Addressing the Sustainability Conundrums and Challenges within the Polymer Value Chain

Abstract

:1. Introduction

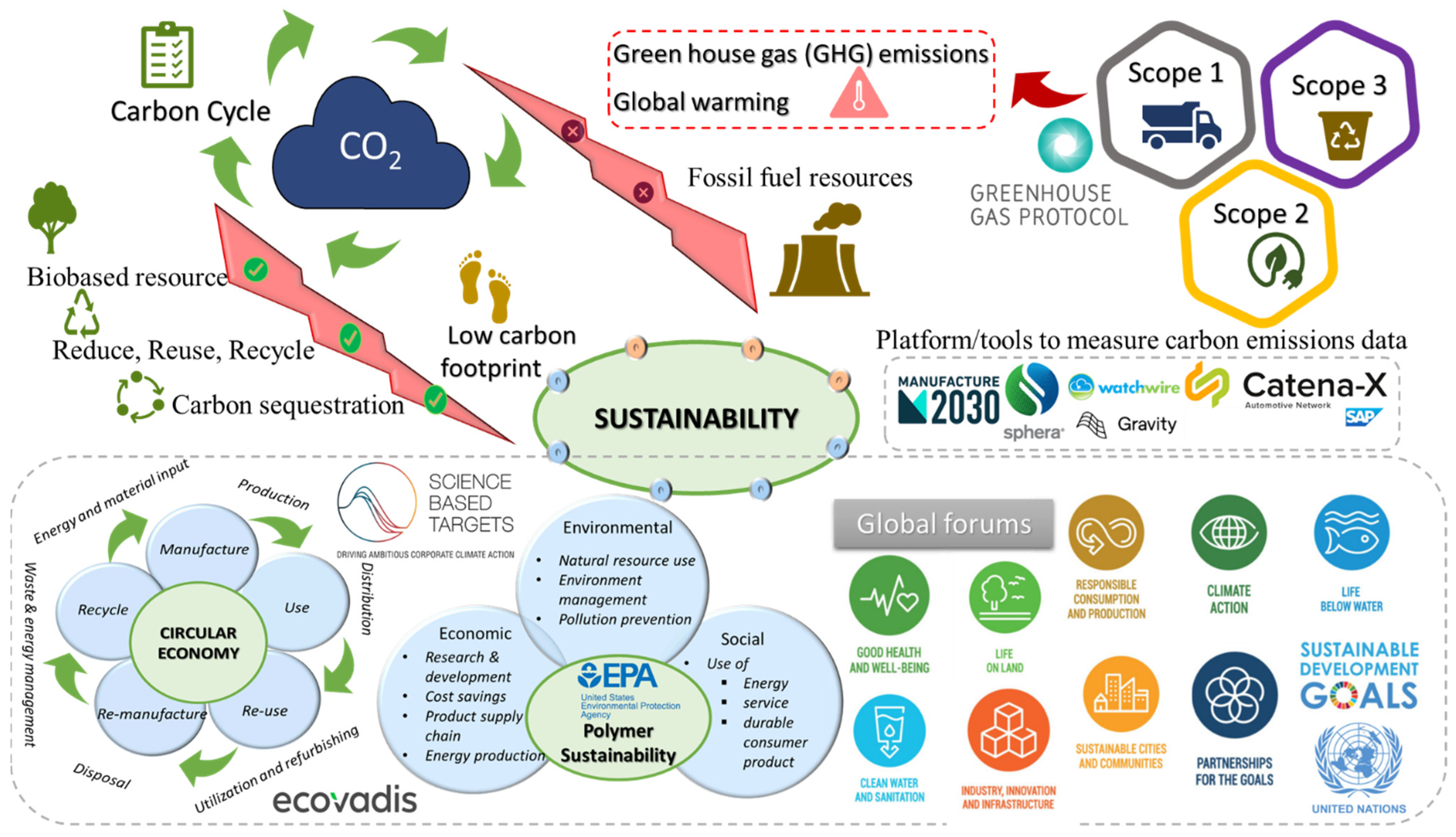

2. Decoding the Jargon Regarding Sustainability

3. Greenwashing in the Fashion Industry

4. Bioplastics Conundrum: Biobased vs. Biodegradable

5. The Everyday Conundrum: Plastic Alternatives Assessment

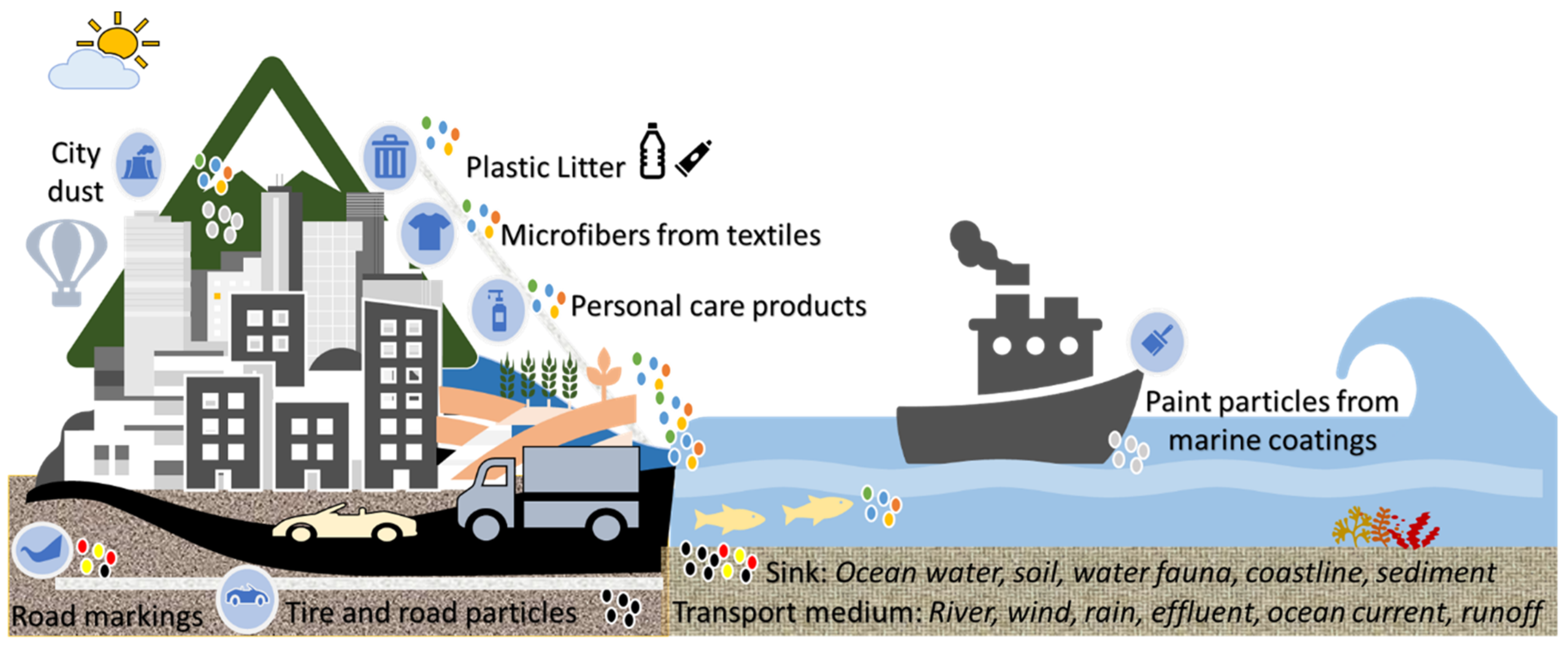

6. Microplastics Challenge

7. Discussion and Future Directions

- 1.

- To reduce:

- a.

- What are the alternatives available? (Paper, metal, glass, biodegradable etc.);

- b.

- If degradable alternatives are available, compare degradable vs. biobased/polymer:

- i.

- Which type of degradable material is the most suitable?

- ii.

- How much energy is consumed during the product manufacture?

- iii.

- Any special conditions requirement for degradation?

- iv.

- Any environmental impact during degradation?

- v.

- Does material need to be shipped somewhere to ensure degradation process?

- 2.

- To reuse:

- a.

- How many times do we need to reuse it before environmental impact is equivalent to single use plastic?

- 3.

- To recycle:

- a.

- feasibility to recycle?

- b.

- Is infrastructure available for recycling?

- 1.

- Use of biobased raw materials as opposed to petroleum-derived materials, lowering carbon footprint;

- 2.

- Value addition from recycled resources, recycling, or upcycling products;

- 3.

- Favorable life cycle analysis (LCA) in terms of carbon sequestration, minimal energy resources used, lowest GHG emissions, and degradability/reusability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Thomas, J.; Patil, R.S.; John, J.; Patil, M. A Comprehensive Outlook of Scope within Exterior Automotive Plastic Substrates and Its Coatings. Coatings 2023, 13, 1569. [Google Scholar] [CrossRef]

- Patil, R.S.; Narayanan, A.; Tantisuwanno, C.; Sancaktar, E. Immobilization of Glucose Oxidase on pH-Responsive Polyimide-Polyacrylic Acid Smart Membranes Fabricated Using 248 nm KrF Excimer Laser for Drug Delivery. Biointerface Res. Appl. Chem. 2023, 13, 1–10. [Google Scholar] [CrossRef]

- Constantin, C.P.; Aflori, M.; Damian, R.F.; Rusu, R.D. Biocompatibility of polyimides: A mini-review. Materials 2019, 12, 3166. [Google Scholar] [CrossRef] [PubMed]

- Thomas, J.; Bouscher, R.F.; Nwosu, J.; Soucek, M.D. Sustainable Thermosets and Composites Based on the Epoxides of Norbornylized Seed Oils and Biomass Fillers. ACS Sustain. Chem. Eng. 2022, 10, 12342–12354. [Google Scholar] [CrossRef]

- Thomas, J.; Patil, R. Enabling Green Manufacture of Polymer Products via Vegetable Oil Epoxides. Ind. Eng. Chem. Res. 2023, 62, 1725–1735. [Google Scholar] [CrossRef]

- Grishanov, S. Structure and Properties of Textile Materials; Woodhead Publishing Limited: Sawston, UK, 2011. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Jung, H.; Shin, G.; Kwak, H.; Hao, L.T.; Jegal, J.; Kim, H.J.; Jeon, H.; Park, J.; Oh, D.X. Review of polymer technologies for improving the recycling and upcycling efficiency of plastic waste. Chemosphere 2023, 320, 138089. [Google Scholar] [CrossRef]

- Besley, A.; Vijver, M.G.; Behrens, P.; Bosker, T. A standardized method for sampling and extraction methods for quantifying microplastics in beach sand. Mar. Pollut. Bull. 2017, 114, 77–83. [Google Scholar] [CrossRef]

- ONU. Sustainable Development Goals: Guidelines for the Use of the SDG. U. N. Dep. Glob. Commun. 2020, 1–68. Available online: https://www.un.org/sustainabledevelopment/news/communications-material/ (accessed on 1 August 2023).

- EPA. Report Learn About Sustainability, What is Sustainability ? Why Is Sustainability Important? How Does EPA Promote; EPA: Washington, DC, USA, 2022; pp. 1–5.

- Fiksel, J.R.; Eason, T.; Frederickson, H. A Framework for Sustainability Indicators at EPA. Livest. Res. Rural Dev. 2012. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=af768fd03660ea37ed5c093f302acc0c19a4ad2d (accessed on 1 August 2023).

- U.S. Department of Defense. 2022 Department of Defense Sustainability Plan; U.S. Department of Defense: Washington, DC, USA, 2022; pp. 1–5.

- Webber, D.M.E. Harnessing Sustainability in U.S. Higher Education; AASHE: Philadelphia, PA, USA, 2023; pp. 1–4. [Google Scholar]

- Walker, T.R. (Micro)plastics and the UN Sustainable Development Goals. Curr. Opin. Green Sustain. Chem. 2021, 30, 100497. [Google Scholar] [CrossRef]

- EPA (U.S. Environmental Protection Agency). Sustainable Materials Management: The Road Ahead; EPA: Washington, DC, USA, 2009; pp. 1–49.

- U.S. Environmental Protection Agency. Inventory of U.S. Greenhouse Gas Emissions and Sinks; EPA 430-R-13-001; U.S. Environmental Protection Agency: Washington, DC, USA, 2015; p. 564. Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks (accessed on 4 November 2023).

- Zehnder, A.J.B. The Carbon Cycle. Handb. Environ. Chem. 1982, 1, 82–110. [Google Scholar] [CrossRef]

- Selley, R.C.; Sonnenberg, S.A. Carbon Capture, Utilization, and Sequestration. Elements of Petroleum Geology; Academic Press: Cambridge, MA, USA, 2023; pp. 567–584. [Google Scholar] [CrossRef]

- Rodgers, S.; Meng, F.; Poulston, S.; Conradie, A.; McKechnie, J. Renewable butadiene: A case for hybrid processing via bio-and chemo-catalysis. J. Clean. Prod. 2022, 364, 132614. [Google Scholar] [CrossRef]

- Gayathri, R.; Mahboob, S.; Govindarajan, M.; Al-Ghanim, K.A.; Ahmed, Z.; Al-Mulhm, N.; Vodovnik, M.; Vijayalakshmi, S. A review on biological carbon sequestration: A sustainable solution for a cleaner air environment, less pollution and lower health risks. J. King Saud Univ.-Sci. 2021, 33, 101282. [Google Scholar] [CrossRef]

- EPA. Overview of Greenhouse Gases; EPA: Washington, DC, USA, 2012; p. 1.

- World Resources Institiute RELEASE: Greenhouse Gas Protocol Receives $9.25 Million Grant from the Bezos Earth Fund. 2023, pp. 1–5. Available online: https://Www.Wri.Org/News/Release-Greenhouse-Gas-Protocol-Receives-9-25-Million-Grant-Bezos-Earth-Fund (accessed on 1 August 2023).

- Protocol, G.G. Why Are There Three Scopes of Emissions? 2022, pp. 4–7. Available online: https://plana.earth/academy/what-are-scope-1-2-3-emissions (accessed on 3 October 2023).

- Greenhalgh, T. What Is the Difference between Scope 1, 2 and 3 Emissions? 2023, pp. 1–16. Available online: https://www.savemoneycutcarbon.com/learn-save/what-is-the-difference-between-scope-1-2-and-3-emissions/ (accessed on 4 November 2023).

- Our Story. About EcoVadis Our Story. 2013, pp. 8–11. Available online: https://ecovadis.com/about-us/ (accessed on 3 October 2023).

- WRI. Science Based Targets Initiative (SBTi); World Resources Institute: Washington, DC, USA, 2023; pp. 8–11. Available online: https://www.wri.org/initiatives/science-based-targets (accessed on 1 August 2023).

- Goddin, J.R.J. The Role of a Circular Economy for Energy Transition; Elsevier Inc.: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Bell, M.G.H. City Logistics and the Urban Environment; Elsevier Inc.: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- EPA. Building a Circular Economy for All: Progress toward Transformative Change. 2022, pp. 1–5. Available online: https://www.oecd.org/environment/plastics/increased-plastic-leakage-and-greenhouse-gas-emissions.htm (accessed on 1 August 2023).

- Parliament, E. Circular Economy: Definition, importance and benefits. News European Parliament, 24 May 2023; pp. 23–26. [Google Scholar]

- Mathews, J.A. Greening of Business, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Kosloski-Oh, S.C.; Wood, Z.A.; Manjarrez, Y.; De Los Rios, J.P.; Fieser, M.E. Catalytic methods for chemical recycling or upcycling of commercial polymers. Mater. Horizons 2021, 8, 1084–1129. [Google Scholar] [CrossRef]

- Jehanno, C.; Alty, J.W.; Roosen, M.; De Meester, S.; Dove, A.P.; Chen, E.Y.X.; Leibfarth, F.A.; Sardon, H. Critical advances and future opportunities in upcycling commodity polymers. Nature 2022, 603, 803–814. [Google Scholar] [CrossRef] [PubMed]

- Balu, R.; Dutta, N.K.; Roy Choudhury, N. Plastic Waste Upcycling: A Sustainable Solution for Waste Management, Product Development, and Circular Economy. Polymers 2022, 14, 4788. [Google Scholar] [CrossRef] [PubMed]

- Johansen, M.B.; Donslund, B.S.; Larsen, E.; Olsen, M.B.; Pedersen, J.A.L.; Boye, M.; Smedsgård, J.K.C.; Heck, R.; Kristensen, S.K.; Skrydstrup, T. Closed-Loop Recycling of Polyols from Thermoset Polyurethanes by tert-Amyl Alcohol-Mediated Depolymerization of Flexible Foams. ACS Sustain. Chem. Eng. 2023, 11, 10737–10745. [Google Scholar] [CrossRef]

- Santos, C.; Coelho, A.; Marques, A. A systematic literature review on greenwashing and its relationship to stakeholders: State of art and future research agenda. Manag. Rev. Q. 2023, 1–25. [Google Scholar] [CrossRef]

- Ftc, A.M.; Walmart, H.; Penalty, M.G.; Commission, F.T.; Commission, F.T.; Authority, P.O.; Court, D.; Ftc, T.; Levine, S.; Protection, C. FTC Hits Walmart with $ 3 Million Greenwashing Penalty. Winsight Grocery Business, 12 April 2022; pp. 1–7. [Google Scholar]

- Kardashian, K. Coca-Cola, Ikea Ikea, and Kim Kardashian’s fashion brand accused of ‘greenwashing’. Independent, 30 June 2022; pp. 5–9. [Google Scholar]

- Laville, S. Coca-Cola among brands greenwashing over packaging, report says. The Guardian, 6 June 2022; pp. 1–7. [Google Scholar]

- Hotten, R. Volkswagen: The scandal explained. BBC News, 10 December 2015; pp. 1–14. Available online: https://www.bbc.com/news/business-34324772(accessed on 12 August 2023).

- McCarthy, A. Are Our Clothes Doomed for the Landfill? Remake, 22 March 2018; pp. 1–6. Available online: https://remake.world/stories/news/are-our-clothes-doomed-for-the-landfill/(accessed on 22 August 2023).

- Nygaard, A.; Silkoset, R. Sustainable development and greenwashing: How blockchain technology information can empower green consumers. Bus. Strateg. Environ. 2022, 32, 3801–3813. [Google Scholar] [CrossRef]

- Yang, Z.; Nguyen, T.T.H.; Nguyen, H.N.; Nguyen, T.T.N.; Cao, T.T. Greenwashing behaviours: Causes, taxonomy and consequences based on a systematic literature review. J. Bus. Econ. Manag. 2020, 21, 1486–1507. [Google Scholar] [CrossRef]

- Pellegrino, S. Explainer: Household brands accused of greenwashing. Capital Monitor, 10 March 2023; pp. 1–8. Available online: https://capitalmonitor.ai/sector/consumer/explainer-household-brands-accused-of-greenwashing/(accessed on 12 August 2023).

- Fair, L. $5.5 Million Total FTC Settlements with Kohl’s and Walmart Challenge “Bamboo” and Eco Claims, Shed Light on Penalty Offense Enforcement. Federal Trade Commission; 8 April 2022; pp. 23–25. Available online: https://www.ftc.gov/business-guidance/blog/2022/04/55-million-total-ftc-settlements-kohls-and-walmart-challenge-bamboo-and-eco-claims-shed-light (accessed on 15 August 2023).

- Hitti, N. H&M Called out for “greenwashing” in its Conscious fashion collection. Dezeen, 2 August 2019; pp. 6–11. Available online: https://www.dezeen.com/2019/08/02/hm-norway-greenwashing-conscious-fashion-collection-news/(accessed on 23 August 2023).

- Xu, W.; Li, M.; Xu, S. Unveiling the “Veil” of information disclosure: Sustainability reporting “greenwashing” and “shared value”. PLoS ONE 2023, 18, 0279904. [Google Scholar] [CrossRef]

- Ferris, B.T.; Lawlor, J.; Ketterer, E.; Lawlor, J. Guidance for ‘sustainabl’ claims after dismissal of H & M ‘greenwashing’ class action. Reuters, 2 June 2023; pp. 1–7. 1–7. [Google Scholar]

- Zara, I.; Fashion, F. Is Zara Fast Fashion, Ethical, or Sustainable? Is Zara Fast Fashion, Ethical or Sustainable? IndieGetup, 14 February 2023; pp. 1–9. Available online: https://indiegetup.com/is-zara-fast-fashion-ethical-or-sustainable/#:~:text=Zara’sowner%2CtheInditexGropu,topeopleandtheenvironment(accessed on 13 August 2023).

- Zara JOIN LIFE|ZARA United States. pp. 23–25. Available online: https://www.zara.com/us/ (accessed on 3 October 2023).

- Release, P. Zara set new ambitious sustainability goals. Climate Action, 17 July 2023; pp. 23–26. [Google Scholar]

- Gigaton, P. Project Gigaton How to Participate Making a Difference-Together. 2017, pp. 24–25. Available online: https://www.walmartsustainabilityhub.com/project-gigaton (accessed on 3 October 2023).

- News European Parliament. EU to ban greenwashing and improve consumer information on product durability. News European Parliament, 19 September 2023; pp. 23–25.

- Wackett, L.P. Bio-based and biodegradable plastics: An annotated selection of World Wide Web sites relevant to the topics in microbial biotechnology. Microb. Biotechnol. 2019, 12, 1492–1493. [Google Scholar] [CrossRef] [PubMed]

- Paben, J.; State, G.; Wholesale, C.; News, T.M.; Recycling, R. Amazon settles ‘biodegradable’ claims case. Plastics Recycling Update, 15 August 2018; pp. 8–9. [Google Scholar]

- Ferreira-Filipe, D.A.; Paço, A.; Duarte, A.C.; Rocha-Santos, T.; Silva, A.L.P. Are biobased plastics green alternatives?—A critical review. Int. J. Environ. Res. Public Health 2021, 18, 7729. [Google Scholar] [CrossRef]

- European Commission Directorate-General for Environment. Biobased Plastic: Sustainable Sourcing and Content: Final Report; The Publications Office of the European Union: Luxembourg, 2022.

- Thomas, J.; Patil, R. The Road to Sustainable Tire Materials: Current State-of-the-Art and Future Prospectives. Environ. Sci. Technol. 2023, 57, 2209–2216. [Google Scholar] [CrossRef]

- Coatings, E.; Finishings, I.; Pertilla, P.E.E. High Solids Coating Composition of a Blend of a Low Molecular Weight Acrylic Polymer and a Medium Molecular Weight Acrylic Polymer and an Alkylated Melamine Cross-Linking Agent. U.S. Patent 4,330,458, 18 May 1982. [Google Scholar]

- Li, P.; Ma, S.; Dai, J.; Liu, X.; Jiang, Y.; Wang, S.; Wei, J.; Chen, J.; Zhu, J. Itaconic Acid as a Green Alternative to Acrylic Acid for Producing a Soybean Oil-Based Thermoset: Synthesis and Properties. ACS Sustain. Chem. Eng. 2017, 5, 1228–1236. [Google Scholar] [CrossRef]

- Thomas, J.; Singh, V.; Jain, R. Synthesis and characterization of solvent free acrylic copolymer for polyurethane coatings. Prog. Org. Coatings 2020, 145, 105677. [Google Scholar] [CrossRef]

- Thomas, J.; Nwosu, J.; Soucek, M.D. Acid-Cured Norbornylized Seed Oil Epoxides for Sustainable, Recyclable, and Reprocessable Thermosets and Composite Application. ACS Appl. Polym. Mater. 2023, 5, 2230–2242. [Google Scholar] [CrossRef]

- ASTM D6866-22; Standard Test Methods for Determining the Biobased Content of Solid, Liquid, and Gaseous Samples Using Radiocarbon Analysis. ASTM International: West Conshohocken, PA, USA, 2022.

- CSN EN 16640; Bio-based Products—Bio-based Carbon Content—Determination of the Bio-based Carbon Content Using the Radiocarbon Method. European Standards: Pilsen, Czech Republic, 2017.

- CSN EN 16785-1; Bio-based Content—Part 1: Determination of the Bio-based Content Using the Radiocarbon Analysis and Elemental Analysis. European Standards: Pilsen, Czech Republic, 2016.

- ASTM D6691-17; Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials in the Marine Environment by a Defined Microbial Consortium or Natural Sea Water Inoculum. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D6400-21; Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D5511-18; Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under High-Solids Anaerobic-Digestion Conditions. ASTM International: West Conshohocken, PA, USA, 2018.

- BS EN 13432:2000; Packaging—Requirements for Packaging Recoverable through Composting and Biodegradation—Test Scheme and Evaluation Criteria for the Final Acceptance of Packaging. European Standards: Pilsen, Czech Republic, 2007.

- ISO 16221:2001; Biodegradability Test—Seawater: Guidance for Determination of Biodegradability in the Marine Environment. Internal Organization for Standardization: Geneva, Switzerland, 2001.

- AS 5810; Biodegradable Plastics Suitable for Home Compositing. Standards Australia: Sydney, Australia, 2010.

- RameshKumar, S.; Shaiju, P.; O’Connor, K.E. Bio-based and biodegradable polymers—State-of-the-art, challenges and emerging trends. Curr. Opin. Green Sustain. Chem. 2020, 21, 75–81. [Google Scholar] [CrossRef]

- Al-Khairy, D.; Fu, W.; Alzahmi, A.S.; Twizere, J.C.; Amin, S.A.; Salehi-Ashtiani, K.; Mystikou, A. Closing the Gap between Bio-Based and Petroleum-Based Plastic through Bioengineering. Microorganisms 2022, 10, 2320. [Google Scholar] [CrossRef] [PubMed]

- Thomas, J.; Nwosu, J.; Soucek, M.D. Sustainable biobased composites from norbornylized linseed oil and biomass sorghum fillers. Compos. Commun. 2023, 42, 101695. [Google Scholar] [CrossRef]

- ISCC. Iscc Plus. 2023. version 3.4. pp. 1–51. Available online: https://www.iscc-system.org/wp-content/uploads/2023/03/ISCC-PLUS-System-Document_V3.4.pdf (accessed on 3 October 2023).

- Roundtable on Sustainable Biomaterials. A Guide to RSB Certification; Roundtable on Sustainable Biomaterials: Vernier, Switzerland, 2017; pp. 1–13. [Google Scholar]

- Frequently Asked Questions (FAQ) about the REDcert2 System. 2016, pp. 1–16. Available online: https://www.redcert.org/images/FAQ_REDcert2_March_2016.pdf (accessed on 3 October 2023).

- IEA. Bioenergy Standards and Labels Related to Biobased Products; IEA: Paris, France, 2018.

- Lucas, N.; Bienaime, C.; Belloy, C.; Queneudec, M.; Silvestre, F.; Nava-Saucedo, J.E. Polymer biodegradation: Mechanisms and estimation techniques—A review. Chemosphere 2008, 73, 429–442. [Google Scholar] [CrossRef]

- Patil, R.S.; Sancaktar, E. Effect of solution parameters on pH-response of polyacrylic acid grafted polyimide smart membrane fabricated using 248 nm krypton fluoride excimer laser. Polymer 2021, 233, 124181. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, J. Biodegradable and Biobased Polymers, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Madaan, S. What is Plastic Pollution? 2018, pp. 1–6. Available online: https://www.eartheclipse.com/environment/environmental-effects-plastic-pollution.html (accessed on 19 August 2023).

- Wilkes, R.A.; Aristilde, L. Degradation and metabolism of synthetic plastics and associated products by Pseudomonas sp.: Capabilities and challenges. J. Appl. Microbiol. 2017, 123, 582–593. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Sinha, J.K.; Ghosh, S.; Vashisth, K.; Han, S.; Bhaskar, R. Microplastics as an Emerging Threat to the Global Environment and Human Health. Sustainability 2023, 15, 10821. [Google Scholar] [CrossRef]

- Gómez, I.D.L.; Escobar, A.S. The dilemma of plastic bags and their substitutes: A review on LCA studies. Sustain. Prod. Consum. 2022, 30, 107–116. [Google Scholar] [CrossRef]

- Miller, S.A. Five Misperceptions Surrounding the Environmental Impacts of Single-Use Plastic. Environ. Sci. Technol. 2020, 54, 14143–14151. [Google Scholar] [CrossRef] [PubMed]

- Walker, T.R.; McKay, D.C. Comment on “five Misperceptions Surrounding the Environmental Impacts of Single-Use Plastic”. Environ. Sci. Technol. 2021, 55, 1339–1340. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Puig, R.; Hauschild, M.; Fullana-i-Palmer, P. Life cycle assessment of carrier bags and development of a littering indicator. Sci. Total Environ. 2019, 685, 621–630. [Google Scholar] [CrossRef]

- Ekvall, T.; Liptow, C.; Miliutenko, S. Single-Use Plastic Bags and Their Alternatives: Recommendations from Life Cycle Assessments; United Nations Environment Programme: Nairobi, Kenya, 2020; pp. 1–76. [Google Scholar]

- The Danish Environmental Protection Agency. Life Cycle Assessment of Supermarket Carrier Bags: A Review of the Bags Available in 2006. 2018. Available online: https://www2.mst.dk/udgiv/publications/2018/02/978-87-93614-73-4.pdf (accessed on 3 October 2023).

- ISO 14040; Environmental Management: Life Cycle Assessment: Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management: Life Cycle Assessment: Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland,, 2006.

- Das, S.; Liang, C.; Dunn, J.B. Life Cycle Assessment of Polymers and Their Recycling. ACS Symp. Ser. 2021, 1391, 143–170. [Google Scholar] [CrossRef]

- Mannheim, V. Life cycle assessment model of plastic products: Comparing environmental impacts for different scenarios in the production stage. Polymers 2021, 13, 777. [Google Scholar] [CrossRef]

- Ramesh, P.; Vinodh, S. State of art review on Life Cycle Assessment of polymers. Int. J. Sustain. Eng. 2020, 13, 411–422. [Google Scholar] [CrossRef]

- Sandin, G.; Miliutenko, S.; Liptow, C. Single-Use Plastic Bottles and Their Alternatives—Recommendations from Life Cycle Assessments; Life Cycle Initiative: Paris, France, 2020; pp. 1–44. [Google Scholar]

- Hamade, R.; Hadchiti, R.; Ammouri, A. Making the Environmental Case for Reusable PET Bottles. Procedia Manuf. 2020, 43, 201–207. [Google Scholar] [CrossRef]

- Garfí, M.; Cadena, E.; Sanchez-Ramos, D.; Ferrer, I. Life cycle assessment of drinking water: Comparing conventional water treatment, reverse osmosis and mineral water in glass and plastic bottles. J. Clean. Prod. 2016, 137, 997–1003. [Google Scholar] [CrossRef]

- Genovesi, A.; Aversa, C.; Barletta, M.; Cappiello, G.; Gisario, A. Comparative life cycle analysis of disposable and reusable tableware: The role of bioplastics. Clean. Eng. Technol. 2022, 6, 100419. [Google Scholar] [CrossRef]

- Lewis, Y.; Gower, A.; Notten, P. Recommendations from Life Cycle Assessments Single-Use Plastic Tableware and Its Alternatives; United Nations Environment Programme: Nairobi, Kenya, 2021; Available online: www.rothko.co.za (accessed on 10 August 2023).

- Vieyra, H.; Molina-Romero, J.M.; de Calderón-Nájera, J.D.; Santana-Díaz, A. Engineering, Recyclable, and Biodegradable Plastics in the Automotive Industry: A Review. Polymers 2022, 14, 3412. [Google Scholar] [CrossRef]

- Wang, R.M.; Zheng, S.R.; Zheng, Y.P. Polymer Matrix Composites and Technology; Woodhead Publishing: Sawston, UK, 2011. [Google Scholar] [CrossRef]

- Patil, R.S.; Sancaktar, E. Fabrication of pH-Responsive Polyimide Polyacrylic Acid Smart Gating Membranes: Ultrafast Method Using 248 nm Krypton Fluoride Excimer Laser. ACS Appl. Mater. Interfaces 2021, 13, 24431–24441. [Google Scholar] [CrossRef]

- European Commission. Microplastics from Textiles: Towards a Circular Economy for Textiles in Europe; European Commission: Brussels, Belgium, 2022; pp. 1–15.

- Hale, R.C.; Seeley, M.E.; La Guardia, M.J.; Mai, L.; Zeng, E.Y. A Global Perspective on Microplastics. J. Geophys. Res. Ocean. 2020, 125, e2018JC014719. [Google Scholar] [CrossRef]

- Arthur, C.; Baker, J.; Bamford, H. Proceedings of the International Research Workshop on the Occurrence, Effects, and Fate of Microplastic Marine Debris, 9–11 September 2008, University of Washington Tacoma, Tacoma, WA, USA; National Oceanic and Atmospheric Administration: Washington, DC, USA, 2009; p. 530.

- UNEP (United Nations Environment Programme). From Pollution to Solution: A Global Assessment of Marine Litter and Plastic Pollution; UNEP (United Nations Environment Programme): Nairobi, Kenya, 2021; Available online: https://www.unep.org/resources/pollution-solution-global-assessment-marine-litter-and-plastic-pollution (accessed on 30 August 2023).

- Ceccarini, A.; Corti, A.; Erba, F.; Modugno, F.; La Nasa, J.; Bianchi, S.; Castelvetro, V. The Hidden Microplastics: New Insights and Figures from the Thorough Separation and Characterization of Microplastics and of Their Degradation Byproducts in Coastal Sediments. Environ. Sci. Technol. 2018, 52, 5634–5643. [Google Scholar] [CrossRef]

- Henry, B.; Laitala, K.; Klepp, I.G. Microfibres from apparel and home textiles: Prospects for including microplastics in environmental sustainability assessment. Sci. Total Environ. 2019, 652, 483–494. [Google Scholar] [CrossRef]

- Herzke, D.; Ghaffari, P.; Sundet, J.H.; Tranang, C.A.; Halsband, C. Microplastic Fiber Emissions From Wastewater Effluents: Abundance, Transport Behavior and Exposure Risk for Biota in an Arctic Fjord. Front. Environ. Sci. 2021, 9, 1–14. [Google Scholar] [CrossRef]

- Panko, J.M.; Chu, J.; Kreider, M.L.; Unice, K.M. Measurement of airborne concentrations of tire and road wear particles in urban and rural areas of France, Japan, and the United States. Atmos. Environ. 2013, 72, 192–199. [Google Scholar] [CrossRef]

- Thomas, D.; Schütze, B.; Heinze, W.M.; Steinmetz, Z. Sample preparation techniques for the analysis of microplastics in soil—A review. Sustain. 2020, 12, 9074. [Google Scholar] [CrossRef]

- Thomas, J.; Moosavian, S.K.; Cutright, T.; Pugh, C.; Soucek, M.D. Method Development for Separation and Analysis of Tire and Road Wear Particles from Roadside Soil Samples. Environ. Sci. Technol. 2022, 56, 11910–11921. [Google Scholar] [CrossRef]

- Klöckner, P.; Reemtsma, T.; Eisentraut, P.; Braun, U.; Ruhl, A.S.; Wagner, S. Tire and road wear particles in road environment—Quantification and assessment of particle dynamics by Zn determination after density separation. Chemosphere 2019, 222, 714–721. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Liu, Q.; An, L.; Wang, M.; Yang, Q.; Zhu, B.; Ding, J.; Ye, C.; Xu, Y. Microfiber Pollution in the Earth System. Rev. Environ. Contam. Toxicol. 2022, 260, 1–16. [Google Scholar] [CrossRef]

- Baensch-Baltruschat, B.; Kocher, B.; Stock, F.; Reifferscheid, G. Tyre and road wear particles (TRWP)—A review of generation, properties, emissions, human health risk, ecotoxicity, and fate in the environment. Sci. Total Environ. 2020, 733, 137823. [Google Scholar] [CrossRef]

- Baensch-Baltruschat, B.; Kocher, B.; Kochleus, C.; Stock, F.; Reifferscheid, G. Tyre and road wear particles—A calculation of generation, transport and release to water and soil with special regard to German roads. Sci. Total Environ. 2021, 752, 141939. [Google Scholar] [CrossRef]

- Panko, J.M.; Kreider, M.L.; McAtee, B.L.; Marwood, C. Chronic toxicity of tire and road wear particles to water- and sediment-dwelling organisms. Ecotoxicology 2013, 22, 13–21. [Google Scholar] [CrossRef]

- Campanale, C.; Galafassi, S.; Savino, I.; Massarelli, C.; Ancona, V.; Volta, P.; Uricchio, V.F. Microplastics pollution in the terrestrial environments: Poorly known diffuse sources and implications for plants. Sci. Total Environ. 2022, 805, 150431. [Google Scholar] [CrossRef]

- Siegfried, M.; Koelmans, A.A.; Besseling, E.; Kroeze, C. Export of microplastics from land to sea. A modelling approach. Water Res. 2017, 127, 249–257. [Google Scholar] [CrossRef]

- Vidal, J. We eat and breathe plastic. How does it affect our. Common Seas, 29 April 2019. Available online: https://commonseas.com/news/plastic-and-health(accessed on 9 August 2023).

- United Nations Environment Programme Sustainability and Circularity in the Textile Value Chain. Glob. Stock. 2020, 19. Available online: https://www.oneplanetnetwork.org/sites/default/files/unep_sustainability_and_circularity_in_the_textile_value_chain.pdf (accessed on 11 August 2023).

- Galgani, L.; Goßmann, I.; Scholz-Böttcher, B.; Jiang, X.; Liu, Z.; Scheidemann, L.; Schlundt, C.; Engel, A. Hitchhiking into the Deep: How Microplastic Particles are Exported through the Biological Carbon Pump in the North Atlantic Ocean. Environ. Sci. Technol. 2022, 56, 15638–15649. [Google Scholar] [CrossRef]

- Vogelsang, C.; Lusher, A.; Dadkhah, M.E.; Sundvor, I.; Umar, M.; Ranneklev, S.B.; Eidsvoll, D.; Meland, S. Microplastics in Road Dust—Characteristics, Pathways and Measures; Norsk Institutt for Vannforskning: Oslo, Norway, 2019; Available online: https://niva.brage.unit.no/niva-xmlui/handle/11250/2493537 (accessed on 16 August 2023).

- Tavelli, R.; Callens, M.; Grootaert, C.; Abdallah, M.F.; Rajkovic, A. Foodborne pathogens in the plastisphere: Can microplastics in the food chain threaten microbial food safety? Trends Food Sci. Technol. 2022, 129, 1–10. [Google Scholar] [CrossRef]

- Tian, Z.; Zhao, H.; Peter, K.T.; Gonzalez, M.; Wetzel, J.; Wu, C.; Hu, X.; Prat, J.; Mudrock, E.; Hettinger, R.; et al. A ubiquitous tire rubber–derived chemical induces acute mortality in coho salmon. Science 2021, 371, 185–189. [Google Scholar] [CrossRef] [PubMed]

- McIntyre, J.K.; Prat, J.; Cameron, J.; Wetzel, J.; Mudrock, E.; Peter, K.T.; Tian, Z.; Mackenzie, C.; Lundin, J.; Stark, J.D.; et al. Treading Water: Tire Wear Particle Leachate Recreates an Urban Runoff Mortality Syndrome in Coho but Not Chum Salmon. Environ. Sci. Technol. 2021, 55, 11767–11774. [Google Scholar] [CrossRef] [PubMed]

- Rogers, S.S. (Ed.) The Vanderbilt Rubber Handbook; R.T Vanderbilt company, Inc.: Norwalk, Connecticut, USA, 1948. [Google Scholar]

- De-la-Torre, G.E. Microplastics: An emerging threat to food security and human health. J. Food Sci. Technol. 2020, 57, 1601–1608. [Google Scholar] [CrossRef] [PubMed]

- Zarus, G.M.; Muianga, C.; Hunter, C.M.; Pappas, R.S. A review of data for quantifying human exposures to micro and nanoplastics and potential health risks. Sci. Total Environ. 2021, 756, 144010. [Google Scholar] [CrossRef]

- Rahman, A.; Sarkar, A.; Yadav, O.P.; Achari, G.; Slobodnik, J. Potential human health risks due to environmental exposure to nano- and microplastics and knowledge gaps: A scoping review. Sci. Total Environ. 2021, 757, 143872. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Zhang, Y.; Kang, S.; Wang, Z.; Wu, C. Microplastics in soil: A review on methods, occurrence, sources, and potential risk. Sci. Total Environ. 2021, 780, 146546. [Google Scholar] [CrossRef]

- Mattsson, K.; da Silva, V.H.; Deonarine, A.; Louie, S.M.; Gondikas, A. Monitoring anthropogenic particles in the environment: Recent developments and remaining challenges at the forefront of analytical methods. Curr. Opin. Colloid Interface Sci. 2021, 56, 101513. [Google Scholar] [CrossRef]

- Thomas, J.; Cutright, T.; Pugh, C.; Soucek, M.D. Quantitative assessment of additive leachates in abiotic weathered tire cryogrinds and its application to tire wear particles in roadside soil samples. Chemosphere 2023, 311, 137132. [Google Scholar] [CrossRef]

- Releases, N. Goodyear Unveils 90% Demonstration Tire. PR Newswire, 4 January 2023. [Google Scholar]

- Group, M. Michelin Sustainable Goals Report 2020. 2020. Available online: https://www.michelin.com/en/documents/the-un-sustainable-development-goals-michelins-approach/ (accessed on 4 November 2023).

- Yildirim, S. Greenwashing: A rapid escape from sustainability or a slow transition? LBS J. Manag. Res. 2023, 21, 53–63. [Google Scholar] [CrossRef]

- Action, C. Greenwashing—The Deceptive Tactics Behind Environmental Claims. Why Care about Greenwashing, and How Does It Relate to Climate Change; United Nations: New York, NY, USA, 2022; pp. 1–7.

- UNFCCC. Fashion Industry Charter for Climate Action Information Pack. 2022. Available online: https://unfccc.int/climate-action/sectoral-engagement/global-climate-action-in-fashion/about-the-fashion-industry-charter-for-climate-action (accessed on 4 November 2023).

- Rodden, G. Turning Off the Tap. 1997. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/42277/Plastic_pollution.pdf?sequence=4 (accessed on 3 October 2023).

- Mariam George. Global Waste Trade and its Effects on Landfills in Developing Countries—Global Waste Cleaning Network. Glob. Waste Clean. Netw. 2021, 1–201. Available online: https://gwcnweb.org/2021/11/14/global-waste-trade-and-its-effects-on-landfills-in-developing-countries/ (accessed on 22 August 2023).

- Ferronato, N.; Torretta, V. Waste mismanagement in developing countries: A review of global issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef] [PubMed]

- Tarazona, N.A.; Machatschek, R.; Balcucho, J.; Castro-Mayorga, J.L.; Saldarriaga, J.F.; Lendlein, A. Opportunities and challenges for integrating the development of sustainable polymer materials within an international circular (bio)economy concept. MRS Energy Sustain. 2022, 9, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Kelly, C.L. Addressing the sustainability challenges for polymers in liquid formulations. Chem. Sci. 2023, 14, 6820–6825. [Google Scholar] [CrossRef]

- Knoblauch, D.; Mederake, L.; Stein, U. Developing countries in the lead-what drives the diffusion of plastic bag policies? Sustainability 2018, 10, 1994. [Google Scholar] [CrossRef]

- Ng, C.H.; Mistoh, M.A.; Teo, S.H.; Galassi, A.; Ibrahim, A.; Sipaut, C.S.; Foo, J.; Seay, J.; Taufiq-Yap, Y.H.; Janaun, J. Plastic waste and microplastic issues in Southeast Asia. Front. Environ. Sci. 2023, 11, 1–15. [Google Scholar] [CrossRef]

- Babayemi, J.O.; Nnorom, I.C.; Osibanjo, O.; Weber, R. Ensuring sustainability in plastics use in Africa: Consumption, waste generation, and projections. Environ. Sci. Eur. 2019, 31, 1–20. [Google Scholar] [CrossRef]

- Okeke, E.S.; Olagbaju, O.A.; Okoye, C.O.; Addey, C.I.; Chukwudozie, K.I.; Okoro, J.O.; Deme, G.G.; Ewusi-Mensah, D.; Igun, E.; Ejeromedoghene, O.; et al. Microplastic burden in Africa: A review of occurrence, impacts, and sustainability potential of bioplastics. Chem. Eng. J. Adv. 2022, 12, 100402. [Google Scholar] [CrossRef]

- CARES North American Forum. Global Transdisciplinary Forum for Sustainability in Automotive Manufacturing. 2023, pp. 1–12. Available online: https://www.cares-sustainableforum.com/2023-cares-north-american-forum/ (accessed on 4 November 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thomas, J.; Patil, R.S.; Patil, M.; John, J. Addressing the Sustainability Conundrums and Challenges within the Polymer Value Chain. Sustainability 2023, 15, 15758. https://doi.org/10.3390/su152215758

Thomas J, Patil RS, Patil M, John J. Addressing the Sustainability Conundrums and Challenges within the Polymer Value Chain. Sustainability. 2023; 15(22):15758. https://doi.org/10.3390/su152215758

Chicago/Turabian StyleThomas, Jomin, Renuka Subhash Patil, Mahesh Patil, and Jacob John. 2023. "Addressing the Sustainability Conundrums and Challenges within the Polymer Value Chain" Sustainability 15, no. 22: 15758. https://doi.org/10.3390/su152215758

APA StyleThomas, J., Patil, R. S., Patil, M., & John, J. (2023). Addressing the Sustainability Conundrums and Challenges within the Polymer Value Chain. Sustainability, 15(22), 15758. https://doi.org/10.3390/su152215758