Antecedents of Safety and Health in the Workplace: Sustainable Approaches to Welding Operations

Abstract

:1. Introduction

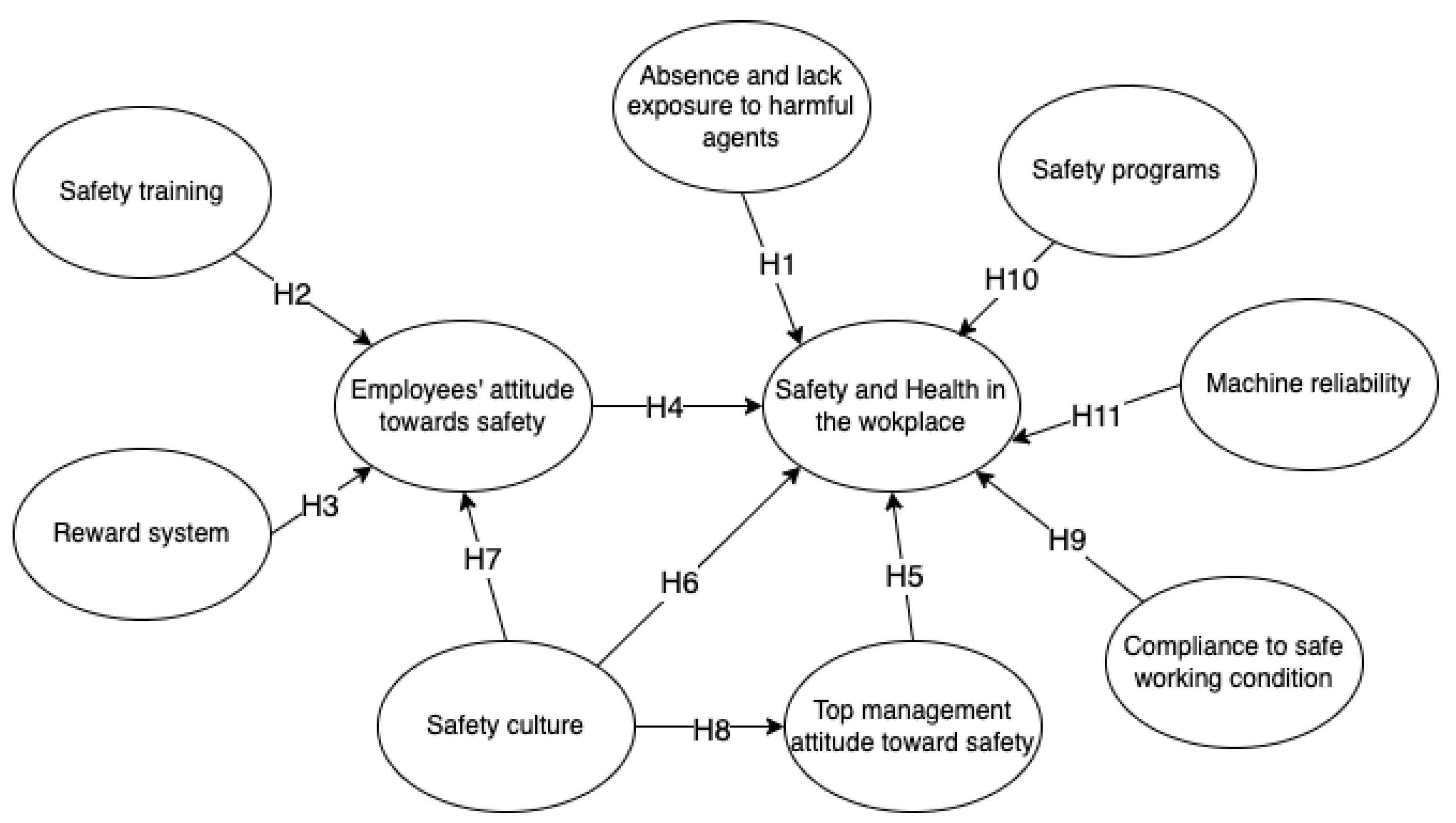

2. Conceptual Framework

3. Methodology

3.1. Participants

3.2. Instruments

3.3. Structural Equation Modeling

4. Results

4.1. Profile of the Respondents

4.2. Validity of the Results

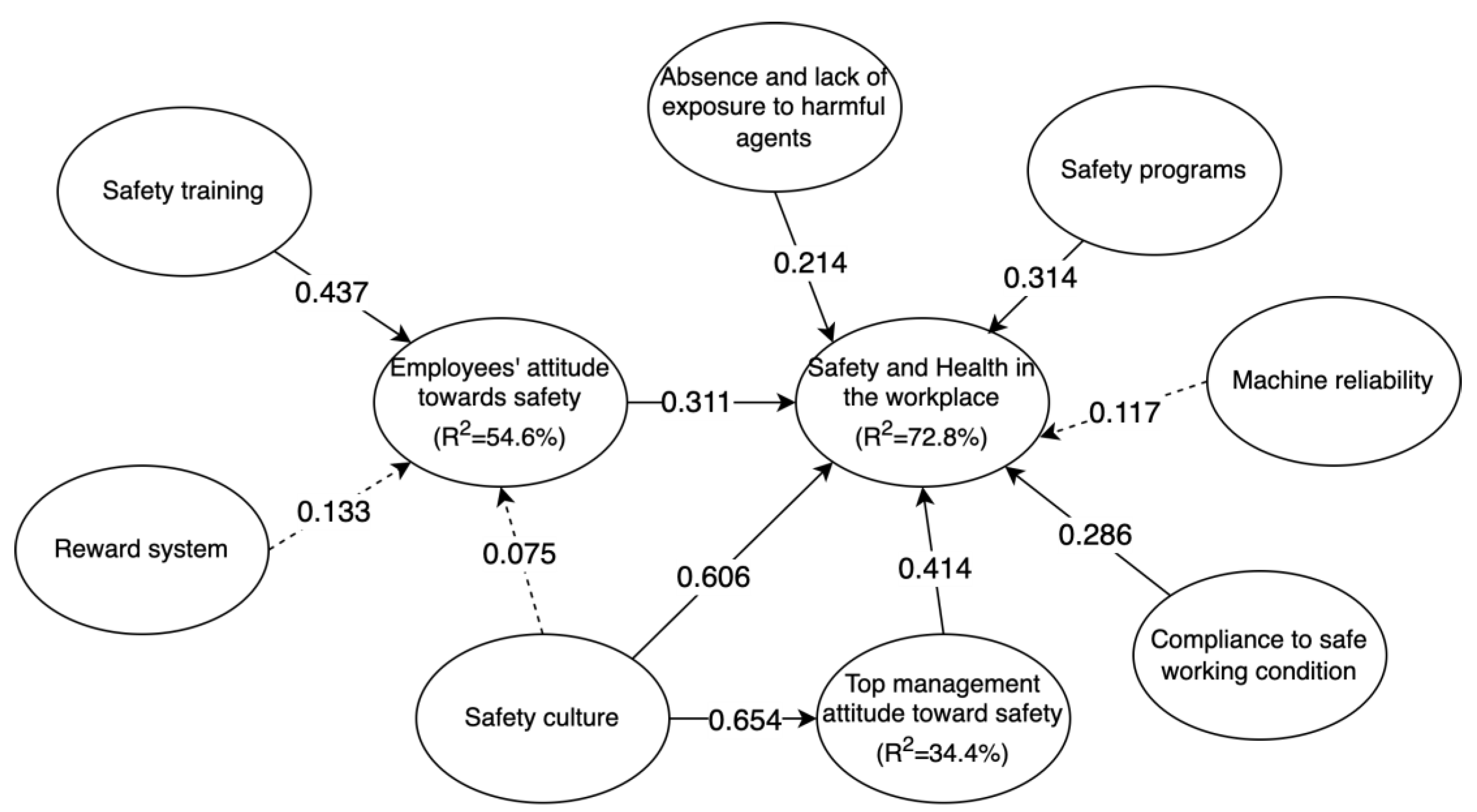

4.3. Hypothesis Test

5. Discussion

6. Conclusions

6.1. Practical Implications and Managerial Insights

6.2. Theoretical Implications

6.3. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Horvathova, P.; Mokra, K.; Konecny, F. The level of occupational safety and health promotion in Czech family manufacturing enterprises. Saf. Sci. 2023, 157, 105946. [Google Scholar] [CrossRef]

- Suparna, N.S.; Jaiswal, A. The Occupational Health and Safety. Anthr.-Indialogs 2021, 1, 261–269. [Google Scholar]

- Workplace Safety and Health Report; Ministry of Manpower: Singapore, 2021.

- Huda, Z. Welding and Joining Processes. Mater. Process. Eng. Manuf. 2016, 159. [Google Scholar]

- Barnes, T.A.; Pashby, I.R. Joining techniques for aluminium spaceframes used in automobiles: Part II—Adhesive bonding and mechanical fasteners. J. Mater. Process. Technol. 2000, 99, 72–79. [Google Scholar]

- Quintino, L.; Hourmat, B.; Pires, I. Health and Safety in Welding in the European Union. In Proceedings of the XXXV CONSOLDA—Congresso Nacional de Soldagem, Piracicaba, Brasil, 26–29 October 2009. [Google Scholar]

- Castleman, B.I.; Ziem, G.E. American conference of governmental industrial hygienists: Low threshold of credibility. Am. J. Ind. Med. 1994, 26, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Melton, G. Exposure to Welding Fumes. Available online: https://www.fronius.com/en/welding-technology/info-centre/magazine/2019/welding-fumes (accessed on 5 April 2023).

- Welding, Cutting, and Brazing—Overview. Occupational Safety and Health Administration. Available online: https://www.osha.gov/welding-cutting-brazing (accessed on 5 April 2023).

- Occupational Safety and Health Administration. Recommended Practices for Safety and Health Programs. Retrieved from United States Department of Labor. 2018. Available online: https://www.osha.gov/safety-management (accessed on 23 March 2023).

- Mehrifar, Y.; Zamanian, Z.; Pirami, H. Respiratory Exposure to Toxic Gases and Metal Fumes Produced by Welding Processes and Pulmonary Function Tests. Int. J. Occup. Envoron. Med. 2019, 10, 40–49. [Google Scholar]

- Noweir, M.H.; Alidrisi, M.M.; Al-Darrab, I.A.; Zytoon, M.A. Occupational safety and health performance of the manufacturing sector in Jeddah Industrial Estate, Saudi Arabia: A 20-years follow-up study. Saf. Sci. 2013, 53, 11–24. [Google Scholar] [CrossRef]

- Neal, A.; Griffin, M. Safety Climate and Safety Behaviour. Aust. J. Manag. 2002, 27, 67–76. [Google Scholar] [CrossRef]

- Mazrouei, M.A.; Khalid, K.; Davidson, R. Development and Validation of a Safety Climate Scale for United Arab Emirates Oil and Gas Industries. Entrep. Sustain. Issues 2020, 7, 2863–2882. [Google Scholar] [CrossRef]

- Vinodkumar, M.N.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar]

- Aziz, S.F.; Osman, F. Does compulsory training improve occupational safety and health implementation? The case of Malaysian. Saf. Sci. 2019, 111, 205–212. [Google Scholar] [CrossRef]

- Beck-Krala, E.; Klimkiewicz, K. Occupational safety and health as an element of a complex compensation system evaluation within an organization. Int. J. Occup. Saf. Ergon. 2016, 22, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.; Chen, C.C.; Hu, D.C. Employee perceptions of safety leadership, safety climate, and safety outcomes: Evidence from China. Saf. Sci. 2014, 62, 211–217. [Google Scholar]

- Clarke, S. Safety leadership: A meta-analytic review of transformational and transactional leadership styles as antecedents of safety behaviours. J. Occup. Organ. Psychol. 2010, 83, 376–399. [Google Scholar]

- Choudhry, R.M.; Fang, D.; Mohamed, S. The nature of safety culture: A survey of the state-of-the-art. Saf. Sci. 2007, 45, 993–1012. [Google Scholar]

- Abdullah, N.A.C.; Spickett, J.T.; Rumchev, K.B.; Dhaliwal, S.S. Assessing employees perception on health and safety management in public hospitals. Int. Rev. Bus. Res. Pap. 2009, 5, 54–72. [Google Scholar]

- Flin, R.; Mearns, K.; O’Connor, P.; Bryden, R. Measuring safety climate: Identifying the common features. Saf. Sci. 2000, 34, 177–192. [Google Scholar] [CrossRef]

- Singh, A.; Misra, S.C. A Dominance based Rough Set analysis for investigating employee perception of safety at workplace and safety compliance. Saf. Sci. 2020, 127, 104702. [Google Scholar]

- Viera, S. Employees’ Attitudes towards Health and Safety at Work. Retrieved from European Foundation for the Improvement of Living and Working Conditions. Available online: https://www.eurofound.europa.eu/publications/article/2006/employees-attitudes-towards-health-and-safety-at-work (accessed on 3 August 2006).

- Singer, S.J.; Gaba, D.M.; Geppert, J.J.; Sinaiko, A.D.; Howard, S.K.S.; Park, K.C. The culture of safety: Results of an organization-wide survey in 15 California hospitals. BMJ Qual. Saf. 2003, 12, 112–118. [Google Scholar] [CrossRef]

- Saleem, F.; Malik, M.I.; Qureshi, S.S. Work stress hampering employee performance during COVID-19: Is safety culture needed? Front. Psychol. 2021, 12, 655839. [Google Scholar]

- Glendon, A.I.; Stanton, N.A. Perspectives on safety culture. Saf. Sci. 2000, 34, 193–214. [Google Scholar] [CrossRef]

- The State of Queensland. Workplace Safety and Health Queensland. Retrieved from Understanding Safety Culture. 2013. Available online: https://www.worksafe.qld.gov.au/__data/assets/pdf_file/0024/19365/understanding-safety-culture.pdf (accessed on 12 May 2023).

- Zwetsloot, G.; van Kampen, J.; Steijn, W.; Post, S. Ranking of process safety cultures for risk-based inspections using indicative safety culture assessments. J. Loss Prev. Process Ind. 2020, 64, 104065. [Google Scholar] [CrossRef]

- Zou, P.X. Fostering a strong construction safety culture. Leadersh. Manag. Eng. 2011, 11, 11–22. [Google Scholar] [CrossRef]

- Haddad, A.M.; Pardo-del-Val, M. Safety culture and its impact on occupational accidents: A systematic review. Saf. Sci. 2019, 120, 274–284. [Google Scholar]

- Nordlöf, H.; Wiitavaara, B.; Winblad, U.; Wijk, K.; Westerling, R. Safety culture and reasons for risk-taking at a large steel-manufacturing company: Investigating the worker perspective. Saf. Sci. 2015, 73, 126–135. [Google Scholar] [CrossRef]

- Stiles, S.; Golightly, D.; Ryan, B. Impact of COVID-19 on health and safety in the construction sector. Hum. Factors Ergon. Manuf. Serv. Ind. 2021, 31, 425–437. [Google Scholar] [CrossRef]

- Burke, M.J.; Sarpy, S.A.; Tesluk, P.E.; Smith-Crowe, K. General safety performance: A test of a grounded theoretical model. Pers. Psychol. 2002, 55, 429–457. [Google Scholar] [CrossRef]

- Kaila, H.L. Top Management’s Will To Support Safety Culture. Int. J. Res. GRANTHAALAYAH 2022, 10, 223–228. [Google Scholar] [CrossRef]

- Othman, A.A.E. A study of the causes and effects of contractors’ non-compliance with the health and safety regulations in the South African construction industry. Arch. Eng. Des. Manag. 2012, 8, 180–191. [Google Scholar] [CrossRef]

- Santos, G.; Barros, S.; Mendes, F.; Lopes, N. The main benefits associated with health and safety management systems certification in Portuguese small and medium enterprises post quality management system certification. Saf. Sci. 2013, 51, 29–36. [Google Scholar] [CrossRef]

- Colligan, M.J.; Cohen, A. The role of training in promoting workplace safety and health. In The Psychology of Workplace Safety; American Psychological Association: Washington, DC, USA, 2004; pp. 223–248. [Google Scholar]

- Kaminski, M. Unintended consequences: Organizational practices and their impact on workplace safety and productivity. J. Occup. Health Psychol. 2001, 6, 127. [Google Scholar] [CrossRef] [PubMed]

- Agustiady, T.K.; Cudney, E.A. Total productive maintenance. Total Qual. Manag. Bus. Excell. 2018, 1–8. [Google Scholar] [CrossRef]

- Neitzel, R.L.; Seixas, N.S.; Ren, K.K. A review of crane safety in the construction industry. Appl. Occup. Environ. Hyg. 2001, 16, 1106–1117. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Hua, X.; Huang, G.; Shi, X. How Does Leadership in Safety Management Affect Employees’ Safety Performance? A Case Study from Mining Enterprises in China. Int. J. Environ. Res. Public Health 2022, 19, 6187. [Google Scholar] [PubMed]

- Li, S.; Liang, S. Effects of machinery reliability and safety performance on manufacturing performance. J. Clean. Prod. 2020, 269, 122294. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, Y.; Jia, X. A review of the relationship between equipment reliability and industrial safety. Saf. Sci. 2021, 138, 105192. [Google Scholar] [CrossRef]

- Johnson, D. Strengthen Safety by Emphasizing Equipment Reliability. Retrieved from Industrial Safety & Hygiene News. Available online: https://www.ishn.com/articles/112412-strengthen-safety-by-emphasizing-equipment-reliability (accessed on 1 April 2022).

- Dehghan, S.F.; Mehrifar, Y. Occupational exposure to fumes and gases during different arc welding processes. Int. J. Occup. Hyg. 2019, 11, 136–145. [Google Scholar]

- Gharibi, V.; Mortazavi, S.B.; Jafari, A.J.; Malakouti, J.; Abadi, M.B. The Relationship between Workers’ Attitude towards Safety and Occupational Accidents Experience. Int. J. Occup. Hyg. 2016, 8, 145–150. [Google Scholar]

- Michael, J.H.; Evans, D.D.; Jansen, K.J.; Haight, J.M. Management commitment to safety as organizational support: Relationships with non-safety outcomes in wood manufacturing employees. J. Saf. Res. 2005, 36, 171–179. [Google Scholar]

- Dash, G.; Paul, J. CB-SEM vs. PLS-SEM methods for research in social sciences and technology forecasting. Technol. Forecast. Soc. Change 2021, 173, 121092. [Google Scholar] [CrossRef]

- Ofori, E.K.; Aram, S.A.; Saalidong, B.M.; Gyimah, J.; Niyonzima, P.; Mintah, C.; Ahakwa, I. Exploring new antecedent metrics for safety performance in Ghana’s oil and gas industry using partial least squares structural equation modeling (PLS-SEM). Resour. Policy 2023, 81, 103368. [Google Scholar]

- Azeez, S.T.; Akinlabi, E.T. Friction Stir Welding of Aluminum Alloy: Principle, Processing, and Safety. In Advances in Welding Technologies for Process Development; CRC Press: Boca Raton, FL, USA, 2019; pp. 261–279. [Google Scholar]

- Alexander, V.; Sindhu, K.N.C.; Zechariah, P.; Resu, A.V.; Nair, S.R.; Kattula, D.; Mohan, V.R.; Alex, T.R.G. Occupational safety measures and morbidity among welders in Vellore, Southern India. Int. J. Occup. Environ. Health 2016, 22, 300–306. [Google Scholar] [CrossRef]

- McSween, T.E. Values-Based Safety Process: Improving Your Safety Culture with Behavior-Based Safety; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Ekenedo, G.O. Framework for developing and sustaining sound safety culture in a developing economy. Eur. J. Nat. Appl. Sci. 2013, 1, 28–37. [Google Scholar]

- Sabitu, K.; Iliyasu, Z.; Dauda, M.M. Awareness of occupational hazards and use of safety measures amongst welders in northern Nigeria. Ann. Afr. Med. 2009, 8, 46–51. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Mei, Q.; Liu, S.; Wang, Q. Dual-effects of core enterprise management and media attention on occupational health and safety of small and medium suppliers in China. Technol. Soc. 2020, 63, 101419. [Google Scholar]

- Oh, J.; Sol, V. The policy program improving occupational safety in The Netherlands: An innovative view on occupational safety. Saf. Sci. 2008, 46, 155–163. [Google Scholar] [CrossRef]

- Lingard, H. The effect of first aid training on Australian construction workers’ occupational health and safety motivation and risk control behavior. J. Saf. Res. 2002, 33, 209–230. [Google Scholar] [CrossRef]

- Subedi, S.; Jeng, A.; Bush, D. Metal Fumes from Welding Processes and Health Impact. Va. J. Public Health 2019, 3, 32–57. [Google Scholar]

- Rahul, M.; Sivapirakasam, S.; Vishnu, B.; Balasubramanian, K.; Mohan, S. Health issue owing to exposure with welding fumes and their control strategies at the source–A review. Mater. Today Proc. 2021, 46, 9239–9245. [Google Scholar]

- Rajendran, S.; Giridhar, S.; Chaudhari, S.; Gupta, P.K. Technological advancements in occupational health and safety. Meas. Sens. 2021, 15, 100045. [Google Scholar] [CrossRef]

- Gebrezgiabher, B.B.; Tetemke, D.; Yetum, T. Awareness of Occupational Hazards and Utilization of Safety Measures among Welders in Aksum and Adwa Towns, Tigray Region, Ethiopia, 2013. J. Environ. Public Health 2019, 2019, 4174085. [Google Scholar] [CrossRef] [PubMed]

- Dahl, Ø. Safety compliance in a highly regulated environment: A case study of workers’ knowledge of rules and procedures within the petroleum industry. Saf. Sci. 2013, 60, 185–195. [Google Scholar]

| Variable | Items | Measure | Supporting Reference |

|---|---|---|---|

| Lack of exposure and absence of harmful substance | EX1 | I am not exposed to metal fumes. | [46,47,48] |

| EX2 | I am not exposed to harmful gases | ||

| EX3 | I am not exposed to unsafe hot work processes. | ||

| EX4 | I am not exposed to harmful dust. | ||

| EX5 | I am not exposed to ultraviolet (UV) radiation. | ||

| Safety training | ST1 | I am provided with safety training which contributes to ensuring I am safe and healthy. | |

| ST2 | I am provided with safety training which shapes how I regard safety and health. | ||

| ST3 | Safety training provided to me is adequate. | ||

| ST4 | My commitment to safety and health is not compromised because of the safety training provided by the company. | ||

| ST5 | Safety training provided to me is relevant in ensuring a safe and healthy workplace for me. | ||

| Reward system | RS1 | The reward given by the company for positive contribution to safety is adequate. | |

| RS2 | I am motivated to ensure that the workplace is safe and healthy because of the reward. | ||

| RS3 | Commitment to safety and health has been instilled in me because of the reward system. | ||

| RS4 | It is necessary for my company to compensate my performance with regards to safety. | ||

| RS5 | I tend to remember the need to be safe at work more because of rewards and incentives. | ||

| Employee attitude | EA1 | I have a positive attitude towards safety. | |

| EA2 | I like to participate in programs related to safety and health. | ||

| EA3 | I like to be informed by the management with updates regarding safety and health. | ||

| EA4 | I am willing to volunteer my time and effort to ensure that our workplace is safe for everyone. | ||

| EA5 | I am interested in anything about safety and health. | ||

| Top management attitude | TM1 | Our top management is committed to providing a safe and healthy workplace for their employees. | |

| TM2 | Our top management put high regard to safety more than anything else. | ||

| TM3 | Our top management prioritizes its employees’ overall safety through its program. | ||

| TM4 | Our top management influences everyone in the workplace to have a positive attitude towards safety. | ||

| TM5 | Our top management encourages us to work safely. | ||

| Safety culture | SC1 | The shared beliefs of the company regarding safety have positively affected our attitude towards safety and health in workplace. | |

| SC2 | The shared beliefs of the company regarding safety have positively affected the attitude of the top management towards safety and health in workplace. | ||

| SC3 | I am confident that my safety is the top priority of the company because of its shared beliefs regarding safety. | ||

| SC4 | Safety culture in the company aids in avoiding accidents and near misses in our workplace. | ||

| SC5 | Our company’s safety performance is the result of our company’s safety culture. | ||

| Safety program | SP1 | There are safety programs being implemented in the company. | |

| SP2 | The safety programs in our company ensure the general safety and health of everyone in the workplace. | ||

| SP3 | Without safety programs in our company, it will be difficult to achieve our goal of having a safe and healthy workplace. | ||

| SP4 | The safety programs in the company provide information on risky situations, therefore decreasing the likelihood of accidents. | ||

| SP5 | The presence of safety programs in the company is relevant and effective. | ||

| Reliable equipment and machines | RE1 | Machines and equipment that we are using in the company are reliable and safe. | |

| RE2 | Machines that are faulty are tagged properly to avoid any accidents. | ||

| RE3 | Proper machine guards are installed to ensure the safety of operators. | ||

| RE4 | Ensuring that machines and equipment in the company are working properly contributes to the overall safety and health of workplace. | ||

| RE5 | The importance of maintaining a reliable machine is part of our company’s safety program. | ||

| Compliance with safe working conditions | CS1 | Our company sees to it that safe working conditions are provided to its employees. | |

| CS2 | My company complies with safe working conditions stipulated by authorities. | ||

| CS3 | My company doesn’t have any problem following the prescribed safe working conditions with its employees. | ||

| CS4 | My company hasn’t infringed on any recommended safe working conditions. | ||

| CS5 | Our safety policy adheres to strict compliance with safe working conditions. | ||

| Safety and health in the workplace | SH1 | I am working in a safe and healthy workplace. | |

| SH2 | I am working in a workplace where safety is the top priority. | ||

| SH3 | Since joining, there are no major accidents and/or fatalities in the workplace that I am part of. | ||

| SH4 | Our company hasn’t been penalized by authorities due to safety violations. | ||

| SH5 | Our company has received recognition because of our safety performance. |

| Construct | Items | Mean | S.D. | FL (≥0.7) | α (≥0.7) | CR (≥0.7) | AVE (≥0.5) |

|---|---|---|---|---|---|---|---|

| Presence and exposure to harmful fumes (EX) | EX1 | 3.08 | 1.14 | 0.946 | 0.943 | 0.952 | 0.800 |

| EX2 | 3.48 | 0.93 | 0.915 | ||||

| EX3 | 3.62 | 0.93 | 0.826 | ||||

| EX4 | 3.20 | 0.96 | 0.861 | ||||

| EX5 | 3.26 | 1.10 | 0.920 | ||||

| Safety training (ST) | ST1 | 4.25 | 0.46 | - | 0.771 | 0.806 | 0.689 |

| ST2 | 4.23 | 0.47 | 0.831 | ||||

| ST3 | 4.07 | 0.55 | 0.704 | ||||

| ST4 | 4.15 | 0.51 | 0.896 | ||||

| ST5 | 4.18 | 0.48 | 0.877 | ||||

| Reward system (RS) | RS1 | 3.37 | 0.63 | 0.844 | 0.859 | 0.867 | 0.702 |

| RS2 | 3.32 | 0.70 | 0.846 | ||||

| RS3 | 3.20 | 0.78 | - | ||||

| RS4 | 3.35 | 0.79 | 0.817 | ||||

| RS5 | 3.27 | 0.76 | 0.844 | ||||

| Employee attitude (EA) | EA1 | 4.20 | 0.50 | 0.702 | 0.845 | 0.855 | 0.618 |

| EA2 | 4.39 | 0.55 | 0.759 | ||||

| EA3 | 4.39 | 0.53 | 0.802 | ||||

| EA4 | 4.20 | 0.60 | 0.796 | ||||

| EA5 | 4.23 | 0.53 | 0.862 | ||||

| Top management attitude (TM) | TM1 | 4.14 | 0.42 | 0.855 | 0.727 | 0.808 | 0.678 |

| TM2 | 3.83 | 0.69 | 0.858 | ||||

| TM3 | 3.93 | 0.49 | 0.835 | ||||

| TM4 | 4.09 | 0.42 | 0.790 | ||||

| TM5 | 4.17 | 0.40 | - | ||||

| Safety culture (SC) | SC1 | 4.10 | 0.30 | - | 0.781 | 0.789 | 0.695 |

| SC2 | 4.07 | 0.43 | 0.858 | ||||

| SC3 | 4.04 | 0.42 | 0.845 | ||||

| SC4 | 4.18 | 0.44 | 0.813 | ||||

| SC5 | 4.08 | 0.36 | 0.828 | ||||

| Compliance with safety (CS) | CS1 | 4.22 | 0.44 | 0.737 | 0.830 | 0.841 | 0.663 |

| CS2 | 4.17 | 0.44 | - | ||||

| CS3 | 4.15 | 0.41 | 0.883 | ||||

| CS4 | 4.16 | 0.44 | 0.786 | ||||

| CS5 | 4.10 | 0.36 | 0.843 | ||||

| Safety programs (SP) | SP1 | 4.21 | 0.41 | - | 0.842 | 0.848 | 0.678 |

| SP2 | 4.16 | 0.36 | 0.797 | ||||

| SP3 | 4.16 | 0.41 | 0.800 | ||||

| SP4 | 4.17 | 0.42 | 0.879 | ||||

| SP5 | 4.18 | 0.41 | 0.815 | ||||

| Machine reliability (RE) | RE1 | 4.09 | 0.35 | 0.822 | 0.784 | 0.832 | 0.606 |

| RE2 | 4.02 | 0.52 | - | ||||

| RE3 | 3.96 | 0.46 | 0.713 | ||||

| RE4 | 4.13 | 0.39 | 0.860 | ||||

| RE5 | 4.14 | 0.37 | 0.815 | ||||

| Safety and health in the workplace (SH) | SH1 | 4.42 | 0.50 | 0.873 | 0.882 | 0.886 | 0.895 |

| SH2 | 4.09 | 0.70 | - | ||||

| SH3 | 4.35 | 0.52 | 0.941 | ||||

| SH4 | 4.31 | 0.49 | 0.951 | ||||

| SH5 | 3.32 | 0.74 | 0.879 |

| CS | EA | RE | EX | RS | SC | SH | SP | ST | TM | |

| CS | 0.814 | |||||||||

| EA | 0.650 | 0.786 | ||||||||

| RE | 0.626 | 0.650 | 0.778 | |||||||

| EA | 0.622 | 0.626 | 0.681 | 0.948 | ||||||

| RS | 0.592 | 0.622 | 0.690 | 0.770 | 0.838 | |||||

| SC | 0.663 | 0.592 | 0.707 | 0.560 | 0.768 | 0.834 | ||||

| SH | 0.581 | 0.663 | 0.729 | 0.648 | 0.638 | 0.766 | 0.946 | |||

| SP | 0.745 | 0.581 | 0.648 | 0.674 | 0.594 | 0.675 | 0.766 | 0.823 | ||

| ST | 0.631 | 0.627 | 0.562 | 0.713 | 0.560 | 0.623 | 0.675 | 0.827 | 0.830 | |

| TM | 0.543 | 0.562 | 0.626 | 0.677 | 0.634 | 0.712 | 0.623 | 0.604 | 0.821 | 0.823 |

| CS | EA | RE | EX | RS | SC | SH | SP | ST | TM | |

| CS | ||||||||||

| EA | 0.677 | |||||||||

| RE | 0.481 | 0.425 | ||||||||

| EA | 0.624 | 0.377 | 0.230 | |||||||

| RS | 0.541 | 0.648 | 0.434 | 0.349 | ||||||

| SC | 0.449 | 0.379 | 0.306 | 0.286 | 0.704 | |||||

| SH | 0.303 | 0.537 | 0.348 | 0.695 | 0.345 | 0.304 | ||||

| SP | 0.681 | 0.387 | 0.670 | 0.308 | 0.443 | 0.354 | 0.480 | |||

| ST | 0.680 | 0.122 | 0.432 | 0.650 | 0.427 | 0.443 | 0.559 | 0.324 | ||

| TM | 0.580 | 0.135 | 0.433 | 0.390 | 0.626 | 0.327 | 0.691 | 0.397 | 0.207 |

| No | Relationship | Beta Coefficient | p-Value | Result | Significance | Hypothesis |

|---|---|---|---|---|---|---|

| 1 | EX→SH | 0.214 | 0.002 | Positive | Significant | Accept |

| 2 | ST→EA | 0.437 | <0.001 | Positive | Significant | Accept |

| 3 | RS→EA | 0.133 | 0.199 | Positive | Not Significant | Reject |

| 4 | EA→SH | 0.311 | <0.001 | Positive | Significant | Accept |

| 5 | TM→SH | 0.414 | <0.001 | Positive | Significant | Accept |

| 6 | SC→SH | 0.606 | <0.001 | Positive | Significant | Accept |

| 7 | SC→EA | 0.075 | 0.527 | Positive | Not Significant | Reject |

| 8 | SC→TM | 0.654 | <0.001 | Positive | Significant | Accept |

| 9 | CS→SH | 0.286 | 0.031 | Positive | Significant | Accept |

| 10 | SP→SH | 0.314 | <0.001 | Positive | Significant | Accept |

| 11 | RE→SH | 0.117 | 0.084 | Positive | Not significant | Reject |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belmoro, B.J.B.; Gumasing, M.J. Antecedents of Safety and Health in the Workplace: Sustainable Approaches to Welding Operations. Sustainability 2023, 15, 14641. https://doi.org/10.3390/su151914641

Belmoro BJB, Gumasing MJ. Antecedents of Safety and Health in the Workplace: Sustainable Approaches to Welding Operations. Sustainability. 2023; 15(19):14641. https://doi.org/10.3390/su151914641

Chicago/Turabian StyleBelmoro, Bernadette Joy B., and Ma Janice Gumasing. 2023. "Antecedents of Safety and Health in the Workplace: Sustainable Approaches to Welding Operations" Sustainability 15, no. 19: 14641. https://doi.org/10.3390/su151914641

APA StyleBelmoro, B. J. B., & Gumasing, M. J. (2023). Antecedents of Safety and Health in the Workplace: Sustainable Approaches to Welding Operations. Sustainability, 15(19), 14641. https://doi.org/10.3390/su151914641