1. Introduction

Construction projects generate significant quantities of solid waste [

1,

2,

3,

4], which presents many difficulties for sustainable development and circular economy [

2]. New construction projects have promoted economic growth in developing countries [

5], but simultaneously generated new waste management challenges to overcome [

6,

7]. Santoso et al. [

7], for example, investigated waste management as a critical factor affecting the performance of large construction projects in developing countries. According to McDermot et al. [

8], a lack of an efficient material management is one of the most common failure factors that decrease the performance of infrastructure projects in developing countries. Kassem et al. [

9] argued that construction waste is one of the most important risk factors in oil and gas construction projects in developing countries. Other studies considered that the inclusion of material management, among other criteria, guarantees the success of public-private partnership infrastructure projects in developing countries [

10]. This situation has put construction industries under pressure to consider appropriate methods for managing construction waste [

11,

12,

13]. Recycling represents an efficient way to counter the risk of construction waste [

4,

14,

15,

16]. Within this context, large amounts of dredged sediment are produced as part of the construction of new ports, marine structures or waterways [

17]. Marine sediment can be generated by other activities such as the deepening of access channels and port basins, and regular dredging operations to maintain adequate depths [

18,

19,

20,

21,

22]. The enormous quantities of sediment are explained by the presence of anthropogenic activities occurring naturally [

21]. Considered as waste [

23], dredged sediment is often disposed of into the sea [

24], causing adverse consequences on the aquatic environment and human well-being [

17,

25,

26,

27,

28,

29,

30]. Given the increasing legal requirements regarding sediment management, conventional methods or the “no-action” option are no longer viable for economic, environmental and social plans [

31,

32,

33]. Dredged sediment management is therefore a challenge and an opportunity for port authorities [

28,

34,

35] to apply circular economy principles by considering sediment as a sustainable resource rather than hazardous waste [

36,

37,

38].

In addition, construction projects have accelerated at an unprecedented rate due to rapid urbanization [

39]. Requiring large volumes of raw materials [

40,

41], the construction industry is disadvantaged by the scarcity of natural resources [

42,

43]. As future construction projects are planned to expand [

44,

45,

46], it is critical to adopt development plans that promote the use of responsible production channels, including waste materials recycling [

47,

48,

49,

50]. From this perspective, sustainable reuse of harbor dredged sediment may provide a valuable alternative to the overexploitation of the non-renewable natural resources needed for construction [

51,

52]. Dredging operations, performed periodically in order to guarantee adequate navigation levels and ports safety [

28,

53,

54,

55], generate more than 1 billion cubic meters of sediment per year worldwide [

56]. To this effect, many studies have examined the feasibility of reusing dredged sediment as construction material [

57,

58]. Research into this field has focused on recycling dredged sediment as a secondary raw material in different applications as a way to preserve non-renewable resources and reduce the environmental impacts of off-site marine disposal [

53]. Although the material obtained from dredged sediment is non-renewable, it has several characteristics and advantages in terms of sustainability [

59]. Firstly, the quantities generated by dredging operations are immense and present a significant resource to fill the need for construction materials [

60]. Secondly, dredged sediment is the result of a natural phenomenon called sedimentation; it is a continuous and permanent process resulting from the transport of particles and their ultimate accumulation in the marine basin to form a deposit [

54,

55,

61]. This is confirmed by the rising statistics of the quantities dredged per year. It should be noted that recent years have recorded, at the world level, an amplification of the phenomenon of sedimentation and an increase of its speed due to erosion and an increase in anthropic contributions [

62]. Therefore, unlike the case of quarries and natural deposits, the reuse of dredged sediment in the construction sector does not face constraints related to the rational management of non-renewable resources.

As the bridge which links dredging operations and extracted products management, the beneficial reuse of dredged sediment as construction material represents a concrete application of efficient waste management [

63]. It allows for both a sustainable dredging disposal mechanism and the promotion of a waste-to-wealth approach [

56,

64,

65,

66,

67,

68]. A number of studies have identified paths to valorize dredged material in the construction industry [

59,

69,

70]. Dredged sediment can be used as an alternative source of conventional aggregate used for the manufacture of concrete or mortar [

24,

60,

71,

72,

73,

74] by acting as a substitute for sand. It can also partially replace raw materials for cement production [

75,

76,

77]; this often requires adequate treatment before use. More studies have focused on the reuse of dredged sediment as foundation or base layers in road engineering [

34,

78,

79,

80,

81,

82,

83]. Some researchers have investigated the feasibility of recycling dredged sediment in brick production [

51,

84,

85,

86,

87,

88], artificial aggregate [

53,

87,

88] and urban landscaping works [

89,

90]. As a result, the technical feasibility of recycling dredged sediment in the construction industry has been confirmed. However, most of these studies do not examine real applications of recycled sediment. Few researchers have attempted to realize projects based on these materials. Amar [

90,

91], for example, worked on three in-site projects at the seaport of Dunkerque; the first was the replacement of a 600-m-long road (Freycinet 12) of degraded pavement using base layers from non-immersible sediment. The second project consisted of valorizing dredged sediment into maritime concrete blocks that are used to stabilize the jetty at the West Foreport to control the agitation of water bodies. The third project served to enhance sediment into a landscaped eco-model; this project consisted of the implementation of landscaping eco-models made of sediments from 5 to 7 m high and covered with 0.25 m of topsoil to ensure the stability of the structure. In addition, dredged sediment has been used in some countries in major infrastructure projects, such us Palm Island in Dubai, Rotterdam harbor, the National Theatre in London and the artificial island of Chek Lap Kok where the Hong Kong airport is located [

72,

92,

93]. The success of these projects confirms and verifies the economic and technical validity of reusing dredged sediment in civil engineering [

94].

Research has proven the potential of recycling dredged sediment in many applications related to the construction industry [

36,

56,

94]. However, market demand appears to be lagging behind encouraging study results; the real beneficial reuse of dredged sediment is still very limited [

95,

96]. From a technical point of view, the identification of the appropriate path to valorize dredged sediment as construction material should be based on the study of its properties [

56]. It requires a case-by-case basis in order to determine the required characteristics of sediment extracted from the study site [

27]. Characterizing the dredged sediment is therefore considered as an essential phase towards identifying the possible recycling paths of sediment [

23,

35]. This constitutes a primordial and decisive step in the valorization process [

97,

98]. Research efforts in this context were often conducted from the perspective of providing a study of all parameters related to dredged sediment characterization, including on-site analysis and laboratory tests [

99]. Researchers have opted for physical, microscopic, chemical, mineralogical, environmental, mechanical and geotechnical characterizations [

72,

85,

100,

101,

102,

103]. With a growing interest in sustainable development issues, characterization tests of dredged sediments are often imposed by regulatory frameworks in order to determine their best destination [

27,

104]. However, prior research has focused mostly on case studies in developed countries, and there have been limited efforts to explore how these approaches can be implemented in developing countries [

101]. Developed and developing countries have quite divergent concerns; while in developing countries the pursuit of more cost-effective development opportunities frequently overrides environmental considerations and concerns, developed countries are often economically strong and able to place a higher emphasis on sustainable development and environmental issues [

29,

98,

105,

106,

107,

108]. Such an approach to complete and full characterization is not applicable in developing countries; in addition to the legal gap in which dredged sediment management does not mandate any type of characterization [

23,

56,

109], it requires an investment in terms of cost, time and advanced techniques for conducting all types of laboratory tests. The number and complexity of characterization tests are an obstacle to the valorization process in developing countries. Hence, optimizing and justifying the choice of laboratory tests carried out to characterize dredged sediment is instrumental for recycling it as construction material in developing countries.

On the other hand, previous studies have focused only on the technical feasibility of reusing dredged sediment in civil engineering [

110]. This reuse process combines an environmental issue with an economic advantage [

56]. Indeed, the final objective of this process is to no longer to store or dump the dredged sediment, but rather to use it as commercial material. Beneficial reuse of dredged material may become more cost-effective in the future due to the scarcity of natural resources and the possible increase of their price [

56]. Accordingly, estimating the necessary costs to obtain construction material from dredged sediment is important in order to compare it with the cost of purchasing a similar conventional material [

17,

28,

111,

112,

113].

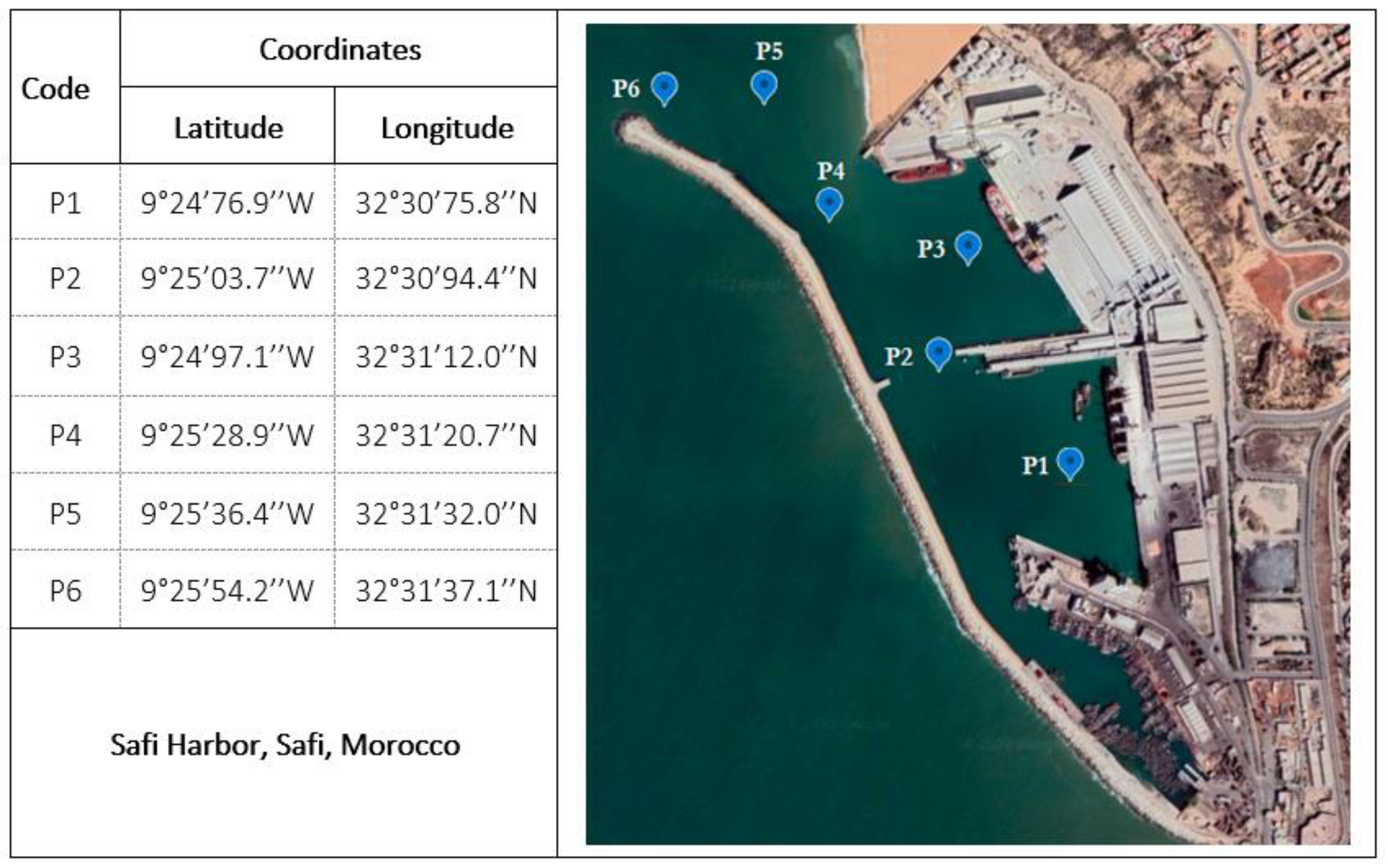

In this study, only the characteristics necessary for the evaluation of the feasibility of dredged sediment reuse as construction material have been determined, through an experimental study completed by a statistical approach. The use of each laboratory test was justified. Prior to the characterization study, some essential criteria needed be taken into consideration. First was the choice of the study site, which depended on the level of silting in the basins and channels of the selected port, its size and its geographical position, as well as the nature and volume of traffic transiting through this port. Second was the choice of the sampling method that would provide the best information value of studied sediment [

91]. Furthermore, collection in the field and storage conditions of the sediment samples were decisive criteria for the quality of obtained results [

114].

With the longest coastline in Africa (3500 km), Morocco has 43 ports, including 14 ports open to foreign trade, 22 fishing ports and 7 marinas. More than 3.4 million cubic meters of sediment is dredged annually to fight against the silting up of Moroccan ports [

115]. Among others, Safi harbor is experiencing heavy silting [

116,

117], which requires the regular dredging of 250,000 cubic meters per year from the access channel [

118]. In order to determine the properties of sediment extracted from the port of Safi, the essential parameters for the physical, geotechnical, chemical and mineralogical characterization have been analyzed. The characteristics related to particle size analysis, water content, methylene blue value, sand equivalent, apparent density, absolute density, chloride content, sulfate content and mineral composition were obtained through an experimental study and a statistical approach. The need for each test was justified. The outputs were used to classify dredged sediment based on the European standards in force. Recommendations were then put forward to determine the possible recycling paths of dredged sediment in the construction industry, considering the cost of obtaining the final product in comparison with the cost of conventional material. This study provides the necessary outcome that offers the means for decision making with respect to the sustainable reuse of dredged sediment.

3. Results

The results presented in this research are the averages of the outcomes of the six tests performed by sample point; first, the average of each of the three tests performed per sample was calculated, giving two values per sampling point, and then the result of averaging the two values obtained was taken into consideration.

3.1. Geotechnical Characterization

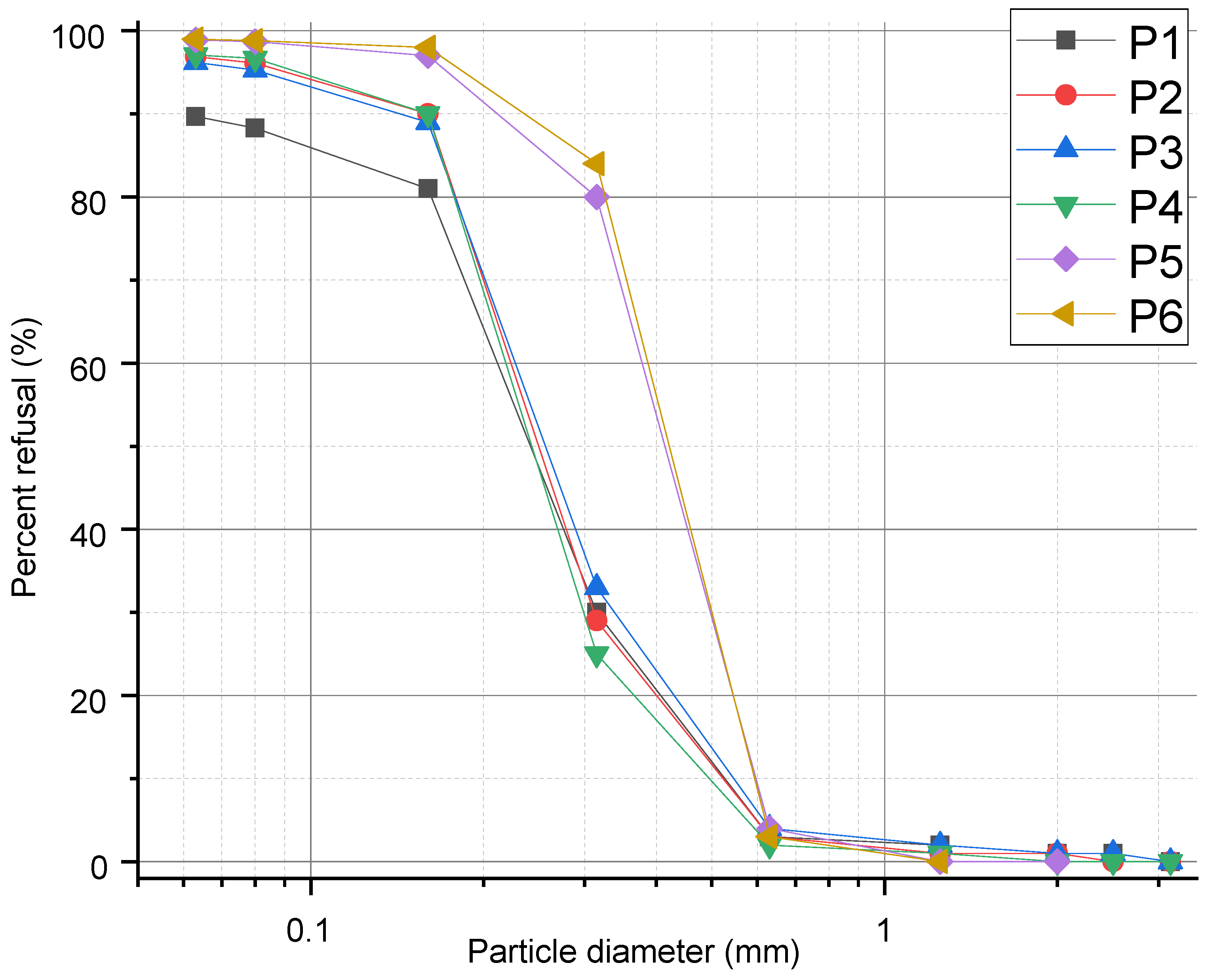

Grain size analysis provided the particle size distribution of dredged sediment.

Table 2 shows the cumulative percentages of material passing through each of the used sieves. In general, dredged sediment is composed of grains with diameters between 0.063 mm and 3.15 mm. On average, 90% of dredged sediment grain diameters are between 0.315 mm and 1.25 mm. Samples P1, P2, P3 and P4 contained more fine particles than samples P5 and P6. The first four samples were composed of 86% grains with diameters ranging from 0.16 mm to 1.25 mm. The two other samples were composed of 82% grains with diameters between 0.315 mm and 1.25 mm. According to the triangle of textures [

137], sediment dredged from the port of Safi is mainly sandy.

Figure 3 represents the cumulative percentage distributions of refusals. The distributions of samples P2, P3 and P4 have the same shape. Sample P1 distribution differs on the finest particles diameters. The distributions of samples P5 and P6 have the same shape; it is visibly different from of the other samples distributions on all diameters.

3.1.1. Granulometric Parameters

Granulometric parameters were determined by calculating the granular class, the fineness modulus and the uniformity and curvature coefficients.

Table 3,

Table 4 and

Table 5 summarize the calculations results. The granular class of the six samples is 0/4; according to the standard EN 12620, sediment dredged from Safi harbor corresponds to sand. On average, the fineness modulus of dredged sediment is 1.42; according to the standard EN 12620, sediment dredged from Safi harbor is considered as fine-grained sand (

between 0.6 and 2.1). The finesses modulus of samples P1, P2, P3 and P4 is included between 0.6 and 2.1; they are considered as fine-grained sands. Samples P5 and P6 correspond to sand of medium to fine grains (

between 1.5 and 2.8). The mean value of uniformity coefficient is 2.19; this result is clearly influenced by the excessive value of 4.44 corresponding to sample P1. According to the standard

NF P 18-545, sediment dredged from Safi harbor has a uniform or close grain size for all samples (

Cu < 2), with the exception of sample P1, which has a varied or spread grain size (

Cu > 2). On average, the curvature coefficient is 1.18. Under the standard

NF P 18-545, the sediment dredged from the port of Safi has a well-graded grain size (1 <

Cc < 3), excluding the samples P2 and P3, which have a badly graded grain size marked by the presence of a large quantity of fine elements (

Cc < 1).

3.1.2. Statistical Parameters

Quantile values

,

,

,

,

,

and

were deducted from the grain size curves.

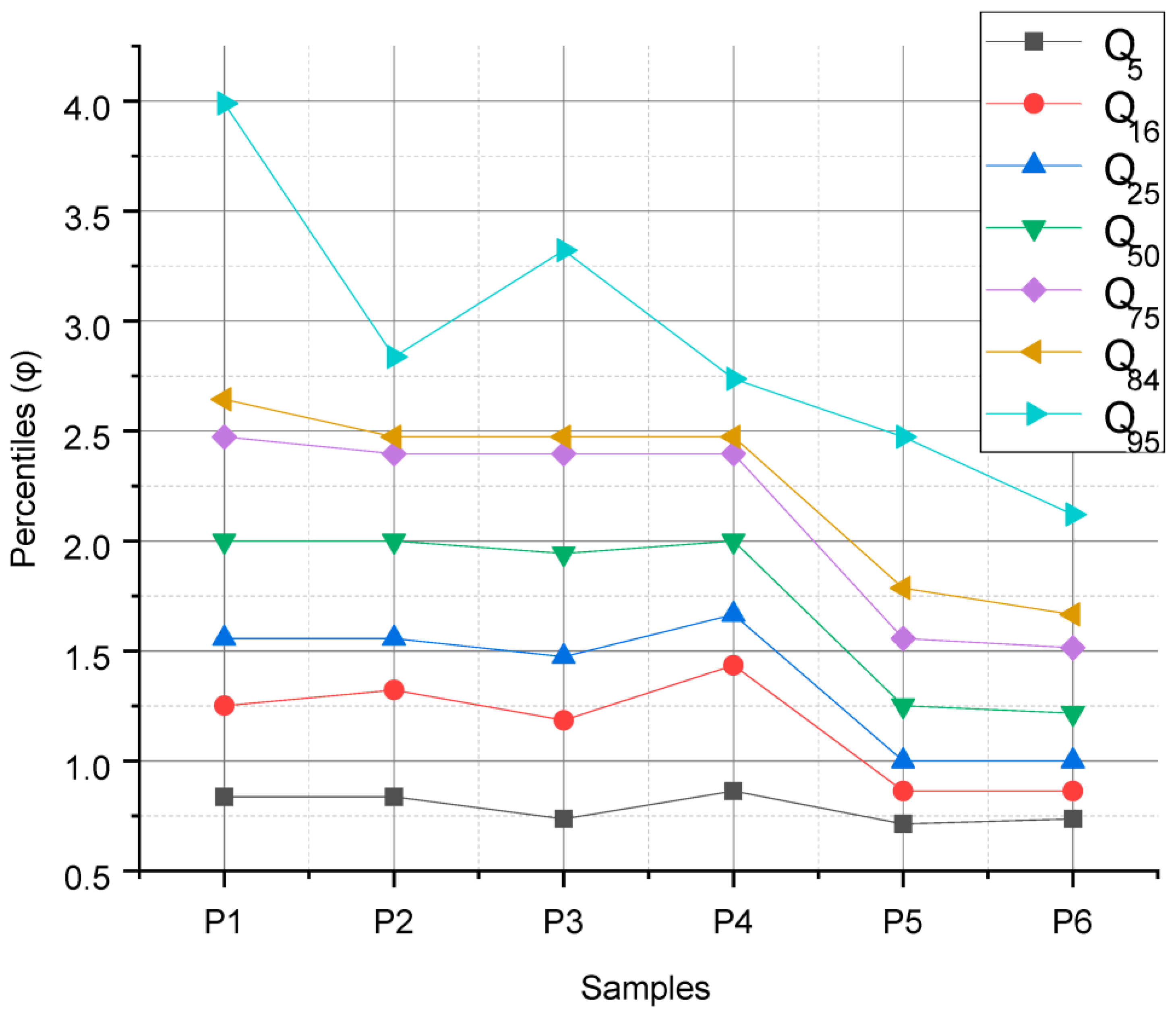

Figure 4 gives the distribution of all sample percentiles in unit

. Distribution curves of the quantiles follow a similar shape, with the exception of quantile

, particularly for sample P1. Extreme values of quartile

can be substantiated by the presence of more fine particles in sample P1 or to the slight inaccuracies obtained in the case of the incomplete curves for high quantiles such as

and

[

138]. Quantiles corresponding to samples P5 and P6 are visibly lower than the same quantiles of the other samples. The low values of the median

reflect the predominance of the sandy fraction.

Statistical parameters related to dispersion, asymmetry and acuity were calculated according to the presented formulas.

Table 6 gives the results of statistical parameters characterizing the sediment dredged from Safi harbor. Dispersion parameters indicated similarities between the characteristics of samples P1, P2 and P3 on the one hand, and P5 and P6 on the other hand. While sample P4 was characterized by a mean grain of the same range as the first three samples, the sorting index and standard deviation values converged towards those of samples P5 and P6. The mean value of sorting-index is 1.297 mm; the values concerning the six samples were all strictly less than 2.5 mm, which indicates that Safi harbor sediment is well classified. The smaller the index sorting becomes from sample P1 to sample P6, the less accentuated the heterometry. While the mean value of standard deviation is 0.597 φ, reference tables for Folk and Ward index identifies two classes. Samples P1, P2, P3 and P4 are considered moderately classified (0.5 <

σ < 1). Samples P5 and P6 are well classified (0.35 <

σ < 0.50). On average, the mean size is in the range of 0.3 mm. Samples P1, P2, P3 and P4 were characterized by similar mean size values of about 0.25 mm, while samples P5 and P6 had a mean size of about 0.4 mm. The mean value of the Trask asymmetry index was 1.034 mm. All samples had values close to 1; this indicates that sediment dredged from Safi harbor is characterized by a slight asymmetry. Skewness index represented relatively divergent values, with an average of 0.034. The negative values related to samples P2, P3 and P4 indicate the presence of more fine particles. The positive values corresponding to samples P1, P5 and P6 show a better classification of the coarse fraction compared to the fine fraction. The mean value of kurtosis was 1.164, with a range between 0.976 for sample P2 and 1.408 for sample P1; particle distribution is moderately to well classified. The curve is considered mesokurtic for samples P2, P4 and P6 (0.90 <

Kσ < 1.11) and leptokurtic for samples P1, P3 and P5 (1.11 <

Kσ < 1.50). None of the samples is considered misclassified.

3.2. Physical Characterization

Physical properties of dredged sediment were identified by the results of the tests of water content (

w), methylene blue value (

MBV), sand equivalent (

SE), apparent density (

ρapparent) and absolute density (

ρabsolute).

Table 7 represents the physical parameters characterizing Safi harbor sediment.

- (1)

Water Content

Dredged sediment water content varied between 36 for sample P6 and 138 for sample P1, with an average value of 93.67%. The high water content is explained by the origin of the sediment, which is taken from a marine area. Water content was higher for samples P1, P2 and P3, located in the harbor exploitation basins, than for the samples located in the access channel (P4, P5 and P6). According to the particle size analysis, the first three points contained more fine particles, which justifies their high water content.

- (2)

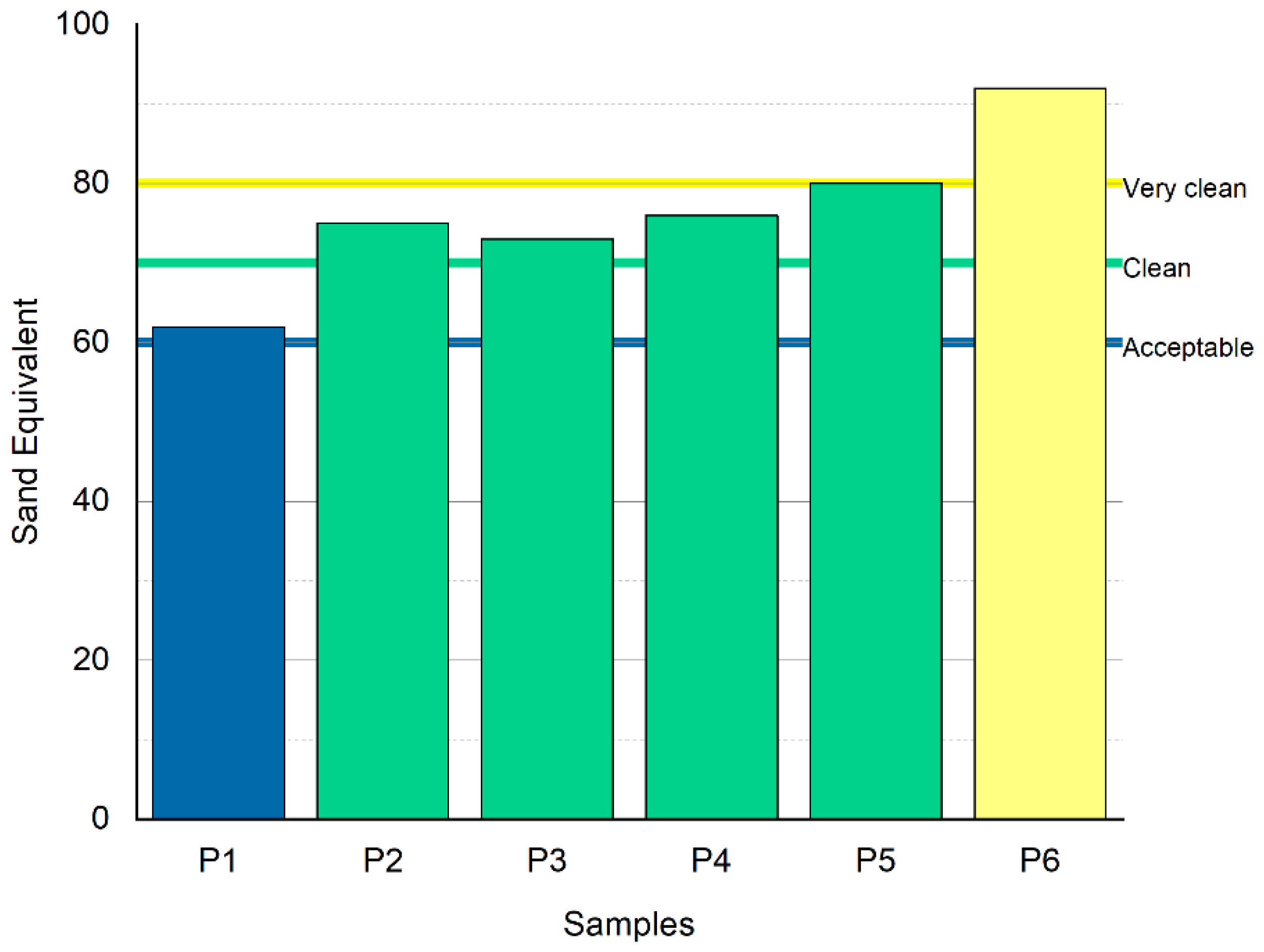

Sand equivalent

The mean value of sand equivalent was 76.33. Test results fluctuated between 62 for sample P1 and 92 for sample P6. Based on values recommended by the literature [

139], sediment dredged from Safi harbor is generally clean (

SE > 60). The cleanliness of the sand increases significantly when moving from the inside basins to the harbor access channel. The sand in sample P1 was slightly clayey (60 ≤

SE < 70), of acceptable cleanliness for quality concrete when shrinkage is not a particular concern. Samples P2, P3, P4 and P5 were considered clean (70 ≤

SE < 80), with a low percentage of clayey fines, sand perfectly suitable for high-quality concrete. Sample P6 was very clean (

SE > 80), characterized by an almost total absence of clayey fines; it presents the risk of causing a lack of plasticity in the concrete and requires correction by increasing the water dosage.

Figure 5 presents an interpretation of the sand equivalent test per sample.

- (3)

Apparent and absolute densities

The apparent density for dredged sediment varied from 1.43 for sample P6 to 1.51 for samples P2 and P3, with a mean value of 1.48. Results of the absolute were very similar for the six samples; on average, dredged sediment absolute density was 2.61. The values obtained confirmed that the dredged sediment meets the requirements for construction (ρapparent between 1.35 to 1.50 and ρabsolute around 2.65).

- (4)

Methylene blue value

On average, the methylene blue value was 0.95; this result was clearly influenced by the excessive value of 2.5 corresponding to sample P1. According to the standards in effect, sediment dredged from Safi harbor has a sandy-loamy nature sensitive to water (0.2 ≤ MBV < 1.5), with the exception of sample P1, which had a loamy nature characterized by medium plasticity (2.5 ≤ MBV < 6).

3.3. Chemical Characterization

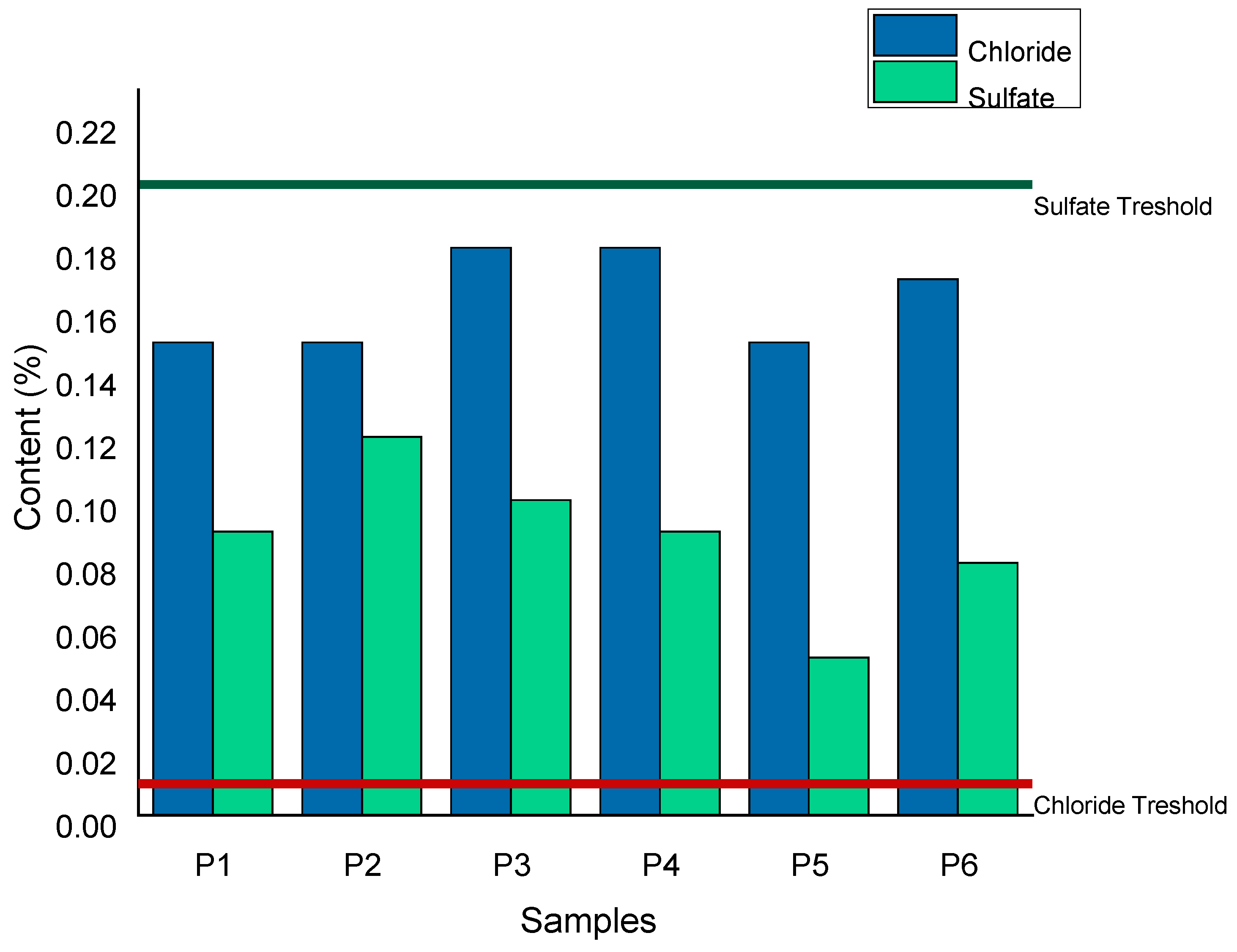

Chemical analysis was performed to study the reaction of dredged sediment as a concrete aggregate. The contents of chloride and sulfate, considered as contaminants, were calculated.

Figure 6 shows the test results and their comparison with the accepted threshold values for the aggregates according to the standard XP P18-545. The chloride content varied between 0.15% and 0.18%. For all samples, chloride content was high; it exceeded the reference threshold. The high chloride content was justified by the marine origin of the sediments; seawater contains dissolved substances, i.e., salts consisting of ions, mainly halide ions such as chloride ion and alkaline ions such as sodium ion. The sulfate content was below the reference threshold for all samples; it ranged between 0.05% and 0.12%.

3.4. Mineralogical Characterization

A mineralogical analysis of the studied sediment was carried out. As the sediment dredged from Safi harbor has the same origin, i.e., the erosion by sea of the neighboring dunes and beaches, the mineralogical composition is in principle the same in all the basins of the port. To confirm this hypothesis, two tests were carried out: first, one on the mixture of samples taken from P1, P2 and P3 (SF1), and a second one on the mixture of samples taken from P4, P5 and P6 (SS2). Quartz

SiO2 and Calcite

CaCO3 were found to be the two main crystalline phases.

Figure 7 presents X-ray Diffractograms of mixtures SF1 and SS2.

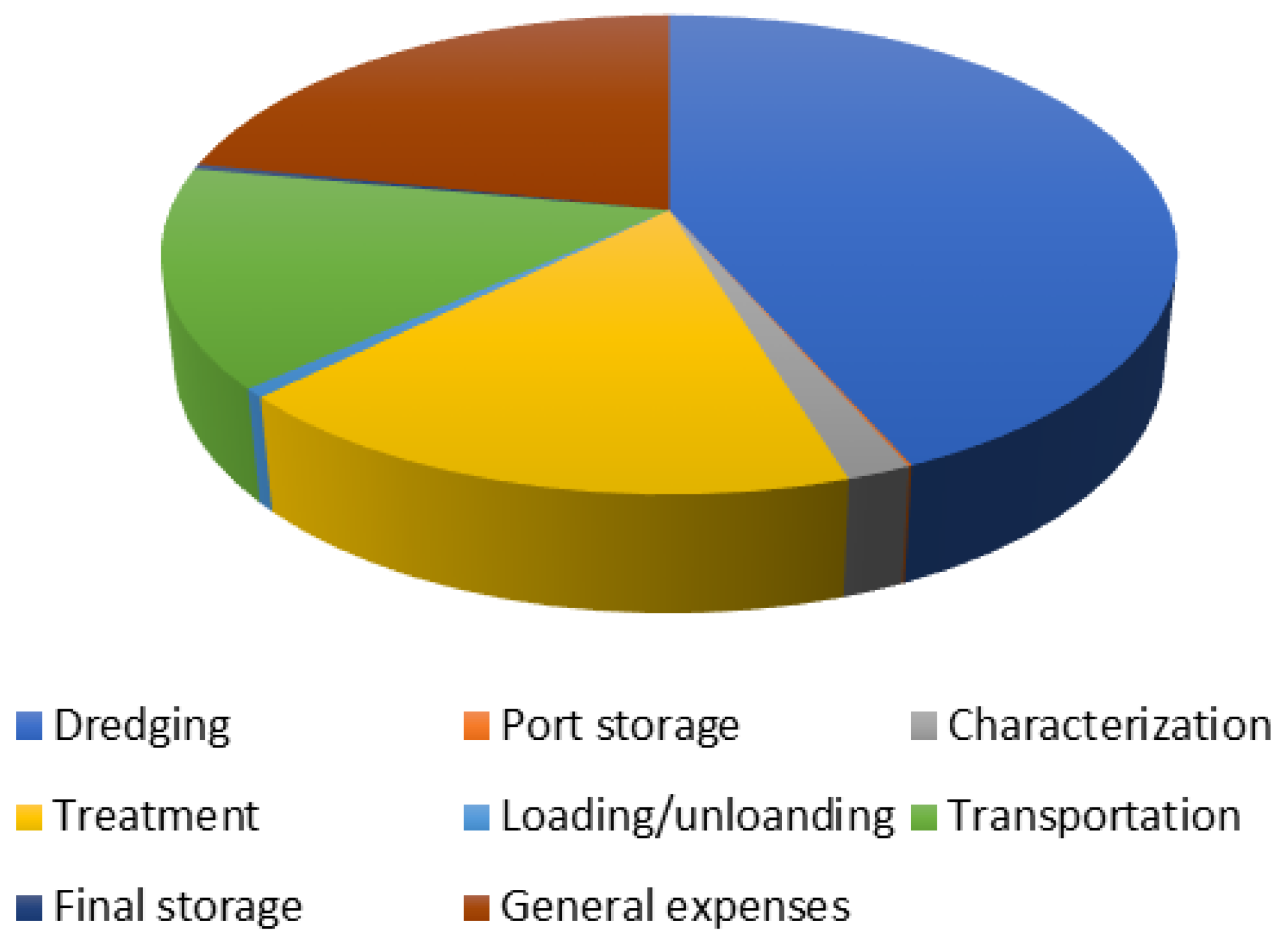

3.5. Cost-Benefit Analysis

For the purpose of studying the economic feasibility of dredged sediment reuse as construction material, costs of the various items were estimated according to the current Moroccan market, and then converted into dollars to allow a better assimilation to the international market. To obtain the final cost of recycling dredged sediment, basic hypotheses have been established as follows:

- (1)

Costs considered

Dredging cost: this cost includes the expenses related to regular dredging operation to maintain the depths of the port basins;

Port storage cost: the cost of renting land in the port for the storage of dredging material (for characterizing, washing, dehydrating, etc.);

Characterization cost: the sum of the costs of all the tests carried out to obtain an appropriate material to be reused in construction;

Treatment cost: the cost of artificial fresh-water washing to remove impurities from the dredged sediment;

Loading/unloading cost: costs associated with loading the sediment for delivery outside the port and unloading at the final point of sale;

Transportation cost: expenses related to the transportation by truck of the sediment from the port to the distribution point;

Final storage cost: the cost of renting land in a rural area of the Safi region (for distribution, sale, etc.);

General expenses: costs related to the installation, staff, material, etc.

It is worth noting that none of these costs depend on the point of collection or the dredging area in the port; therefore, it is not necessary to perform a site-specific cost-benefit analysis, which will lead to the same result.

- (2)

Costs estimation

The cost of dredging is calculated by reference to the unit prices, per cubic meter, applied in Morocco. The cost of storage in the port is calculated on the basis of the rates for temporary occupation of the public port domain for a 1000 m2 land plot. Characterization cost is inspired by the modalities applied in the case of quarries extracting aggregates for construction, in order to confirm the regularity and stability of the properties identified. The cost of characterization includes the costs of all the characterization tests conducted by this study once every two years, and the costs of tests of grain size analysis and sand equivalent once every 100 m3. The treatment cost is calculated based on fresh-water consumption rates. The cost of loading/unloading is calculated according to the current rates applied by truckers. Transportation cost is calculated based on current fuel rates for an estimated distance of 25 km. The final storage cost is calculated based on the rental rates for a 1000 m2 plot of land in a rural area. All costs are reported per cubic meter to enable summation.

The purchase cost corresponds to conventional sand used in civil engineering, with the same granulometric characteristics as that of the sediment extracted from the port of Safi.

Table 8 summarizes the calculations made to analyze the cost-benefit of reusing harbor dredged sediment as construction material. Results from the cost evaluation show that dredged sediment reuse is the most cost-effective option, with a reduction of 74% compared to the purchase of conventional material.

5. Conclusions

Waste valorization represents a sustainable way to face the scarcity of natural resources used in the construction industry. Large amounts of dredged sediment are extracted annually and disposed of at sea; this constitutes a potential alternative to conventional construction material. Furthermore, the valorization of dredging waste avoids the environmental impacts associated with its disposal at sea and with the extraction of natural resources from the soil. In this study, we characterized sediment dredged from Safi harbor in Morocco for reuse as construction material. Due to its high level of silting, Safi port offers an opportunity for further recycling of its sediment dredged in significant quantities. Six samples were collected to cover all the port areas. The choice of laboratory tests was based on the essential tests usually performed for the characterization of dredged sediment, taking into consideration the means available in developing countries. Laboratory tests were completed using the calculation of statistical parameters, in order to provide an integral overview of sediment properties and to confirm experimental results. As it constitutes a primordial and decisive step in the valorization process, the characterization of physical, geotechnical, chemical and mineralogical properties was conducted. The results showed that, according to the standards of construction material classification, sediment dredged from the port of Safi is a sand classified into category B, related to the sands used for the confection of current concretes of resistance higher than 25 MPa. Therefore, the studied sediment is readily reusable in the form of a construction aggregate as a conventional sand substitute. Chloride and water content was obviously higher than reference levels, mainly because of the sediment’s marine origin. Sediment properties slightly differed from one sample to another; a remarkable improvement was observed when passing from the interior basins of the port towards its access channel. The industrial and urban activity of the port seems to influence the characteristics of sediment extracted from exploitation basins. The obtained classification allows the beneficial reuse of dredged sediment in several applications in the construction industry. We were interested in concrete works; concrete remains the most cost-effective and versatile construction material. In addition, treatment was suggested to reduce the content of chloride that promotes corrosion in reinforced concrete, and thereby limits the use of dredged sediment to unreinforced concrete. Reuse of dredged sand as a concrete aggregate was then the most recommended path for the case study of the port of Safi.

Subsequently, a comprehensive evaluation of economic feasibility was carried out based on a cost-benefit analysis. The costs related to the valorization of sediment dredged from Safi port were analyzed and compared with the cost of purchasing conventional sand of the same class. The purchase cost remains higher than the cost of recycling with a decrease of 74%, which indicated that the beneficial reuse of dredged sediment as construction material is cost saving and presents financial and non-financial gains.

Therefore, promoting a holistic view of prerequisites for the valorization of dredged sediment in developing countries—such as selecting ports that generate significant quantities of dredged sediment, standardizing characterization tests during dredging operations, and estimating the cost of recycling taking into account the necessary treatments—is encouraged to meet the market’s need for construction material.

This study contributes to a deeper understanding of the process evaluating the feasibility of reusing dredged sediment as construction material for research in other developing countries. A thorough characterization of the dredged waste is crucial to the identification of potential recycling paths for achieving sustainable development.