A Novel Modeling Approach for Soil and Rock Mixture and Applications in Tunnel Engineering

Abstract

1. Introduction

2. Methodology

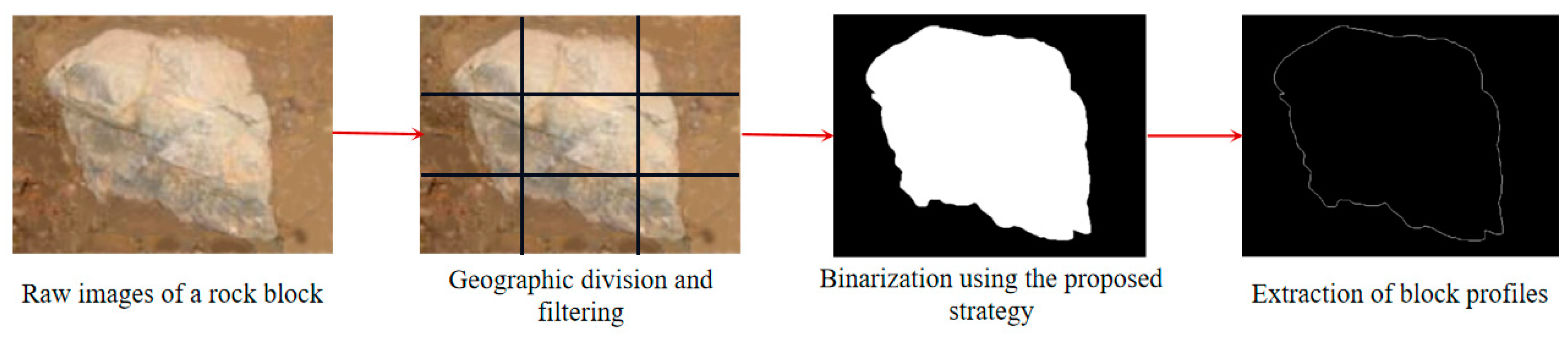

2.1. Strategy to Obtain Realistic Block Profiles from Raw Images

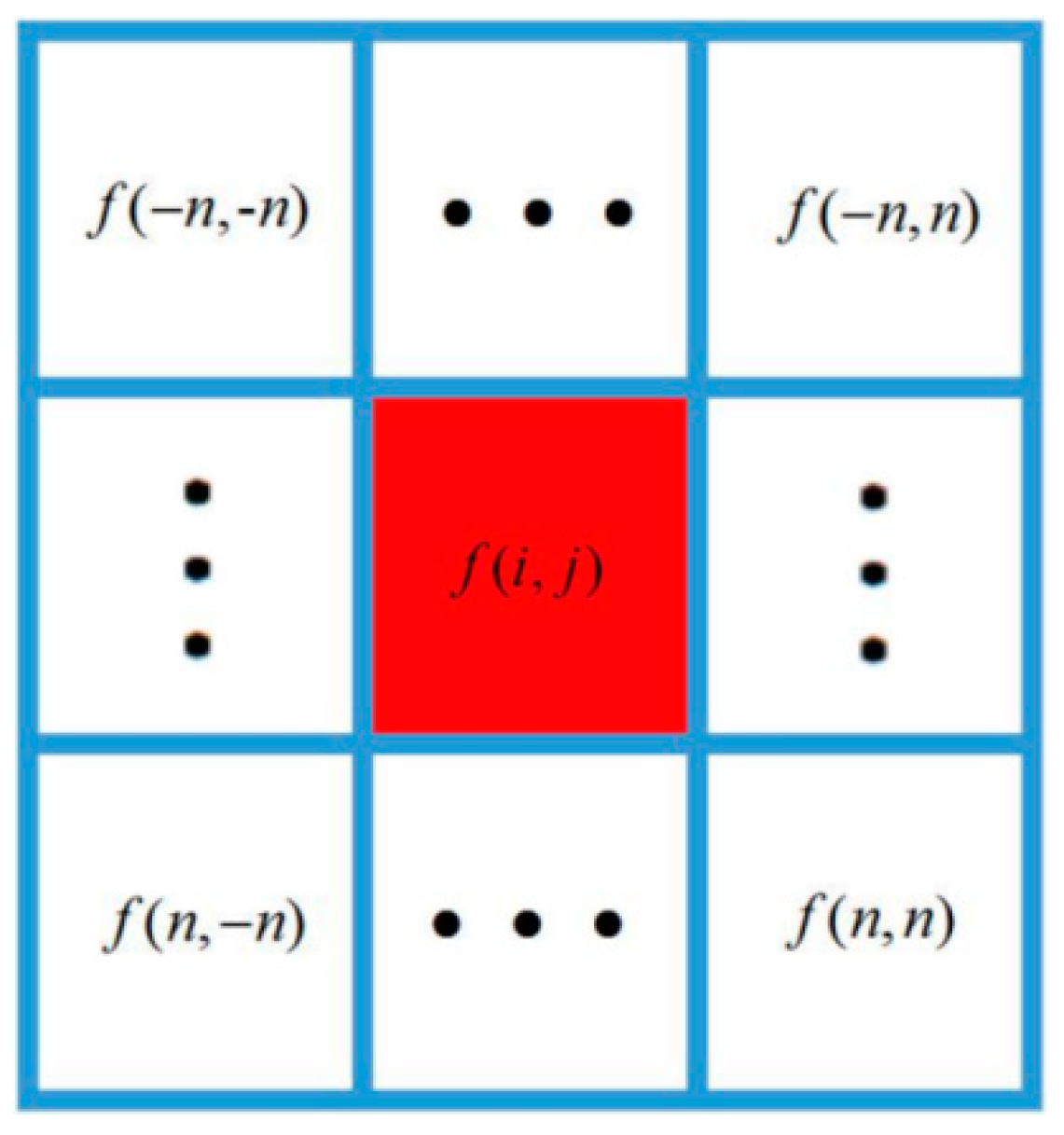

- Combined image filtering technique

- 2.

- Method of image segmentation using multi-thresholds

2.2. Methodology to Generate Stochastic and Realistic Soil and Rock Mixture

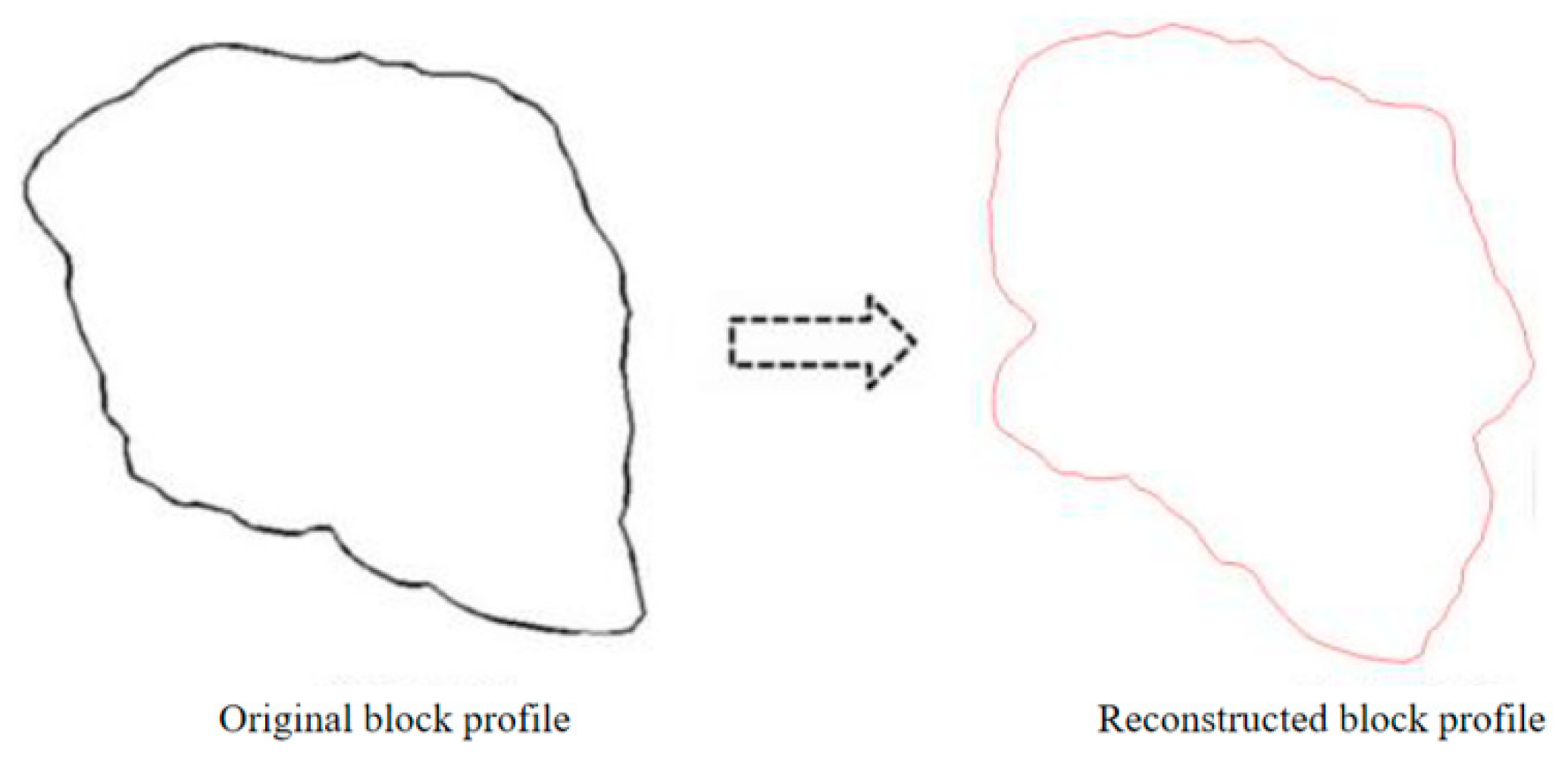

2.2.1. Mathematical Representation of Rock Profile Using Fourier Analysis

2.2.2. Methodology to Approach Real Size Distribution of Rock Blocks

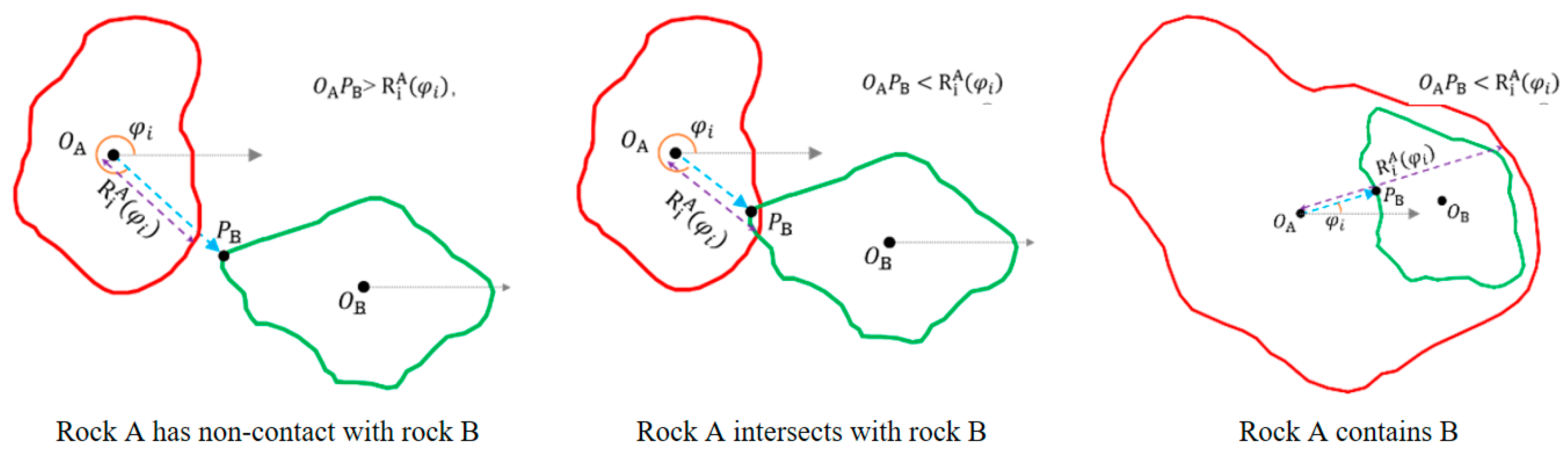

2.2.3. Strategy to Conduct Overlap Detection among Rock Blocks

2.2.4. Systematic Approach to Generate Soil and Rock Mixtures with Specific Characteristics

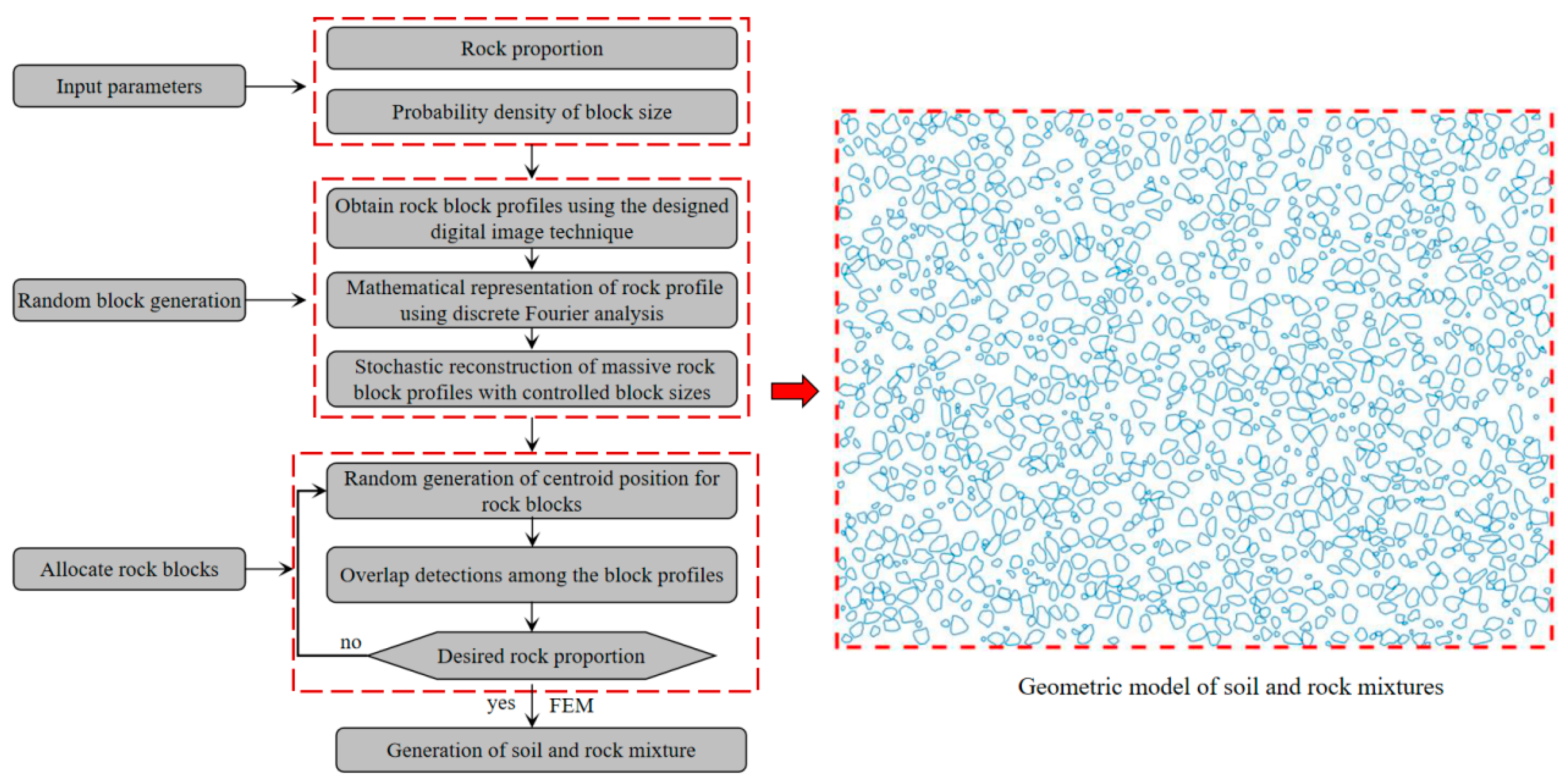

- Based on the obtained realistic block profiles, Fourier analysis, and overlap detection algorithm, the models of soil and rock mixture with a specific rock proportion and gradation can be generated effectively and efficiently. The process is listed as follows.

- Given the shape features of target block inclusions, appropriate block morphology can be chosen from the block morphology database. Considerable stochastic block morphology can be generated efficiently using Fourier analysis.

- Taking a rectangular region for instance, the volume of total blocks is determined based on a given inclusion content and a region’s volume. By referring to the gradation calculation method proposed in Section 2.2.2, sizes for each irregular inclusion can be obtained. Then, the chosen inclusions are scaled to approach the target size distribution.

- The obtained rock blocks are then allocated to the rectangular regions from large to small with the help of the designed overlap detection method proposed in Section 2.2.3. A quick example and flowchart are presented in Figure 9.

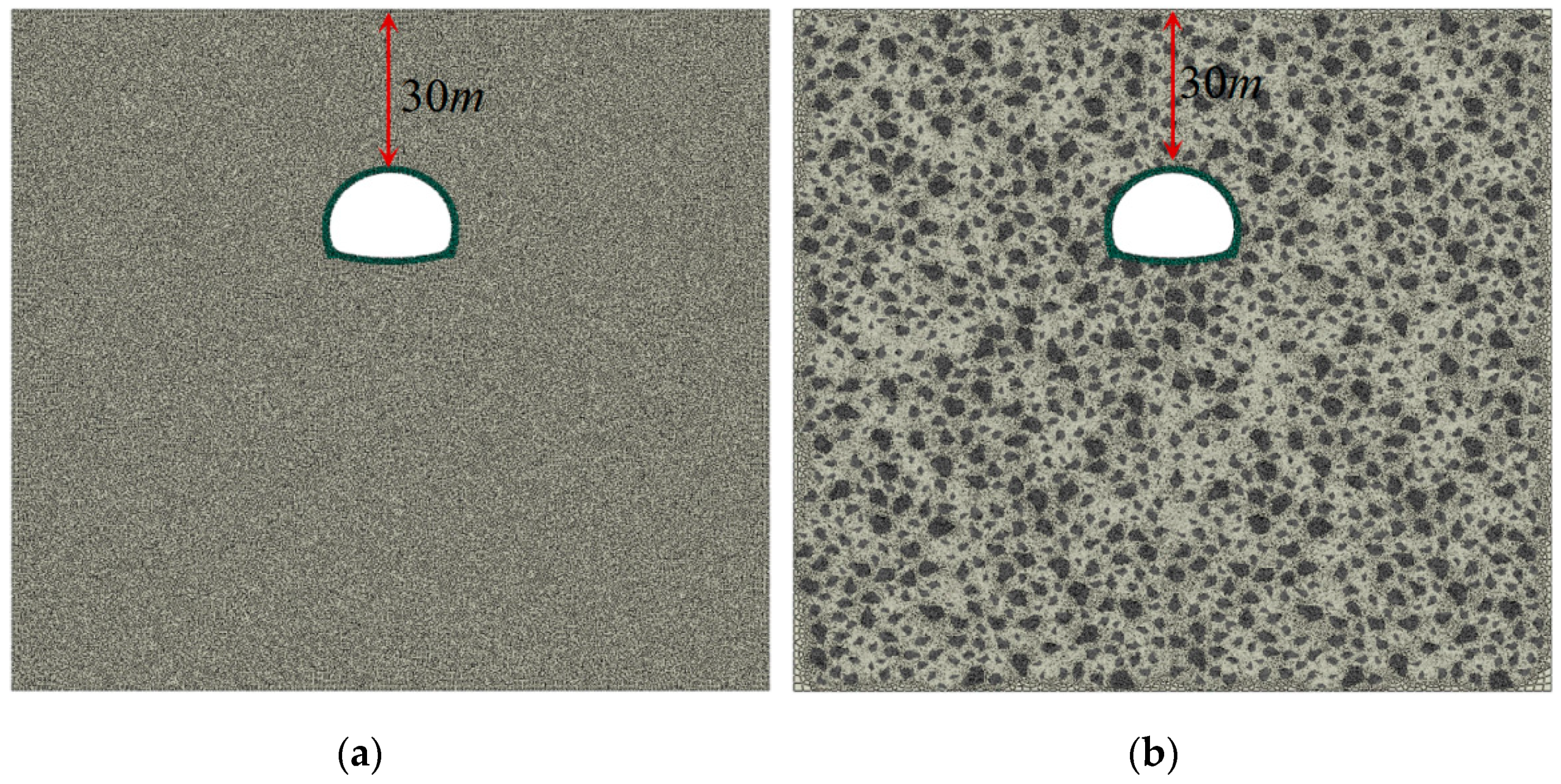

2.3. Application of the Developed Method in Numerical Analysis of Tunnel Engineering

2.3.1. Generation of Numerical Models Using Proposed Method

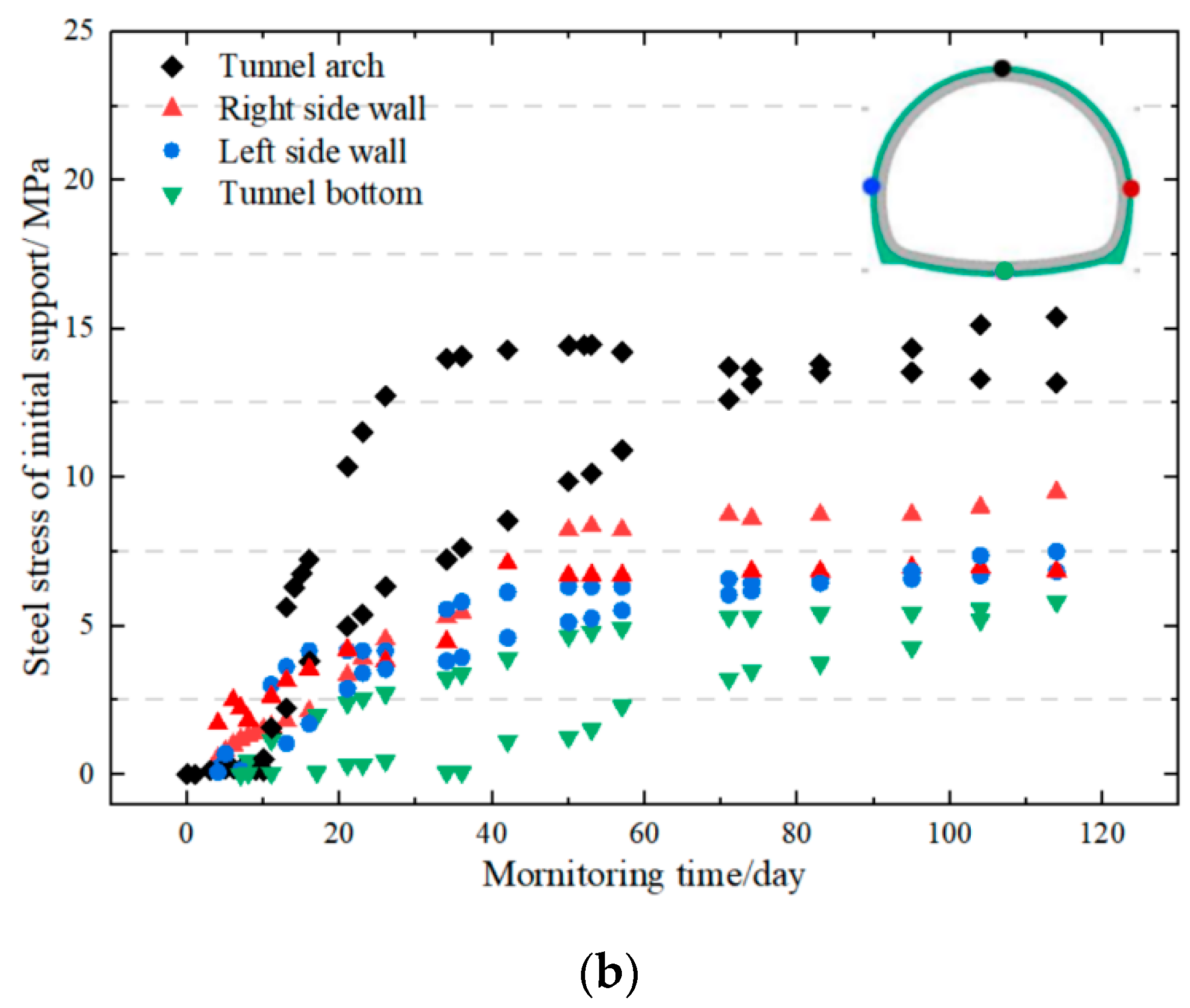

2.3.2. Field Monitoring and Testing for Model Validation

3. Results and Discussion

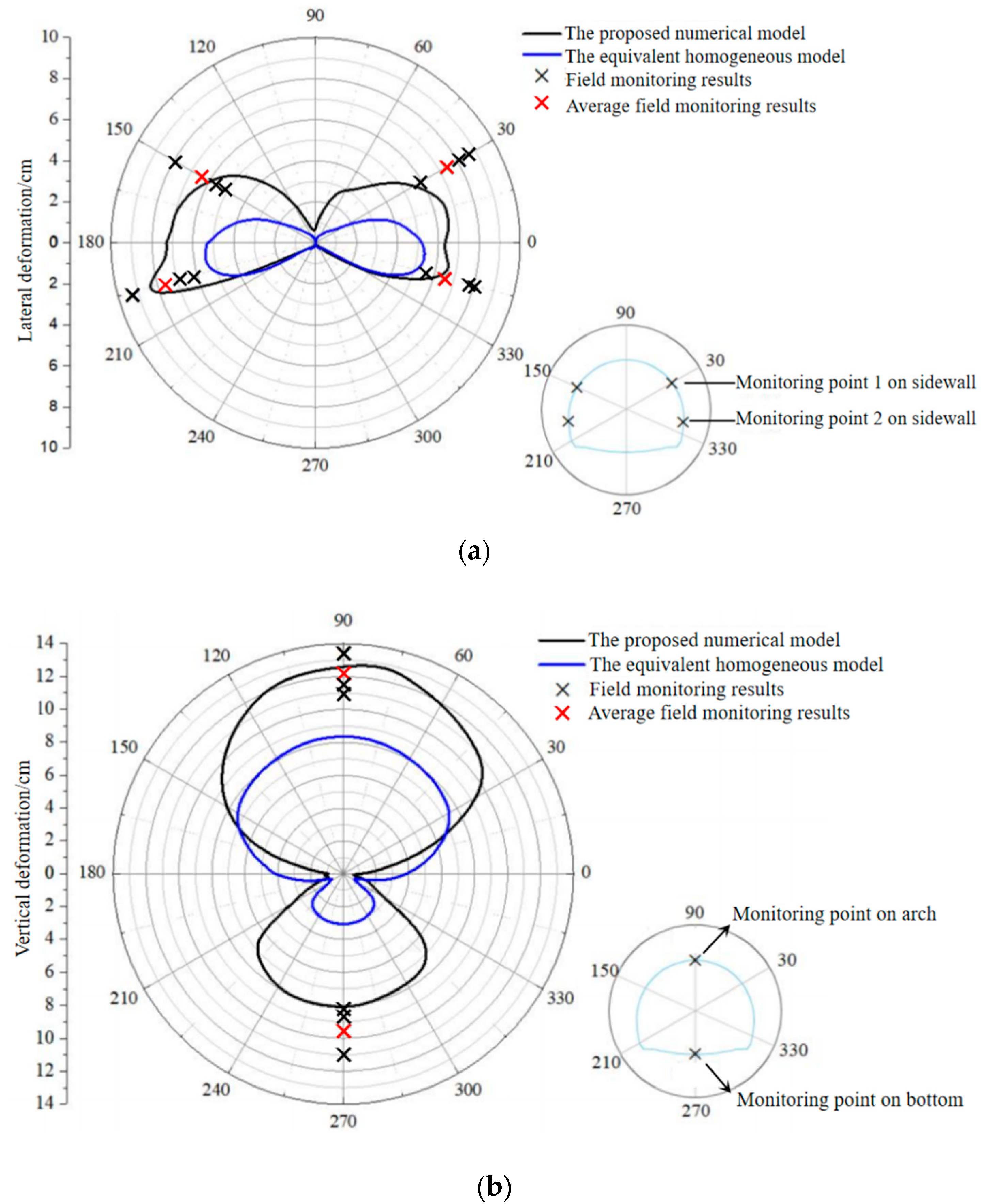

3.1. Deformation Comparison between Numerical Models

3.2. Comparison of Plastic Zones between Numerical Models

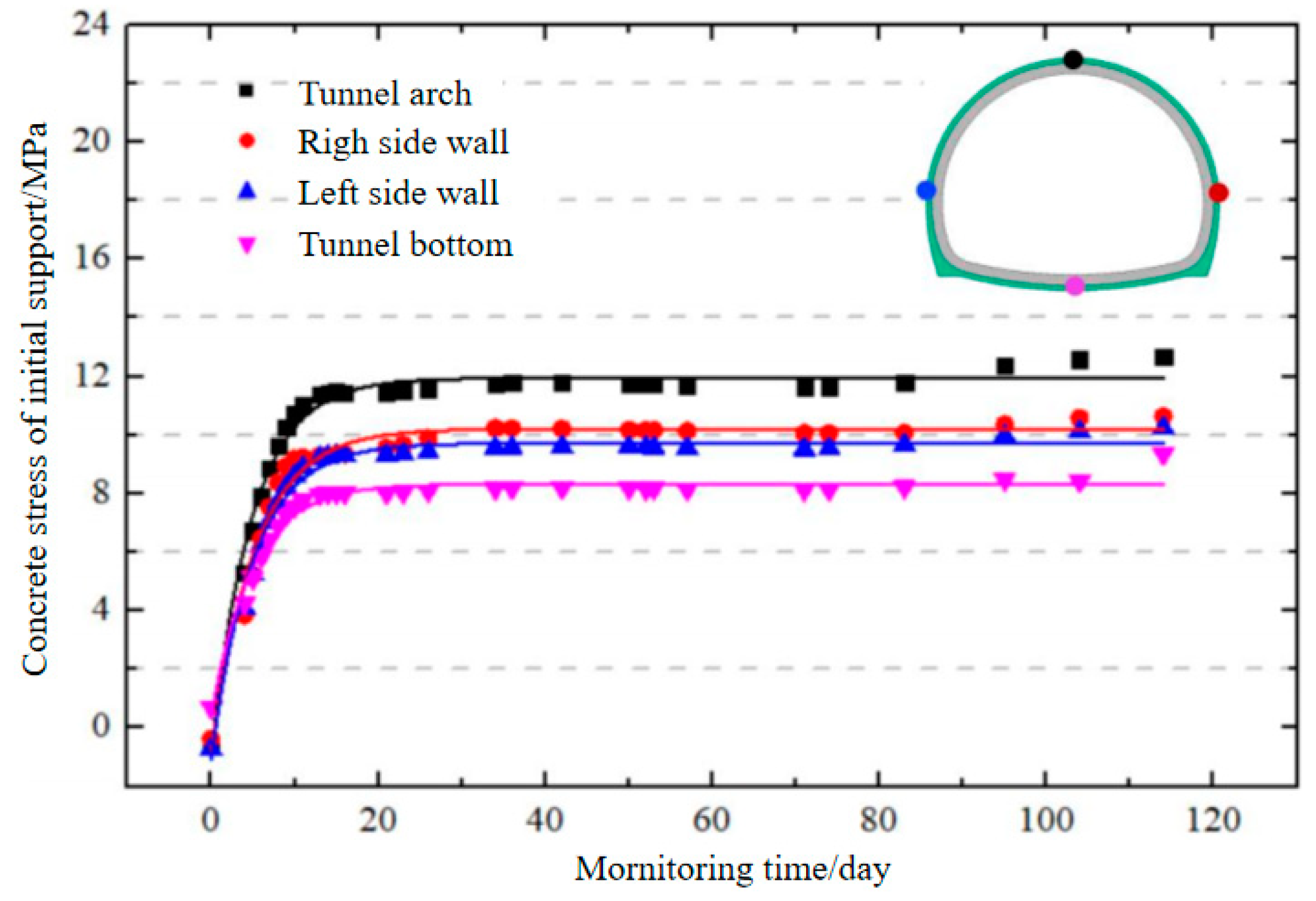

3.3. Comparison with the Field Monitoring Results

3.4. Failure Mechanism and Reinforcement Strategy of the Tunnel in Soil and Rock Mixture

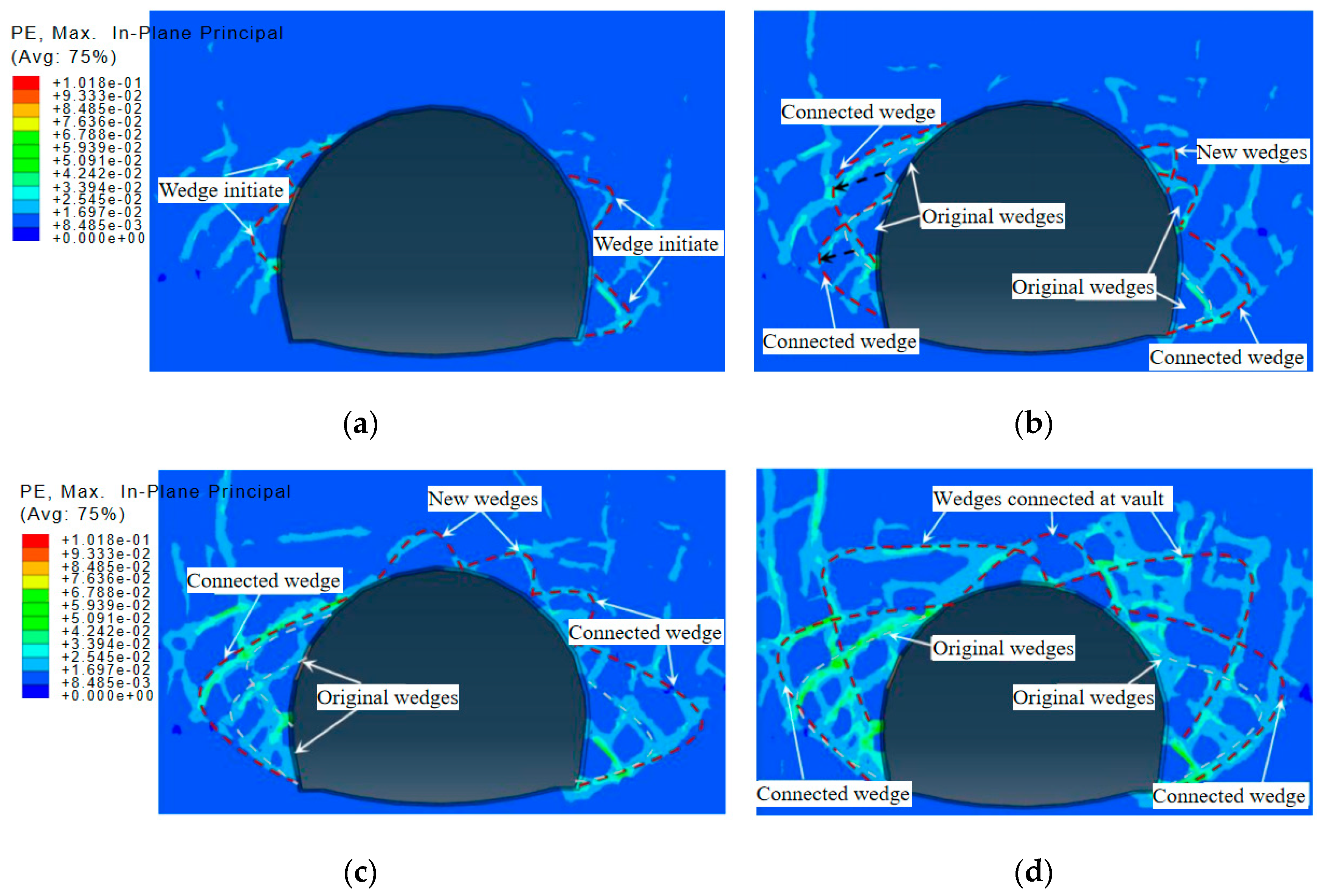

- As shown in Figure 18a, the plastic deformation is observed only in limited regions of the side walls when the stiffness of support is 1.5 times the designed value. Most plastic deformations initiate at the interfaces between soil and rocks and have a great tendency to expand and connect with each other. Only some small wedges are formed by the limited plastic deformations at this stage. Note that these wedges are loose and have a great tendency to collapse. The maximum plastic deformation is only 0.08, which indicates that the surrounding rocks are still stable at this stage.

- With decreasing stiffness, the plastic deformation would develop rapidly along the interfaces between blocks and matrix. A larger wedge is formed based on the original small wedges. The plastic strain increases to 0.1 with a larger area of surrounding rocks being loosened. As with the different spatial distribution of rock blocks, the plastic deformation is also asymmetric. The loosened area of surrounding rocks on the left is much larger than that of those on the right of the tunnel.

- With the support stiffness further weakened, the plastic deformation at the side walls develops further, and a larger shear wedge structure begins to form. In addition, the plastic shear deformation extends to the vault, which has a chance to connect the left and right plastic zones. At this time, the peak value of plastic strain is raised to 0.14, and the local shear failure already appears at the side wall of the tunnel.

- As the initial support is completely removed, the plastic zones of the left and right surrounding rocks have been connected, and the failure zone around the tunnel is completely formed. At this time, the peak value of plastic strain rapidly increases to 0.19. At this stage, the shearing failure paths are well-developed, and the overall failure of the surrounding rock is inevitable.

4. Conclusions

- Realistic rock block files can be obtained from raw images by combining the designed image filtering technique and multi-threshold binarization method. Using Fourier analysis and the fast-overlapping detection strategy, a numerical model of soil and rock mixture with specific internal characteristics can be generated effectively and efficiently.

- The proposed heterogeneous numerical model has been verified as being effective in modeling the mechanical and failure characteristics of soil and rock mixtures by comparing it with the conventional homogeneous numerical model. In addition, the numerical results of the proposed numerical method were in good agreement with the field test results from deformation characteristics to failure patterns, wherein the rock blocks mainly consisted of limestone.

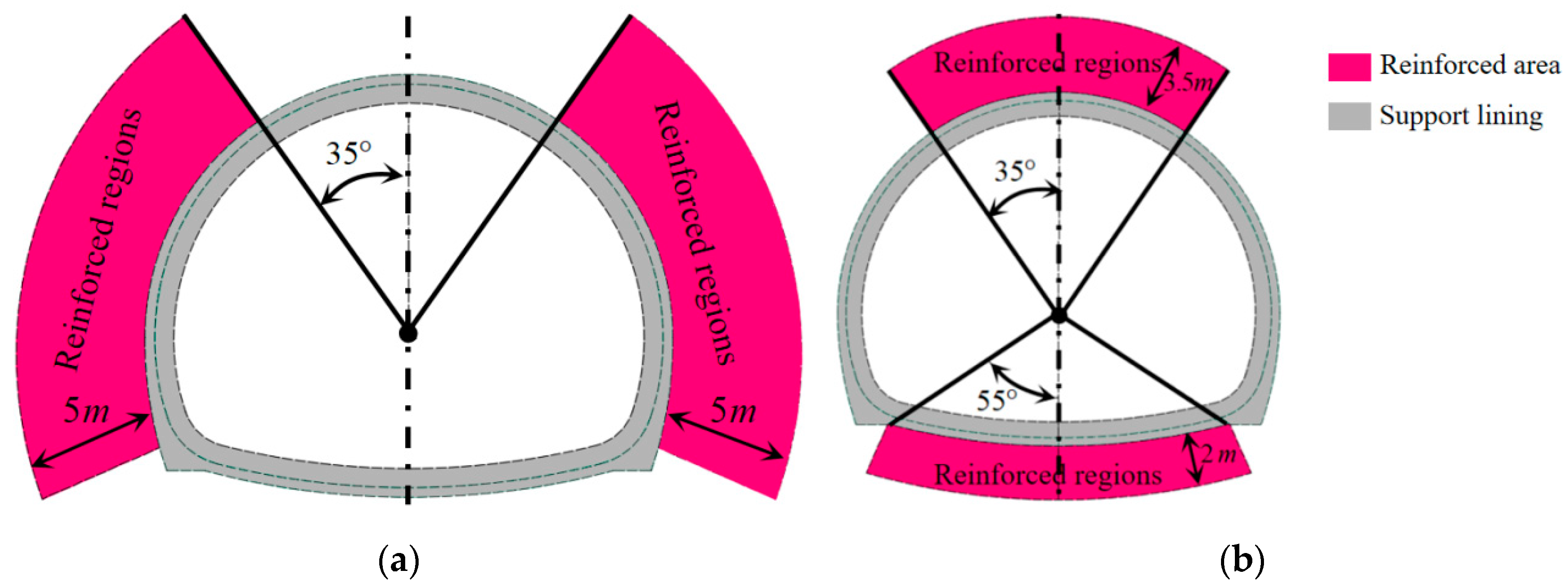

- Considering the distribution characteristics of plastic deformation in surrounding rock and field investigations, reinforced regions of surrounding rocks were suggested and defined. The reinforced depth at the side walls was 5 m; whereas, the reinforced depths at the vault and the bottom of the tunnel were 3.5 m and 2 m, respectively. The reinforcement strategy was proven to be effective by the field test results.

- It is admitted that the obtained conclusions are mainly for areas in the west of China such as the Ningxia area and Yunnan province. In addition, the interface effects among the rock blocks and matrix have not been considered in the proposed method. Thus, the proposed model would not be suitable to model situations wherein interface effects cannot be neglected. In future work, the effects of interfaces would be considered by introducing zero-thickness cohesive elements to model the interfaces so that the proposed model could be further improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, Y.; Yin, Z.-Y.; Wang, X.; Huang, L. A systematic 3D simulation method for geomaterials with block inclusions from image recognition to fracturing modelling. Theor. Appl. Fract. Mech. 2021, 117, 103194. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, X.; Ma, J.; Huang, L. A finite-discrete element based appoach for modelling the hydraulic fracturing of rocks with irregular inclusions. Eng. Fract. Mech. 2022, 261, 108209. [Google Scholar] [CrossRef]

- Ma, J.; Chen, J.; Guan, J.; Lin, Y.; Chen, W.; Huang, L. Implementation of Johnson-Holmquist-Beissel model in four-dimensional lattice spring model and its application in projectile penetration. Int. J. Impact Eng. 2022, 170, 104340. [Google Scholar] [CrossRef]

- Napoli, M.L.; Barbero, M.; Ravera, E.; Scavia, C. A stochastic approach to slope stability analysis in bimrocks. Int. J. Rock Mech. Min. Sci. 2018, 101, 41–49. [Google Scholar] [CrossRef]

- VTran, D.; Meguid, M.; Chouinard, L. A fifiniteediscrete element framework for the 3D modeling of geogride soil interaction under pullout loading conditions. Geotext. Geomembranes 2013, 37, 1–9. [Google Scholar] [CrossRef]

- Zheng, K.; Shi, C.; Lin, Y.; Lei, M.; Liu, J. Transfer station cracks induced by cutting anchor cables and crack stabilization: A case study. Eng. Fail. Anal. 2021, 126, 105460. [Google Scholar] [CrossRef]

- Napoli, M.L.; Milan, L.; Barbero, M.; Scavia, C. Identifying uncertainty in estimates of bimrocks volumetric proportions from 2D measurements. Eng. Geol. 2020, 278, 105831. [Google Scholar] [CrossRef]

- Wang, X.; Nie, Z.; Gong, J.; Liang, Z. Random generation of convex aggregates for DEM study of particle shape effect. Constr. Build. Mater. 2021, 268, 121468. [Google Scholar] [CrossRef]

- Xu, W.-J.; Hu, L.-M.; Gao, W. Random generation of the meso-structure of a soil-rock mixture and its application in the study of the mechanical behavior in a landslide dam. Int. J. Rock Mech. Min. Sci. 2016, 86, 166–178. [Google Scholar] [CrossRef]

- Nie, Z.; Fang, C.; Gong, J.; Liang, Z. DEM study on the effect of roundness on the shear behaviour of granular materials. Comput. Geotech. 2018, 121, 103457. [Google Scholar] [CrossRef]

- Clarke, A.P.; Vannucchi, P. Structural anisotropy: Using image analysis to quantify block-in-matrix fabrics. J. Struct. Geol. 2020, 131, 103939. [Google Scholar] [CrossRef]

- Wang, P.; Yin, Z.-Y.; Wang, Z.-Y. Micromechanical Investigation of Particle-Size Effect of Granular Materials in Biaxial Test with the Role of Particle Breakage. J. Eng. Mech. 2022, 148, 04021133. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, D.; Du, X.; Qi, J. A division method for shallow tunnels and deep tunnels considering soil stress path dependency. Comput. Geotech. 2021, 135, 104012. [Google Scholar] [CrossRef]

- Wang, X.; Liang, Z.; Nie, Z.; Gong, J. Stochastic numerical model of stone-based materials with realistic stone-inclusion features. Constr. Build. Mater. 2018, 197, 830–848. [Google Scholar] [CrossRef]

- Wang, X.; Gong, J.; An, A.; Zhang, K.; Nie, Z. Random generation of convex granule packing based on weighted Voronoi tessellation and cubic-polynomial-curve fitting. Comput. Geotech. 2019, 113, 103088. [Google Scholar] [CrossRef]

- Zheleznyakova, A.L. A cost-effective computational approach based on molecular dynamics for generating 3D packs of irregularly-shaped grains in a container of complex geometry. Powder Technol. 2021, 394, 403–423. [Google Scholar] [CrossRef]

- Yin, Z.-Y.; Wang, P.; Zhang, F. Effect of particle shape on the progressive failure of shield tunnel face in granular soils by coupled FDM-DEM method. Tunn. Undergr. Space Technol. 2020, 100, 103394. [Google Scholar] [CrossRef]

- Huang, G.; Zhang, S.; Xu, Y. A sphere-triangle contact model with complex boundary face problems. Appl. Math. Model. 2020, 93, 395–411. [Google Scholar] [CrossRef]

- Huang, G.; Tong, C.; Zhang, S.; Chen, X. A thermo-solid coupling model for disk discontinuous deformation analysis to simulate heating and stirring particles in rotary drums. Powder Technol. 2022, 402, 117326. [Google Scholar] [CrossRef]

- Wang, P.; Yin, Z.-Y.; Zhou, W.-H.; Chen, W.-B. Micro-mechanical analysis of soil–structure interface behavior under constant normal stiffness condition with DEM. Acta Geotech. 2021, 17, 2711–2733. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, X.; Ma, J.; Huang, L. A systematic framework for the 3D finite-discrete modelling of binary mixtures considering irregular block shapes and cohesive block-matrix interfaces. Powder Technol. 2021, 398, 117070. [Google Scholar] [CrossRef]

- Lin, Y.; Li, C.; Ma, J.; Lei, M.; Huang, L. Effects of void morphology on fracturing characteristics of porous rock through a finite-discrete element method. J. Nat. Gas Sci. Eng. 2022, 104, 104684. [Google Scholar] [CrossRef]

- Yan, C.; Zheng, Y.; Huang, D.; Wang, G. A coupled contact heat transfer and thermal cracking model for discontinuous and granular media. Comput. Methods Appl. Mech. Eng. 2021, 375, 113587. [Google Scholar] [CrossRef]

- Yan, C.; Wei, D.; Wang, G. Three-dimensional finite discrete element-based contact heat transfer model considering thermal cracking in continuous–discontinuous media. Comput. Methods Appl. Mech. Eng. 2022, 388, 114228. [Google Scholar] [CrossRef]

- Yan, C.; Guo, H.; Tang, Z. Three-dimensional continuous-discrete pore-fracture mixed seepage model and hydro-mechanical coupling model to simulate hydraulic fracturing. J. Pet. Sci. Eng. 2022, 215, 110510. [Google Scholar] [CrossRef]

- Montoya-Araque, E.A.; Suarez-Burgoa, L.O. Automatic generation of tortuous failure surfaces in block-in-matrix materials for 2D slope stability assessments. Comput. Geotech. 2019, 112, 17–22. [Google Scholar] [CrossRef]

- Zhang, P.; Jin, L.; Du, X.; Lu, D. Computational homogenization for mechanical properties of sand cobble stratum based on fractal theory. Eng. Geol. 2018, 232, 82–93. [Google Scholar] [CrossRef]

- Luerkens, D.W. Theory and Applications of Morphological Analysis: Fine Particles and Surfaces; CRC Press: London, UK, 1991. [Google Scholar]

- Sudeep, P.; Niwas, S.I.; Palanisamy, P.; Rajan, J.; Xiaojun, Y.; Wang, X.; Luo, Y.; Liu, L. Enhancement and bias removal of optical coherence tomography images: An iterative approach with adaptive bilateral filtering. Comput. Biol. Med. 2016, 71, 97–107. [Google Scholar] [CrossRef]

- Russ, J.C. Computer Assisted Microscopy: The Measurement and Analysis of Images; Plenum Press: New York, NY, USA, 1990. [Google Scholar]

- Feng, Y.; Zhao, H.; Li, X.; Zhang, X.; Li, H. A multi-scale 3D Otsu thresholding algorithm for medical image segmentation. Digit. Signal Process. 2017, 60, 186–199. [Google Scholar] [CrossRef]

| Material | Elastic Modulus/MPa | Poisson’s Ratio | Cohesion /MPa | Friction Angle/° |

|---|---|---|---|---|

| Model of the proposed heterogeneous model | ||||

| Soil | 58 | 0.32 | 0.12 | 28 |

| Limestone | 20,000 | 0.2 | 10 | 40 |

| Reinforcement area | 1500 | 0.2 | 0.4 | 30 |

| Lining structures | 20,000 | 0.2 | - | - |

| Model of the equivalent homogeneous model | ||||

| Equivalent surrounding rocks | 75 | 0.3 | 0.15 | 33 |

| Reinforcement area | 1500 | 0.2 | 0.4 | 30 |

| Initial support system | 20,000 | 0.2 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, H.; Xu, K.; Yang, W.; Yan, R.; Ma, Z.; Wang, Y.; Su, Z.; Wu, H. A Novel Modeling Approach for Soil and Rock Mixture and Applications in Tunnel Engineering. Sustainability 2023, 15, 3077. https://doi.org/10.3390/su15043077

Zhang X, Li H, Xu K, Yang W, Yan R, Ma Z, Wang Y, Su Z, Wu H. A Novel Modeling Approach for Soil and Rock Mixture and Applications in Tunnel Engineering. Sustainability. 2023; 15(4):3077. https://doi.org/10.3390/su15043077

Chicago/Turabian StyleZhang, Xiujie, Hongzhong Li, Kaiyan Xu, Wenwei Yang, Rongtao Yan, Zhanwu Ma, Yonghong Wang, Zhihua Su, and Haizhi Wu. 2023. "A Novel Modeling Approach for Soil and Rock Mixture and Applications in Tunnel Engineering" Sustainability 15, no. 4: 3077. https://doi.org/10.3390/su15043077

APA StyleZhang, X., Li, H., Xu, K., Yang, W., Yan, R., Ma, Z., Wang, Y., Su, Z., & Wu, H. (2023). A Novel Modeling Approach for Soil and Rock Mixture and Applications in Tunnel Engineering. Sustainability, 15(4), 3077. https://doi.org/10.3390/su15043077