Enhancing Cementitious Concrete Durability and Mechanical Properties through Silica Fume and Micro-Quartz

Abstract

:1. Introduction

1.1. Background

1.2. Bibliographical Overview

- Type of cement and, accordingly, its chemistry and activity.

- The packing of both the ingredients for the cementitious matrix and aggregate skeleton.

- Chemical and volume stability of the individual cementitious, mortar, and concrete phases.

- A sieve analysis, fineness, and chemical stability of fine and coarse aggregates.

1.3. Scope and Significance of the Research

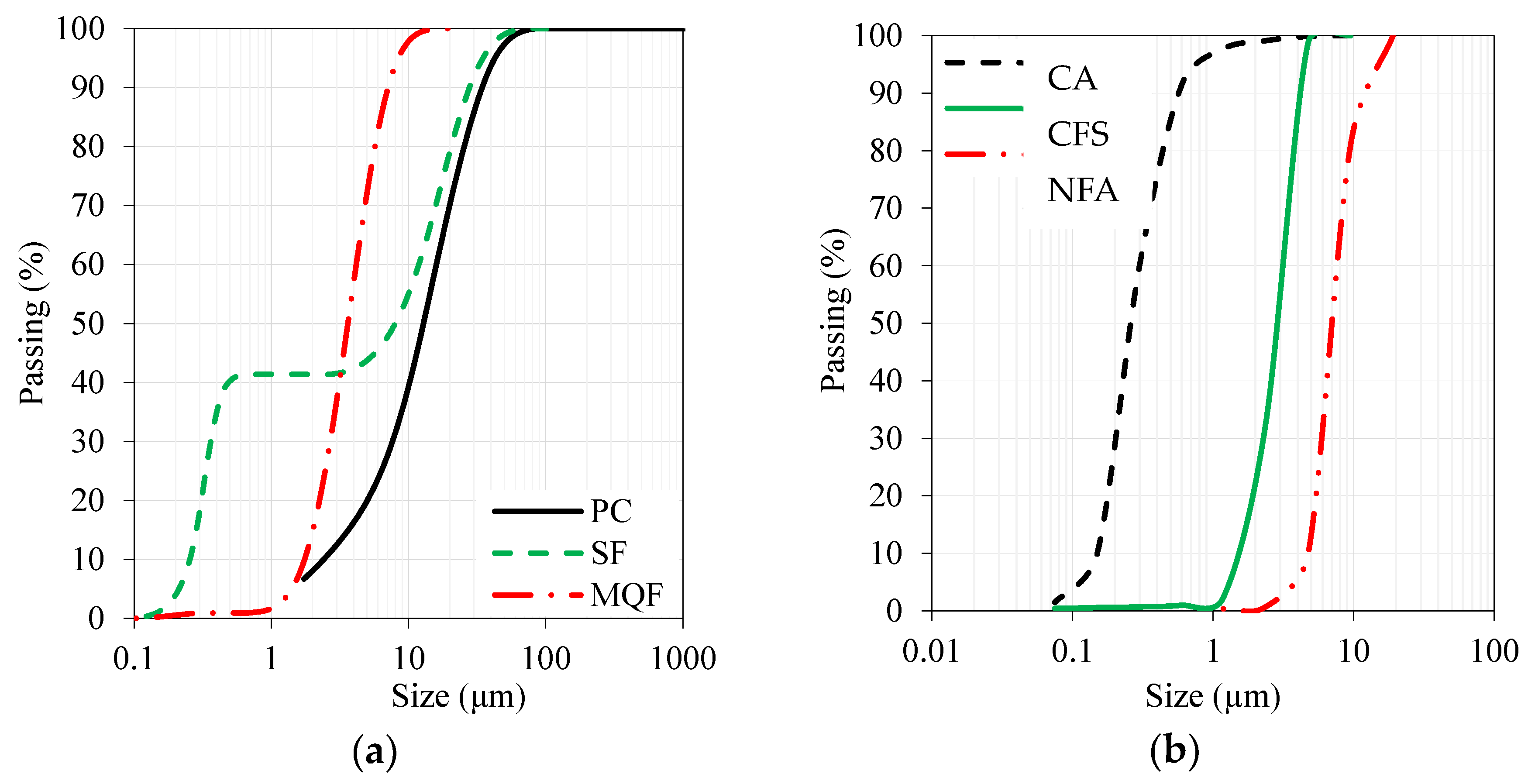

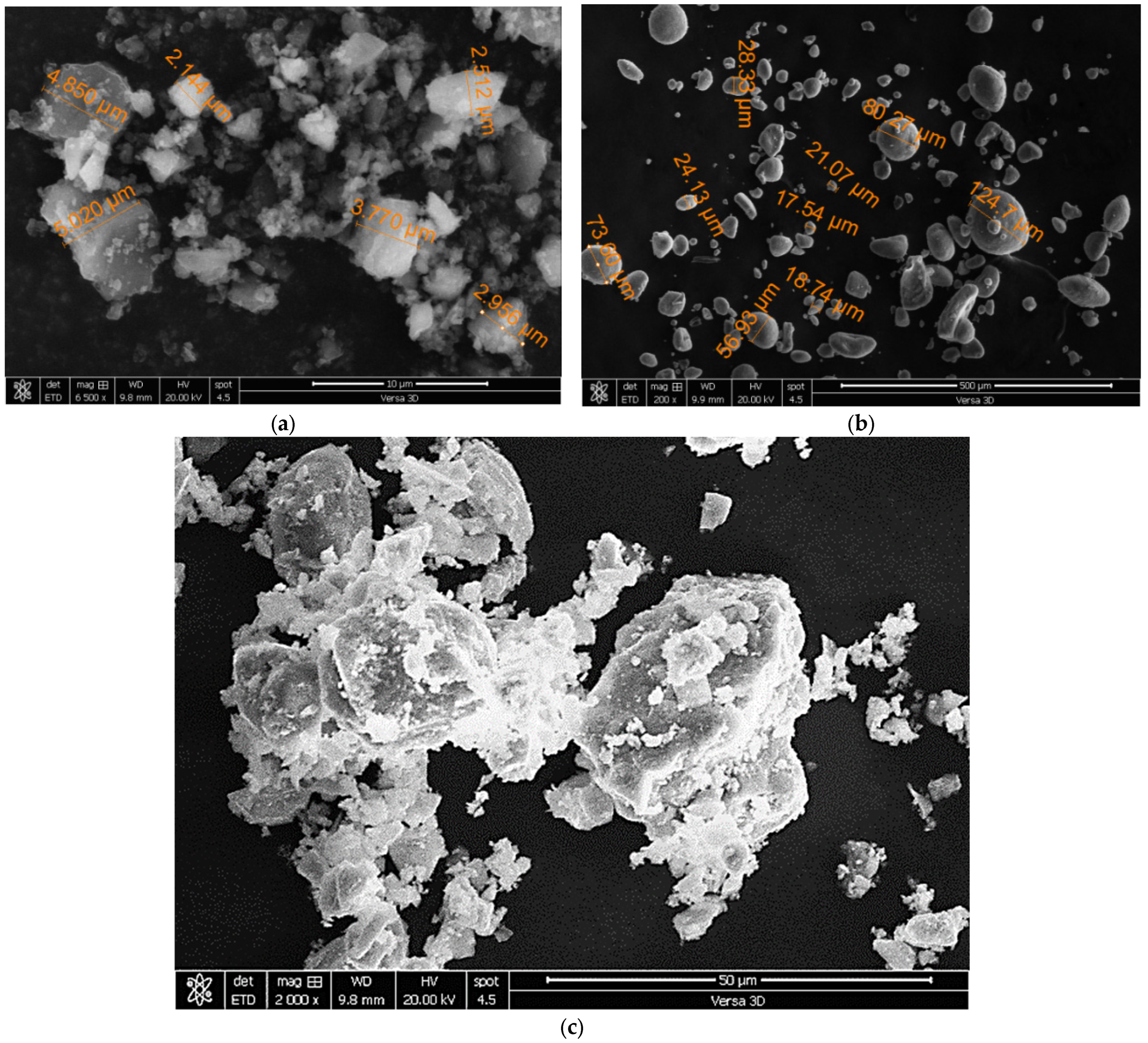

2. Materials

3. Methodology

3.1. Detail of Mixes

3.2. Mixing, Casting, and Curing

3.3. Testing Procedures

3.3.1. Uniaxial Compression Test

3.3.2. Rapid Chloride-Ion Permeability Test

3.3.3. Porosity Test

4. Results and Discussion

4.1. Strength Characteristics

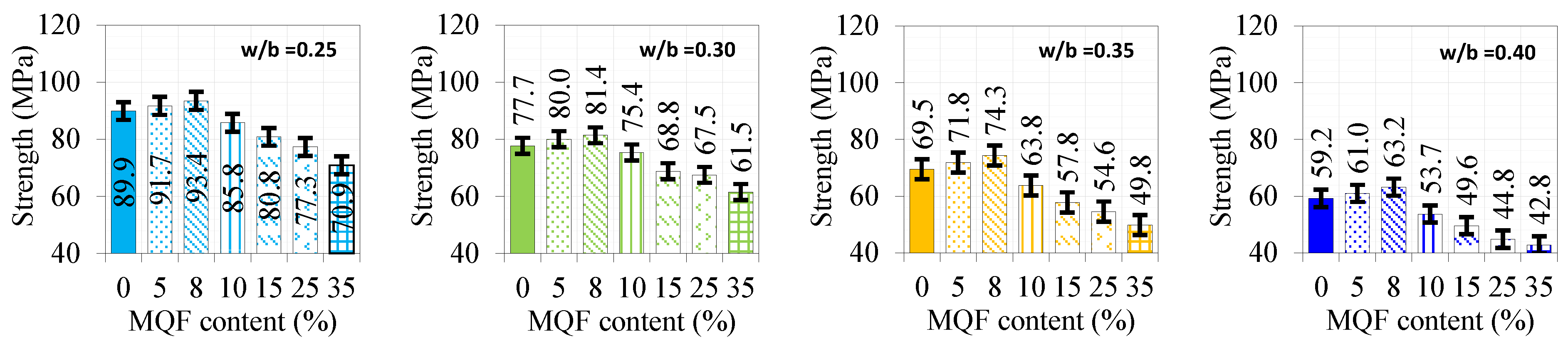

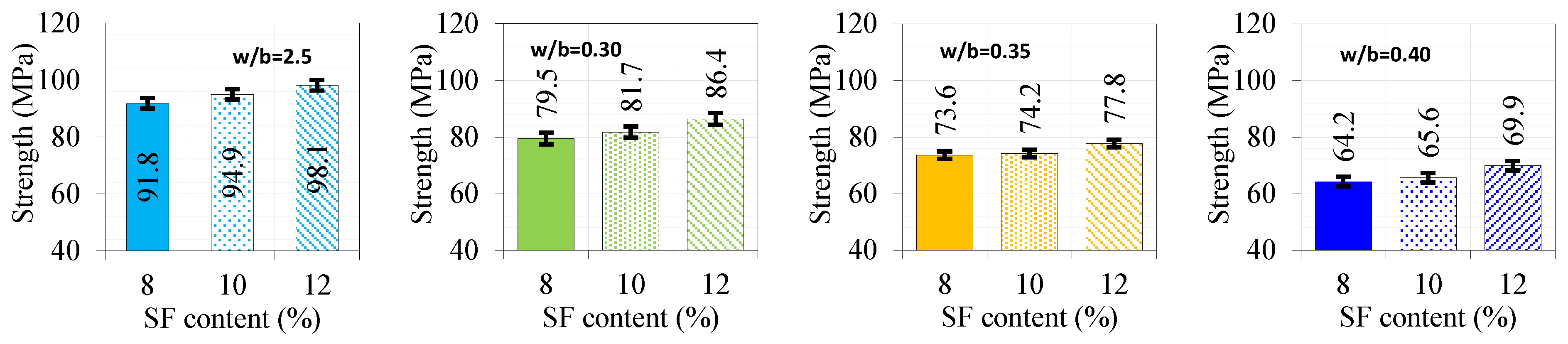

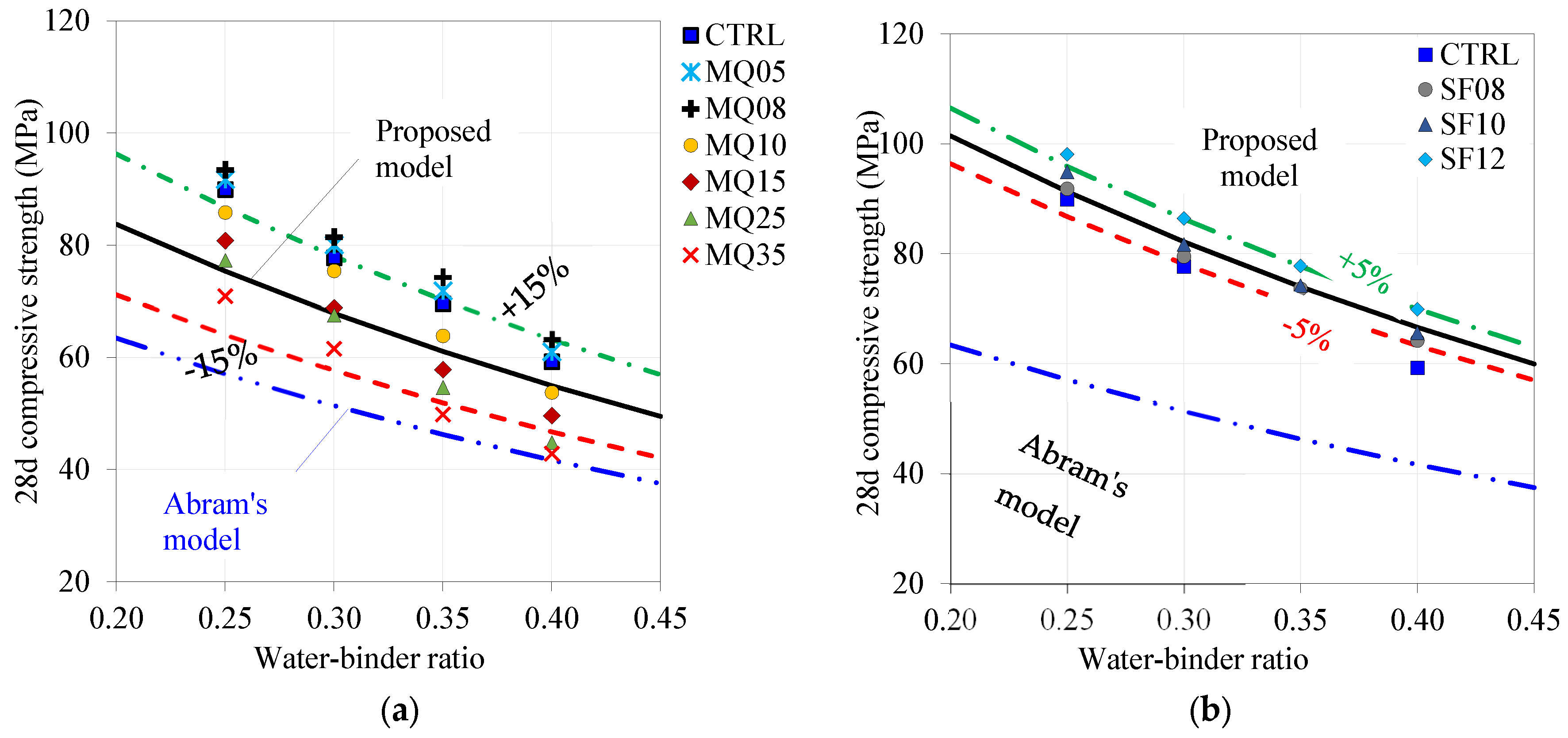

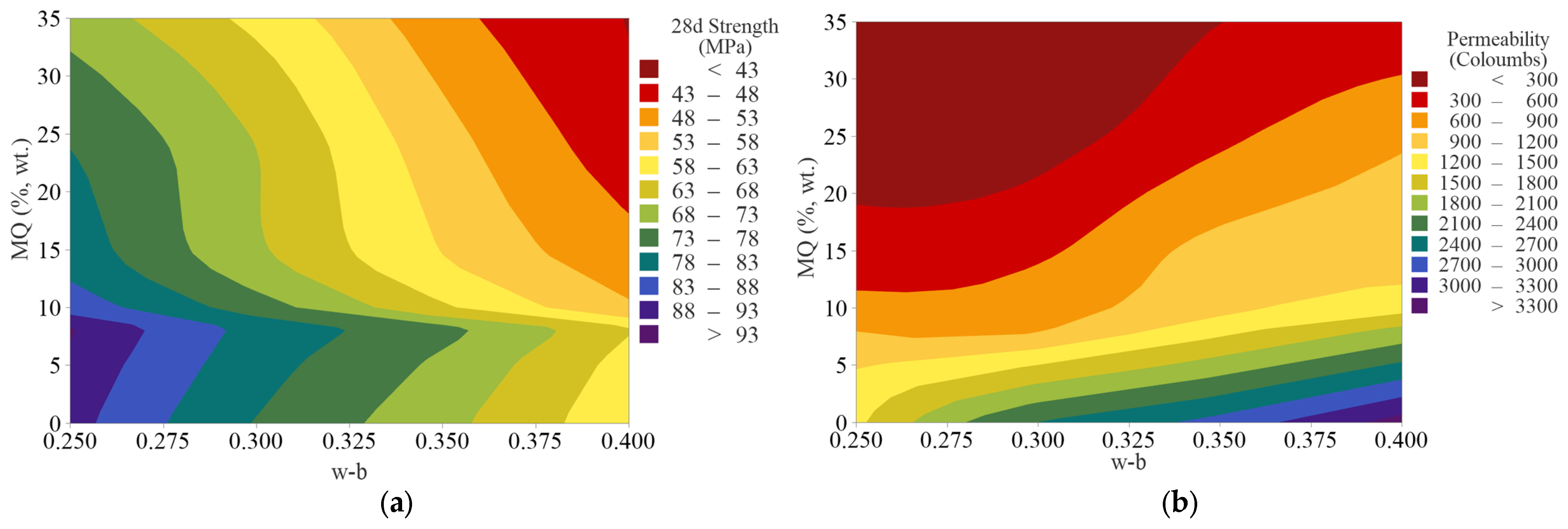

4.1.1. The 28 d Compressive Strength of SF and MQF Concrete

4.1.2. A Modified ABRAM’s Model for SF and MQF Concrete

- : the concrete’s compressive strength at a certain age (here, considered 28 d).

- and : the empirical-based factors reflect the effects of individual constituent materials, the curing system, testing parameters, and the age of concrete.

- x: the water–binder ratio.

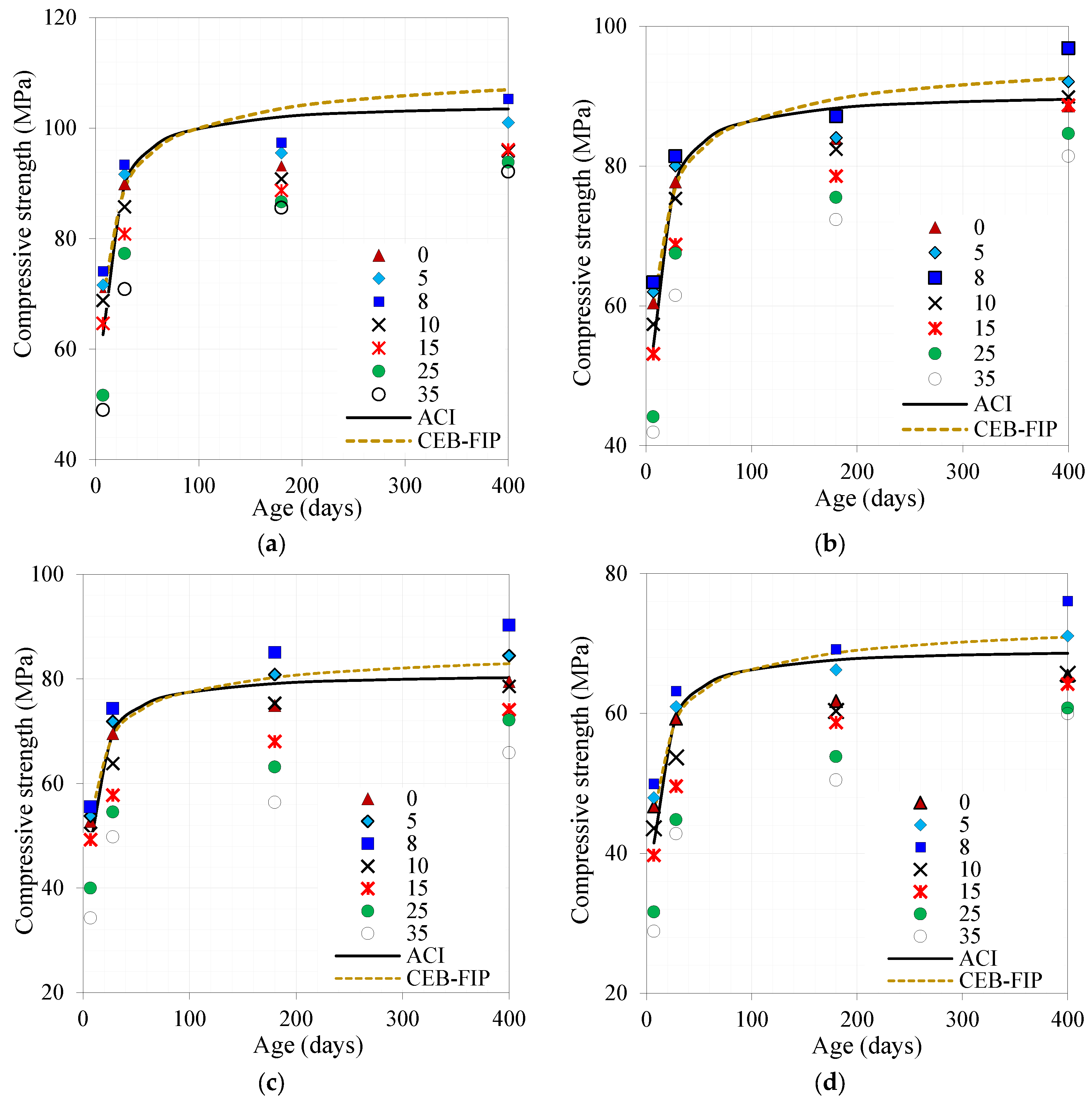

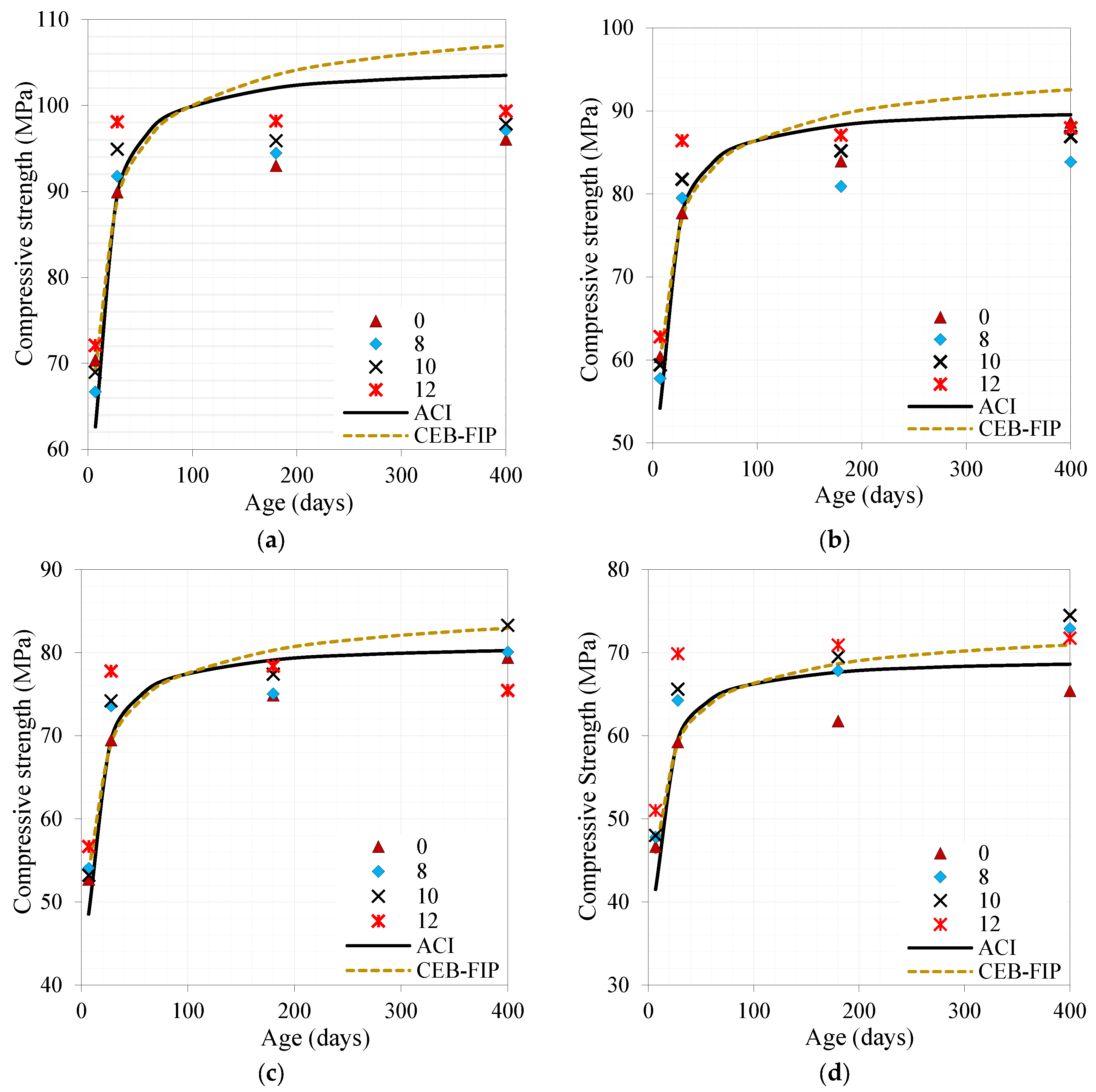

4.1.3. The Age-Dependent Compressive Strength

- : mean compressive strength at age t days.

- : a coefficient that depends on the cement type (0.20 for high early strength, 0.25 for normal hardening, and 0.38 for slow hardening).

- : 1 day.

4.2. Durability Characteristics

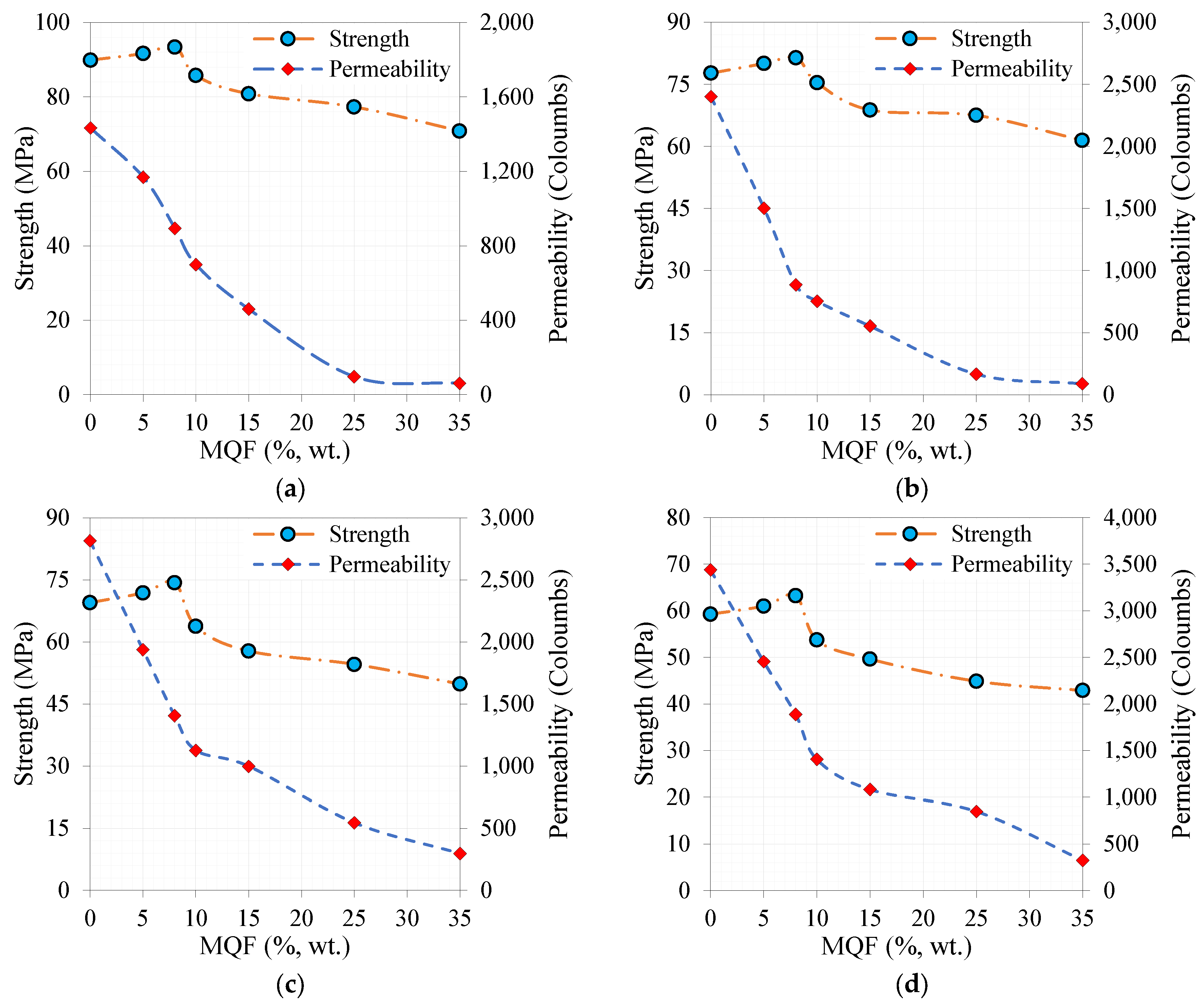

4.2.1. The Chloride-Ion Permeability

4.2.2. The Porosity

4.3. Correlations of Different Parameters of Concrete Mixtures

5. Conclusions, Limitations, and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Charge Passed (Coulombs) | Chloride Ion Penetrability |

|---|---|

| >4000 | High |

| 2000–4000 | Moderate |

| 1000–2000 | Low |

| 100–1000 | Very low |

| <100 | Negligible |

References

- Initiative Cement Sustainability (CSI). Recycling Concrete; World Business Council for Sustainable Development-WBCSD: Geneva, Switzerland, 2009. [Google Scholar]

- Aıtcin, P. The durability characteristics of high performance concrete: A review. Cem. Concr. Compos. 2003, 25, 409–420. [Google Scholar] [CrossRef]

- Stroeven, M. Discrete Numerical Modelling of Composite Materials-Application to Cementitious Materials. Ph.D. Thesis, Civil Engineering and Geosciences, Delft University of Technology, Delft, The Netherlands, 1999. [Google Scholar]

- Bai, G.; Wang, L.; Ma, G.; Sanjayan, J.; Bai, M. 3D printing eco-friendly concrete containing under-utilised and waste solids as aggregates. Cem. Concr. Compos. 2021, 120, 104037. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, D.; Xing, F.; Guo, M. Multiscale mechanical characteristics of ultra-high performance concrete incorporating different particle size ranges of recycled fine aggregate. Constr. Build. Mater. 2021, 307, 125131. [Google Scholar] [CrossRef]

- Bui, D.; Hu, J.; Stroeven, P. Particle size effect on the strength of rice husk ash blended gap-graded Portland cement concrete. Cem. Concr. Compos. 2005, 27, 357–366. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, T.; Liu, H. Performance evolution of the interfacial transition zone (ITZ) in recycled aggregate concrete under external sulfate attacks and dry-wet cycling. Constr. Build. Mater. 2019, 229, 116938. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Z.; Liu, A.; Zhang, L. Numerical insights into the effect of ITZ and aggregate strength on concrete properties. Theor. Appl. Fract. Mech. 2022, 120, 103415. [Google Scholar] [CrossRef]

- Lagerblad, B.; Kjellsen, K. Normal and High Strength Concretes with Conventional Aggregates; RILEM REPORT: Kyoto, Japan, 1999; pp. 53–70. [Google Scholar]

- Kaufmann, J.; Winnefeld, F. Influence of addition of ultrafine cement on the rheological properties and strength of Portland cement paste. In Innovations and Developments in Concrete Materials and Construction, Proceedings of the International Conference Held at the University of Dundee, Scotland, UK, 9–11 September 2002; Thomas Telford Publishing: London, UK, 2002; pp. 827–836. [Google Scholar]

- Bayramov, F.; Tasdemir, M.; Ilki, A.; Yerlikaya, M. Steel fibre reinforced concrete for heavy traffic load conditions. In Proceedings of the 9th International Symposium on Concrete Roads, Istambul, Turkey, 13–16 September 2004; pp. 3–6. [Google Scholar]

- Andersen, V.; Einarsrud, K.E.; Rasouli, A.; Tranell, G. Silica Fume Formation in Different Gas Atmospheres. Ind. Eng. Chem. Res. 2023, 62, 4246–4259. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Pearson: London, UK, 2004; Volume 4. [Google Scholar]

- Dobiszewska, M.; Schindler, A.K.; Pichór, W. Mechanical properties and interfacial transition zone microstructure of concrete with waste basalt powder addition. Constr. Build. Mater. 2018, 177, 222–229. [Google Scholar] [CrossRef]

- Adamu, M.; Ibrahim, Y.E.; Al-Atroush, M.E.; Alanazi, H. Mechanical properties and durability performance of concrete containing calcium carbide residue and nano silica. Materials 2021, 14, 6960. [Google Scholar] [CrossRef]

- Mazloom, M.; Ramezanianpour, A.; Brooks, J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Karaoğlu, S.; Mermerdaş, K. Strength, permeability and shrinkage cracking of silica fume and metakaolin concretes. Constr. Build. Mater. 2012, 34, 120–130. [Google Scholar] [CrossRef]

- Shi, H.-s.; Xu, B.-w.; Zhou, X.-c. Influence of mineral admixtures on compressive strength, gas permeability and carbonation of high performance concrete. Constr. Build. Mater. 2009, 23, 1980–1985. [Google Scholar] [CrossRef]

- Behnood, A.; Ziari, H. Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cem. Concr. Compos. 2008, 30, 106–112. [Google Scholar] [CrossRef]

- Wong, H.; Razak, H.A. Efficiency of calcined kaolin and silica fume as cement replacement material for strength performance. Cem. Concr. Res. 2005, 35, 696–702. [Google Scholar] [CrossRef]

- Barger, G.S.; Hill, R.L.; Ramme, B.W.; Bilodeau, A.; Hooton, R.D.; Ravina, D.; Bury, M.A.; Humphrey, H.J.; Reddy, D.; Carrasquillo, R.L. Use of Fly Ash in Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Papadakis, V.G. Effect of fly ash on Portland cement systems: Part I. Low-calcium fly ash. Cem. Concr. Res. 1999, 29, 1727–1736. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.; Lam, L.; Lin, Z. Activation of fly ash/cement systems using calcium sulfate anhydrite (CaSO4). Cem. Concr. Res. 2001, 31, 873–881. [Google Scholar] [CrossRef]

- Russell, M.; Basheer, P.; Rao, J. Potential use of spent mushroom compost ash as an activator for pulverised fuel ash. Constr. Build. Mater. 2005, 19, 698–702. [Google Scholar] [CrossRef]

- Zhang, J.; Lv, T.; Hou, D.; Dong, B. Synergistic effects of fly ash and MgO expansive additive on cement paste: Microstructure and performance. Constr. Build. Mater. 2023, 371, 130740. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Li, Z. Utilization of fly ash cenosphere as lightweight filler in cement-based composites–A review. Constr. Build. Mater. 2017, 144, 373–384. [Google Scholar] [CrossRef]

- Khan, M. Permeation of high performance concrete. J. Mater. Civ. Eng. 2003, 15, 84–92. [Google Scholar] [CrossRef]

- Yazıcı, H. The effect of curing conditions on compressive strength of ultra high strength concrete with high volume mineral admixtures. Build. Environ. 2007, 42, 2083–2089. [Google Scholar] [CrossRef]

- Demirboğa, R. Thermal conductivity and compressive strength of concrete incorporation with mineral admixtures. Build. Environ. 2007, 42, 2467–2471. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Azmee, N.; Abbas, Y.M.; Shafiq, N.; Fares, G.; Osman, M.; Iqbal Khan, M. Enhancing the microstructure and sustainability of ultra-high-performance concrete using ultrafine calcium carbonate and high-volume fly ash under different curing regimes. Sustainability 2021, 13, 3900. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Khan, M.I. Optimization of Arabian-Shield-Based Natural Pozzolan and Silica Fume for High-Performance Concrete Using Statistical Design of Experiments. Adv. Civ. Eng. 2021, 2021, 5512666. [Google Scholar] [CrossRef]

- Abbas, Y. Simplex-lattice strength and permeability optimization of concrete incorporating silica fume and natural pozzolan. Constr. Build. Mater. 2018, 168, 199–208. [Google Scholar] [CrossRef]

- Khan, M.I.; Abbas, Y.M. Curing optimization for strength and durability of silica fume and fuel ash concretes under hot weather conditions. Constr. Build. Mater. 2017, 157, 1092–1105. [Google Scholar] [CrossRef]

- Khan, M.I.; Abbas, Y.M. Robust Extreme Gradient Boosting Regression Model for Compressive Strength Prediction of Blast Furnace Slag and Fly Ash Concrete. Mater. Today Commun. 2023, 35, 105793. [Google Scholar] [CrossRef]

- Bouzoubaa, N.; Bilodeau, A.; Sivasundaram, V.; Fournier, B.; Golden, D.M. Development of ternary blends for high-performance concrete. Mater. J. 2004, 101, 19–29. [Google Scholar] [CrossRef]

- Özyıldırım, C.; Halstead, W. Improved concrete quality with combinations of fly ash and silica fume. ACI Mater. J. 1994, 91, 587–594. [Google Scholar]

- Ronne, M. Effect of condensed silica fume and fly ash on compressive strength development of concrete. Spec. Publ. 1989, 114, 175–190. [Google Scholar]

- Abed, M.; Nemes, R. Long-term durability of self-compacting high-performance concrete produced with waste materials. Constr. Build. Mater. 2019, 212, 350–361. [Google Scholar] [CrossRef]

- Bakker, R. Application and Advantages of Blended Cement Concretes; Technical Note; QCL Group: Newstead, Australia, 1999. [Google Scholar]

- Moosberg-Bustnes, H.; Lagerblad, B.; Forssberg, E. The function of fillers in concrete. Mater. Struct. 2004, 37, 74–81. [Google Scholar] [CrossRef]

- Nehdi, M. Microfiller Effect on Rheology, Microstructure, and Mechanical Properties of High-Performance Concrete. Ph.D. Thesis, Civil Engineering Department, National Library of Canada = Bibliothèque nationale du Canada, Ottawa, The University of British Columbia, Ottawa, ON, Canada, 1999. [Google Scholar]

- Fennis, S. Design of Ecological Concrete by Particle Packing Optimization. Ph.D. Thesis, University of Technology, Delft, The Netherlands, 2011. [Google Scholar]

- Vogt, C. Ultrafine Particles in Concrete: Influence of Ultrafine Particles on Concrete Properties and Application to Concrete Mix Design. Ph.D. Thesis, School of Architecture and the Built Environment, Royal Institute of Technology, Stockholm, Sweden, 2010. [Google Scholar]

- Cyr, M.; Lawrence, P.; Ringot, E. Mineral admixtures in mortars: Quantification of the physical effects of inert materials on short-term hydration. Cem. Concr. Res. 2005, 35, 719–730. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Effect of particle-size distribution and specific surface area of different binder systems on packing density and flow characteristics of cement paste. Cem. Concr. Compos. 2017, 78, 120–131. [Google Scholar] [CrossRef]

- Yousuf, S.; Sanchez, L.; Shammeh, S. The use of particle packing models (PPMs) to design structural low cement concrete as an alternative for construction industry. J. Build. Eng. 2019, 25, 100815. [Google Scholar] [CrossRef]

- Kosmatka, S.H.; Kerkhoff, B.; Panarese, W. Fly ash, slag, silica fume, and natural pozzolans. Des. Control. Concr. Mix. 2002, 13, 57–72. [Google Scholar]

- Zagar, L. Methods of determination of pore structure, permeability and diffusion. In Proceedings of the RILEM/IUPAC International Symposium on the Pore Structure and Properties of Materials, Prague, Czech Republic, 18–21 September 1973; pp. C249–C278. [Google Scholar]

- Cheerarot, R.; Tangpagasit, J.; Jaturapitakkul, C. Compressive strength of mortars due to pozzolanic reaction of fly ash. Spec. Publ. 2004, 221, 411–426. [Google Scholar] [CrossRef]

- Jaturapitakkul, C.; Tangpagasit, J.; Songmue, S.; Kiattikomol, K. Filler effect and pozzolanic reaction of ground palm oil fuel ash. Constr. Build. Mater. 2011, 25, 4287–4293. [Google Scholar] [CrossRef]

- Khan, M.; Abbas, Y.; Fares, G. Review of high and ultrahigh performance cementitious composites incorporating various combinations of fibers and ultrafines. J. King Saud Univ.-Eng. Sci. 2017, 29, 339–347. [Google Scholar] [CrossRef]

- Wang, X.; Wu, D.; Zhang, J.; Yu, R.; Hou, D.; Shui, Z. Design of sustainable ultra-high performance concrete: A review. Constr. Build. Mater. 2021, 307, 124643. [Google Scholar] [CrossRef]

- Kirthika, S.; Singh, S.; Chourasia, A. Alternative fine aggregates in production of sustainable concrete-A review. J. Clean. Prod. 2020, 268, 122089. [Google Scholar] [CrossRef]

- Loland, K.; Hustad, T. Report 2 Mechanical Properties; FCB/SINTEF: Trondheim, Norway, 1981. [Google Scholar]

- Sellevold, E.J.; Nilsen, T. Condensed silica fume in concrete: A world review. In Proceedings of the Supplementary Cementing Materials for Concrete CANMET, Ottawa, ON, Canada, 1987; pp. 165–243. [Google Scholar]

- Newman, J.; Choo, B.S. Advanced Concrete Technology 2: Concrete Properties; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Benli, A.; Karataş, M.; Bakir, Y. An experimental study of different curing regimes on the mechanical properties and sorptivity of self-compacting mortars with fly ash and silica fume. Constr. Build. Mater. 2017, 144, 552–562. [Google Scholar] [CrossRef]

- Lamond, J.F.; Pielert, J.H. Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM International: West Conshohocken, PA, USA, 2006; Volume 169. [Google Scholar]

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J. Advances in understanding hydration of Portland cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Abrams, L. Properties of Concrete; Pitman Publishing Ltd.: London, UK, 1919. [Google Scholar]

- Oluokun, F.A. Fly ash concrete mix design and the water-cement ratio law. Mater. J. 1994, 91, 362–371. [Google Scholar] [CrossRef]

- Abd Elaty, M.A.A. Compressive strength prediction of Portland cement concrete with age using a new model. HBRC J. 2014, 10, 145–155. [Google Scholar] [CrossRef]

- Taerwe, L. Constitutive Modelling of High Strength/High Performance Concrete: State-of-Art Report; Fédération Internationale du Béton (FIB): Los Santos, SA, USA, 2008; Volume 42. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Burg, R.; Ost, B. Engineering Properties of Commercially Available High-Strength Concretes (Including Three-Year Data); The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 1994. [Google Scholar]

- Hu, J.; Ge, Z.; Wang, K. Influence of cement fineness and water-to-cement ratio on mortar early-age heat of hydration and set times. Constr. Build. Mater. 2014, 50, 657–663. [Google Scholar] [CrossRef]

- Qi, T.; Zhou, W.; Liu, X.; Wang, Q.; Zhang, S. Predictive hydration model of Portland cement and its main minerals based on dissolution theory and water diffusion theory. Materials 2021, 14, 595. [Google Scholar] [CrossRef]

- Shen, D.; Wang, X.; Wu, S. Determining hydration mechanisms for initial fall and main hydration peak in tricalcium silicate hydration using a two-scale hydration simulation model. Cem. Concr. Res. 2022, 156, 106763. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Mehta, P.K. Chemical and physical effects of silica fume on the mechanical behavior of concrete. Mater. J. 1989, 86, 609–614. [Google Scholar] [CrossRef]

- Goldman, A.; Bentur, A. Properties of cementitious systems containing silica fume or nonreactive microfillers. Adv. Cem. Based Mater. 1994, 1, 209–215. [Google Scholar] [CrossRef]

- Ibrahim, R.K.; Hamid, R.; Taha, M. Strength and Microstructure of Mortar Containing Nanosilica at High Temperature. ACI Mater. J. 2014, 111, 163–170. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of ferrosilicon and silica fume on mechanical, durability, and microstructure characteristics of ultra high-performance concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

| Oxide Composition (%) | PC | SF | MQF |

|---|---|---|---|

| SiO2 | 20.2 | 93.2 | 99.5 |

| Al2O3 | 5.49 | 0.2 | 0.20 |

| Fe2O3 | 4.12 | 0.03 | 0.03 |

| CaO | 65.43 | 0.72 | 0.01 |

| MgO | 0.71 | 0.14 | - |

| Na2Oeq | 0.26 | 0.07 | - |

| SO3 | 2.61 | <0.01 | - |

| Loss on ignition (%) | 1.38 | 5.4 | - |

| Specific gravity | 3.14 | 2.27 | - |

| Fineness (m2/kg) | 373 | 19,000 | 16,500 |

| Material | Specific Gravity | Absorption, % | Unit Weight, kg/m3 |

|---|---|---|---|

| NFA | 2.63 | 0.77 | 1725 |

| CFA | 2.68 | 1.52 | 1552 |

| CA | 2.65 | 1.45 | 1570 |

| Sr. No. | Mix ID | w/b | Fine Powders | |||

|---|---|---|---|---|---|---|

| PC | SF | MQF | Total | |||

| (kg/m3) | ||||||

| 1 | CTRL-25 | 0.25 | 550 | - | - | 550 |

| 2 | SF08-25 | 506 | 44.0 | - | 550 | |

| 3 | SF10-25 | 405 | 45.0 | - | 550 | |

| 4 | SF12-25 | 484 | 66.0 | - | 550 | |

| 5 | MQF05-25 | 523 | - | 27.5 | 550 | |

| 6 | MQF08-25 | 506 | - | 44.0 | 550 | |

| 7 | MQF10-25 | 405 | - | 45.0 | 450 | |

| 8 | MQF15-25 | 468 | - | 82.5 | 550 | |

| 9 | MQF25-25 | 413 | - | 137.5 | 550 | |

| 10 | MQF35-25 | 358 | - | 192.5 | 550 | |

| 11 | CTRL-30 | 0.30 | 500 | - | - | 500 |

| 12 | SF08-30 | 460 | 40.0 | - | 500 | |

| 13 | SF10-30 | 360 | 40.0 | - | 400 | |

| 14 | SF12-30 | 440 | 60.0 | - | 500 | |

| 15 | MQF05-30 | 475 | - | 25.0 | 500 | |

| 16 | MQF08-30 | 460 | - | 40.0 | 500 | |

| 17 | MQF10-30 | 360 | - | 40.0 | 400 | |

| 18 | MQF15-30 | 425 | - | 75.0 | 500 | |

| 19 | MQF25-30 | 375 | - | 125.0 | 500 | |

| 20 | MQF35-30 | 325 | - | 175.0 | 500 | |

| 21 | CTRL-35 | 0.35 | 450.0 | - | - | 450 |

| 22 | SF08-35 | 414.0 | 36.0 | - | 450 | |

| 23 | SF10-35 | 495.0 | 55.0 | - | 550 | |

| 24 | SF12-35 | 352.0 | 48.0 | - | 400 | |

| 25 | MQF05-35 | 427.5 | - | 22.5 | 450 | |

| 26 | MQF08-35 | 414.0 | - | 36.0 | 450 | |

| 27 | MQF10-35 | 495.0 | - | 55.0 | 550 | |

| 28 | MQF15-35 | 382.5 | - | 67.5 | 450 | |

| 29 | MQF25-35 | 337.5 | - | 112.5 | 450 | |

| 30 | MQF35-35 | 292.5 | - | 157.5 | 450 | |

| 31 | CTRL-40 | 0.40 | 400.0 | - | - | 400 |

| 32 | SF08-40 | 368.0 | 32.0 | - | 400 | |

| 33 | SF10-40 | 450.0 | 50.0 | - | 500 | |

| 34 | SF12-40 | 396.0 | 54.0 | - | 450 | |

| 35 | MQF05-40 | 380.0 | - | 20.0 | 400 | |

| 36 | MQF08-40 | 368.0 | - | 32.0 | 400 | |

| 37 | MQF10-40 | 450.0 | - | 50.0 | 500 | |

| 38 | MQF15-40 | 340.0 | - | 60.0 | 400 | |

| 39 | MQF25-40 | 300.0 | - | 100.0 | 400 | |

| 40 | MQF35-40 | 260.0 | - | 140.0 | 400 | |

| Test | Uniaxial Compression | Rapid Chloride-Ion Permeability |

|---|---|---|

| Specimen dimensions (mm) |

| Mix ID | Strength (MPa) | Porosity % | Permeability Coulombs | |||

|---|---|---|---|---|---|---|

| 7 d | 28 d | 180 d | 400 d | |||

| CTRL-25 | 70.4 | 89.9 | 93.0 | 96.0 | 7.9 | 1433.3 |

| MQF05-25 | 71.6 | 91.7 | 95.5 | 101.0 | 7.0 | 1169.0 |

| MQF08-25 | 74.1 | 93.4 | 97.4 | 105.3 | 6.3 | 893.7 |

| MQF10-25 | 68.8 | 85.8 | 90.9 | 95.8 | 5.4 | 699.3 |

| MQF15-25 | 64.7 | 80.8 | 88.7 | 96.1 | 4.7 | 460.0 |

| MQF25-25 | 51.6 | 77.3 | 86.7 | 93.9 | 3.0 | 97.7 |

| MQF35-25 | 49.0 | 70.9 | 85.6 | 92.2 | 2.7 | 61.7 |

| SF08-25 | 66.7 | 91.8 | 94.4 | 97.1 | 4.2 | 332.7 |

| SF10-25 | 69.0 | 94.9 | 95.9 | 97.9 | 3.6 | 235.3 |

| SF12-25 | 72.1 | 98.1 | 98.2 | 99.3 | 3.1 | 150.0 |

| CTRL-30 | 60.4 | 77.7 | 83.9 | 88.6 | 8.1 | 2400.7 |

| MQF05-30 | 62.0 | 80.0 | 84.1 | 92.1 | 7.6 | 1502.3 |

| MQF08-30 | 63.4 | 81.4 | 87.1 | 96.9 | 7.0 | 885.7 |

| MQF10-30 | 57.4 | 75.4 | 82.4 | 89.9 | 6.2 | 753.3 |

| MQF15-30 | 53.1 | 68.8 | 78.6 | 88.7 | 5.9 | 553.3 |

| MQF25-30 | 44.1 | 67.5 | 75.5 | 84.7 | 5.2 | 167.0 |

| MQF35-30 | 41.9 | 61.5 | 72.3 | 81.4 | 4.3 | 89.7 |

| SF08-30 | 57.8 | 79.5 | 80.9 | 83.9 | 5.5 | 413.7 |

| SF10-30 | 59.4 | 81.7 | 85.2 | 86.9 | 5.3 | 332.7 |

| SF12-30 | 62.8 | 86.4 | 87.1 | 88.0 | 4.0 | 312.7 |

| CTRL-35 | 52.7 | 69.5 | 74.9 | 79.4 | 9.2 | 2814.7 |

| MQF05-35 | 53.8 | 71.8 | 80.8 | 84.4 | 8.8 | 1936.7 |

| MQF08-35 | 55.5 | 74.3 | 85.0 | 90.2 | 8.6 | 1406.0 |

| MQF10-35 | 50.5 | 63.8 | 75.3 | 78.5 | 8.0 | 1125.0 |

| MQF15-35 | 49.3 | 57.8 | 68.0 | 74.1 | 7.5 | 997.5 |

| MQF25-35 | 40.0 | 54.6 | 63.1 | 72.1 | 6.6 | 544.7 |

| MQF35-35 | 34.3 | 49.8 | 56.4 | 65.9 | 6.5 | 296.7 |

| SF08-35 | 54.1 | 73.6 | 75.0 | 80.1 | 6.7 | 523.0 |

| SF10-35 | 53.2 | 74.2 | 77.4 | 83.3 | 6.3 | 483.0 |

| SF12-35 | 56.7 | 77.8 | 78.4 | 75.5 | 6.1 | 423.7 |

| CTRL-40 | 46.7 | 59.2 | 61.8 | 65.4 | 11.3 | 3437.0 |

| MQF05-40 | 48.0 | 61.0 | 66.2 | 71.1 | 10.2 | 2453.0 |

| MQF08-40 | 49.9 | 63.2 | 69.2 | 76.1 | 9.6 | 1886.7 |

| MQF10-40 | 43.6 | 53.7 | 60.4 | 65.7 | 8.9 | 1404.0 |

| MQF15-40 | 39.7 | 49.6 | 58.7 | 64.2 | 8.5 | 1080.3 |

| MQF25-40 | 31.6 | 44.8 | 53.8 | 60.8 | 8.0 | 847.0 |

| MQF35-40 | 28.9 | 42.8 | 50.5 | 60.0 | 7.2 | 323.0 |

| SF08-40 | 47.8 | 64.2 | 67.8 | 72.9 | 7.4 | 851.3 |

| SF10-40 | 48.0 | 65.6 | 69.5 | 74.5 | 7.1 | 782.7 |

| SF12-40 | 51.0 | 69.9 | 70.9 | 71.8 | 6.9 | 740.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.I.; Abbas, Y.M.; Fares, G. Enhancing Cementitious Concrete Durability and Mechanical Properties through Silica Fume and Micro-Quartz. Sustainability 2023, 15, 15913. https://doi.org/10.3390/su152215913

Khan MI, Abbas YM, Fares G. Enhancing Cementitious Concrete Durability and Mechanical Properties through Silica Fume and Micro-Quartz. Sustainability. 2023; 15(22):15913. https://doi.org/10.3390/su152215913

Chicago/Turabian StyleKhan, Mohammad Iqbal, Yassir M. Abbas, and Galal Fares. 2023. "Enhancing Cementitious Concrete Durability and Mechanical Properties through Silica Fume and Micro-Quartz" Sustainability 15, no. 22: 15913. https://doi.org/10.3390/su152215913

APA StyleKhan, M. I., Abbas, Y. M., & Fares, G. (2023). Enhancing Cementitious Concrete Durability and Mechanical Properties through Silica Fume and Micro-Quartz. Sustainability, 15(22), 15913. https://doi.org/10.3390/su152215913