Abstract

In today’s construction industry, a topic of paramount importance is reducing energy consumption within buildings. This study endeavors to combine Life Cycle Assessment (LCA) and Building Information Modeling (BIM) through a multi-objective optimization algorithm to enhance the environmental efficiency of buildings. The core objective is the optimization of materials used in the building’s outer shell to effectively curtail operational energy consumption. To achieve this, we employed BIM modeling, parametric simulations with the Energy Plus engine, and Athena to assess the embodied energy in materials. The multi-objective optimization algorithm NSGAII was harnessed to determine the most suitable materials. The results derived from the LCA and BIM analyses illustrate that the selection of optimal materials for residential building facades in Iran can lead to a remarkable 40% reduction in annual average energy consumption. Furthermore, this approach contributes significantly to mitigating global warming potential (GWP). Experts and architects can apply this method to evaluate and select the best materials for various building components, especially in high-rise buildings.

1. Introduction

In today’s energy landscape, particularly in industrialized and densely populated countries, the excessive consumption of fossil fuels stands as a pressing concern. Reports indicate that residential buildings alone account for 0.6% of average energy consumption, and this figure is projected to rise annually from 2018 to 2050. Alarmingly, over 39% of the United States’ total energy consumption is derived from the building sector [1]. The consequential increase in greenhouse gas emissions, directly attributed to construction activities, has raised significant environmental concerns [2]. Annual estimates reveal that enhancing energy efficiency within buildings can potentially boost performance and energy savings by up to 27%, also creating a direct link between reduced energy consumption, reduced costs, and decreased greenhouse gas emissions [3]. The increasing demand for construction materials underscores the imperative to mitigate the utilization of raw resources and their extraction from the natural environment. This practice not only leads to environmental degradation but also incurs significant costs [4]. A substantial portion of the energy expended during a building’s life cycle results from the production and use of construction materials [5]. Given that residential buildings are responsible for consuming more than 40% of the world’s total energy, energy consumption patterns in buildings are contingent upon building type and local climate [6]. Increasing energy efficiency and choosing the necessary materials in the construction industry are crucial. Throughout a building’s life cycle, energy consumption is directly related to the type and quality of construction materials used [7]. Throughout a building’s life cycle, two types of energy are intertwined: embodied energy (related to materials, their extraction, production, and use) and operational energy (which encompasses the energy consumed for heating, cooling, lighting, and HVAC systems) [8]. In other words, as the demand for energy in the operational phase of a building decreases, the need for using renewable energy systems and suitable materials increases, thus increasing embodied energy. In nearly zero-energy buildings, this relationship between operational energy and embodied energy becomes more apparent [9]. Therefore, integrating Building Information Modeling (BIM) and multi-objective optimization is an appropriate solution for reducing energy consumption in buildings [10].

Studies have shown that energy consumption and Life Cycle Assessment (LCA), as well as the adverse environmental effects of material production and extraction, play vital roles [11]. Therefore, presenting and utilizing innovative methods to reduce energy demand and enhance the sustainability of buildings and the use of renewable energy sources should be a top priority [12].

Research Proposal: This research was conducted to offer an efficient framework for optimizing energy consumption in buildings, with a specific focus on the exterior facade of residential buildings.

Research Questions: Why is reducing energy consumption in buildings, especially in the exterior facade, important? How can construction materials influence energy consumption in buildings? Is there a connection between energy consumption in the conceptual life phases of buildings (embodied energy) and the operational life phases (operational energy)? How can the integration of BIM and multi-objective optimization contribute to reducing energy consumption in buildings?

Research Hypotheses: Increasing the efficiency of heating, ventilation, and air conditioning (HVAC) systems in buildings through appropriate material selection leads to a reduction in air pollutants and the optimization of energy consumption. Construction materials play a crucial role in the energy consumption of buildings, and the correct choice of materials can result in over 45% annual energy savings for heating and cooling in buildings. The integration of BIM and multi-objective optimization aids in decreasing energy consumption in buildings [8].

Research Methodology: To investigate and validate the research hypotheses, relevant studies regarding energy consumption in buildings, the impact of construction materials, and the selection of optimal materials for HVAC systems were explored [7]. Additionally, information about the integration of BIM and multi-objective optimization for reducing energy consumption in buildings was considered. Data analysis and computational modeling was employed to examine the influence of construction materials on energy reduction in buildings. This research framework was centered around studies related to optimizing energy consumption in buildings, particularly by utilizing suitable materials for the exterior facades of residential buildings. Nevertheless, this approach is applicable to other parameters and various building types.

2. Literature Review: BIM and LCA for Energy Consumption in Buildings

Energy optimization methods in buildings aim to reduce energy consumption, life cycle costs (LCC), and environmental impacts (LCA) while adhering to existing budgets, particularly in the context of renovation. Among the significant contributors to a building’s energy performance are air conditioning and lighting systems. One proposed framework for energy optimization is the integration of BIM and Simulation-Based Multi-Objective Optimization (SBMO), along with building energy consumption simulations, which offers an effective solution [13,14]. The integration of BIM and LCA to optimize energy performance and environmental sustainability in buildings has been extensively discussed in the academic literature, demonstrating the considerable potential of these processes in addressing various aspects of energy efficiency in buildings. However, the application of mathematical optimization modeling in the retrofitting of existing buildings has received limited attention [12,15,16]. This study focuses on enhancing the annual energy efficiency of residential buildings, specifically mid-rise apartments, and analyzing the energy consumption associated with different construction materials throughout the building’s life cycle. This study explores cost reductions in residential complexes by employing optimal materials in façade construction through SBMO-based programming with the support of BIM and LCA modeling [17,18,19]. LCA stands out as a pivotal method for systematically evaluating the environmental impacts of products or services across their entire life cycle. This method assesses the environmental effects of construction materials, encompassing extraction, production, distribution, implementation, and the eventual recycling or disposal stages [8,20,21]. Numerous studies have delved into the integration of LCA and BIM across various phases, such as construction, maintenance, operation, and the utilization of optimization algorithms. These studies often prioritize the selection of effective methods, including energy analysis, which holds great significance in numerous societies, including developed countries. To address these concerns, researchers have emphasized the use of multi-objective optimization algorithms like Particle Swarm Optimization (PSO) algorithms, Genetic Algorithms (GAs), and the Non-Dominated Sorting Genetic Algorithm II (NSGAII) [22,23,24]. In summary, BIM is a comprehensive process that provides essential information about building projects, starting from the initial planning stages. This information modeling encompasses 2D and 3D design, progressive modeling during construction, post-construction stages (operation, maintenance, and examination), and maintenance modeling with consistent data, various software tools, and standardized data transmission. BIM offers a structured framework that benefits all project stakeholders involved in the construction process [25,26]. Materials wield a significant influence over energy efficiency (energy consumption) and building maintenance costs [27].

This study aims to determine the objective function and establish an optimization function connecting annual energy consumption and reduced environmental effects, such as global warming. It serves as a case study, validating the methodological framework regarding the roles of BIM and LCA in design and construction practices in Iran. For this study, fuel, electricity, heating, and cooling components in residential buildings were thoroughly investigated. In this research study, relevant data are summarized, our research methodologies and findings are presented (as is the NSGAII algorithm’s optimization function), and key recommendations for the future and any limitations associated with the present study are discussed.

2.1. Integrating BIM and LCA

One of the most significant and influential aspects of construction, particularly in the context of energy efficiency and environmental sustainability, is the adoption of LCA as a globally recognized standard and the assessment of various materials’ roles in the construction industry. This topic has garnered considerable attention among researchers, being discussed in numerous research studies [28,29]. LCA is a crucial process for addressing contemporary environmental concerns in the construction sector. It plays a pivotal role in reducing natural resources, consequently mitigating long-term environmental impacts [9,30]. The integration of LCA and BIM presents a promising opportunity to simplify this powerful tool using a robust database accessible to all stakeholders. The selection of information, data, and desired environmental impact indicators is vital within the LCA process. To facilitate this, efficient plugins and software tools like Athena Impact Estimator for Building 5.4, Sima Pro 9.5, and Gabi 10.6.1 can be employed. An efficient programming language can significantly enhance communication between LCA and BIM [27]. The examination of environmental effects and the assessment of energy consumption in both new construction projects and existing buildings through simulation and 3D modeling techniques have become paramount in recent years within the domain of construction and building operations [21,25]. Numerous studies emphasize the importance of integrating LCA with BIM and the effective utilization of databases and powerful software to simplify and enhance these processes. For example the authors of [31] demonstrated the development of an integrated 3D thermal system using 3D data, digital images, and thermal data, allowing for real-time updates and accurate energy consumption simulation. The authors of [5] introduced a BIM plugin that assesses energy consumption costs for residential buildings based on BIM data and parameter calculations, creating a comprehensive database that links input and output in the BIM process. This database is likely to be cloud-based. Furthermore the authors of [30,32] underlined the significance of integrating LCA with BIM in the early stages of building design. They proposed plans focusing on the embodied effects between building elements and material choices that minimize energy loss, ultimately reducing carbon dioxide emissions. Additional studies such as [33,34,35] affirmed the efficacy of LCA and BIM integration by utilizing three-dimensional modules, LCA tools, and BIM assessment tools to create a sustainable integrated system, enhancing the understanding of these modules. This initiative aims to establish a specific process and framework for data exchange and compatibility between LCA and BIM, aligning with the LEED green building system to inform designers about environmental effects during construction. In the early design phases, data derived from BIM modeling enables accurate energy consumption calculations, aligning with the LEED standard [36]. In the assessment of material life cycles, environmental impact assessment software such as Athena Impact Estimator for Building 5.4 is employed to scrutinize the materials’ life cycles. Additionally, integrating LCA with BIM has been applied to complex design scenarios, such as the parametric architecture of solar panels and their placement on the exteriors of diverse buildings. In [37], BIM and life cycle modeling, alongside Dynamo programming, were employed to create a framework for a solar energy system. This system allowed for the placement of solar panels with varying orientations and sizes on building facades, facilitating individual light absorption analysis and precise energy cost calculations for each panel and facade. Table 1 provides a summary of research methods, objectives, tools, and findings from previous studies.

Table 1.

Overview of articles.

2.2. Multi-Objective Optimization Algorithms

When exploring various approaches for identifying and estimating energy consumption in a building, it is essential to employ optimization methods to select the most suitable and rational approach for different phases of assessing BIM and evaluating the life cycle of the intended structure. Optimization plays a pivotal role in assisting the designer in achieving this goal. The optimization process aims to either maximize or minimize a specific dataset or a combination of data and materials to determine the optimal solution for quantifying energy consumption and, more importantly, for selecting the most appropriate materials for construction [40]. During this stage, both single-objective and multi-objective optimization techniques are considered to determine the optimal materials. In the realm of single-objective optimization lies the Particle Swarm Optimization (PSO) method, as suggested by the authors of [10]. In the case of multi-objective optimization, algorithms such as NSGAII and the Strength Pareto Evolutionary Algorithm (SPEA2) can be utilized to accommodate a larger number of genomes. Furthermore, implementing programming languages like MATLAB or Python can yield accurate and efficient results within shorter time frames, as proposed by the authors of [24]. To curtail energy consumption and insulation expenses in residential buildings and enhance thermal comfort for their inhabitants by regulating thermostat settings, a novel method that employs the NSGAII optimization algorithm for optimizing heating device temperature adjustments in residential structures has been introduced. This approach has the potential to yield favorable outcomes in reducing energy usage within residential buildings, as highlighted by the authors of [38,39]. The application of modeling and simulation techniques can facilitate the prediction of energy consumption in public buildings such as schools and elevate the thermal comfort of their occupants. Additionally, the integration of the Least Square Support Vector Machine (LSSVM) and the Non-Dominant Sorting Genetic Algorithm (NSGA-II) can be instrumental in comprehensively and effectively studying the influence of exterior wall materials and coverings on a building’s energy consumption, as demonstrated by the authors of [39].

2.3. Previous Research Approaches and Limitations

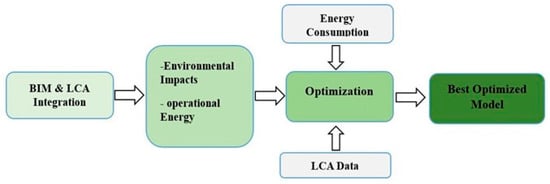

In previous research [5,8,17], there has been limited focus on multi-objective optimization techniques, and it appears that the integration of energy optimization methods with the process of BIM and LCA has received limited attention. The use of modeling software and energy consumption simulation, as well as the selection of optimal materials during the design phases of buildings, can be highly effective. In Iran, energy consumption in residential buildings is significantly higher than the global average, and modern construction methods and standards are limited. Furthermore, global standards for LCA are not adequately emphasized in Iran. Therefore, the main purpose of this article is to present a framework for multi-objective optimization by integrating BIM and LCA to determine the annual operational energy in buildings and the embodied energy in materials. This method is focused on the materials used for the external envelopes of buildings. For validation, the proposed method was applied to a case study to evaluate its accuracy and performance. The BIM model and LCA data introduce an optimal function, as depicted in Figure 1. The innovative aspect of this research lies in the emphasis on the materials used in the external envelope of residential buildings, highlighting that the selection and use of materials that effectively reduce energy consumption in buildings can reduce operational energy and lead to carbon emission reductions. The integration of BIM modeling with LCA to obtain reliable data and the use of a multi-objective optimization algorithm NSGAII to determine optimal materials for use in the external envelope of residential buildings was our main methodology. Considering the high energy consumption in Iran compared to the global average and the prevalent use of materials with higher durability but with increased energy consumption within the nation’s building, this study could provide an effective and practical approach for engineers and architects. It could significantly contribute to energy consumption reduction in Iran and other countries through influencing the selection of materials in different building components, making it a valuable step towards a more sustainable construction industry.

Figure 1.

Flowchart of this work.

3. Research Methodology

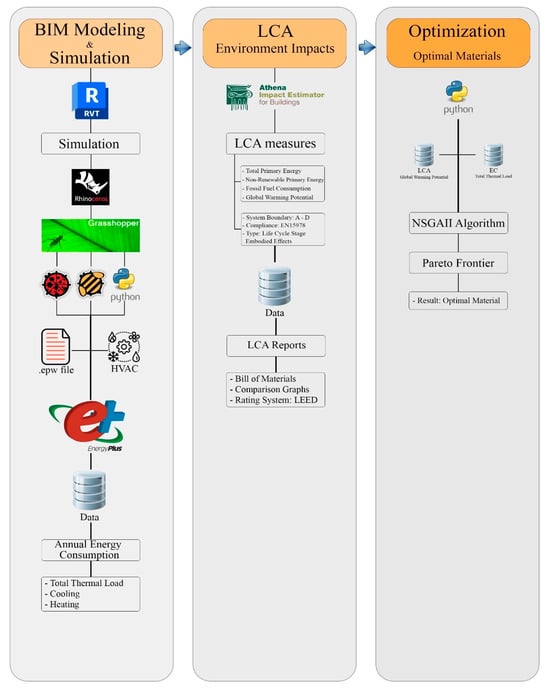

This study aims to evaluate and select optimal materials for the external shell of apartment buildings constructed and utilized in Iran. Our research methodology is shown in Figure 2. The research process consisted of three primary stages: BIM, LCA, and Optimization. It is important to note that all activities were based on these three fundamental axes.

Figure 2.

General chart of methodology.

3.1. BIM and Simulation

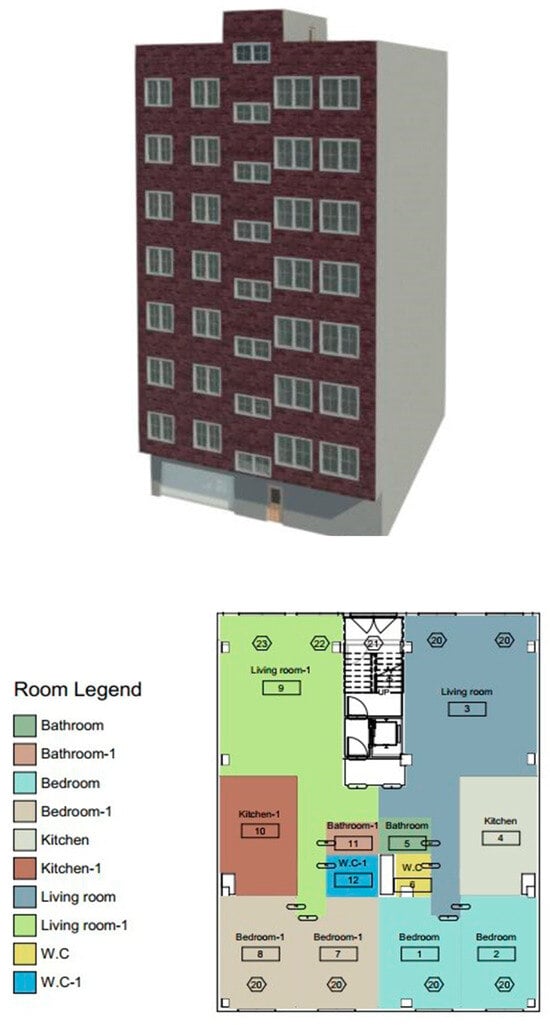

The first level of BIM involved selecting a residential apartment in Tehran. This apartment building spans seven floors, with each floor containing two units, accounting for a total of 14 residential units in a typical layout. Each floor covers an area of 230 and has north and south views, resulting in a total area of 1610 . Mid-rise buildings, ranging from 4 to 12 floors, encompass diverse architectural styles and generally house more residents compared to smaller buildings. These buildings have elevators for access. Heating and cooling systems, either centralized or separate, are also present. Some medium-sized buildings integrate energy-efficient features and eco-friendly elements such as green roofs. The building was modeled using Revit version 2022, and a 3D representation of the building is shown in Figure 3.

Figure 3.

Three-dimensional BIM model and plan of residential building.

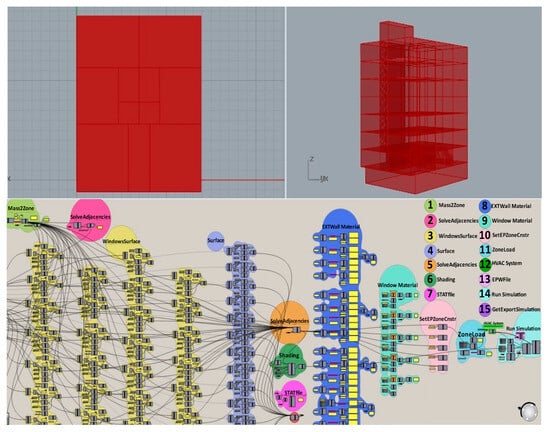

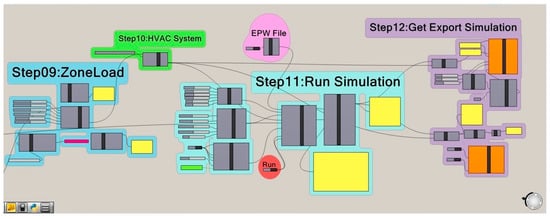

The model’s output was applied to simulate thermal zones, compute annual energy consumption, and assess building performance. In order to facilitate the energy simulation, a 3D model was imported into Rhino version 5, where the Grasshopper plugin was employed in conjunction with plugins like Honeybee and Ladybug, alongside Python programming for the development of step-by-step algorithms. The Grasshopper version 09.76.0 environment is graphical, and all the processes are conducted by stringing together geometric algorithms from its database, also making use of the ASHRAE standard library. Ultimately, this leads to the calculation of annual Energy Consumption (). Figure 4 illustrates the stages of this process.

Figure 4.

Simulation in Rhino and Energy Plus zoning in Grasshopper–Honeybee–Ladybug plugins.

Initially, the three-dimensional building model was divided into thermal zones to identify areas where energy was utilized. After determining thermal coefficients and openings, including windows in the outer wall, all relevant Honeybee (HB) Zones were consolidated within a solve adjacencies algorithm. This assembly was instrumental in connecting the desired outputs to the materials used for the building’s external shell. We examined five types of materials for the outer shell, considering the prevalent construction materials in Iran, particularly Tehran. This analysis included an exploration of 100 additional materials beyond the primary five. All building elements, such as windows, concrete, bricks, and so on, were composed of constituent details that, in this study, encompass over 100 materials in the LCA embodied energy stage. Table 2 provides an overview of the materials involved in this stage. The Ladybug plugin was employed with the ASHRAE standard [41] to determine the appropriate stat file. Furthermore, based on the ASHRAE standard, the thermal zone for Tehran was classified as 3B.

Table 2.

Materials of exterior walls.

The stat file was integrated into the Honeybee plugin. Weather files were run within the Grasshopper environment, connecting the identified thermal zones to the external shell materials and glazing shown in Table 3. These materials align with the typical choices in building construction in Tehran. Given the primary focus of our research, which centered around selecting the most optimal external shell material and determining annual energy consumption in residential buildings, the study considered five proposed external layer materials: brick, metal, stucco, travertine, and wood. To maintain consistency, the study assumed that the various layers of the external wall within each material type were the same, with differences occurring only in the outermost layer and windows. The thermal zones were then linked to each desired material within the Energy Plus (EP) zone loads function, resulting in data related to Heating, Ventilation, and Air Conditioning (HVAC), as well as lighting. Additionally, the type of HVAC system was determined to be PTAC/Residential (Packaged Terminal Air Conditioner). For this particular residential apartment building, we employed the Energy Plus function in Honeybee and an Energy Plus Weather (EPW) climate file specific to Tehran (downloaded from the Ladybug website) [42]. The inputs for the Energy Plus model are provided in Figure 5.

Table 3.

Exterior window and glazing types.

Figure 5.

Energy Plue was ran to calculate the annual operating energy of the building.

The data in this section, including total thermal load, cooling, and heating for the residential apartment, correspond to the location of Tehran. Table 4 offers a detailed breakdown of these items for the materials used in building facades.

Table 4.

Annual energy consumption (results derived from running Energy Plus).

3.2. Life Cycle Assessment (LCA)

The LCA domain represents embodied energy in the process of determining optimal materials and reducing carbon dioxide emissions over the entire lifespan of products. Accurate and comprehensive data play a critical role in obtaining LCA results. In this phase, Athena Impact Estimator for Building 5.4 was utilized to assess the environmental impact and the embodied energy of the materials. The LCA approach we adopted focuses on the life cycle stage and an A-D bounding system. Following the EN15978 standard [43], this standard covers all levels of the life cycle of buildings, from the extraction and processing of raw materials to construction, use, and end-of-life compliance. The primary objective of this phase is to estimate the energy embedded in the materials, emphasizing their contribution to global warming potential (GWP) within the building. Detailed information regarding the five materials—brick shell (Table 5), metal shell (Table 6), stucco shell (Table 7), natural stone (travertine) shell (Table 8), and wooden external shell (Table 9)—can be found in Table 5, Table 6, Table 7, Table 8 and Table 9. During the assessment of embodied energy within LCA and the determination of Tehran’s climate zone, it became apparent that no ASHRAE standard data for Tehran exist. To advance progress toward our research goals, we adopted and applied embodied energy data from Atlanta, which closely aligns with Tehran’s thermal zone 3 [27].

Table 5.

Bill of materials—brick cladding.

Table 6.

Bill of materials—metal cladding.

Table 7.

Bill of materials—stucco cladding.

Table 8.

Bill of materials—natural stone (travertine) cladding.

Table 9.

Bill of materials—wood cladding.

LCA Comparison

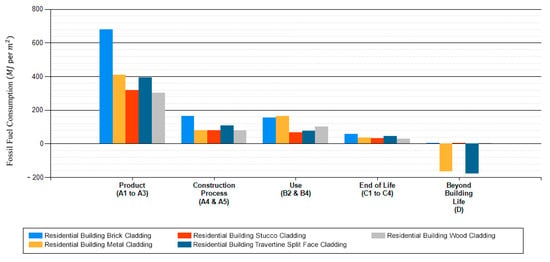

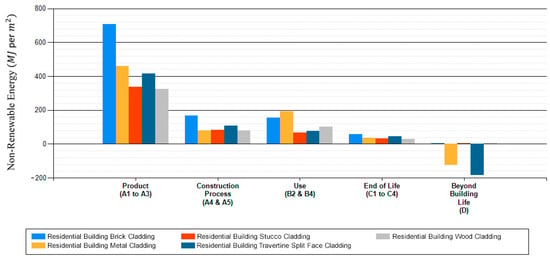

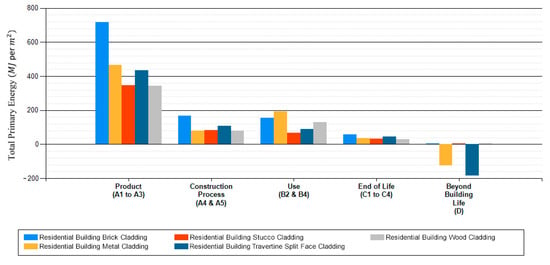

Another crucial aspect of the building’s LCA process is the comparative analysis of materials based on key components, including fossil fuel consumption () (Figure 6), global warming potential (

per ) (Figure 7), non-renewable energy usage () (Figure 8), and total primary energy () (Figure 9); it is worth noting that a megajoule (MJ) is a unit of energy equivalent to one million joules. The comparison involved a comprehensive assessment of five distinct facade types commonly employed in residential constructions, considering various phases of a building’s life cycle. Table 10 summarizes the comparison of global warming potential ( per ) during the optimization process (categorized by different life cycle stages).

Figure 6.

Comparison of fossil fuel consumption by life cycle stage (embodied effects) (per ).

Figure 7.

Comparison of global warming potential by life cycle stage (embodied effects) (per ).

Figure 8.

Comparison of non-renewable energy by life cycle stage (embodied effects) (per ).

Figure 9.

Comparison of total primary energy by life cycle stage (embodied effects) (per ).

Table 10.

Comparison of global warming potential by life cycle stage (embodied effects) (per ).

3.3. Optimization of Materials

In the final stage of our research, we sought to identify the most optimal material(s) using the NSGAII optimization algorithm. To achieve this, data from the operational energy and the embodied energy focused on global warming potential were employed with the aid of Python programming. The Grasshopper and Athena data were loaded into Pymoo, a Python library. NSGAII was utilized to interact with the available data for the optimization process. Both functions aimed to minimize annual operational energy in residential buildings, increase embodied energy, and reduce global warming potential ( per ), as depicted in Figure 1. The NSGAII algorithm was implemented by encoding and introducing target functions.

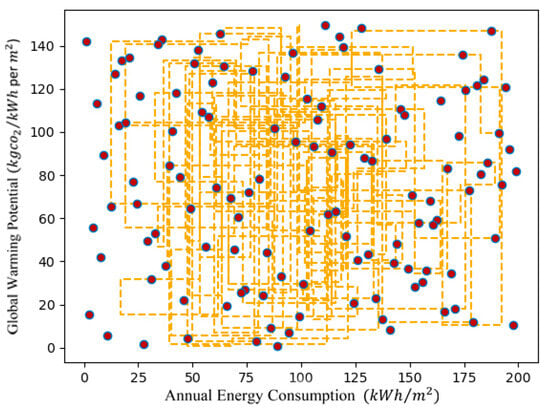

The Pareto frontier curve depicted in Figure 10 utilized data from 100 materials and details, with the x-axis representing annual energy consumption () as Function 1, and the y-axis representing global warming potential ( per ), obtained from LCA data, as Function 2, which encompasses 100 materials and details, these materials are depicted as dots, and the dashed lines representing the dominant range connect them, irrespective of how close they are within this range. These points or materials are distant from the Pareto curve and are not suitable options for optimization. To determine the most optimal materials by increasing the iterations in the NSGAII algorithm. It was observed that after 500 iterations, only a limited number of materials remained non-dominant compared to the Pareto front curve, signifying their superior performance in minimizing both functions.

Figure 10.

Pareto frontier.

4. Results and Comprehensive Analysis

The annual energy consumption data, along with the comparison of 100 materials utilized in the exterior shell of the residential building under consideration, complete with specific dimensions and sizes, reveal that the wooden facade exhibits the lowest energy consumption at 142.111249 (); alternative materials such as brick, metal, travertine, and stucco register annual energy consumption values of 146.626923 (), 153.622104 (), 153.734802 (), and 154.99127 (), respectively. Regarding data sourced from the LCA concerning global warming potential and carbon dioxide emissions, as elaborated in Table 5, Table 6, Table 7, Table 8 and Table 9 for all five facades, the wooden shell facade notably stands out, with only 25.2 ( per emissions. This level of carbon dioxide production is significantly lower than that of the other materials employed in the exterior shell of the residential building. Among the 100 materials considered within the Pareto frontier curve, Figure 10 visually represents the number of dominant and non-dominant materials. The data were encoded using Python, and output was generated through using NSGAII with a population size of 50 and 250 iterations, as depicted in Figure 11. The results were then compared to the Pareto frontier curve, and it was observed that the number of non-dominant points closely approximated this curve. The optimal configuration in this study is defined as follows:

Optimization algorithm = NSGAII, max iteration = 250, pop Size = 50.

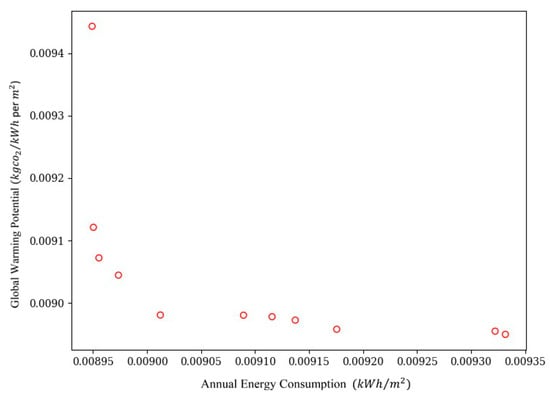

Figure 11.

Optimal pareto set.

Regarding Function 1, which pertains to annual energy consumption (EC), the minimum, maximum, and average annual energy consumption figures are 0.0895 (), 0.00935 (), and 0.00915 (), respectively. These figures encompass energy consumption aspects related to fossil fuels, lighting, cooling, and heating on an annual basis.

Function 2 represents global warming potential (GWP), as selected from various LCA factors. The minimum, maximum, and average global warming potential values are 0.0090 per , 0.0094 per , and 0.0092 per , respectively.

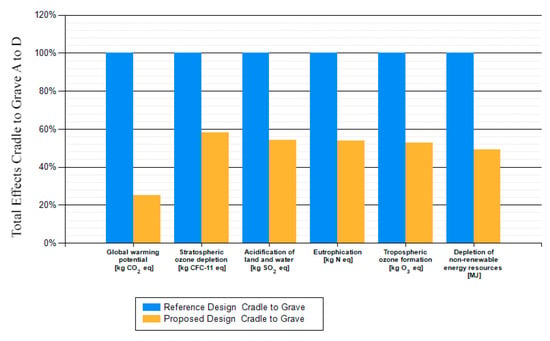

Based on these findings, the most optimal execution of the algorithm, as illustrated in Figure 11, closely aligns with the Pareto frontier curve. It is evident that when evaluating the Leadership in Energy and Environmental Design (LEED) rating system, wood stands out as the preferred material of choice in comparison to brick, as depicted in Figure 12. Nevertheless, it is crucial to recognize that the selection of materials, windows, and glass types for construction is subject to the choices made by architects and builders, which are influenced by the unique construction conditions and available resources in Tehran. Despite the advantages of wood, the local climate in Tehran, characterized by hot and dry conditions, often leads to materials such as brick or travertine being commonly used due to their abundance and cost-effectiveness. The ultimate decision on materials and construction specifics remains the responsibility of architects and builders, who must consider the specific conditions and requirements of the Tehran region.

Figure 12.

Comparison of LEED LCA measures from cradle to grave (A to D).

5. Discussion

The results of this study offer valuable insights into the selection of materials for the exterior shell of residential buildings, with a particular emphasis on energy consumption and environmental impact. When specific case studies were employed in the modeling process, such as residential buildings with precise dimensions, defined areas, and specific spaces, the simulation results tended to be more reliable. The analysis involved the evaluation of 100 different materials in terms of their energy consumption and global warming potential. The results revealed significant variations among these materials, and this study’s findings could have important implications for sustainable building practices. In terms of energy consumption, the annual energy consumption data indicate that facade wood, with an impressively low energy consumption of 142.111249 (), stands out as the most efficient choice. In contrast, materials such as brick, metal, travertine, and stucco exhibit higher energy consumption values, ranging from 146.626923 () to 154.99127 (). These results underscore the important role of material selection in achieving energy-efficient building designs. Additionally, Energy Plus, a powerful engine that employs Python scripts for processing data in simulating a building’s operational energy within Grasshopper version 09.76.0 software, was utilized for this study. As essential data, including thermal and climate zones, as well as the LCA data of materials, were extracted from the ASHRAE standard library, the results of the energy plan are highly reliable.

Furthermore, the results from our assessment of global warming potential, measured by carbon emission production, highlight the environmental advantages of wooden shell facades. The wood facade demonstrates the lowest carbon dioxide production, emitting only 25.2 ( per ) throughout its life cycle (from extraction to implementation and beyond). This aligns with the proposed method in this study, i.e., the LCA module, emphasizing the stages of material extraction to implementation in the building. This contrasts with other materials considered in the study, emphasizing the environmental benefits of choosing wood for the outer shells of buildings. The study’s optimization process involved using the NSGAII algorithm, resulting in an optimal configuration with 250 maximum iterations and a population size of 50. The proximity of the obtained results to the Pareto frontier curve indicates the effectiveness of this approach in identifying non-dominant materials, thus guiding material selection for energy efficiency and environmental sustainability.

Our findings further support the suitability of wood as an optimal material for the exterior shells of buildings. When comparing wood and brick, considering the LEED Rating system, wood emerges as the preferred option. However, it is essential to acknowledge contextual factors, such as the hot and dry climate of Tehran, which influences the choice of materials. In such regions, the practicality and cost-effectiveness of materials like brick and travertine may make them more popular choices, despite their relatively higher energy consumption.

In conclusion, this study contributes to the identification of optimal materials for residential building exteriors, emphasizing the role of wood as a sustainable and energy-efficient choice. Nevertheless, it is crucial to recognize that the final decision ultimately rests with architects and builders, who must consider various factors, including regional climate conditions and construction constraints, to make informed choices that align with the goals of their specific project(s).

6. Conclusions

This article underscores the pivotal role of building facades and the materials used in them in influencing annual energy consumption, cost reduction, and the mitigation of environmental factors like greenhouse gas emissions. This section will delve deeper into the key findings and implications of the research presented in the previous sections.

The Impact of Facades and Materials: This study emphasizes that the choice of materials for the external shell of a building, including facade materials, windows, and glasses, significantly affects both annual energy consumption and the LCA of the building. This observation is of utmost importance when aiming to optimize the overall efficiency of a building’s exterior shell.

Influence of Various Factors: Several factors come into play when determining the annual energy consumption of a building. Material properties, the presence of openings, the size of the building, its geographical location, and the surrounding urban environment all play critical roles. It is evident that decisions made at the design and construction stages regarding these factors have far-reaching effects on a building’s energy performance.

Optimal Material Selection: Construction engineers are key decision makers when it comes to selecting optimal materials for building exteriors. The present study highlights the importance of their precision in material selection. By considering target functions such as reducing energy consumption and mitigating global warming potential, engineers can make informed choices regarding materials.

Role of the NSGAII Algorithm: This study introduces the NSGAII algorithm, which was used to investigate and compare target functions, guiding the selection of optimal materials through a Pareto front curve. This algorithm is a valuable tool for decision makers in the construction industry, allowing them to strike a balance between energy efficiency and environmental responsibility.

Practical Application: The methodology described in this study has practical implications for builders and engineers. By utilizing data from annual energy consumption simulations and LCA, construction professionals can make more informed decisions regarding the materials they use. The approach we adopted offers a structured way to evaluate and select materials based on their environmental impact and energy efficiency.

Scalability: While the focus of this study was on exterior shell materials for residential buildings, our methodology can be adapted and extended to other components within buildings, such as internal walls, floors, and ceilings. This adaptability opens up new possibilities for enhancing the sustainability and energy efficiency of a broader range of building types, from one-story commercial structures to high-rise towers.

In summary, the present study underscores the importance of facade materials and their impact on the energy consumption and sustainability of buildings. It provides a valuable approach for material selection and can be extended to benefit a wide range of construction projects, ultimately contributing to more energy-efficient and environmentally responsible building practices.

Author Contributions

Conceptualization, E.N.; Methodology, H.A.; Software, H.A.; Validation, H.A.; Formal analysis, H.A.; Investigation, H.A.; Resources, E.N.; Data curation, H.A.; Writing—original draft, H.A.; Visualization, H.A.; Supervision, E.N.; Project administration, E.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- U.S. Energy Information Administration (EIA). U.S. International Energy Outlook 2019 with Projections to 2050; Office of Energy Analysis, U.S. Department of Energy: Washington, DC, USA, 2019. [Google Scholar]

- U.S. Environmental Protection Agency (EPA). Climate Change Indicators in the United States; Climate Science and Impacts Branch, Climate Change Division: Washington, DC, USA, 2016. [Google Scholar]

- Tuominen, P.; Klobut, K.; Tolman, A.; Adjei, A.; de Best-Waldhober, M. Energy savings potential in buildings and overcoming market barriers in member states of the European Union. Energy Build. 2012, 51, 48–55. [Google Scholar] [CrossRef]

- de Lassio, J.; França, J.; Santo, K.E.; Haddad, A. Case Study: LCA Methodology Applied to Materials Management in a Brazilian Residential Construction Site. J. Eng. 2016, 2016, 9. [Google Scholar] [CrossRef]

- Ahmad, T.; Thaheem, M.J. Economic Sustainability Assessment of Residential Buildings: A dedicated assessment framework and implications for BIM. Sustain. Cities Soc. 2018, 38, 476–491. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Buildings and Climate Change: Status, Challenges and Opportunities; European Commission DG Environment News Alert Service: Bruxelles/Brussel, Belgium, 2007. [Google Scholar]

- Assiego de La, A.; Calleja Rodríguez, G.; Cejudo López, J.M.; Raugei, M.; Fullana i Palmer, P. A decision-making LCA for energy refurbishment of buildings: Conditions of comfort. Energy Build. 2014, 70, 333–342. [Google Scholar] [CrossRef]

- Ziyadi, M.; Al-Qadi, I.L. Model uncertainty analysis using data analytics for life-cycle assessment (LCA) applications. Int. J. Life Cycle Assess. 2018, 24, 945–959. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical Review of Bim-Based LCA Method to Buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Waibel, C.; Wortmann, T.; Evins, R.; Carmeliet, J. Building energy optimization: An extensive benchmark of global search algorithms. Energy Build. 2019, 187, 23. [Google Scholar] [CrossRef]

- Ubando, A.T.; Rivera, D.R.T.; Chen, W.-H.; Culaba, A.B. A comprehensive review of life cycle assessment (LCA) of microalgal and lignocellulosic bioenergy products from thermochemical processes. Bioresour. Technol. 2019, 291, 121837. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H. A multi-stage optimization of passively designed high-rise residential buildings in multiple building operation scenarios. Appl. Energy 2017, 206, 541–557. [Google Scholar] [CrossRef]

- Sharif, S.A.; Hammad, A. Simulation-Based Multi-Objective Optimization of Institutional Building Renovation Considering Energy Consumption, Life-Cycle Cost and Life-Cycle Assessment. J. Build. Eng. 2018, 21, 429–445. [Google Scholar] [CrossRef]

- Noorzai, E.; Bakmohammadi, P.; Garmaroudi, M.A. Optimizing daylight, energy and occupant comfort performance of classrooms with photovoltaic integrated vertical shading devices. Archit. Eng. Des. Manag. 2023, 19, 394–418. [Google Scholar] [CrossRef]

- Hollberg, A.; Genova, G.; Habert, G. Evaluation of BIM-based LCA results for building design. Autom. Constr. 2019, 109, 102972. [Google Scholar] [CrossRef]

- Rezaei, F.; Bulle, C.; Lesage, P. Integrating building information modeling and life cycle assessment in the early and detailed building design stages. Build. Environ. 2019, 153, 158–167. [Google Scholar] [CrossRef]

- Yılmaz, E.; Arslan, H.; Bideci, A. Environmental performance analysis of insulated composite facade panels using life cycle assessment (LCA). Constr. Build. Mater. 2019, 202, 806–813. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, J.; Wang, Y.; Xu, Y.; Xiao, J. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 2019, 209, 115–125. [Google Scholar] [CrossRef]

- Kiss, B.; Szalay, Z. Modular approach to multi-objective environmental optimization of buildings. Autom. Constr. 2020, 111, 103044. [Google Scholar] [CrossRef]

- Yang, Y.; Heijungs, R. Moving from completing system boundaries to more realistic modeling of the economy in life cycle assessment. Int. J. Life Cycle Assess. 2018, 24, 211–218. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Harmonising methodological choices in life cycle assessment of hydrogen: A focus on acidification and renewable hydrogen. Int. J. Hydrogen Energy 2018, 44, 19426–19433. [Google Scholar] [CrossRef]

- Awad, H.; Salim, K.E.; Gül, M. Multi-objective design of grid-tied solar photovoltaics for commercial flat rooftops using particle swarm optimization algorithm. J. Build. Eng. 2019, 28, 101080. [Google Scholar] [CrossRef]

- Rapone, G.; Saro, O. Optimisation of curtain wall façades for office buildings by means of PSO algorithm. Energy Build. 2012, 45, 189–196. [Google Scholar] [CrossRef]

- Mortezaei Farizhendy, M.; Noorzai, E.; Golabchi, M. Implementing the NSGA-II genetic algorithm to select the optimal repair and maintenance method of jack-up drilling rigs in Iranian shipyards. Ocean Eng. 2020, 211, 107548. [Google Scholar] [CrossRef]

- Singh, P.; Sadhu, A. Multicomponent energy assessment of buildings using building information modeling. Sustain. Cities Soc. 2019, 49, 101603. [Google Scholar] [CrossRef]

- Xu, Z.; Lu, X.; Zeng, X.; Xu, Y.; Li, Y. Seismic loss assessment for buildings with various-LOD BIM data. Adv. Eng. Inform. 2019, 39, 112–126. [Google Scholar] [CrossRef]

- Abbasi, S.; Noorzai, E. The BIM-Based multi-optimization approach in order to determine the trade-off between embodied and operation energy focused on renewable energy use. J. Clean. Prod. 2020, 281, 125359. [Google Scholar] [CrossRef]

- Asadi, E.; da Silva, M.G.; Antunes, C.H.; Dias, L.; Glicksman, L. Multi-Objective Optimization For Building Retrofit: A Model Using Genetic Algorithm And Artificial Neural Network And An Application. Energy Build. 2014, 81, 444–456. [Google Scholar] [CrossRef]

- Jalali, Z.; Noorzai, E.; Heidari, S. Design and optimization of form and facade of an office building using the genetic algorithm. Sci. Technol. Built Environ. 2019, 26, 128–140. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Integration of LCA and LCC analysis within a BIM-based environment. Autom. Constr. 2019, 103, 127–149. [Google Scholar] [CrossRef]

- Ham, Y.; Golparvar-Fard, M. Mapping actual thermal properties to building elements in gbXML-based BIM for reliable building energy performance modeling. Autom. Constr. 2015, 49, 214–224. [Google Scholar] [CrossRef]

- Basbagill, J.; Flager, F.; Lepech, M.; Fischer, M. Application of life-cycle assessment to early stage building design for reduced embodied environmental impacts. Build. Environ. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Jrade, A.; Jalaei, F. Integrating building information modelling with sustainability to design building projects at the conceptual stage. Build. Simul. 2013, 16, 429–444. [Google Scholar] [CrossRef]

- Jalaei, F.; Jrade, A. Integrating BIM with Green Building Certification System, Energy Analysis and Cost Estimating Tools to Conceptually Design Sustainable Buildings. Constr. Res. Congr. 2014, 10, 140–149. [Google Scholar]

- Jalaei, F.; Jrade, A. Integrating building information modeling (BIM) and LEED system at the conceptual design stage of sustainable buildings. Sustain. Cities Soc. 2015, 18, 12. [Google Scholar] [CrossRef]

- LEED v4.1; Leadership in Energy and Environmental Design: Building Design +Construction (LEED BD+C). U.S. Green Building Council: Washington, DC, USA, 2021.

- Salimzadeh, N.; Vahdatikhaki, F.; Hammad, A. Parametric modeling and surface-specific sensitivity analysis of PV module layout on building skin using BIM. Energy Build. 2020, 216, 14. [Google Scholar] [CrossRef]

- Bagheri-Esfeh, H.; Dehghan, M.R. Multi-objective optimization of setpoint temperature of thermostats in residential buildings. Energy Build. 2022, 261, 111955. [Google Scholar] [CrossRef]

- Chen, B.; Liu, Q.; Chen, H.; Wang, L.; Deng, T.; Zhang, L.; Wu, X. Multiobjective optimization of building energy consumption based on BIM-DB and LSSVM-NSGA-II. J. Clean. Prod. 2021, 294, 126153. [Google Scholar] [CrossRef]

- Abdallah, M.; El-Rayes, K. Optimizing the selection of building upgrade measures to minimize the operational negative environmental impacts of existing buildings. Build. Environ. 2015, 84, 32–43. [Google Scholar] [CrossRef]

- 62.1-2022; ANSI/ASHRAE Standard: Ventilation and Acceptable Indoor Air Quality. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE): Atlanta, GA, USA, 2022.

- ladybug.tools/epwmap. 2022. Available online: https://www.ladybug.tools/epwmap/ (accessed on 15 September 2023).

- EN 15978; Sustainability of Construction Works: Assessment of Environmental Performance of Buildings. British Standard Institution (BSI): London, UK, 2011.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).