuzzy | Fuzzy | Fuzzy | Fuzzy |

| Preference flexibility | Yes | No | No | No | No | No |

| Weights of experts | Calculated | Not calculated | Not calculated | Not calculated | Not calculated | Not calculated |

| Criteria interactions | Considered | Not considered | Not considered | Not considered | Not considered | Not considered |

| Hesitation of experts | Considered | Not considered | Not considered | Not considered | Not considered | Not considered |

| Compromised solution | Yes | No | No | No | No | No |

| Consideration of weights | Both experts and criteria | Only criteria | Only criteria | Only criteria | Only criteria | Only criteria |

| Uncertainty | Modeled via three degrees | Modeled via single degree | Modeled via single degree | Modeled via single degree | Modeled via single degree | Modeled via single degree |

| Subjective randomness | Minimized adequately | Moderately minimized | Moderately minimized | Moderately minimized | Moderately minimized | Moderately minimized |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krishankumar, R.; Mishra, A.R.; Rani, P.; Cavallaro, F.; Ravichandran, K.S. A Novel Integrated q-Rung Fuzzy Framework for Biomass Location Selection with No Apriori Weight Choices. Sustainability 2023, 15, 3377. https://doi.org/10.3390/su15043377

Krishankumar R, Mishra AR, Rani P, Cavallaro F, Ravichandran KS. A Novel Integrated q-Rung Fuzzy Framework for Biomass Location Selection with No Apriori Weight Choices. Sustainability. 2023; 15(4):3377. https://doi.org/10.3390/su15043377

Chicago/Turabian StyleKrishankumar, Raghunathan, Arunodaya Raj Mishra, Pratibha Rani, Fausto Cavallaro, and Kattur Soundarapandian Ravichandran. 2023. "A Novel Integrated q-Rung Fuzzy Framework for Biomass Location Selection with No Apriori Weight Choices" Sustainability 15, no. 4: 3377. https://doi.org/10.3390/su15043377

APA StyleKrishankumar, R., Mishra, A. R., Rani, P., Cavallaro, F., & Ravichandran, K. S. (2023). A Novel Integrated q-Rung Fuzzy Framework for Biomass Location Selection with No Apriori Weight Choices. Sustainability, 15(4), 3377. https://doi.org/10.3390/su15043377