Research on the Construction Method of Double Prevention Mechanism in Chinese Heating Enterprises Based on Bidirectional Dynamic Risk-Hidden Danger Transmission

Abstract

:1. Introduction

2. Construction of Double Prevention Mechanism for Heating Enterprises Based on PDCA

2.1. Overview of Double Prevention Mechanism

2.2. PDCA Operation Mode of Double Prevention Mechanism in Heating Enterprises

3. The Concrete Construction Implementation Steps of Double Prevention Mechanism in Heating Enterprises

3.1. Preparation Stage

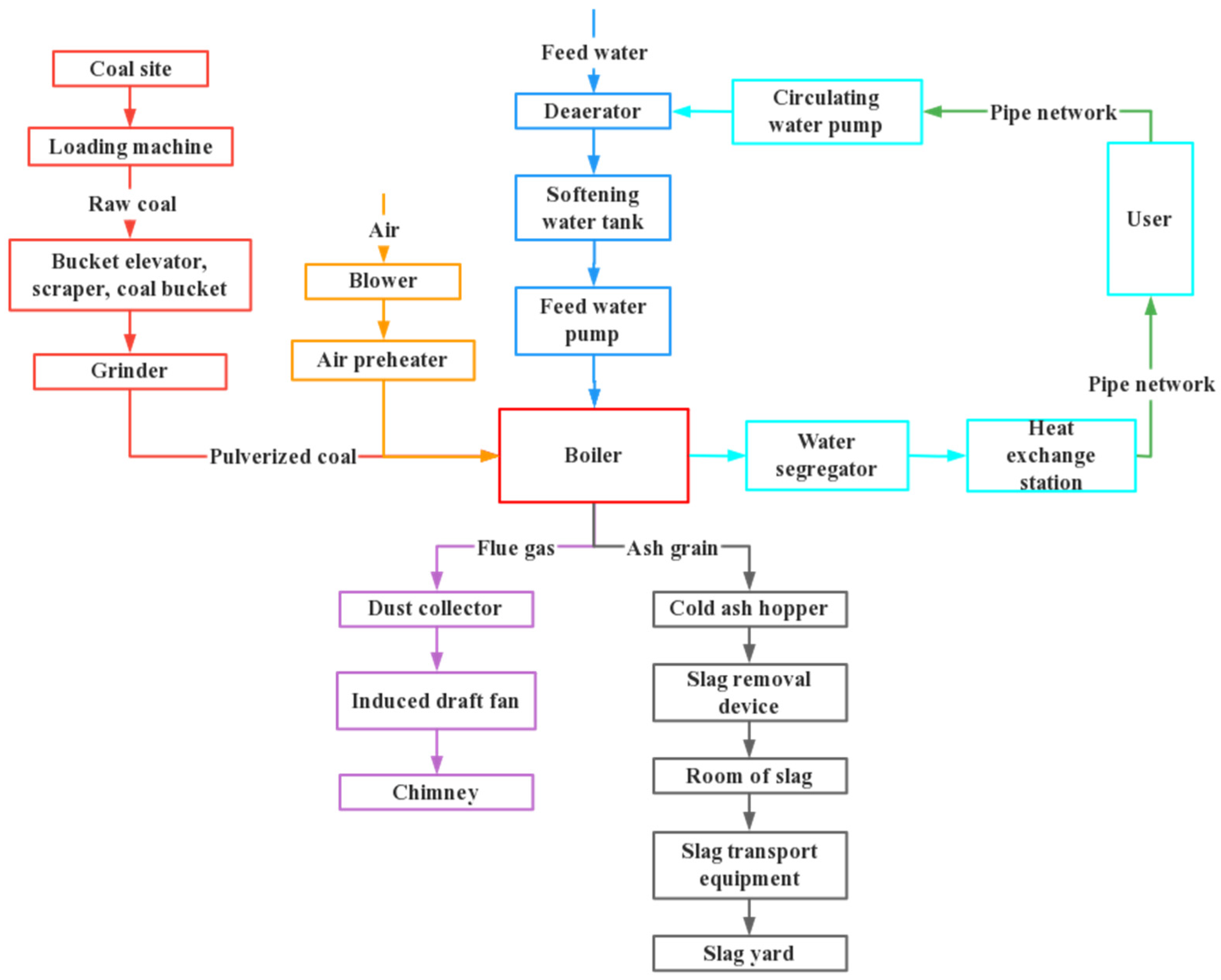

3.2. Risk Identification

- (1)

- Division of risk assessment units (risk points)

- (2)

- Identification of hazard sources (dangerous and harmful factors)

3.3. Risk Assessment

3.3.1. The Improved Dynamic Risk Assessment Method

- (1)

- The improved risk assessment method for operating conditions

- (2)

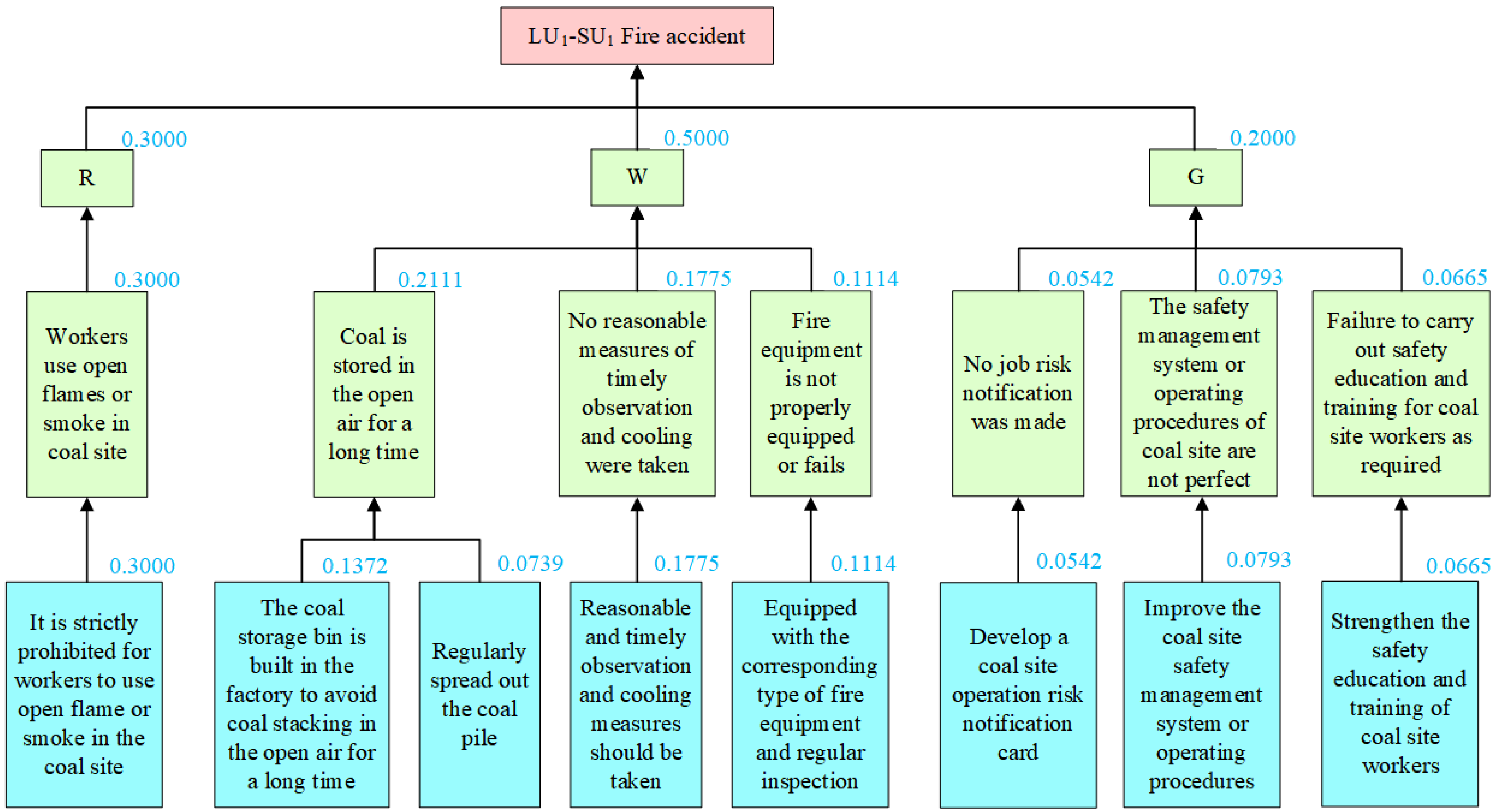

- Determine the weight of each level element of an accident type by using the analytic hierarchy process (AHP)

3.3.2. Result of Risk Assessment

3.4. Risk Hierarchical Control

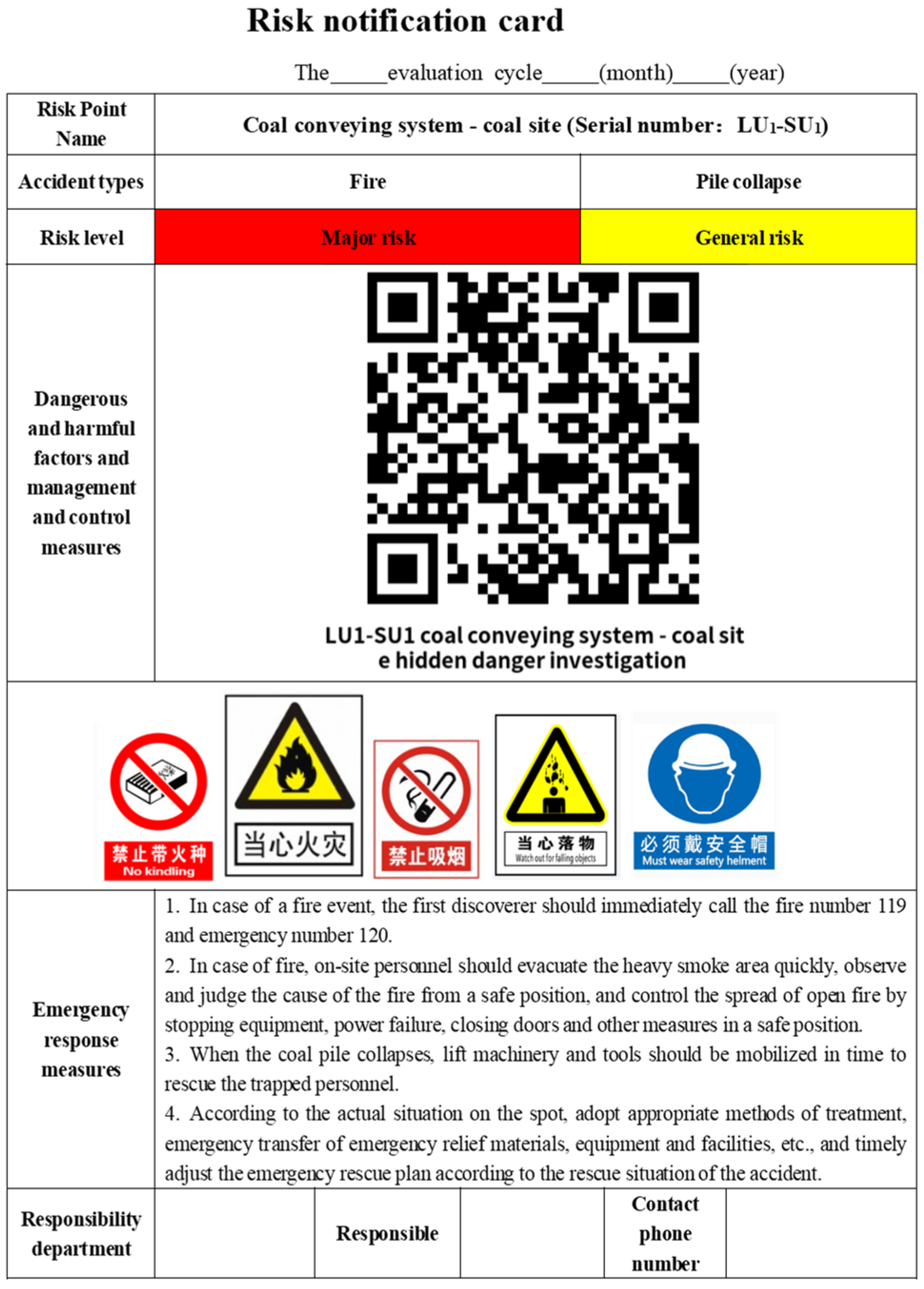

3.5. Risk Notification

3.6. Hidden Danger Investigation and Treatment

3.6.1. Hidden Danger Investigation

3.6.2. Hidden Danger Classification

3.6.3. Hidden Danger Treatment

3.7. Management Review and Continuous Improvement

4. Discussions

- (1)

- The heating enterprises need to establish a comprehensive and perfect double prevention mechanism that can operate effectively. It requires that the leaders of heating enterprises must learn and master the relevant contents of the construction of enterprise double prevention mechanism, improve the relevant documents and systems, carry out the education and training of all staff, increase the investment in safety, and pay attention to the research and development of the double prevention mechanism information system, etc.

- (2)

- Chinese government supervision departments at all levels should establish and improve the documents, systems, standards and norms for the construction of the double prevention mechanism according to the actual situation in their jurisdiction, so that the enterprises can have rules to follow. The government supervision departments should broaden the way of learning the double prevention mechanism and provide technical support for enterprises. Meanwhile, the hierarchical risk control and supervision responsibilities should be fully implemented, and differentiated dynamic management of risks should be realized.

- (3)

- The division method of risk assessment units proposed in this paper needs to be determined in combination with the actual production process or production system of heat supply enterprises. Users can reset unit numbers of each level according to certain rules. At the same time, users can further dig into the functions of the analytic hierarchy process software, so as to obtain a reasonable and standardized judgment matrix through expert group decision making. Thus, the actual calculated value of the accident possibility (L) calculated by the software is more accurate.

- (4)

- The construction method of double prevention mechanism proposed in this paper requires the close cooperation and participation of on-site technical personnel and safety management personnel familiar with heating enterprises so as to ensure the effectiveness of risk identification and evaluation unit results, control measures, and hidden danger investigation and treatment results. At the same time, the staff should truthfully and accurately record the daily hidden danger investigation and treatment, form a strict and standardized record ledger, and combine the hidden danger investigation and treatment with risk hierarchical control. Therefore, the bidirectional dynamic conduction of risk-hidden danger can be truly realized.

5. Conclusions

- (1)

- Combined with the current situation of safety management and double prevention mechanism construction in heating enterprises in China, based on the PDCA operation mode the overall process and specific steps of the double prevention mechanism construction in heating enterprises were elaborated in detail. By improving the traditional risk assessment method for operating conditions and combining with analytic hierarchy process, a new dynamic risk assessment method was proposed to realize dynamic risk assessment and accurate hierarchical control of accident risk.

- (2)

- The concept of “failure frequency” was put forward, and the definition of “hidden danger” was added. By organically combining the risk hierarchical control and hidden danger investigation and treatment of heating enterprises, the bidirectional dynamic conduction of risk-hidden danger was truly realized, which could avoid the disconnect between hidden danger investigation and risk assessment, and ensure the construction effect of double prevention mechanism in heating enterprises.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. 2020 Statistical Yearbook of Urban Construction. China Statistics Press, 2021. Available online: https://www.mohurd.gov.cn/gongkai/fdzdgknr/sjfb/tjxx/jstjnj/index.html (accessed on 15 October 2022).

- Ji, L. Study on current situation and development trend of urban district heating. Resid. Facil. China 2020, 2, 62–63. [Google Scholar]

- Liu, X.D. Research on the present situation and Development of heating in Weifang City Center. Constr. Technol. 2020, 2, 66–69. [Google Scholar] [CrossRef]

- Xu, H. Current situation of central heating, cause of energy consumption and analysis of energy saving technology. Petrochem. Technol. 2019, 26, 221+223. [Google Scholar] [CrossRef]

- Zhang, Y.Q. Analysis of current situation and planning development of urban district heating. Sci. Technol. Innov. Appl. 2020, 4, 49–50. [Google Scholar]

- Hui, Y.; Hu, Y.; Wang, W.K.; Jia, X. Analysis of current situation of heating boiler operation in Shenyang. Sci. Environ. Prot. 2019, 45, 95–99. [Google Scholar] [CrossRef]

- Min, Y.H. Current situation of heating safety in thermoelectric enterprises and countermeasures against accidents. Power Safety Technol. 2014, 16, 52–54. [Google Scholar] [CrossRef]

- The Office of the Work Safety Commission of the State Council. The Security and Commission Office of the State Council Issued Opinions to Promote the Construction of the Double Pre-Vention Mechanism of Safety Risk Hierarchical Control and Hidden Danger Investigation and Treatment. Available online: https://www.mem.gov.cn/awhsy_3512/awhbgswj/201610/t20161011_247664.shtml (accessed on 15 October 2022).

- Chen, Y.; Zhang, X.A.; Liu, Y.J.; Chen, Y.; Zhang, P. Research status of double prevention system of safety production in enterprises. Inn. Mong. Coal Econ. 2021, 6, 5–7. [Google Scholar] [CrossRef]

- The General Office of the Henan Provincial People’s Government. Notice of General Office of Henan Provincial People’s Government on the Issuance of Action Plan for Deepening the Construction of Double Prevention System of Production Safety Risks in Henan Province. Available online: https://www.henan.gov.cn/2018/11-28/724035.html (accessed on 15 October 2022).

- The General Office of the Shandong Provincial People’s Government. The General Office of the Shandong Provincial People’s Government Forwarded the Notice of the Provincial Safety Supervision Bureau on Further Improving the Construction of the Double Prevention System of Hierarchical Control of Production Safety Risks and Investigation and Management of Hidden Danger. Available online: http://www.shandong.gov.cn/art/2017/12/5/art_2259_27676.html (accessed on 15 October 2022).

- Wang, Z.Y.; Feng, B.X.; Wang, H.R. Analysis and discussion of double prevention safety management evaluation based on waste incineration power plant boiler. Boil. Technol. 2021, 52, 59–62. [Google Scholar] [CrossRef]

- Song, Y.; Chen, Z.; Zhang, S.; Wang, J.; Li, C.; Li, X.; Yuan, J.; Zhang, X. Comprehensive Evaluation System of Occupational Hazard Prevention and Control in Iron and Steel Enterprises Based on A Modified Delphi Technique. Int. J. Environ. Res. Public Health 2020, 17, 667. [Google Scholar] [CrossRef]

- Can, G.F.; Toktas, P. A novel fuzzy risk matrix based risk assessment approach. Kybernetes 2018, 47, 1721–1751. [Google Scholar] [CrossRef]

- Chen, M.; Wang, Y.; Leung, R.F.; Yang, S.C. Fuzzy comprehensive evaluation of single gully debris flow hazard based on cloud model. Yangtze River 2018, 49, 66–71. [Google Scholar] [CrossRef]

- Lin, D.Y.; Lei, M.F.; Cao, H.R.; Li, Y.F. Study on fuzzy comprehensive evaluation Method of railway construction risk under shield tunneling operation. J. Railw. Sci. Eng. 2018, 15, 1347–1355. [Google Scholar] [CrossRef]

- Zhang, K.; Duan, M.; Luo, X.; Hou, G. A fuzzy risk matrix method and its application to the installation operation of subsea collet connector. J. Loss Prev. Process Ind. 2017, 45, 147–159. [Google Scholar] [CrossRef]

- Lei, C.Q. Analysis of basic concepts and double prevention mechanism in the field of safety in production. China Sci. Technol. Saf. Prod. 2017, 13, 17–21. [Google Scholar] [CrossRef]

- Yan, W. Suggestions on the construction process of double prevention mechanism in heating enterprises. Build. Mater. Decor. 2020, 17, 177–180. [Google Scholar]

- Jia, B.L.; Tian, H.G. Key points of construction of double prevention system in using unit of organic heat carrier boiler. Chem. Equip. Technol. 2020, 41, 46–49. [Google Scholar] [CrossRef]

- Cen, Y.G.; Huang, L.; Dou, Q. Application of fangyuan theory and PDCA principle in safety management. Ind. Saf. Environ. Prot. 2017, 43, 90–94. [Google Scholar] [CrossRef]

- GB/T 13861-2022; Classification and Code for the Hazardous and Harmful Factors in Process. Standards Press of China: Beijing, China, 2022.

- GB 6441-1986; Classification Standard for Casualty Accidents of Enterprise Workers. Standards Press of China: Beijing, China, 1986.

- Chen, Y.; Wang, Z. Accident causing theory in construction safety management. IOP Conf. Ser. Earth Environ. Sci. 2021, 638, 012097. [Google Scholar] [CrossRef]

- Zhang, Y.B. Research on hazard source control theory and its application in coal mine accident prevention. Min. Saf. Environ. Prot. 2017, 44, 105–108+113. [Google Scholar] [CrossRef]

- Sun, L.H.; Shang, K.; Yuan, X.F. Research on Safety Risk Assessment of Coal Mining Mining Jobs based on LEC Method. Saf. Coal Mines. 2019, 50, 248–252. [Google Scholar] [CrossRef]

- Liu, H. Research on Risk Evaluation of 500 m long rail welding System based on LEC evaluation method. Railw. Stand. Des. 2019, 63, 39–43. [Google Scholar] [CrossRef]

- Jia, W.Z.; Liu, Y.; Wang, J.; Bai, X.L. Application of operating condition risk assessment method in vehicle maintenanceoperation risk assessment. Urban Mass Transit. 2019, 22, 143–146. [Google Scholar] [CrossRef]

- Liu, L.Z.; Ke, G.H.; Shi, L.; Shan, Q. Application of LEC evaluation method in heating system risk classification. China Resour. Compr. Util. 2019, 37, 161–164. [Google Scholar] [CrossRef]

- Cheng, G.; Lu, W.D. Research on hazard evaluation method of FTA-LEM. Min. Saf. Environ. Prot. 2018, 45, 105–108+114. [Google Scholar] [CrossRef]

- Chen, Y. Research on Construction Method and Information System of Double Prevention System in Non-Coal Mine Mountains. Master’s Thesis, Inner Mongolia University of Science and Technology, Baotou, China, 2021. [Google Scholar] [CrossRef]

- Chen, Y.; Tao, K.; Liu, Y.J.; Ren, Y.H.; Liu, J.C.; Li, T.; Li, M.L. Study on the construction method of non-coal mine mountain risk classification control and hidden trouble investigation and management. Ind. Saf. Environ. Prot. 2021, 47, 55–58. [Google Scholar] [CrossRef]

- Li, R.G.; Liu, Z.Q. Causes analysis and countermeasures of coal pile spontaneous combustion in coal yard of thermal power plant. J. Shenyang Inst. Eng. 2016, 12, 319–322. [Google Scholar] [CrossRef]

- Han, S.C.; Yang, Y.C.; Liu, Y.D.; Zhang, P.; Li, S.W. Research on comprehensive evaluation method for heating project based on analytic hierarchy processing. IOP Conf. Ser. Earth Environ. Sci. 2018, 108, 052085. [Google Scholar] [CrossRef]

- Industry and trade industry major production accidents decision criteria. China Saf. Prod. J. 2017, 12, 6.

- Vanderhaegen, F. Erik hollnagel: Safety-I and safety-II, the past and future of safety management. Cogn. Technol. Work. 2015, 17, 461–464. [Google Scholar] [CrossRef]

- Koivupalo, M.; Sulasalmi, M.; Rodrigo, P.; Väyrynen, S. Health and safety management in a changing organisation: Case study global steel company. Saf. Sci. 2015, 74, 128–139. [Google Scholar] [CrossRef]

- Khan, F.; Rathnayaka, S.; Ahmed, S. Methods and models in process safety and risk management: Past, present and future. Process Saf. Environ. Prot. 2015, 98, 116–147. [Google Scholar] [CrossRef]

| Serial Number | Large Unit | Sub-Unit | Position Unit (Equipment and Facilities/Operational Activities) |

|---|---|---|---|

| 1 | Coal conveying system (LU1) | Coal site (LU1-SU1) | Coal pile (LU1-SU1-PU1) |

| Windbreak and dust suppression net (LU1-SU1-PU2) | |||

| Coal conveying device (LU1-SU2) | The inlet through which coal enters (LU1-SU2-PU1) | ||

| Bucket machine (LU1-SU2-PU2) | |||

| Scraper (LU1-SU2-PU3) | |||

| Coal scuttle (LU1-SU2-PU4) | |||

| Loading machine (LU1-SU3) | Loading machine (LU1-SU3-PU1) |

| Serial Number | Accident Category | The Weight of Dangerous and Harmful Factors Category (Qi) | The Weight of Dangerous and Harmful Factors (qi) | Proposed Control Measures and Weights | Existing Measures | Fci | Li | Accident Risk Assessment D = LEC | Hazard Level | Risk Level | Supplement Measures | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Suggested Control Measures | qci | Actual Calculated Value of L | Lmax | E | C | D | ||||||||||

| 1 | Fire | R (0.3) | Workers use open flames or smoke in coal site (0.3000) | It is strictly prohibited for workers to use open flame or smoke in the coal site | 0.3000 | It is strictly prohibited for workers to use open flame or smoke in the coal site | 1/3 | 1.0000 | 5.7470 | 6 | 6 | 15 | 540 | Level 1 | Major risk | |

| W (0.5) | Coal is stored in the open air for a long time (0.2111) | The coal storage bin is built in the factory to avoid coal stacking in the open air for a long time | 0.1372 | 1 | 1.3720 | The coal storage bin is built in the factory to avoid coal stacking in the open air for a long time | ||||||||||

| Regularly spread out the coal pile | 0.0739 | Regularly spread out the coal pile | 0 | 0.0000 | ||||||||||||

| No reasonable measures of timely observation and cooling are taken (0.1775) | Reasonable and timely observation and cooling measures should be taken | 0.1775 | 1 | 1.7750 | Reasonable and timely observation and cooling measures should be taken | |||||||||||

| Fire equipment is not properly equipped or fails (0.1114) | Equipped with the corresponding type of fire equipment and regular inspection | 0.1114 | 1 | 1.1140 | Equipped with the corresponding type of fire equipment and regular inspection | |||||||||||

| G (0.2) | No job risk notification is made (0.0542) | Develop a coal site operation risk notification card | 0.0542 | Develop a coal site operation risk notification card | 0 | 0.0000 | ||||||||||

| The safety management system or operating procedures of coal site are not perfect (0.0793) | Improve the coal site safety management system or operating procedures | 0.0793 | Improve the coal site safety management system or operating procedures | 1/3 | 0.2643 | |||||||||||

| Failure to carry out safety education and training for coal site workers as required (0.0665) | Strengthen the safety education and training of coal site workers | 0.0665 | Strengthen the safety education and training of coal site workers | 1/3 | 0.2217 | |||||||||||

| Probability of Accident (L) | Value of Fraction | Frequency of Human Exposure to Hazardous Environments (E) | Value of Fraction | Consequences of the Accident (C) | Value of Fraction |

|---|---|---|---|---|---|

| Totally expected | 10 | Continuous exposure | 10 | More than ten people died | 100 |

| Quite likely | 6 | Exposure during daily working hours | 6 | Several people were killed | 40 |

| Maybe, but not often | 3 | Once a week or occasional exposure | 3 | One person died | 15 |

| Completely unexpected, rarely possible | 1 | Monthly exposure | 2 | Severe disability | 7 |

| You can imagine, very unlikely | 0.5 | Several exposures per year | 1 | Have a disability | 3 |

| Highly unlikely | 0.2 | Very rare exposure | 0.5 | Minor injuries required medical care | 1 |

| It’s practically impossible | 0.1 |

| Corresponding Improved LEC Method Hazard Level | Level 1 | Level 2 | Level 3 | Level 4 and Level 5 |

|---|---|---|---|---|

| Risk level | Major risk | Greater risk | General risk | Low risk |

| General accident hidden danger level | Level 1 hidden danger | Level 2 hidden danger | Level 3 hidden danger | Level 4 hidden danger |

| management and control level | The company | The departmental | District team | Team |

| Corresponding color | Red | Orange | Yellow | Blue |

| Investigation Type | ☐Comprehensive Hidden Danger Investigation ☐Professional Hidden Danger Investigation ☐DAILY Hidden Danger Investigation ☐Post Hidden Danger Investigation | |||||||

|---|---|---|---|---|---|---|---|---|

| Investigation Personnel | Investigation Department/Team | Investigation Date | ___(day)___(month)___(year) | |||||

| Serial Number | Accident Category | Dangerous and Harmful Factors Category | Dangerous and Harmful Factors | Control Measures | Whether It Is Effective | Existing Problems | ||

| √ | × | |||||||

| 1 | Fire | R | Workers use open flames or smoke in coal site | It is strictly prohibited for workers to use open flame or smoke in the coal site | ||||

| W | Coal is stored in the open air for a long time | The coal storage bin is built in the factory to avoid coal stacking in the open air for a long time | ||||||

| Regularly spread out the coal pile | ||||||||

| No reasonable measures of timely observation and cooling are taken | Reasonable and timely observation and cooling measures should be taken | |||||||

| Fire equipment is not properly equipped or fails | Equipped with the corresponding type of fire equipment and regular inspection | |||||||

| G | No job-risk notification is made | Develop a coal site operation risk notification card | ||||||

| The safety management system or operating procedures of coal site are not perfect | Improve the coal site safety management system or operating procedures | |||||||

| Failure to carry out safety education and training for coal site workers as required | Strengthen the safety education and training of coal site workers | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Teng, T.; Duan, Z.; Cui, M.; Wang, W.; Ren, Y.; Tian, Z. Research on the Construction Method of Double Prevention Mechanism in Chinese Heating Enterprises Based on Bidirectional Dynamic Risk-Hidden Danger Transmission. Sustainability 2023, 15, 2849. https://doi.org/10.3390/su15032849

Liu Y, Teng T, Duan Z, Cui M, Wang W, Ren Y, Tian Z. Research on the Construction Method of Double Prevention Mechanism in Chinese Heating Enterprises Based on Bidirectional Dynamic Risk-Hidden Danger Transmission. Sustainability. 2023; 15(3):2849. https://doi.org/10.3390/su15032849

Chicago/Turabian StyleLiu, Yejiao, Ting Teng, Zeyu Duan, Mengyuan Cui, Wencai Wang, Yuhui Ren, and Zhichao Tian. 2023. "Research on the Construction Method of Double Prevention Mechanism in Chinese Heating Enterprises Based on Bidirectional Dynamic Risk-Hidden Danger Transmission" Sustainability 15, no. 3: 2849. https://doi.org/10.3390/su15032849

APA StyleLiu, Y., Teng, T., Duan, Z., Cui, M., Wang, W., Ren, Y., & Tian, Z. (2023). Research on the Construction Method of Double Prevention Mechanism in Chinese Heating Enterprises Based on Bidirectional Dynamic Risk-Hidden Danger Transmission. Sustainability, 15(3), 2849. https://doi.org/10.3390/su15032849