1. Introduction

Since the Industrial Revolution, due to increasingly intensive human activities, atmospheric CO

2 concentration has increased by 50%, from 280 ppm in 1750 to 419 ppm in 2022. In 2019, the International Energy Agency (IEA) reported that since 2010, the power generation/heating and transportation sectors accounted for about two-thirds of the total CO

2 emissions [

1]. The huge increase in CO

2 emissions has not only caused global climate change but also posed significant challenges to human life and production. To address this issue, it is urgent to develop a low-carbon economy that can promote sustainable development. The fundamental principle of a low-carbon economy is to lower energy consumption and carbon emissions while achieving economic growth [

2].

The logistics industry is a vital component of economic activities and plays a crucial role in realizing a low-carbon economy. As a major energy consumption industry, the logistics industry generates a large amount of CO

2 emissions during its operation, and it has caused severe environmental pollution problems. Thus, low-carbon logistics is the key to establishing a sustainable low-carbon economic system. In recent years, the rapid development of the e-commerce industry has further driven the growth of the logistics industry, requiring more vehicles for logistics services. The vehicle routing problem (VRP) is worth studying as it helps to minimize the transportation costs of logistics enterprises [

3]. With the increasing awareness of environmental protection, the carbon emissions caused by fuel vehicles have also attracted more and more attention. Therefore, some researchers have extended this problem to the green vehicle routing problem (GVRP) to achieve a reduction in carbon emissions while reducing transportation costs. Costa et al. studied the GVRP to minimize CO

2 emissions and solved the problem by an improved genetic algorithm (GA) [

4]. Koç et al. studied the joint impact of location, fleet composition, and routing on emissions in a city logistics context, with the goal of minimizing the total depot, vehicle, and routing cost. Three speed zones were divided in city and a new adaptive large search algorithm was used to solve the problem [

5]. Zhou et al. established the time-dependent green location-routing problem model considering the carbon cap-and-trade emission policy to minimize the total cost which consisted of fuel consumption, carbon emissions, construction cost of distribution centers, vehicle use, driving labor, and dispatch of vehicles, and solved the model through a two-stage hybrid heuristic algorithm [

6].

However, governments have begun to restrict the sale of fuel vehicles due to the increasing demand for reducing carbon emissions and relieving the adverse effects of traffic on the environment [

7]. For the advantages of low emissions and low noise, electric vehicles (EVs) are gradually replacing fuel vehicles as the mainstream for logistics services, providing an important means to achieve low-carbon logistics [

8,

9]. But there are some challenges when EVs participate in logistics services: (1) Compared to fuel vehicles, EVs have a shorter driving range. (2) EVs require charging to ensure the completion of long-distance logistics services. (3) EVs require more time to charge than the refueling time of fuel vehicles [

10,

11]. Based on the above points, many scholars had conducted research on electric vehicle routing problem (EVRP) to provide groundbreaking solutions for achieving low-carbon logistics and sustainable development. Conrad et al. assumed that charging time was constant, and it allowed EVs to be charged at selected customer locations when the state-of-charge (SoC) was low during logistics distribution [

12]. However, the charging time is not a fixed value, and the delivery of goods must be within a time frame acceptable to the customer. Schneider et al. introduced an electric vehicle routing problem with time windows (EVRPTW), where the charging time depended on the SoC when an electric vehicle (EV) arrived at the station, and modified Solomon’s data sets for this purpose [

13]. Wang et al. proposed a tailored hybrid heuristic that combined a large neighborhood search algorithm with a set partitioning component to solve the electric fleet size and mixed vehicle routing problem with time windows and recharging stations [

14]. Although EVs themselves do not produce any harmful gases, carbon emissions will be indirectly caused when charging [

15,

16]. Zhang et al. studied the EVRP with the objective function of minimizing energy consumption and estimated the indirect carbon emissions from the EV based on the amount of battery energy used [

17]. Li et al. proposed an optimization model of EVRP in view of the sharing economy considering carbon tax and time-of-use electricity price to minimize the total cost consisting of the operation, penalty, queuing (waiting at the charging stations), electricity, and environment costs [

18]. Foroutan et al. proposed the green vehicle routing and scheduling problem with a heterogeneous fleet, including reverse logistics in the form of collecting returned goods along with weighted earliness and tardiness costs, to establish a trade-off between operational and environmental costs and to minimize both simultaneously [

19]. Nolz et al. considered a consistent EVRP for the delivery of parcels with EVs where EVs returned to the depot to charge with a limited number of charging piles during the lunch break. It aimed to reduce carbon emissions and implement innovative and efficient last-mile logistics services [

20]. Based on the hybrid electric vehicle routing problem, Seyfi et al. proposed a multimode hybrid electric vehicle routing problem where different drive modes had different costs and travel times on each arc of a given distribution network and established a mixed-integer linear model to minimize the total cost of the distances traveled at different modes. A method combining variable neighborhood search and mathematical programming was proposed to solve the problem [

21].

As a new concept proposed in recent years, green power trading can not only be used to meet the demand of power users for purchasing and consuming green power, but also provide corresponding green power consumption certification [

22]. Previous studies did not involve green power trading, but it helps to promote the use of renewable energy and reduce carbon emissions, and makes important contributions to achieving sustainable economic, social, and environmental development goals. Based on considering carbon emissions, this paper further introduces the green power trading mechanism to mitigate the negative impacts of EVs on the environment, and minimizes the total cost of the EV logistics distribution by rationally planning the distribution path with time windows. The main contributions of this paper are as follows:

When considering the environmental cost, the green power trading is introduced, and an objective function of the total minimum cost consisting of fixed cost, driving cost, charging cost, penalty cost, and environmental cost is proposed.

A hybrid adaptive genetic algorithm (HAGA) is designed to solve this function. During the initialization, an improved nearest-neighbor algorithm based on minimum cost (NNC) is proposed to improve the quality of the initial population. Meanwhile, adaptive crossover and mutation operators are introduced to achieve the better solution.

Based on the Schneider case, the experiment simulations are carried out, and the results show that HAGA can effectively solve the path optimization problem of EVs and reduce the total cost by 22.27%.

The remaining sections of this paper are organized as follows.

Section 2 illustrates the assumptions and proposes the GVRP model.

Section 3 describes the HAGA.

Section 4 presents the detailed experimental case and settings along with the analysis of results.

Section 5 concludes the paper and gives future directions for future research.

3. Model Solution

GVRP is an NP-hard problem, and solved by many modern heuristic optimization algorithms, such as neighborhood search, particle swarm optimization, GA, etc. Among these algorithms, GA is proved to be an effective and powerful algorithm [

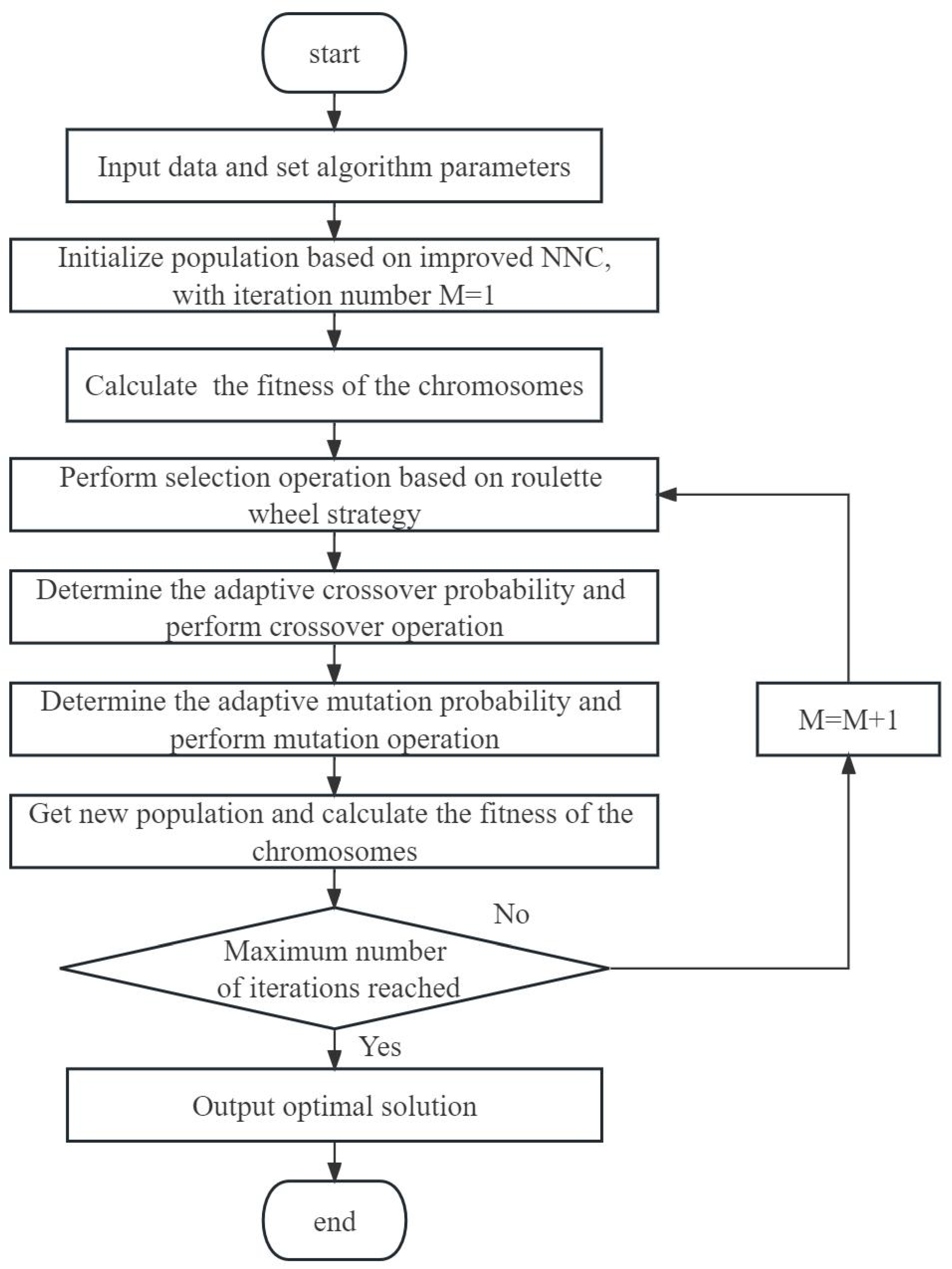

23]. The object of GA is the population, and each individual in the population is called a chromosome, which consists of genes and represents a solution to the problem according to a certain coding. Selection, crossover, and mutation operations are applied to the population to improve the fitness of population, so as to achieve the purpose of reaching the optimum. However, the traditional GA easily falls into local optimum; a HAGA is proposed to solve GVRP. An improved NNC is adopted to obtain a high-quality initial population, and adaptive crossover and mutation operators are used to achieve better global search ability. The specific flow chart is shown in

Figure 1.

3.1. Solution Coding

To ensure that each customer can only be served by one EV, natural number encoding is adopted to encode the chromosomes with the staining length of

before initializing the population, where

v is the number of customers and

k represents the number of EVs available [

24]. For example, if there are currently three EVs providing distribution services to 10 customers, numbers 1 to 10 represent customers. Numbers 11 and 12 are only used to divide the chromosome and have no special significance. There are three charging stations, numbered 13 to 15. After encoding, the chromosome is represented as (4, 7, 3, 11, 5, 8, 6, 2, 12, 10, 1, 9), with three distribution paths. It is worth noting that in the proposed encoding, the chromosomes only represent customers information and the orders of access paths, and do not include the charging stations. As a result, it can prevent charging stations form participating in crossover and mutation operations. After each generation of population completes the update operation, distribution center and charging stations are inserted into the decoded chromosomes for calculating the fitness. The decoding process is shown in

Figure 2.

3.2. Initialization of the Population

NNC is a construction algorithm, which can produce a better feasible solution and was first proposed by Solomon and applied to VRP [

25,

26]. An improved NNC is proposed to obtain the high-quality initial population, and its specific steps are as follows:

Step1: Dispatch the first EV from the available EVs at the start of logistics distribution and randomly visit the first customer node.

Step2: The customer node that is closest to the last visited customer node and has not been visited is selected and inserted into the current path.

Step3: Repeat Step2 until the maximum capacity limit of the current EV is reached and save the current path. Then, dispatch a new EV from the distribution center until all customer nodes have been accessed.

The distance

between two customer nodes can be expressed by time, and it consists of three parts: (1)

, which is the time to move from the previous customer node to the next customer node, which includes the driving time and the charging time in the midway; (2)

, which is the time difference between the start service time of the next customer node and the completion service time of the previous customer node; (3)

, which is the time difference between the latest service time and the start service time of the customer node. Then,

can be expressed as:

where

,

,

stand for the weights and

+

+

= 1,

> 0,

> 0,

> 0.

3.3. Fitness Assessment

To calculate the fitness, the charging stations need to be inserted into the initial path. If the SoC of an EV at a customer node on the path is less than 20% of its maximum SoC, the EV needs to drive to the nearest charging station for charging. Then the fitness function can be expressed as:

where the fitness function is the reciprocal of function

Z. The total cost

F is calculated through (

8).

limits that the total customer load demands of EVs do not exceed the maximum capacity.

limits that the time for the EV to return to the distribution center after the distribution task cannot exceed its maximum working time.

and

are two very large numbers, such as

=

=

.

3.4. Population Regeneration

To ensure the better chromosomes selected with higher probability and eliminate the inferior chromosomes, the roulette wheel selection is adopted for selection operation.

- (2)

Crossover and mutation

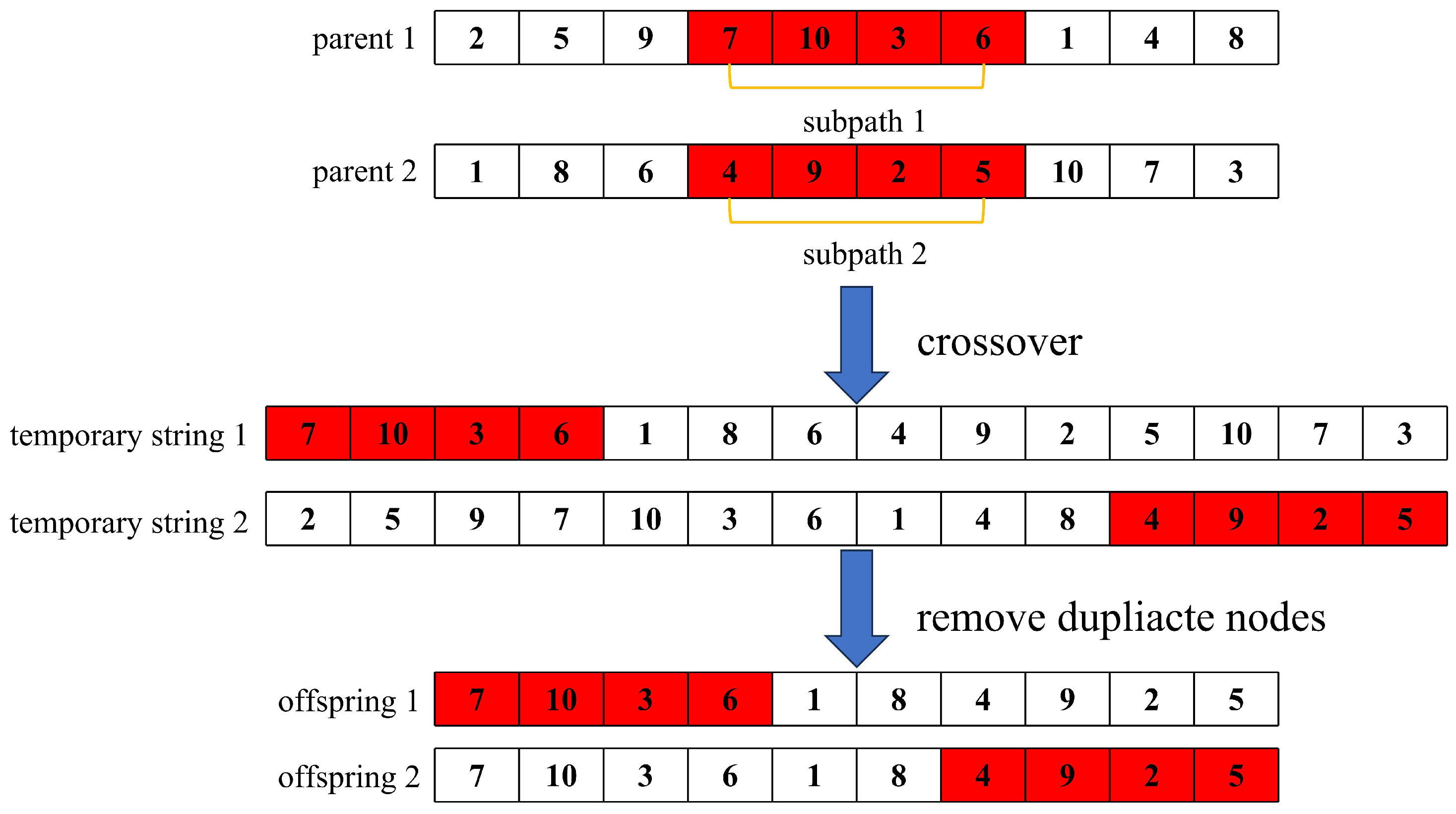

To obtain a better solution, this paper adopts an improved-order crossover operation and a two-point interchange mutation operation. The specific steps of the improved-order crossover operation are as follows: Firstly, determine the parent 1 and parent 2 that need to undergo the crossover operation, and randomly select two gene crossover points. The region between the two crossover points is called the cross subpath. Secondly, copy the cross subpath 1 in parent 1 and place it in the front of parent 2. Similarly, copy the cross subpath 2 in parent 2 and place it at the back of parent 1. Finally, delete the duplicated genes in parent 1 and parent 2, respectively, to form two new crossover offsprings [

27], as shown in

Figure 3.

In traditional GA, both the crossover probability and mutation probability are constants, which can cause the algorithm to converge slowly at the beginning of the iteration and rapidly at the end, resulting in local optimum. To address this issue, adaptive crossover and mutation operators are adopted. The adaptive

and

are as follows:

where

,

,

, and

are values in [0, 1];

is the maximal fitness in the population;

is the average fitness in the population;

is the larger fitness of the two crossover chromosomes;

is the fitness of the mutation chromosome. After the improvement, the

and

of the chromosomes with larger fitness become smaller, while the chromosomes with smaller fitness are the opposite, so the high-quality chromosomes can be inherited, and the global search ability of the algorithm is improved.

5. Conclusions

With the increasingly serious environmental pollution problem and the encouragement of government policies, it is an inevitable trend for logistics enterprises to adopt EVs. In addition to the positive impact on the environment, EVs have also made significant contributions to the economy and society. EVs are an effective means to enhance the competitiveness of logistics enterprises and promote sustainable economic development. Aiming to reduce environmental pollution while minimizing logistics costs for enterprises and achieving optimization of logistics resource allocation, this paper introduces the green power trading and studies an EV logistics distribution path optimization model with time windows. The model aims to minimize the total cost, which includes fixed cost, driving cost, charging cost, penalty cost, and environmental cost. Furthermore, HAGA is proposed to solve this issue. The improved NNC is proposed to obtain the high-quality initial population, and the adaptive operators are introduced in the crossover and mutation to achieve a better solution. HAGA overcomes the limitations of the traditional GA and ensures both population quality and convergence, thereby the optimization ability of the GA is improved. Based on the Schneider case, the experimental simulations are carried out and the results show that while customer demands are met, carbon emissions are also significantly reduced. The NNC-GA can reduce the total cost by 31.68% compared to the traditional GA. And the adaptive operators are effective at minimizing the total cost to CNY 2126.63. The experimental simulations based on different scale cases show that green power trading can effectively reduce total cost and carbon emissions.

This paper assumes that the power consumption and speed of EVs are constant, but in practice, these are variable and how to consider these factors is one goal of our future work. At the same time, the integration mechanism of green certificate and green power is only considered in this paper, while considering the distribution and usage of power throughout the whole region, the separation trading mechanism of green certificate and green power is necessary to be introduced, and it is another goal of our future work.