Optimization of the Granular Mixture of Natural Rammed Earth Using Compressible Packing Model

Abstract

1. Introduction

2. Review of Standards, Norms, Articles, and Mix Design Methods for RE Construction

2.1. Summarized Review of Norms, Standards, and Scientific Publications Related to RE Mix Design

2.2. Mix Design Theory and Models for RE Material

3. Materials and Methods

3.1. Context of the Study

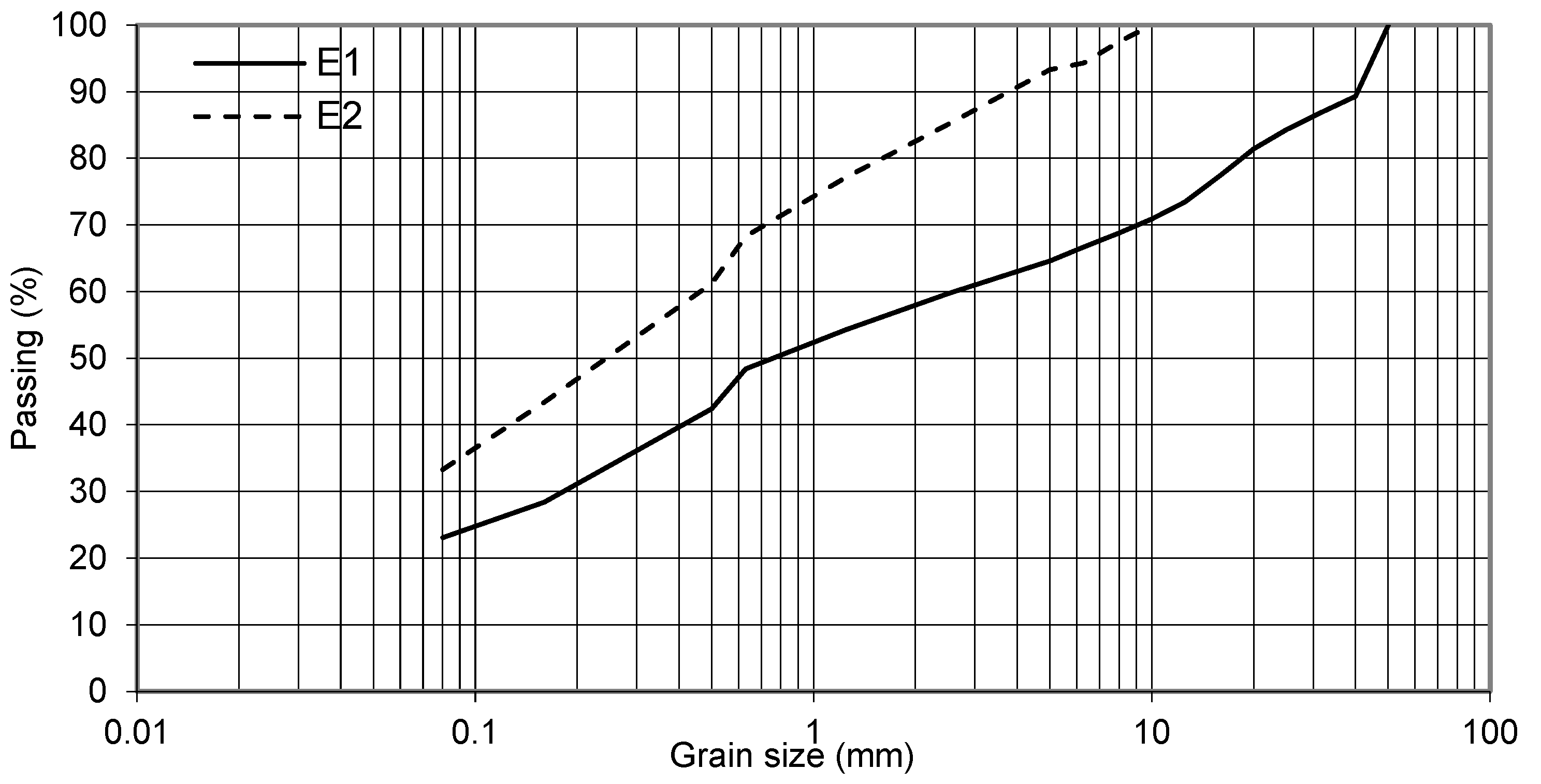

3.2. Experimental Soil Characterization

3.3. Elementary Compactness

- Clay: Particle size (PS) less than 0.002 mm;

- Silt: PS between 0.002 mm and 0.06 mm;

- Sand: PS between 0.06 mm and 2 mm;

- Gravel: PS between 2 mm and 60 mm.

3.3.1. Fine Elements (FE) Elementary Compactness

3.3.2. Sand and Gravel Elementary Compactness

3.3.3. Experimental Compactness and Compaction Index

3.4. Preparation of Specimens

3.5. Mechanical Tests

4. Results and Discussions

4.1. Experimental Compactness and RE Compaction Index

4.2. Granularity Effect on the Mixture’s Compactness

- Choose the right dosage and the right granular class to add or reduce to optimize compactness;

- Evaluate the effect of any granular class on compactness;

- Define the granular corrections considering available raw materials in site.

4.3. Mechanical Performances: Stiffness and Compressive Strength

5. Conclusions

- Existing norms and technical documents give suitable grading for rammed earth without considering aggregate types and their granular arrangement after compaction. Some normative dosages do not ensure optimal compactness and compressive strength and can be revised;

- Compaction index K has to be defined before starting simulations. Ramming operations in the laboratory should resemble real conditions. Further investigations and more tests could be carried out to estimate an average compaction index for the rammed earth technique;

- A significant dispersion of compaction index values could be observed especially when manual compaction is used on site. Therefore, determining its value is always necessary;

- The optimum dosage of fine elements, sand, and gravel depends on the original soil composition, the elementary compactness of each granular class, and raw granular materials to use for correction;

- In order to limit the number of simulations, the CPM can be combined with some mixed design methods such as the Bolomey method;

- In this article, the correction of the original soils E1 (Dmax = 50 mm) and E2 (Dmax = 10 mm) allows for achieving a high UCS of 2.75 MPa. A direct correlation between UCS and compactness is still not clear and difficult to assess. As a perspective, a large number of tests could be performed to help to link these two parameters;

- All the studied soils are natural. The found UCS can be even higher using some natural stabilizing elements like lime;

- A mix design workflow can be utilized in any RE construction project using any soil extracted from any region;

- A general workflow, proposed in Figure 12, can be applied to design an optimized granular mixture according to the CPM.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lomite, H.; Kare, S. Impact of Construction Material on Environment; University College of Borås: Borås, Sweden, 2009; p. 66. [Google Scholar]

- Johnson, D.C., III. The Energy Efficiency and Living Comfort of a Stabilized Rammed Earth Dwelling in Comparison with a Traditional Stud Frame Building. Master’s Thesis, West Virginia University, Morgantown, WV, USA, 2020. [Google Scholar]

- Walker, P. Standards Australia International. The Australian Earth Building Handbook; Standards Australia International: Sydney, Australia, 2000. [Google Scholar]

- Bui, Q.B.; Morel, J.C.; Venkatarama Reddy, B.V.; Ghayad, W. Durability of Rammed Earth Walls Exposed for 20 Years to Natural Weathering. Build. Environ. 2009, 44, 912–919. [Google Scholar] [CrossRef]

- Maniatidis, V.; Walker, P. Structural Capacity of Rammed Earth in Compression. J. Mater. Civ. Eng. 2008, 20, 230–238. [Google Scholar] [CrossRef]

- El-Nabouch, R.; Bui, Q.-B.; Plé, O.; Perrotin, P. Assessing the In-Plane Seismic Performance of Rammed Earth Walls by Using Horizontal Loading Tests. Eng. Struct. 2017, 145, 153–161. [Google Scholar] [CrossRef]

- Jiménez Delgado, M.C.; Guerrero, I.C. The Selection of Soils for Unstabilised Earth Building: A Normative Review. Constr. Build. Mater. 2007, 21, 237–251. [Google Scholar] [CrossRef]

- Koutous, A.; Hilali, E. Grain Shape Effects on the Mechanical Behavior of Compacted Earth. Case Stud. Constr. Mater. 2019, 11, e00303. [Google Scholar] [CrossRef]

- Burroughs, S. Recommendations for the Selection, Stabilization, and Compaction of Soil for Rammed Earth Wall Construction. J. Green Build. 2010, 5, 101–114. [Google Scholar] [CrossRef]

- Houben, H.; Guillaud, H. Traité de Construction En Terre; Editions Parenthèses: Marseille, France, 1989. [Google Scholar]

- NZS 4298; Materials and Workmanship for Earth Buildings. Materials and Workmanship for Earth Buildings. Joint Australia/New Zealand Technical Committee-Standards New Zealand. Standards New Zealand: Wellington, New Zealand, 1998.

- Ciancio, D.; Jaquin, P.; Walker, P. Advances on the Assessment of Soil Suitability for Rammed Earth. Constr. Build. Mater. 2013, 42, 40–47. [Google Scholar] [CrossRef]

- Middleton, G.F.; Schneider, L.M. Earth-Wall Construction; CSIRO Publishing: Clayton, Australia, 1987. [Google Scholar]

- Walker, P.; Keable, R.; Martin, J.; Maniatidis, V. Rammed Earth: Design and Construction Guidelines; BRE Bookshop Watford: Watford, UK, 2005. [Google Scholar]

- Hall, M.; Djerbib, Y. Rammed Earth Sample Production: Context, Recommendations and Consistency. Constr. Build. Mater. 2004, 18, 281–286. [Google Scholar] [CrossRef]

- Bui, Q.-B.; Morel, J.-C.; Hans, S.; Meunier, N. Compression Behaviour of Non-Industrial Materials in Civil Engineering by Three Scale Experiments: The Case of Rammed Earth. Mater. Struct. 2009, 42, 1101–1116. [Google Scholar] [CrossRef]

- Bui, T.T.; Mesbah, A.; Maximillien, S.; Limam, A. Behavior of Rammed Earth Walls under Compression or Shear Stress. J. Mater. Environ. Sci. 2016, 7, 3584–3594. [Google Scholar]

- Nahouo, S. Étude de Caractérisation de La Terre Jaune, de Formulation de Bétons de Terre et de Caractérisation Mécanique Des Bétons de Terre Confectionnés. Ph.D. Thesis, ETS, Princeton, NJ, USA, 2017. [Google Scholar]

- Stovall, T.; De Larrard, F.; Buil, M. Linear Packing Density Model of Grain Mixtures. Powder Technol. 1986, 48, 1–12. [Google Scholar] [CrossRef]

- Mooney, M. The Viscosity of a Concentrated Suspension of Spherical Particles. J. Colloid Sci. 1951, 6, 162–170. [Google Scholar] [CrossRef]

- Sedran, T.; de Larrard, F.; Angot, D. Prediction of Granular Mixtures Compactness Applying the Solid Suspension Model-II- Validation, Case of Confined Mixtures. Bull. Liaison Lab. Ponts Chaussées 1994, 194, 71–86. [Google Scholar]

- de Larrard, F. Concrete Mixture-Proportioning—A Scientific Approach; CRC Press: London, UK, 2014. [Google Scholar] [CrossRef]

- Sedran, T.; De Larrard, F. RENE-LCPC–Un Logiciel Pour Optimiser La Granularité Des Matériaux de Génie Civil. Bull. Lab. Ponts Chaussées 1994, 194, 87–93. [Google Scholar]

- Lecomte, A.; Mechling, J.-M. Compacité Des Mélanges et Propriétés Des Grains. Bull.-Lab. Ponts Chaussees 1999, 194, 21–34. [Google Scholar]

- Pouliot, N.; Sedran, T.; de LARRARD, F.; Marchand, J. Prédiction de la compacité des bétons compactés au rouleau à l’aide d’un modèle d’empilement granulaire. Bull. Lab. Des Ponts Chaussées 2001, 14, 23–36. [Google Scholar]

- Kölbl, O.; Boussahl, M.; Hostettler, H. Requirements in an Inventory on Cultural Heritage in Morocco and Reflections on the Presentation of the Information. In Proceedings of the XIXth International Symposium, CIPA, Antalya, Turkey, 30 September–4 October 2003; pp. 25–28. [Google Scholar]

- Cheikhi, W.; Baba, K.; Lamrani, S.M.; Nounah, A.; Khalfaoui, M.; Bahi, L. Study of Indoor Performances of a Building Using Rammed Earth. MATEC Web Conf. 2018, 149, 02089. [Google Scholar] [CrossRef]

- Boussalh, M.; Cancino, C.; Marcus, B.; Wong, L. The Development of a Conservation and Rehabilitation Plan (CRP) for the Earthen Kasbah of Taourirt in Southern Morocco. J. Mater. Environ. Sci. 2016, 7, 3579–3583. [Google Scholar]

- AFNOR. NF P94-050; Soil: Investigation and Testing. Determination of Moisture Content. Oven Drying Method. AFNOR Editions: La Plaine Saint-Denis, France, 1995.

- AFNOR. NF P94-056; Soil: Investigation and Testing. Granulometric Analysis. Dry Sieving Method after Washing. AFNOR Editions: La Plaine Saint-Denis, France, 1996.

- ISO/TC 24/SC 4. ISO 13320:2020; Particle Size Analysis—Laser Diffraction Methods. AFNOR Editions: La Plaine Saint-Denis, France, 2020.

- AFNOR. NF P94-051; Soil: Investigation and Testing. Determination of Atterberg’s Limits. Liquid Limit Test Using Casagrande apparatus. Plastic limit test on rolled thread. AFNOR Editions: La Plaine Saint-Denis, France, 1993.

- AFNOR. NF P94-054; Soil: Investigation and Testing. Determination of Particle Density. Pycnometer Method. AFNOR Editions: La Plaine Saint-Denis, France, 1991.

- AFNOR. NF EN ISO 11272; Soil quality-Determination of Dry Bulk Density. AFNOR Editions: La Plaine Saint-Denis, France, 2014.

- AFNOR. NF P94-093; Soils: Investigation and Testing-Determination of the Compaction Reference Values of a Soil Type-Standard Proctor Test-Modified Proctor Test. AFNOR Editions: La Plaine Saint-Denis, France, 2015.

- ISO/TC 182. ISO/TS 17892-3:2004; Determination of Particle Density—Pycnometer Method. ISO: Geneva, Switzerland, 2004.

- AFNOR. NF EN 12504-4; Testing Concrete in Structures—Part 4: Determination of Ultrasonic Pulse Velocity. AFNOR Editions: La Plaine Saint-Denis, France, 2021.

- AFNOR. NF EN 12390-4; Testing Hardened Concrete—Part 4: Compressive Strength-Specification for Testing Machines. AFNOR Editions: La Plaine Saint-Denis, France, 2020.

- ISO/TC 182. ISO 14688-2:2017; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 2: Principles for a Classification. ISO: Geneva, Switzerland, 2017.

- Cintré, M. Recherche d’un Mode Opératoire de Mesure de Compacité de Mélanges Vibrés à Sec de Classes Élémentaires de Granulats; Rapport LRPC Blois Janvier; LRPC: Blois, France, 1988. [Google Scholar]

- Rao, K.V. Study on the Mix Design of Polymer Concrete Made with Polyester and Epoxy Resins. Ph.D. Thesis, IIT Delhi, Delhi, India, 1991. [Google Scholar]

- Ávila, F.; Puertas, E.; Gallego, R. Characterization of the Mechanical and Physical Properties of Unstabilized Rammed Earth: A Review. Constr. Build. Mater. 2021, 270, 121435. [Google Scholar] [CrossRef]

| Gravel (%) | Sand (%) | Silt (%) | Clay (%) | |

|---|---|---|---|---|

| RPCT 2011 | 2–10% | 32–58% | 8–16% | 8–26% |

| NZS 4298 | 50–70% | 15–30% | 5–15% | |

| CRA-Terre guide | 0–15% | 40–50% | 20–35% | 15–25% |

| HB 195 | 45–75% | 10–30% | 0–20% | |

| Test | Standard/Technical Document Used |

|---|---|

| Water content | NF P 94-050 [29] |

| Sieving | NF P 94-056 [30] |

| Laser granulometry | ISO 13320: 2020 [31] |

| Atterberg limits | NF P 94-051 [32] |

| Absolute density | NF P 94-054 [33] |

| Dry bulk density | NF EN ISO 11272 [34] |

| Elementary compactness | LCPC protocol [23] |

| Modified Proctor test | NF P 94-093 [35] |

| Specific gravity of soil solids by Pycnometer method | ISO/TS 17892-3: 2004 [36] |

| Ultrasonic pulse velocity test | NF EN 12504-4 [37] |

| Compressive strength | NF EN 12390-4 [38] |

| Proportions (%) | Liquid Limit wL (%) | Plasticity Index (Ip) | Water Content w (%) | Wopt (%) | ρopt (Kg/m3) | Dmax (mm) | ||

|---|---|---|---|---|---|---|---|---|

| E1 | Clay | 1.16 | 27.6 | 8.2 | 6.4 | 9.9 | 1872 | 50 |

| silt | 19.45 | |||||||

| sand | 36.39 | |||||||

| gravel | 43 | |||||||

| E2 | clay | 1.67 | 27.4 | 7.8 | 6.1 | 9.58 | 1850 | 10 |

| silt | 28.04 | |||||||

| sand | 53.11 | |||||||

| gravel | 17.18 | |||||||

| FE | Sand | Gravel | |

|---|---|---|---|

| Density (Kg/m3) | 775.5 | 1312 | 1600 |

| Average diameter di (mm) | 0.03 | 1.03 | 6 |

| Elementary compactness Ci | 0.733 | 0.481 | 0.778 |

| Corrected elementary compactness βi | 0.842 | 0.550 | 0.912 |

| Placement Process | Pouring [40] | Tamping with a Rod [41] | Vibration [22] | Vibration and 10 kPa Pressure [22] | Roller Compacted Concrete [25] |

|---|---|---|---|---|---|

| K | 4.1 | 4.5 | 4.75 | 9 | 14 |

| Recipe | FE Dosage (%) | γd (KN/m3) | Void Ratio e | Cexp | Kexp | C |

|---|---|---|---|---|---|---|

| E1 | 20.61 | 18.87 | 0.339 | 0.747 | 7.39 | 0.746 |

| E2 | 29.71 | 17.14 | 0.374 | 0.710 | 7.58 | 0.706 |

| Soil | UV (m/s) | UCS (MPa) | Young’s Modulus (MPa) |

|---|---|---|---|

| E2 | 500 | 1.16 | 31.43 |

| E3 | 1180 | 2.75 | 133.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dialmy, A.; Rguig, M.; Meliani, M. Optimization of the Granular Mixture of Natural Rammed Earth Using Compressible Packing Model. Sustainability 2023, 15, 2698. https://doi.org/10.3390/su15032698

Dialmy A, Rguig M, Meliani M. Optimization of the Granular Mixture of Natural Rammed Earth Using Compressible Packing Model. Sustainability. 2023; 15(3):2698. https://doi.org/10.3390/su15032698

Chicago/Turabian StyleDialmy, Atar, Mustapha Rguig, and Mehdi Meliani. 2023. "Optimization of the Granular Mixture of Natural Rammed Earth Using Compressible Packing Model" Sustainability 15, no. 3: 2698. https://doi.org/10.3390/su15032698

APA StyleDialmy, A., Rguig, M., & Meliani, M. (2023). Optimization of the Granular Mixture of Natural Rammed Earth Using Compressible Packing Model. Sustainability, 15(3), 2698. https://doi.org/10.3390/su15032698