1. Introduction

The globalization of the economy and the boom of e-commerce have given logistics service providers (LSPs) great potential for growth and an increasing market value [

1]. The services provided by LSPs are employed by more than 90% of the Fortune 500 enterprises, representing a

$735 billion global business market [

2]. Benefiting from specialization and economies of scale, LSPs can offer customers lower costs but with better quality logistics services, as well as provide customized services to meet customers’ needs [

3,

4]. Therefore, the services provided by LSPs have attracted a lot of attention. Meanwhile, the increased demand for logistics outsourcing services has placed higher demands on the relationship management between LSPs and their customers [

5,

6]. As the number of customers partnering with LSPs increases, the network they build will expand, involving more supply chain (SC) members and more opportunities for interaction and collaboration within the network, resulting in a more complex supply chain network [

7,

8]. External integration between LSPs and customers is becoming increasingly important in this context [

9]. The pursuit of increasing logistics services quality and customer satisfaction rate enables LSPs to strengthen their collaborative networks and conduct external integration to achieve superior service performance [

10,

11].

Numerous types of research highlighted the significance of external integration for firms’ performance [

12,

13]. For example, Raue and Wieland [

14] indicate that horizontal collaboration among LSPs can be used to gain cost advantages and improve logistics performance through resource sharing and joint activities, such as improving the efficiency of the transportation network and speeding up transportation. Consequently, external integration has emerged as a critical factor for LSPs to acquire better performance and keep their competitive edge, as well as become a significant area of academic study [

15]. Given the fast-changing logistics needs and the development of LSPs in past few year, the services provided by LSPs have evolved from basic outsourced logistics services to more advanced value-added services [

8]. Accordingly, the role of LSPs in the supply chain has evolved from simple participants, to integrators and orchestrators [

16]. In other words, LSPs can expand their control and scope of integration within the supply chain network and contribute more to external integration [

17].

Nevertheless, the positive role that LSPs play in external integration has been overlooked. Although there are substantial studies examining the external integration relationship between logistics service providers and customers, most of them start from the perspective of manufacturer-initiated SCI, lacking the exploration of external integration from the perspective of LSPs acting as integration initiators [

18]. In addition, although existing research has shown that external integration helps companies improve firm performance, the research on this performance is more focused on, for example, service quality performance and financial performance, which are often understood from a single dimension, overlooking their holistic nature [

19,

20]. Operational performance, on the other hand, covers a variety of measures such as logistics performance, financial performance, and service capability. Therefore, this study will take operational performance as the object of study in the firm performance of LSPs.

As a result of increased specialization and globalization, enterprises’ supply networks have not only grown more complicated but also face more regular and varied unanticipated events [

21]. COVID-19 also prompts many LSPs to focus on the importance of logistics resilience. The ability to be resilient to cope with risk and uncertainty is one of the key measures of firm performance for LSPs [

22]. If LSPs do not respond to changes promptly, original demand will be delayed, which will lead to greater operational stress [

23]. Innovation is widely recognized as a key capability for LSPs to cope with the volatile business environment, as the innovation capability helps LSPs develop new services and products which are customized based on customer needs; this unique ability is the basis for LSPs to gain an advantage in long-term market competition and is a driving force for LSPs to achieve better firm performance [

24,

25]. Considering the changing needs and escalating expectations of customers, as well as the intensifying competitive environment, LSPs need to improve their innovation capabilities [

26]. LSPs, especially those in China, generally, lack sufficient innovation in service options or products [

27]. The rapidly growing and diversified demands of customers are putting pressure on LSPs to improve their logistics services through innovative capabilities [

28]. Bellingkrodt and Wallenburg [

29] argue that the innovation capability helps LSPs to increase customer satisfaction, capture more market share, and achieve a first-mover edge over competitors, and consequently, the performance of LSPs is significantly improved [

30]. Competing in the dynamic and uncertain environments in the logistics industry, LSPs should leverage resources with resilience and innovation capability to gain more competitiveness and improve operational performance.

The main contributions of this paper are as follows: Firstly, to bridge the gap of external integration from the perspective of LSPs-initiated and the ignorance of LSPs’ operational performance, this study examines the influence of LSPs as external integration initiators on the their operational performance [

18,

19,

20]. Secondly, based on ROT, this research constructs and evaluates a conceptual model of the associations between external integration, logistics resilience, innovation capability, and operational performance, which extends the existing knowledge of the relationship between external integration and operational performance from the perspective of LSPs, Thirdly, this study provides practical insights for LSPs to deal with a dynamic and uncertain environment. Specifically, LSPs should highlight the external horizontal and vertical integration, and fully leverage the innovation capability during the integration process. The key research questions are raised as follows:

- RQ1:

Does external integration affect logistics resilience and innovation capability?

- RQ2:

Do logistics resilience and innovation capability have influences on operational performance?

- RQ3:

Does external integration improve operational performance through the mediation role of logistics resilience and innovation capability?

The remaining parts of this study were structured as follows:

Section 2 introduces the underpinning theory and performs the literature review on external integration, logistics resilience, innovation, and operational performance, and subsequently proposes the hypotheses to be analyzed. Then, a conceptual framework is developed.

Section 3 is the research methodology, including the development of the survey instrument and data collection. In

Section 4, we present the data analysis and results.

Section 5 presents the discussion according to the results of data analysis.

Section 6 makes an overall conclusion and discusses limitations and future research suggestions.

5. Discussion

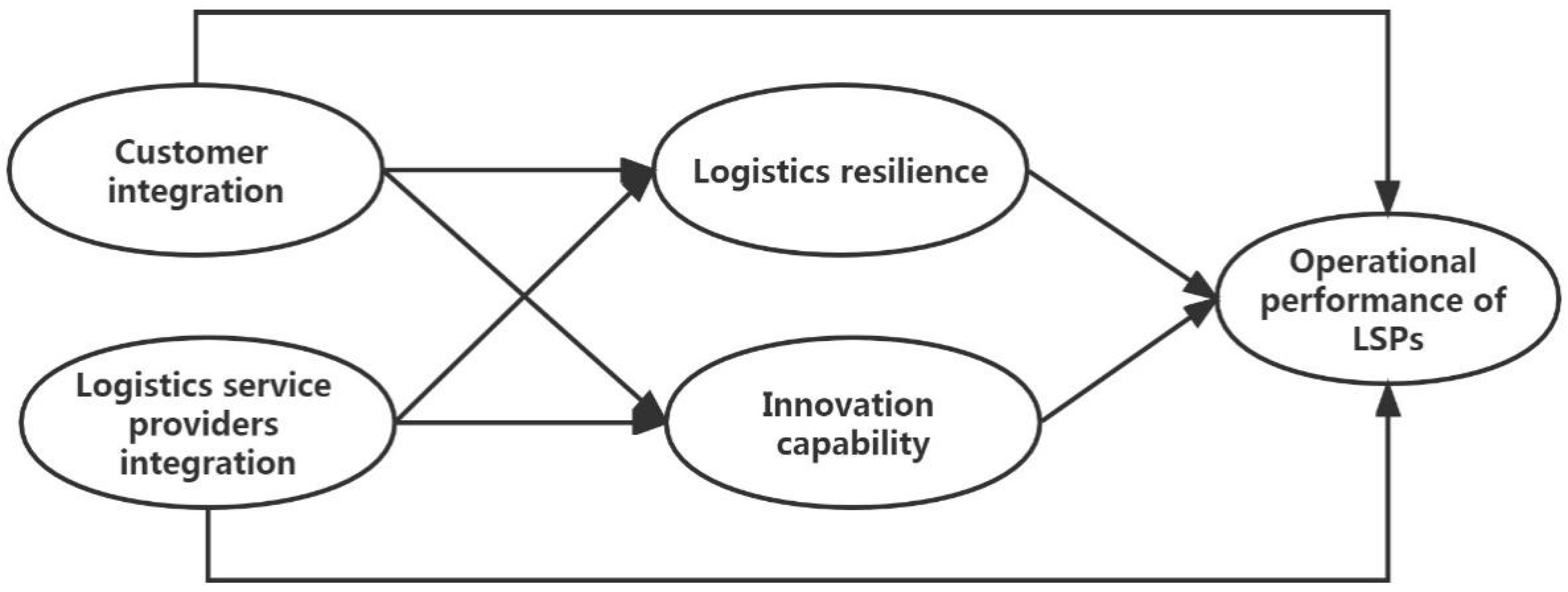

This study focuses on the analysis of the direct association between external integration (customer and LSPs) and operational performance. Additionally, this research examined the mediating effect of LR and IC between external integration and operation performance of LSPs.

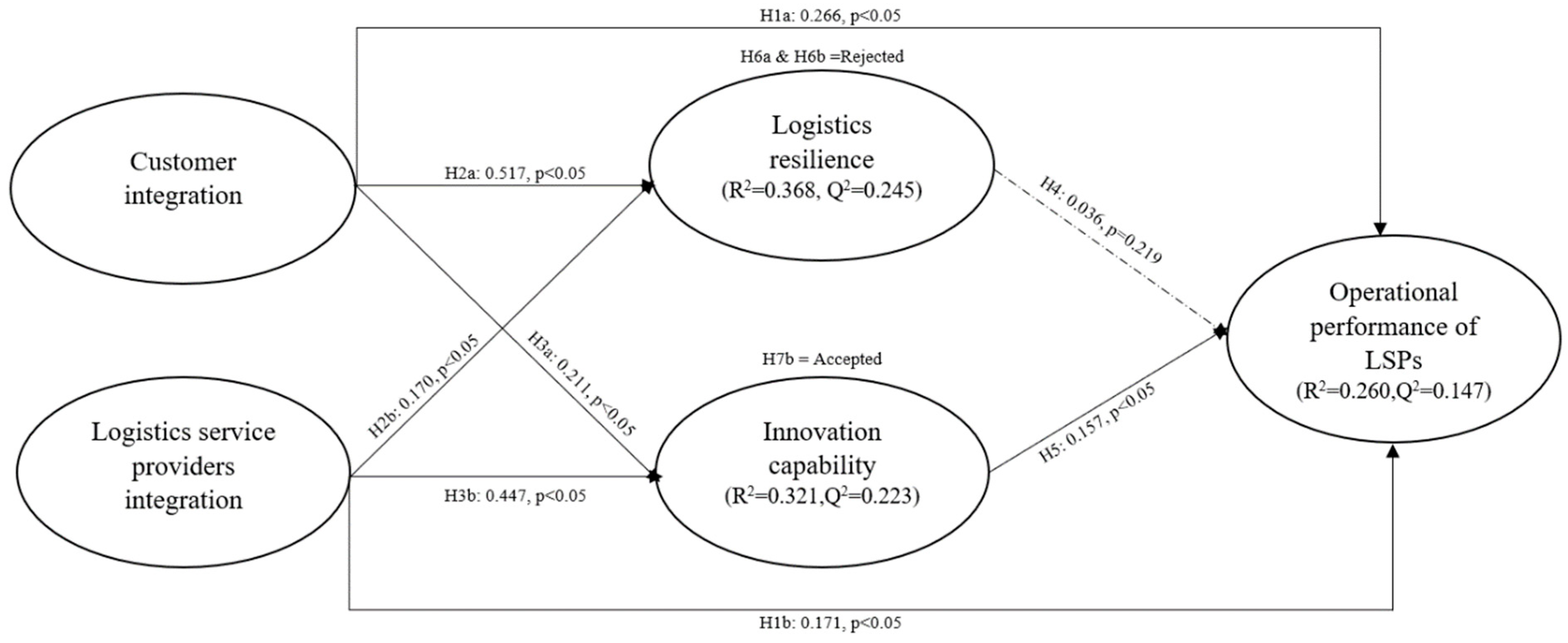

The first research hypothesis (H1) affirmed that external integration (CI & LI) has a significant and positive relationship with LSPs operational performance. This hypothesis is further subdivided into H1a and H1b. The results of SEM indicated that external integration (CI & LI) has a positive and significant relationship with operational performance. The finding of H1 are in accordance with previous studies. For example, Demeter et al. [

77] concluded that external integration is a significant driver of operational performance in manufacturing firms. Likewise, Chen et al. [

79] affirmed that both supplier and customer integration are necessary to achieve higher firm operational performance. Although the significance of external integration in enhancing operational performance has already been demonstrated by past research, but our findings further emphasize its worth for LSPs firms.

The second hypothesis (H2) affirmed that external integration has a positive association with logistics resilience. This hypothesis is further subdivided into H2a (CI → LR) and H2b (LI → LR). The empirical findings highlight that CI and LI are positively correlated with logistics resilience. Therefore, H2a and H2b have been accepted. The findings of this research are in accordance with previous studies. For example, Siagian et al. [

126] argued that there is a positive and significant association between external integration and resilience among Indonesian manufacturing firms. They further argued that the positive association between SCI and logistics resilience helps organizations to respond to sudden market changes. Similarly, Liu and Lee [

45] affirmed that SCI (customer and internal) is positively correlated with logistics resilience among logistics service providers. CI and LI can directly increase LR; however, CI has a stronger impact on LR. It indicates that LSPs can achieve better effects when coping with change and responding to the changing market by integrating with the customer.

The third hypothesis (H3) affirmed that external integration (CI & LI) has a positive and significant association with IC. To achieve this, H3a and H3b have been formulated. The results show that there is a significant association between external integration and IC; thus, H3a and H3b have been accepted. The study results are consistent with past literature. For example, Freije et al. [

128] highlighted that SCI is positively correlated with IC among manufacturing companies. Likewise, this conclusion was also confirmed by Tian et al. [

86] and Adebanjo et al. [

129]. Theoretically, the results of the study suggest facing demand pressures, such as those demands from SC customers, facilitating the development of innovation capabilities, such as the development of novel products, and novel services. In fact, the results indicate that institutional forces formed based on SC relationships and integration strengths contribute to the development of LSPs’ innovation capabilities [

129]. From the view of market competition, the results of this study imply that LSPs are increasingly focused on enhancing their innovation abilities. Once this capability is developed to a more advanced level, it helps to strengthen the competitiveness and performance of firms.

The fourth hypothesis (H4) affirmed that LR has a significant association with operational performance. Surprisingly, the results affirmed that logistics resilience has an insignificant association with performance. Thus, H4 has been rejected. Gupta et al. [

130] argued that lack of digital resources is the barrier to promoting logistics resilience in manufacturing firms. Moreover, James et al. [

131] argued that small manufacturing firms have a lack of financial resources to implement digital technology. Consequently, their logistics or supply chain is not resilient to cope the future challenges. Thus, the firm cannot gain competitive advantage. Therefore, the potential explanation for the insignificant relationship between LR and PR might be due to the lack of use of digital technology and its financial support. Hence, if enterprises aim to increase operational performance through logistics resilience, they should emphasize the role of digital technology and its financial investment.

The fifth research hypothesis (H5) affirmed that IC has significant linkages with operational performance. The empirical findings confirmed the positive relationship; thus, H5 has been accepted. The results are in line with past literature. Altaweel et al. [

110] concluded that the link between IC and organizational performance is highly significant. Similarly, Liu et al. [

108] affirmed that the link between IC and organizational performance is statistically significant. Companies with innovation capability are more capable to develop innovative products and services to fulfil the diverse customers’ demands and thus to improve operational performance in a changing market environment.

Apart from the direct effect, the indirect effect hypotheses were also been formulated through the examination of mediators. The sixth research hypothesis (H6) affirmed that logistics resilience has a mediating role between external integration and performance. To achieve this, H6a and H6b have been formulated. The empirical findings indicated that LR has no mediating role between external integration and performance. Thus, H6a and H6b have been rejected. The results show that the logistics resilience is insignificant for the improvement of LSPs operational performance. It might because the logistics of Chinese LSPs are not highly resilient yet. This results can be explained by a research conducted by Abeysekara et al. [

112]: this study claimed that an organization’s resilience ability has no direct effect on performance. The logistics resilience abilities contain various kinds of factors; hence, increasing the positive effect of LR on performance requires LSPs to build resilience capabilities in multiple dimensions.

Finally, the seventh research hypothesis (H7) affirmed that IC has a mediating role between external integration and performance. To achieve this, H7a, and H7b have been proposed. The empirical findings indicated that IC has a partial mediating association between external integration (LR) and PR. Therefore, H7b has been accepted. The results of this study are in agreement with past research. Shou et al. [

68] concluded that IC positively mediates the relationship between organizational resources and organizational performance. Likewise, AlTaweel and Al-Hawary [

110] argued that IC has a mediating effect between the agility and performance of enterprise. Finally, Tian et al. [

86] concluded that IC significantly mediates the relationship between SCI and organizational performance in Ghanaian SMEs manufacturing. These results proved that integration and IC are crucial success elements for dealing with change and uncertainty, which thereby increase operational performance of LSPs to achieve more advantages in the market. In particular, the results of this study show that the mediation effect of IC between customer integration and operational performance is stronger than its mediation effect between LI and operational performance. Therefore, in order to increase the operational performance, compared to the horizontal integration with other LSPs, LSPs should concentrate more on the integration with SC customers.

6. Conclusions, Contributions, and Implications

6.1. Key Findings

This study explores the mediating role of LR and IC in the framework of examining the relationship between external integration and LSPs operational performance. According to the results, external integration can positively promote the operational performance of LSPs; moreover, the two different subdivisions of external integration (CI & LI) differ in the extent to which they exert positive effects on performance. Specifically, CI has a more significant effect on the LSPs’ operational performance. IC positively mediates the relationship between external integration and operational performance, while LR fails to mediate their relationship. Overall, the findings indicated that CI and LI are the essential elements for increasing PR. Meanwhile, IC partially mediates the relationship between external integration and PR. Therefore, enhancing CI is a valuable strategy to realize better PR.

6.2. Theoretical Contributions

This study developed an integration-resilience-innovation-performance model in the Chinese LSPs context. This model is supported by the resource orchestration theory. Our findings expand the existing understanding of the connection between integration and operational performance. Firstly, the results endorse the theoretical mechanisms of how external integration facilitates in enhancing innovation capability and contributes to superior operational performance. Secondly, this research has highlighted the importance of external integration in improving LSPs’ operational performance. Thirdly, this study provides insight on the mediator role played by IC in the linkage between external integration and PR. Apart from that, this study provides empirical evidence to bridge the gap in the existing studies on external integration from the perspective of LI.

6.3. Practical Implications

Apart from research findings, this research offers several implications for logistics service providers. First, it is critical to conduct external integration which contributes to superior operational performance. Hence, LSPs need to establish closer vertical and horizontal collaborative partnerships with SC members. Particularly, this study reveals that the direct effect of CI on PR was higher than the effect of LI on PR Thus, we recommend that LSPs firms should first focus on CI, and deepen collaborative relationships with customers to guarantee a high potential for improving better PR. Second, the results highlight that IC helps to improve the PR of LSPs in China. It shows that LSPs managers may develop innovation capability concurrently with a strategic purpose, because Chinese LSPs confront increasingly fierce competition. In this situation, innovation capability can be efficient and effective strategic weapons for LSPs to grow and sustain their competitiveness. Furthermore, it helps LSPs to stand out from rivals and obtaining financial stability in the marketplace. Third, the LSPs practitioners need to understand the value of external integration in their operations to promote IC. As the results of this study revealed, external integration is capable of enhancing the IC of LSPs. Therefore, managers may dedicate themselves to the development of external integration, which serves as a source of IC. Moreover, the association between external integration, IC, and operational performance forms a robust system that allows the organization to anticipate quick market changes and minimize disruption to enhance competitiveness. Finally, these findings assist LSPs practitioners to better understand the importance of integration and innovation in a holistic manner to improve firms’ operational performance. This highlights that each external integration is a prerequisite of IC to enhance operational performance.

6.4. Limitations and Implications for Future Research

Although this study addressed critical constructs of logistics management, there were several limitations which lay the foundation for future studies. Firstly, this model only contributes 26% to the LSPs operational performance, which means that, in future studies, more factors should be included in the improvement of operational performance. In addition, surprisingly, logistics resilience fails to mediate the association between external integration and operational performance. In the current situation, the Chinese LSPs fail to have a high logistics resilience, resulting in the difficulty of enhancing operational performance. Therefore, for future study, how to guide LSPs and other relevant or similar industries in other countries to develop more resilient logistics to improve resource deployment capabilities and operational performance in a dynamic and changing environment could be a direction for future research.