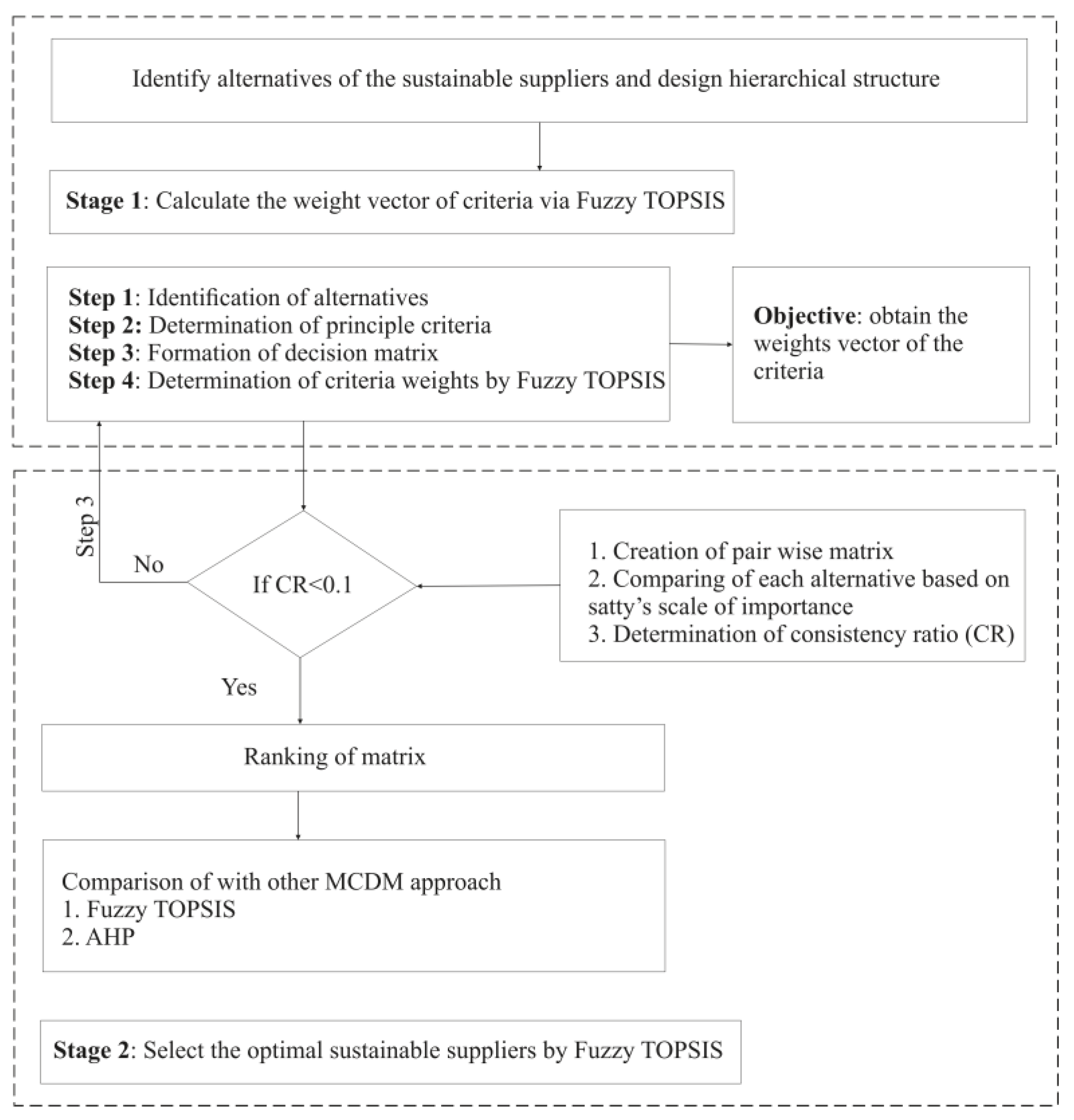

This section used a hierarchical structure and the Fuzzy Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) to assist with sustainable supplier selection in supply chain management. The term “fuzzy” signifies the presence of uncertainty as well as imprecision in decision making. When reviewing and ranking suppliers by considering environmental and social factors, this strategy handles ambiguous or imprecise information. The supplier assessment criteria’s inherent uncertainties and ambiguity were addressed using the Fuzzy TOPSIS approach, and the hierarchical structure offered a structured framework for managing the decision-making process [

26,

27,

28,

29,

30]. This study aims to make informed decisions by leveraging the experience of 55 managerial-level professionals, including top-level managers, business analysts, and senior researchers. Expert profiles were created to collect raw data based on their qualifications, expertise, and relevance to the research subject. We conducted structured interviews with these experts, utilizing a pre-determined list of questions covering major parts of the research issue. To gain expert opinions, we conducted in-depth interviews with each professional, allowing us to tap into their significant knowledge and experience in the field. The process for using the Fuzzy TOPSIS approach within the hierarchical structure is described in this part, including the selection of criteria, criteria weighting, fuzzy evaluation, and final supplier ranking.

3.2. Hierarchical Model for the Selection of Sustainable Supplier

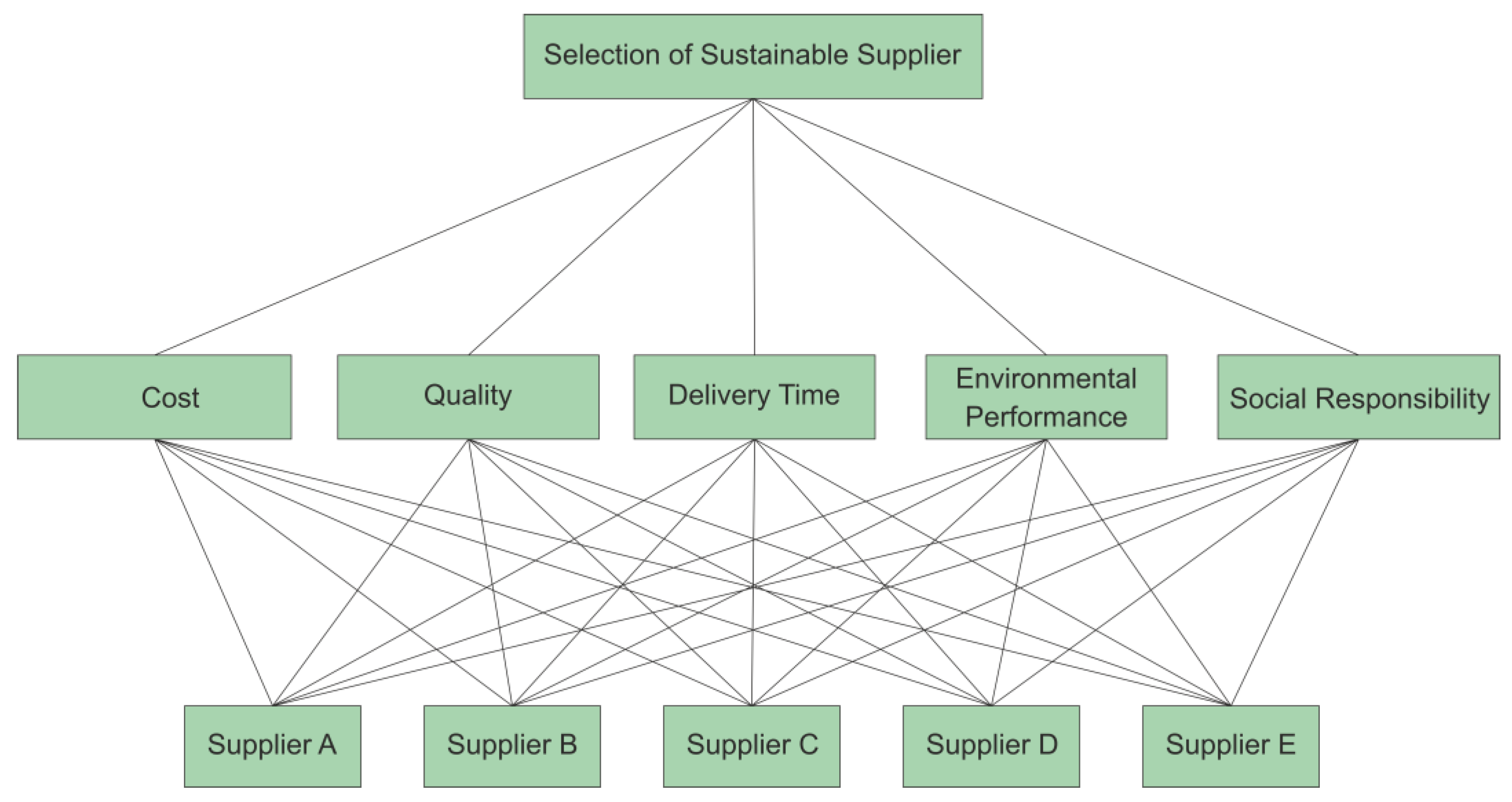

In order to properly organize the selection process of sustainable supplier, a hierarchical model is proposed, taking into account the multi-faceted character of sustainable supplier selection. The introduction of an innovative and thorough supplier selection framework based on five important aspects—cost, quality, delivery time, environmental performance, and social responsibility—is intended to revolutionize long-term supply chain management. This specific framework includes cutting-edge approaches and adheres to sustainability, ethical, and efficiency principles. The first element, cost, goes beyond the traditional method of focusing exclusively on purchasing price. Instead, it incorporates total cost of ownership (TCO) assessment, which includes procurement, shipping, inventory keeping, and other pertinent costs. Organizations can make better-informed choices that match with their financial objectives as well as long-term profitability by evaluating suppliers via this holistic cost lens. Quality remains an essential criterion in the framework, emphasising the consistency and dependability of suppliers’ products or services. Using sophisticated quality management approaches such as Six Sigma and Statistical Process Control, suppliers with a solid track record of regularly delivering high-quality goods and services can be identified. Delivery time, in addition to cost and quality, appears to be a critical element in the framework. For efficiency in operations, meeting customer demand, and lowering lead times, timely delivery is critical. The hierarchical model employs performance data and cutting-edge delivery tracking tools to find suppliers who can consistently meet tight deadlines.

The innovative supplier selection framework is also the first to incorporate environmental performance as a critical factor. The environmental impact of suppliers is thoroughly analysed through life cycle analyses and environmental certifications, including greenhouse gas emissions, water usage, and waste generation. Suppliers who exhibit a strong commitment to sustainability and have embraced eco-friendly practises can be prioritised by organisations. Additionally, the framework prioritises social responsibility, emphasising suppliers’ ethical behaviour and social impact. Labour practises, human rights compliance, diversity and inclusion activities, and interaction with local communities are all evaluated. Organisations may cultivate a positive reputation, increase their brand value, and positively contribute to society by cooperating with socially responsible suppliers. This specific supplier selection framework’s incorporation of cost, quality, delivery time, environmental performance, and social responsibility as the main pillars symbolises an innovation in supply chain management. Organisations can accomplish sustainable procurement practises, make responsible decisions, and form long-term partnerships with suppliers that align with their ethical as well as business goals by adopting this comprehensive strategy. Furthermore, this novel approach ushers in the next phase of supply chain sustainability by empowering organisations to set the standard for corporate social responsibility as well as environmental stewardship. The hierarchy makes it possible to evaluate suppliers holistically, ensuring that all pertinent criteria are taken into account and given the proper weighting during the decision-making process. The hierarchical representation for choosing a sustainable supplier is shown in

Figure 3 below.

3.2.1. Criteria Identification

The main goals of this part were to develop and define the essential standards for assessing suppliers’ sustainability performance in supply chain management. Given the importance of taking into account many sustainability-related factors, a methodical approach was used to identify the pertinent standards. The process used to determine the criteria is described in this section, which included a thorough assessment of the literature, discussions with business professionals, and consideration of organisational goals. This section establishes the groundwork for a rigorous and inclusive evaluation framework by defining a thorough set of criteria, ensuring that all pertinent sustainability-related factors are taken into account during the supplier selection process. The five criteria that were determined for this research study are listed below.

Cost: This criterion evaluates each supplier’s price strategy, total cost of ownership, and overall financial impact. It takes into account things like the cost of the product, the conditions of payment, discounts, and any supplemental expenses like shipping or customisation.

Quality: The capacity of the supplier to consistently supply goods or services which satisfy or go above the predetermined standards is referred to as quality. This criterion assesses elements including product dependability, compliance with quality control procedures, certifications, and customer satisfaction scores.

Delivery Time: The primary concern of delivery time is the supplier’s capacity to fulfil orders promptly and adhere to established delivery schedules. It takes into account things like lead times, production capacity, effective order processing, and delivery performance.

Environmental Performance: This criterion assesses the supplier’s dedication to eco-friendly business practises. It evaluates elements including carbon footprint, waste management, energy efficiency, reliance on renewable resources, and adherence to environmental laws.

Social Responsibility: The supplier’s ethical as well as social practises are evaluated by the social responsibility criterion. It takes into account elements like working conditions, ethical business practices, diversity and inclusion strategies, health and safety regulations, and community involvement programmes.

3.2.2. Identification of Alternatives

The selection and identification of potential supplier alternatives to be considered during the sustainable supplier selection process were the main objectives of this section. This section covers the methodical process used to find and shortlist the alternatives because it is crucial to take into account a wide range of options. To create a complete list of potential suppliers, this approach involved market research, supplier databases, and cooperation with important parties. In order to ensure that only the alternatives with the greatest potential for sustainable performance are taken into consideration for further review, the section also discusses the criteria used to filter and prioritise the alternatives. This part carefully identifies and chooses the alternatives, laying the groundwork for a thorough and efficient supplier evaluation procedure. The recognised options for this examination and selection are listed below.

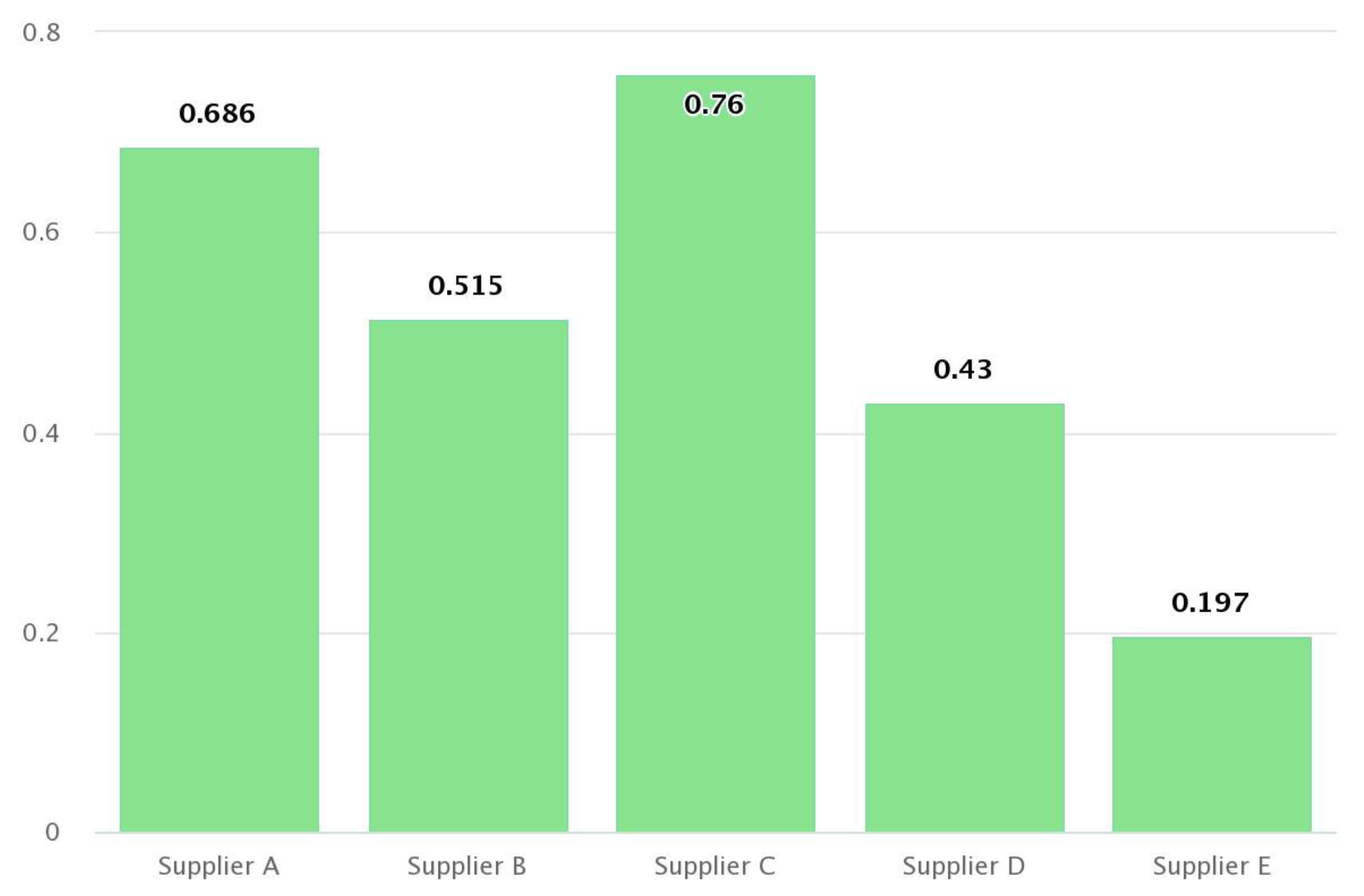

Supplier A: A reputable supplier with a competitive pricing structure, a proven track record of supplying high-quality items, and a solid track record of completing orders on time. They have put in place strategies for environmental sustainability and operate active social responsibility initiatives.

Supplier B: A reasonable provider with reasonable prices; however, they need to enhance their quality control procedures and delivery performance. They have already begun putting environmental sustainability practises into practise and are currently working to improve their social responsibility programmes.

Supplier C: A high-end source with more expensive prices, but outstanding product quality as well as prompt delivery. They actively take part in social responsibility initiatives and have a strong environmental sustainability policy in place.

Supplier D: A reasonable in terms of pricing, quality, and timeliness of delivery performance source. They have few social responsibility programmes, and they are just starting to apply environmental sustainability initiatives.

Supplier E: A provider whose low prices are accompanied by variable product quality and lengthy delivery windows. They make only modest efforts to uphold social responsibility and implement minimal environmental sustainability practises.

In Fuzzy-TOPSIS-based multiple criteria decision-making (MCDM) analysis, identifying criteria and alternatives is critical. The selection of proper criteria is critical since it establishes the dimensions or traits that will be used to evaluate the options. These criteria constitute guiding principles that match with the decision making process’s aims and requirements. A thorough investigation and precise criteria specification guarantee that all essential parts of the problem are considered, resulting in a more comprehensive and accurate review. In a comparable manner, proper alternative determination is critical since they provide prospective solutions or possibilities to be evaluated against the established criteria. A well-defined set of alternatives guarantees that the decision-making process covers a wide range of possible consequences, providing a thorough review of prospective options. This, in turn, enables decision makers to make informed and sound decisions by taking into account a variety of viable options. In general, methodical identification of criteria as well as alternatives in Fuzzy-TOPSIS-based MCDM analysis improves decision-making objectivity and rigour. It enables a more thorough and inclusive review of various alternatives, enabling the selection of the best option that matches with the decision makers’ interests and values. As an outcome, in complicated and unpredictable decision-making contexts, this technique assists in making well-informed choices.