A Complex Circular-Economy Quality Indicator for Assessing Production Systems at the Micro Level

Abstract

:1. Introduction

2. Methods

Determination of a Set of Four Options for the Analysis of Production Systems

- Technical (T) options are based on CP methods, considered a key strategy for CE due to better integration into other environmental strategies of a company, the introduction of cleaner products, processes, and services to reduce waste and emission, and prevention of the use of non-renewable streams and harmful input materials [44]. CP aims to achieve the goals of CE to change the perception of the relationship between business and the environment [45]. The technical options presented allow for the assessment of: the difficulty level and implementation time of the technology and its innovation degree in comparison to the global level; production method simplification, i.e., the reduction of the number of unit processes and the shortening of transport routes; the decreased consumption of materials and energy, and the use of renewable energy; an approaching to a possible index of reused goods, raw materials, recycling of waste, and recovering energy. These options are based on the best available techniques (BAT), i.e., processes with the least possible influence on the environment attained without a decrease in the economic conditions of the involved industrial companies.BAT assessment is typically performed by specialist estimation. The methodology described in [46] shows that expert evaluation determines straight and clear on-base calculated scores for implementation achievability, environmental impact, and economic profitability.

- Environmental (En) options provide CE strategic actions; the models described in [47,48] were selected. These comprise recirculation, cleaner production, and projecting for remanufacturing, reuse, renewable energy, high-quality recycling, and prolongation of the product life-cycle. There are two types of important principles, the first one concerns the R framework and the second one concerns the system availability, and these were differentiated. The 9R approach [49,50] was chosen, including the following extensions: refuse, rethinking, reduction, reuse, repair, refurbishment, remanufacture, repurpose, recycling, and recovery. To assess environmental profits or losses and the possible influence on the environment of waste incineration, LCA should be performed to develop a life-cycle inventory [1]. Therefore, some results from the literature have been analyzed to compare with the proposed methodology. The set of proposed environmental options allows for the estimation of: decreased environmental impact through the increase of manufacturing productivity, using changes in process manuals, project solutions, and modifications of existing technologies; waste release reduction and prevention of pollution emission; reductions in the toxicity degree of waste; the obtaining of secondary waste using spent goods in new products; the quality of recycling of materials and energy; solutions that render the optimum levels of waste collection; the incineration of materials to recover energy.

- Economic/Business (Ec) options include the group of CE activities consisting of waste management, improvements in the durability of goods to enable them possibly to persist within the manufacturing system for a long time, production cost, and efficiency of investment expenditures at as low as possible an investment cost. CE strategic actions [37,47] allow implementation options associated with resource productivity and economic benefits. Options allow for: evaluation of the effective use of resources; productive project strategies, goods, and service levels; the maintenance of resource and product values and changeable and modifiable manufacturing; efficient investment expenditures and implementation; assessment of production costs, including labor demand, energy expenses, materials costs, and reparation and conservation costs; calculating the degree of substitution for natural resources by waste; an increase of the longevity of the product, for staying within the economy as long as possible; and consistency with state and EU economic policy.

- Societal (Soc) options [47,48] are developed according to CE strategic actions for the implementation of socioeconomic benefits. These options were analyzed in terms of the aims of: improving relationships with the public due to reduced damage to human health caused by industrial processes; promotion of better-quality products; keeping the higher value of goods as long as possible; workplace formation and increases in the number of highly-qualified employees; shifting consumption patterns due to use by consumer of the optimum quantity of goods, energies, or services; reuse as the effect of a changing approach in terms of repairs and renovations; and increasing the degree of adaptation to local conditions.

3. Results and Discussion

3.1. Selection and Collection Options and the Construction of the Theoretical Framework for Assessment of CE Micro Levels Indicators

3.1.1. Evaluation of Options to Obtain a Set of Options Single-Scores (S) for the Core Group

3.1.2. Determination of a Degree of Validity for the Core Group of Options

3.1.3. The Use of Trimmed Mean (TM) to Calculate the Value for the Group of Options

3.1.4. Calculation of the Circular-Economy Indicator (CEI)

3.1.5. Comparison of Production Systems

3.2. Illustration of the System of Calculation for CE Indicators; Their Proposed Application to the Case Study

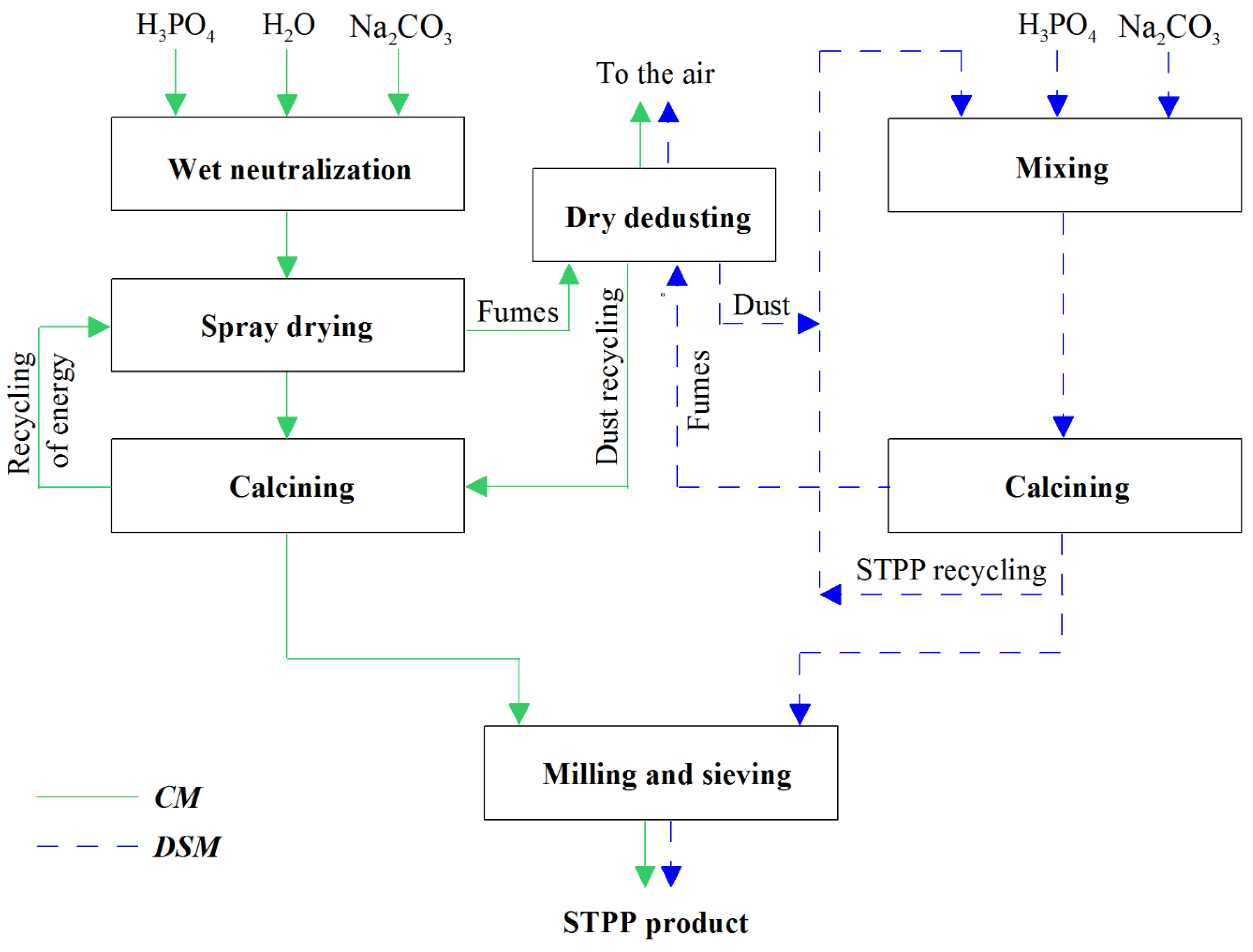

3.2.1. Description of the Compared Sodium Tripolyphosphate (STPP) Production Technologies

3.2.2. Calculation and Comparison of Micro-Level Indicators (CEIs) of Two STPP Production Processes

3.3. Study Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Tognato de Oliveira, C.; Tavares Dantas, T.E.; Soares, R.S. Nano and micro level circular economy indicators: Assisting decision-makers in circularity assessments. Sustain. Prod. Consum. 2021, 26, 455–468. [Google Scholar] [CrossRef]

- Colley, T.A.; Birkved, M.; Olsen, S.I.; Hauschild, M.Z. Using a gate-to-gate LCA to apply circular economy principles to a food processing SME. J. Clean. Prod. 2020, 251, 119566. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Goedkoop, M.; Guinée, J.; Heijungs, R.; Huijbregts, M.; Jolliet, O.; Margni, M.; De Schryver, A.; Humbert, S.; Laurent, A.; et al. Identifying best existing practice for characterization modeling in life cycle impact assessment. Int. J. Life Cycle Assess. 2013, 18, 683–697. [Google Scholar] [CrossRef]

- Petit-Boix, A.; Llorach-Massana, P.; Sanjuan-Delmás, D.; Sierra-Pérez, J.; Vinyes, E.; Gabarrell, X.; Rieradevall, J.; Sanyé-Mengual, E. Application of life cycle thinking towards sustainable cities: A review. J. Clean. Prod. 2017, 166, 939–951. [Google Scholar] [CrossRef]

- Directorate-General for Environment (European Commission); Joint Research Centre (European Commission). Making Sustainable Production and Consumption a Reality. A Guide for Business and Policymakers to Life Cycle Thinking and Assessment. Publication Office of European Union. 2010. Available online: https://op.europa.eu/en/publication-detail/-/publication/be847e7e-b28f-4968-a980-c595cc2307a5/language-en (accessed on 2 May 2023).

- Papamichael, I.; Voukkali, I.; Loizia, P.; Pappas, G.; Zorpas, A.A. Existing tools used in the framework of environmental performance. Sustain. Chem. Pharm. 2023, 32, 101026. [Google Scholar] [CrossRef]

- Graedel, T.E.; Allwood, J.; Birat, J.P.; Buchert, M.; Hagelüken, C.; Reck, B.K.; Sibley, S.F.; Sonnemann, G. What do we know about metal recycling rates? J. Ind. Ecol. 2011, 15, 355–366. [Google Scholar] [CrossRef]

- Ardente, F.; Mathieux, F. Identification and assessment of product’s measures to improve resource efficiency: The case-study of an Energy using Product. J. Clean. Prod. 2014, 83, 126–141. [Google Scholar] [CrossRef]

- Huysman, S.; Debaveye, S.; Schaubroeck, T.; Meester, S.D.; Ardente, F.; Mathieux, F.; Dewulf, J. The recyclability benefit rate of closed-loop and open-loop systems: A case study on plastic recycling in Flanders. Resour. Conserv. Recycl. 2015, 101, 53–60. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104533. [Google Scholar] [CrossRef]

- Crișan, O.A.; Crișan, H.G.; Dan, V.; Șerdean, F.M. Approaching the circular economy in Romania—A higher alternative to linear economy. Acta Tech. Napoc. Ser. Appl. Math. Mech. Eng. 2019, 62, 193–200. [Google Scholar]

- Papamichael, I.; Pappas, G.; Siegel, J.E.; Zorpas, A.A. Unified waste metrics: A gamified tool in next-generation strategic planning. Sci. Total Environ. 2022, 833, 154835. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical appraisal of the circular economy standard BS8001: 2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy—Moving away from the three dimensions of sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Linder, M.; Sarasini, S.; van Loon, P. A metric for quantifying product-level circularity. J. Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef]

- Franklin-Johnson, E.; Figge, F.; Canning, L. Resource duration as a managerial indicator for Circular Economy performance. J. Clean. Prod. 2016, 133, 589–598. [Google Scholar] [CrossRef]

- Azevedo, S.; Godina, R.; de Oliveira Matias, J.C. Proposal of a sustainable circular index for manufacturing companies. Resources 2017, 6, 63. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef] [PubMed]

- Vanegas, P.; Peeters, J.R.; Cattrysse, D.; Tecchio, P.; Ardente, F.; Mathieux, F.; Dewulf, W.; Duflou, J.R. Ease of disassembly of products to support circular economy strategies. Resour. Conserv. Recycl. 2018, 135, 323–334. [Google Scholar] [CrossRef] [PubMed]

- Handbook on Constructing Composite Indicators: Methodology and User Guide. JRC European Commission, © OECD Publications, No. 56327. 2008. Available online: http://search.oecd.org/sdd/42495745.pdf (accessed on 17 August 2023).

- Ellen MacArthur Foundation. Circular Indicators: An Approach to Measuring Circularity. Methodology; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Crișan, O.A.; Bîrleanu, C.; Crișan, H.-G.; Pustan, M.; Merie, V.; Șerdean, F. Eco-innovation analyses in the management of drinking water provided by the main suppliers in Romania. Int. J. Environ. Res. Public Health 2021, 18, 6232. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Official Journal of the European Union, Opinion of the European Economic and Social Committee on the ‘Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on a Monitoring Framework for the Circular Economy’ (COM(2018) 29 Final). 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A52018AE0464 (accessed on 2 May 2023).

- Akhtulov, A.; Ivanova, L.; Charushina, E. Method of quality assessment of design of complex objects in mechanical engineering. IOP Conf. Ser. Mater. Sci. Eng. 2020, 709, 022116. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Borgianni, Y.; Maccioni, L.; Pigosso, D.C.A. An expert system for circular economy business modelling: Advising manufacturing companies in decoupling value creation from resource consumption. Sustain. Prod. Consum. 2021, 27, 534–550. [Google Scholar] [CrossRef]

- Jabareen, Y. Building a Conceptual Framework: Philosophy, Definitions, and Procedure. Int. J. Qual. Methods 2009, 8, 49–62. [Google Scholar] [CrossRef]

- Jianzhong, L.; Jingkun, H.; Yiyang, S.; Heng, L. Qualitative evaluation technology of complex equipment guarantee resources based on grey theory. IOP Conf. Ser. Earth Environ. Sci. 2020, 440, 052059. [Google Scholar] [CrossRef]

- Janeková, J.; Onofrejová, D. Quality assessment of production. Transf. Inovácií 2016, 33, 192–194. [Google Scholar]

- Lewis, J. Redefining Qualitative Methods: Believability in the Fifth Moment. Int. J. Qual. Methods 2009, 8, 1–14. [Google Scholar] [CrossRef]

- Vuk, T. Quality indicators: A tool for quality monitoring and improvement. In Proceedings of the 32nd International Congress of the International Society of Blood Transfusion in Joint Cooperation with the 10th Congress of AMMTAC, Cancun, Mexico, 7–12 July 2012. ISBT Science Series Volume 7, Special Issue: State of the Art Presentations. [Google Scholar] [CrossRef]

- Graser, K.; Walzer, A.N.; Hunhevicz, J.; Jähne, R.; Seiler, F.; Wüst, R.; MHall, D.M. Qualitative technology evaluation of digital fabrication with concrete: Conceptual framework and scoreboard. Autom. Constr. 2023, 154, 104964. [Google Scholar] [CrossRef]

- Kowalski, Z.; Kulczycka, J.; Makara, A.; Verhé, R.; De Clercq, G. Assessment of energy recovery from municipal waste management systems using circular economy quality indicators. Energies 2022, 15, 8625. [Google Scholar] [CrossRef]

- Kowalski, Z.; Makara, A. Comparison of technologies for the sodium tripolyphosphate production by conventional spray and new one-stage dry methods. Przem. Chem. 2017, 96, 187–192. (In Polish) [Google Scholar] [CrossRef]

- Kowalski, Z.; Generowicz, A.; Makara, A.; Kulczycka, J. Evaluation of municipal waste landfilling using the technology quality assessment method. Environ. Prot. Eng. 2015, 41, 167–179. [Google Scholar] [CrossRef]

- Ramu, P.; Shiva Bhushan, J.Y.V.; Shravani, B.; Nagarani, I. Cinder coal-aggregate quality index (AQI) appraisal based on weighted arithmetic index method and fuzzy logic. In Advances in Geotechnical and Transportation Engineering. Lecture Notes in Civil Engineering; Saride, S., Umashankar, B., Avirneni, D., Eds.; Springer: Singapore, 2020; Volume 71, pp. 153–163. [Google Scholar] [CrossRef]

- Satish Chandra, D.; Asadi, S.S.; Raju, M.V.S. Estimation of water quality index by weighted arithmetic water quality index method: A model study. Int. J. Civ. Eng. Technol. 2017, 8, 1215–1222. Available online: https://sdbindex.com/documents/00000001/00000-62352 (accessed on 10 May 2022).

- Sheu, D.D.; Hou, C.T. TRIZ-based trimming for process-machine improvements: Slit-valve innovative redesign. Comput. Ind. Eng. 2013, 66, 555–556. [Google Scholar] [CrossRef]

- Li, M.; Ming, X.; He, L.; Zheng, M.; Xu, Z. A TRIZ-based trimming method for patent design around. Comput. Aided Des. 2015, 62, 20–30. [Google Scholar] [CrossRef]

- Bilitewski, B. The circular economy and its risks. Waste Manag. 2012, 32, 1–2. [Google Scholar] [CrossRef]

- Van Berkel, R. Cleaner production and eco-efficiency initiatives in Western Australia 1996–2004. J. Clean. Prod. 2007, 15, 741–755. [Google Scholar] [CrossRef]

- Dijkmans, R. Methodology for selection of best available techniques (BAT) at the sector level. J. Cleaner Prod. 2000, 8, 11–21. [Google Scholar] [CrossRef]

- Rizos, V.; Tuokko, K.; Behrens, A. The Circular Economy: A Review of Definitions, Processes and Impacts. CEPS Research Reports, No. 2017/08. Available online: https://www.ceps.eu/wp-content/uploads/2017/04/RR2017-08_CircularEconomy_0.pdf/ (accessed on 10 May 2022).

- Bicket, M.; ten Brink, P.; van Dijl, E.; Guilcher, S.; Hestin, M.; Hudson, C.; Razzini, P.; Tan, A.; Vanner, R.; Watkins, E.; et al. Scoping Study to Identify Potential Circular Economy Actions, Priority Sectors, Material Flows and Value Chains; Publications Office of the European Union: Luxembourg, 2014; Available online: https://www.eesc.europa.eu/resources/docs/scoping-study.pdf/ (accessed on 18 May 2023).

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Policy Report; PBL Netherlands Environmental Assessment Agency: Hague, The Netherlands, 2017; Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf (accessed on 10 May 2022).

- Van Buren, N.; Demmers, M.; Van der Heijden, R.; Witlox, F. Towards a circular economy: The role of Dutch logistics industries and governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef]

- Kaltenbach, H.M. A Concise Guide to Statistics; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Kowalski, Z.; Makara, A.; Henclik, A.; Kulczycka, J.; Cholewa, M. Comparative evaluation of sodium tripolyphosphate production technologies with the use of a complex quality method. Pol. J. Chem. Technol. 2020, 22, 48–54. [Google Scholar] [CrossRef]

- Kowalski, Z.; Makara, A. The synthesis of tripolyphosphate using a one-stage method and a laboratory rotary kiln. Pol. J. Chem. Technol. 2014, 16, 36–40. [Google Scholar] [CrossRef]

| Options Group Framework | Option Symbol | Option Description |

|---|---|---|

| Technical (T) | T1 | Accessibility of production methods. Difficulty level and implementation time. |

| T2 | Technology and project innovation level. Degree of modernity in comparison to the global level according to BAT. | |

| T3 | Technology and production difficulty level. Risk of implementation and probability of success. | |

| T4 | Production method simplification. Reduction in the number of operations and unit processes. | |

| T5 | Reduction/shortening of transport routes. | |

| T6 | Reduction of energy consumption figures. | |

| T7 | Reduction in materials consumption figures and of harmful materials used. | |

| T8 | Use of renewable energy/bioenergy. | |

| T9 | Improvement in product quality and stability. | |

| T10 | Eco-design for sustainable products, which covers energy-related products. It should be consistent with the CP methodology of cleaner production and compatible with SD goals. | |

| T11 | Consistency with the methodology of cleaner production. | |

| T12 | Compatibility with the purposes of sustainability. | |

| T13 | Efficient packaging-design strategies. | |

| T14 | Evaluation of physical characteristics from the production cycles based on LCT procedures, e.g., index of reusability/recyclability/recoverability (RRR) in approaching a possible index of the reuse of goods, decreased use of raw materials, increased recycling of waste, and the recovery of energy. | |

| T15 | Required legal authorizations. | |

| Environmental (En) | En1 | Decreased environmental impact through the increase of manufacturing productivity by using a lower number of primary resources. |

| En2 | Changes in process manuals. Changes in project solutions and modifications of existing technologies. | |

| En3 | Waste release reduction and prevention of pollution emission. Reductions of the toxicity degree of waste and in the formation of secondary waste. | |

| En4 | Assessment of the amount and properties of emissions in terms to the release of waste into the environment. | |

| En5 | Refurbishment of older products for their modernization and using spent goods or their parts in new products with different functions. | |

| En6 | Waste reduction at the source. | |

| En7 | Incentivized high-quality recycling. In-process recirculation of substrates. | |

| En8 | On-site and off-site recirculation of materials. | |

| En9 | Incentivized high-quality recycling. In-process recirculation of energy. | |

| En10 | On-site and off-site recirculation of energy. | |

| En11 | Remanufacturing of used products or their elements into new goods with the same characteristics. | |

| En12 | Solutions that render the optimum levels of waste collection. | |

| En13 | Take-back schemes of remanufacturing. Separating waste flows and bringing the waste to remanufacture/recirculation/sorting sites. | |

| En14 | Recycling process substrates to produce the same goods with higher or lower degrees of quality. | |

| En15 | Combustion of materials to recover energy. | |

| Economic (Ec) | Ec1 | Effective management of waste and by-products. |

| Ec2 | Optimum location. | |

| Ec3 | Consistency with state and EU economic policy. | |

| Ec4 | End-of-life management and disassembly. | |

| Ec5 | Increasing the longevity of the product, with the aim of its staying within the economy as long as possible. | |

| Ec6 | Regeneration and recirculation as the most important activities for CE development. | |

| Ec7 | Substitution for natural resources by waste. | |

| Ec8 | Labor demand. | |

| Ec9 | Total energy expenses. | |

| Ec10 | Total materials cost. | |

| Ec11 | Reparation and conservation costs. | |

| Ec12 | Production cost. | |

| Ec13 | Capital expenditures. Tme investment, outlays recovery, and implementation efficiency. | |

| Ec14 | Amortization. | |

| Ec15 | Product-life extension. | |

| Societal (Soc) | Soc1 | Participation in novel types of consumption (e.g., readiness to pay more for products’ persistence). |

| Soc2 | Reuse as the effect of a changing approach in terms of repairs and renovations. | |

| Soc3 | Keeping the higher value of goods as long as possible. | |

| Soc4 | Workplace formation in regions with rising unemployment. | |

| Soc5 | Increased numbers of higher-qualified employees. | |

| Soc6 | Influence on distribution between parts of society with differentiated revenue. | |

| Soc7 | Decreased hazard for societal healthiness. | |

| Soc8 | Shift in consumption patterns. Consumer could use optimum quantity of goods, energies, or services. | |

| Soc9 | Advantageous influence of high-quality goods on human healthiness. | |

| Soc10 | Improvement of relationships with consumer. | |

| Soc11 | Improvement of relationships with society. | |

| Soc12 | Degree of adaptation to local conditions. | |

| Soc13 | Reuse by other consumers of discarded goods having adequate quality and having achieved their primary objective. | |

| Soc14 | Abandonment of product by eliminating its function or by proposing the same characteristic for completely different goods. | |

| Soc15 | Goods used more intensively. |

| Options Group Framework | Options Symbol | Single Option Score (S) | Single Score S*dwi Considered as Degree Validity | Single Score S*dwi Considered as Degree Validity after the Rejection of Extreme Values (k = 1) | |||

|---|---|---|---|---|---|---|---|

| DSM | CM | DSM | CM | DSM | CM | ||

| Technical (T) Degree of Validity | T1 | 10 | 10 | 10 | 10 | ||

| T2 | 9 | 2 | 9 | 2 | 9 | 2 | |

| T3 | 9 | 2 | 9 | 2 | 9 | 2 | |

| T4 | 10 | 2 | 10 | 2 | 10 | 2 | |

| T5 | 9 | 2 | 9 | 2 | 9 | 2 | |

| T6 | 9 | 1 | 9 | 1 | 9 | 1 | |

| T7 | 6 | 5 | 6 | 5 | 6 | 5 | |

| T8 | 0 | 0 | 0 | 0 | |||

| T9 | 8 | 7 | 8 | 7 | 8 | 7 | |

| T10 | 9 | 3 | 9 | 3 | 9 | 3 | |

| T11 | 7 | 4 | 7 | 4 | 7 | 4 | |

| T12 | 7 | 4 | 7 | 4 | 7 | 4 | |

| T13 | 8 | 8 | 8 | 8 | 8 | 8 | |

| T14 | 7 | 6 | 7 | 6 | 7 | 6 | |

| T15 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Trimmed mean of Technical group partial indicator ∑S*T | 8.31 | 4.31 | |||||

| Environmental (En) Degree of Validity | En1 | 8 | 2 | 32 | 8 | 32 | 8 |

| En2 | 7 | 3 | 28 | 12 | 28 | 12 | |

| En3 | 8 | 3 | 32 | 12 | 32 | 12 | |

| En4 | 8 | 2 | 32 | 8 | 32 | 8 | |

| En5 | 0 | 0 | 0 | 0 | |||

| En6 | 9 | 4 | 36 | 16 | 36 | 16 | |

| En7 | 9 | 1 | 36 | 4 | 36 | 4 | |

| En8 | 9 | 4 | 36 | 16 | 36 | 16 | |

| En9 | 5 | 8 | 20 | 32 | 20 | ||

| En10 | 0 | 0 | 0 | 0 | 0 | 0 | |

| En11 | 0 | 0 | 0 | 0 | 0 | 0 | |

| En12 | 8 | 5 | 32 | 20 | 32 | 20 | |

| En13 | 8 | 6 | 32 | 24 | 32 | 24 | |

| En14 | 10 | 1 | 40 | 4 | 4 | ||

| En15 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Trimmed mean of Environmental group partial indicator ∑S*En | 24.31 | 9.54 | |||||

| Economic (Ec) Degree of Validity | Ec1 | 10 | 10 | 30 | 30 | ||

| Ec2 | 10 | 10 | 30 | 30 | 30 | 30 | |

| Ec3 | 9 | 6 | 27 | 18 | 27 | 18 | |

| Ec4 | 7 | 1 | 21 | 3 | 21 | ||

| Ec5 | 6 | 6 | 18 | 18 | 18 | 18 | |

| Ec6 | 1 | 1 | 3 | 3 | 3 | ||

| Ec7 | 9 | 3 | 27 | 9 | 27 | 9 | |

| Ec8 | 8 | 4 | 24 | 12 | 24 | 12 | |

| Ec9 | 8 | 7 | 24 | 21 | 24 | 21 | |

| Ec10 | 8 | 3 | 24 | 9 | 24 | 9 | |

| Ec11 | 8 | 3 | 24 | 9 | 24 | 9 | |

| Ec12 | 8 | 7 | 24 | 21 | 24 | 21 | |

| Ec13 | 9 | 3 | 27 | 9 | 27 | 9 | |

| Ec14 | 8 | 2 | 24 | 6 | 24 | 6 | |

| Ec15 | 8 | 7 | 24 | 21 | 24 | 21 | |

| Trimmed mean of Economic group partial indicator ∑S*Ec | 24.46 | 14.31 | |||||

| Societal (Soc) Degree of Validity | Soc1 | 3 | 1 | 6 | 2 | 6 | 2 |

| Soc2 | 0 | 0 | 0 | 0 | |||

| Soc3 | 8 | 7 | 16 | 14 | 16 | ||

| Soc4 | 1 | 1 | 2 | 2 | 2 | 2 | |

| Soc5 | 2 | 2 | 4 | 4 | 4 | 4 | |

| Soc6 | 3 | 2 | 6 | 4 | 6 | 4 | |

| Soc7 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Soc8 | 2 | 1 | 4 | 2 | 4 | 2 | |

| Soc9 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Soc10 | 9 | 5 | 18 | 10 | 10 | ||

| Soc11 | 8 | 3 | 16 | 6 | 16 | 6 | |

| Soc12 | 9 | 3 | 18 | 6 | 18 | 6 | |

| Soc13 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Soc14 | 9 | 1 | 18 | 2 | 18 | 2 | |

| Soc15 | 8 | 5 | 16 | 10 | 16 | 10 | |

| Trimmed mean of Societal group partial indicator ∑S*Soc | 8.15 | 3.69 | |||||

| CEI indicator | 65.23 | 31.85 | |||||

| Relative increase of CEI (RICEI) | 104.80% | ||||||

| Option Group Partial Indicators | Trimmed Means of Partial Indicator | DSM/CM (%) | |

|---|---|---|---|

| DSM | CM | ||

| Technical CET | 8.31 | 4.31 | 192.81 |

| Environmental CEEn | 24.31 | 9.54 | 254.82 |

| Economic CEEc | 24.46 | 14.31 | 170.93 |

| Societal CESoc | 8.15 | 3.69 | 220.87 |

| CEI | 65.23 | 31.85 | 204.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalski, Z.; Kulczycka, J.; Banach, M.; Makara, A. A Complex Circular-Economy Quality Indicator for Assessing Production Systems at the Micro Level. Sustainability 2023, 15, 13495. https://doi.org/10.3390/su151813495

Kowalski Z, Kulczycka J, Banach M, Makara A. A Complex Circular-Economy Quality Indicator for Assessing Production Systems at the Micro Level. Sustainability. 2023; 15(18):13495. https://doi.org/10.3390/su151813495

Chicago/Turabian StyleKowalski, Zygmunt, Joanna Kulczycka, Marcin Banach, and Agnieszka Makara. 2023. "A Complex Circular-Economy Quality Indicator for Assessing Production Systems at the Micro Level" Sustainability 15, no. 18: 13495. https://doi.org/10.3390/su151813495

APA StyleKowalski, Z., Kulczycka, J., Banach, M., & Makara, A. (2023). A Complex Circular-Economy Quality Indicator for Assessing Production Systems at the Micro Level. Sustainability, 15(18), 13495. https://doi.org/10.3390/su151813495