Methodology for Resilience Assessment of Oil Pipeline Network System Exposed to Earthquake

Abstract

1. Introduction

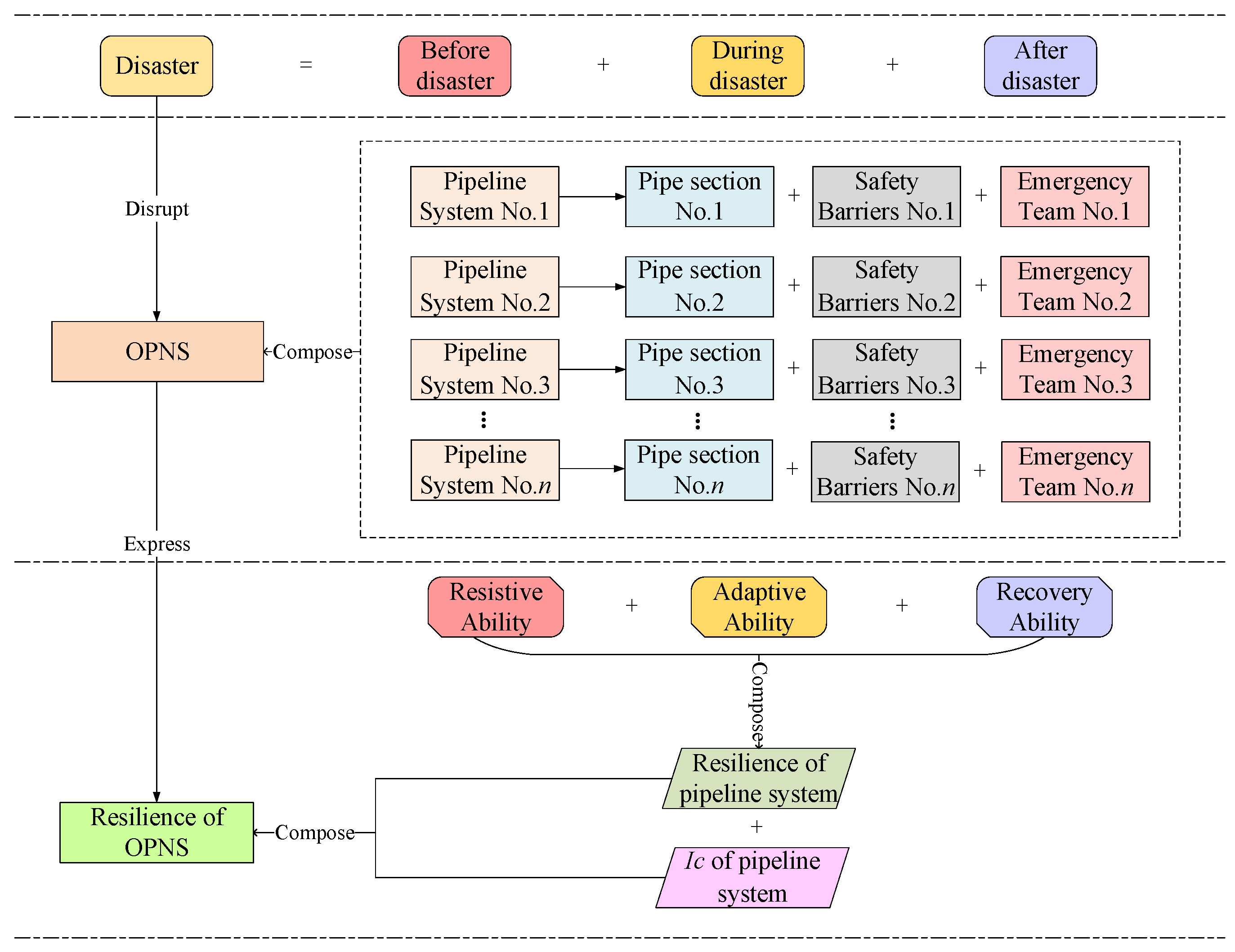

2. Resilience of OPNS

2.1. Connotation of Resilience

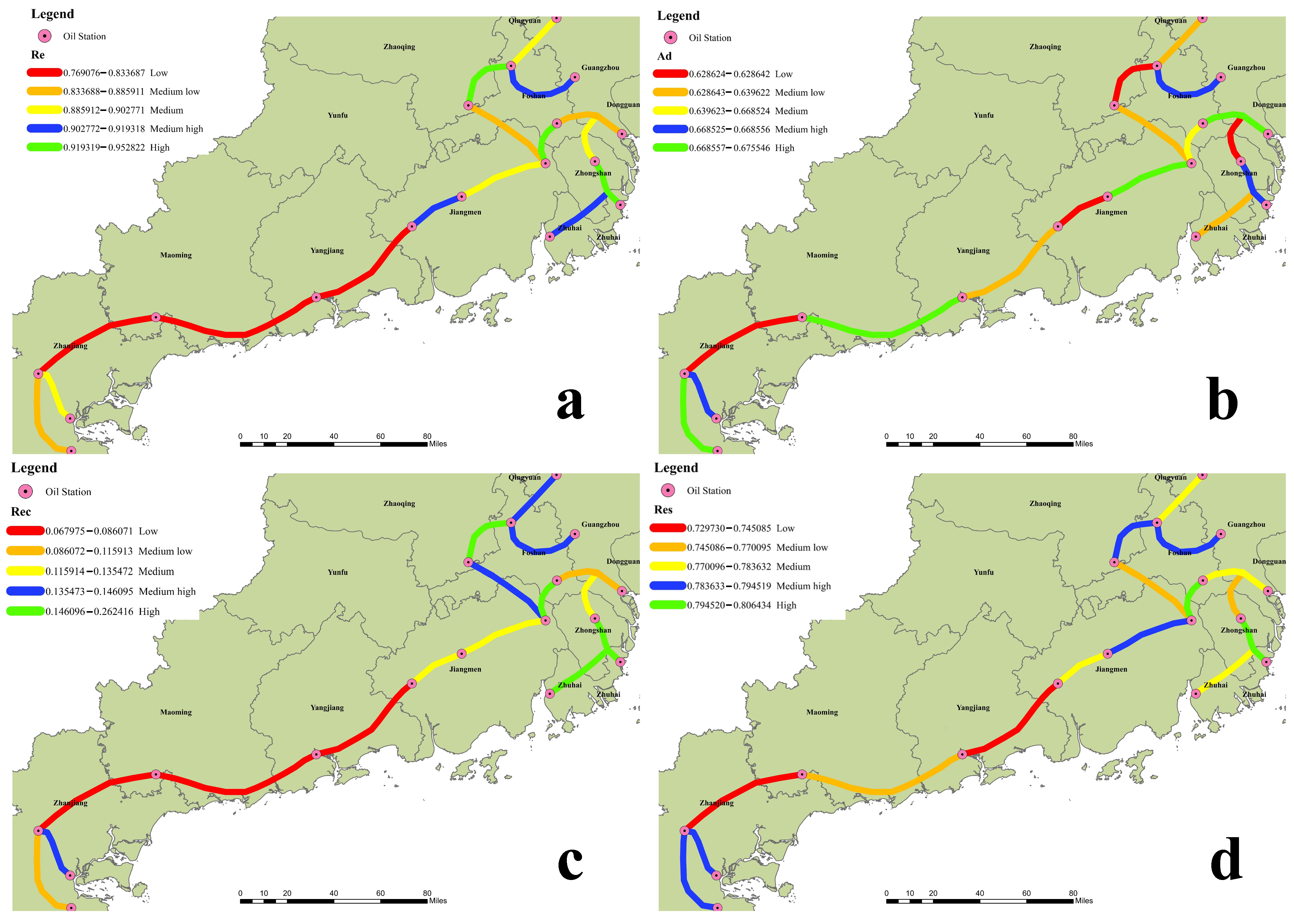

- The resistive ability—refers to the power of the system to resist disaster damage and maintain structural stability [36].

- The adaptive ability—refers to how a system adapts to the process of disaster evolution and ensures its function is stable [37].

- The recovery ability—the ability of system performance to recover to a certain level after a disaster under the action of recovery measures [38].

2.2. Definition of OPNS Resilience

2.3. Resilience Metrics

3. Quantification Model of OPNS Resilience

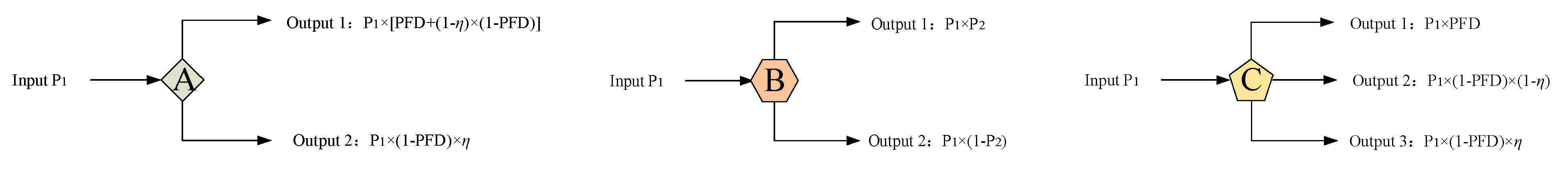

3.1. Quantification of Resistive Ability

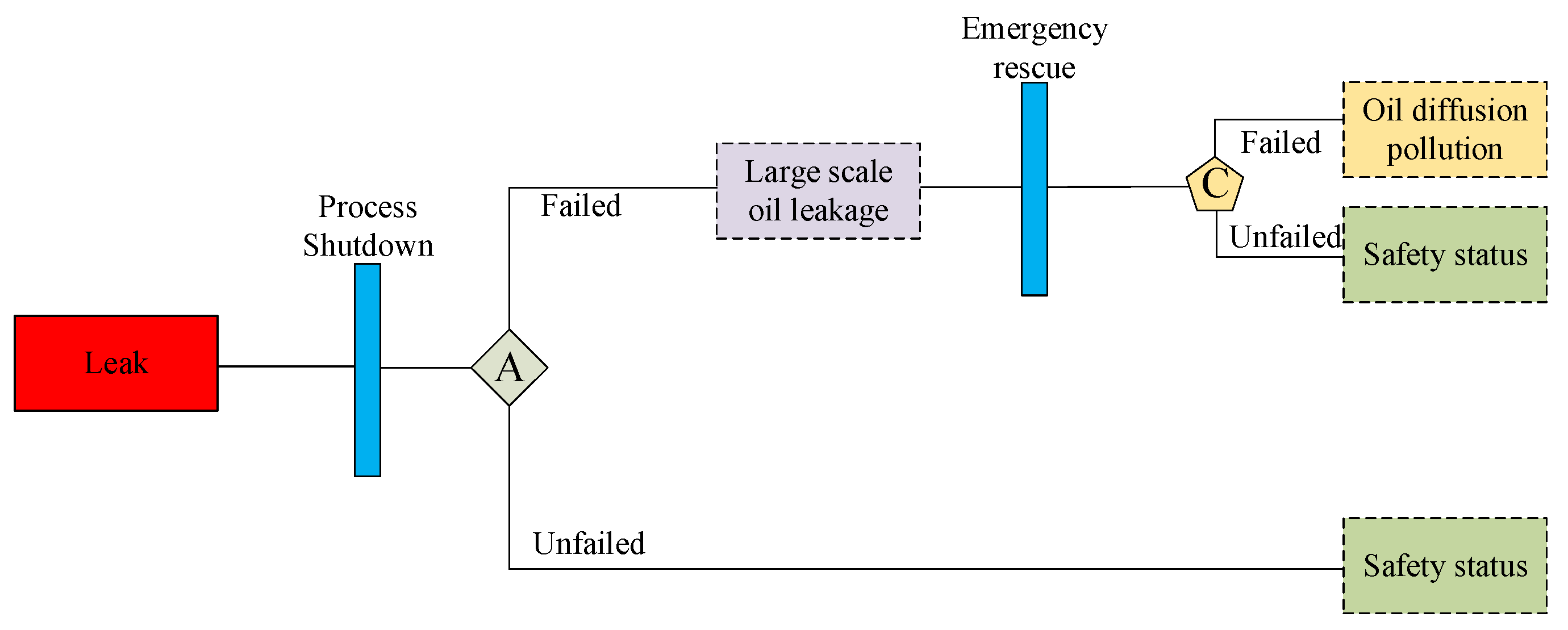

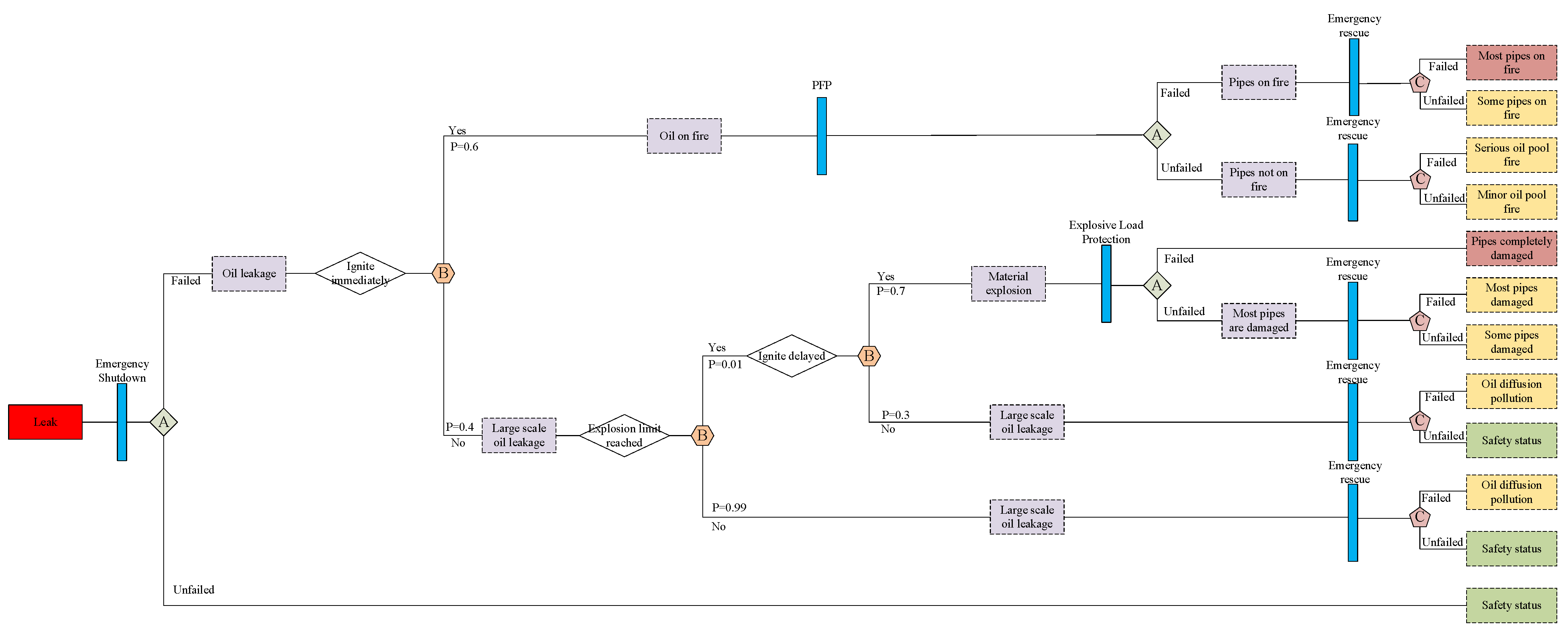

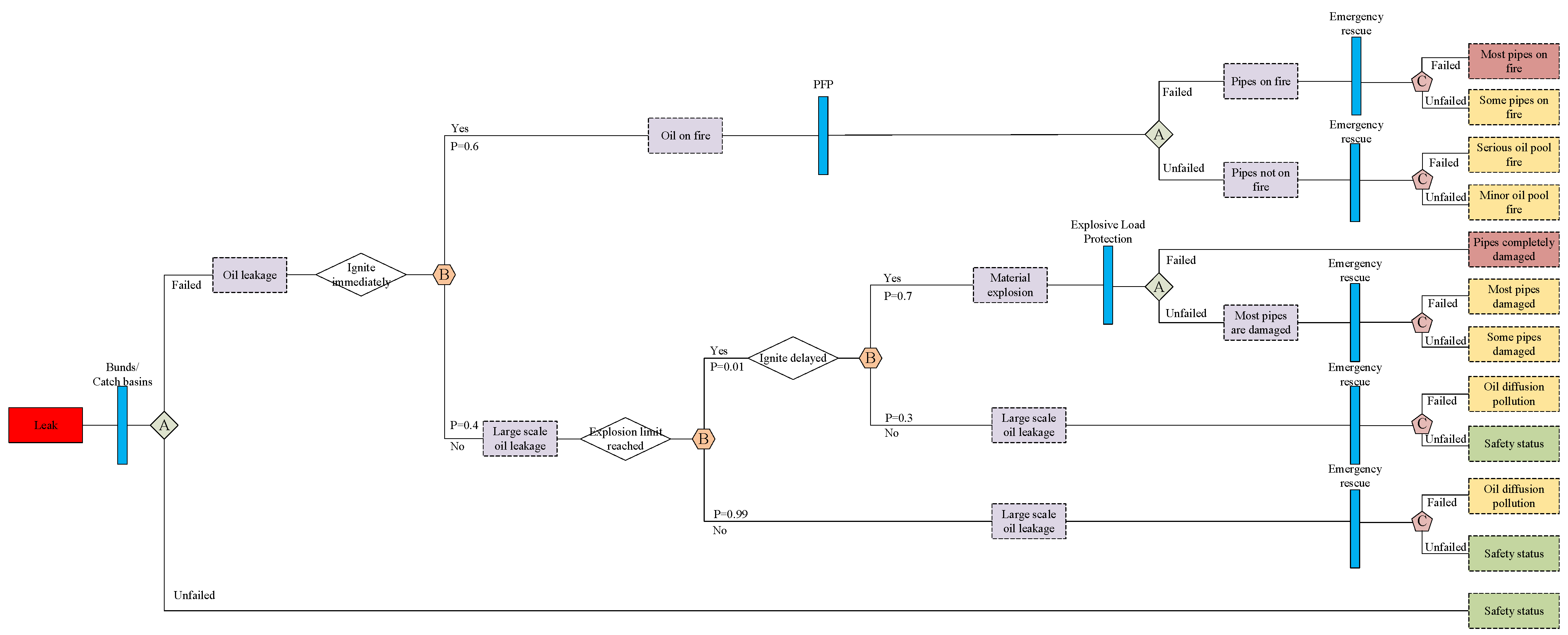

3.2. Quantification of Adaptive Ability

3.3. Quantification of Recovery Ability

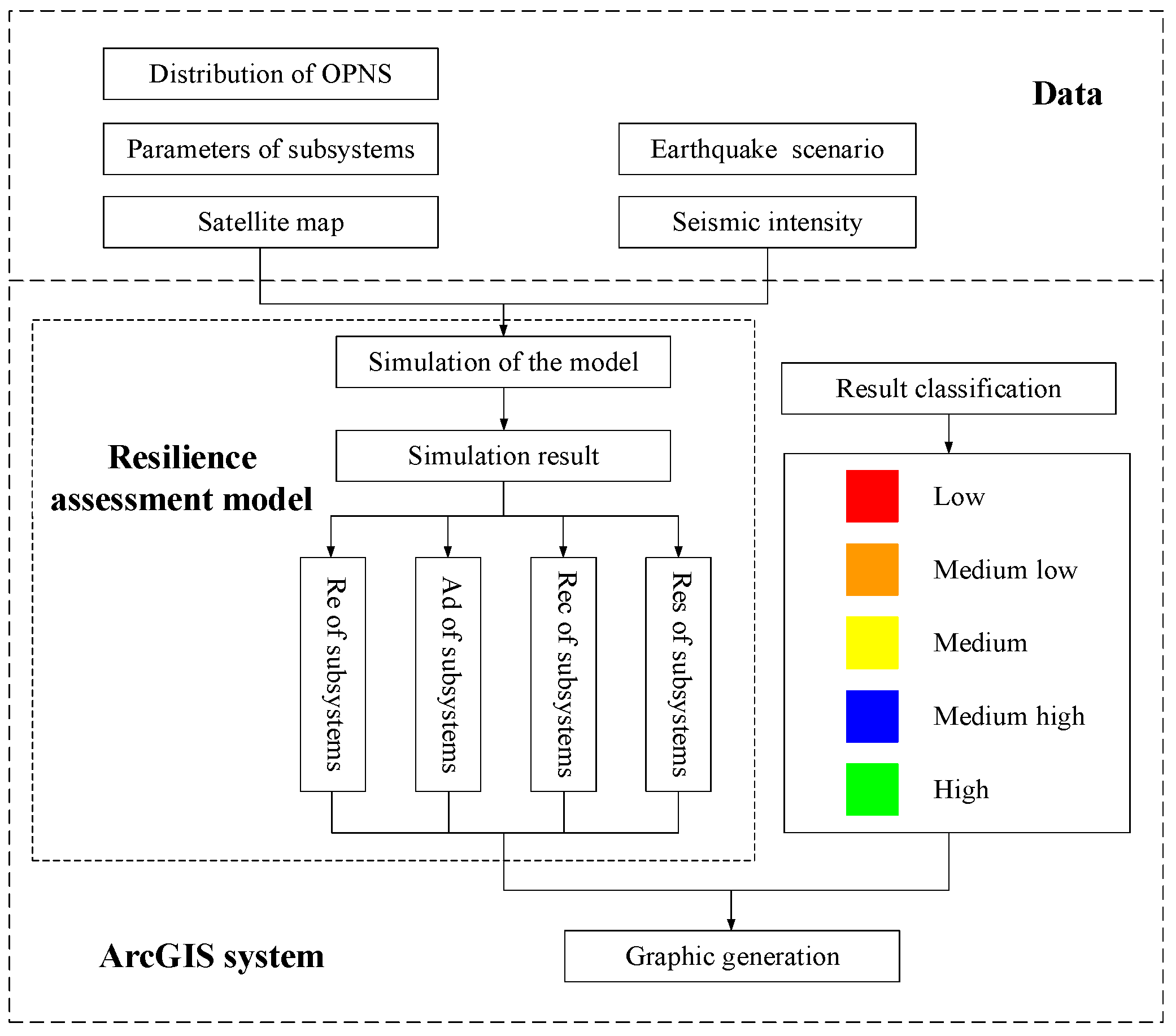

4. Methodology of OPNS Resilience Exposed to Earthquake and the Resilience Partitioning Platform

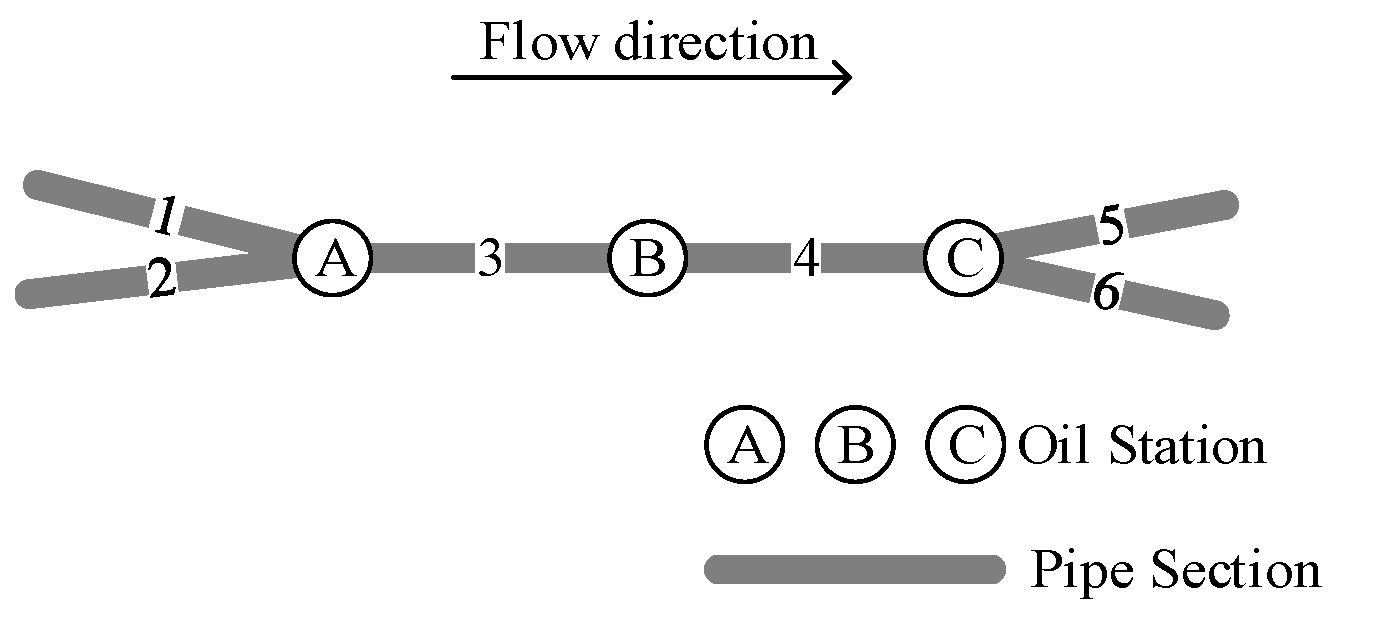

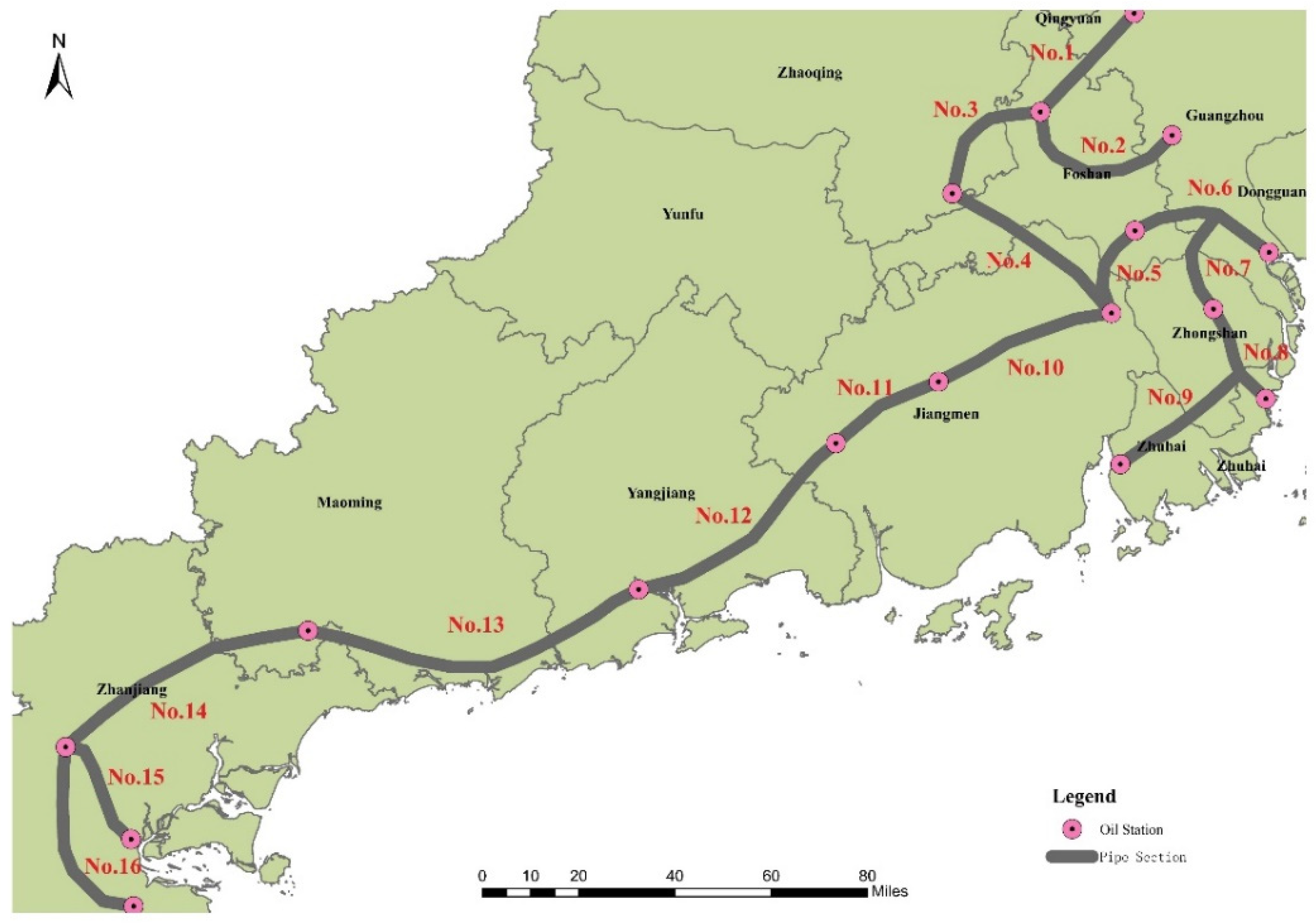

5. Case Study Description

5.1. Data Collection

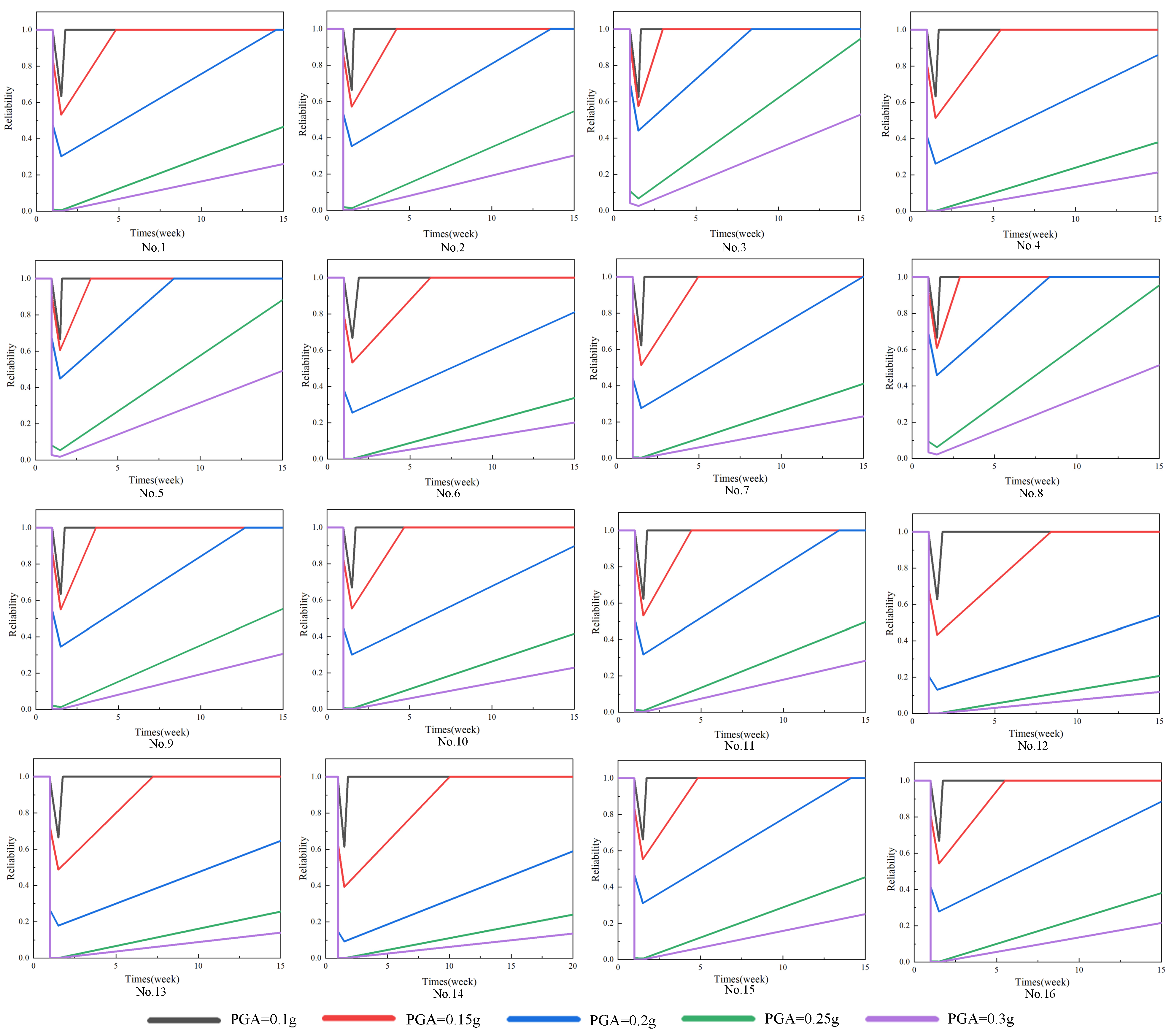

5.2. Calculation of Resilience Assessment Indexes

5.3. Calculation of Network Resilience

5.4. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Urlainis, A.; Shohet, I.M.; Levy, R. Probabilistic Risk Assessment of Oil and Gas Infrastructures for Seismic Extreme Events. Procedia Eng. 2015, 123, 590–598. [Google Scholar] [CrossRef]

- Girgin, S.; Elisabeth, K. Lessons Learned from Oil Pipeline Natech Accidents and Recommendations for Natech Scenario Development Final Report; Institute for the Protection and Security of the Citizen, Joint Research Centre: Luxembourg, 2015; Volume 2749, p. 21027. [Google Scholar] [CrossRef]

- Wang, X.; Guo, E.; Zhang, M. Analysis and Countermeasures on Seismic Damages to Gas Pipeline in Wenchuan Earthquake. World Inf. Earthq. Eng. 2012, 194, 1938–1942. [Google Scholar] [CrossRef]

- Psyrras, N.K.; Sextos, A.G. Safety of Buried Steel Natural Gas Pipelines under Earthquake-Induced Ground Shaking: A Review. Soil Dyn. Earthq. Eng. 2018, 106, 254–277. [Google Scholar] [CrossRef]

- Schuster, R. The March 5, 1987, Ecuador Earthquakes: Mass Wasting and Socioeconomic Effects; National Academies Press: Washington, DC, USA, 1991; ISBN 9780309044448. [Google Scholar]

- Leveille, T.P.; Shane, D.; Morris, J. Northridge earthquake pipeline rupture into the santa clara river. Int. Oil Spill Conf. Proc. 1995, 1995, 489–494. [Google Scholar] [CrossRef]

- Pasquarè, F.A.; Tormey, D.; Vezzoli, L.; Okrostsvaridze, A. Mitigating the Consequences of Extreme Events on Strategic Facilities: Evaluation of Volcanic and Seismic Risk Affecting the Caspian Oil and Gas Pipelines in the Republic of Georgia. J. Environ. Manag. 2011, 92, 1774–1782. [Google Scholar] [CrossRef]

- Liu, A.; Chen, K.; Wu, J. State of Art of Seismic Design and Seismic Hazard Analysis for Oil and Gas Pipeline System. Earthq. Sci. 2010, 23, 259–263. [Google Scholar] [CrossRef]

- Zhong, Z.; Filiatrault, A.; Aref, A. Numerical Simulation and Seismic Performance Evaluation of Buried Pipelines Rehabilitated with Cured-in-place-pipe Liner under Seismic Wave Propagation. Earthq. Eng. Struct. Dyn. 2017, 46, 811–829. [Google Scholar] [CrossRef]

- Jahangiri, V.; Shakib, H. Seismic Risk Assessment of Buried Steel Gas Pipelines under Seismic Wave Propagation Based on Fragility Analysis. Bull. Earthq. Eng. 2018, 16, 1571–1605. [Google Scholar] [CrossRef]

- Chen, C.; Li, C.; Reniers, G.; Yang, F. Safety and Security of Oil and Gas Pipeline Transportation: A Systematic Analysis of Research Trends and Future Needs Using WoS. J. Clean. Prod. 2021, 279, 123583. [Google Scholar] [CrossRef]

- Sarvanis, G.C.; Karamanos, S.A. Analytical Model for the Strain Analysis of Continuous Buried Pipelines in Geohazard Areas. Eng. Struct. 2017, 152, 57–69. [Google Scholar] [CrossRef]

- Wu, X.N.; Lu, H.F.; Wu, S.J.; Kun, H.; Chen, X.; Kang, F.X.; Liu, Z.L. Analysis of Suspended Pipeline Stress Sensitivity. Appl. Mech. Mater. 2014, 501, 2331–2334. [Google Scholar] [CrossRef]

- Makhoul, N.; Navarro, C. A Comparative Study of Buried Pipeline Fragilities Using the Seismic Damage to the Byblos Wastewater Network. Int. J. Disaster Risk Reduct. 2020, 51, 101775. [Google Scholar] [CrossRef]

- Germoso, C.; Gonzalez, O.; Chinesta, F. Seismic Vulnerability Assessment of Buried Pipelines: A 3D Parametric Study. Soil Dyn. Earthq. Eng. 2021, 143, 106627. [Google Scholar] [CrossRef]

- Shabarchin, O.; Tesfamariam, S. Risk Assessment of Oil and Gas Pipelines with Consideration of Induced Seismicity and Internal Corrosion. J. Loss Prev. Process Ind. 2017, 47, 85–94. [Google Scholar] [CrossRef]

- Tserng, H.P.; Cho, I.C.; Chen, C.H.; Liu, Y.F. Developing a Risk Management Process for Infrastructure Projects Using Idef0. Sustainability 2021, 13, 6958. [Google Scholar] [CrossRef]

- Lin, G.; Wang, S.; Lin, C.; Bu, L.; Xu, H. Evaluating Performance of Public Transport Networks by Using Public Transport Criteria Matrix Analytic Hierarchy Process Models—Case Study of Stonnington, Bayswater, and Cockburn Public Transport Network. Sustainability 2021, 13, 6949. [Google Scholar] [CrossRef]

- Pajek, L.; Košir, M. Exploring Climate-Change Impacts on Energy Efficiency and Overheating Vulnerability of Bioclimatic Residential Buildings under Central European Climate. Sustainability 2021, 13, 6791. [Google Scholar] [CrossRef]

- Assad, A.; Bouferguene, A. Resilience Assessment of Water Distribution Networks–Bibliometric Analysis and Systematic Review. J. Hydrol. 2022, 607, 127522. [Google Scholar] [CrossRef]

- Cimellaro, G.P.; Villa, O.; Bruneau, M. Resilience-Based Design of Natural Gas Distribution Networks. J. Infrastruct. Syst. 2015, 21, 5014005. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, Z.; Gong, H.; Qiang, L. Review on the Study of Disaster Resilience of Critical Infrastructure Systems. China Civ. Eng. J. 2017, 50, 62–71. [Google Scholar] [CrossRef]

- Li, X.; Su, H.; Zhang, J. A Systematic Assessment Method of Supply Resilience for Natural Gas Supply Systems. Chem. Eng. Res. Des. 2022, 182, 207–215. [Google Scholar] [CrossRef]

- Cimellaro, G.P.; Reinhorn, A.M.; Bruneau, M. Framework for Analytical Quantification of Disaster Resilience. Eng. Struct. 2010, 32, 3639–3649. [Google Scholar] [CrossRef]

- Han, L.; Zhao, X.D.; Chen, Z.L. Seismic Resilience Assessment and Optimization of Urban Water Distribution Network. China Saf. Sci. J. 2021, 31, 135–142. [Google Scholar]

- Song, Z.; Liu, W.; Shu, S. Resilience-Based Post-Earthquake Recovery Optimization of Water Distribution Networks. Int. J. Disaster Risk Reduct. 2022, 74, 102934. [Google Scholar] [CrossRef]

- Bi, X.; Ji, K.; Wen, R.; Zong, C.; Zhang, X. Seismic Resilience Quantification Assessment of Urban Gas Network Considering Recovery Efficiency and Methods. Yingyong Jichu Yu Gongcheng Kexue Xuebao/J. Basic Sci. Eng. 2021, 29, 1561–1575. [Google Scholar] [CrossRef]

- Zong, C.C.; Ji, K.; Wen, R.Z.; Bi, X.R.; Zhang, X.R. Three-Dimensional Seismic Resilience Quantification Framework for the Urban Gas Network. Gongcheng Lixue/Eng. Mech. 2021, 38, 146–156. [Google Scholar] [CrossRef]

- Vairo, T.; Gualeni, P.; Reverberi, A.P.; Fabiano, B. Resilience Dynamic Assessment Based on Precursor Events: Application to Ship Lng Bunkering Operations. Sustainability 2021, 13, 6836. [Google Scholar] [CrossRef]

- Ptak-Wojciechowska, A.; Januchta-Szostak, A.; Gawlak, A.; Matuszewska, M. The Importance of Water and Climate-Related Aspects in the Quality of Urban Life Assessment. Sustainability 2021, 13, 6573. [Google Scholar] [CrossRef]

- Liu, W.; Song, Z. Review of Studies on the Resilience of Urban Critical Infrastructure Networks. Reliab. Eng. Syst. Saf. 2020, 193, 106617. [Google Scholar] [CrossRef]

- Zhang, J.; Su, H.; Gao, P. Resilience-Based Supply Assurance of Natural Gas Pipeline Networks and Its Research Prospects. Shiyou Xuebao/Acta Pet. Sin. 2020, 41, 1665–1678. [Google Scholar] [CrossRef]

- Brunner, R.D.; Gunderson, L.H.; Holling, C.S.; Light, S.S. Barriers and Bridges to the Renewal of Ecosystems and Institutions. J. Wildl. Manag. 1997, 61, 1437. [Google Scholar] [CrossRef]

- Allenby, B.; Fink, J. Social and Ecological Resilience: Toward Inherently Secure and Resilient Societies. Science 2005, 309, 1034–1036. [Google Scholar] [CrossRef]

- Sharifi, A.; Yamagata, Y. On the Suitability of Assessment Tools for Guiding Communities towards Disaster Resilience. Int. J. Disaster Risk Reduct. 2016, 18, 115–124. [Google Scholar] [CrossRef]

- Bi, W.; Tang, Y.; Mao, T.T.; Sun, X.H.; Li, Q.M. Review on Resilience Management of Urban Infrastructure System. China Saf. Sci. J. (CSSJ) 2021, 31, 14–28. [Google Scholar] [CrossRef]

- Ji, C.; Wei, Y.; Poor, H.V. Resilience of Energy Infrastructure and Services: Modeling, Data Analytics, and Metrics. Proc. IEEE 2017, 105, 1354–1366. [Google Scholar] [CrossRef]

- Liu, Y.P.; He, J.X. Review on Infrastructure Resilience Assessment and Future Direction. J. Catastrophology 2021, 36, 153. [Google Scholar] [CrossRef]

- Yarveisy, R.; Gao, C.; Khan, F. A Simple yet Robust Resilience Assessment Metrics. Reliab. Eng. Syst. Saf. 2020, 197, 106810. [Google Scholar] [CrossRef]

- Ryûji, I.; Êsuke, I.; Sêji, Y.; Nobu, S. Research on Earthquake Damage Prediction of Water Pipes. J. Watercourse Assoc. 1998, 67, 25–40. [Google Scholar]

- Hollnagel, E. Barriers and Accident Prevention; Routledge: London, UK, 2016. [Google Scholar] [CrossRef]

- Hollnagel, E. Risk + Barriers = Safety? Saf. Sci. 2008, 46, 221–229. [Google Scholar] [CrossRef]

- Wei, C.; Rogers, W.J.; Mannan, M.S. Layer of Protection Analysis for Reactive Chemical Risk Assessment. J. Hazard. Mater. 2008, 159, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Lees, F.P. Loss Prevention in the Process Industries (Partially Updated by S. Mannan); Butterworths: Burlington, NJ, USA, 2015; Volume 1. [Google Scholar]

- Frank, K.; Gravestock, N.; Spearpoint, M.; Fleischmann, C. A Review of Sprinkler System Effectiveness Studies. Fire Sci. Rev. 2013, 2, 6. [Google Scholar] [CrossRef]

- SINTEF. Guidance for Barrier Management in the Petroleum Industry. SINTEF Rep. A 2016, 27623, 62. [Google Scholar]

- Misuri, A.; Landucci, G.; Cozzani, V. Assessment of Safety Barrier Performance in the Mitigation of Domino Scenarios Caused by Natech Events. Reliab. Eng. Syst. Saf. 2021, 205, 107278. [Google Scholar] [CrossRef]

- Misuri, A.; Landucci, G.; Cozzani, V. Assessment of Risk Modification Due to Safety Barrier Performance Degradation in Natech Events. Reliab. Eng. Syst. Saf. 2021, 212, 107634. [Google Scholar] [CrossRef]

- Landucci, G.; Argenti, F.; Tugnoli, A.; Cozzani, V. Quantitative Assessment of Safety Barrier Performance in the Prevention of Domino Scenarios Triggered by Fire. Reliab. Eng. Syst. Saf. 2015, 143, 30–43. [Google Scholar] [CrossRef]

- Landucci, G.; Argenti, F.; Spadoni, G.; Cozzani, V. Domino Effect Frequency Assessment: The Role of Safety Barriers. J. Loss Prev. Process Ind. 2016, 44, 706–717. [Google Scholar] [CrossRef]

- Ramadhani, A.; Khan, F.; Colbourne, B.; Ahmed, S.; Taleb-Berrouane, M. Resilience Assessment of Offshore Structures Subjected to Ice Load Considering Complex Dependencies. Reliab. Eng. Syst. Saf. 2022, 222, 108421. [Google Scholar] [CrossRef]

- Wang, Y. Seismic Risk Assessment of Water Supply Systems. In Handbook of Seismic Risk Analysis and Management of Civil Infrastructure Systems; Woodhead Publishing: London, UK, 2013; Volume 26, pp. 659–684, 682e–684e. [Google Scholar] [CrossRef]

- Mr, H.-M. Multi-Hazard Loss Estimation Methodology: Earthquake Model; Department of Homeland Security, Federal Emergency Management Agency: Washington, DC, USA, 2003; pp. 235–260.

- China Seismological Bureau; Institute of Engineering Mechanics; China Earthquake Administration. Chinese Seismic Intensity Scale; Standardization Administration of the People’s Republic of China: Beijing, China, 2020.

| ID | Name | Classification | ID | Name | Classification |

|---|---|---|---|---|---|

| a | Fire retardant valve | Active | i | Regular patrol | Active |

| b | Isolating valves | Active | j | Emergency teams | Active |

| c | Blowdown valves | Active | A | Passive fireproofing (PFP) | Passive |

| d | Overpressure detection | Active | B | Flood control measures | Passive |

| e | Clogging detection | Active | C | Explosive load protection | Passive |

| f | Pressure reducing valve | Active | D | Anticorrosive coatings | Passive |

| g | Emergency shutdown | Active | E | Bunds/ catch basins | Passive |

| h | Process shutdown | Active | F | Emergency blowdown line to flare stack | Passive |

| No. | Diameter (mm) | Thickness (mm) | Length (km) | Geological Topography | Material | Flow (m3/h) |

|---|---|---|---|---|---|---|

| 1 | 219.1 | 5.6 | 44.8 | Hill | Q235 | 116 |

| 2 | 219.1 | 5.6 | 52 | Mountain | Q235 | 116 |

| 3 | 219 | 5.6 | 31.75 | Alluvial plain | Q235 | 116 |

| 4 | 273.1 | 6.4 | 72.94 | Mountain | Q235 | 179 |

| 5 | 323.9 | 9.5 | 35.79 | Alluvial plain | Q235 | 250 |

| 6 | 323.9 | 6.4 | 58.079 | Hill | Q235 | 250 |

| 7 | 219 | 5.6 | 49.233 | Hill | Q235 | 116 |

| 8 | 219 | 5.6 | 33.7 | Alluvial plain | Q235 | 116 |

| 9 | 219 | 5.6 | 55.267 | Alluvial plain | Q235 | 116 |

| 10 | 406.4 | 7.1 | 48.535 | Hill | Q235 | 397 |

| 11 | 406.4 | 7.1 | 40.775 | Hill | Q235 | 397 |

| 12 | 406.4 | 7.1 | 95.177 | Hill | Q235 | 397 |

| 13 | 406.4 | 7.1 | 119.503 | Alluvial plain | Q235 | 397 |

| 14 | 406.4 | 7.1 | 115 | Hill | Q235 | 397 |

| 15 | 406.4 | 7.1 | 68.741 | Alluvial plain | Q235 | 397 |

| 16 | 406.4 | 7.1 | 79.486 | Alluvial plain | Q235 | 397 |

| No. | Active Barrier | Passive Barrier | No. | Active Barrier | Passive Barrier | No. | Active Barrier | Passive Barrier | No. | Active Barrier | Passive Barrier |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | c, d, e, g, i, j | A, C, D, G | 5 | a, b, e, f, i, j | C, D, G | 9 | c, d, e, g, i, j | A, C, D, G | 13 | c, d, e, i, j | A, C, D, E, G |

| 2 | a, b, e, f, i, j | C, D, G | 6 | c, d, e, i, j | A, C, D, E, G | 10 | c, d, e, i, j | A, C, D, E, G | 14 | c, f, g, i, j | C, D, F, G |

| 3 | c, f, g, i, j | C, D, F, G | 7 | c, f, g, i, j | C, D, F, G | 11 | c, f, g, i, j | C, D, F, G | 15 | a, b, e, f, i, j | C, D, G |

| 4 | c, d, e, g, i, j | A, C, D, G | 8 | a, b, e, f, i, j | C, D, G | 12 | c, d, e, g, i, j | A, C, D, G | 16 | c, d, e, i, j | A, C, D, E, G |

| No. | P0 | P1 | P2 | P3 | t0 | t1 | t2 | t3 | Re | Ad | Rec |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.902771 | 0.577416 | 1 | 0 | 0.5 | 0.511347 | 2.335156 | 0.902771 | 0.639604 | 0.144950 |

| 2 | 1 | 0.916617 | 0.61281 | 1 | 0 | 0.5 | 0.52641 | 2.183899 | 0.916617 | 0.668556 | 0.146095 |

| 3 | 1 | 0.952822 | 0.598968 | 1 | 0 | 0.5 | 0.528437 | 1.445601 | 0.952822 | 0.628625 | 0.262416 |

| 4 | 1 | 0.885037 | 0.566073 | 1 | 0 | 0.5 | 0.511091 | 2.406749 | 0.885037 | 0.639604 | 0.143258 |

| 5 | 1 | 0.946981 | 0.63311 | 1 | 0 | 0.5 | 0.513848 | 1.560726 | 0.946981 | 0.668556 | 0.214595 |

| 6 | 1 | 0.875811 | 0.591651 | 1 | 0 | 0.5 | 0.513889 | 2.778828 | 0.875811 | 0.675546 | 0.113557 |

| 7 | 1 | 0.89368 | 0.56179 | 1 | 0 | 0.5 | 0.506092 | 2.534191 | 0.893680 | 0.628625 | 0.135472 |

| 8 | 1 | 0.949998 | 0.635127 | 1 | 0 | 0.5 | 0.524866 | 1.436539 | 0.949998 | 0.668556 | 0.242361 |

| 9 | 1 | 0.919318 | 0.588 | 1 | 0 | 0.5 | 0.51925 | 1.799679 | 0.919318 | 0.639604 | 0.198183 |

| 10 | 1 | 0.895105 | 0.604685 | 1 | 0 | 0.5 | 0.522184 | 2.517126 | 0.895105 | 0.675546 | 0.124538 |

| 11 | 1 | 0.911106 | 0.572744 | 1 | 0 | 0.5 | 0.519778 | 2.630141 | 0.911106 | 0.628625 | 0.127169 |

| 12 | 1 | 0.804684 | 0.514679 | 1 | 0 | 0.5 | 0.517993 | 4.340835 | 0.804684 | 0.639604 | 0.080391 |

| 13 | 1 | 0.833687 | 0.563194 | 1 | 0 | 0.5 | 0.515711 | 3.726815 | 0.833687 | 0.675546 | 0.086071 |

| 14 | 1 | 0.769076 | 0.483461 | 1 | 0 | 0.5 | 0.524772 | 5.343992 | 0.769076 | 0.628625 | 0.067975 |

| 15 | 1 | 0.900656 | 0.602139 | 1 | 0 | 0.5 | 0.522495 | 2.260626 | 0.900656 | 0.668556 | 0.143255 |

| 16 | 1 | 0.885911 | 0.598473 | 1 | 0 | 0.5 | 0.515839 | 2.696689 | 0.885911 | 0.675546 | 0.115913 |

| No. | Res | Ic | No. | Res | Ic | No. | Res | Ic | No. | Res | Ic |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.777272 | 2.79% | 5 | 0.806434 | 6.02% | 9 | 0.780589 | 2.79% | 13 | 0.76952 | 9.56% |

| 2 | 0.794519 | 2.79% | 6 | 0.783632 | 6.02% | 10 | 0.790182 | 9.56% | 14 | 0.72973 | 9.56% |

| 3 | 0.787381 | 2.79% | 7 | 0.76988 | 2.79% | 11 | 0.776316 | 9.56% | 15 | 0.788104 | 9.56% |

| 4 | 0.770095 | 4.31% | 8 | 0.805704 | 2.79% | 12 | 0.745085 | 9.56% | 16 | 0.787481 | 9.56% |

| No. | 0.1 g | 0.15 g | 0.2 g | 0.25 g | 0.3 g |

|---|---|---|---|---|---|

| 1 | 0.81139 | 0.75473 | 0.64158 | 0.49428 | 0.49408 |

| 2 | 0.82216 | 0.77325 | 0.66705 | 0.49582 | 0.49526 |

| 3 | 0.80357 | 0.77498 | 0.70975 | 0.51769 | 0.50328 |

| 4 | 0.80990 | 0.74551 | 0.62229 | 0.49408 | 0.49208 |

| 5 | 0.82713 | 0.79233 | 0.71302 | 0.51209 | 0.50029 |

| 6 | 0.82830 | 0.75583 | 0.61971 | 0.49443 | 0.49224 |

| 7 | 0.80625 | 0.74525 | 0.62818 | 0.49422 | 0.49390 |

| 8 | 0.82551 | 0.79102 | 0.71835 | 0.51501 | 0.50192 |

| 9 | 0.81050 | 0.76036 | 0.66273 | 0.49643 | 0.49545 |

| 10 | 0.82652 | 0.76354 | 0.64146 | 0.49418 | 0.49283 |

| 11 | 0.80420 | 0.75360 | 0.64881 | 0.49505 | 0.49127 |

| 12 | 0.80447 | 0.70533 | 0.55841 | 0.49607 | 0.49374 |

| 13 | 0.82425 | 0.73227 | 0.58168 | 0.49523 | 0.49134 |

| 14 | 0.79470 | 0.68539 | 0.53969 | 0.49662 | 0.49108 |

| 15 | 0.82324 | 0.76485 | 0.64499 | 0.49413 | 0.49225 |

| 16 | 0.82730 | 0.76041 | 0.63031 | 0.49413 | 0.49203 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Chen, G.; Zeng, T.; Zhou, L.; Zhao, J.; Zhao, Y. Methodology for Resilience Assessment of Oil Pipeline Network System Exposed to Earthquake. Sustainability 2023, 15, 972. https://doi.org/10.3390/su15020972

Ma J, Chen G, Zeng T, Zhou L, Zhao J, Zhao Y. Methodology for Resilience Assessment of Oil Pipeline Network System Exposed to Earthquake. Sustainability. 2023; 15(2):972. https://doi.org/10.3390/su15020972

Chicago/Turabian StyleMa, Jiajun, Guohua Chen, Tao Zeng, Lixing Zhou, Jie Zhao, and Yuanfei Zhao. 2023. "Methodology for Resilience Assessment of Oil Pipeline Network System Exposed to Earthquake" Sustainability 15, no. 2: 972. https://doi.org/10.3390/su15020972

APA StyleMa, J., Chen, G., Zeng, T., Zhou, L., Zhao, J., & Zhao, Y. (2023). Methodology for Resilience Assessment of Oil Pipeline Network System Exposed to Earthquake. Sustainability, 15(2), 972. https://doi.org/10.3390/su15020972

_Su.png)