A Comparative Study on Smart Windows Focusing on Climate-Based Energy Performance and Users’ Comfort Attributes

Abstract

1. Introduction

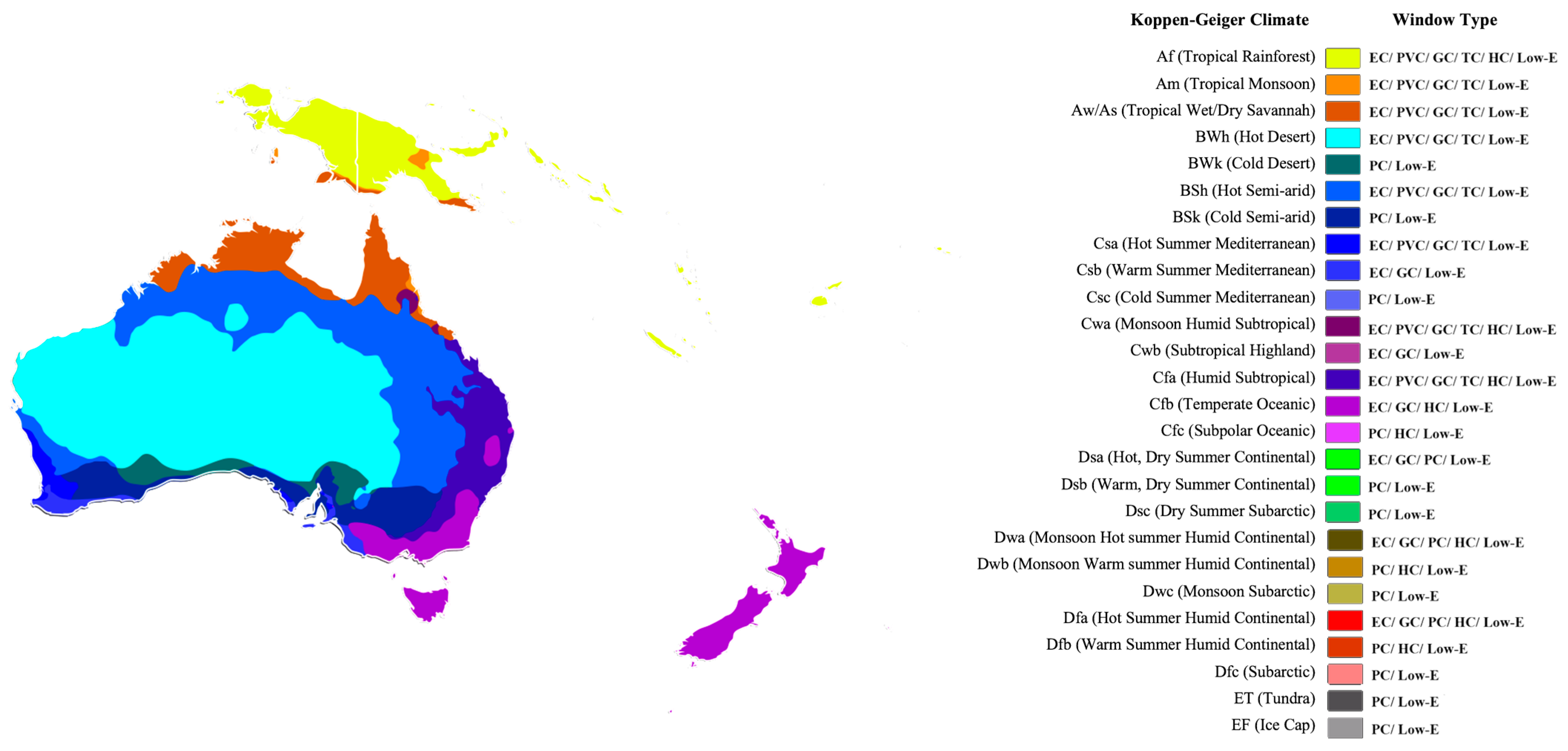

2. Methodology

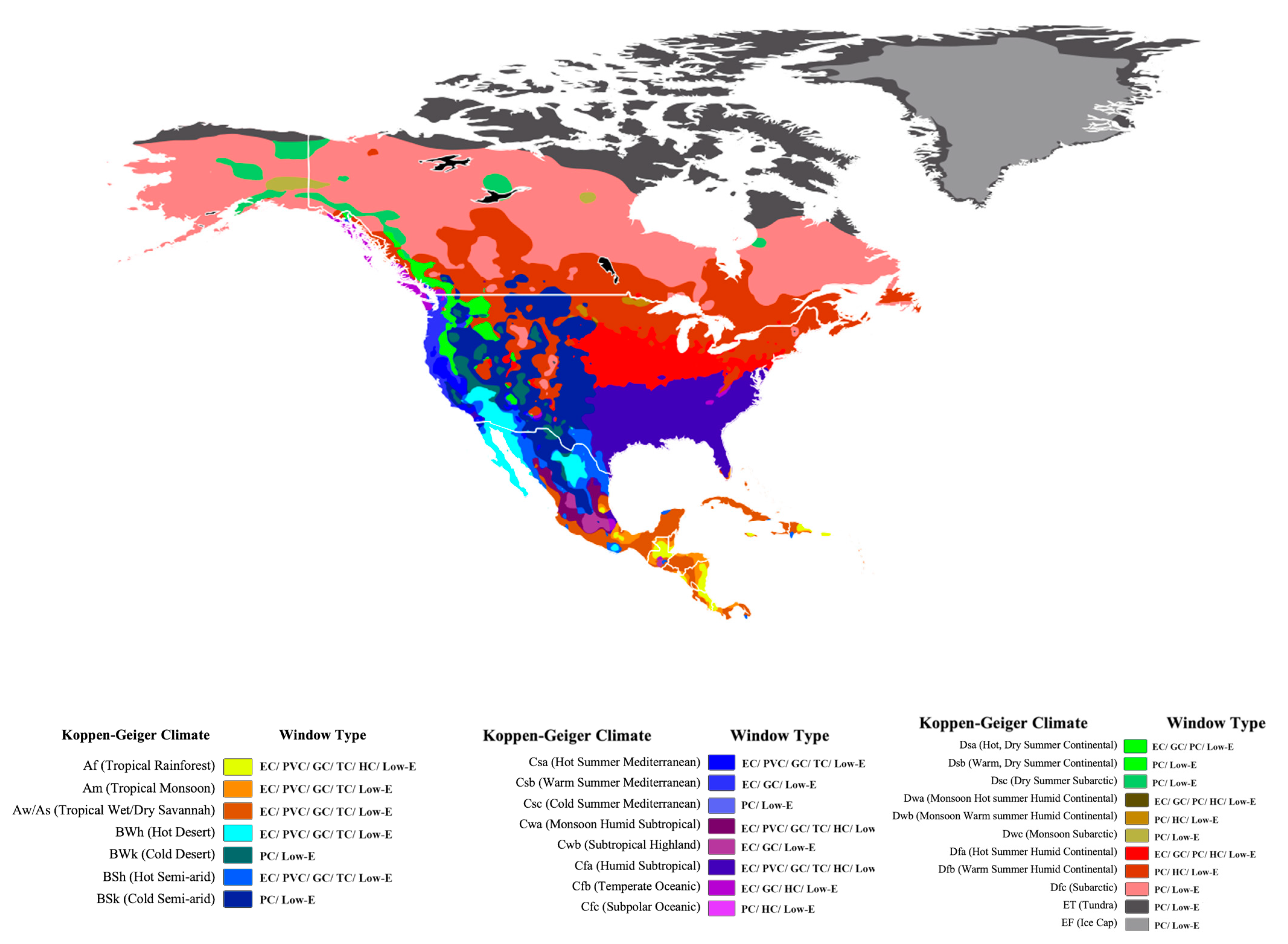

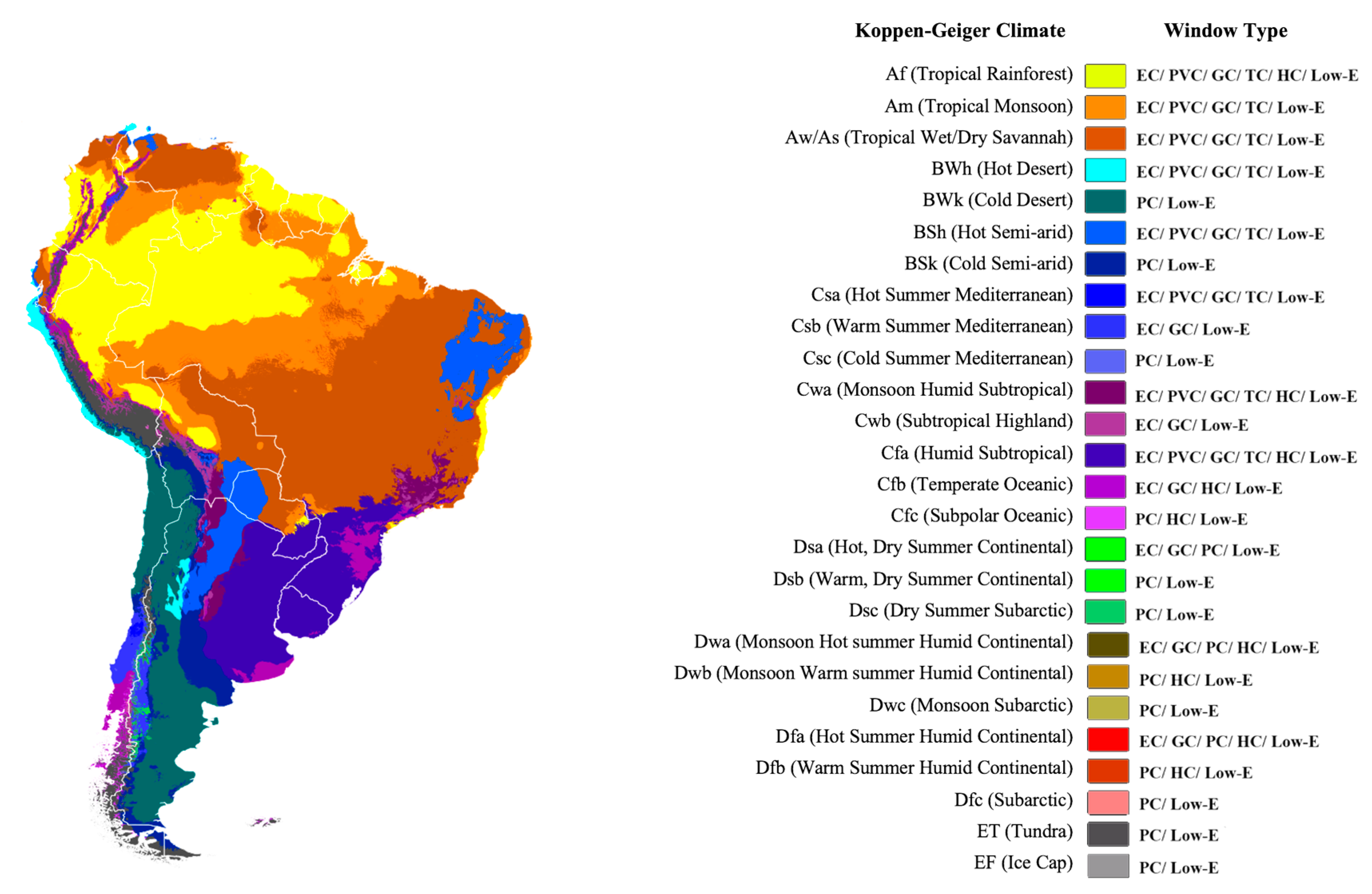

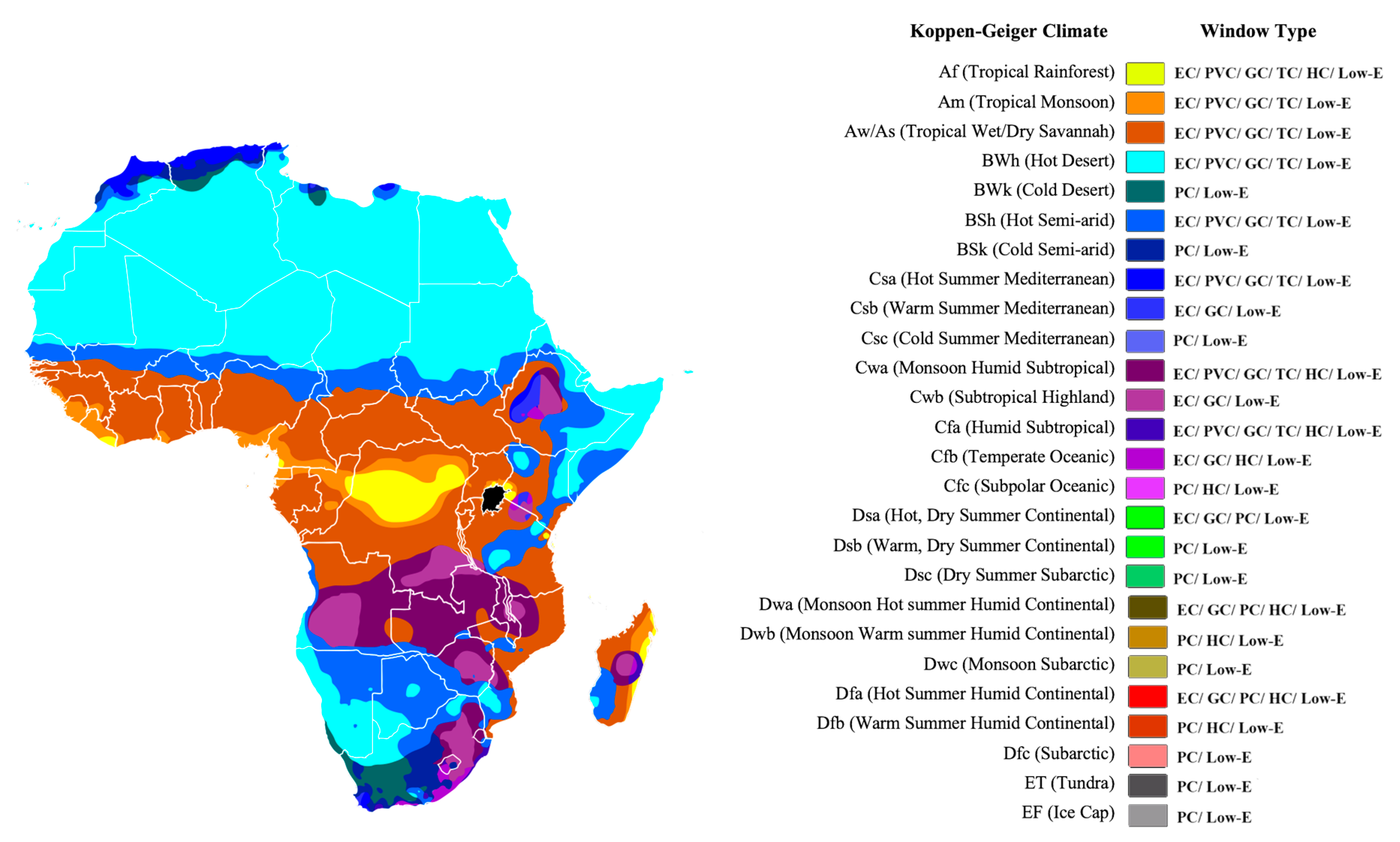

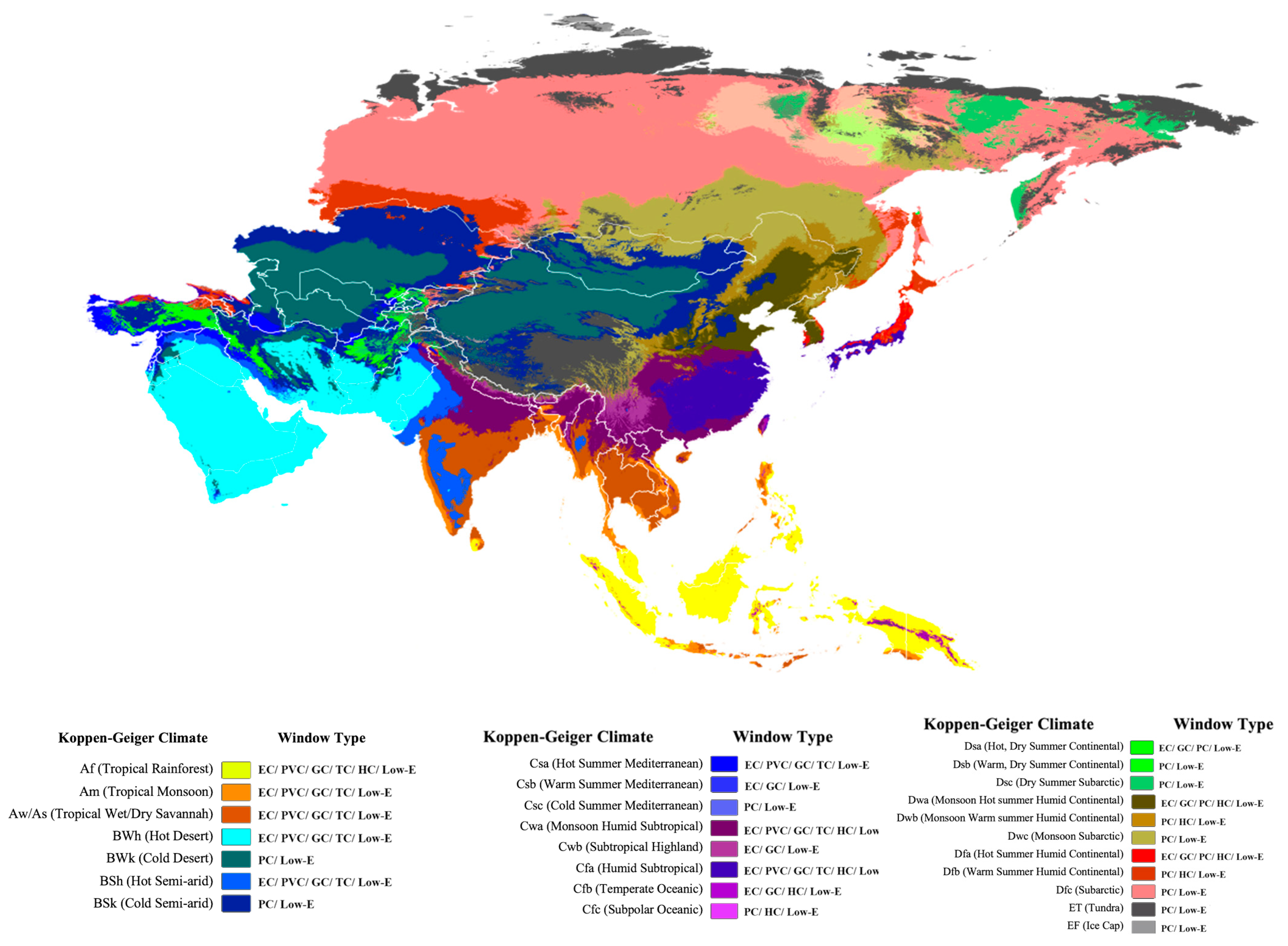

3. The Koppen-Geiger Climate Classification System

4. Smart Windows

4.1. Different Kinds of Smart Windows

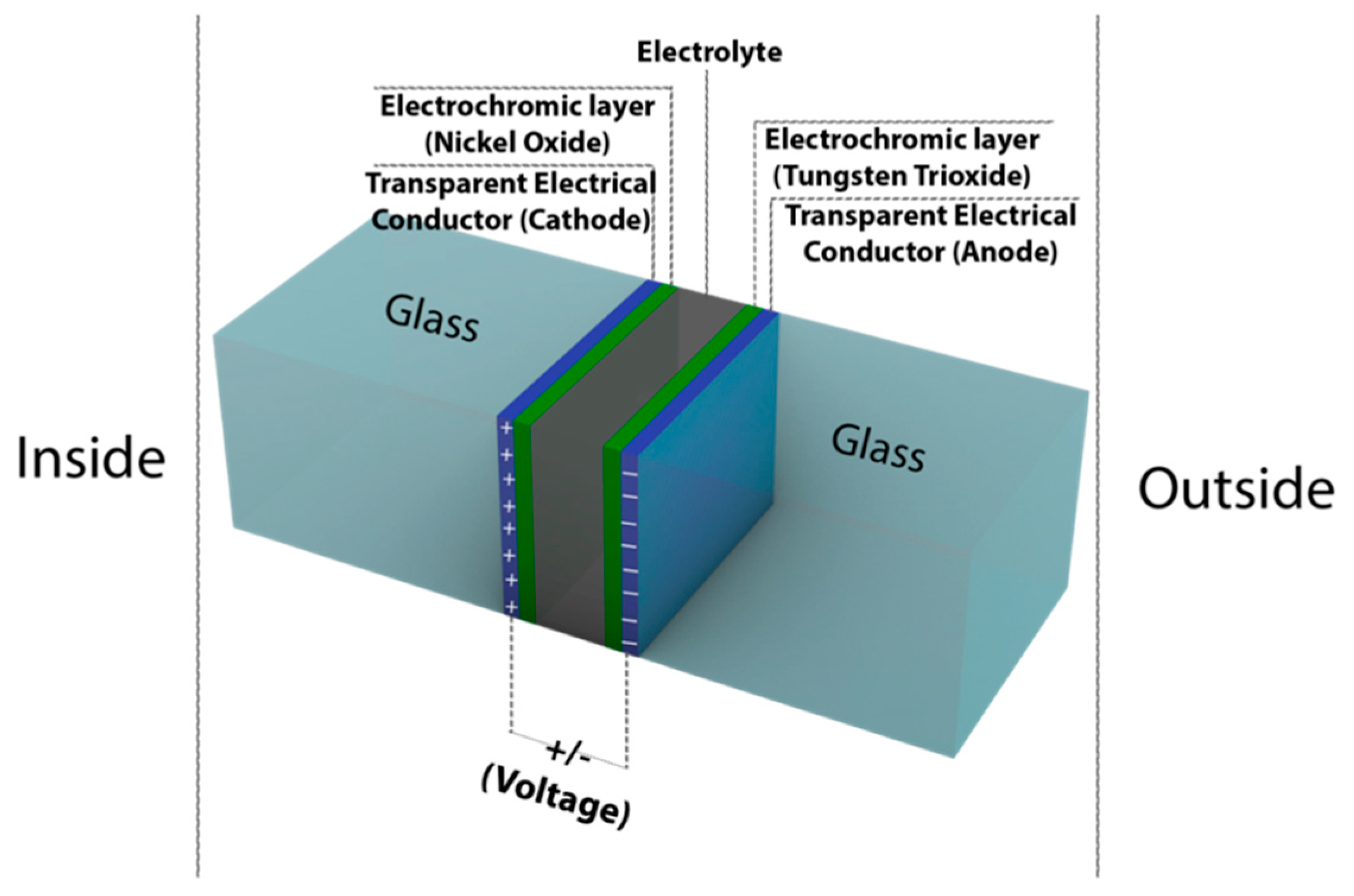

4.2. Electrochromic Smart Windows

4.2.1. EC Windows’ Energy Efficiency Based on Koppen-Geiger Climate Zones

4.2.2. EC Windows’ Energy Efficiency Based on Window Orientation

4.2.3. EC Windows’ Visual Comfort

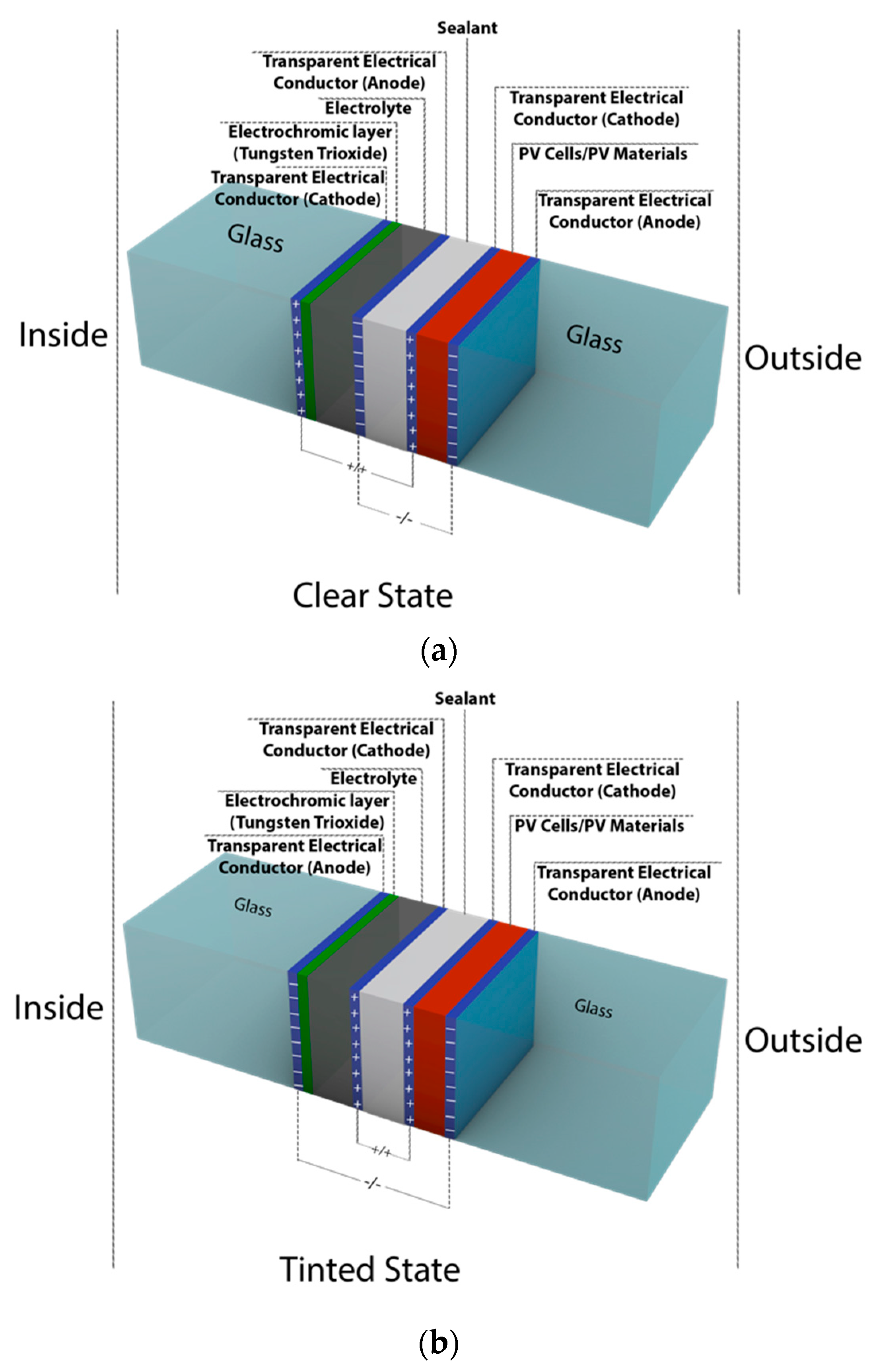

4.3. Photovoltachromic Smart Windows

4.3.1. PVC Windows’ Energy Efficiency Based on Koppen-Geiger Climate Zones

4.3.2. PVC Windows’ Energy Efficiency Based on Window Orientation and WWR

4.4. Gasochromic Smart Windows

4.4.1. GC Windows’ Energy Efficiency Based on Koppen-Geiger Climate Zones

4.4.2. GC Windows’ Energy Efficiency Based on Coating Materials

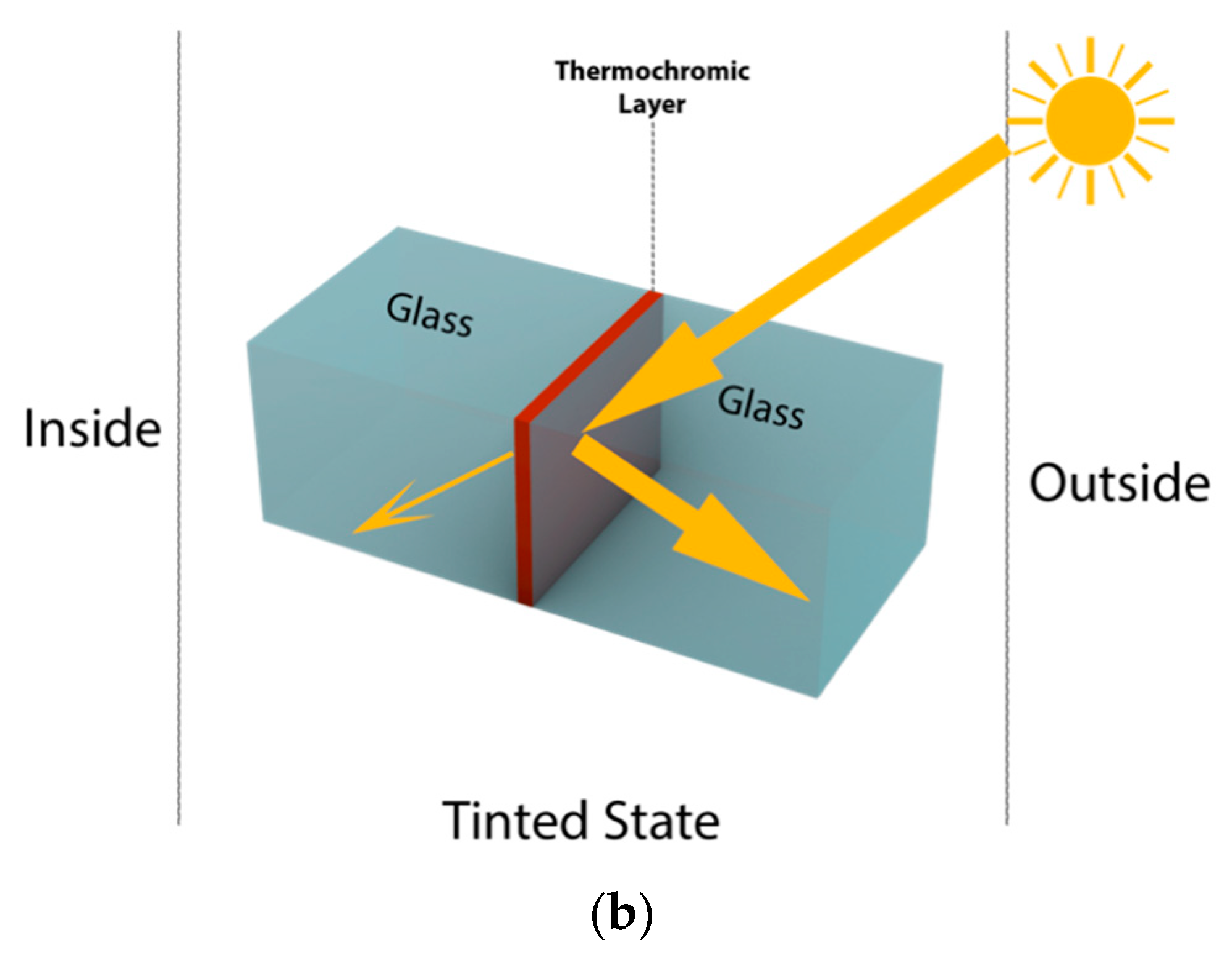

4.5. Thermochromic Smart Windows

4.5.1. TC Windows’ Energy Efficiency Based on Koppen-Geiger Climate Zones

4.5.2. TC Windows’ Energy Efficiency Based on Coating Materials

4.5.3. TC Windows’ Visual Comfort

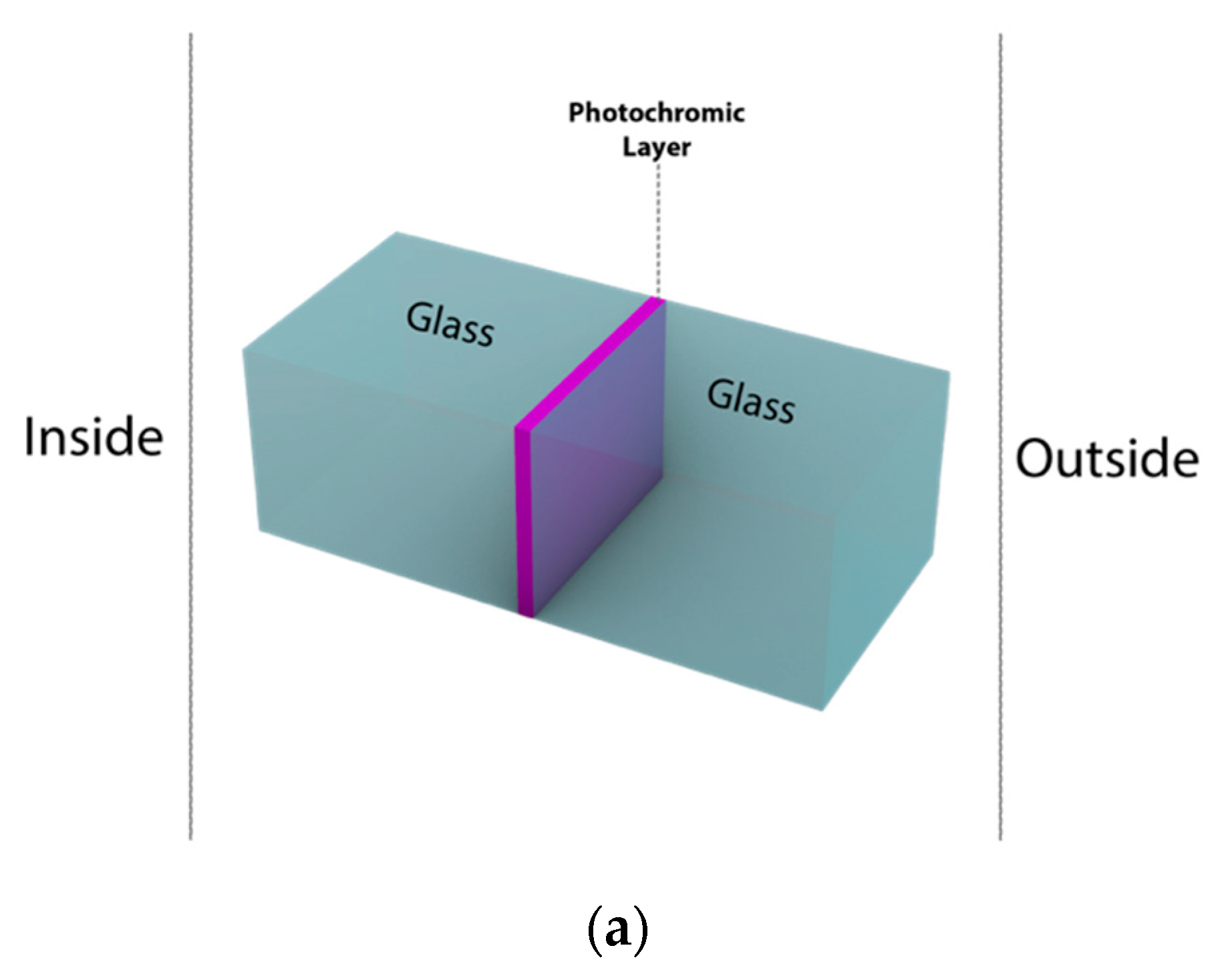

4.6. Photochromic Smart Windows

4.6.1. PC Windows’ Energy Efficiency Based on Koppen-Geiger Climate Zones

4.6.2. PC Windows’ Energy Efficiency Based on Material’s Structure

4.6.3. PC Windows’ Visual Comfort

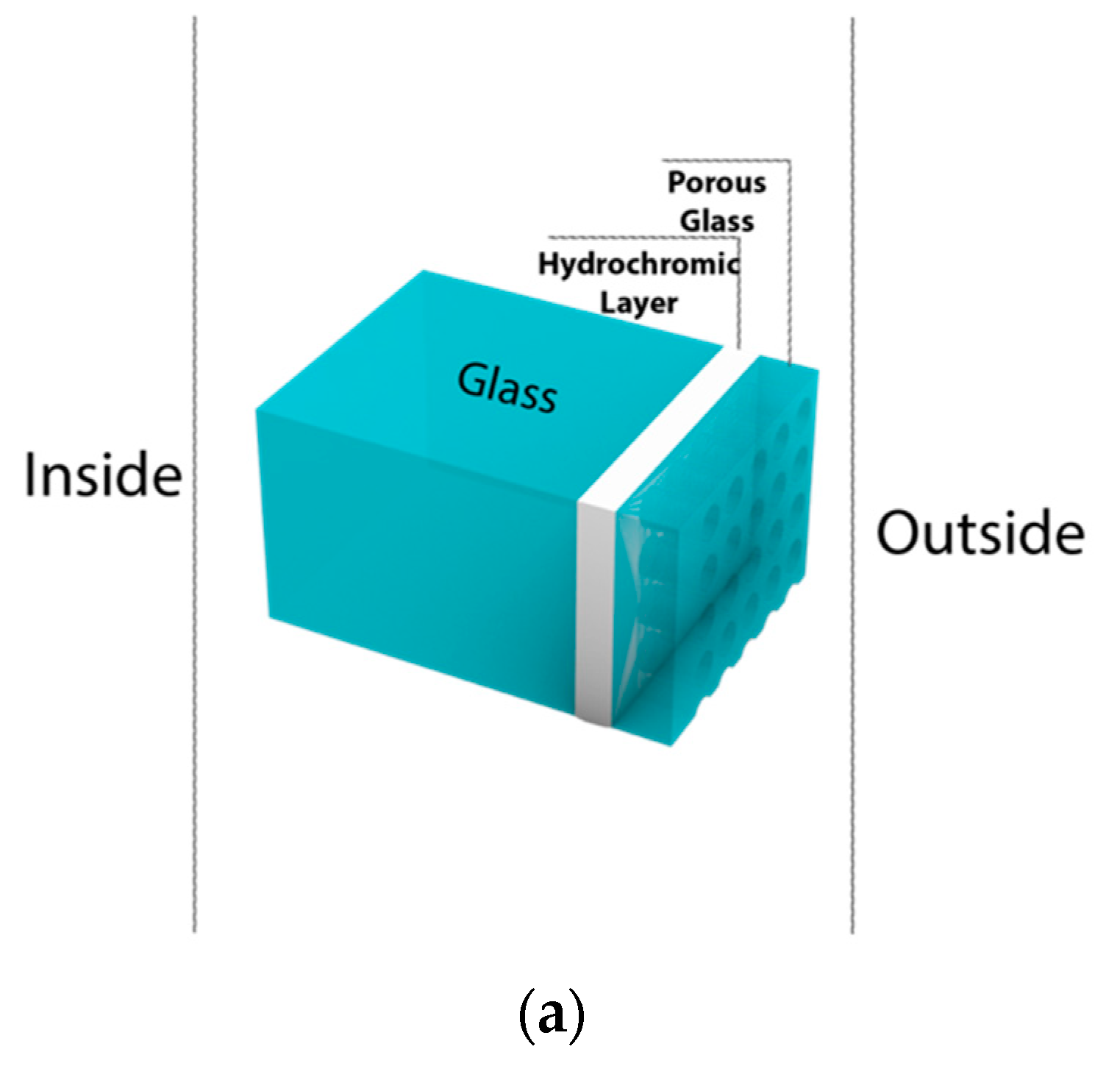

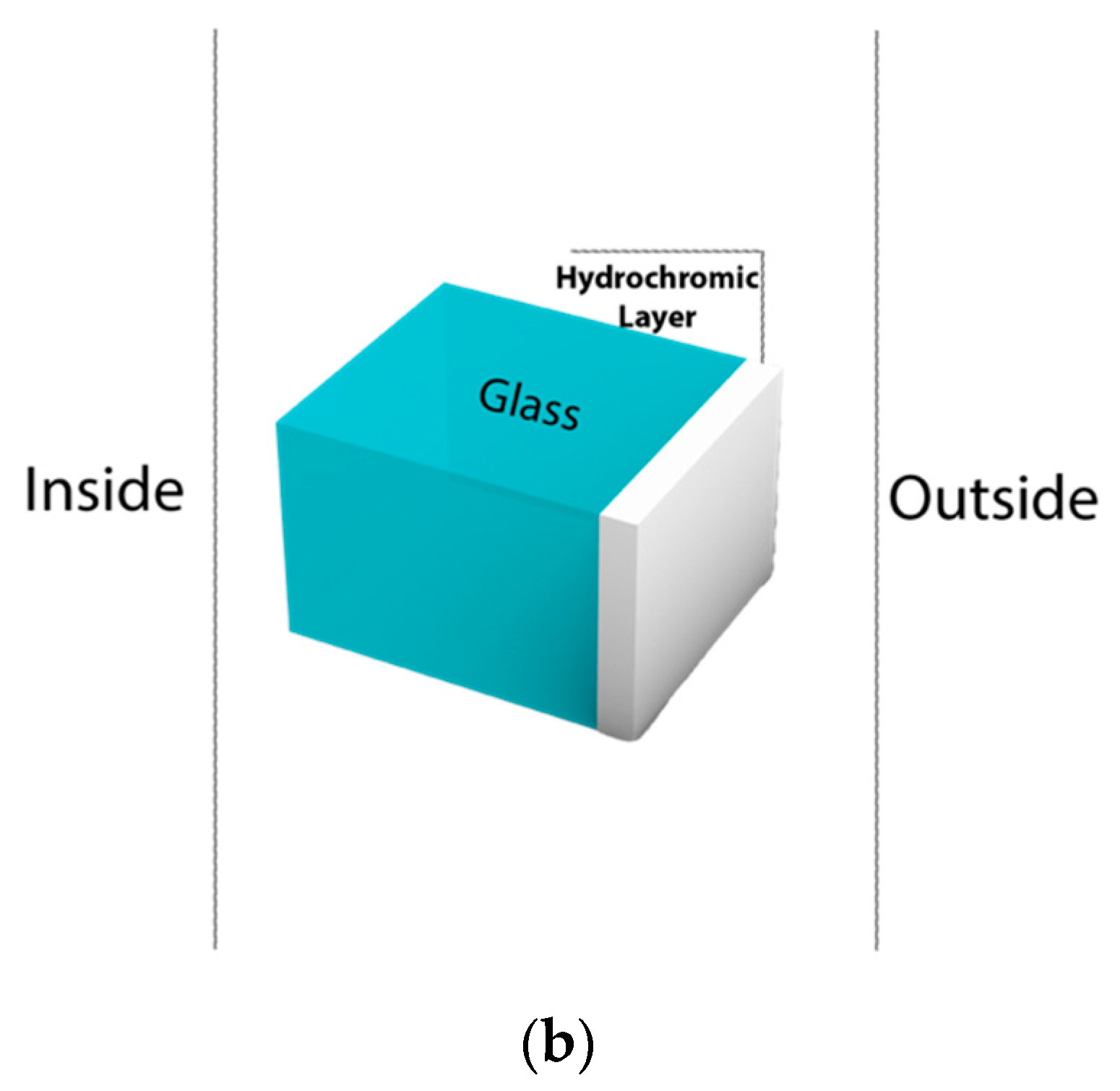

4.7. Hydrochromic Smart Windows

HC Windows’ Energy Efficiency and Visual Comfort

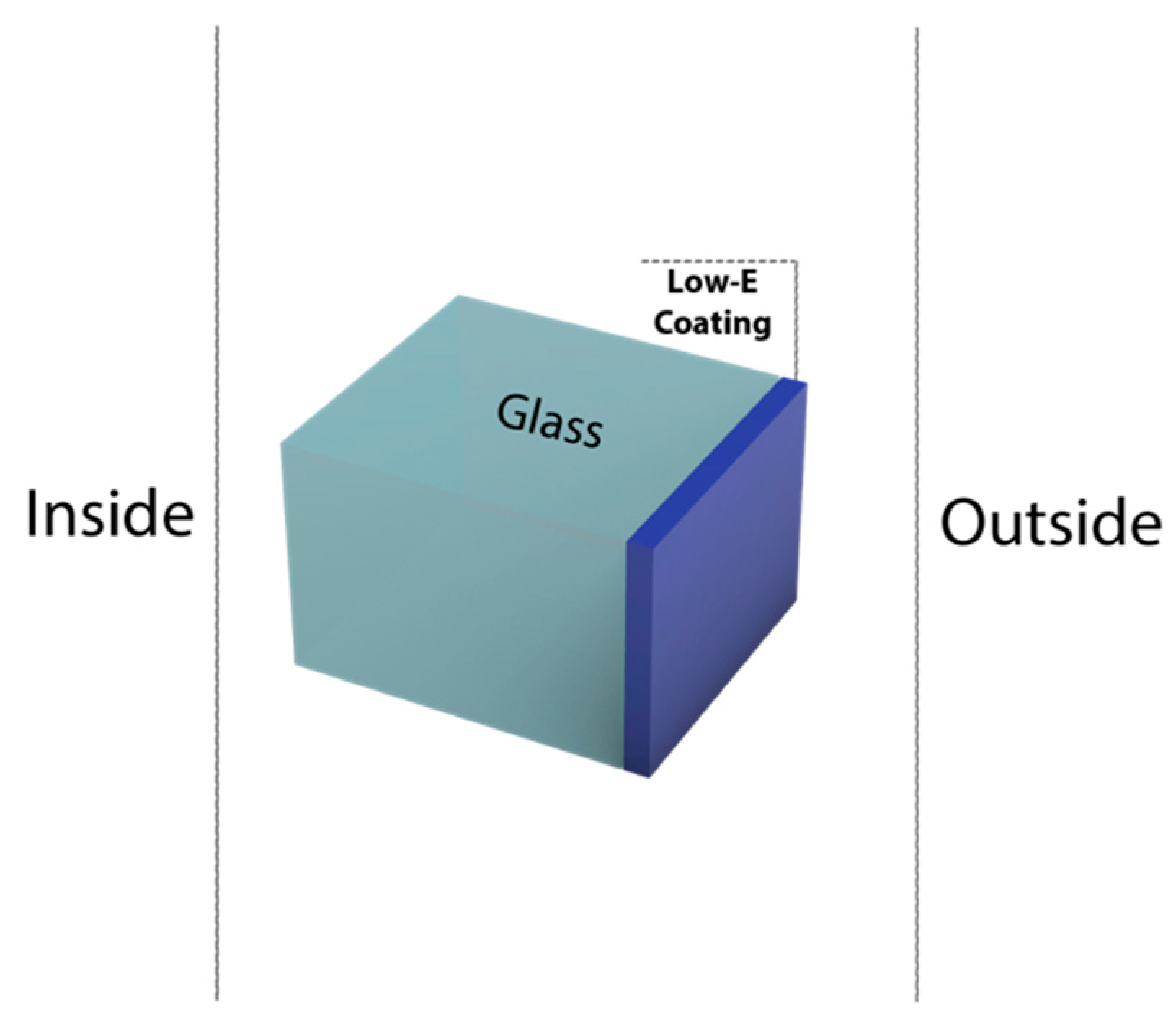

4.8. Low Emissivity Smart Windows

4.8.1. Low-E Windows’ Energy Efficiency Based on Koppen-Geiger Climate Zones

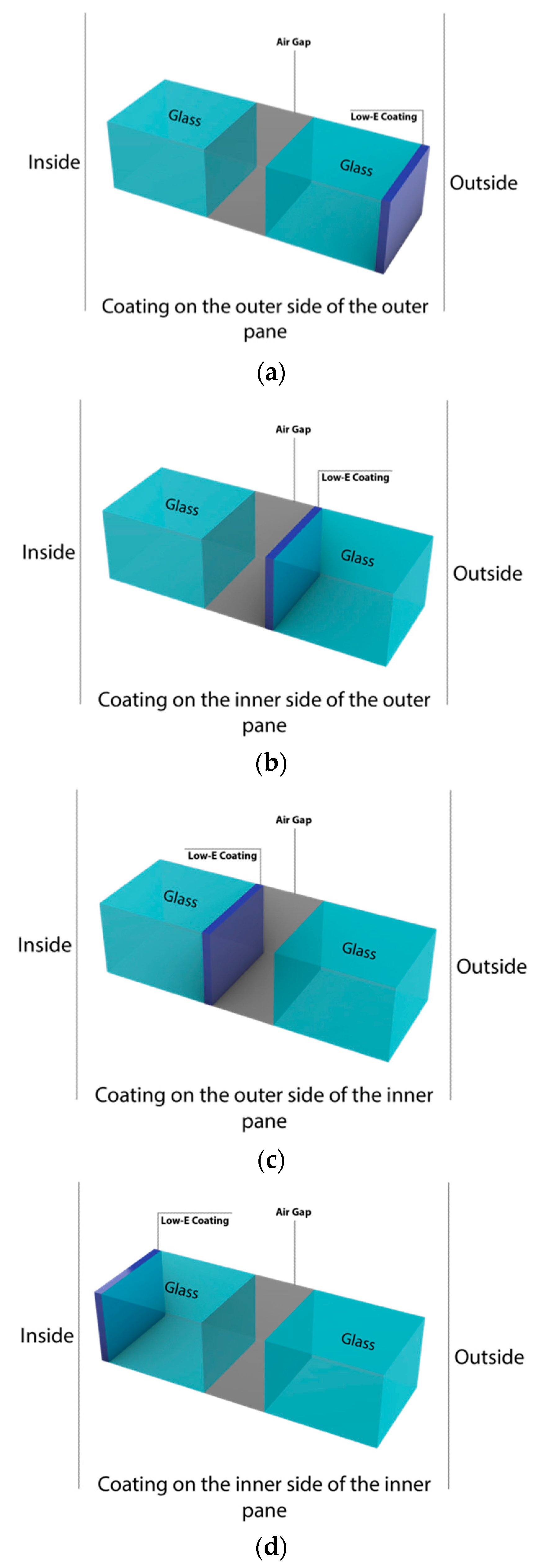

4.8.2. Low-E Windows’ Energy Efficiency Based on Coating’s Implementing Location

4.8.3. Low-E Windows’ Energy Efficiency Based on Material’s Structure

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HVAC | Heating ventilation and air conditioning system |

| SW | Smart Window |

| EC | Electrochromic |

| PVC | Photovoltachromic |

| GC | Gasochromic |

| TC | Thermochromic |

| PC | Photochromic |

| HC | Hydrochromic |

| Low-E | Low emission |

| DGP | Double glazing pane |

| SGP | Single glazing pane |

| U-value | Thermal Transmittance |

| SHGC | Solar Heat Gain Coefficient |

| LSG | Light to solar gain ratio |

| SC | Shading coefficient |

| Tvis | Visible light transmittance ratio |

| Tsol | Solar light transmittance ratio |

| VT | Visible transmittance |

References

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Varun Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Webb, M. Biomimetic building facades demonstrate potential to reduce energy consumption for different building typologies in different climate zones. Clean Technol. Environ. Policy 2022, 24, 493–518. [Google Scholar] [CrossRef] [PubMed]

- Heidari Matin, N.; Eydgahi, A. Technologies used in responsive facade systems: A comparative study. Intell. Build. Int. 2019, 14, 54–73. [Google Scholar] [CrossRef]

- Aelenei, D.; Aelenei, L.; Pacheco, C. Adaptive Façade: Concept, applications, research questions. Energy Procedia 2016, 91, 269–275. [Google Scholar] [CrossRef]

- Morteza, S.; Mohammadi, M.; Rosemann, A.; Schröder, T. A morphological approach for kinetic façade design process to improve visual and thermal comfort: Review A morphological approach for kinetic façade design process to improve visual and thermal comfort: Review. Build. Environ. 2019, 153, 186–204. [Google Scholar]

- Dewidar, K.; Mahmoud, A.H.; Magdy, N.; Ahmed, S. The role of intelligent façades in energy conservation. In Proceedings of the International Conference on Sustainability and the Future: Future Intermediate Sustainable Cities (FISC 2010), Elshourouq, Egypt, 23–25 November 2010; Volume 1. [Google Scholar]

- Carlucci, F. A review of smart and responsive building technologies and their classifications. Future Cities Environ. 2021, 7, 10. [Google Scholar] [CrossRef]

- Su, M.; Song, Y. Printable Smart Materials and Devices: Strategies and Applications. Chem. Rev. 2022, 122, 5144–5164. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Chapter 5: Increasing Efficiency of Building Systems and Technologies. In An Assessment of Energy Technologies and Research Opportunities; U.S. Department of Energy: Washington, DC, USA, 2015. [Google Scholar]

- Casini, M. Smart windows for energy efficiency of buildings. In Proceedings of the Second International Conference on Advances in Civil, Structural and Environmental Engineering–ACSEE, Zurich, Switzerland, 25–26 October 2014. [Google Scholar]

- Granqvist, C.G.; Azens, A.; Hjelm, A.; Kullman, L.; Niklasson, G.A.; Rönnow, D.; Strømme Mattsson, M.; Veszelei, M.; Vaivars, G. Recent advances in electrochromics for smart windows applications. Sol. Energy 2017, 63, 199–216. [Google Scholar] [CrossRef]

- Feng, W.; Zou, L.; Gao, G.; Wu, G.; Shen, J.; Li, W. Gasochromic smart window: Optical and thermal properties, energy simulation and feasibility analysis. Sol. Energy Mater. Sol. Cells 2016, 144, 316–323. [Google Scholar] [CrossRef]

- Malara, F.; Cannavale, A.; Carallo, S.; Gigli, G. Smart windows for building integration: A new architecture for photovoltachromic devices. ACS Appl. Mater. Interfaces 2014, 6, 9290–9297. [Google Scholar] [CrossRef]

- Tällberg, R.; Jelle, B.P.; Loonen, R.; Gao, T.; Hamdy, M. Comparison of the energy saving potential of adaptive and controllable smart windows: A state-of-the-art review and simulation studies of thermochromic, photochromic and electrochromic technologies. Sol. Energy Mater. Sol. Cells 2019, 200, 109828. [Google Scholar] [CrossRef]

- Cui, Y.; Ke, Y.; Liu, C.; Chen, Z.; Wang, N.; Zhang, L.; Zhou, Y.; Wang, S.; Gao, Y.; Long, Y. Thermochromic VO2 for Energy-Efficient Smart Windows. Joule 2018, 2, 1707–1746. [Google Scholar] [CrossRef]

- Ke, Y.; Chen, J.; Lin, G.; Wang, S.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 9, 1902066. [Google Scholar] [CrossRef]

- Cannavale, A.; Zampini, G.; Carlucci, F.; Pugliese, M.; Martellotta, F.; Ayr, U.; Maiorano, V.; Ortica, F.; Fiorito, F.; Latterini, L. Energy and daylighting performance of building integrated spirooxazine photochromic films. Sol. Energy 2021, 242, 424–434. [Google Scholar] [CrossRef]

- Pyun, S.B.; Song, J.E.; Kim, J.Y.; Cho, E.C. Hydrochromic Smart Windows to Remove Harmful Substances by Mimicking Medieval European Stained Glasses. ACS Appl. Mater. Interfaces 2020, 12, 16937–16945. [Google Scholar] [CrossRef]

- Addonizio, M.L.; Ferrara, M.; Castaldo, A.; Antonaia, A. Air-stable low-emissive AlN-Ag based coatings for energy-efficient retrofitting of existing windows. Energy Build. 2021, 250, 111259. [Google Scholar] [CrossRef]

- Brzezicki, M. A systematic review of the most recent concepts in smart windows technologies with a focus on electrochromics. Sustainability 2021, 13, 9604. [Google Scholar] [CrossRef]

- Marchwiński, J. Study of Electrochromic (Ec) and Gasochromic (Gc) Glazing for Buildings in Aspect of Energy Efficiency. Archit. Civ. Eng. Environ. 2021, 14, 27–38. [Google Scholar] [CrossRef]

- Amirkhani, S.; Bahadori-Jahromi, A.; Mylona, A.; Godfrey, P.; Cook, D. Impact of Low-E window films on energy consumption and CO2 emissions of an existing UK hotel building. Sustainability 2019, 11, 4265. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, X.; Mi, Y.; Fan, F.; Xu, Q.; Zhao, H.; Wang, S.; Long, Y. Hydrogel smart windows. J. Mater. Chem. A Mater. 2020, 8, 10007–10025. [Google Scholar] [CrossRef]

- Cao, D.; Xu, C.; Lu, W.; Qin, C.; Cheng, S. Sunlight-Driven Photo-Thermochromic Smart Windows. Sol. RRL 2018, 2, 1870163. [Google Scholar] [CrossRef]

- Chan, Y.C.; Tzempelikos, A.; Konstantzos, I. A systematic method for selecting roller shade properties for glare protection. Energy Build. 2015, 92, 81–94. [Google Scholar] [CrossRef]

- Yu, J.H.; Nam, S.H.; Lee, J.W.; Boo, J.H. Enhanced visible transmittance of thermochromic VO2 thin films by SiO2 passivation layer and their optical characterization. Materials 2016, 9, 556. [Google Scholar] [CrossRef] [PubMed]

- Sadhukhan, D.; Peri, S.; Sugunaraj, N.; Biswas, A.; Selvaraj, D.F.; Koiner, K.; Rosener, A.; Dunlevy, M.; Goveas, N.; Flynn, D.; et al. Estimating Surface Temperature from Thermal Imagery of Buildings for Accurate Thermal Transmittance (U-Value): A Machine Learning Perspective. J. Build. Eng. 2020, 32, 101637. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Y.; Zhang, L.; Zhao, C.; Yan, J.; Liu, M.; Zhao, L. Seasonal variation in leaf area index and its impact on the shading effects of vertical green facades in subtropical areas. Build. Environ. 2022, 225, 109629. [Google Scholar] [CrossRef]

- Villalba, A.; Correa, E.; Pattini, A.; Vicare, D. Hot-cool box calorimetric determination of the solar heat gain coefficient and the U-value of internal shading devices. Energy Effic. 2017, 10, 1553–1571. [Google Scholar] [CrossRef]

- Mahdieh, M.H.; Sohrabi, M. Precise design of VO2 thin films for smart windows by employing thickness dependent refractive index. arXiv 2021, arXiv:2112.04582. [Google Scholar]

- Lee, J.W.; Jung, H.J.; Park, J.Y.; Lee, J.B.; Yoon, Y. Optimization of building window system in Asian regions by analyzing solar heat gain and daylighting elements. Renew. Energy 2013, 50, 522–531. [Google Scholar] [CrossRef]

- Davis, J.; Mengersen, K.; Bennett, S.; Mazerolle, L. Viewing systematic reviews and meta-analysis in social research through different lenses. Springerplus 2014, 3, 511. [Google Scholar] [CrossRef]

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future köppen-geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef]

- Belda, M.; Holtanová, E.; Halenka, T.; Kalvová, J. Climate classification revisited: From Köppen to Trewartha. Clim. Res. 2014, 59, 1–13. [Google Scholar] [CrossRef]

- Peel, M.C.; Finlayson, B.L.; Mcmahon, T.A. Hydrology and Earth System Sciences Updated world map of the Köppen-Geiger climate classification. Hydrol. Earth Syst. Sci. 2007, 11, 1633–1644. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef] [PubMed]

- Baetens, R.; Petter, B.; Gustavsen, A. Solar Energy Materials & Solar Cells Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar]

- Granqvist, C.G. Electrochromics for smart windows: Oxide-based thin fi lms and devices. Thin Solid Film. 2014, 564, 1–38. [Google Scholar] [CrossRef]

- Casini, M. Active dynamic windows for buildings: A review. Renew. Energy 2018, 119, 923–934. [Google Scholar] [CrossRef]

- Kamalisarvestani, M.; Saidur, R.; Mekhilef, S.; Javadi, F.S. Performance, materials and coating technologies of thermochromic thin fi lms on smart windows. Renew. Sustain. Energy Rev. 2013, 26, 353–364. [Google Scholar] [CrossRef]

- Wang, Y.; Runnerstrom, E.L.; Milliron, D.J. Switchable Materials for Smart Windows. Annu. Rev. Chem. Biomol. Eng. 2016, 7, 283–304. [Google Scholar] [CrossRef]

- Aburas, M.; Soebarto, V.; Williamson, T.; Liang, R. Thermochromic smart window technologies for building application: A review. Appl. Energy 2019, 255, 113522. [Google Scholar] [CrossRef]

- Allen, K.; Connelly, K.; Rutherford, P.; Wu, Y. Smart windows—Dynamic control of building energy performance. Energy Build. 2017, 139, 535–546. [Google Scholar] [CrossRef]

- Tavares, P.F.; Gaspar, A.R.; Martins, A.G.; Frontini, F. Evaluation of electrochromic windows impact in the energy performance of buildings in mediterranean climates. Energy Policy 2014, 67, 68–81. [Google Scholar] [CrossRef]

- Reynisson, H.E.; Guðmundsson, K. Energy Performance of Dynamic Windows in Different Climates. Master’s Thesis, KTH, School of Architecture and the Built Environment (ABE), Civil and Architectural Engineering, Building Technology, Stockholm, Sweden, 2015. [Google Scholar]

- Sibilio, S.; Rosato, A.; Scorpio, M.; Iuliano, G.; Ciampi, G.; Vanoli, G.P.; de Rossi, F. A review of electrochromic windows for residential applications. Int. J. Heat Technol. 2016, 34, S481–S488. [Google Scholar] [CrossRef]

- Dussault, J.M.; Gosselin, L. Office buildings with electrochromic windows: A sensitivity analysis of design parameters on energy performance, and thermal and visual comfort. Energy Build. 2017, 153, 50–62. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Pehlivan, İ.B.; Niklasson, G.A. Electrochromics on a roll: Web-coating and lamination for smart windows. Surf. Coat. Technol. 2018, 336, 133–138. [Google Scholar] [CrossRef]

- Cannavale, A.; Ayr, U.; Fiorito, F.; Martellotta, F. Smart electrochromic windows to enhance building energy efficiency and visual comfort. Energies 2020, 13, 1449. [Google Scholar] [CrossRef]

- Bui, D.K.; Nguyen, T.N.; Ghazlan, A.; Ngo, T.D. Biomimetic adaptive electrochromic windows for enhancing building energy efficiency. Appl. Energy 2021, 300, 117341. [Google Scholar] [CrossRef]

- Favoino, F.; Fiorito, F.; Cannavale, A.; Ranzi, G.; Overend, M. Optimal control and performance of photovoltachromic switchable glazing for building integration in temperate climates. Appl. Energy 2016, 178, 943–961. [Google Scholar] [CrossRef]

- Pierucci, A.; Cannavale, A.; Martellotta, F.; Fiorito, F. Smart windows for carbon neutral buildings: A life cycle approach. Energy Build. 2018, 165, 160–171. [Google Scholar] [CrossRef]

- Fiorito, F.; Cannavale, A.; Santamouris, M. Development, testing and evaluation of energy savings potentials of photovoltachromic windows in office buildings. A perspective study for Australian climates. Sol. Energy 2020, 205, 358–371. [Google Scholar] [CrossRef]

- Pugliese, M.; Bisconti, F.; Rizzo, A.; Colella, S.; Prontera, C.T.; Gigli, G.; Maiorano, V.; Cossari, P. Highly efficient all-solid-state WO3-perovskite photovoltachromic cells for single-glass smart windows. ACS Appl. Energy Mater. 2020, 3, 10453–10462. [Google Scholar] [CrossRef]

- Liang, R.; Liu, D.; Sun, Y.; Luo, X.; Grant, D.; Walker, G.; Wu, Y. Investigation of Mg-Y coated gasochromic smart windows for building applications. Build. Simul. 2019, 12, 99–112. [Google Scholar] [CrossRef]

- Gao, G.; Xue, S.; Wang, H.; Zhang, Z.; Wu, G.; Debela, T.T.; Kang, H.S. Highly Thermally Stable and Transparent WO3-SiO2 Gasochromic Films Obtained by an Automated Printing Method. ACS Sustain. Chem. Eng. 2021, 9, 17319–17329. [Google Scholar] [CrossRef]

- Nageib, A.; Elzafarany, A.M.; Elhefnawy, M.H.; Mohamed, F.O. Using smart glazing for reducing energy consumption on existing office building in hot dry climate. HBRC J. 2020, 16, 157–177. [Google Scholar] [CrossRef]

- Liang, R.; Wu, Y.; Wilson, R. Thermal and Visual Comfort Analysis of an Office with Thermochromic Smart Windows Applied. In Proceedings of the International Conference CISBAT 2015 Future Buildings and Districts Sustainability from Nano to Urban Scale, Lausanne, Switzerland, 9–11 September 2015. [Google Scholar]

- Liang, R.; Sun, Y.; Aburas, M.; Wilson, R.; Wu, Y. Evaluation of the thermal and optical performance of thermochromic windows for office buildings in China. Energy Build. 2018, 176, 216–231. [Google Scholar] [CrossRef]

- Ke, Y.; Yin, Y.; Zhang, Q.; Tan, Y.; Hu, P.; Wang, S.; Tang, Y.; Zhou, Y.; Wen, X.; Wu, S.; et al. Adaptive Thermochromic Windows from Active Plasmonic Elastomers. Joule 2019, 3, 858–871. [Google Scholar] [CrossRef]

- Li, X.H.; Liu, C.; Feng, S.P.; Fang, N.X. Broadband Light Management with Thermochromic Hydrogel Microparticles for Smart Windows. Joule 2019, 3, 290–302. [Google Scholar] [CrossRef]

- Ke, Y.; Zhang, Q.; Wang, T.; Wang, S.; Li, N.; Lin, G.; Liu, X.; Dai, Z.; Yan, J.; Yin, J.; et al. Cephalopod-inspired versatile design based on plasmonic VO2 nanoparticle for energy-efficient mechano-thermochromic windows. Nano Energy 2020, 73, 104785. [Google Scholar] [CrossRef]

- Liang, R.; Kent, M.; Wilson, R.; Wu, Y. The effect of thermochromic windows on visual performance and sustained attention. Energy Build. 2021, 236, 110778. [Google Scholar] [CrossRef]

- Arnaoutakis, G.E.; Katsaprakakis, D.A. Energy performance of buildings with thermochromic windows in mediterranean climates. Energies 2021, 14, 6977. [Google Scholar] [CrossRef]

- Lin, C.; Hur, J.; H Chao, C.Y.; Liu, G.; Yao, S.; Li, W.; Huang, B. All-weather thermochromic windows for synchronous solar and thermal radiation regulation. Sci. Adv. 2022, 8, eabn7359. [Google Scholar] [CrossRef]

- Ke, Y.; Tan, Y.; Feng, C.; Chen, C.; Lu, Q.; Xu, Q.; Wang, T.; Liu, H.; Liu, X.; Peng, J.; et al. Tetra-Fish-Inspired aesthetic thermochromic windows toward Energy-Saving buildings. Appl. Energy 2022, 315, 119053. [Google Scholar] [CrossRef]

- Zou, X.; Ji, H.; Zhao, Y.; Lu, M.; Tao, J.; Tang, P.; Liu, B.; Yu, X.; Mao, Y. Research progress of photo-/electro-driven thermochromic smart windows. Nanomaterials 2021, 11, 3335. [Google Scholar] [CrossRef] [PubMed]

- Zeng, R.; Chini, A.; Srinivasan, R.S.; Jiang, P. Energy efficiency of smart windows made of photonic crystal. Int. J. Constr. Manag. 2017, 17, 100–112. [Google Scholar] [CrossRef]

- Miyazaki, H.; Ishigaki, T.; Ota, T. Photochromic Smart Windows Employing WO3-Based Composite Films. J. Mater. Sci. Res. 2017, 6, 62. [Google Scholar] [CrossRef]

- Hočevar, M.; Opara Krašovec, U. A photochromic single glass pane. Sol. Energy Mater. Sol. Cells 2018, 186, 111–114. [Google Scholar] [CrossRef]

- Kang, M.J.; Santoro, E.G.; Kang, Y.S. Enhanced Efficiency of Functional Smart Window with Solar Wavelength Conversion Phosphor-Photochromic Hybrid Film. ACS Omega 2018, 3, 9505–9512. [Google Scholar] [CrossRef]

- Timmermans, G.H.; Saes, B.W.H.; Debije, M.G. Dual-responsive “smart” window and visually attractive coating based on a diarylethene photochromic dye. Appl. Opt. 2019, 58, 9823. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Zhan, X.; Luo, D.; Sun, X. Photochromic transparent wood for photo-switchable smart window applications. J. Mater. Chem. C Mater. 2019, 7, 8649–8654. [Google Scholar] [CrossRef]

- You, C.C.; Karazhanov, S.Z. Effect of temperature and illumination conditions on the photochromic performance of yttrium oxyhydride thin films. J. Appl. Phys. 2020, 128, 013106. [Google Scholar] [CrossRef]

- Al-Qahtani, S.D.; Binyaseen, A.M.; Aljuhani, E.; Aljohani, M.; Alzahrani, H.K.; Shah, R.; El-Metwaly, N.M. Production of smart nanocomposite for glass coating toward photochromic and long-persistent photoluminescent smart windows. Ceram. Int. 2022, 48, 903–912. [Google Scholar] [CrossRef]

- Cai, G.; Wang, J.; Eh, A.L.S.; Chen, J.; Qian, K.; Xiong, J.; Thangavel, G.; Lee, P.S. Diphylleia grayi-Inspired Stretchable Hydrochromics with Large Optical Modulation in the Visible-Near-Infrared Region. ACS Appl. Mater. Interfaces 2018, 10, 37685–37693. [Google Scholar] [CrossRef] [PubMed]

- Yoo, G.Y.; Lee, S.; Ko, M.; Kim, H.; Lee, K.N.; Kim, W.; Do, Y.R. Diphylleia grayi-Inspired Intelligent Hydrochromic Adhesive Film. ACS Appl. Mater. Interfaces 2020, 12, 49982–49991. [Google Scholar] [CrossRef] [PubMed]

- Hedge, A.; MacNaughton, P.; Woo, M.; Guglielmetti, R.; Tinianov, B. Airport passenger experiences in concourses with either electrochromic or low-e glass windows. Int. J. Aviat. Manag. 2021, 5, 1. [Google Scholar] [CrossRef]

- Lin, S.; Wang, H.; Zhang, X.; Wang, D.; Zu, D.; Song, J.; Liu, Z.; Huang, Y.; Huang, K.; Tao, N.; et al. Direct spray-coating of highly robust and transparent Ag nanowires for energy saving windows. Nano Energy 2019, 62, 111–116. [Google Scholar] [CrossRef]

- Grosjean, A.; le Baron, E. Longtime solar performance estimations of low-E glass depending on local atmospheric conditions. Sol. Energy Mater. Sol. Cells 2022, 240, 111730. [Google Scholar] [CrossRef]

- Granqvist, C.-G. Electrochromic Foil: A Case Study. In Electrochromic Materials and Devices; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 525–544. [Google Scholar]

- Cannavale, A.; Cossari, P.; Eperon, G.E.; Colella, S.; Fiorito, F.; Gigli, G.; Snaith, H.J.; Listorti, A. Forthcoming perspectives of photoelectrochromic devices: A critical review. Energy Environ. Sci. 2016, 9, 2682–2719. [Google Scholar] [CrossRef]

- Gugliermetti, F.; Bisegna, F. Visual and energy management of electrochromic windows in Mediterranean climate. Build. Environ. 2003, 38, 479–492. [Google Scholar] [CrossRef]

- Lee, E.S.; Dibartolomeo, D.L. LBNL-45841 OM-426 Application issues for large-area electrochromic windows in commercial buildings. Sol. Energy Mater. Sol. Cells 2002, 71, 465–491. [Google Scholar] [CrossRef]

- Lee, E.S.; Tavil, A. Energy and visual comfort performance of electrochromic windows with overhangs. Build. Environ. 2007, 42, 2439–2449. [Google Scholar] [CrossRef]

- King, D.L.; Boyson, W.E.; Kratochvil, J.A. Photovoltaic Array Performance Model; U.S. Department of Energy: Washington, DC, USA, 2003.

- Cannavale, A.; Hörantner, M.; Eperon, G.E.; Snaith, H.J.; Fiorito, F.; Ayr, U.; Martellotta, F. Building integration of semitransparent perovskite-based solar cells: Energy performance and visual comfort assessment. Appl. Energy 2017, 194, 94–107. [Google Scholar] [CrossRef]

- Cannavale, A.; Fiorito, F.; Resta, D.; Gigli, G. Visual comfort assessment of smart photovoltachromic windows. Energy Build. 2013, 65, 137–145. [Google Scholar] [CrossRef]

- Mirzaei, M.R.; Rostami, A.; Matloub, S.; Mirtaghizadeh, H. Ultra-high-efficiency luminescent solar concentrator using superimposed colloidal quantum dots. Opt. Quantum Electron. 2020, 52, 327. [Google Scholar] [CrossRef]

- Rastkar Mirzaei, M.; Rostami, A.; Matloub, S.; Nazari, M. Design and optimization of graphene quantum dot-based luminescent solar concentrator using Monte-Carlo simulation. Energy Built Environ. 2021, 4, 140–147. [Google Scholar] [CrossRef]

- Li, D.; Wu, G.; Gao, G.; Shen, J.; Huang, F. Ultrafast coloring-bleaching performance of nanoporous WO3-SiO2 gasochromic films doped with Pd catalyst. ACS Appl. Mater. Interfaces 2011, 3, 4573–4579. [Google Scholar] [CrossRef] [PubMed]

- Delalat, F.; Ranjbar, M.; Salamati, H. Blue colloidal nanoparticles of molybdenum oxide by simple anodizing method: Decolorization by PdCl2 and observation of in-liquid gasochromic coloration. Sol. Energy Mater. Sol. Cells 2016, 144, 165–172. [Google Scholar] [CrossRef]

- Smith, G.B. Green nanotechnology. In Nanostructured Thin Films IV, Proceedings of the SPIE Optics + Photonics, NanoScience + Engineering, San Diego, CA, USA, 21–25 August 2011; SPIE: Bellingham, WA, USA, 2011; Volume 8104, p. 810402. [Google Scholar]

- Ulaeto, S.B.; Pancrecious, J.K.; Rajan, T.P.D.; Pai, B.C. Smart Coatings. In Noble Metal-Metal Oxide Hybrid Nanoparticles: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 341–372. [Google Scholar]

- Heidari Matin, N.; Mirabedini, S.M.; Rashidzadeh, Z. Smart Colored Window Technology Improving Users’ Comfort with an Interdisciplinary Approach. In Proceedings of the Facade Tectonics 2022 World Congress, Los Angeles, CA, USA, 12–13 October 2022. [Google Scholar]

- Matin, N.H.; Eydgahi, A.; Gharipour, A.; Matin, P. A Novel Framework for Optimizing Indoor Illuminance and Discovering Association of Involved Variables. Buildings 2022, 12, 878. [Google Scholar] [CrossRef]

- Heidari Matin, N.; Eydgahi, A.; Matin, P. The Effect of Smart Colored Windows on Visual Performance of Buildings. Buildings 2022, 12, 861. [Google Scholar] [CrossRef]

- Duan, Q.; Zhao, Y.; Wang, J. Thermal performance and condensation risk of single-pane glazing with low emissivity coatings. MRS Adv. 2020, 5, 2555–2564. [Google Scholar] [CrossRef]

| Major Category | Full Category | Name | Description |

|---|---|---|---|

| A | Af | Tropical Rainforest Climate | Tropical Rainforest Climate |

| Am | Tropical Monsoon Climate | Tropical Monsoon Climate | |

| Aw | Tropical Wet Savannah Climate | Tropical Savannah with Dry Winter | |

| As | Tropical Dry Savannah Climate | Tropical Savannah with Dry Summer | |

| B | BWh | Hot Desert Climate | Hot Desert Climate |

| BWk | Cold Desert Climate | Cold Desert Climate | |

| BSh | Hot Semi-arid Climate | Hot Steppe Climate | |

| BSk | Cold Semi-arid Climate | Cold Steppe Climate | |

| C | Cfa | Humid Subtropical Climate | Humid Temperate Climate with Hot Summer |

| Cfb | Temperate Oceanic Climate | Humid Temperate Climate with Warm Summer | |

| Cfc | Subpolar Oceanic Climate | Humid Temperate Climate with Cold Summer | |

| Cwa | Monsoon-Influenced Humid Subtropical Climate | Temperate Climate with Dry Winter and Hot Summer | |

| Cwb | Subtropical Highland Climate | Temperate Climate with Dry Winter and Warm Summer | |

| Cwc | Cold Subtropical Highland Climate | Temperate Climate with Dry Winter and Cold Summer | |

| Csa | Hot Summer Mediterranean Climate | Temperate Climate with Dry and Hot Summer | |

| Csb | Warm Summer Mediterranean Climate | Temperate Climate with Dry and Warm Summer | |

| Csc | Cold Summer Mediterranean Climate | Temperate Climate with Dry and Cold Summer | |

| D | Dfa | Hot Summer Humid Continental Climate | Humid Cold Climate with Hot Summer |

| Dfb | Warm Summer Humid Continental Climate | Humid Cold Climate with Warm Summer | |

| Dfc | Subarctic Climate | Humid Cold Climate with Cold Summer | |

| Dfd | Extremely Cold Subarctic Climate | Humid Cold Climate with Extremely Cold Winter | |

| Dwa | Monsoon Influenced Hot Summer Humid Continental Climate | Cold Climate with Dry Winter and Hot Summer | |

| Dwb | Monsoon Influenced Warm Summer Humid Continental Climate | Cold Climate with Dry Winter and Warm Summer | |

| Dwc | Monsoon-Influenced Subarctic Climate | Cold Climate with Dry Winter and Cold Summer | |

| Dwd | Monsoon-Influenced Extremely Cold Subarctic Climate | Cold Climate with Dry and Extremely Cold Winter | |

| Dsa | Hot, Dry Summer Continental Climate | Cold Climate with Dry and Hot Summer | |

| Dsb | Warm, Dry Summer Continental Climate | Cold Climate with Dry and Warm Summer | |

| Dsc | Dry Summer Subarctic Climate | Cold Climate with Dry and Cold Summer | |

| Dsd | Dry Summer Extremely Cold Subarctic Climate | Cold Climate with Dry Summer and very Cold Winter | |

| E | ET | Tundra Climate | Tundra Polar Climate |

| EF | Ice Cap Climate | Frost Polar Climate |

| No. | Study | Year | Coating Type/Independent Variable | Dependent Variables | Methods |

|---|---|---|---|---|---|

| 1 | [44] | 2014 | Electrochromic | Building Energy Efficiency & cost efficiency | Simulations |

| 2 | [45] | 2015 | Electrochromic | Energy consumption | Simulations |

| 3 | [46] | 2016 | Electrochromic | Visual Comfort & Building Energy Efficiency | Review |

| 4 | [46] | 2016 | Electrochromic | Energy saving & Visual comfort | Laboratory & Physical experiment |

| 5 | [47] | 2017 | Electrochromic | Thermal comfort, Visual comfort & Energy consumption | Simulations |

| 6 | [48] | 2018 | Electrochromic | Energy efficiency with indoor comfort | Review |

| 7 | [49] | 2020 | Electrochromic | Visual comfort, Building energy efficiency & Control Strategies | Review |

| 8 | [17] | 2021 | Electrochromic | Building Energy Efficiency & Visual Comfort | Review |

| 9 | [20] | 2021 | Electrochromic | Visual comfort & Building energy efficiency | Review |

| 10 | [50] | 2021 | Electrochromic | Building energy efficiency & Cost efficiency | Simulations |

| 11 | [13] | 2014 | Photovoltachromic | Building energy efficiency & Visual Comfort | Laboratory & Simulation & Physical experiment |

| 12 | [51] | 2016 | Photovoltachromic | Visual comfort & Building energy efficiency | Laboratory & Simulations |

| 13 | [52] | 2018 | Photovoltachromic | Building energy efficiency (Lighting, Cooling, & Heating demand) | Laboratory & Simulation |

| 14 | [53] | 2020 | Photovoltachromic | Visual comfort & Building energy efficiency | Laboratory & Simulations |

| 15 | [54] | 2020 | Photovoltachromic | Building energy efficiency | Laboratory & Physical experiment |

| 16 | [12] | 2016 | Gasochromic & electrochromic | Energy consumption | Simulation |

| 17 | [21] | 2021 | Gasochromic & electrochromic | Energy consumption | Simulation |

| 18 | [55] | 2019 | Gasochromic | Visual comfort & Building energy efficiency | Simulations |

| 19 | [56] | 2021 | Gasochromic | Building energy efficiency | Laboratory & Simulations |

| 20 | [57] | 2020 | Gasochromic, thermochromic &electrochromic | Energy consumption | Simulation |

| 21 | [40] | 2013 | Thermochromic | Energy-saving potentials & Thermal comfort | Review |

| 22 | [45] | 2015 | Thermochromic | Energy efficiency cooling load | Laboratory |

| 23 | [58] | 2015 | Thermochromic | Thermal comfort, Visual comfort & Energy consumption | Simulations |

| 24 | [15] | 2018 | Thermochromic | Energy-saving performance | Review |

| 25 | [59] | 2018 | Thermochromic | Visual comfort & Building energy efficiency | Laboratory & Simulations |

| 26 | [42] | 2019 | Thermochromic | Energy-saving performance, Thermal & Visual comfort | Review |

| 27 | [60] | 2019 | Thermochromic | Building energy efficiency | Laboratory & Physical experiment & Simulations |

| 28 | [61] | 2019 | Thermochromic | Visual comfort | Physical experiment & Simulations |

| 29 | [62] | 2020 | Thermochromic | Building energy efficiency | Laboratory & Physical experiment |

| 30 | [63] | 2021 | Thermochromic | Visual comfort | questionnaires |

| 31 | [64] | 2021 | Thermochromic | Building energy efficiency | Simulations |

| 32 | [65] | 2022 | Thermochromic | Building energy efficiency | Laboratory & Simulations |

| 33 | [66] | 2022 | Thermochromic | Building energy efficiency | Laboratory & Simulations |

| 34 | [23] | 2020 | Thermochromic & Electrochromic & Hydrochromic | Energy consumption with heat storage | Laboratory & Simulation |

| 35 | [24] | 2018 | Photo-thermochromic | Energy consumption | Laboratory & Simulation |

| 36 | [67] | 2021 | photo-/electro-driven &Thermochromic | Energy efficiency | Review |

| 37 | [14] | 2019 | Photochromic & Electrochromic & Thermochromic | Energy consumption | Simulation |

| 38 | [68] | 2017 | Photochromic | Energy performance | Simulation |

| 39 | [69] | 2017 | Photochromic | Optical properties | Laboratory |

| 40 | [70] | 2018 | Photochromic | Visual comfort | Laboratory & Simulations |

| 41 | [71] | 2018 | Photochromic | Visual comfort & Building energy efficiency | Laboratory & Simulations |

| 42 | [72] | 2019 | Photochromic | Building energy efficiency | Laboratory |

| 43 | [73] | 2019 | Photochromic | Visual comfort & Building energy efficiency | Laboratory |

| 44 | [74] | 2020 | Photochromic | Visual comfort & Building energy efficiency | Laboratory & Physical experiment |

| 45 | [17] | 2021 | Photochromic | Building energy efficiency | Laboratory & Simulation |

| 46 | [75] | 2022 | Photochromic | Visual comfort | Laboratory & Simulations |

| 47 | [76] | 2018 | Hydrochromic | Visual comfort & Building energy efficiency | Laboratory & Simulations |

| 48 | [18] | 2020 | Hydrochromic | Visual comfort | Laboratory & Physical experiment |

| 49 | [77] | 2020 | Hydrochromic | Visual comfort | Laboratory & Physical experiment |

| 50 | [78] | 2021 | Low-E & Electrochromic | Visual comfort | Review & Simulations |

| 51 | [22] | 2019 | Low-E | Building energy efficiency & CO2 emissions | Simulations |

| 52 | [79] | 2019 | Low-E | Building energy efficiency | Laboratory & Physical experiment |

| 53 | [19] | 2021 | Low-E | Visual comfort, Building energy efficiency & Resistance | Laboratory & Physical experiment & Simulations |

| 54 | [80] | 2022 | Low-E | Visual Comfort | Simulations |

| Type | Reference | U-Value | SGHC | LSG | SC | Tvis | Tsol | VT | Reflectance |

|---|---|---|---|---|---|---|---|---|---|

| Electrochromic | [47] [14] [68] [39] [21] [57] | 1–1.6 2.2 | 0.09 0.64–0.15 0.49–0.09 0.6–0.05 | 1.32–0.22 | 0.74–0.16 | 0.75–0.01 | 0.52–0.01 | 0.73–0.14 | 0.168 |

| Gasochromic | [39] [21] [57] | 0.9–1.03 | 0.65–0.28 0.75–0.14 2.6 | NA | NA | 0.54 | 0.46 | 0.54–0.15 0.75–0.01 | 0.161 |

| Thermochromic | [14] [42] [57] | 2.76–1.31 | 0.31–0.12 0.65 | NA | 0.542–0.255 | 0.6–0.043 | 0.49–0.02 0.53 | 0.545–0.023 | 0.078 |

| Photochromic | [14] [68] | 5.7–5.9 | 0.26–0.71 | 1.79 | 0.31–0.81 | 0.83–0.48 | 0.78–0.09 | 0.79 | 0.12 |

| Low-E | [68] [22] [12] | 3.58 | 0.26 | 1.4–1.3 | 0.31 | 0.8–0.478 | 0.570–0.212 | 0.55 | 0.576–0.04 |

| Single Clear Glass | [68] [12] [57] | 5.41 2.8 | 0.82–1.02 0.75 | 2.73–1.42 | 0.94 | 0.74 0.89 | 0.74 | 0.88 | 0.12 |

| Type | Pros | Cons | ||

|---|---|---|---|---|

| 1-Electrochromic | Energy Efficiency improvement | 6–64% |

|

|

| Visual Comfort | 16–60% | |||

| Colors | Blue | |||

| Best Performing Climates | Af, Am, Aw, BWh, BSh, Csa, Csb, Cwa, Cwb, Cfa, Cfb, Dsa, Dfa | |||

| 2-Photovoltachromic | Energy Efficiency improvement | 2–41% |

|

|

| Visual Comfort | 40–45.5% | |||

| Colors | Purple Yellow | |||

| Best Performing Climates | Af, Am, Aw, BWh, BSh, Csa, Cwa, Cfa | |||

| 3-Gasochromic | Energy Efficiency improvement | 25–84% |

|

|

| Visual Comfort | NA | |||

| Colors | Blue | |||

| Best Performing Climates | Af, Am, Aw, BWh, BSh, Csa, Csb, Cwa, Cwb, Cfa, Cfb, Dsa, Dfa | |||

| 4-Thermochromic | Energy Efficiency improvement | 3–57.1% |

|

|

| Visual Comfort | 15.5–43% | |||

| Colors | Blue | |||

| Best Performing Climates | Af, Am, Aw, BWh, BSh, Csa, Cwa, Cfa | |||

| 5-Photochromic | Energy Efficiency improvement | 20–92.7% |

|

|

| Visual Comfort | Up to 41% | |||

| Colors | All colors | |||

| Best Performing Climates | BWk, BSk, Csc, Cwc, Cfc, Dsa, Dsb, Dsc, Dsd, Dwa, Dwb, Dwc, Dwd, Dfa, Dfb, Dfc, Dfd, ET, EF | |||

| 6-Hydrochromic | Energy Efficiency improvement | Further research required in that area |

|

|

| Visual Comfort | Further research required in that area | |||

| Colors | White | |||

| Best Performing Climates | Af, Cwa, Cfa, Cfb, Cfc, Dwa, Dwb, Dfa, Dfb, Dfc, Dfd | |||

| 7-Low-E | Energy Efficiency improvement | 2.7–20% |

|

|

| Visual Comfort | Up to 5% | |||

| Colors | Transparent | |||

| Best Performing Climates | All climates (depends on the coating’s position on the window) | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashidzadeh, Z.; Heidari Matin, N. A Comparative Study on Smart Windows Focusing on Climate-Based Energy Performance and Users’ Comfort Attributes. Sustainability 2023, 15, 2294. https://doi.org/10.3390/su15032294

Rashidzadeh Z, Heidari Matin N. A Comparative Study on Smart Windows Focusing on Climate-Based Energy Performance and Users’ Comfort Attributes. Sustainability. 2023; 15(3):2294. https://doi.org/10.3390/su15032294

Chicago/Turabian StyleRashidzadeh, Zhina, and Negar Heidari Matin. 2023. "A Comparative Study on Smart Windows Focusing on Climate-Based Energy Performance and Users’ Comfort Attributes" Sustainability 15, no. 3: 2294. https://doi.org/10.3390/su15032294

APA StyleRashidzadeh, Z., & Heidari Matin, N. (2023). A Comparative Study on Smart Windows Focusing on Climate-Based Energy Performance and Users’ Comfort Attributes. Sustainability, 15(3), 2294. https://doi.org/10.3390/su15032294