Green Supply Chain Management Practices of Firms with Competitive Strategic Alliances—A Study of the Automobile Industry

Abstract

1. Introduction

1.1. Study Model

1.2. Aims and Objectives

- To ascertain the influence of green supply chain performance management on manufacturing in automobile firms.

- To demonstrate the impact of green supply chain performance management on procurement in automobile firms.

- To evaluate the influence of green supply chain performance management on reverse logistics in automobile firms.

- To establish the influence of green supply chain performance management on eco-design in automobile firms.

- To determine the influence of green supply chain performance management on transportation in automobile firms.

1.3. Research Questions

- What is the correlation between green supply chain performance management and manufacturing in automobile firms?

- What is the relationship between green supply chain performance management and procurement in automobile firms?

- What is the correlation between green supply chain performance management and reverse logistics in automobile firms?

- What is the correlation between green supply chain performance management and eco-design in automobile firms?

- What is the correlation between green supply chain performance management and transportation in automobile firms?

1.4. Research Hypotheses

2. Literature Review

2.1. Supply Chain Management

Responsibility/Processes of Supply Chain Management

2.2. Green Supply Chain Management

2.2.1. Green Supply Chain Management for Effective Firm Performance

2.2.2. Green Supply Chain Management Application, Sustainability, and Collaboration

2.2.3. Green Supply Chain Management for Effective Integration of Strategic Alliances

3. Methodology

4. Results

4.1. Structural Equation Modeling (SEM)

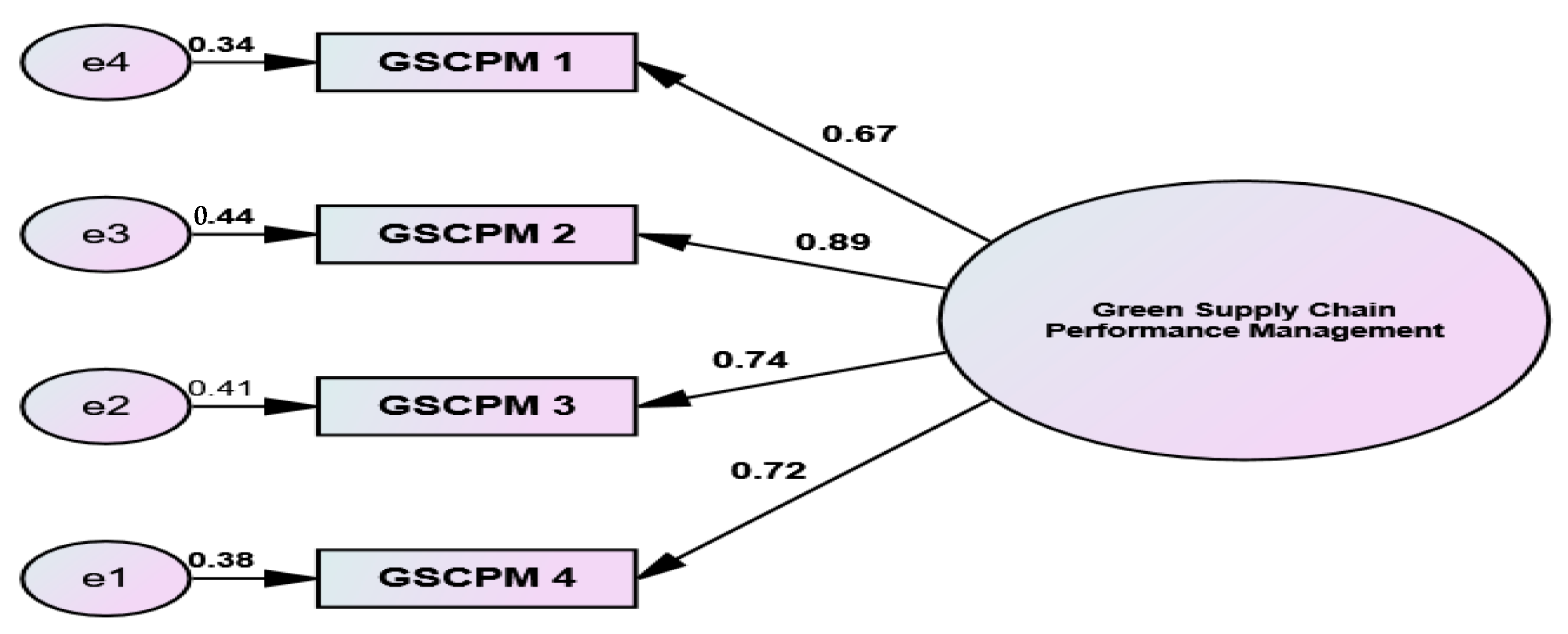

4.1.1. Measurement Model of Green Supply Chain Performance Management (Figure 2)

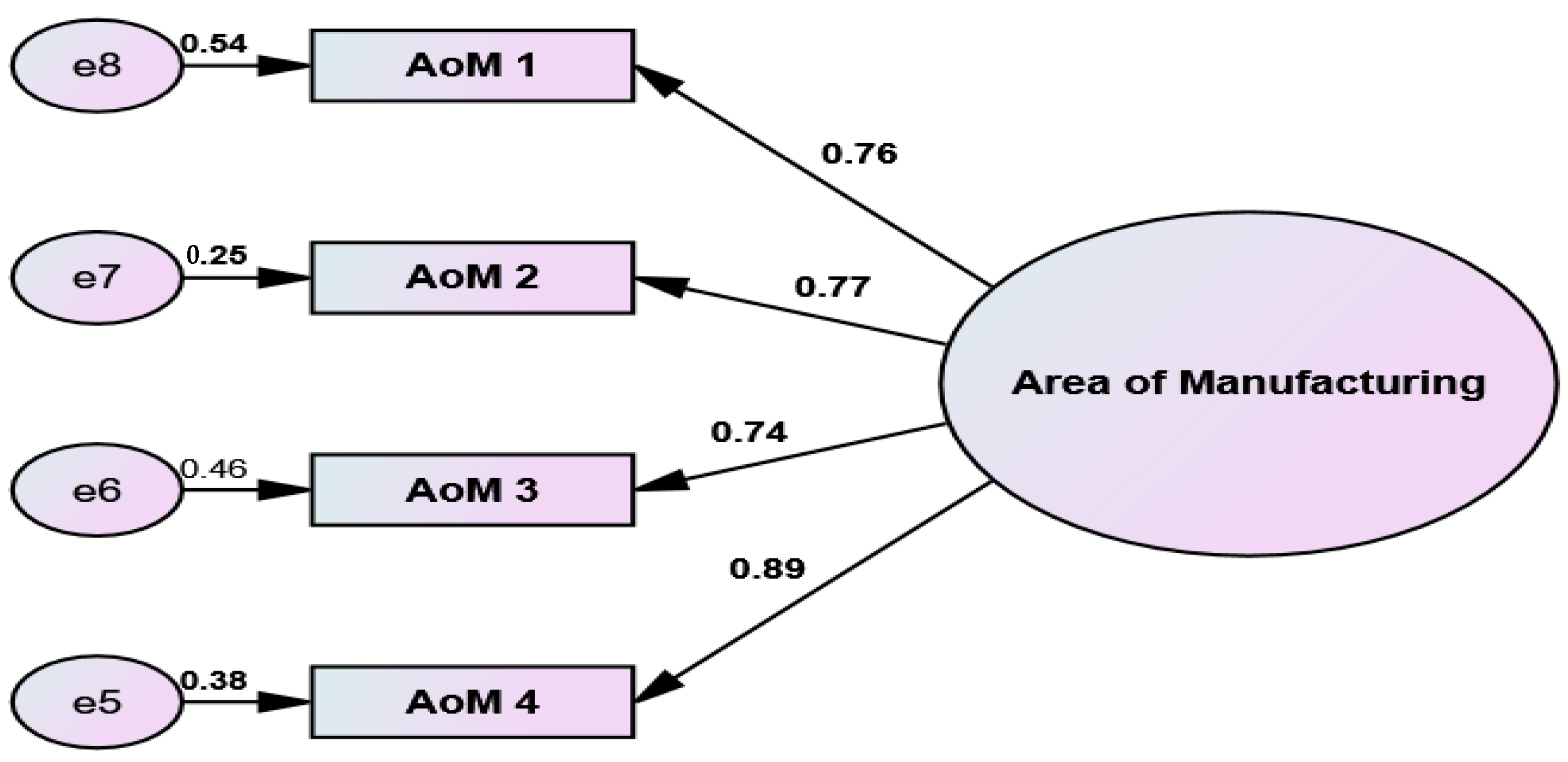

4.1.2. Measurement Model of Area of Manufacturing (Figure 3)

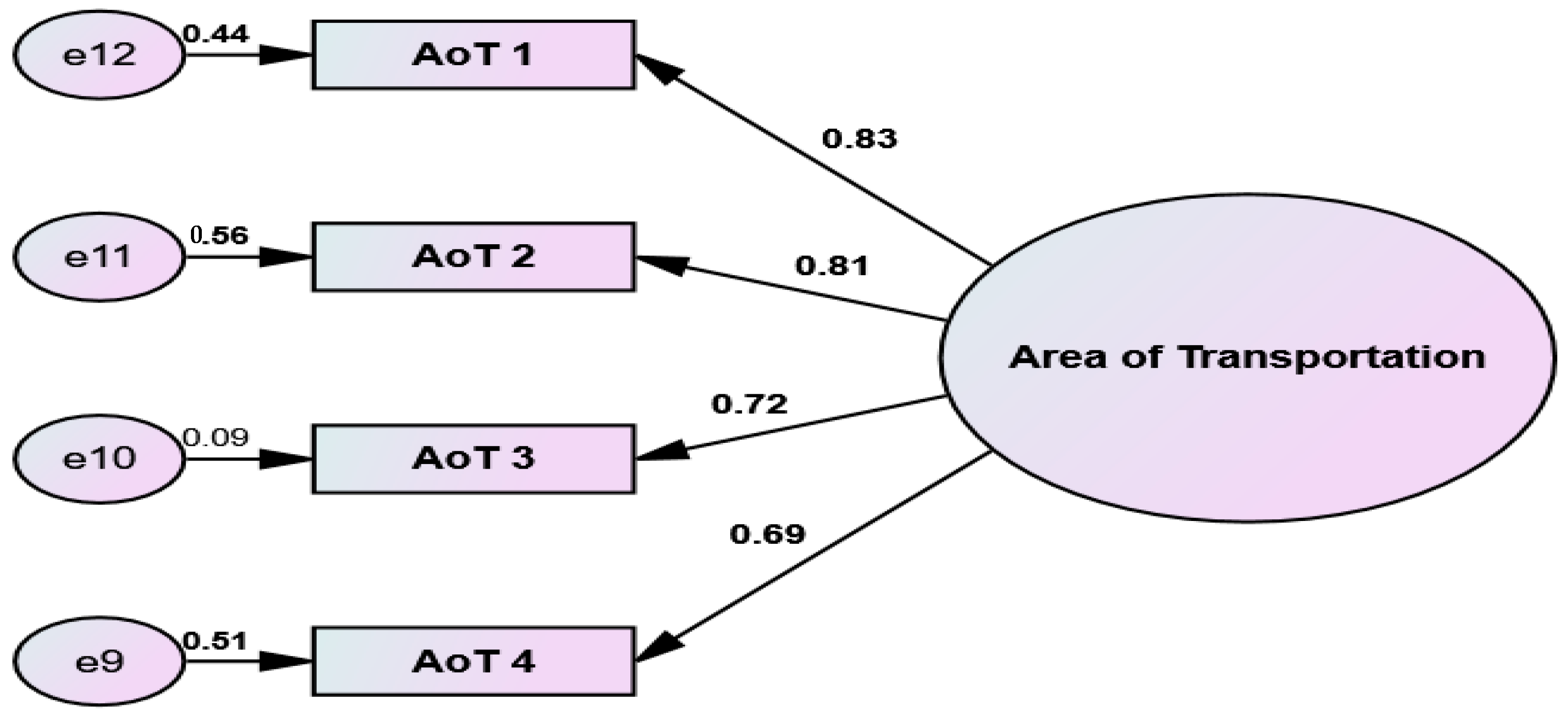

4.1.3. Measurement Model of Area of Transportation (Figure 4)

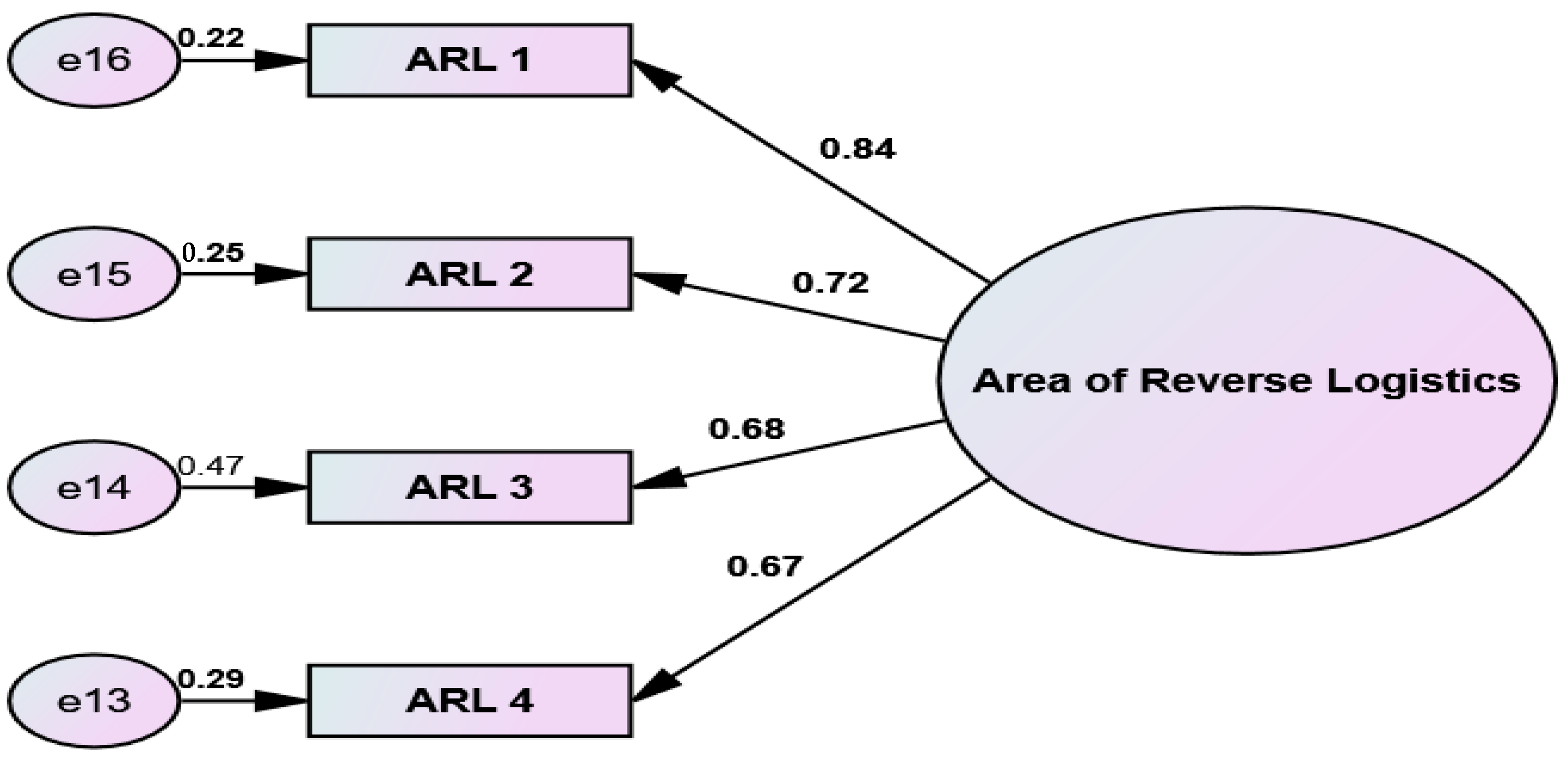

4.1.4. Measurement Model of Area of Reverse Logistics (Figure 5)

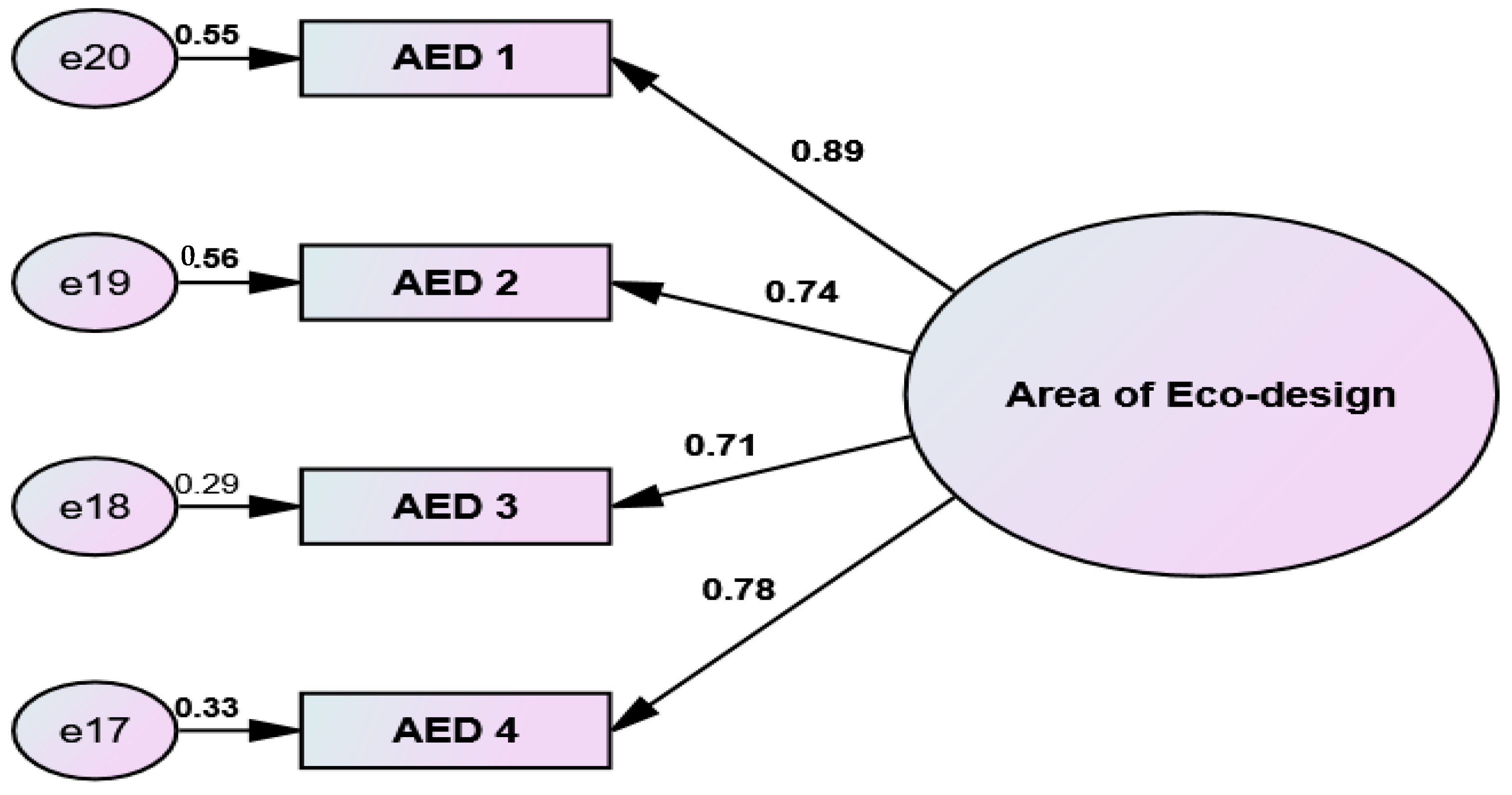

4.1.5. Measurement Model of Area of Eco-Design (Figure 6)

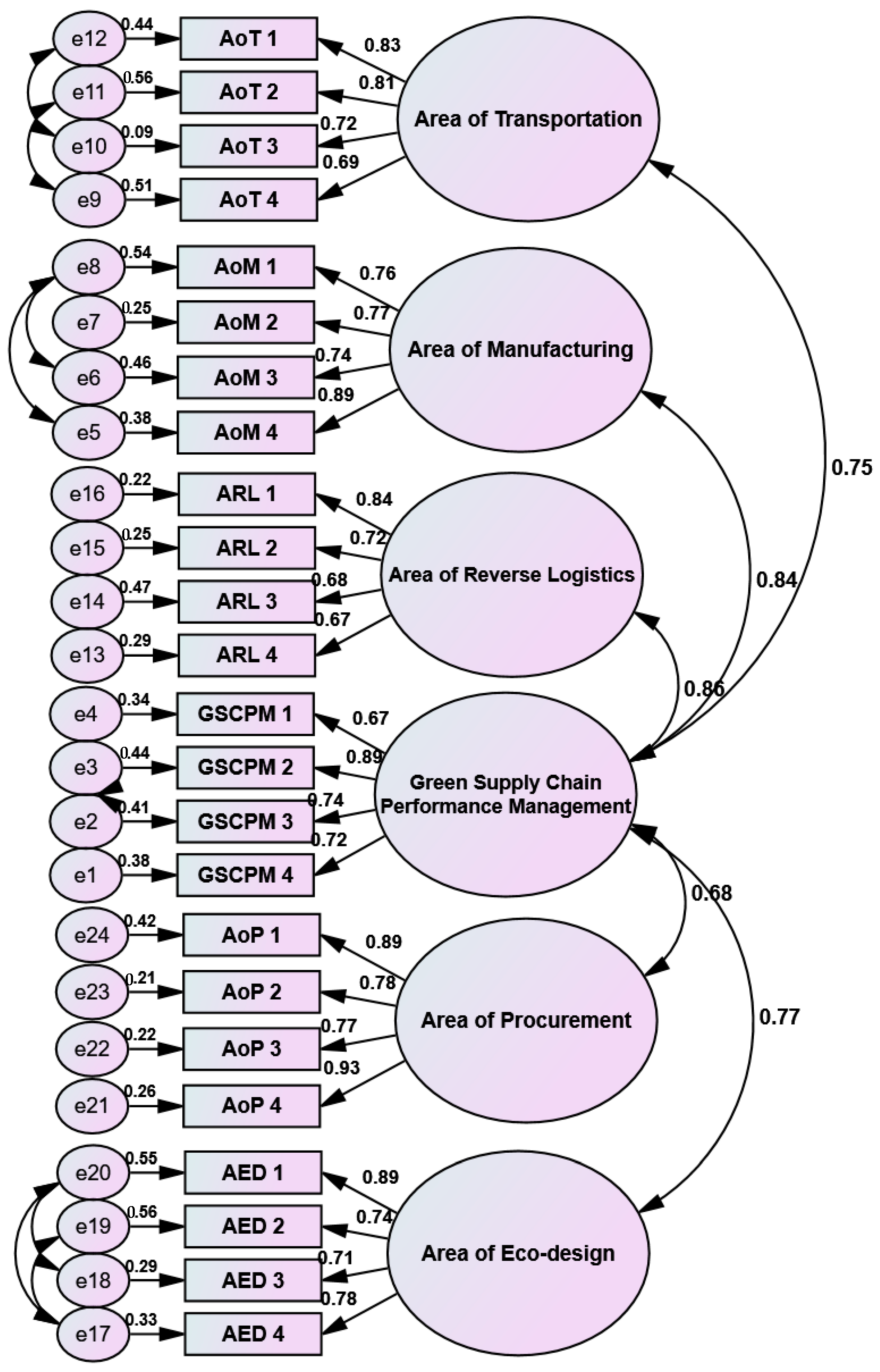

4.1.6. Structural Covariance Model of Green Supply Chain Performance Management and Measures of Competitive Strategic Alliances (Transportation, Manufacturing, Reverse Logistics, Procurement, and Eco-Design) (Figure 7)

5. Discussion

6. Managerial Implications

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Muduli, K.; Govindan, K.; Barve, A.; Kannan, D.; Geng, Y. Role of Behavioural Factors in Green Supply Chain Management Implementation in Indian Mining Industries. Resour. Conserv. Recycl. 2013, 76, 50–60. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An Analysis of the Drivers Affecting the Implementation of Green Supply Chain Management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Cabral, I.; Grilo, A.; Cruz-Machado, V. A Decision-Making Model for Lean, Agile, Resilient and Green Supply Chain Management. Int. J. Prod. Res. 2012, 50, 4830–4845. [Google Scholar] [CrossRef]

- Ageron, B.; Gunasekaran, A.; Spalanzani, A. Sustainable Supply Management: An Empirical Study. Int. J. Prod. Econ. 2012, 140, 168–182. [Google Scholar] [CrossRef]

- Arimura, T.H.; Darnall, N.; Katayama, H. Is ISO 14001 a Gateway to More Advanced Voluntary Action? The Case of Green Supply Chain Management. J. Environ. Econ. Manag. 2011, 61, 170–182. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Duarte, S.; Cruz-Machado, V. Influence of Green and Lean Upstream Supply Chain Management Practices on Business Sustainability. IEEE Trans. Eng. Manag. 2012, 59, 753–765. [Google Scholar] [CrossRef]

- Yang, C.S.; Lu, C.S.; Haider, J.J.; Marlow, P.B. The Effect of Green Supply Chain Management on Green Performance and Firm Competitiveness in the Context of Container Shipping in Taiwan. Transp. Res. Part E: Logist. Transp. Rev. 2013, 55, 55–73. [Google Scholar] [CrossRef]

- Barve, A.; Muduli, K. Modelling the Challenges of Green Supply Chain Management Practices in Indian Mining Industries. J. Manuf. Technol. Manag. 2013, 24, 1102–1122. [Google Scholar] [CrossRef]

- Beske, P.; Land, A.; Seuring, S. Sustainable Supply Chain Management Practices and Dynamic Capabilities in the Food Industry: A Critical Analysis of the Literature. Int. J. Prod. Econ. 2014, 152, 131–143. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative Models for Sustainable Supply Chain Management: Developments and Directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Nkakleu, R.; Biboum, A.D. Governance and Performance of Strategic Alliances in Africa: The Role of Institutions. J. Afr. Bus. 2019, 20, 242–258. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. Evaluation of the Green Supply Chain Management Practices: A Fuzzy ANP Approach. Prod. Plan. Control 2012, 23, 405–418. [Google Scholar] [CrossRef]

- Carvalho, H.; Cruz-Machado, V. Integrating Lean, Agile, Resilience and Green Paradigms in Supply Chain Management (LARG_SCM). In Supply Chain Management; IntechOpen: London, UK, 2011; ISBN 978-953-307-184-8. [Google Scholar]

- Chan, H.K.; He, H.; Wang, W.Y.C. Green Marketing and Its Impact on Supply Chain Management in Industrial Markets. Ind. Mark. Manag. 2012, 41, 557–562. [Google Scholar] [CrossRef]

- Chan, R.Y.K.; He, H.; Chan, H.K.; Wang, W.Y.C. Environmental Orientation and Corporate Performance: The Mediation Mechanism of Green Supply Chain Management and Moderating Effect of Competitive Intensity. Ind. Mark. Manag. 2012, 41, 621–630. [Google Scholar] [CrossRef]

- Chardine-Baumann, E.; Botta-Genoulaz, V. A Framework for Sustainable Performance Assessment of Supply Chain Management Practices. Comput. Ind. Eng. 2014, 76, 138–147. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Cruz Machado, V. The Influence of Green Practices on Supply Chain Performance: A Case Study Approach. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Chen, C.C.; Shih, H.S.; Shyur, H.J.; Wu, K.S. A Business Strategy Selection of Green Supply Chain Management via an Analytic Network Process. Comput. Math. Appl. 2012, 64, 2544–2557. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z. Green Supply Chain Management, Environmental Collaboration and Sustainability Performance. In Proceedings of the Procedia CIRP; Elsevier: Amsterdam, The Netherlands, 2015; Volume 26, pp. 695–699. [Google Scholar]

- De Giovanni, P.; Esposito Vinzi, V. Covariance versus Component-Based Estimations of Performance in Green Supply Chain Management. Int. J. Prod. Econ. 2012, 135, 907–916. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A Comparative Literature Analysis of Definitions for Green and Sustainable Supply Chain Management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Latan, H.; Teixeira, A.A.; de Oliveira, J.H.C. Quality Management, Environmental Management Maturity, Green Supply Chain Practices and Green Performance of Brazilian Companies with ISO 14001 Certification: Direct and Indirect Effects. Transp. Res. Part E Logist. Transp. Rev. 2014, 67, 39–51. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S.; Ramayah, T. Green Supply Chain Initiatives among Certified Companies in Malaysia and Environmental Sustainability: Investigating the Outcomes. Resour. Conserv. Recycl. 2011, 55, 495–506. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green Supply Chain Management: A Review and Bibliometric Analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable Supply Chain Management and Inter-Organizational Resources: A Literature Review. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 230–245. [Google Scholar] [CrossRef]

- Perotti, S.; Zorzini, M.; Cagno, E.; Micheli, G.J.L. Green Supply Chain Practices and Company Performance: The Case of 3PLs in Italy. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 640–672. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Govindan, K.; Esmaeili, A.; Sabaghi, M. Application of Fuzzy VIKOR for Evaluation of Green Supply Chain Management Practices. Ecol. Indic. 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers Analysis for Green Supply Chain Management Implementation in Indian Industries Using Analytic Hierarchy Process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Govindan, K.; Kannan, D.; Mathiyazhagan, K.; de Sousa Jabbour, A.B.L.; Jabbour, C.J.C. Analysing Green Supply Chain Management Practices in Brazil’s Electrical/Electronics Industry Using Interpretive Structural Modelling. Int. J. Environ. Stud. 2013, 70, 477–493. [Google Scholar] [CrossRef]

- Purba, H.H.; Fitra, A.; Nindiani, A. Control and Integration of Milk-Run Operation in Japanese Automotive Company in Indonesia. Manag. Prod. Eng. Rev. 2019, 10, 79–88. [Google Scholar] [CrossRef]

- Sharma, R.; Shishodia, A.; Kamble, S.; Gunasekaran, A.; Belhadi, A. Agriculture Supply Chain Risks and COVID-19: Mitigation Strategies and Implications for the Practitioners. Int. J. Logist. Res. Appl. 2020, 1–27. [Google Scholar] [CrossRef]

- De Giovanni, P. Leveraging the Circular Economy with a Closed-Loop Supply Chain and a Reverse Omnichannel Using Blockchain Technology and Incentives. Int. J. Oper. Prod. Manag. 2022, 42, 959–994. [Google Scholar] [CrossRef]

- Lim, J.; Norman, B.A.; Rajgopal, J. Redesign of Vaccine Distribution Networks. Int. Trans. Oper. Res. 2022, 29, 200–225. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Sorooshian, S.; Okfalisa, O. Digital Twins Driven Supply Chain Visibility within Logistics: A New Paradigm for Future Logistics. Appl. Syst. Innov. 2021, 4, 29. [Google Scholar] [CrossRef]

- Xue, X.; Dou, J.; Shang, Y. Blockchain-Driven Supply Chain Decentralized Operations—Information Sharing Perspective. Bus. Process Manag. J. 2021, 27, 184–203. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; de Sousa Jabbour, A.B.L. Green Human Resource Management and Green Supply Chain Management: Linking Two Emerging Agendas. J. Clean. Prod. 2016, 112, 1824–1833. [Google Scholar] [CrossRef]

- Laosirihongthong, T.; Adebanjo, D.; Choon Tan, K. Green Supply Chain Management Practices and Performance. Ind. Manag. Data Syst. 2013, 113, 1088–1109. [Google Scholar] [CrossRef]

- Shi, V.G.; Koh, S.C.L.; Baldwin, J.; Cucchiella, F. Natural Resource Based Green Supply Chain Management. Supply Chain Manag. 2012, 17, 54–67. [Google Scholar] [CrossRef]

- Lee, S.M.; Kim, S.T.; Choi, D. Green Supply Chain Management and Organizational Performance. Ind. Manag. Data Syst. 2012, 112, 1148–1180. [Google Scholar] [CrossRef]

- Lin, R.J. Using Fuzzy DEMATEL to Evaluate the Green Supply Chain Management Practices. J. Clean. Prod. 2013, 40, 32–39. [Google Scholar] [CrossRef]

- Zimon, D.; Tyan, J.; Sroufe, R. Implementing Sustainable Supply Chain Management: Reactive, Cooperative, and Dynamic Models. Sustainability 2019, 11, 7227. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big Data Analytics as an Operational Excellence Approach to Enhance Sustainable Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Murniati, S.; Harjuno, H.A.C.; Mambuhu, N.; Jenni Indriakati, A.; Murniati STIE Wira Bhakti Makassar, S.; Alfabetian Harjuno Condro Haditomo, I. Analyzing Mediation Effect of Competitive Advantage on Firm Performance as Measured by Total Quality Management and Supply Chain Management. J. Apl. Manaj. 2022, 20, 66–74. [Google Scholar] [CrossRef]

- Khokhar, M.; Hou, Y.; Rafique, M.A.; Iqbal, W. Evaluating the Social Sustainability Criteria of Supply Chain Management in Manufacturing Industries: A Role of BWM in MCDM. Probl. Ekorozw. 2020, 15, 185–194. [Google Scholar] [CrossRef]

- Al-Ghwayeen, W.S.; Abdallah, A.B. Green Supply Chain Management and Export Performance: The Mediating Role of Environmental Performance. J. Manuf. Technol. Manag. 2018, 29, 1233–1252. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Choi, T.M.; Sethi, S.P. Green Supply Chain Management in Chinese Firms: Innovative Measures and the Moderating Role of Quick Response Technology. J. Oper. Manag. 2020, 66, 958–988. [Google Scholar] [CrossRef]

- Hazen, B.T.; Cegielski, C.; Hanna, J.B. Diffusion of Green Supply Chain Management: Examining Perceived Quality of Green Reverse Logistics. Int. J. Logist. Manag. 2011, 22, 373–389. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, L. Research on Optimal Pricing Decisions of the Service Supply Chain Oriented to Strategic Consumers. J. Ind. Manag. Optim. 2022, 2022, 1–25. [Google Scholar] [CrossRef]

- Guo, J.; Xi, M. Greening, Pricing and Marketing Coordination for a Complex Three-Level Supply Chain Under the Carbon Tax in China. IEEE Access 2022, 10, 76895–76905. [Google Scholar] [CrossRef]

- Liu, X.; Yang, J.; Qu, S.; Wang, L.; Shishime, T.; Bao, C. Sustainable Production: Practices and Determinant Factors of Green Supply Chain Management of Chinese Companies. Bus. Strategy Environ. 2012, 21, 1–16. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, V.; Kumar, S.; Haleem, A.; Luthra, S.; Kumar, V.; Kumar, S.; Haleem, A. Barriers to Implement Green Supply Chain Management in Automobile Industry Using Interpretive Structural Modeling Technique: An Indian Perspective. J. Ind. Eng. Manag. 2011, 4, 231–257. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM Approach for the Barrier Analysis in Implementing Green Supply Chain Management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating Sustainability and Resilience in the Supply Chain: A Systematic Literature Review and a Research Agenda. Bus. Strategy Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Sutduean, J.; Singsa, A.; Sriyakul, T.; Jermsittiparsert, K. Supply Chain Integration, Enterprise Resource Planning, and Organizational Performance: The Enterprise Resource Planning Implementation Approach. J. Comput. Theor. Nanosci. 2019, 16, 2975–2981. [Google Scholar] [CrossRef]

- Singh, J.; Singh, H.; Kumar, A. Impact of Lean Practices on Organizational Sustainability through Green Supply Chain Management—An Empirical Investigation. Int. J. Lean Six Sigma 2020, 11, 1049–1082. [Google Scholar] [CrossRef]

- Sahoo, S.; Vijayvargy, L. Green Supply Chain Management Practices and Its Impact on Organizational Performance: Evidence from Indian Manufacturers. J. Manuf. Technol. Manag. 2020, 32, 862–886. [Google Scholar] [CrossRef]

- Jum’a, L.; Ikram, M.; Alkalha, Z.; Alaraj, M. Factors Affecting Managers’ Intention to Adopt Green Supply Chain Management Practices: Evidence from Manufacturing Firms in Jordan. Environ. Sci. Pollut. Res. 2021, 29, 5605–5621. [Google Scholar] [CrossRef]

- Sajjad, A.; Eweje, G.; Tappin, D. Managerial Perspectives on Drivers for and Barriers to Sustainable Supply Chain Management Implementation: Evidence from New Zealand. Bus. Strategy Environ. 2020, 29, 592–604. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.; Mutebi, H.; Kyomuhendo, R. Competitive Advantage in SMEs: Effect of Supply Chain Management Practices, Logistics Capabilities and Logistics Integration in a Developing Country. J. Bus. Socio-Econ. Dev. 2021. ahead of the print. [Google Scholar] [CrossRef]

- Walker, H.; Jones, N. Sustainable Supply Chain Management across the UK Private Sector. Supply Chain Manag. 2012, 17, 15–28. [Google Scholar] [CrossRef]

- Mitra, S.; Datta, P.P. Adoption of Green Supply Chain Management Practices and Their Impact on Performance: An Exploratory Study of Indian Manufacturing Firms. Int. J. Prod. Res. 2014, 52, 2085–2107. [Google Scholar] [CrossRef]

- Mohanty, R.P.; Prakash, A. Green Supply Chain Management Practices in India: A Confirmatory Empirical Study. Prod. Manuf. Res. 2014, 2, 438–456. [Google Scholar] [CrossRef]

- Hsu, C.W.; Kuo, T.C.; Chen, S.H.; Hu, A.H. Using DEMATEL to Develop a Carbon Management Model of Supplier Selection in Green Supply Chain Management. J. Clean. Prod. 2013, 56, 164–172. [Google Scholar] [CrossRef]

- Hu, A.H.; Hsu, C.W. Critical Factors for Implementing Green Supply Chain Management Practice: An Empirical Study of Electrical and Electronics Industries in Taiwan. Manag. Res. Rev. 2010, 33, 586–608. [Google Scholar] [CrossRef]

- Kumar, A.; Mangla, S.K.; Luthra, S.; Ishizaka, A. Evaluating the Human Resource Related Soft Dimensions in Green Supply Chain Management Implementation. Prod. Plan. Control 2019, 30, 699–715. [Google Scholar] [CrossRef]

- Ferraris, A.; Mazzoleni, A.; Devalle, A.; Couturier, J. Big Data Analytics Capabilities and Knowledge Management: Impact on Firm Performance. Manag. Decis. 2019, 57, 1923–1936. [Google Scholar] [CrossRef]

- Sima, V.; Gheorghe, I.G.; Subić, J.; Nancu, D. Influences of the Industry 4.0 Revolution on the Human Capital Development and Consumer Behavior: A Systematic Review. Sustainability 2020, 12, 4035. [Google Scholar] [CrossRef]

- Tate, W.L.; Ellram, L.M.; Kirchoff, J.F. Corporate Social Responsibility Reports: A Thematic Analysis Related to Supply Chain Management. J. Supply Chain Manag. 2010, 46, 19–44. [Google Scholar] [CrossRef]

- Muduli, K.; Govindan, K.; Barve, A.; Geng, Y. Barriers to Green Supply Chain Management in Indian Mining Industries: A Graph Theoretic Approach. J. Clean. Prod. 2013, 47, 335–344. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An Organizational Theoretic Review of Green Supply Chain Management Literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Cuypers, I.R.P.; Hennart, J.F.; Silverman, B.S.; Ertug, G. Transaction Cost Theory: Past Progress, Current Challenges, and Suggestions for the Future. Acad. Manag. Ann. 2021, 15, 111–150. [Google Scholar] [CrossRef]

- Lee, K.H. Integrating Carbon Footprint into Supply Chain Management: The Case of Hyundai Motor Company (HMC) in the Automobile Industry. J. Clean. Prod. 2011, 19, 1216–1223. [Google Scholar] [CrossRef]

- Tseng, M.L. Green Supply Chain Management with Linguistic Preferences and Incomplete Information. Appl. Soft Comput. 2011, 11, 4894–4903. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.; Mutebi, H.; Isabirye, D. Supplier Performance in the Public Healthcare: Internal Social Capital, Logistics Capabilities and Supply Chain Risk Management Capabilities as Antecedents in a Developing Economy. J. Bus. Socio-Econ. Dev. 2021. ahead of print. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiu, A.S.F. Evaluating Firm’s Green Supply Chain Management in Linguistic Preferences. J. Clean. Prod. 2013, 40, 22–31. [Google Scholar] [CrossRef]

- Sheu, J.B.; Talley, W.K. Green Supply Chain Management: Trends, Challenges, and Solutions. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 791–792. [Google Scholar] [CrossRef]

- Wang, Y.F.; Chen, S.P.; Lee, Y.C.; Tsai, C.T. (Simon) Developing Green Management Standards for Restaurants: An Application of Green Supply Chain Management. Int. J. Hosp. Manag. 2013, 34, 263–273. [Google Scholar] [CrossRef]

- Wu, G.-C.; Cheng, Y.; Huang, S.-Y. The Study of Knowledge Transfer and Green Management Performance in Green Supply Chain Management. Afr. J. Bus. Manag. 2010, 4, 44–48. [Google Scholar]

- Wu, J.; Dunn, S.; Forman, H. A Study on Green Supply Chain Management Practices among Large Global Corporations. J. Supply Chain Oper. Manag. 2012, 10, 182–194. [Google Scholar]

- Wu, K.J.; Tseng, M.L.; Vy, T. Evaluation the Drivers of Green Supply Chain Management Practices in Uncertainty. In Proceedings of the Procedia—Social and Behavioral Sciences; Elsevier: Amsterdam, The Netherlands, 2011; Volume 25, pp. 384–397. [Google Scholar]

- Wu, Z.; Pagell, M. Balancing Priorities: Decision-Making in Sustainable Supply Chain Management. J. Oper. Manag. 2011, 29, 577–590. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable Supply Chain Management (SSCM) in Malaysia: A Survey. Int. J. Prod. Econ. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Sarkis, J.; Lai, K. hung Evaluating Green Supply Chain Management among Chinese Manufacturers from the Ecological Modernization Perspective. Transp. Res. Part E: Logist. Transp. Rev. 2011, 47, 808–821. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Fujita, T.; Hashimoto, S. Green Supply Chain Management in Leading Manufacturers: Case Studies in Japanese Large Companies. Manag. Res. Rev. 2010, 33, 380–392. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Examining the Effects of Green Supply Chain Management Practices and Their Mediations on Performance Improvements. Int. J. Prod. Res. 2012, 50, 1377–1394. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Green Supply Chain Management Innovation Diffusion and Its Relationship to Organizational Improvement: An Ecological Modernization Perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. hung Institutional-Based Antecedents and Performance Outcomes of Internal and External Green Supply Chain Management Practices. J. Purch. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Zhu, Q.; Tian, Y.; Sarkis, J. Diffusion of Selected Green Supply Chain Management Practices: An Assessment of Chinese Enterprises. Prod. Plan. Control 2012, 23, 837–850. [Google Scholar] [CrossRef]

- Bose, I.; Pal, R. Do Green Supply Chain Management Initiatives Impact Stock Prices of Firms? Decis. Support Syst. 2012, 52, 624–634. [Google Scholar] [CrossRef]

- Ji, Y.; Li, H.; Zhang, H. Risk-Averse Two-Stage Stochastic Minimum Cost Consensus Models with Asymmetric Adjustment Cost. Group Decis. Negot. 2022, 31, 261–291. [Google Scholar] [CrossRef]

- Qu, S.; Li, Y.; Ji, Y. The Mixed Integer Robust Maximum Expert Consensus Models for Large-Scale GDM under Uncertainty Circumstances. Appl. Soft Comput. 2021, 107, 107369. [Google Scholar] [CrossRef]

- Qu, S.; Xu, L.; Mangla, S.K.; Chan, F.T.S.; Zhu, J.; Arisian, S. Matchmaking in Reward-Based Crowdfunding Platforms: A Hybrid Machine Learning Approach. Int. J. Prod. Res. 2022, 1–21. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green Supply Chain Management Practices: Impact on Performance. Supply Chain Manag. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Jawaad, M.; Hasan, T.; Amir, A.; Imam, H. Exploring the Impact of Green Human Resource Management on Firm Sustainable Performance: Roles of Green Supply Chain Management and Firm Size. J. Manag. Organ. 2022, 1–23. [Google Scholar] [CrossRef]

- Rao, P. Greening the Supply Chain: A New Initiative in South East Asia. Int. J. Oper. Prod. Manag. 2002, 22, 632–655. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Extending Green Practices across the Supply Chain: The Impact of Upstream and Downstream Integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Aggerholm, H.K.; Andersen, S.E.; Thomsen, C. Conceptualising Employer Branding in Sustainable Organisations. Corp. Commun. 2011, 16, 105–123. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, D.; Liang, L.; Olson, D.L. Supply Chain Loss Averse Newsboy Model with Capital Constraint. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 646–658. [Google Scholar] [CrossRef]

- Luo, Z.; Chen, X.; Chen, J.; Wang, X. Optimal Pricing Policies for Differentiated Brands under Different Supply Chain Power Structures. Eur. J. Oper. Res. 2017, 259, 437–451. [Google Scholar] [CrossRef]

- Boon-itt, S.; Wong, C.Y. The Moderating Effects of Technological and Demand Uncertainties on the Relationship between Supply Chain Integration and Customer Delivery Performance. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 253–276. [Google Scholar] [CrossRef]

| Variable | Classification | Frequency | Percentage (%) |

|---|---|---|---|

| Age | 20–25 | 33 | 10.3 |

| 26–30 | 62 | 19.4 | |

| 31–35 | 113 | 35.3 | |

| 36–40 | 81 | 25.3 | |

| 40 and above | 31 | 9.7 | |

| Province of | Guangdong | 85 | 26.6 |

| Jilin | 47 | 14.7 | |

| Shanghai | 43 | 13.4 | |

| Hubei | 33 | 10.3 | |

| Guangxi | 12 | 3.8 | |

| Beijing | 16 | 5.0 | |

| Chongqing | 8 | 2.5 | |

| Anhui | 16 | 5.0 | |

| Shandong | 8 | 2.5 | |

| Hebei | 16 | 5.0 | |

| Tianjin | 12 | 3.8 | |

| Zhejiang | 16 | 5.0 | |

| Jiangsu | 8 | 2.5 | |

| Experience | 1–4 | 31 | 9.7 |

| 5–8 | 110 | 34.4 | |

| 9–12 | 133 | 41.6 | |

| 13 and above | 46 | 14.4 | |

| Status | Procurement manager | 49 | 15.3 |

| Reverse logistics manager | 64 | 20.0 | |

| Eco-design manager | 92 | 28.8 | |

| Transport manager | 79 | 24.7 | |

| Production manager | 36 | 11.3 |

| Model | Chi-Square (df), Significance | NFI | TLI | CFI | RMSEA | Variable | Standardized Factor Loading Estimate | Error VAR |

|---|---|---|---|---|---|---|---|---|

| Green supply chain performance management | (5 df) 5.86, p > 0.000 | 0.96 | 0.95 | 0.98 | 0.043 | GSCPM1 | 0.67 | 0.34 |

| GSCPM2 | 0.89 | 0.44 | ||||||

| GSCPM3 | 0.74 | 0.41 | ||||||

| GSCPM4 | 0.72 | 0.38 |

| Model | Chi-Square (df), Significance | NFI | TLI | CFI | RMSEA | Variable | Standardized Factor Loading Estimate | Error VAR |

|---|---|---|---|---|---|---|---|---|

| Manufacturing | (67 df) 255, p > 0.000 | 1.05 | 0.96 | 0.95 | 0.06 | AoM1 | 0.76 | 0.54 |

| AoM2 | 0.77 | 0.25 | ||||||

| AoM3 | 0.74 | 0.46 | ||||||

| AoM4 | 0.89 | 0.38 |

| Model | Chi-Square (df), Significance | NFI | TLI | CFI | RMSEA | Variable | Standardized Factor Loading Estimate | Error VAR |

|---|---|---|---|---|---|---|---|---|

| Transportation | (49 df) 60.5, p > 0.000 | 0.98 | 1.04 | 1.00 | 0.054 | ARL 1 | 0.83 | 0.44 |

| ARL 2 | 0.81 | 0.56 | ||||||

| ARL 3 | 0.72 | 0.09 | ||||||

| ARL 4 | 0.69 | 0.51 |

| Model | Chi-Square (df), Significance | NFI | TLI | CFI | RMSEA | Variable | Standardized Factor Loading Estimate | Error VAR |

|---|---|---|---|---|---|---|---|---|

| Reverse logistics | (89 df) 356, p > 0.000 | 1.02 | 0.97 | 0.99 | 0.038 | ARl1 | 0.84 | 0.22 |

| ARL 2 | 0.72 | 0.25 | ||||||

| ARL 3 | 0.68 | 0.47 | ||||||

| ARL 4 | 0.67 | 0.29 |

| Model | Chi-Square (df), Significance | NFI | TLI | CFI | RMSEA | Variable | Standardized Factor Loading Estimate | Error VAR |

|---|---|---|---|---|---|---|---|---|

| Eco-design | (78 df) 541, p > 0.000 | 1.04 | 1.06 | 1.01 | 0.036 | AED 1 | 0.89 | 0.55 |

| AED 2 | 0.74 | 0.56 | ||||||

| AED 3 | 0.71 | 0.29 | ||||||

| AED 4 | 0.78 | 0.33 |

| S/N | Mediation Stage | Relationship | Std. Beta | Actual Beta | SE | CR | P |

|---|---|---|---|---|---|---|---|

| 1. | X→Y (Hypothesis 1) | Green supply chain performance management and manufacturing | 0.87 | 0.75 | 0.13 | 1.99 | 0.000 |

| 2. | X→Y (Hypothesis 2) | Green supply chain performance management and transportation | 0.77 | 0.79 | 0.36 | 3.11 | 0.000 |

| 3. | X→Y (Hypothesis 3) | Green supply chain performance management and reverse logistics | 0.78 | 0.85 | 0.34 | 3.08 | 0.000 |

| 4. | X→Y (Hypothesis 4) | Green supply chain performance management and eco-design | 0.96 | 0.68 | 0.21 | 2.18 | 0.000 |

| 5. | X→Y (Hypothesis 5) | Green supply chain performance management and procurement | 0.85 | 0.86 | 0.19 | 2.21 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, H.; Tong, S. Green Supply Chain Management Practices of Firms with Competitive Strategic Alliances—A Study of the Automobile Industry. Sustainability 2023, 15, 2156. https://doi.org/10.3390/su15032156

Abbas H, Tong S. Green Supply Chain Management Practices of Firms with Competitive Strategic Alliances—A Study of the Automobile Industry. Sustainability. 2023; 15(3):2156. https://doi.org/10.3390/su15032156

Chicago/Turabian StyleAbbas, Hassan, and Shu Tong. 2023. "Green Supply Chain Management Practices of Firms with Competitive Strategic Alliances—A Study of the Automobile Industry" Sustainability 15, no. 3: 2156. https://doi.org/10.3390/su15032156

APA StyleAbbas, H., & Tong, S. (2023). Green Supply Chain Management Practices of Firms with Competitive Strategic Alliances—A Study of the Automobile Industry. Sustainability, 15(3), 2156. https://doi.org/10.3390/su15032156