Pathways and Interactions for Integrating Mechanisation into Sustainable Agricultural Production: The Case of Rice Production in Asutsuare, Ghana

Abstract

:1. Introduction

Background

2. Materials and Methods

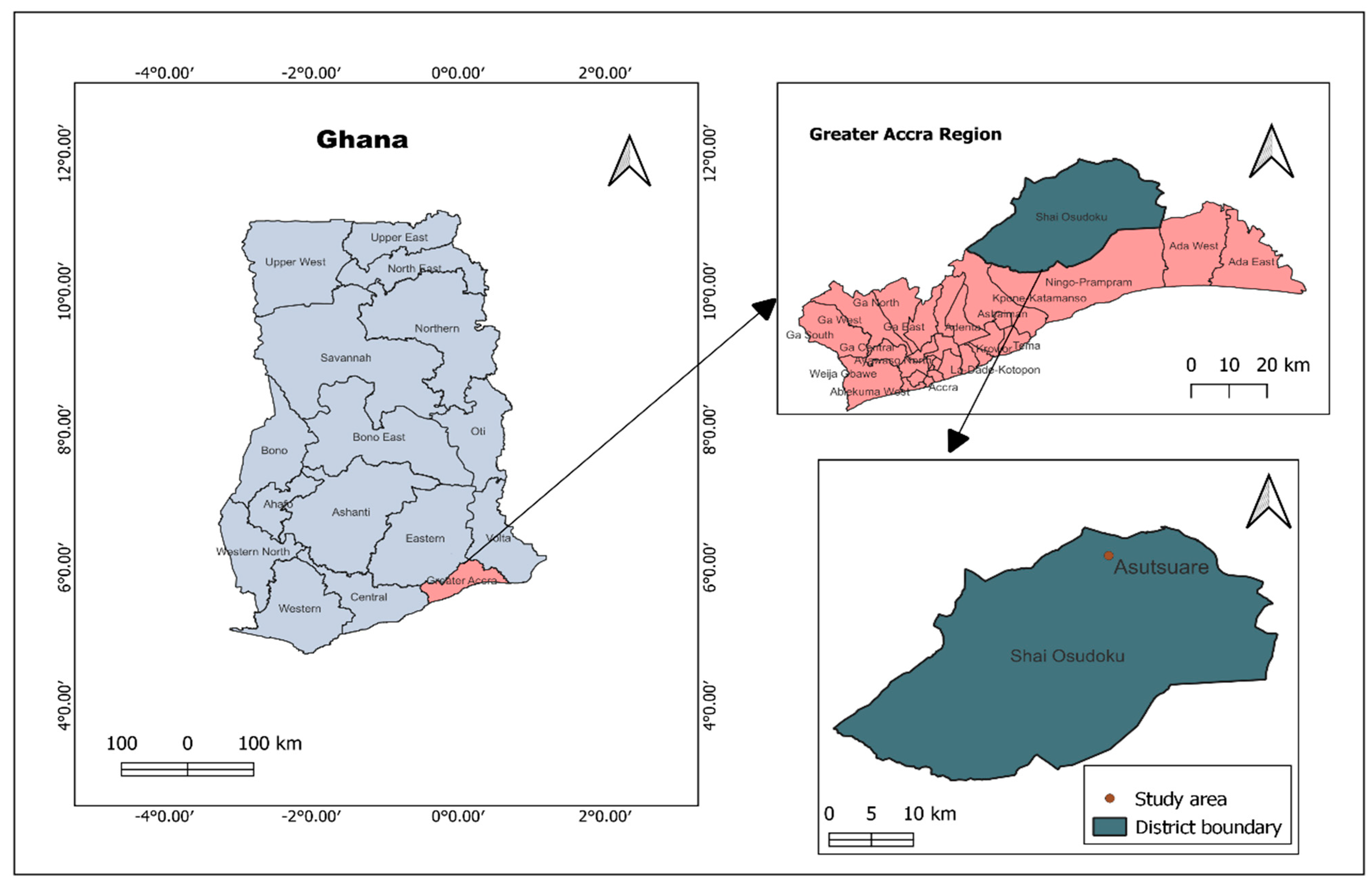

2.1. Study Area

2.2. Data Sources and Sampling Strategy

2.3. Ethics Consideration

2.4. Data Management and Analysis

2.5. Farm Power and Machinery Selection

2.6. Benefit Costs Analysis

3. Results and Discussion

3.1. Descriptive Analysis of Household Demographic and Socioeconomic Characteristics

3.2. Available Machinery for Mechanising Smallholder Rice Production

3.3. Ownership Models

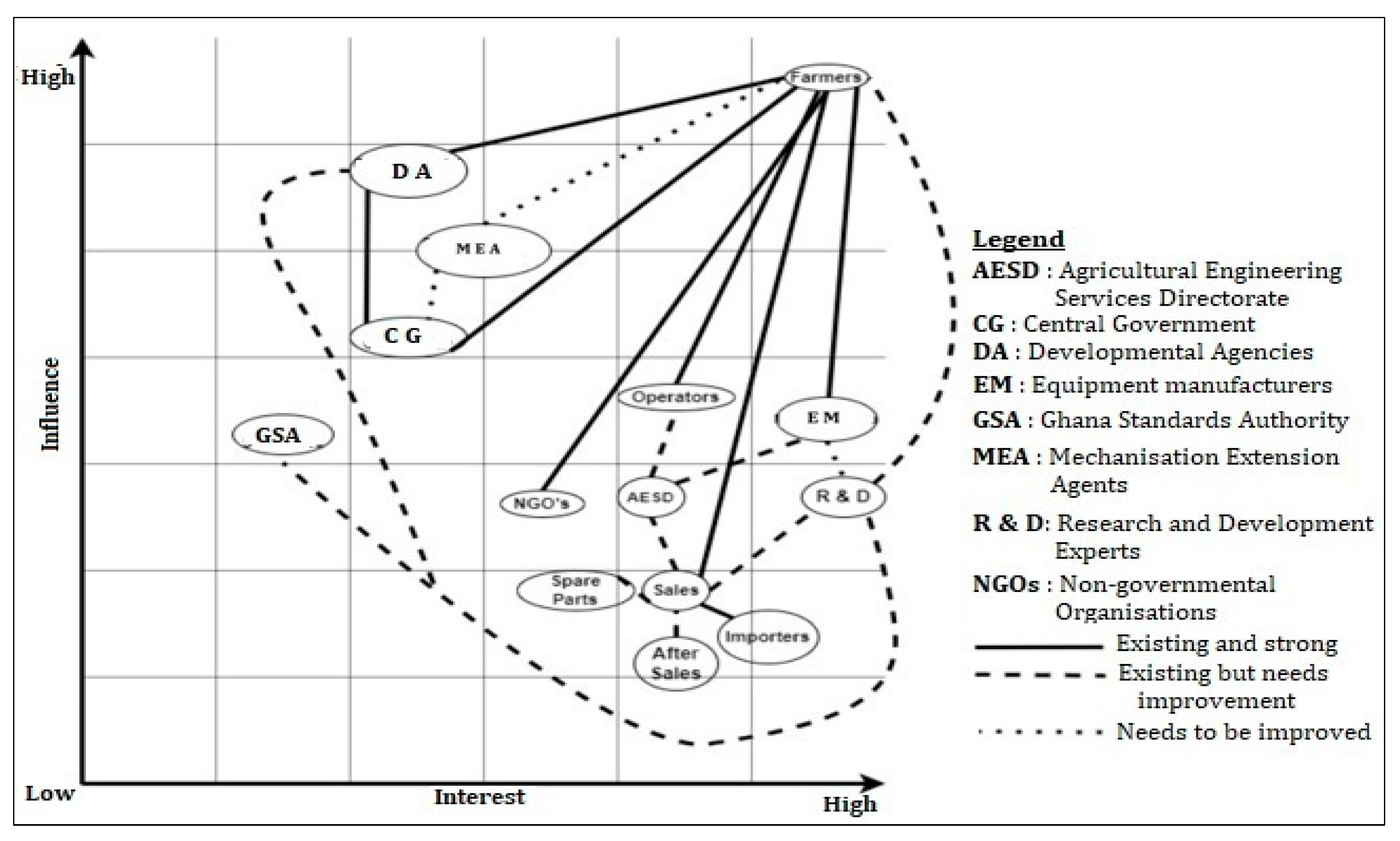

3.4. Possible Interactions to Promote Smallholder Mechanisation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Dijk, M.; Morley, T.; Rau, M.L.; Saghai, Y. A Meta-Analysis of Projected Global Food Demand and Population at Risk of Hunger for the Period 2010–2050. Nat. Food 2021, 2, 494–501. [Google Scholar] [CrossRef] [PubMed]

- Adesina, A.A. Unlocking Africa’s Agricultural Potential. In Sustaining Global Food Security: The Nexus of Science and Policy; Csiro Publishing: Clayton, Australia, 2019; p. 446. [Google Scholar]

- Tripathi, A.D.; Mishra, R.M.; Maurya, K.K.; Singh, R.B.; Wilson, D.W. Tripathi_et Al_2019.Pdf. In The Role of Functional Food Security in Global Health; Singh, R.B., Watson, R.R., Takahashi, T., Eds.; Elsevier: London, UK, 2019; pp. 3–24. [Google Scholar]

- IPCC. Climate Change 2022: Impacts, Adaptation and Vulnerability; IPCC: Geneva, Switzerland, 2022.

- FAO. FAO Strategy on Climate Change 2022–2031; FAO: Rome, Italy, 2022. [Google Scholar]

- FAO; AUC. Sustainable Agricultural Mechanization—A Framework for Africa; Addis Ababa. 2018. Available online: https://reliefweb.int/report/world/sustainable-agricultural-mechanization-framework-africa (accessed on 3 February 2021).

- Gliessman, S. Agroecology—The Ecology of Sustainable Food Systems, 3rd ed.; Engles, E.W., Ed.; Taylor & Francis Group: Abingdon, UK, 2015; ISBN 9781000171990. [Google Scholar]

- Wezel, A.; Herren, B.G.; Kerr, R.B.; Barrios, E.; Gonçalves, A.L.R.; Sinclair, F. Agroecological Principles and Elements and Their Implications for Transitioning to Sustainable Food Systems. A Review. Agron. Sustain. Dev. 2020, 40, 40. [Google Scholar] [CrossRef]

- Lowder, S.K.; Sánchez, M.V.; Bertini, R. Which Farms Feed the World and Has Farmland Become More Concentrated? World Dev. 2021, 142, 105455. [Google Scholar] [CrossRef]

- OECD; FAO. OECD-FAO Agricultural Outlook 2021–2030. 2021. Available online: https://www.oecd-ilibrary.org/agriculture-and-food/oecd-fao-agricultural-outlook-2021-2030_19428846-en (accessed on 22 October 2023).

- FAO. Rice Production Share by Region. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 6 October 2023).

- Otsuka, K.; Mano, Y.; Takahashi, K. The Rice Green Revolution in Sub-Saharan Africa: Issues and Opportunities. In Rice Green Revolution in Sub-Saharan Africa; Otsuka, K., Mano, Y., Takahashi, K., Eds.; Springer Nature: Singapore, 2023; pp. 3–24. ISBN 978-981-19-8046-6. [Google Scholar]

- FAO. FAOSTATS. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 22 April 2019).

- Bagbara, T.; Urowole, P. Rice Production: A Priority to Ghana Ghana. 2023. Available online: https://mofa.gov.gh/site/media-centre/agricultural-articles/393-rice-production-a-priority-to-ghana (accessed on 23 February 2023).

- FAO. Crops and Climate Change Impact Briefs. Climate-Smart Agriculture for More Sustainable, Resilient, and Equitable Food Systems; FAO: Rome, Italy, 2022. [Google Scholar]

- Angelucci, F.; Asante-Poku, A.; Anaadumba, P. Analysis of Incentives and Disincentives for Rice in Ghana; FAO: Rome, Italy, 2013. [Google Scholar]

- Dorvlo, S.Y. Machinery Ownership Model for Effective Smallholder Mechanized Rice Production in Ghana. In Proceedings of the Conference on International Research on Food Security, Natural Resource Management and Rural Development, Prague, Czech Republic, 14–16 September 2022; p. 4. [Google Scholar]

- Mohidem, N.A.; Hashim, N.; Shamsudin, R.; Man, H.C. Rice for Food Security: Revisiting Its Production, Diversity, Rice Milling Process and Nutrient Content. Agriculture 2022, 12, 741. [Google Scholar] [CrossRef]

- MOFA. National Rice Development Strategy; MOFA: Accra, Ghana, 2009.

- Gliessman, S. Transforming Food Systems with Agroecology. Agroecol. Sustain. Food Syst. 2016, 40, 187–189. [Google Scholar] [CrossRef]

- FAO. Sustainable Food Systems—Concept and Framework; Food and Agriculture Organization of the United Nations: Rome, Italy, 2018; pp. 1–8. [Google Scholar]

- Friedrich, T.; Kienzle, J.; Kassam, A. Conservation Agriculture in Developing Countries: The Role of Mechanization. In Proceedings of the Club of Bologna Meeting on Innovation for Sustainable Mechanisation, Hanover, Germany, 2–8 November 2009. [Google Scholar]

- Soethoudt, H.; Broeze, J.; Axmann, H. The Impact of Mechanization in Smallholder Rice Production in Nigeria; CGIAR Research Program on Climate Change, Agriculture and Food Security (CCAFS): Wageningen, The Netherlands, 2021. [Google Scholar]

- Magezi, E.F.; Nakano, Y.; Sakurai, T. Mechanization in Tanzania: Impact of Tractorization on Intensification and Extensification of Rice Farming. In Rice Green Revolution in Sub-Saharan Africa; Otsuka, K., Mano, Y., Takahashi, K., Eds.; Springer Nature: Singapore, 2023; pp. 177–194. ISBN 978-981-19-8046-6. [Google Scholar]

- Diao, X.; Takeshima, H. Agricultural Mechanization in Ghana: Alternative Supply Models for Tractor Hiring Services. In An Evolving Paradigm of Agricultural Mechanization Development: How Much Can Africa Learn from Asia? International Food Policy Research Institute: Washington, DC, USA, 2020; pp. 377–400. [Google Scholar]

- Sims, B.G.; Kienzle, J. Farm Power and Mechanization for Small Farms in Sub-Saharan Africa; Agricultural and Food Engineering Technical Report 3; FAO: Rome, Italy, 2006; 21p. [Google Scholar]

- Sims, B.G.; Kienzle, J. Sustainable Agricultural Mechanization for Smallholders: What Is It and How Can We Implement It? Agriculture 2017, 7, 50. [Google Scholar] [CrossRef]

- Sims, B.G.; Kienzle, J. Making Mechanization Accessible to Smallholder Farmers in Sub-Saharan Africa. Environments 2016, 3, 11. [Google Scholar] [CrossRef]

- Peng, J.; Zhao, Z.; Liu, D. Impact of Agricultural Mechanization on Agricultural Production, Income, and Mechanism: Evidence from Hubei Province, China. Front. Environ. Sci. 2022, 10, 838686. [Google Scholar] [CrossRef]

- Van Loon, J.; Woltering, L.; Krupnik, T.J.; Baudron, F.; Boa, M.; Govaerts, B. Scaling Agricultural Mechanization Services in Smallholder Farming Systems: Case Studies from Sub-Saharan Africa, South Asia, and Latin America. Agric. Syst. 2020, 180, 102792. [Google Scholar] [CrossRef] [PubMed]

- Fonteh, M.F. Agricultural Mechanisation in Mali and Ghana: Strategies, Experiences and Lessons for Sustained Impacts; Agricultural and Food Engineering Working Document 8; FAO: Rome, Italy, 2010. [Google Scholar]

- Amanor, K.S.; Iddrisu, A. Old Tractors, New Policies and Induced Technological Transformation: Agricultural Mechanisation, Class Formation, and Market Liberalisation in Ghana. J. Peasant Stud. 2022, 49, 158–178. [Google Scholar] [CrossRef]

- Cossar, F.; Gollin, D. Small-Scale Farmers and Large Machines: The Why and How of Agricultural Mechanisation in Ghana; Policy Brief 33303. 2018. Available online: https://www.theigc.org/publications/small-scale-farmers-and-large-machines-why-and-how-agricultural-mechanisation-ghana (accessed on 23 February 2022).

- Huo, Y.; Ye, S.; Wu, Z.; Zhang, F.; Mi, G. Barriers to the Development of Agricultural Mechanization in the North and Northeast China Plains: A Farmer Survey. Agriculture 2022, 12, 287. [Google Scholar] [CrossRef]

- Wang, X.; Yamauchi, F.; Huang, J.; Rozelle, S. What Constrains Mechanization in Chinese Agriculture? Role of Farm Size and Fragmentation. China Econ. Rev. 2020, 62, 101221. [Google Scholar] [CrossRef]

- Diao, X.; Cossar, F.; Houssou, N.; Kolavalli, S. Mechanization in Ghana: Emerging Demand, and the Search for Alternative Supply Models. Food Policy 2014, 48, 168–181. [Google Scholar] [CrossRef]

- Benin, S.; Johnson, M.; Abokyi, E.; Ahorbo, G.; Jimah, K.; Nasser, G.; Owusu, V.; Taabazuing, J.; Tenga, A. Revisiting Agricultural Input and Farm Support Subsidies in Africa; IFPRI Discussion Paper. 2013, pp. 1–136. Available online: https://www.ifpri.org/publication/revisiting-agricultural-input-and-farm-support-subsidies-africa-case-ghana%E2%80%99s (accessed on 6 March 2023).

- Ogura, T.; Awuni, J.A.; Sakurai, T. The Impact of Quality-Based Pricing Scheme on Local Paddy Transactions in the Northern Region of Ghana. Jpn. J. Agric. Econ. 2020, 22, 147–151. [Google Scholar] [CrossRef] [PubMed]

- Kuwornu, J.K.M.; Apiors, E.K.; Kwadzo, G.T.-M. Access and Intensity of Mechanization: Empirical Evidence of Rice Farmers in Southern Ghana. Biol. Appl. Sci. 2017, 60, 1–18. [Google Scholar] [CrossRef]

- Apiors, E.K.; Kuwornu, J.K.; Kwadzo, G.T.-M. Effect of Mechanisation Use Intensity on the Productivity of Rice Farms in Southern Ghana. Acta Agric. Slov. 2016, 107, 439–451. [Google Scholar] [CrossRef]

- Diao, X.; Agandin, J.; Fang, P.; Scott, J.E.; Kufoalor, D.; Takeshima, H. Agricultural Mechanization in Ghana: Insights from a Recent Field Study; IFPRI: Accra, Ghana, 2018. [Google Scholar]

- MOFA. Ghana Agricultural Engineering Policy and Strategy; MOFA: Accra, Ghana, 2019.

- Srivastava, A.J.; Goering, C.E.; Rohrbach, R.P.; Buckmaster, D.R. Soil Tillage. In Engineering Principles of Agricultural Machines; ASABE: St. Joseph, MI, USA, 2006; pp. 169–230. [Google Scholar]

- ASABE. Agricultural Machinery Management Data; ASABE: St. Joseph, MI, USA, 2006. [Google Scholar]

- Edwards, W. Estimating Farm Machinery Repair Costs. 2015. Available online: https://www.extension.iastate.edu/agdm/crops/html/a3-29.html (accessed on 4 April 2023).

- Kay, R.D.; Edwards, W.M.; Duffy, P.A. Farm Management; McGraw-Hill: New York, NY, USA, 2020. [Google Scholar]

- Smith, D.W.; Sims, B.G.; O’Neill, D.H. Testing and Evaluation of Agricultural Machinery and Equipment—Principles and Practices; FAO: Rome, Italy, 1994; ISBN 9251034583. [Google Scholar]

- FAO. Building Sustainable Rice Value Chain in Africa and Asia via South-South and Triangular Cooperation. 2022. Available online: https://www.fao.org/partnerships/south-south-cooperation/news/news-article/en/c/1629753/ (accessed on 6 October 2023).

- Justice, S.; Biggs, S. The Spread of Smaller Engines and Markets in Machinery Services in Rural Areas of South Asia. J. Rural Stud. 2020, 73, 10–20. [Google Scholar] [CrossRef]

- Dahm, R.; Byrne, J.R.; Rogers, D.; Wride, M.A. How Research Institutions Can Foster Innovation. BioEssays 2021, 43, e2100107. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Statistics | |

|---|---|---|

| Male | Female | |

| Gender of respondents (%) | 64.5% | 35.5% |

| Average Age, Mean ± SD (years) | 48.0 ± 12.7 * | 47.7 ± 12.0 * |

| Education status (%) | ||

| No formal education | 6.3% | 15.8% |

| Primary | 11.1% | 21.9% |

| JHS | 50.2% | 49.1% |

| SHS | 24.2% | 13.2% |

| Post-Secondary | 1.0% | 0 |

| Tertiary | 7.2% | 0 |

| Farmland size, Mean ± SD (Ha) | 1.50 ± 2.04 | 0.71 ± 0.47 |

| Land tenure (%) | ||

| Leased | 74.4% * | 69.3% * |

| Owned (inherited) | 19.3% * | 20.2% * |

| Sharecrop arrangement | 1.0% * | 4.4% * |

| Field Activity | Current Machinery Being Used by Farmers | Type of Scale-Appropriate Machinery Proposed |

|---|---|---|

| Field preparation | Tractor-and-rotavator aggregate; power tiller; Tractor-and-plough aggregate; | 13 hp power tiller |

| Planting | Human labour | Drum seeder |

| Husbandry activities | Knapsack sprayer | Knapsack sprayer |

| Bird scaring | Human labour | Human labour |

| Harvesting | Combine harvester | Mini Combine |

| Threshing | Thresher |

| FHM | FOM | FOHM | COM | FOHM-2T | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| FHM-T | FHM-B | FOM-T | FOM-B | FOHM-T | FOHM-B | COM-T | COM-B | FOHM-2T | FOHM-2B | |

| Fixed Cost (GHS) | ||||||||||

| Cost of machinery | - | - | 85,000.00 | 85,000.00 | 85,000.00 | 85,000.00 | 4250.00 | 4250.00 | 85,000.00 | 85,000.00 |

| Recurring cost | ||||||||||

| Cost of farm input (GHS) | 6627.00 | 5956.00 | 4525.00 | 3854.00 | 4525.00 | 3854.00 | 4525.00 | 3854.00 | 9050.00 | 7708.00 |

| Total Cost (GHS) | 6627.00 | 5956.00 | 89,525.00 | 88,854.00 | 89,525.00 | 88,854.00 | 8775.00 | 8104.00 | 94,050.00 | 92,708.00 |

| Benefit–Cost (GHS) | ||||||||||

| Revenue from farm produce | 15,000.00 | 15,000.00 | 15,000.00 | 15,000.00 | 15,000.00 | 15,000.00 | 15,000.00 | 15,000.00 | 30,000.00 | 30,000.00 |

| Revenue from machinery hire | - | - | - | - | 2000.00 | 2000.00 | - | - | 2000.00 | 2000.00 |

| Total Benefits (GHS) | 15,000.00 | 15,000.00 | 15,000.00 | 15,000.00 | 17,000.00 | 17,000.00 | 15,000.00 | 15,000.00 | 32,000.00 | 32,000.00 |

| NPV at 10% discount rate | 51,448.46 | 55,571.46 | −12,908.39 | −8785.38 | −619.25 | 3503.75 | 60,500.70 | 64,623.71 | 63,745.09 | 71,991.10 |

| BCR at 10% discount rate | 2.26 | 2.52 | 0.88 | 0.91 | 0.99 | 1.03 | 2.91 | 3.35 | 1.48 | 1.58 |

| NPV at 28% discount rate | 27,370.64 | 29,564.08 | −32,164.35 | −29,970.90 | −25,626.51 | −23,433.07 | 30,921.59 | 33,115.03 | 8615.39 | 13,002.28 |

| BCR at 28% discount rate | 2.26 | 2.52 | 0.60 | 0.62 | 0.68 | 0.70 | 2.71 | 3.08 | 1.09 | 1.14 |

| Return on Investment (%) | 151 | 168 | 21 | 21 | 25 | 26 | 150 | 167 | 42 | 43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dorvlo, S.Y.; Mkandawire, E.; Roelich, K.; Jumbe, C.B. Pathways and Interactions for Integrating Mechanisation into Sustainable Agricultural Production: The Case of Rice Production in Asutsuare, Ghana. Sustainability 2023, 15, 15888. https://doi.org/10.3390/su152215888

Dorvlo SY, Mkandawire E, Roelich K, Jumbe CB. Pathways and Interactions for Integrating Mechanisation into Sustainable Agricultural Production: The Case of Rice Production in Asutsuare, Ghana. Sustainability. 2023; 15(22):15888. https://doi.org/10.3390/su152215888

Chicago/Turabian StyleDorvlo, Selorm Yaotse, Elizabeth Mkandawire, Katy Roelich, and Charles Blessings Jumbe. 2023. "Pathways and Interactions for Integrating Mechanisation into Sustainable Agricultural Production: The Case of Rice Production in Asutsuare, Ghana" Sustainability 15, no. 22: 15888. https://doi.org/10.3390/su152215888

APA StyleDorvlo, S. Y., Mkandawire, E., Roelich, K., & Jumbe, C. B. (2023). Pathways and Interactions for Integrating Mechanisation into Sustainable Agricultural Production: The Case of Rice Production in Asutsuare, Ghana. Sustainability, 15(22), 15888. https://doi.org/10.3390/su152215888