Life Cycle Based GHG Emissions from Algae Based Bioenergy with a Special Emphasis on Climate Change Indicators and Their Uses in Dynamic LCA: A Review

Abstract

1. Introduction

2. Current State of Knowledge on Life Cycle GHG Emissions from Biofuel from Algae Cultivated Using Waste Nutrients

2.1. Industrial Symbiosis

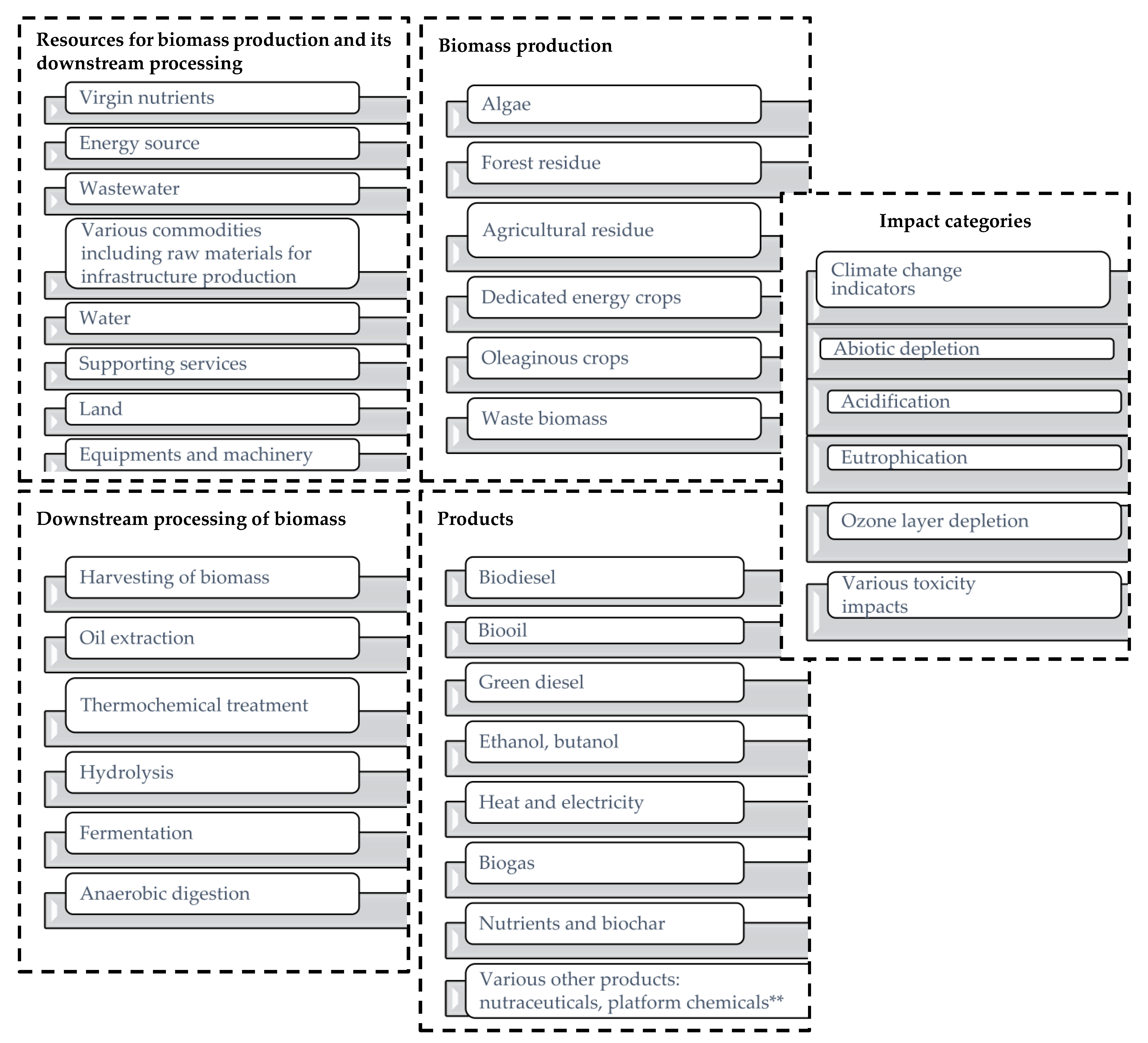

2.2. Life Cycle Assessment-Based Methodology and Scenario Adopted for Algal Biofuel Production

3. Dynamic Issues in LCA

4. Application of LCA Approach for Net Zero Target Achievement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Branco-Vieira, M.; Lopes, M.P.C.; Caetano, N. Algae-Based Bioenergy Production Aligns with the Paris Agreement Goals as a Carbon Mitigation Technology. Energy Rep. 2022, 8, 482–488. [Google Scholar] [CrossRef]

- Cabernard, L.; Pfister, S.; Hellweg, S. Improved Sustainability Assessment of the G20′s Supply Chains of Materials, Fuels, and Food. Environ. Res. Lett. 2022, 17, 034027. [Google Scholar] [CrossRef]

- Rennie, A. Briefing: Embodied Energy and Emissions. In Proceedings of the Proceedings of Institution of Civil Engineers: Energy; ICE Publishing: London, UK, 2011; Volume 164, pp. 139–145. [Google Scholar]

- Zhang, B.; Chen, B. Dynamic Hybrid Life Cycle Assessment of CO2 Emissions of a Typical Biogas Project. In Proceedings of the Energy Procedia; Elsevier: Amsterdam, The Netherlands, 2016; Volume 104, pp. 396–401. [Google Scholar]

- United States Environmental Protection Agency Greenhouse Gas Inventory Data Explorer. Available online: https://cfpub.epa.gov/ghgdata/inventoryexplorer/index.html#transportation/entiresector/allgas/category/current (accessed on 15 April 2022).

- Plevin, R.J.; O’Hare, M.; Jones, A.D.; Torn, M.S.; Gibbs, H.K. Greenhouse Gas Emissions from Biofuels’ Indirect Land Use Change Are Uncertain but May Be Much Greater than Previously Estimated. Environ. Sci. Technol. 2010, 44, 8015–8021. [Google Scholar] [CrossRef]

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and Climate Change Mitigation: An Assessment. GCB Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef]

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.-T.; Show, P.-L. Waste to Bioenergy: A Review on the Recent Conversion Technologies. BMC Energy 2019, 1, 4. [Google Scholar] [CrossRef]

- Ilari, A.; Duca, D.; Boakye-Yiadom, K.A.; Gasperini, T.; Toscano, G. Carbon Footprint and Feedstock Quality of a Real Biomass Power Plant Fed with Forestry and Agricultural Residues. Resources 2022, 11, 7. [Google Scholar] [CrossRef]

- Hiloidhari, M.; Baruah, D.C.; Kumari, M.; Kumari, S.; Thakur, I.S. Prospect and Potential of Biomass Power to Mitigate Climate Change: A Case Study in India. J. Clean. Prod. 2019, 220, 931–944. [Google Scholar] [CrossRef]

- Mottaleb, K.A.; Rahut, D.B. Biogas Adoption and Elucidating Its Impacts in India: Implications for Policy. Biomass Bioenergy 2019, 123, 166–174. [Google Scholar] [CrossRef]

- Mittal, S.; Ahlgren, E.O.; Shukla, P.R. Future Biogas Resource Potential in India: A Bottom-up Analysis. Renew. Energy 2019, 141, 379–389. [Google Scholar] [CrossRef]

- Silva, A.G.; Carter, R.; Merss, F.L.M.; Corrêa, D.O.; Vargas, J.V.C.; Mariano, A.B.; Ordonez, J.C.; Scherer, M.D. Life Cycle Assessment of Biomass Production in Microalgae Compact Photobioreactors. GCB Bioenergy 2015, 7, 184–194. [Google Scholar] [CrossRef]

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy- and Greenhouse Gas-Based LCA of Biofuel and Bioenergy Systems: Key Issues, Ranges and Recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Cherubini, F.; Bright, R.M.; Strømman, A.H. Site-Specific Global Warming Potentials of Biogenic CO2 for Bioenergy: Contributions from Carbon Fluxes and Albedo Dynamics. Environ. Res. Lett. 2012, 7, 045902. [Google Scholar] [CrossRef]

- Garcia, R.; Figueiredo, F.; Brandão, M.; Hegg, M.; Castanheira, É.; Malça, J.; Nilsson, A.; Freire, F. A Meta-Analysis of the Life Cycle Greenhouse Gas Balances of Microalgae Biodiesel. Int. J. Life Cycle Assess. 2020, 25, 1737–1748. [Google Scholar] [CrossRef]

- Cherubini, F.; Strømman, A.H.; Hertwich, E. Effects of Boreal Forest Management Practices on the Climate Impact of CO2 Emissions from Bioenergy. Ecol. Model. 2011, 223, 59–66. [Google Scholar] [CrossRef]

- Rocha, M.H.; Capaz, R.S.; Lora, E.E.S.; Nogueira, L.A.H.; Leme, M.M.V.; Renó, M.L.G.; Olmo, O.A. Del Life Cycle Assessment (LCA) for Biofuels in Brazilian Conditions: A Meta-Analysis. Renew. Sustain. Energy Rev. 2014, 37, 435–459. [Google Scholar] [CrossRef]

- Wiloso, E.I.; Heijungs, R.; De Snoo, G.R. LCA of Second Generation Bioethanol: A Review and Some Issues to Be Resolved for Good LCA Practice. Renew. Sustain. Energy Rev. 2012, 16, 5295–5308. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. How Do Methodological Choices Affect the Carbon Footprint of Microalgal Biodiesel? A Harmonised Life Cycle Assessment. J. Clean. Prod. 2019, 207, 560–568. [Google Scholar] [CrossRef]

- Collet, P.; Lardon, L.; Hélias, A.; Bricout, S.; Lombaert-Valot, I.; Perrier, B.; Lépine, O.; Steyer, J.P.; Bernard, O. Biodiesel from Microalgae—Life Cycle Assessment and Recommendations for Potential Improvements. Renew. Energy 2014, 71, 525–533. [Google Scholar] [CrossRef]

- Thomassen, G.; Van Dael, M.; Lemmens, B.; Van Passel, S. A Review of the Sustainability of Algal-Based Biorefineries: Towards an Integrated Assessment Framework. Renew. Sustain. Energy Rev. 2017, 68, 876–887. [Google Scholar] [CrossRef]

- Levasseur, A.; Cavalett, O.; Fuglestvedt, J.S.; Gasser, T.; Johansson, D.J.A.; Jørgensen, S.V.; Raugei, M.; Reisinger, A.; Schivley, G.; Strømman, A.; et al. Enhancing Life Cycle Impact Assessment from Climate Science: Review of Recent Findings and Recommendations for Application to LCA. Ecol. Indic. 2016, 71, 163–174. [Google Scholar] [CrossRef]

- Collet, P.; Hélias, A.; Lardon, L.; Steyer, J.P.; Bernard, O. Recommendations for Life Cycle Assessment of Algal Fuels. Appl. Energy 2015, 154, 1089–1102. [Google Scholar] [CrossRef]

- Bradley, T.; Maga, D.; Antón, S. Unified Approach to Life Cycle Assessment between Three Unique Algae Biofuel Facilities. Appl. Energy 2015, 154, 1052–1061. [Google Scholar] [CrossRef]

- Tu, Q.; Eckelman, M.; Zimmerman, J. Meta-Analysis and Harmonization of Life Cycle Assessment Studies for Algae Biofuels. Environ. Sci. Technol. 2017, 51, 9419–9432. [Google Scholar] [CrossRef] [PubMed]

- Vergara, S.E.; Damgaard, A.; Horvath, A. Boundaries Matter: Greenhouse Gas Emission Reductions from Alternative Waste Treatment Strategies for California’s Municipal Solid Waste. Resour. Conserv. Recycl. 2011, 57, 87–97. [Google Scholar] [CrossRef]

- Roos, A.; Ahlgren, S. Consequential Life Cycle Assessment of Bioenergy Systems—A Literature Review. J. Clean. Prod. 2018, 189, 358–373. [Google Scholar] [CrossRef]

- Lardon, L.; Hélias, A.; Sialve, B.; Steyer, J.P.; Bernard, O. Life-Cycle Assessment of Biodiesel Production from Microalgae. Environ. Sci. Technol. 2009, 43, 6475–6481. [Google Scholar] [CrossRef]

- Sills, D.L.; Paramita, V.; Franke, M.J.; Johnson, M.C.; Akabas, T.M.; Greene, C.H.; Tester, J.W. Quantitative Uncertainty Analysis of Life Cycle Assessment for Algal Biofuel Production. Environ. Sci. Technol. 2013, 47, 687–694. [Google Scholar] [CrossRef]

- Vasudevan, V.; Stratton, R.W.; Pearlson, M.N.; Jersey, G.R.; Beyene, A.G.; Weissman, J.C.; Rubino, M.; Hileman, J.I. Environmental Performance of Algal Biofuel Technology Options. Environ. Sci. Technol. 2012, 46, 2451–2459. [Google Scholar] [CrossRef]

- Stephenson, A.L.; Kazamia, E.; Dennis, J.S.; Howe, C.J.; Scott, S.A.; Smith, A.G. Life-Cycle Assessment of Potential Algal Biodiesel Production in the United Kingdom: A Comparison of Raceways and Air-Lift Tubular Bioreactors. Energy Fuels 2010, 24, 4062–4077. [Google Scholar] [CrossRef]

- Chowdhury, R.; Viamajala, S.; Gerlach, R. Reduction of Environmental and Energy Footprint of Microalgal Biodiesel Production through Material and Energy Integration. Bioresour. Technol. 2012, 108, 102–111. [Google Scholar] [CrossRef]

- Xu, L.; Wim Brilman, D.W.F.; Withag, J.A.M.; Brem, G.; Kersten, S. Assessment of a Dry and a Wet Route for the Production of Biofuels from Microalgae: Energy Balance Analysis. Bioresour. Technol. 2011, 102, 5113–5122. [Google Scholar] [CrossRef] [PubMed]

- University of Michigan, C. for S.S. Biofuels Factsheet | Center for Sustainable Systems. Available online: https://css.umich.edu/factsheets/biofuels-factsheet (accessed on 15 April 2022).

- Yuan, J.; Kendall, A.; Zhang, Y. Mass Balance and Life Cycle Assessment of Biodiesel from Microalgae Incorporated with Nutrient Recycling Options and Technology Uncertainties. GCB Bioenergy 2015, 7, 1245–1259. [Google Scholar] [CrossRef]

- Branco-Vieira, M.; Costa, D.M.B.; Mata, T.M.; Martins, A.A.; Freitas, M.A.V.; Caetano, N.S. Environmental Assessment of Industrial Production of Microalgal Biodiesel in Central-South Chile. J. Clean. Prod. 2020, 266, 121756. [Google Scholar] [CrossRef]

- Cao, Y.; Pawłowski, A. Life Cycle Assessment of Two Emerging Sewage Sludge-to-Energy Systems: Evaluating Energy and Greenhouse Gas Emissions Implications. Bioresour. Technol. 2013, 127, 81–91. [Google Scholar] [CrossRef] [PubMed]

- Du, Z.; Hu, B.; Shi, A.; Ma, X.; Cheng, Y.; Chen, P.; Liu, Y.; Lin, X.; Ruan, R. Cultivation of a Microalga Chlorella vulgaris Using Recycled Aqueous Phase Nutrients from Hydrothermal Carbonization Process. In Proceedings of the Bioresource Technology; Elsevier: Amsterdam, The Netherlands, 2012; Volume 126, pp. 354–357. [Google Scholar]

- Valdez, P.J.; Nelson, M.C.; Wang, H.Y.; Lin, X.N.; Savage, P.E. Hydrothermal Liquefaction of Nannochloropsis sp.: Systematic Study of Process Variables and Analysis of the Product Fractions. Biomass Bioenergy 2012, 46, 317–331. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Chen, P.; Min, M.; Chen, Y.; Zhu, J.; Ruan, R.R. Anaerobic Digested Dairy Manure as a Nutrient Supplement for Cultivation of Oil-Rich Green Microalgae Chlorella sp. Bioresour. Technol. 2010, 101, 2623–2628. [Google Scholar] [CrossRef]

- Abreu, A.P.; Fernandes, B.; Vicente, A.A.; Teixeira, J.; Dragone, G. Mixotrophic Cultivation of Chlorella vulgaris Using Industrial Dairy Waste as Organic Carbon Source. Bioresour. Technol. 2012, 118, 61–66. [Google Scholar] [CrossRef]

- Rani, S.; Chowdhury, R.; Tao, W.; Nedbalova, L. Microalga-Mediated Tertiary Treatment of Municipal Wastewater: Removal of Nutrients and Pathogens. Sustainability 2021, 13, 9554. [Google Scholar] [CrossRef]

- Dahiya, S.; Chowdhury, R.; Tao, W.; Kumar, P. Biomass and Lipid Productivity by Two Algal Strains of Chlorella sorokiniana Grown in Hydrolysate of Water Hyacinth. Energies 2021, 14, 1411. [Google Scholar] [CrossRef]

- Sturm, B.S.M.; Lamer, S.L. An Energy Evaluation of Coupling Nutrient Removal from Wastewater with Algal Biomass Production. Appl. Energy 2011, 88, 3499–3506. [Google Scholar] [CrossRef]

- Iribarren, D.; Peters, J.F.; Dufour, J. Life Cycle Assessment of Transportation Fuels from Biomass Pyrolysis. Fuel 2012, 97, 812–821. [Google Scholar] [CrossRef]

- Zheng, H.; Gao, Z.; Yin, F.; Ji, X.; Huang, H. Lipid Production of Chlorella vulgaris from Lipid-Extracted Microalgal Biomass Residues through Two-Step Enzymatic Hydrolysis. Bioresour. Technol. 2012, 117, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, R.; Franchetti, M. Life Cycle Energy Demand from Algal Biofuel Generated from Nutrients Present in the Dairy Waste. Sustain. Prod. Consum. 2017, 9, 22–27. [Google Scholar] [CrossRef]

- Chowdhury, R.; Freire, F. Bioenergy Production from Algae Using Dairy Manure as a Nutrient Source: Life Cycle Energy and Greenhouse Gas Emission Analysis. Appl. Energy 2015, 154, 1112–1121. [Google Scholar] [CrossRef]

- de Boer, K.; Moheimani, N.R.; Borowitzka, M.A.; Bahri, P.A. Extraction and Conversion Pathways for Microalgae to Biodiesel: A Review Focused on Energy Consumption. J. Appl. Phycol. 2012, 24, 1681–1698. [Google Scholar] [CrossRef]

- Chowdhury, R.; Keen, P.L.; Tao, W. Fatty Acid Profile and Energy Efficiency of Biodiesel Production from an Alkaliphilic Algae Grown in the Photobioreactor. Bioresour. Technol. Reports 2019, 6, 229–236. [Google Scholar] [CrossRef]

- Pate, R.; Klise, G.; Wu, B. Resource Demand Implications for US Algae Biofuels Production Scale-Up. Appl. Energy 2011, 88, 3377–3388. [Google Scholar] [CrossRef]

- Somers, M.D.; Quinn, J.C. Sustainability of Carbon Delivery to an Algal Biorefinery: A Techno-Economic and Life-Cycle Assessment. J. CO2 Util. 2019, 30, 193–204. [Google Scholar] [CrossRef]

- Ou, L.; Banerjee, S.; Xu, H.; Coleman, A.M.; Cai, H.; Lee, U.; Hawkins, T.R. Utilizing high-purity carbon dioxide sources for algae cultivation and biofuel production in the United States: Opportunities and challenges. J. Clean Prod. 2021, 321, 128779. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, S.; Bi, X.; Clift, R. Greenhouse Gas Emission Reduction Potential and Cost of Bioenergy in British Columbia, Canada. Energy Policy 2020, 138, 111285. [Google Scholar] [CrossRef]

- Tua, C.; Ficara, E.; Mezzanotte, V.; Rigamonti, L. Integration of a Side-Stream Microalgae Process into a Municipal Wastewater Treatment Plant: A Life Cycle Analysis. J. Environ. Manag. 2021, 279, 111605. [Google Scholar] [CrossRef] [PubMed]

- Passell, H.; Dhaliwal, H.; Reno, M.; Wu, B.; Ben Amotz, A.; Ivry, E.; Gay, M.; Czartoski, T.; Laurin, L.; Ayer, N. Algae Biodiesel Life Cycle Assessment Using Current Commercial Data. J. Environ. Manag. 2013, 129, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Kohlheb, N.; van Afferden, M.; Lara, E.; Arbib, Z.; Conthe, M.; Poitzsch, C.; Marquardt, T.; Becker, M.Y. Assessing the Life-Cycle Sustainability of Algae and Bacteria-Based Wastewater Treatment Systems: High-Rate Algae Pond and Sequencing Batch Reactor. J. Environ. Manag. 2020, 264, 110459. [Google Scholar] [CrossRef] [PubMed]

- Mu, D.; Min, M.; Krohn, B.; Mullins, K.A.; Ruan, R.; Hill, J. Life Cycle Environmental Impacts of Wastewater-Based Algal Biofuels. Environ. Sci. Technol. 2014, 48, 11696–11704. [Google Scholar] [CrossRef]

- Verma, S.; Chowdhury, R.; Das, S.K.; Franchetti, M.J.; Liu, G. Sunlight Intensity, Photosynthetically Active Radiation Modelling and Its Application in Algae-Based Wastewater Treatment and Its Cost Estimation. Sustainability 2021, 13, 11937. [Google Scholar] [CrossRef]

- Orfield, N.D.; Levine, R.B.; Keoleian, G.A.; Miller, S.A.; Savage, P.E. Growing Algae for Biodiesel on Direct Sunlight or Sugars: A Comparative Life Cycle Assessment. ACS Sustain. Chem. Eng. 2015, 3, 386–395. [Google Scholar] [CrossRef]

- Leirpoll, M.E.; Næss, J.S.; Cavalett, O.; Dorber, M.; Hu, X.; Cherubini, F. Optimal Combination of Bioenergy and Solar Photovoltaic for Renewable Energy Production on Abandoned Cropland. Renew. Energy 2021, 168, 45–56. [Google Scholar] [CrossRef]

- Morales, M.; Hélias, A.; Bernard, O. Optimal Integration of Microalgae Production with Photovoltaic Panels: Environmental Impacts and Energy Balance. Biotechnol. Biofuels 2019, 12, 239. [Google Scholar] [CrossRef]

- Duran Quintero, C.; Ventura, A.; Lépine, O.; Pruvost, J. Eco-Design of Spirulina Solar Cultivation: Key Aspects to Reduce Environmental Impacts Using Life Cycle Assessment. J. Clean. Prod. 2021, 299, 126741. [Google Scholar] [CrossRef]

- ISO. ISO 14040:2006. Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/standard/37456.html (accessed on 6 June 2021).

- ISO 14044:2006; Environmental Management: Life Cycle Assessment: Requirements and Guidelines. Beuth Verlag: Berlin, Germany, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 28 April 2019).

- European Commission-Joint Research Centre -Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook-General Guide for Life Cycle Assessment-Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Werpy, T.; Petersen, G. Top Value Added Chemicals from Biomass: Volume I. In Results of Screening for Potential Candidates from Sugars and Synthesis Gas; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2004. [Google Scholar] [CrossRef]

- Batan, L.; Quinn, J.; Willson, B.; Bradley, T. Net Energy and Greenhouse Gas Emission Evaluation of Biodiesel Derived from Microalgae. Environ. Sci. Technol. 2010, 44, 7975–7980. [Google Scholar] [CrossRef]

- Koponen, K.; Soimakallio, S.; Kline, K.L.; Cowie, A.; Brandão, M. Quantifying the Climate Effects of Bioenergy—Choice of Reference System. Renew. Sustain. Energy Rev. 2018, 81, 2271–2280. [Google Scholar] [CrossRef]

- McKechnie, J.; Colombo, S.; Chen, J.; Mabee, W.; MacLean, H.L. Forest Bioenergy or Forest Carbon? Assessing Trade-Offs in Greenhouse Gas Mitigation with Wood-Based Fuels. Environ. Sci. Technol. 2011, 45, 789–795. [Google Scholar] [CrossRef]

- Guiton, M.; Suárez-Montes, D.; Sánchez, R.; Baustert, P.; Soukoulis, C.; Okan, B.S.; Serchi, T.; Cambier, S.; Benetto, E. Comparative Life Cycle Assessment of a Microalgae-Based Oil Metal Working Fluid with Its Petroleum-Based and Vegetable-Based Counterparts. J. Clean. Prod. 2022, 338, 130506. [Google Scholar] [CrossRef]

- Bradley, T. MAGIFICENT: Microalgae As a Green Source for Nutritional Ingredients for Food/Feed and Ingredients for Cosmetics by Cost-Effective New Technologies—D4.2: LCA Goal and Scope. 2018. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b7cc3308&appId=PPGMS (accessed on 15 April 2022).

- Sills, D.L.; Van Doren, L.G.; Beal, C.; Raynor, E. The Effect of Functional Unit and Co-Product Handling Methods on Life Cycle Assessment of an Algal Biorefinery. Algal Res. 2020, 46, 101770. [Google Scholar] [CrossRef]

- Carneiro, M.L.N.M.; Pradelle, F.; Braga, S.L.; Gomes, M.S.P.; Martins, A.R.F.A.; Turkovics, F.; Pradelle, R.N.C. Potential of Biofuels from Algae: Comparison with Fossil Fuels, Ethanol and Biodiesel in Europe and Brazil through Life Cycle Assessment (LCA). Renew. Sustain. Energy Rev. 2017, 73, 632–653. [Google Scholar] [CrossRef]

- Bichraoui-Draper, N.; Xu, M.; Miller, S.A.; Guillaume, B. Agent-Based Life Cycle Assessment for Switchgrass-Based Bioenergy Systems. Resour. Conserv. Recycl. 2015, 103, 171–178. [Google Scholar] [CrossRef]

- Chowdhury, R.; Sadhukhan, J.; Traverso, M.; Keen, P.L. Effects of Residence Time on Life Cycle Assessment of Bioenergy Production from Dairy Manure. Bioresour. Technol. Reports 2018, 4, 57–65. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Deschěnes, L.; Samson, R. Considering Time in LCA: Dynamic LCA and Its Application to Global Warming Impact Assessments. Environ. Sci. Technol. 2010, 44, 3169–3174. [Google Scholar] [CrossRef]

- Shimako, A.H.; Tiruta-Barna, L.; Pigné, Y.; Benetto, E.; Navarrete Gutiérrez, T.; Guiraud, P.; Ahmadi, A. Environmental Assessment of Bioenergy Production from Microalgae Based Systems. J. Clean. Prod. 2016, 139, 51–60. [Google Scholar] [CrossRef]

- Bright, R.M.; Cherubini, F.; Strømman, A.H. Climate Impacts of Bioenergy: Inclusion of Carbon Cycle and Albedo Dynamics in Life Cycle Impact Assessment. Environ. Impact Assess. Rev. 2012, 37, 2–11. [Google Scholar] [CrossRef]

- Lan, K.; Yao, Y. Dynamic Life Cycle Assessment of Energy Technologies under Different Greenhouse Gas Concentration Pathways. Environ. Sci. Technol. 2022, 56, 1395–1404. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Sen, S.; Gadkari, S. The Mathematics of Life Cycle Sustainability Assessment. J. Clean. Prod. 2021, 309, 127457. [Google Scholar] [CrossRef]

- Strassmann, K.M.; Joos, F. The Bern Simple Climate Model (BernSCM) v1.0: An Extensible and Fully Documented Open-Source Re-Implementation of the Bern Reduced-Form Model for Global Carbon Cycle-Climate Simulations. Geosci. Model Dev. 2018, 11, 1887–1908. [Google Scholar] [CrossRef]

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 Emissions from Biomass Combustion for Bioenergy: Atmospheric Decay and Contribution to Global Warming. GCB Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef]

- Guest, G.; Cherubini, F.; Strømman, A.H. Global Warming Potential of Carbon Dioxide Emissions from Biomass Stored in the Anthroposphere and Used for Bioenergy at End of Life. J. Ind. Ecol. 2013, 17, 20–30. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B. Global Warming Impact Assessment of a Crop Residue Gasification Project-A Dynamic LCA Perspective. Appl. Energy 2014, 122, 269–279. [Google Scholar] [CrossRef]

- Beloin-Saint-Pierre, D.; Albers, A.; Hélias, A.; Tiruta-Barna, L.; Fantke, P.; Levasseur, A.; Benetto, E.; Benoist, A.; Collet, P. Addressing Temporal Considerations in Life Cycle Assessment. Sci. Total Environ. 2020, 743, 140700. [Google Scholar] [CrossRef] [PubMed]

- IPCC. National Greenhouse Gas Inventory 1997; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Strategies (IGES): Hayama, Japan, 1999; Volume 66, ISBN 4-88788-032-4. [Google Scholar]

- Albers, A.; Collet, P.; Benoist, A.; Hélias, A. Back to the Future: Dynamic Full Carbon Accounting Applied to Prospective Bioenergy Scenarios. Int. J. Life Cycle Assess. 2020, 25, 1242–1258. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Samson, R. Biogenic Carbon and Temporary Storage Addressed with Dynamic Life Cycle Assessment. J. Ind. Ecol. 2013, 17, 117–128. [Google Scholar] [CrossRef]

- Albers, A.; Collet, P.; Benoist, A.; Hélias, A. Data and Non-Linear Models for the Estimation of Biomass Growth and Carbon Fixation in Managed Forests. Data Br. 2019, 23, 103841. [Google Scholar] [CrossRef]

- Albers, A.; Avadí, A.; Benoist, A.; Collet, P.; Hélias, A. Modelling Dynamic Soil Organic Carbon Flows of Annual and Perennial Energy Crops to Inform Energy-Transport Policy Scenarios in France. Sci. Total Environ. 2020, 718, 135278. [Google Scholar] [CrossRef] [PubMed]

- Jørgensen, S.V.; Hauschild, M.Z.; Nielsen, P.H. Assessment of Urgent Impacts of Greenhouse Gas Emissions—The Climate Tipping Potential (CTP). Int. J. Life Cycle Assess. 2014, 19, 919–930. [Google Scholar] [CrossRef]

- Cherubini, F.; Huijbregts, M.; Kindermann, G.; Van Zelm, R.; Van Der Velde, M.; Stadler, K.; Strømman, A.H. Global Spatially Explicit CO2 Emission Metrics for Forest Bioenergy. Sci. Rep. 2016, 6, 20186. [Google Scholar] [CrossRef] [PubMed]

- Guest, G.; Strømman, A.H. Climate Change Impacts Due to Biogenic Carbon: Addressing the Issue of Attribution Using Two Metrics With Very Different Outcomes. J. Sustain. For. 2014, 33, 298–326. [Google Scholar] [CrossRef]

- Pigné, Y.; Gutiérrez, T.N.; Gibon, T.; Schaubroeck, T.; Popovici, E.; Shimako, A.H.; Benetto, E.; Tiruta-Barna, L. A Tool to Operationalize Dynamic LCA, Including Time Differentiation on the Complete Background Database. Int. J. Life Cycle Assess. 2020, 25, 267–279. [Google Scholar] [CrossRef]

- Tiruta-Barna, L.; Pigné, Y.; Navarrete Gutiérrez, T.; Benetto, E. Framework and Computational Tool for the Consideration of Time Dependency in Life Cycle Inventory: Proof of Concept. J. Clean. Prod. 2016, 116, 198–206. [Google Scholar] [CrossRef]

- Chowdhury, R.; Suyal, D.; Freire, F. Effects of Nutrient Recycling on Carbon Sequestration during Algal Biofuel Production. In Proceedings of the International Society of Industrial Ecology biennial Conference; University of Surrey: London, UK, 2015. [Google Scholar]

- Guo, M.; Li, C.; Bell, J.N.B.; Murphy, R.J. Influence of Agro-Ecosystem Modeling Approach on the Greenhouse Gas Profiles of Wheat-Derived Biopolymer Products. Environ. Sci. Technol. 2012, 46, 320–330. [Google Scholar] [CrossRef] [PubMed]

- Hillier, J.; Whittaker, C.; Dailey, G.; Aylott, M.; Casella, E.; Richter, G.M.; Riche, A.; Murphy, R.; Taylor, G.; Smith, P. Greenhouse Gas Emissions from Four Bioenergy Crops in England and Wales: Integrating Spatial Estimates of Yield and Soil Carbon Balance in Life Cycle Analyses. GCB Bioenergy 2009, 1, 267–281. [Google Scholar] [CrossRef]

- Kalt, G.; Höher, M.; Lauk, C.; Schipfer, F.; Kranzl, L. Carbon Accounting of Material Substitution with Biomass: Case Studies for Austria Investigated with IPCC Default and Alternative Approaches. Environ. Sci. Policy 2016, 64, 155–163. [Google Scholar] [CrossRef]

- EPA Greenhouse Gas Inventory Data Explorer. Available online: https://cfpub.epa.gov/ghgdata/inventoryexplorer/#allsectors/allsectors/allgas/econsect/current (accessed on 18 April 2022).

- Coats, E.R.; Searcy, E.; Feris, K.; Shrestha, D.; Mcdonald, A.G.; Briones, A.; Magnuson, T.; Prior, M. An Integrated Two-Stage Anaerobic Digestion and Biofuel Production Process to Reduce Life Cycle GHG Emissions from US Dairies. Biofuels Bioprod. Biorefining 2013, 7, 459–473. [Google Scholar] [CrossRef]

- Cherubini, F. GHG Balances of Bioenergy Systems—Overview of Key Steps in the Production Chain and Methodological Concerns. Renew. Energy 2010, 35, 1565–1573. [Google Scholar] [CrossRef]

- Weber, C.L.; Jaramillo, P.; Marriott, J.; Samaras, C. Life Cycle Assessment and Grid Electricity: What Do We Know and What Can We Know? Environ. Sci. Technol. 2010, 44, 1895–1901. [Google Scholar] [CrossRef] [PubMed]

- Available online: http://www.eiolca.net/ (accessed on 18 April 2022).

- Domenichini, R.; Mancuso, L.; Ferrari, N.; Davison, J. Operating Flexibility of Power Plants with Carbon Capture and Storage (CCS). In Proceedings of the Energy Procedia; Elsevier: Amsterdam, The Netherlands, 2013; Volume 37, pp. 2727–2737. [Google Scholar]

- Penman, J.; Gytarsky, M.; Hiraishi, T.; Irving, W.; Krug, T. 2006 IPCC—Guidelines for National Greenhouse Gas Inventories. 2006. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.htm (accessed on 18 April 2022).

- Li, C.; Frolking, S.; Crocker, G.J.; Grace, P.R.; Klír, J.; Körchens, M.; Poulton, P.R. Simulating Trends in Soil Organic Carbon in Long-Term Experiments Using the DNDC Model. Geoderma 1997, 81, 45–60. [Google Scholar] [CrossRef]

- Palosuo, T.; Foereid, B.; Svensson, M.; Shurpali, N.; Lehtonen, A.; Herbst, M.; Linkosalo, T.; Ortiz, C.; Rampazzo Todorovic, G.; Marcinkonis, S.; et al. A Multi-Model Comparison of Soil Carbon Assessment of a Coniferous Forest Stand. Environ. Model. Softw. 2012, 35, 38–49. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, H. The Development of the DNDC Plant Growth Sub-Model and the Application of DNDC in Agriculture: A Review. Agric. Ecosyst. Environ. 2016, 230, 271–282. [Google Scholar] [CrossRef]

- Bruun, S.; Christensen, B.T.; Hansen, E.M.; Magid, J.; Jensen, L.S. Calibration and Validation of the Soil Organic Matter Dynamics of the Daisy Model with Data from the Askov Long-Term Experiments. Soil Biol. Biochem. 2003, 35, 67–76. [Google Scholar] [CrossRef]

- Yoshida, H.; Nielsen, M.P.; Scheutz, C.; Jensen, L.S.; Bruun, S.; Christensen, T.H. Long-Term Emission Factors for Land Application of Treated Organic Municipal Waste. Environ. Model. Assess. 2016, 21, 111–124. [Google Scholar] [CrossRef]

- Smith, W.N.; Grant, B.B.; Campbell, C.A.; McConkey, B.G.; Desjardins, R.L.; Kröbel, R.; Malhi, S.S. Crop Residue Removal Effects on Soil Carbon: Measured and Inter-Model Comparisons. Agric. Ecosyst. Environ. 2012, 161, 27–38. [Google Scholar] [CrossRef]

- Pathak, H.; Li, C.; Wassmann, R. Greenhouse Gas Emissions from Indian Rice Fields: Calibration and Upscaling Using the DNDC Model. Biogeosciences 2005, 2, 113–123. [Google Scholar] [CrossRef]

- Guillaume, T.; Bragazza, L.; Levasseur, C.; Libohova, Z.; Sinaj, S. Long-Term Soil Organic Carbon Dynamics in Temperate Cropland-Grassland Systems. Agric. Ecosyst. Environ. 2021, 305, 107184. [Google Scholar] [CrossRef]

- Nerger, R.; Klüver, K.; Cordsen, E.; Fohrer, N. Intensive Long-Term Monitoring of Soil Organic Carbon and Nutrients in Northern Germany. Nutr. Cycl. Agroecosystems 2020, 116, 57–69. [Google Scholar] [CrossRef]

- Woloszczyk, P.; Fiencke, C.; Elsner, D.C.; Cordsen, E.; Pfeiffer, E.M. Spatial and Temporal Patterns in Soil Organic Carbon, Microbial Biomass and Activity under Different Land-Use Types in a Long-Term Soil-Monitoring Network. Pedobiologia 2020, 80, 150642. [Google Scholar] [CrossRef]

- Brandão, M.; Levasseur, A.; Kirschbaum, M.U.F.; Weidema, B.P.; Cowie, A.L.; Jørgensen, S.V.; Hauschild, M.Z.; Pennington, D.W.; Chomkhamsri, K. Key Issues and Options in Accounting for Carbon Sequestration and Temporary Storage in Life Cycle Assessment and Carbon Footprinting. Int. J. Life Cycle Assess. 2013, 18, 230–240. [Google Scholar] [CrossRef]

| BERN model | a0 = 0.217 a0 = 0.2173 | a1 = 0.259 a1 = 0.2240 T1 = 172.9 years T1 = 394.4 years | a2 = 0.338 a2 = 0.2824 T2 = 18.51 years T2 = 36.54 years | a3 = 0.186 a3 = 0.2763 T3 = 1.186 years T3 = 4.304 years | [78,81,84] | |||

| BERN SCM 1.0 model | a0 = 0.013691 | a1 = 0.27022 T1 = 0.07027 | a2 = 0.45937 T2 = 0.57621 | a3 = 0.094671 T3 = 2.6900 | a4 = 0.10292 T4 = 13.617 | a5 = 0.0392835 T5 = 86.797 | a6 = 0.012986 T6 = 337.30 | [83] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, R.; Caetano, N.; Franchetti, M.J.; Hariprasad, K. Life Cycle Based GHG Emissions from Algae Based Bioenergy with a Special Emphasis on Climate Change Indicators and Their Uses in Dynamic LCA: A Review. Sustainability 2023, 15, 1767. https://doi.org/10.3390/su15031767

Chowdhury R, Caetano N, Franchetti MJ, Hariprasad K. Life Cycle Based GHG Emissions from Algae Based Bioenergy with a Special Emphasis on Climate Change Indicators and Their Uses in Dynamic LCA: A Review. Sustainability. 2023; 15(3):1767. https://doi.org/10.3390/su15031767

Chicago/Turabian StyleChowdhury, Raja, Nidia Caetano, Matthew J. Franchetti, and Kotnoor Hariprasad. 2023. "Life Cycle Based GHG Emissions from Algae Based Bioenergy with a Special Emphasis on Climate Change Indicators and Their Uses in Dynamic LCA: A Review" Sustainability 15, no. 3: 1767. https://doi.org/10.3390/su15031767

APA StyleChowdhury, R., Caetano, N., Franchetti, M. J., & Hariprasad, K. (2023). Life Cycle Based GHG Emissions from Algae Based Bioenergy with a Special Emphasis on Climate Change Indicators and Their Uses in Dynamic LCA: A Review. Sustainability, 15(3), 1767. https://doi.org/10.3390/su15031767