Effect of Mica Content on Mechanical Properties of Yili River Valley Loess under the Impact of Freezing and Thawing

Abstract

:1. Introduction

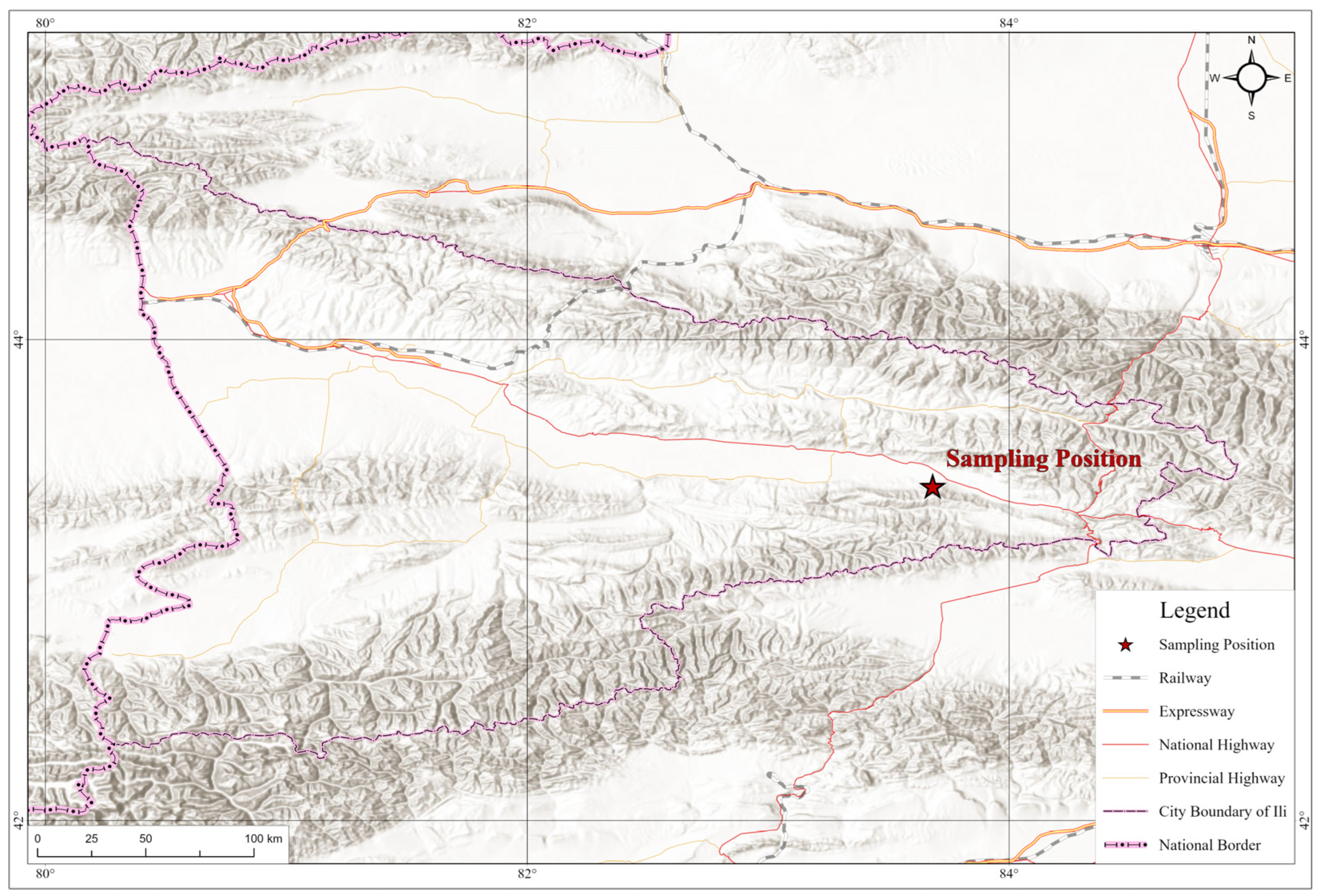

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Methods

2.3.1. Compaction Test

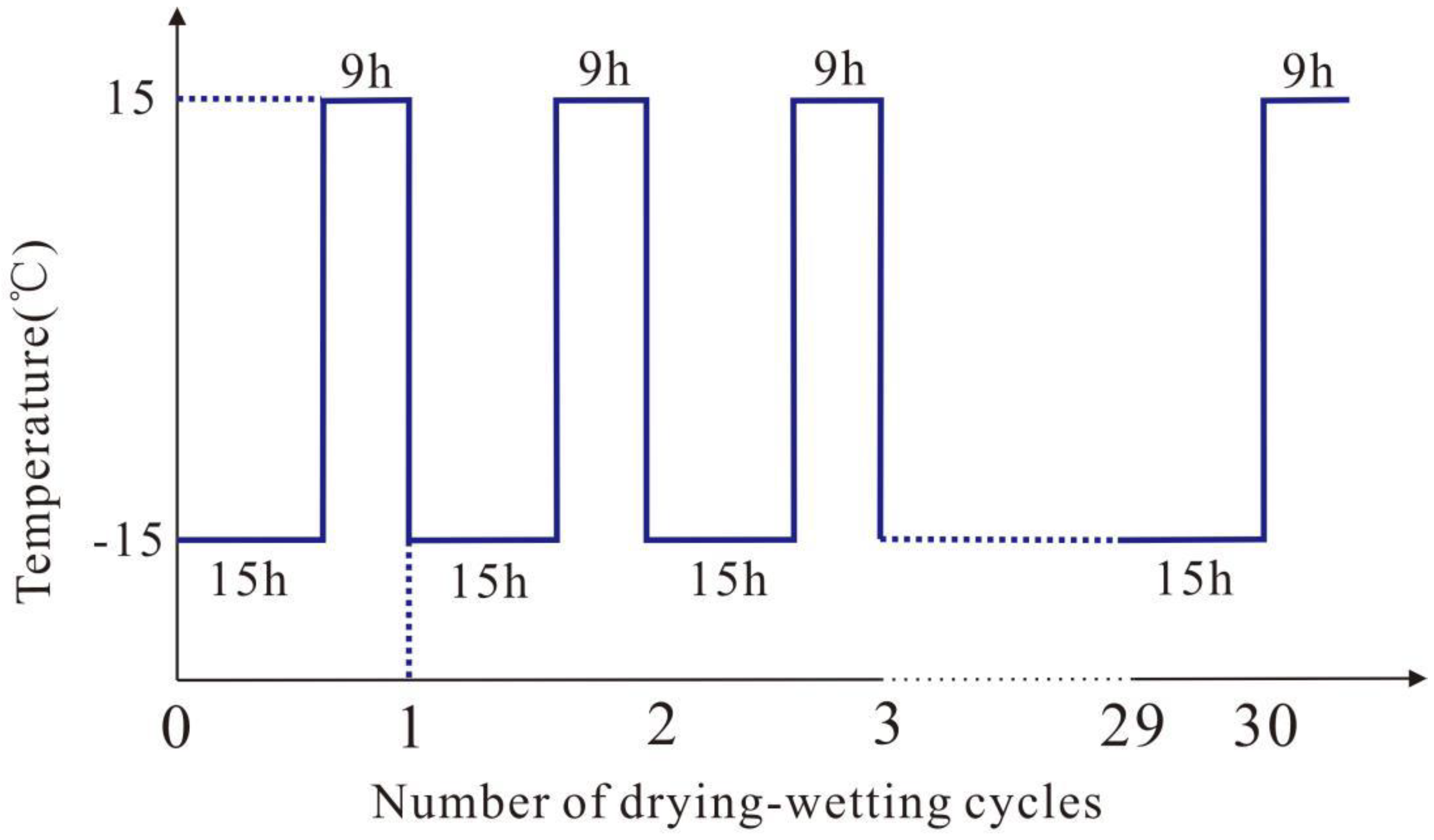

2.3.2. FTC Test

2.3.3. Triaxial Shear Test

3. Results

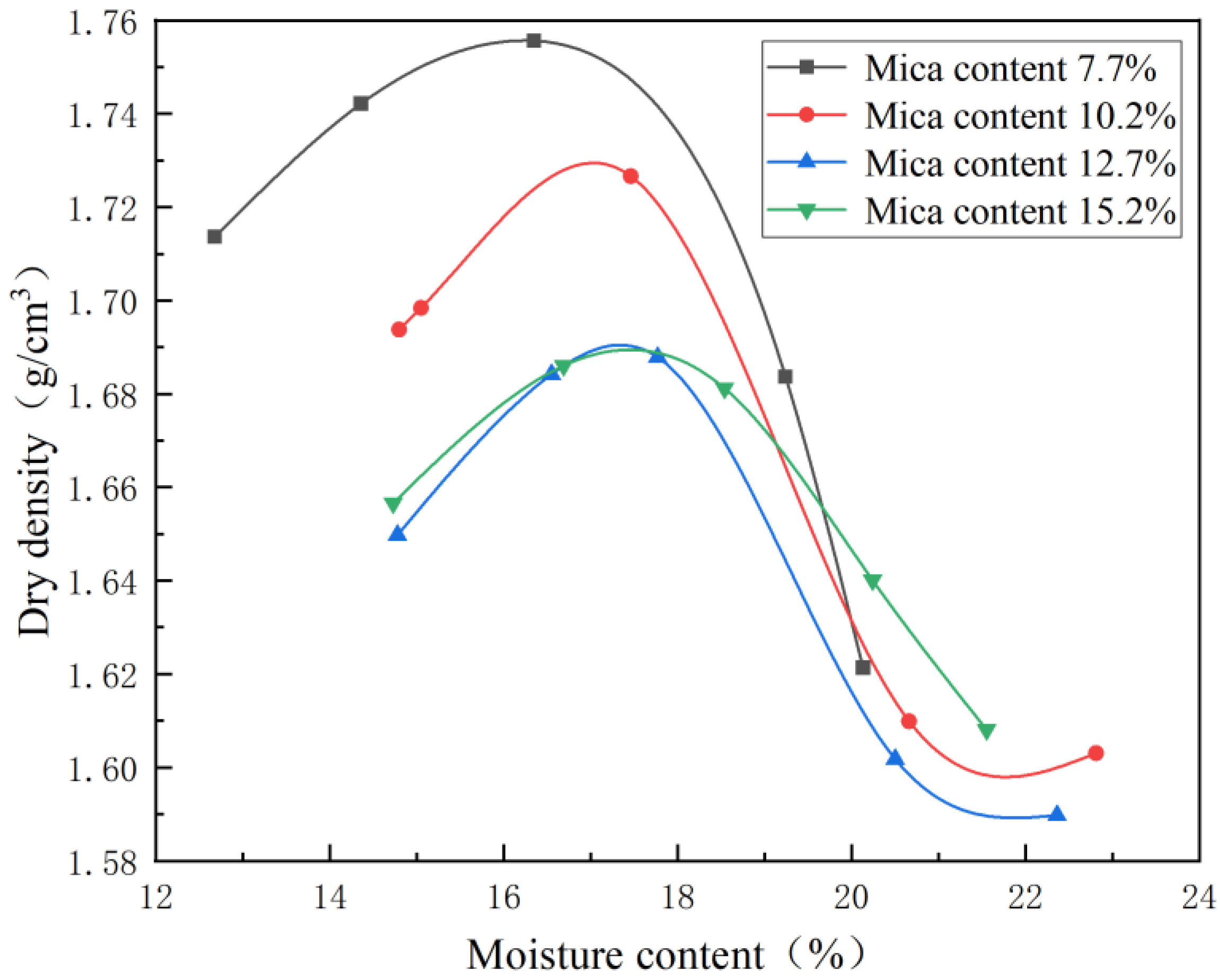

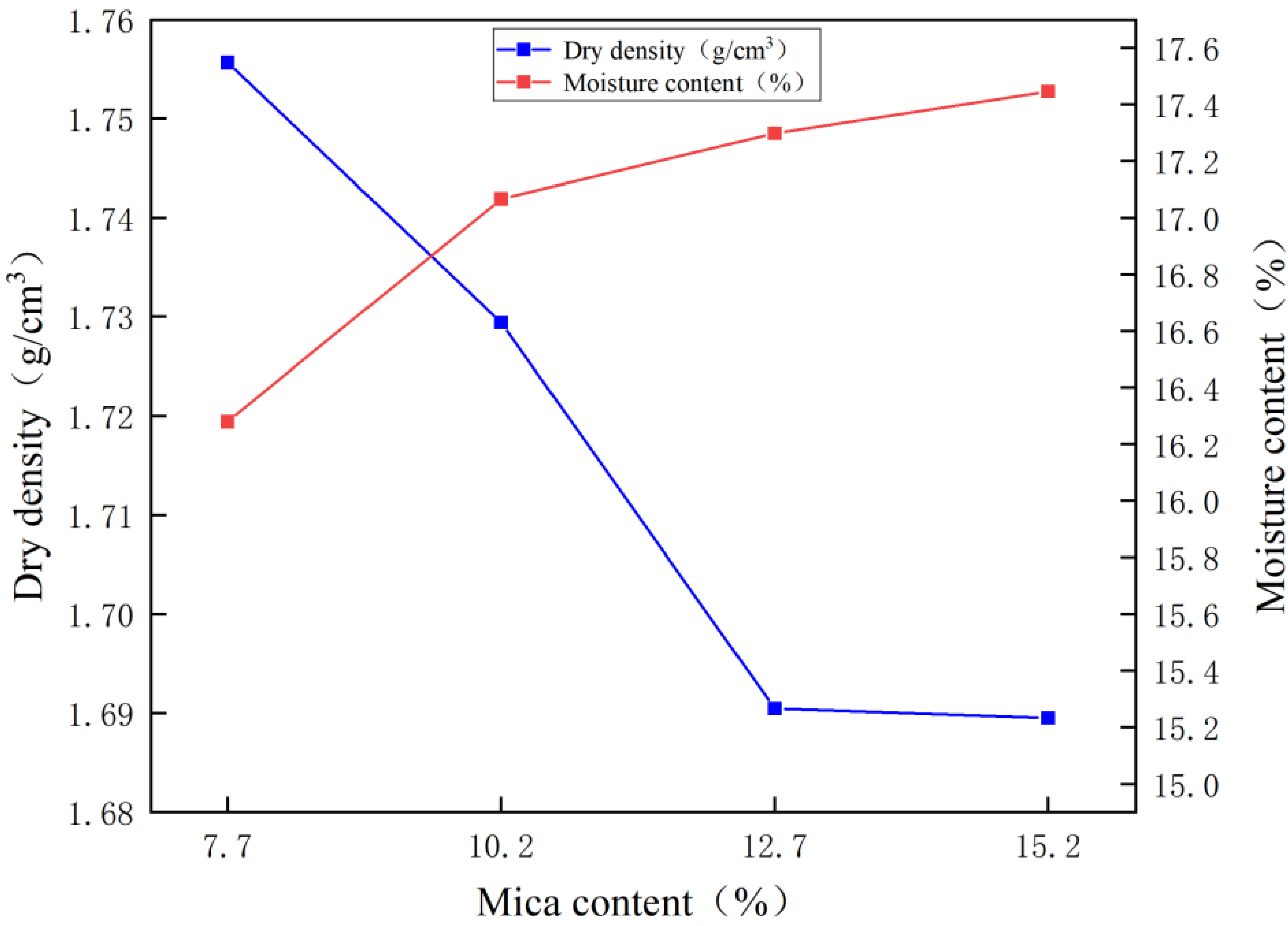

3.1. Compaction Characteristic Analysis

3.2. Triaxial Shear Test Results

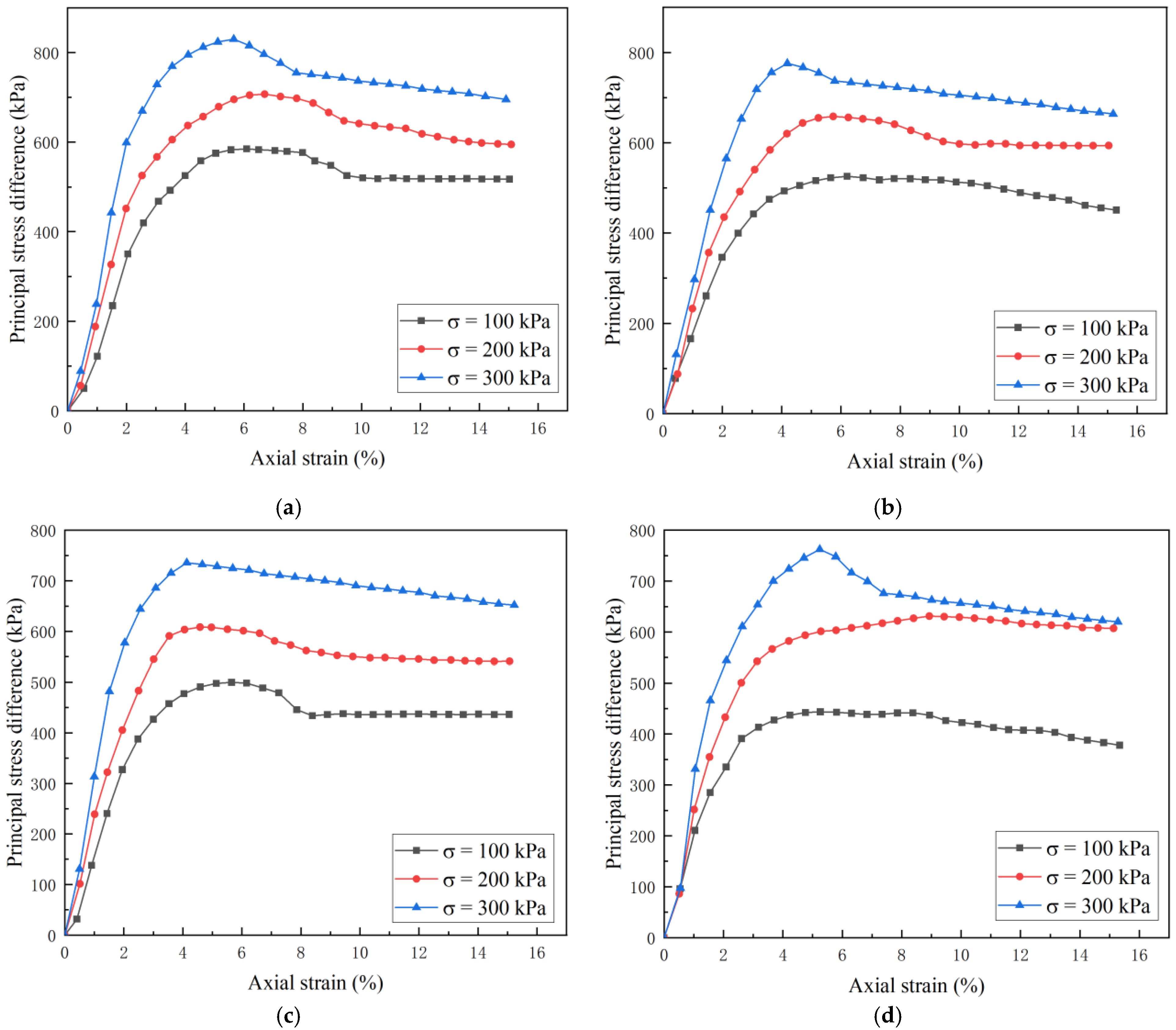

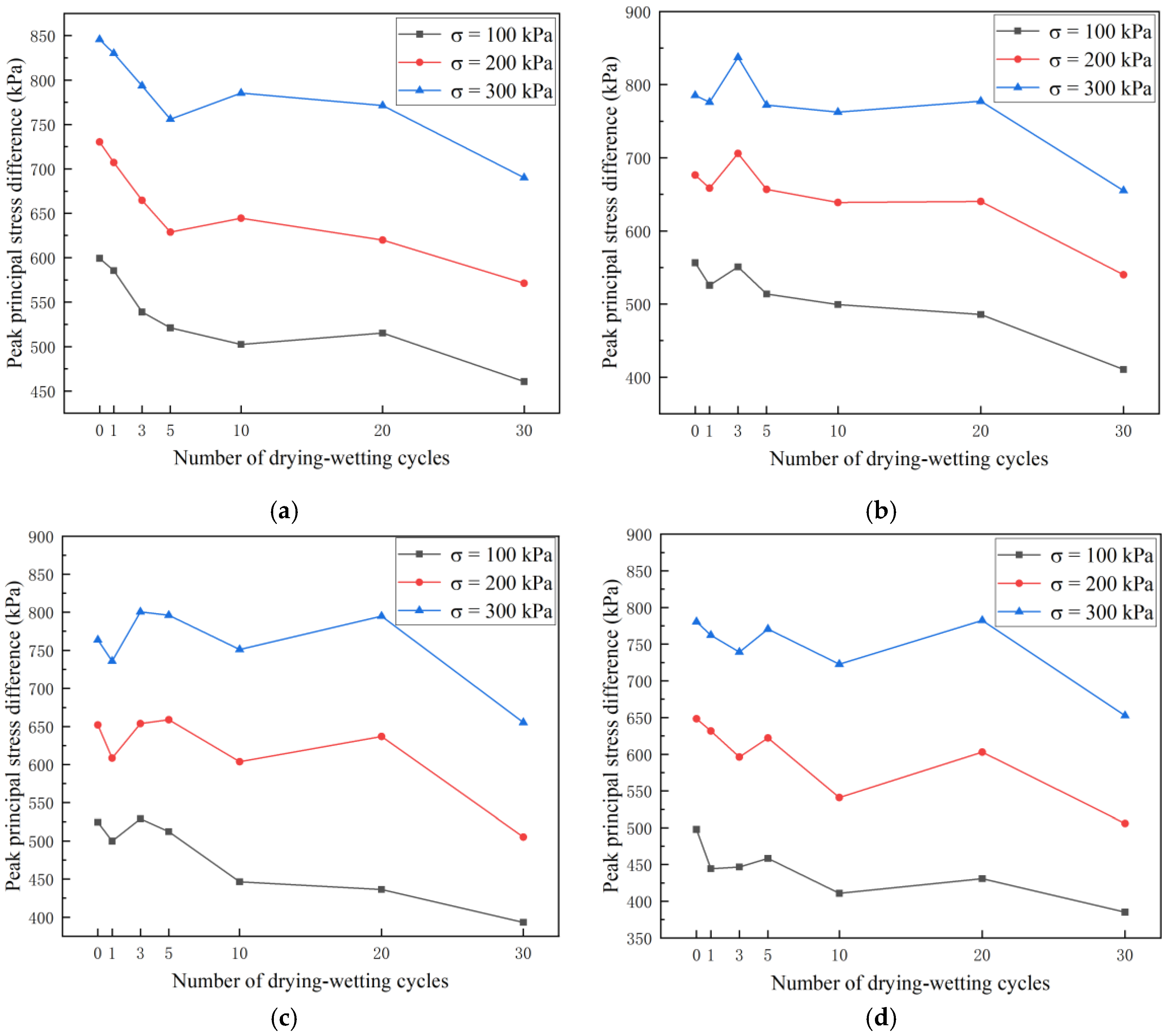

3.2.1. Stress Strain Relationship

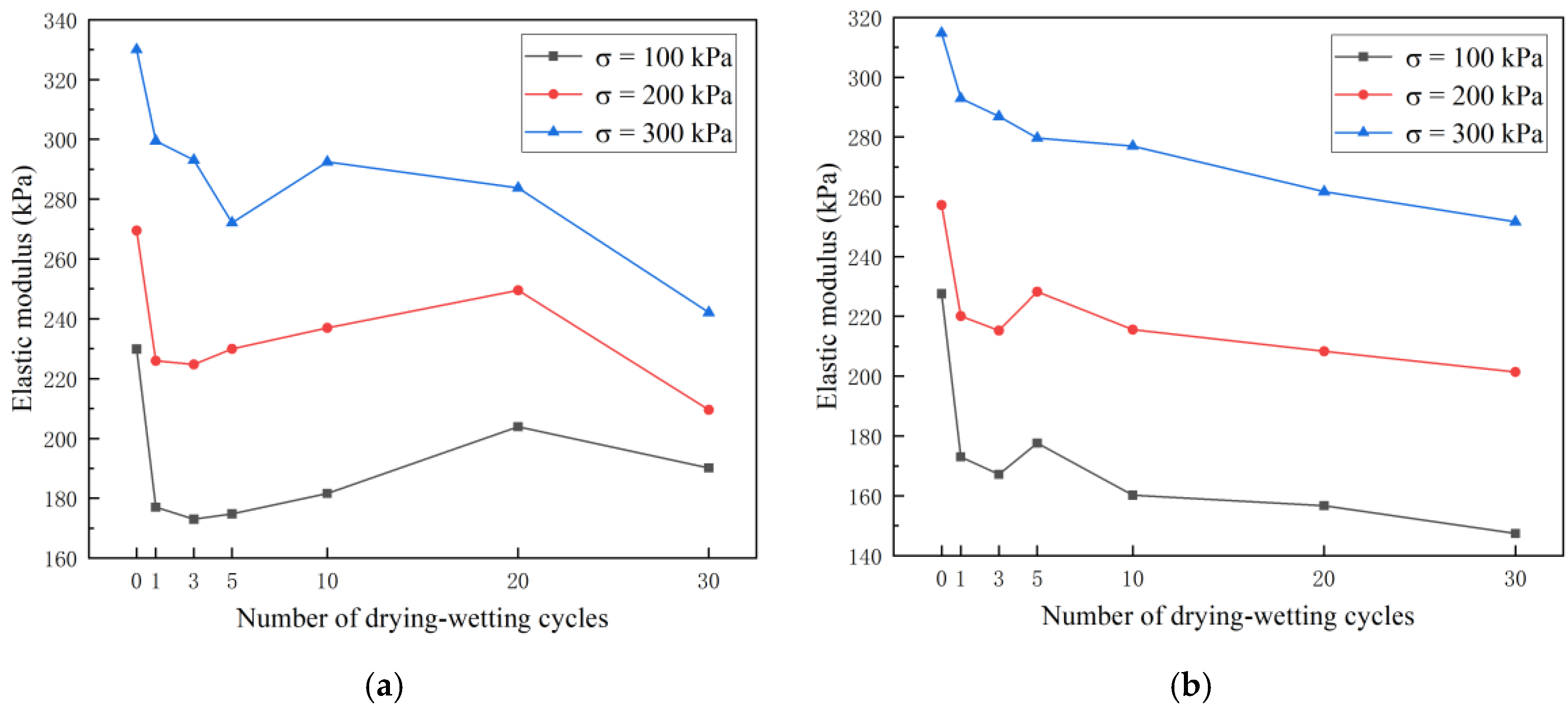

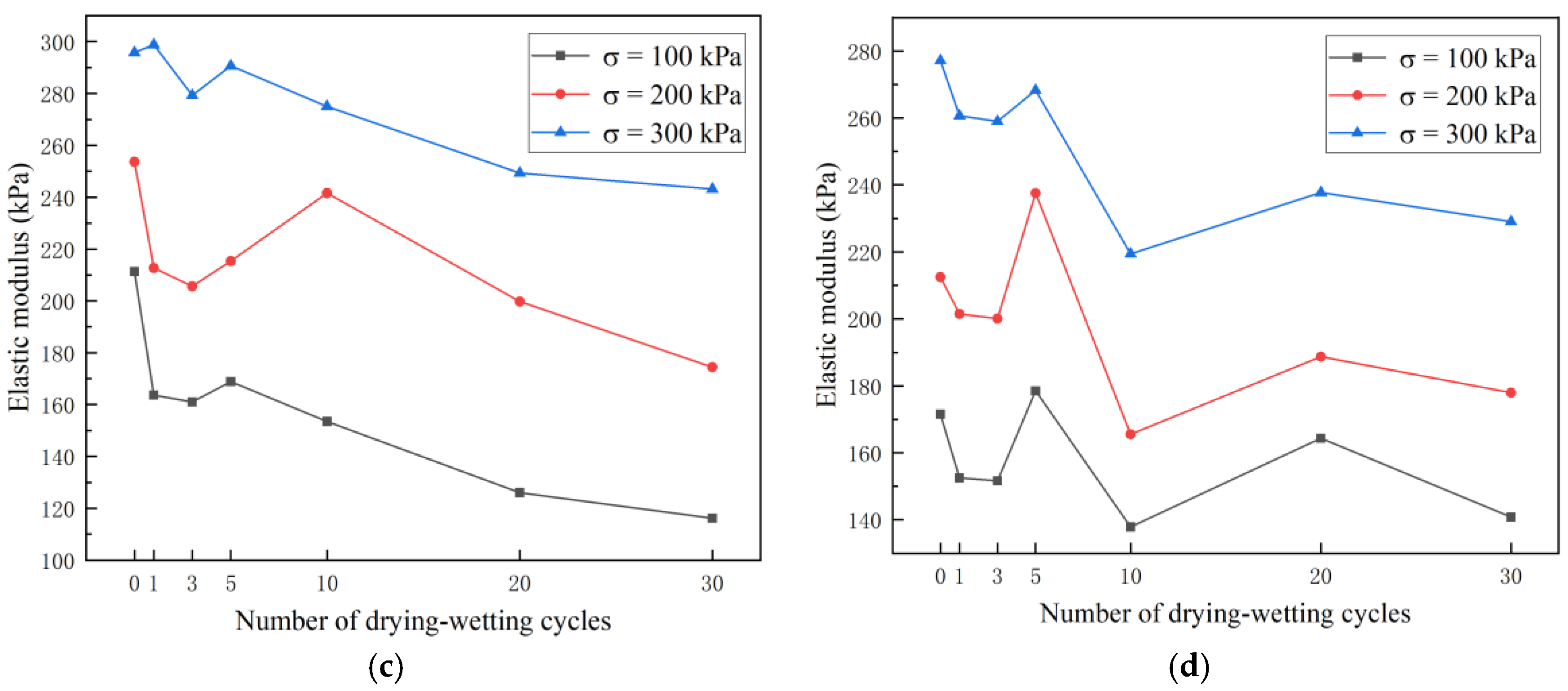

3.2.2. Analysis of the Change in Elastic Modulus

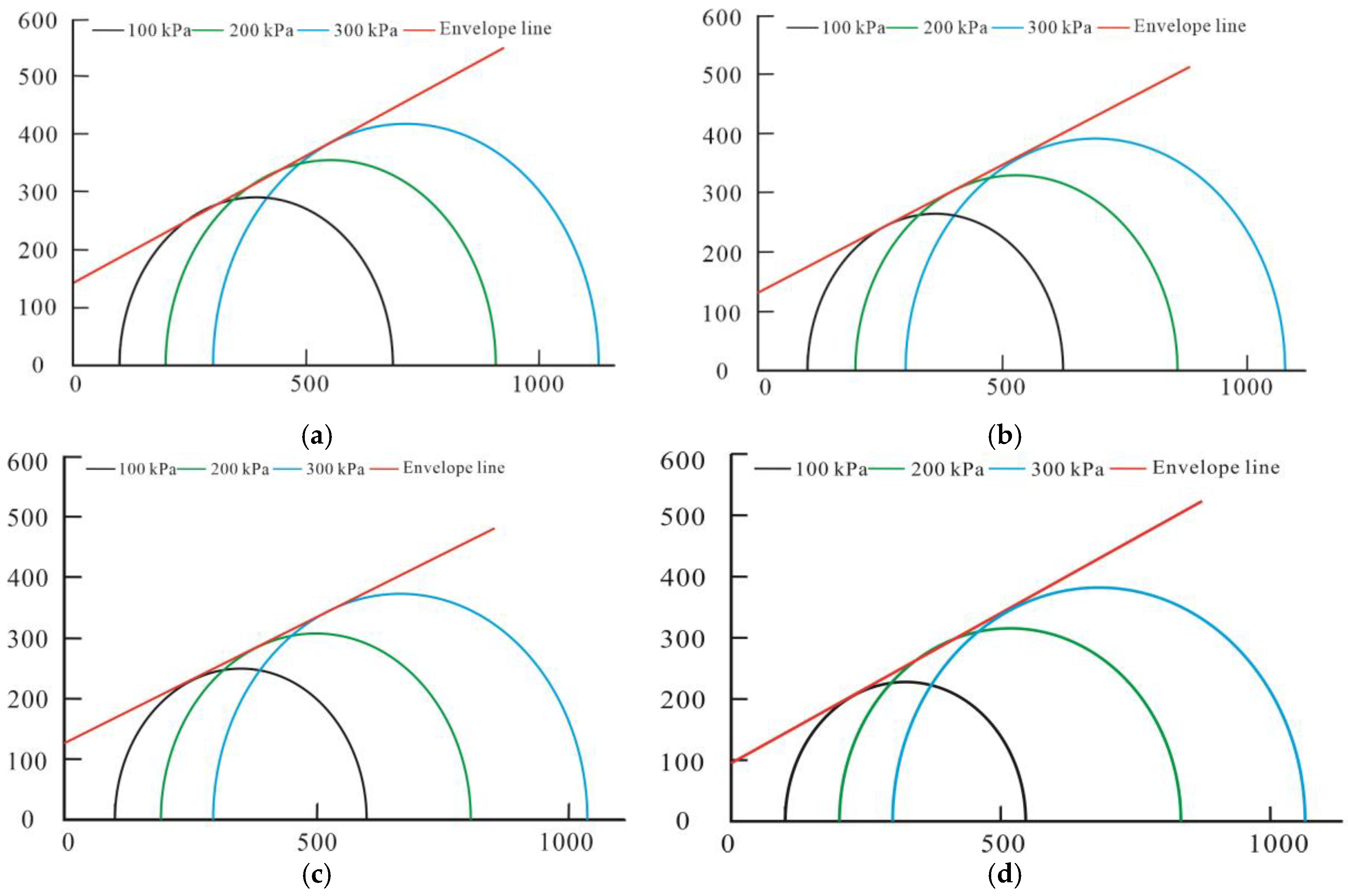

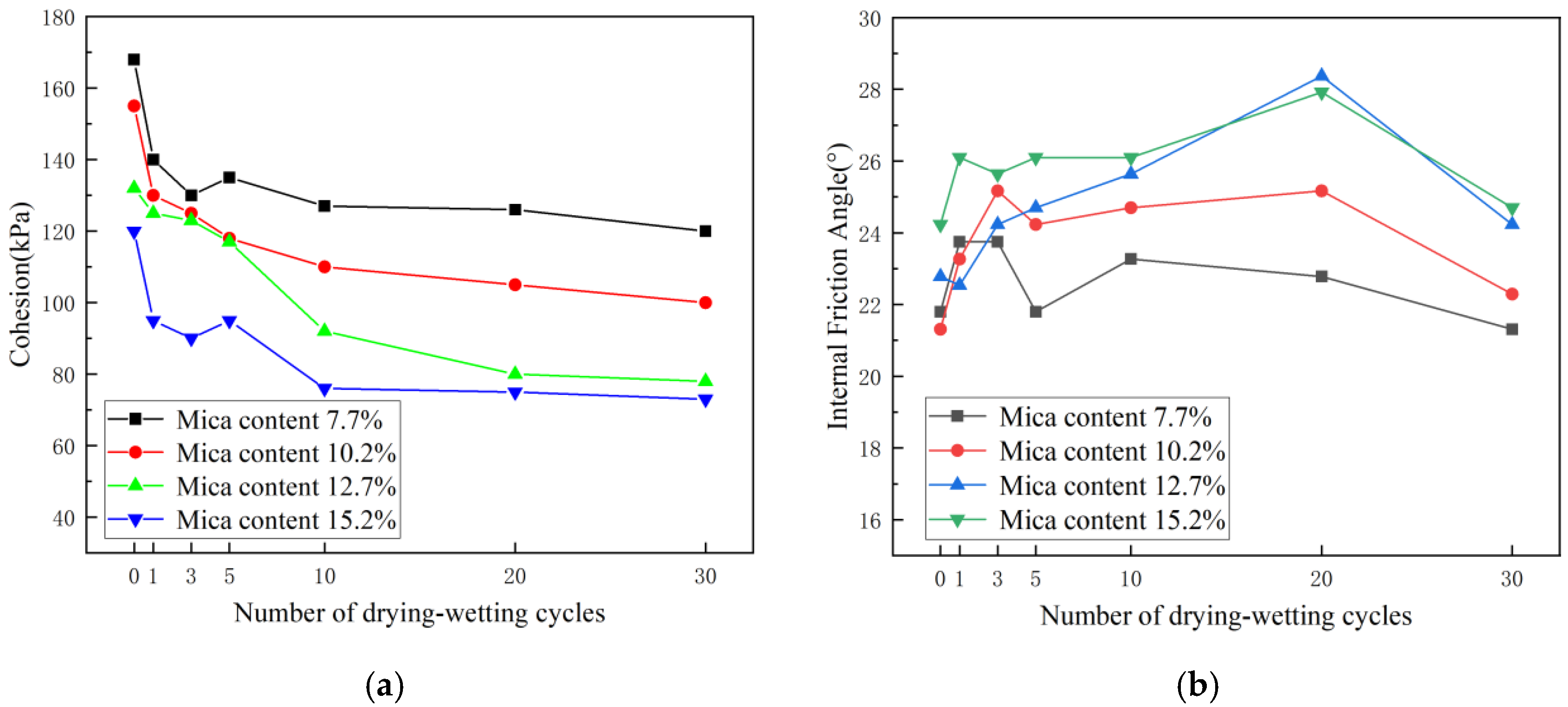

3.2.3. Analysis of Shear Strength Parameters

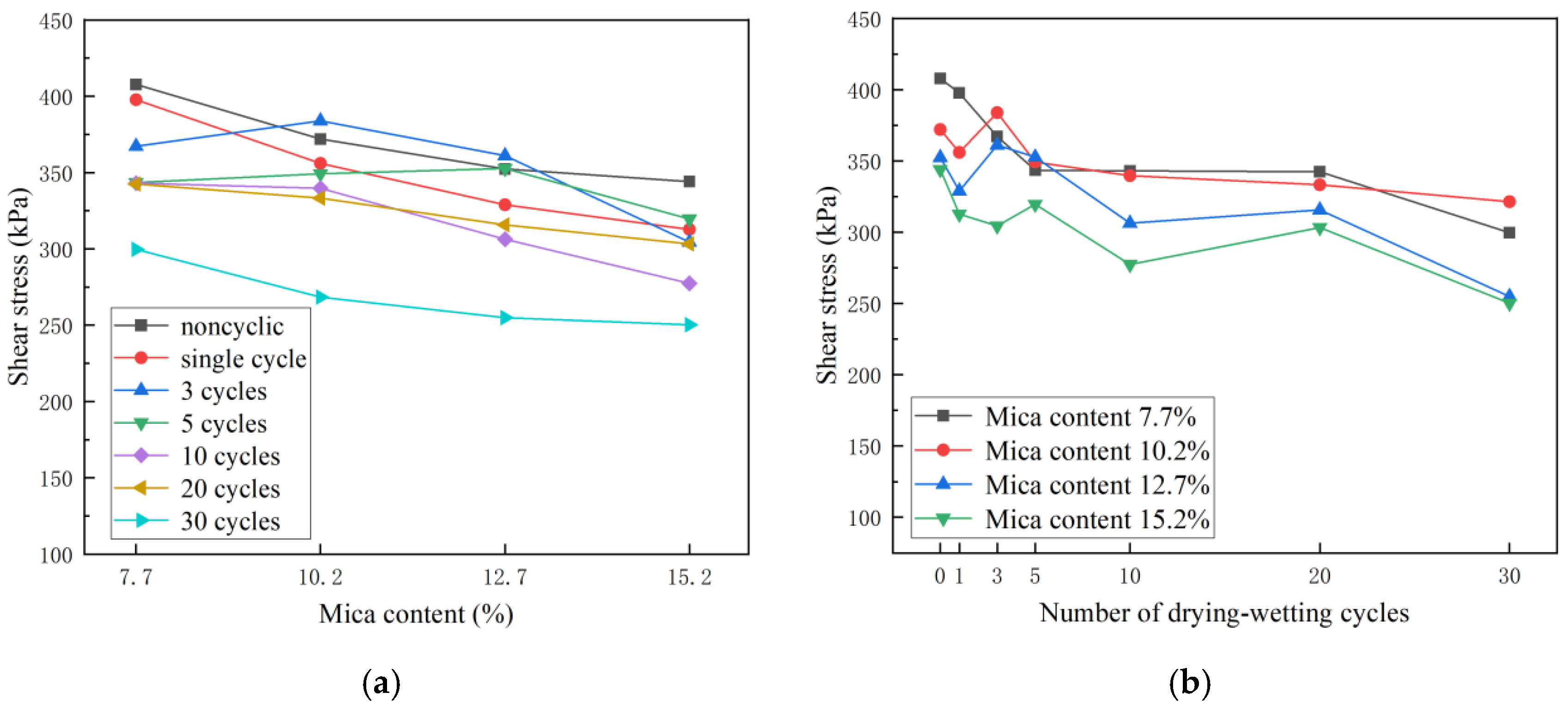

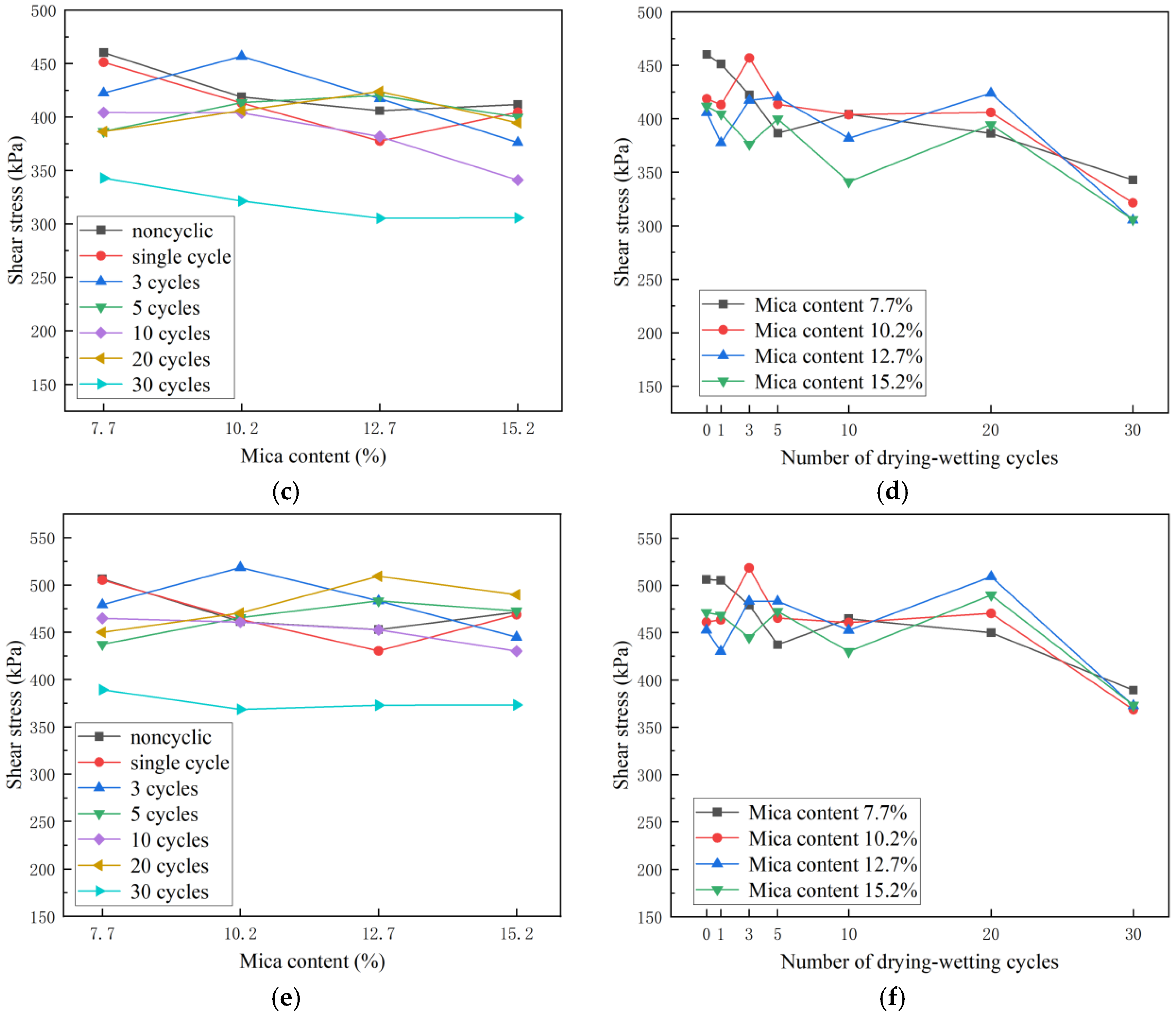

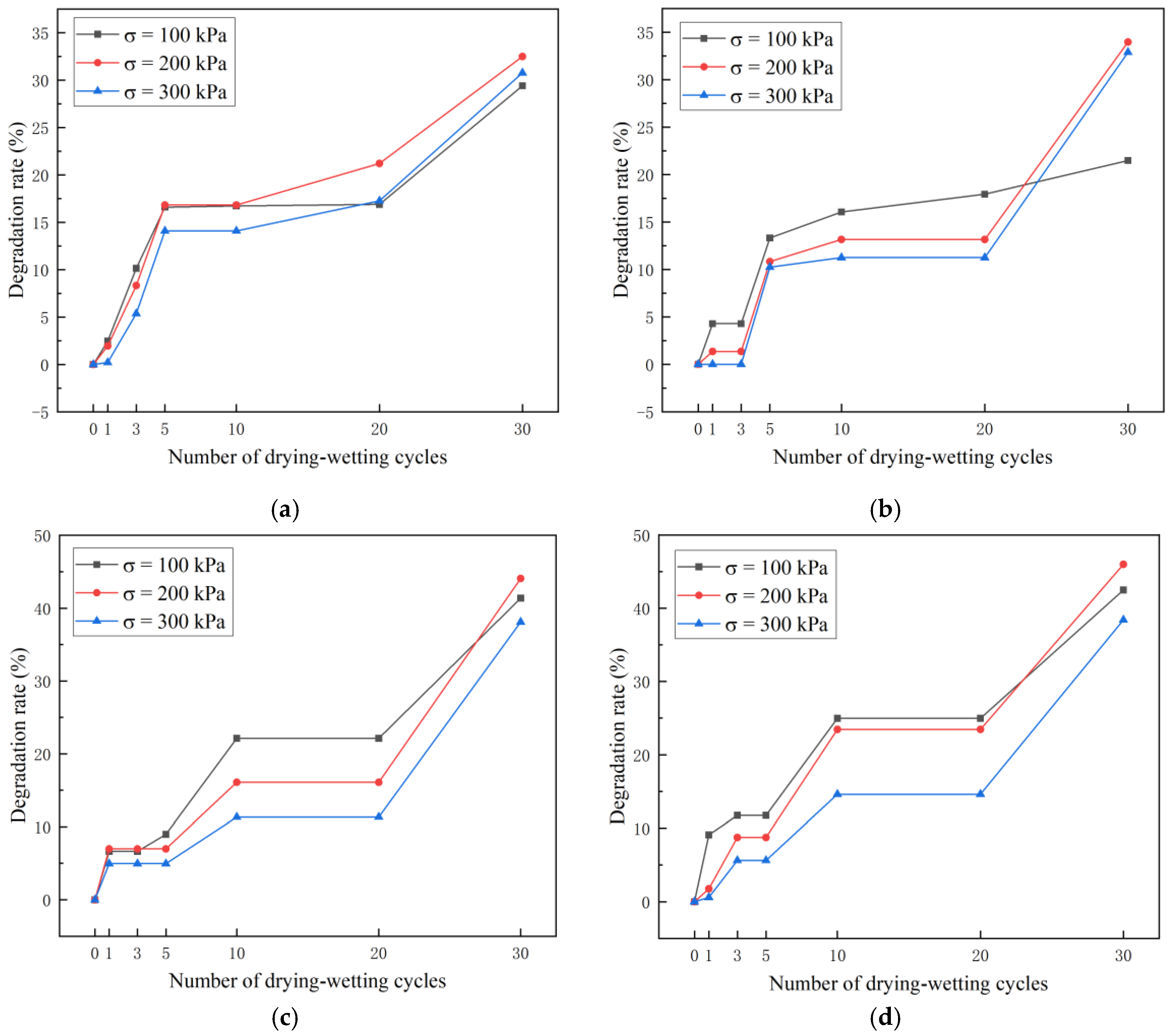

3.2.4. Analysis of Shear Strength Characteristics

4. Discussion

5. Conclusions

- (1)

- The density of the mica was lower than that of the loess. With the increase in the mica content, the maximum dry density of the loess with different mica contents decreased gradually, while the optimal water content showed an upward trend. After the maximum dry density was reached, the water content had a greater impact on the dry density.

- (2)

- As the amount of mica in the mixture increased, the maximum primary stress decreased. The principal stress difference increased with the increase in the confining pressure. Although the peak principal stress difference fluctuated with the change in FTCs for a constant mica content, the trend was generally downward. Under the same FTCs and confining pressure, the peak principal stress difference decreased gradually when the mica content increased. The peak primary stress difference rose with an increase in the confining pressure under the same mica content and FTCs.

- (3)

- With an increase in FTCs, the elastic modulus of the loess with various mica contents dropped to diverse degrees. With the increase in the mica content, the elastic modulus of the loess with different mica contents decreased. With an increase in the confining pressure, the elastic modulus of the loess with various mica contents rose.

- (4)

- When the amount of mica in the soil increased, the cohesiveness of the soil dramatically decreased; however, the internal friction angle changed with an increasing trend under the same FTCs conditions. The internal friction angle increased initially, under varying mica contents, before decreasing, and the soil cohesiveness reduced as the number of FTCs grew.

- (5)

- Under the same FTCs and confining pressure, the shear strength decreased and the degree of the deterioration of the soil strength increased with the increase in the mica content. Under the same mica content and confining pressure, although the shear strength fluctuated, it showed an overall downward trend. The shear strength increased with the confining pressure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yin, G.; Wang, L.; Yuan, Z.; Li, Z.; Liu, H.; Wang, P.; Wu, G. Physical index dynamic property and landslide of IIi loess. J. Arid Lang Geography. 2019, 32, 899–905. [Google Scholar] [CrossRef]

- Wang, X.; Mai, Z. Sliding mechanism and deformation characteristics of typical large loess landslides in Yili Xinjiang. J. Water Resour. Archit. Eng. 2016, 14, 195–200. [Google Scholar]

- Niu, L.; Ren, W.; Zhang, A.; Wang, Y.; Liang, Z.; Han, J. Experimental study on the influence of soluble salt content on unsaturated mechanical characteristics of undisturbed Ili loess. Bulletin of Engineering Geology and the Environment. Bull. Eng. Geol. Environ. 2021, 80, 6689–6704. [Google Scholar] [CrossRef]

- Xiaohong, C.; He, M.; Yanjun, S.; Junmin, Z.; Maimaiti, A.; Juan, X. The development and distribution of loess landslides in Yili Valley and its causes. J. Xinjiang Geol. 2020, 38, 405–411. [Google Scholar]

- Zhu, S.; Yin, Y.; Wang, W.; Wei, Y.; Shao, H.; Huang, Z.; Zhuang, M.; Shi, A. Mechanism of Freeze–thaw Loess Landslide in Yili River Valley, Xinjiang. Acta Geosci. Sin. 2019, 40, 339–349. [Google Scholar]

- Wei, Y. The mineral characteristics of loess and depositing environment in Yili area, Xinjiang. J. Aird Zone Res. 2000, 17, 1–10. [Google Scholar] [CrossRef]

- Xu, J.; Ren, J.; Wang, Z.; Wang, S.; Yuan, J. Strength behaviors and meso-structural characters of loess after freeze-thaw. J. Cold Reg. Sci. Technol. 2018, 148, 104–120. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Lan, W.; Wang, S. Shear strength and damage mechanism of saline intact loess after freeze-thaw cycling. J. Cold Reg. Sci. Technol. 2019, 164, 102779.1–102779.13. [Google Scholar] [CrossRef]

- Qu, Y.L.; Ni, W.K.; Niu, F.J.; Mu, Y.H.; Chen, G.L.; Luo, J. Mechanical and electrical properties of coarse-grained soil affected by cyclic freeze-thaw in high cold regions. J. Cent. South Univ. 2020, 27, 853–866. [Google Scholar] [CrossRef]

- Zhou, Z.; Ma, W.; Zhang, S.; Mu, Y.; Li, G. Effect of freeze-thaw cycles in mechanical behaviors of frozen loess. Cold Reg. Sci. Technol. 2018, 146, 9–18. [Google Scholar] [CrossRef]

- Han, Y.; Wang, Q.; Wang, N.; Wang, J.; Zhang, X.; Cheng, S. Effect of freeze-thaw cycles on shear strength of saline soil. J. Cold Reg. Sci. Technol. 2018, 154, 42–53. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Q.; Liu, S.; ShangGuan, Y.; Fu, H.; Ma, B.; Chen, H.; Yuan, X. Experimental investigation of the geotechnical properties and microstructure of lime-stabilized saline soils under freeze-thaw cycling. J. Cold Reg. Sci. Technol. 2019, 161, 32–42. [Google Scholar] [CrossRef]

- Lu, J.; Wang, T.H.; Cheng, W.C.; Yang, T. Permeability anisotropy of loess under Influence of dry density and freeze-thaw cycles. J. Int. J. Geomech. 2019, 19, 04019103. [Google Scholar] [CrossRef]

- Qian, Z.; Lijun, S.; Hua, L.; Jinxi, Y. Investigation on the influence of freezing-thawing cycle on the permeability coefficient anisotropy of loess. J. Glaciol. Geocryol. 2020, 42, 843–853. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Gao, X.; Shi, D. Effect of freezing and thawing on shear strength of intact loess. J. Civ. Environ. Eng. 2020, 42, 48–55. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, Z.; Yang, C.; Yung, Q.; Ming, J. Study on geometric type changes of Fuping loess microstructure under freeze-thaw cycles. J. Glaciol. Geocryol. 2021, 43, 484–496. [Google Scholar] [CrossRef]

- Liu, Q.; Zhao, K.; Zhao, L.; Wang, L. Methods and exploration for mechanical testing and microscopic testing of loess under freeze-thaw cycles. Environ. MATEC Web Conf. 2022, 358, 01030. [Google Scholar] [CrossRef]

- Luqing, Z.H.A.O.; Gengshe, Y.A.N.G.; Di, W.U. Micro Structure and fractal characteristics loess under Freeze-thaw Cycles. Chin. J. Undergr. Space Eng. 2019, 15, 1680–1690. [Google Scholar]

- She, H.; Hu, Z.; Qu, Z.; Li, H.; Guo, H.; Ma, X. Structural Strength Deterioration Characteristics and a Model of Undisturbed Loess under the Action of Wetting and Freeze-Thaw Cycles. Math. Probl. Eng. 2019, 2019, 4790250. [Google Scholar] [CrossRef]

- Li, G.; Wang, F.; Ma, W.; Fortier, R.; Mu, Y.; Mao, Y.; Hou, X. Variations in strength and deformation of compacted loess exposed to wetting-drying and freeze-thaw cycles. Cold Reg. Sci. Technol. 2018, 151, 159–167. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, Z.; Jing, Y. Characteristics of strength and pore distribution of lime-flyash loess under freeze-thaw cycles and dry-wet cycles. Arab. J. Geosci. 2017, 10, 544. [Google Scholar] [CrossRef]

- Liu, K.; Ye, W.; Jing, H. Shear Strength and Microstructure of Intact Loess Subjected to Freeze-Thaw Cycling. Adv. Mater. Sci. Eng. 2021, 2021, 1173603. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Gao, X.; Shi, D. Experimental study on the triaxial stress-strain curve of undisturbed Loess in Xining by Freeze-thaw Cycles. OP Conf. Ser. Earth Environ. Sci. 2019, 304, 052065. [Google Scholar] [CrossRef]

- Lingling, Z.; Jianhui, L.; Xianli, X.; Xiaojuan, G. Study on the properties of malan loess in lyuliang area under ureeze-thaw cycles. J. Taiyuan Univ. Technol. 2021, 52, 563–577. [Google Scholar]

- Zheng, F.; Shao, S.; Wang, S. Effect of freeze-thaw cycles on the strength behaviour of recompacted loess in true triaxial tests. J. Cold Reg. Sci. Technol. 2021, 181, 103172. [Google Scholar] [CrossRef]

- Yang, M. Study on Mechanical Properties of Sand Loess Modified by Cement under Freeze-Thaw Condition. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2020. [Google Scholar] [CrossRef]

- Kong, F.; Nie, L.; Xu, Y.; Rui, X.; He, Y.; Zhang, T.; Wang, Y.; Du, C.; Bao, C. Effects of freeze-thaw cycles on the erodibility and microstructure of soda-saline loessal soil in Northeastern China. Catena 2022, 209, 105812. [Google Scholar] [CrossRef]

- Liu, J.; Chang, D.; Yu, Q. Influence of freeze-thaw cycles on mechanical properties of a silty sand. Eng. Geol. 2016, 210, 23–32. [Google Scholar] [CrossRef]

- Hao, R.; Zhang, Z.; Guo, Z.; Huang, X.; Lv, Q.; Wang, J.; Liu, T. Investigation of changes to triaxial shear strength parameters and microstructure of Yili loess with drying-wetting cycles. Materials 2022, 15, 255. [Google Scholar] [CrossRef]

- Lv, Q.; Zhang, Z.; Zhang, T.; Hao, R.; Guo, Z.; Huang, X.; Zhu, J.; Liu, T. The trend of permeability of loess in Yili, China, under freeze-thaw cycles and its microscopic mechanism. Water 2021, 13, 3257. [Google Scholar] [CrossRef]

- Shi, G.; Li, X.; Guo, Z.; Zhang, Z.; Zhang, Y. Effect of Mica Content on Shear Strength of the Yili Loess under the Dry-Wet Cycling Condition. Sustainability 2022, 14, 9569. [Google Scholar] [CrossRef]

| Sampling Position | Sample Numbers | Quartz | Calcite | Dolomite | Feldspar | Mica | Other Minerals |

|---|---|---|---|---|---|---|---|

| foot of slope | X-1 | 44.2 | 16.4 | 2.8 | 17.8 | 2.0 | 16.8 |

| X-2 | 42.3 | 17.1 | 1.9 | 15.4 | 1.6 | 21.7 | |

| X-3 | 33.7 | 11.9 | 2.2 | 31.9 | 1.8 | 18.5 | |

| middle of slope | Y-1 | 35.9 | 23.4 | 4.7 | 18.9 | 6.9 | 10.2 |

| Y-2 | 36.3 | 20.9 | 2.6 | 22.5 | 7.5 | 10.2 | |

| Y-3 | 31.7 | 17.5 | 1.9 | 26.2 | 8.6 | 14.1 | |

| top of slope | Z-1 | 27.7 | 21.9 | 4.0 | 19.4 | 15.3 | 11.7 |

| Z-2 | 28.1 | 21.1 | 3.2 | 19.5 | 15.0 | 13.1 |

| Natural Moisture Content (%) | Natural Density (g/cm3) | Natural Dry Density (g/cm3) | Plastic Limit (%) | Liquid Limit (%) | Maximum Dry Density (g/cm3) | Optimum Moisture Content (%) |

|---|---|---|---|---|---|---|

| 21.04 | 1.62 | 1.34 | 16.15 | 27.05 | 1.76 | 16.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, Y.; Zhang, Z.; Zhou, T.; Guo, Z. Effect of Mica Content on Mechanical Properties of Yili River Valley Loess under the Impact of Freezing and Thawing. Sustainability 2023, 15, 3329. https://doi.org/10.3390/su15043329

Mu Y, Zhang Z, Zhou T, Guo Z. Effect of Mica Content on Mechanical Properties of Yili River Valley Loess under the Impact of Freezing and Thawing. Sustainability. 2023; 15(4):3329. https://doi.org/10.3390/su15043329

Chicago/Turabian StyleMu, Yanxiao, Zizhao Zhang, Tiansheng Zhou, and Zekun Guo. 2023. "Effect of Mica Content on Mechanical Properties of Yili River Valley Loess under the Impact of Freezing and Thawing" Sustainability 15, no. 4: 3329. https://doi.org/10.3390/su15043329

APA StyleMu, Y., Zhang, Z., Zhou, T., & Guo, Z. (2023). Effect of Mica Content on Mechanical Properties of Yili River Valley Loess under the Impact of Freezing and Thawing. Sustainability, 15(4), 3329. https://doi.org/10.3390/su15043329