An Experimental Study to Mitigate Environmental Impacts by Transforming Waste Plastic Bags into Paving Blocks and Roof Tiles

Abstract

:1. Introduction

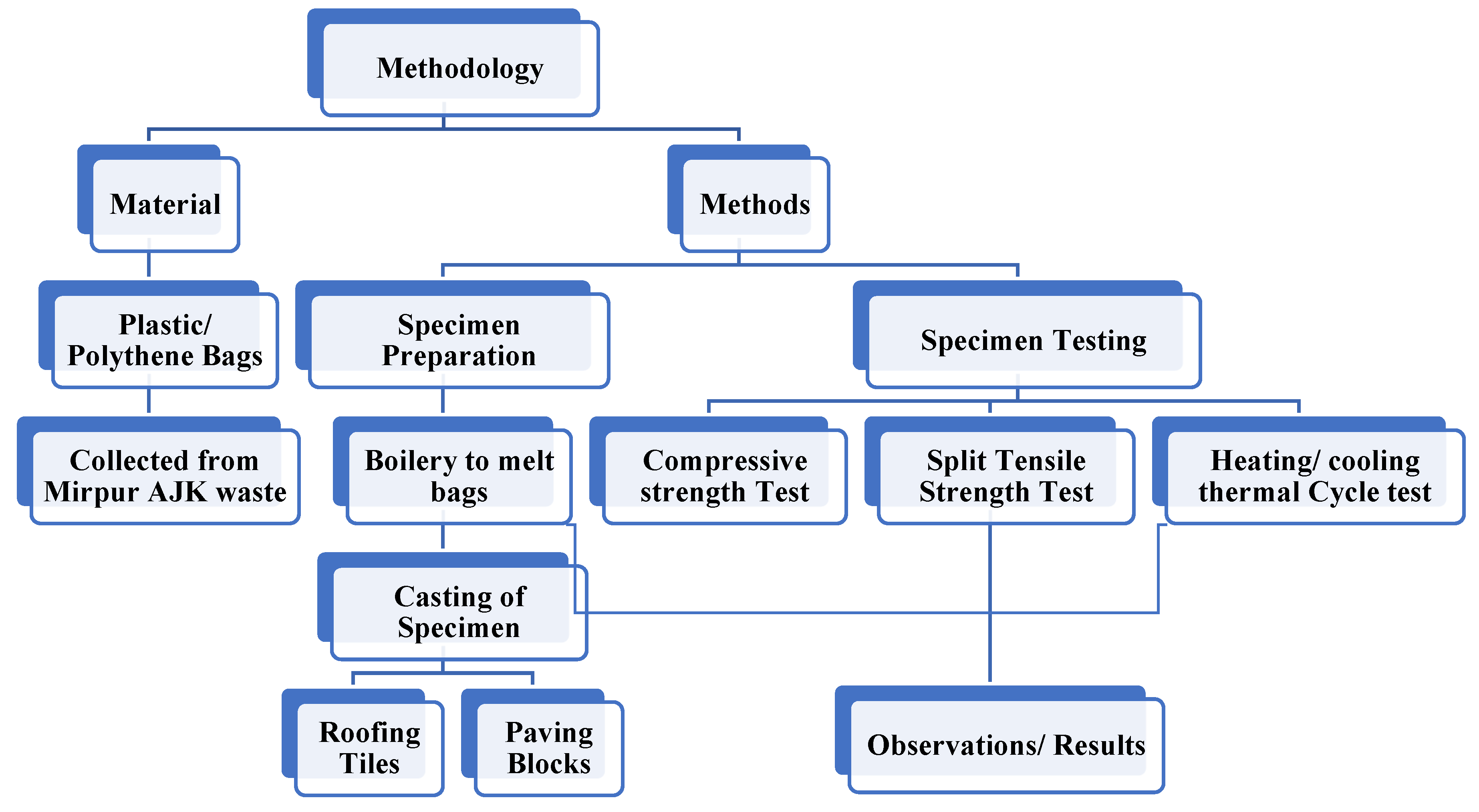

2. Materials and Methods

2.1. Plastic Bags

2.2. Apparatus

2.2.1. Boilery

2.2.2. Molds

2.2.3. Paving Block Molds

2.2.4. Roofing Tile Molds

2.2.5. Scoop

2.3. Casting Methodology

2.3.1. Casting Procedure

2.3.2. Casting of Paving Blocks

2.3.3. Casting of Roofing tiles

2.3.4. De-Molding

2.4. Testing Methodology

2.4.1. Compressive Strength Test

- C = Compressive strength of the specimen;

- P = Maximum load indicated by the testing machine;

- A = Area of the specimen.

2.4.2. Split Tensile Strength Test

- T = Split tensile strength;

- K = Correction factor for thickness;

- P = Maximum load indicated by the testing machine;

- L = Length of paver block;

- T = Thickness of paver block.

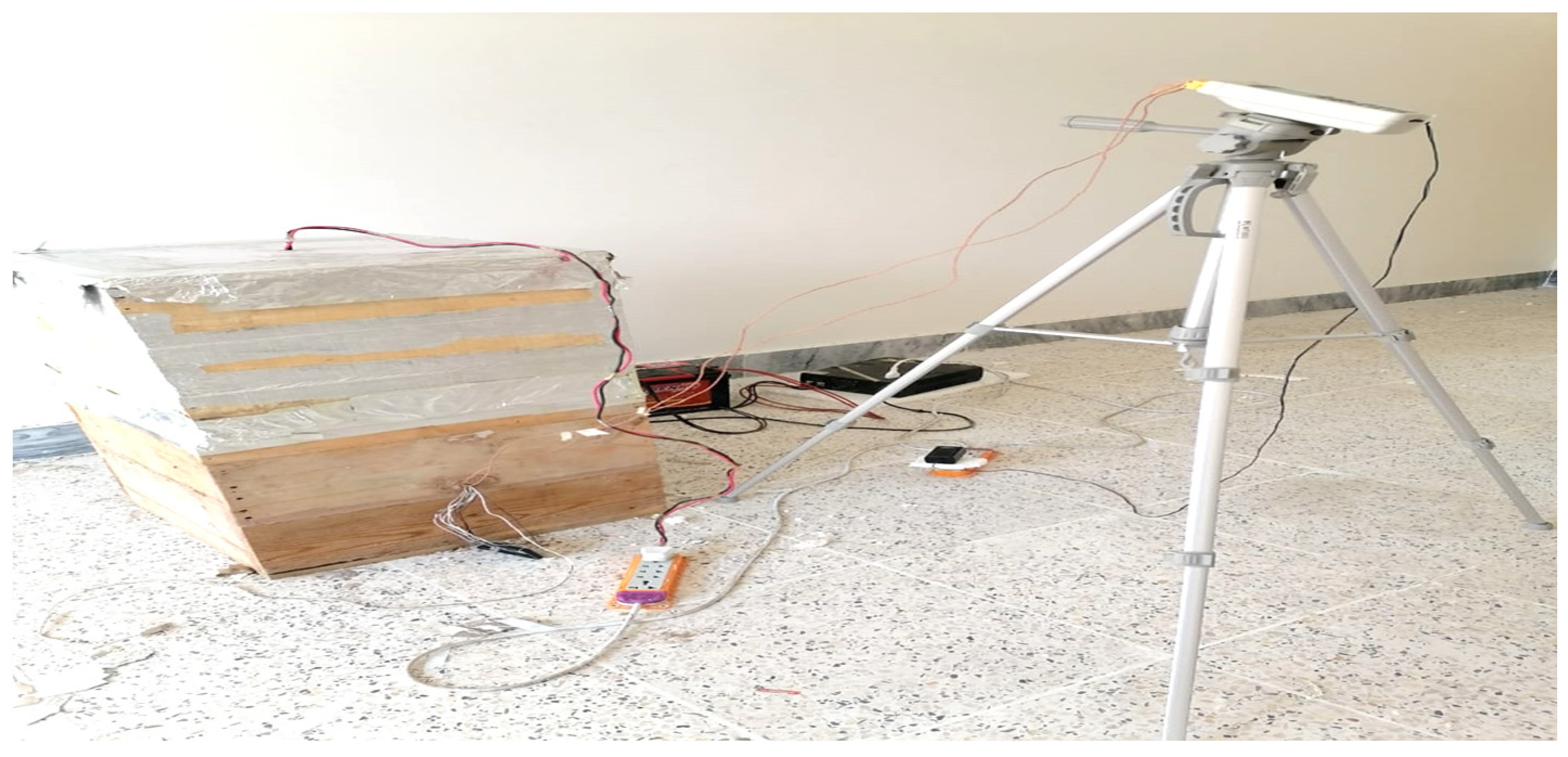

2.4.3. Heating/Cooling Thermal Cycle Test

- T = T2–T4;

- qL = K(ΔT);

- K = qL/ΔT.

2.4.4. Controlled Reinforced Slab

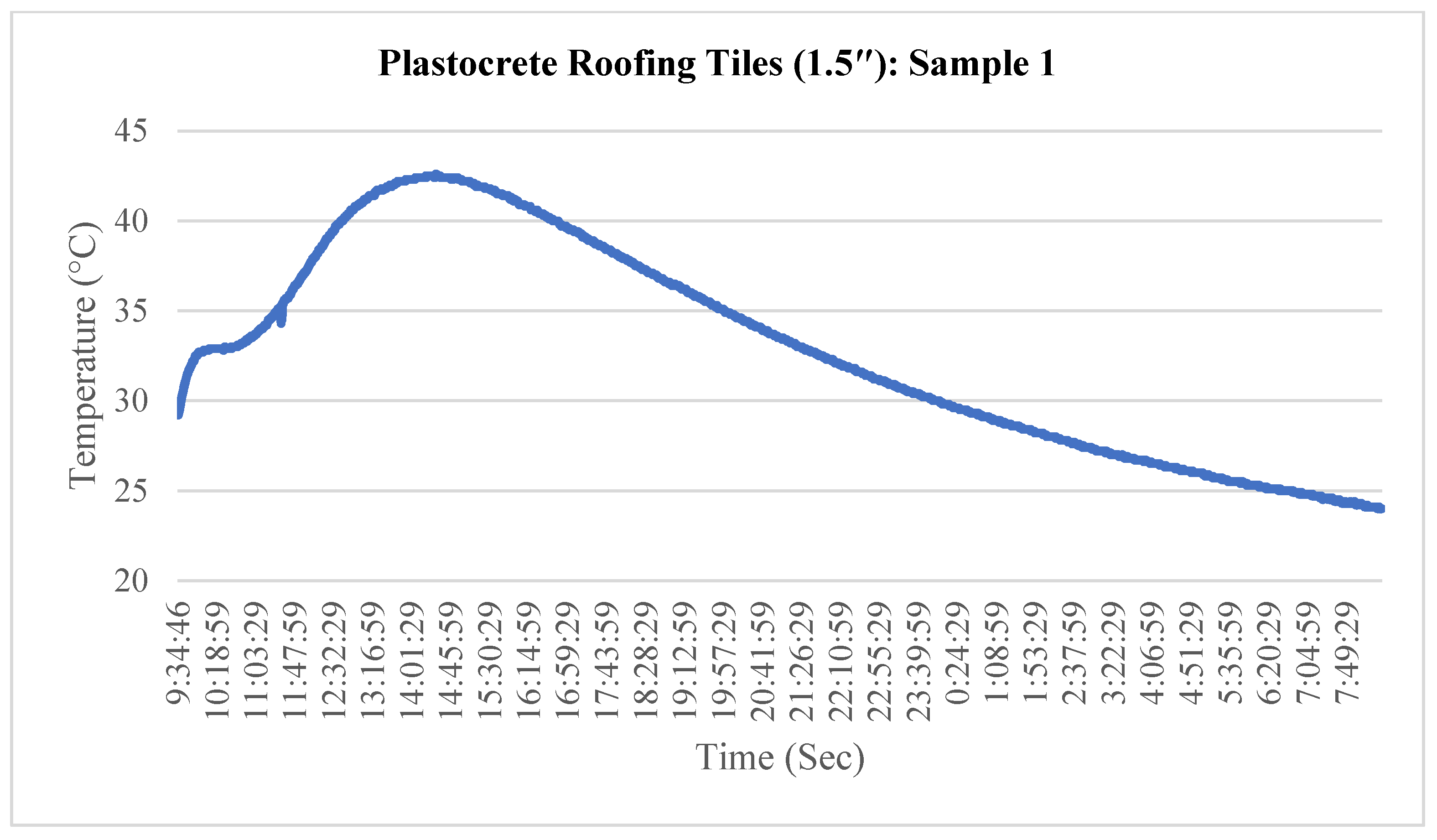

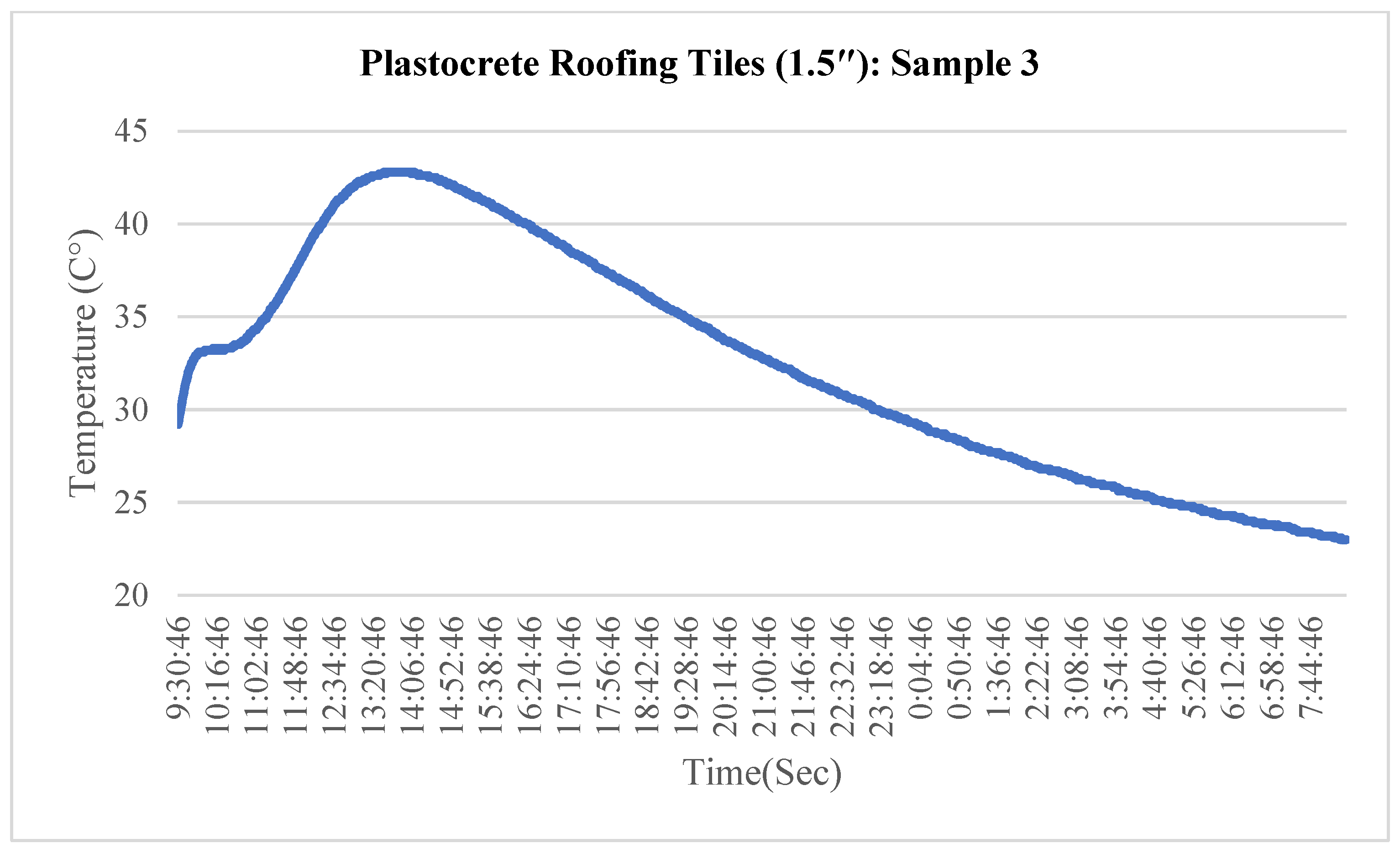

2.4.5. Plastocrete Roofing Tiles (1.5″)

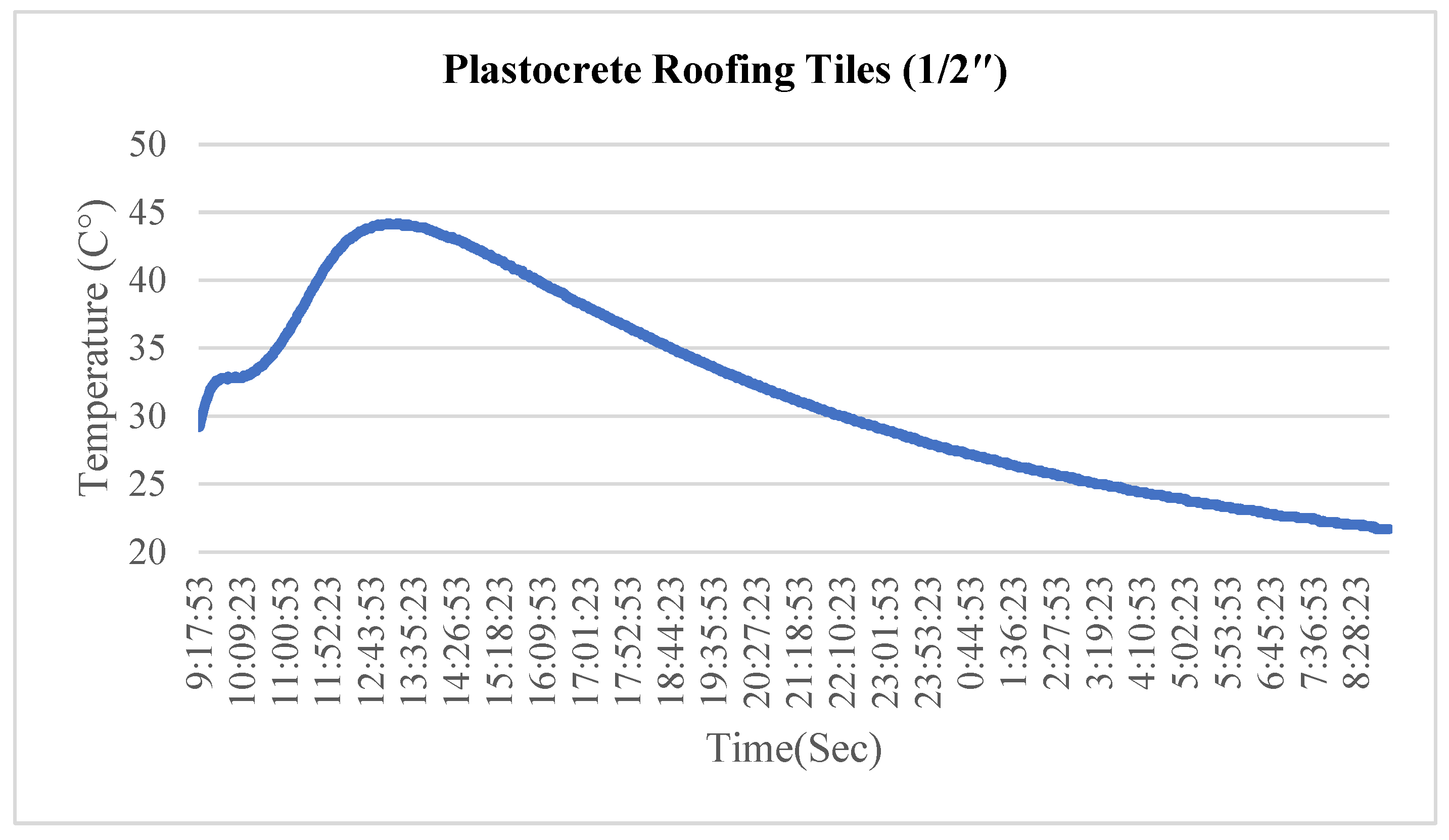

2.4.6. Plastocrete Roofing Tiles (1/2″)

3. Results

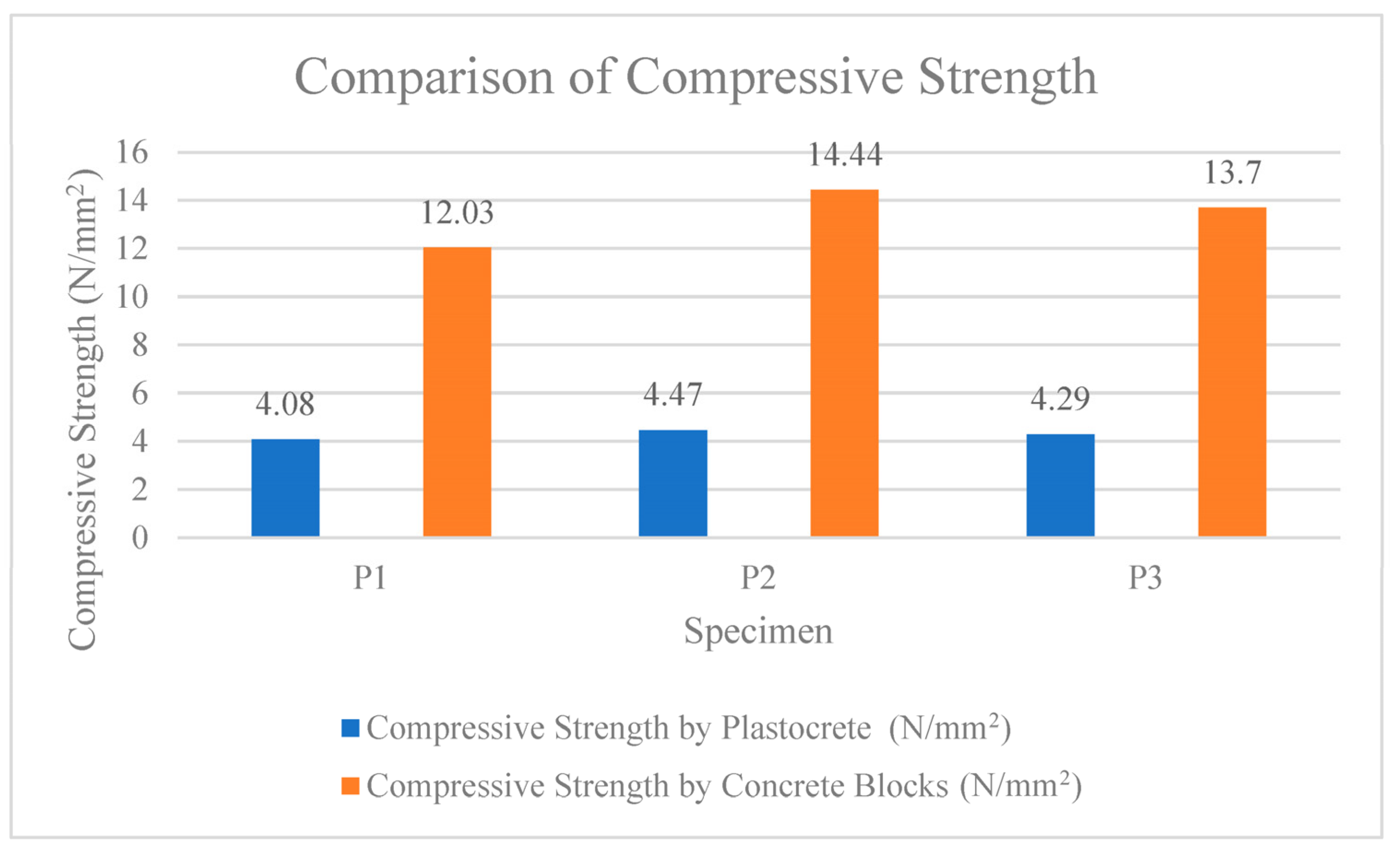

3.1. Compressive Strength

3.2. Split Tensile Strength

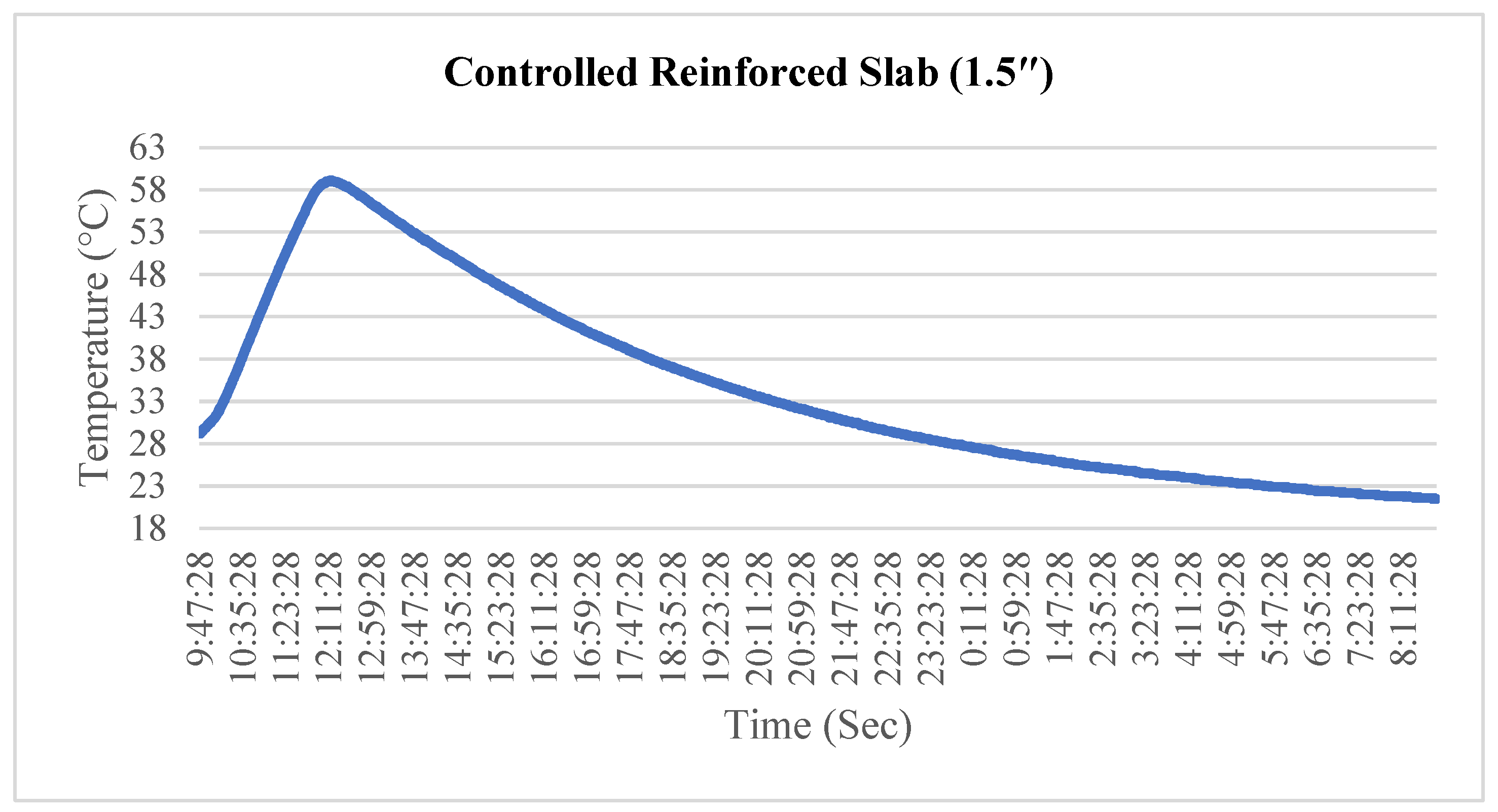

3.3. Thermal Cycle Test

3.3.1. Controlled Reinforced Slab (1.5″)

3.3.2. Plastocrete Roofing Tiles (1.5″)

3.3.3. Plastocrete Roofing Tiles (1/2″)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jassim, A.K. Recycling of polyethylene waste to product plastic cement. Sci. Direct. 2016, 8, 635–642. [Google Scholar]

- Using, S.; Bags, P. Essay on Plastic Bag for Students and Children. 2023. Available online: https://www.toppr.com/guides/essays/essay-on-plastic-bag/ (accessed on 23 September 2023).

- Ghude, A.; Kant, R.; Jaiswal, P.; Dhomne, A.; Thool, A.; Nandanwar, S.; Ghumde, N.; Bele, K. Utilization of Waste Plastic in Paver Blocks. Int. J. Adv. Res. Innov. Ideas Educ. 2019, 5, 2395–2396. [Google Scholar]

- Butt, A.Q.; Shangguan, D.; Waseem, M.; Haq, F.U.; Ding, Y.; Mukhtar, M.A.; Afzal, M.; Muhammad, A. Ascertainment of Hydropower Potential Sites Using Location Search Algorithm in Hunza River Basin, Pakistan. Water 2023, 15, 2929. [Google Scholar] [CrossRef]

- SMEDA. Pre-Feasibility Study Small and Medium Enterprises Development Authority; No. 081; SMEDA: Lahore, Pakistan, 2011. [Google Scholar]

- Shabbir, A. Pakistan Uses 50 Billion Plastic Bags Per Year: Report. 2019. Available online: https://propakistani.pk/2019/02/18/pakistan-uses-50-billion-plastic-bags-per-year-report/ (accessed on 23 September 2023).

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 4, 139–146. [Google Scholar] [CrossRef]

- Salmah, H.; Romisuhani, A.; Akmal, H. Properties of low-density polyethylene/palm kernel shell composites: Effect of polyethylene co-acrylic acid. J. Thermoplast. Compos. Mater. 2013, 26, 3–15. [Google Scholar] [CrossRef]

- Rahiman, A.; Danish; Nesrin, F.; Muhammed, M. Experimental Study of Utilization of Waste Plastic Bags in Pavement Blocks. Int. J. Sci. Eng. Res. 2019, 10, 120–134. [Google Scholar]

- Avinash, G.B.; Roja, A.P.; Santosh, M.R.; Puneetha Kumari, H.M. Utilisation of waste Plastic in manufacturing of Paver Blocks. Int. J. Innov. Res. Sci. Eng. Technol. 2019, 8, 6674–6680. Available online: http://www.ijirset.com/upload/2019/june/25_Utilisation.pdf (accessed on 23 September 2023).

- Laken, J.; Fowler, J.R. Harnessing Thermal Mass with Precast Concrete Construction. 2008. Available online: https://www.osti.gov/etdeweb/biblio/21161779 (accessed on 23 September 2023).

- Saeed, S.A.; Qadir, S.S.; Shaan, R.H. Thermal insulating concrete tiles. Int. J. Eng. Technol. 2012, 2, 1877–1880. [Google Scholar] [CrossRef]

- Liyanage, T.D. Development of Thermal Insulating Textiles. An Innovative IR Reflective Spacer Material; GRIN Verlag: München, Germany, 2014. [Google Scholar]

- Pacheco-Torgal, F.; Jalali, S. Earth construction: Lessons from the past for future eco-efficient construction. Constr. Build. Mater. 2012, 29, 222–230. [Google Scholar] [CrossRef]

- Weber, K.; Koyama, M.; Kraines, S.J.E. CO2-emissions reduction potentinal and costs of a decentralized energy system for providing electricity, cooling, and heating in an office building in Tokyo. Energy 2006, 31, 3041–3061. [Google Scholar] [CrossRef]

- Eker, H. Investigation of the usability of industrial mining wastes in agriculture. Front. Environ. Sci. 2023, 11. [Google Scholar] [CrossRef]

- Adiguzel, D.; Tuylu, S.; Eker, H. Utilization of tailings in concrete products: A review. Constr. Build. Mater. 2022, 360, 129574. [Google Scholar]

- Achitra, M.; Rajasree, R.A.; Pandit, R.V.; Saranya, V. Recycled Plastic and Coconut Fibre used in Concrete Paver Block. Int. J. Eng. Sci. Comput. 2018, 8, 16827–16830. [Google Scholar]

- Mohan, D.M.S.; Vignesh, J.; Iyyappan, P.; Suresh, C. Utilization of plastic bags in pavement blocks. Int. J. Pure Appl. Math. 2018, 119, 1407–1415. [Google Scholar]

- Tapkire, G.; Parihar, S.; Patil, P.; Kumavat, H.R. Recycled Plastic Used in Concrete Paver Block. Int. J. Res. Eng. Technol. 2014, 3, 33–35. [Google Scholar]

- Bindhulal. Utilization of waste plastic polyethylene bags in Bitumen. Int. J. Appl. Eng. Res. 2015, 10, 41738–41743. [Google Scholar]

- Surkar, A.; Bele, A.; Satone, A.; Gupta, P.; Astonkar, S.; Nahate, T.; Nikhar, M. Study on Effects of Plastic Waste in Paver blocks. Int. J. Innov. Res. Technol. 2021, 8, 989–995. [Google Scholar]

- Kazi, B.; Manihar, S.; Shaikh, S. Reusing Plastic Waste in Paver Blocks. Int. J. Eng. Res. Technol. 2021, 9, 39–41. [Google Scholar]

- Raju, S.; Amarnath, M.; Anandhakumar, M.; Elavarasan, K.; Naveenkumar, A. Utilisation of Waste Plastics As a Replacement of Cement in paver blocks. Int. J. Eng. Res. Technol. 2019, 6, 2947–2951. [Google Scholar]

- Ghuge, J.; Surale, S.; Patil, B.M.; Bhutekar, S.B. Utilization of Waste Plastic in Manufacturing of Paver Blocks. Int. Res. J. Eng. Technol. (IRJET) 2019, 6, 1967–1970. Available online: https://www.irjet.net/archives/V6/i4/IRJET-V6I4427.pdf (accessed on 23 September 2023).

- Shanmugavalli, B.; Gowtham, K.; Nalwin, P.J.; Moorthy, B.E. Reuse of Plastic Waste in Paver Blocks. Int. J. Eng. Res. 2017, V6, 313–315. [Google Scholar]

- Nivetha, C.; Rubiya, M.; Shobana, S.; Viswanathan, V.R.G.; Vasanthi, R. Production of plastic paver block from the solid waste (quarry dust, flyash & PET). ARPN J. Eng. Appl. Sci. 2016, 11, 1078–1079. [Google Scholar]

- Agyeman, S.; Obeng-Ahenkora, N.K.; Assiamah, S.; Twumasi, G. Exploiting Recycled Plastic Waste as an Alternative Binder for Paving Blocks Production. Case Stud. Constr. Mater. 2019, 11, e00246. [Google Scholar]

- Panimayam, A.; Chinnadurai, P. Utilization of Waste Plastic in Paver Blocks as A Replacement of Coarse Aggregate. Int. J. Adv. Res. Innov. Ideas Educ. 2017, 10, 211–218. [Google Scholar]

- Anajwala Parth, A.; Maisuria Dhruvi, B.; Tankariya Rohan, N.; Badlawala Kishan, K.; Tiwari Avkash, A. Evaluation of Strength of Plastic Paver Block. Int. J. Res. Appl. Sci. Eng. Technol. 2019, 7, 4. [Google Scholar] [CrossRef]

- United Nations. Sustainable Development Goals. 2023. Available online: https://sdgs.un.org/goals/goal12 (accessed on 23 September 2023).

- Roslan, S.A.H.B. The Effect of Recycled—High Density Polyethylene (HDPE), Mixing Ratio on the Tensile Strength of High Density. 2013. Available online: http://umpir.ump.edu.my/7627/1/CD7757.pdf (accessed on 23 September 2023).

- ASTM, Standard BS 1881-116; Compressive Strength of Concrete by BS 1881-116. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM, Standard BSEN 1338; Split Tensile Strength of Concrete by BSEN 1338. ASTM: West Conshohocken, PA, USA, 2023.

- Xu, B.; Li, Z. Performance of novel thermal energy storage engineered cementitious composites incorporating a paraffin/diatomite composite phase change material. Appl. Energy 2014, 121, 114–122. [Google Scholar] [CrossRef]

- Kumar, C.M.R.; Kumar, A.; Prashanth, M.H.; Reddy, D.V. Experimental studies on Iron-ore tailing based interlocking paver blocks. Int. J. Earth Sci. Eng. 2012, 5, 501–504. [Google Scholar]

- Palmer, J.; Terry, N.; Pope, P. How Much Energy Could be Saved by Making Small Changes to Everyday Household Behaviours? Camb. Archit. Res. 2012, 1–31. Available online: https://www.gov.uk/government/publications/how-much-energy-could-be-saved-by-making-small-changes-to-everyday-household-behaviours (accessed on 23 September 2023).

- Iswahyuni, I.; Hermiyati, I.; Suharyanto, S.; Arifin, U.F.; Hidayati, D.N. Physical-Mechanical Properties of Paving Block from Plastic Shopping Bags Waste and Sand. Key Eng. Mater. 2020, 849, 61–66. [Google Scholar]

| Property | HDPE |

|---|---|

| Density | 0.95–0.97 g/cm3 |

| Melting point | ~135 °C |

| Young’s modulus | 600–1400 MPa |

| Tensile strength | 20–32 MPa |

| Toughness | 3–5 MPa m1/2 |

| Softening temperature | 120–130 °C |

| Sr No. | Specimen | Length (L) (mm) | Width (W) (mm) | Load (KN) | Correction Factor | Thickness (T) (mm) | Compressive Strength (N/mm2) |

|---|---|---|---|---|---|---|---|

| 1 | P1 | 203.2 | 101.6 | 84.3 | 1.06 | 70 | 4.08 |

| 2 | P2 | 203.2 | 101.6 | 92.4 | 1.12 | 78 | 4.47 |

| 3 | P3 | 203.2 | 101.6 | 88.7 | 1 | 63 | 4.29 |

| Sr No. | Specimen | Area (A11) (mm2) | Area (A12) (mm2) | Avg. Area (mm2) | Load (KN) | Correction Factor | Thickness (T) (mm) | Compressive Strength (N/mm2) |

|---|---|---|---|---|---|---|---|---|

| 1 | P11 | 196 × 92 | 200 × 100 | 19,016 | 234 | 1.06 | 60 | 12.03 |

| 2 | P12 | 196 × 92 | 200 × 100 | 19,016 | 274.7 | 1.06 | 60 | 14.44 |

| 3 | P13 | 196 × 92 | 200 × 100 | 19,016 | 260.7 | 1.06 | 60 | 13.70 |

| Specimen | Length (mm) | Thickness (mm) | Correction Factor | P (Max. Load) (KN) | Split Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Block (P1) | 194 | 78 | 1.12 | 21.97 | 0.924 |

| Block (P2) | 200 | 70 | 1.06 | 29.9 | 1.27 |

| Block (P3) | 196 | 63 | 1 | 16.74 | 0.75 |

| Specimen | Length (mm) | Thickness (mm) | Correction Factor | P (Max. Load) (KN) | Split Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Block (P11) | 200 | 60 | 1.06 | 11.73 | 0.567 |

| Block (P12) | 200 | 60 | 1.06 | 12.18 | 0.56 |

| Block (P13) | 200 | 60 | 1.06 | 9.07 | 0.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, F.K.; Shangguan, D.; Butt, A.Q.; Arshad, M.T.; Raja, B.N.K.; Khitab, A.; Ding, Y.; Li, D.; Mukhtar, M.A. An Experimental Study to Mitigate Environmental Impacts by Transforming Waste Plastic Bags into Paving Blocks and Roof Tiles. Sustainability 2023, 15, 15801. https://doi.org/10.3390/su152215801

Butt FK, Shangguan D, Butt AQ, Arshad MT, Raja BNK, Khitab A, Ding Y, Li D, Mukhtar MA. An Experimental Study to Mitigate Environmental Impacts by Transforming Waste Plastic Bags into Paving Blocks and Roof Tiles. Sustainability. 2023; 15(22):15801. https://doi.org/10.3390/su152215801

Chicago/Turabian StyleButt, Faizan Khalid, Donghui Shangguan, Asim Qayyum Butt, Muhammad Tausif Arshad, Babar Nasim Khan Raja, Anwar Khitab, Yongjian Ding, Da Li, and Muhammad Ahsan Mukhtar. 2023. "An Experimental Study to Mitigate Environmental Impacts by Transforming Waste Plastic Bags into Paving Blocks and Roof Tiles" Sustainability 15, no. 22: 15801. https://doi.org/10.3390/su152215801

APA StyleButt, F. K., Shangguan, D., Butt, A. Q., Arshad, M. T., Raja, B. N. K., Khitab, A., Ding, Y., Li, D., & Mukhtar, M. A. (2023). An Experimental Study to Mitigate Environmental Impacts by Transforming Waste Plastic Bags into Paving Blocks and Roof Tiles. Sustainability, 15(22), 15801. https://doi.org/10.3390/su152215801