Optimization and Comparative Analysis of Different CCUS Systems in China: The Case of Shanxi Province

Abstract

1. Introduction

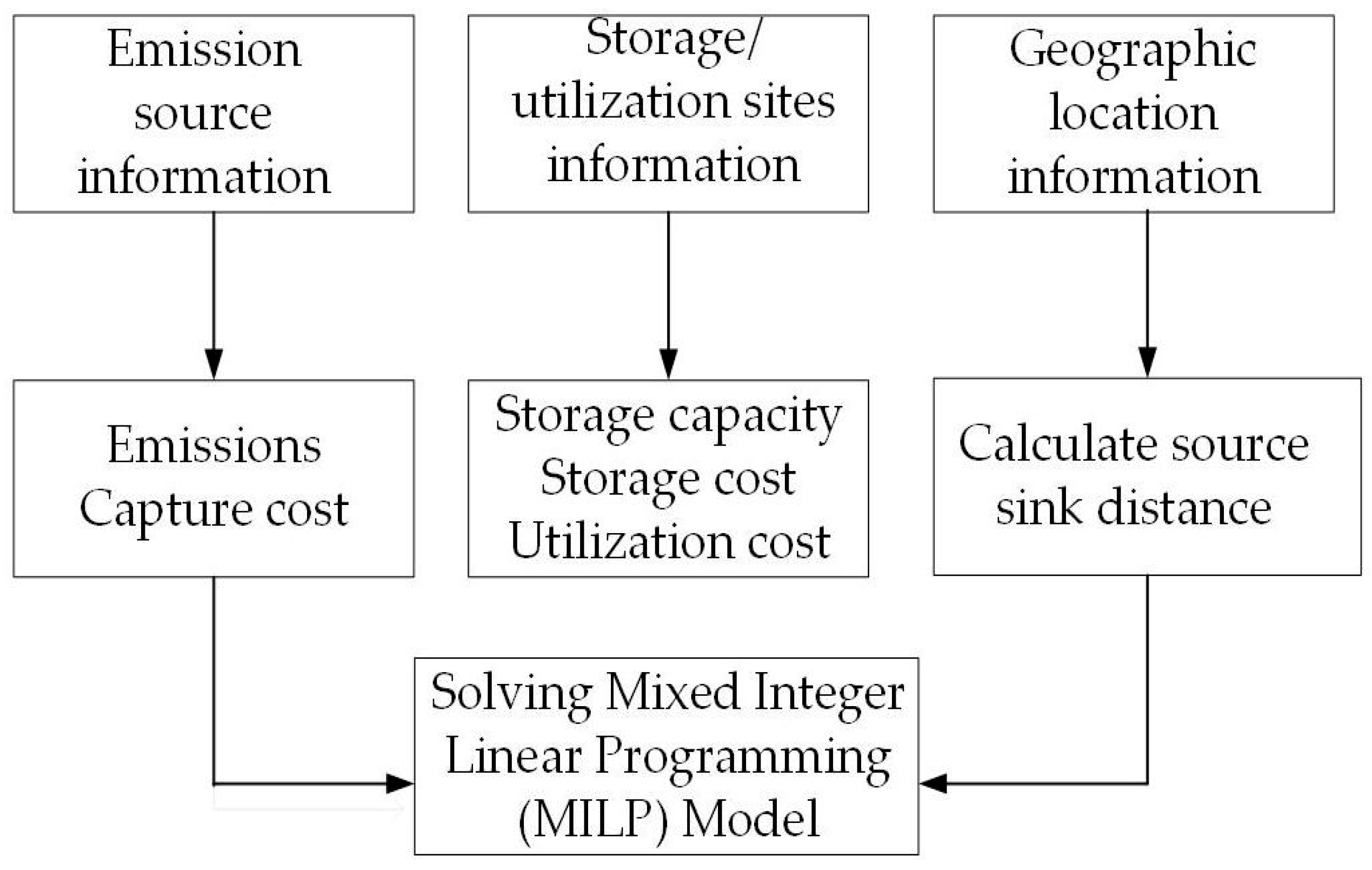

2. Methodology

2.1. Problem Statement

- (1)

- One-to-one coupling, i.e., an emission source corresponds to only one capture node, and a capture node can only receive CO2 from one emission source [17].

- (2)

- Capture plants are located near the sources of CO2 emissions to avoid increased transportation costs.

- (3)

- In the system, CO2 is transported in a supercritical state via a pipeline without considering ship or tanker truck transportation. This is because pipelines are the most established infrastructure that is capable of transporting high flows of CO2 at low cost [25].

- (4)

- The transportation process was relatively safe and closed, and no additional losses were incurred.

- (5)

- An emission source corresponds to a unique sequestration sink or utilization sink; however, a sink can receive CO2 from multiple sources [25].

- (6)

- The sink, source, and pipeline in the system had the same life cycle, with a planned cycle of 20 years [26]. This limits the amount of CO2 transported to the sequestration sink each year.

- (7)

- Stable demand, i.e., over time, the market demand for products converted from carbon dioxide is constant and can be sold at a stable price [27].

- (1)

- Emission sources, including type, location, annual emissions;

- (2)

- CO2 capture and compression, as cost per unit of CO2 capture and compression;

- (3)

- CO2 transport, as transport distance and associated cost;

- (4)

- CO2 sequestration, including type, location, amount sequestered, and related costs;

- (5)

- CO2 utilization, including options, location, and associated cost;

- (6)

- CO2 reduction targets.

2.2. CCUS System Model

2.2.1. Sets

2.2.2. Parameters

- Minimum reduction target (million tons per year);

- Total CO2 emissions per source (million tons per year);

- Maximum capacity of storage or utilized nodes (million tons);

- CCUS life cycle (years);

- CO2 avoidance cost.

2.2.3. Variables

2.3. Mathematical Formulas

2.3.1. Constraints

2.3.2. Cost and Revenue Accounting Equation

- (1)

- Dehydration cost

- (2)

- Capture and compression costs

- (3)

- Transportation cost

- (4)

- Storage cost

- (5)

- Utilization revenue

2.3.3. Objective Function

3. Case Study

4. Results and Discussions

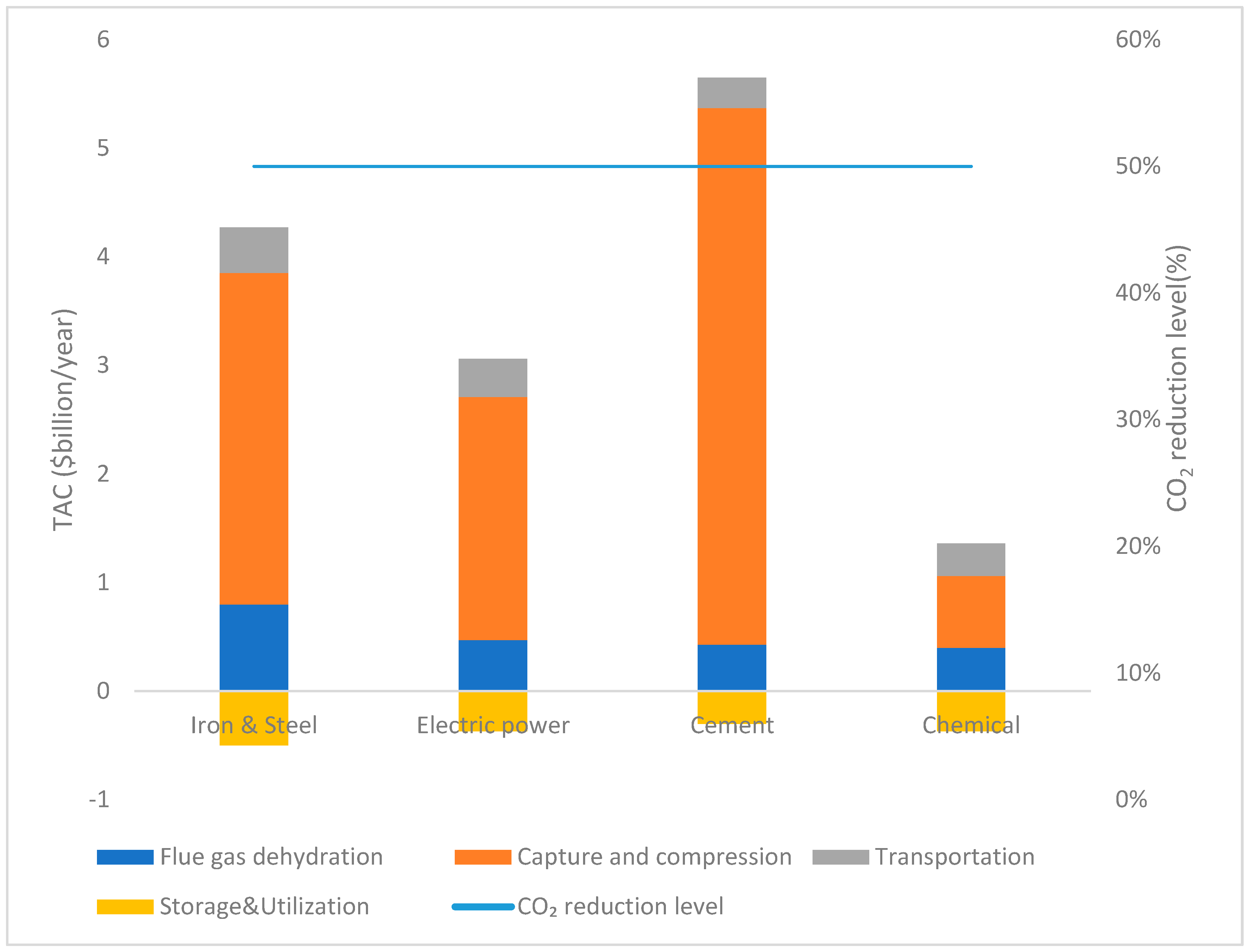

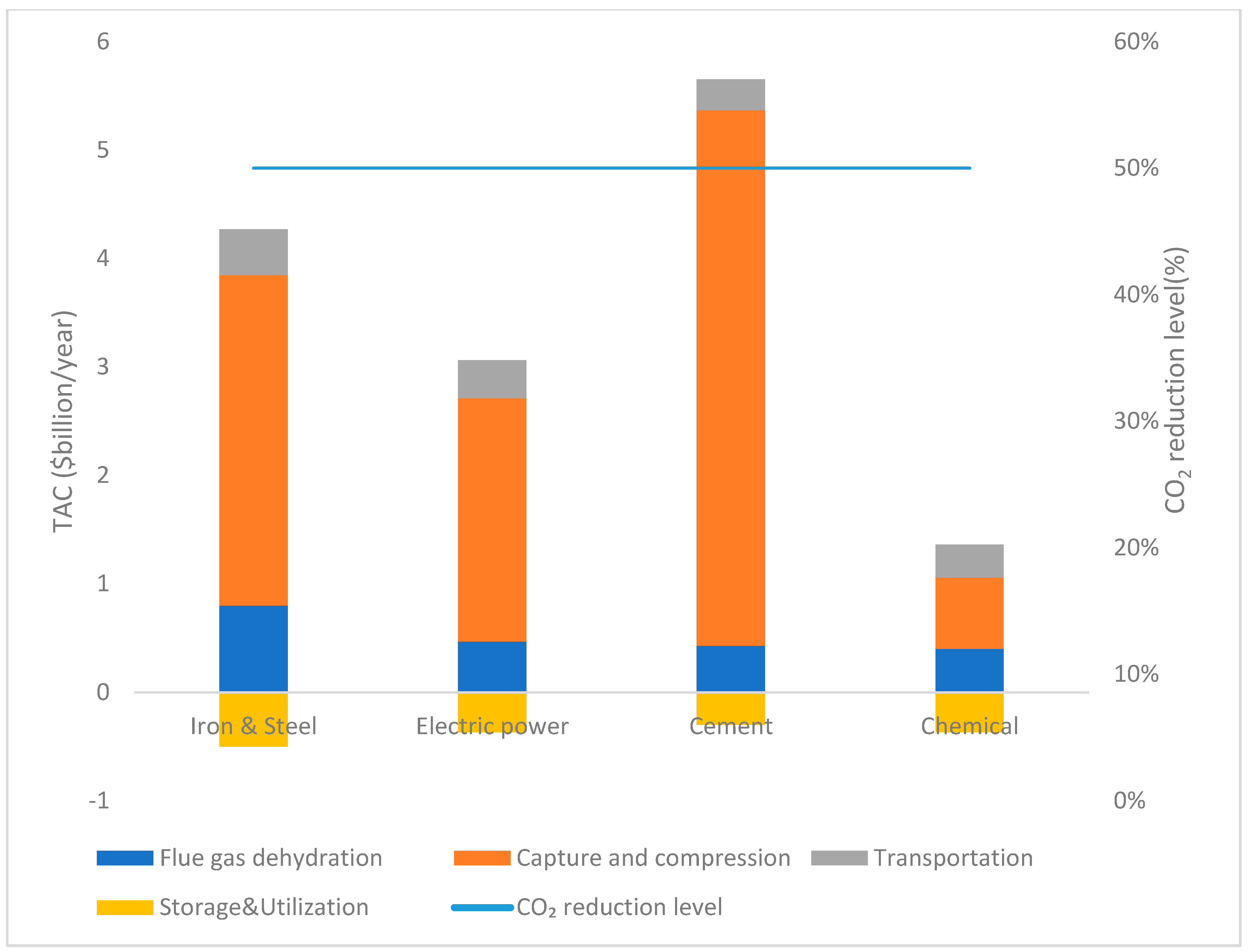

4.1. Results Analysis of CCS Optimization

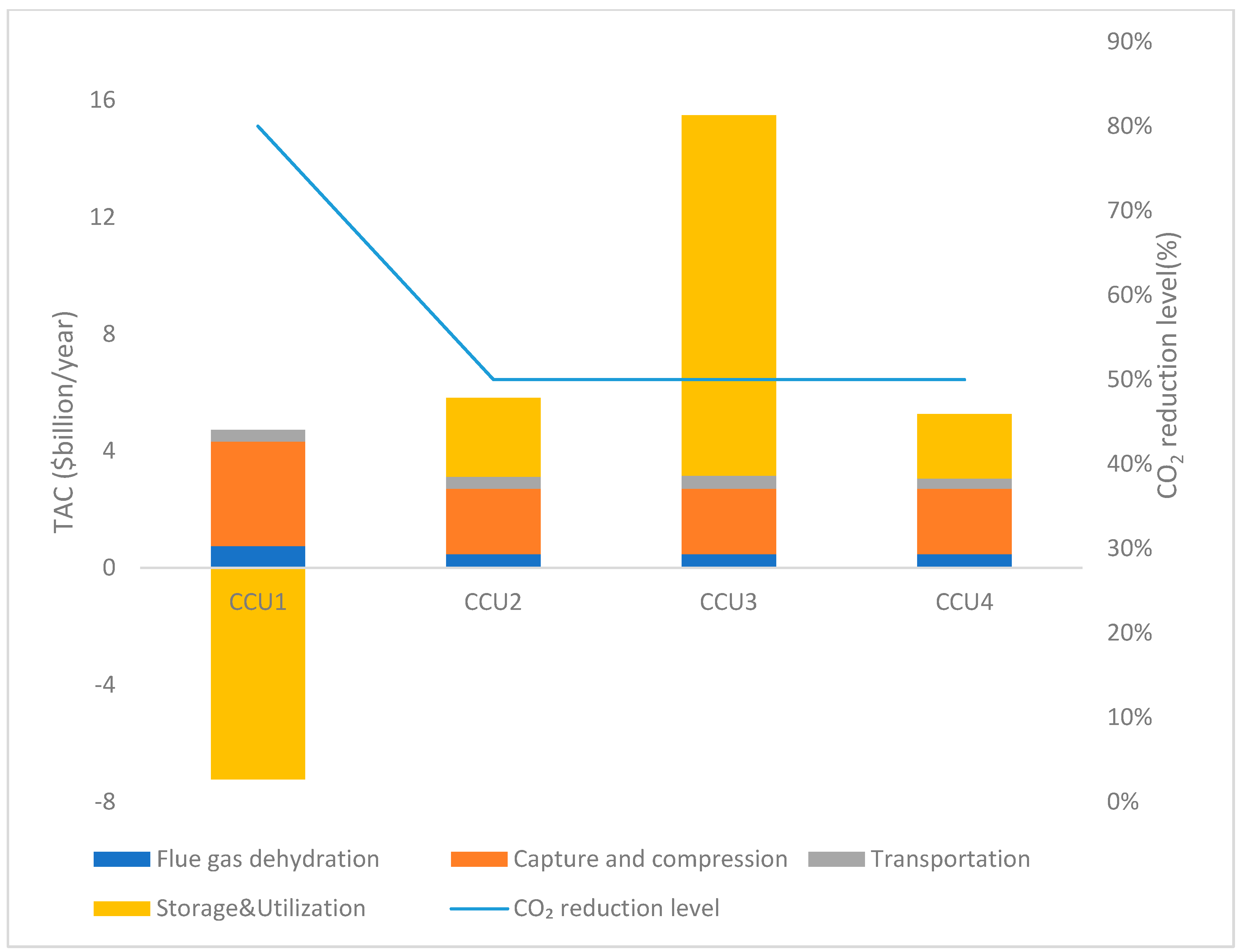

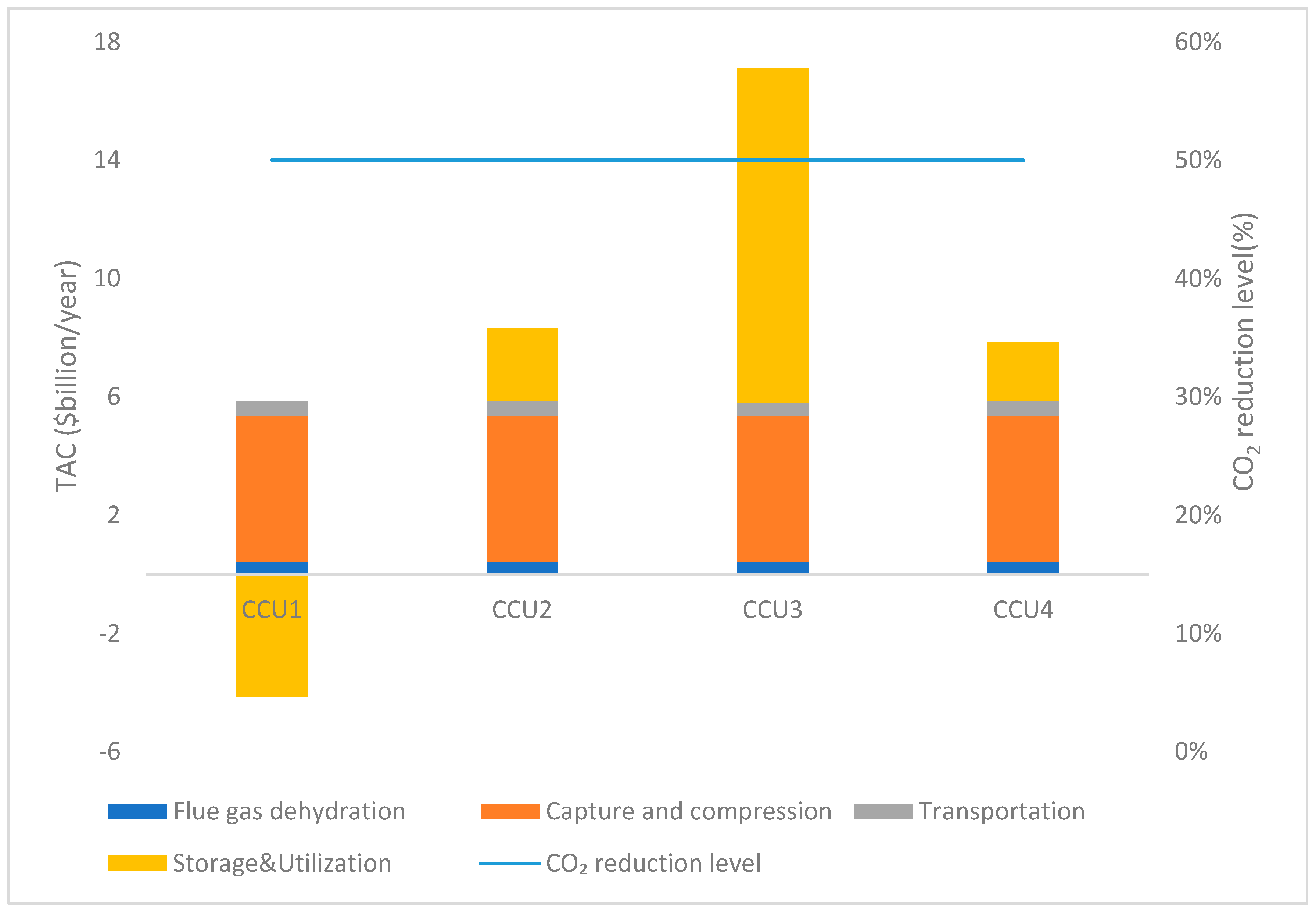

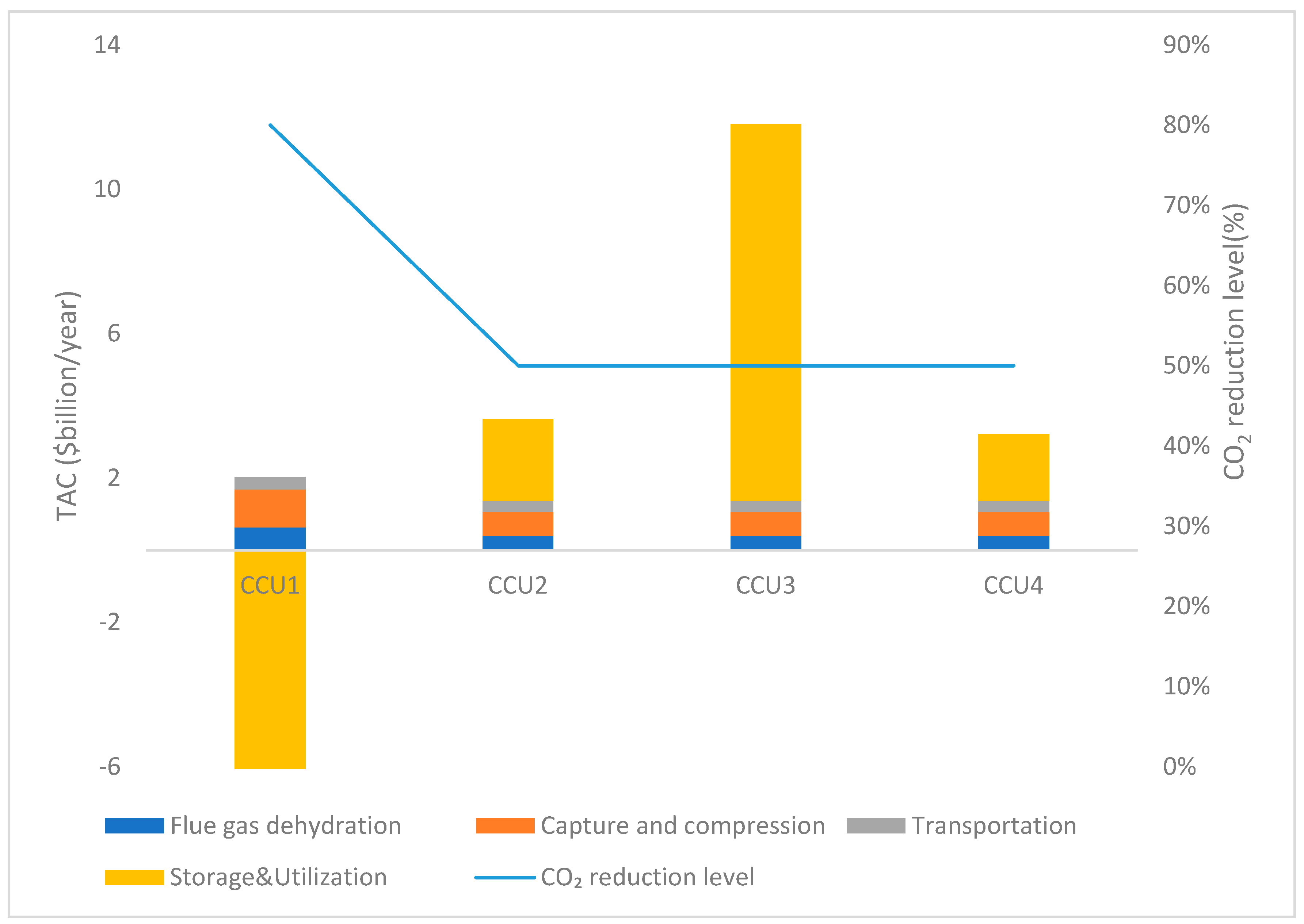

4.2. Results Analysis of CCU Optimization

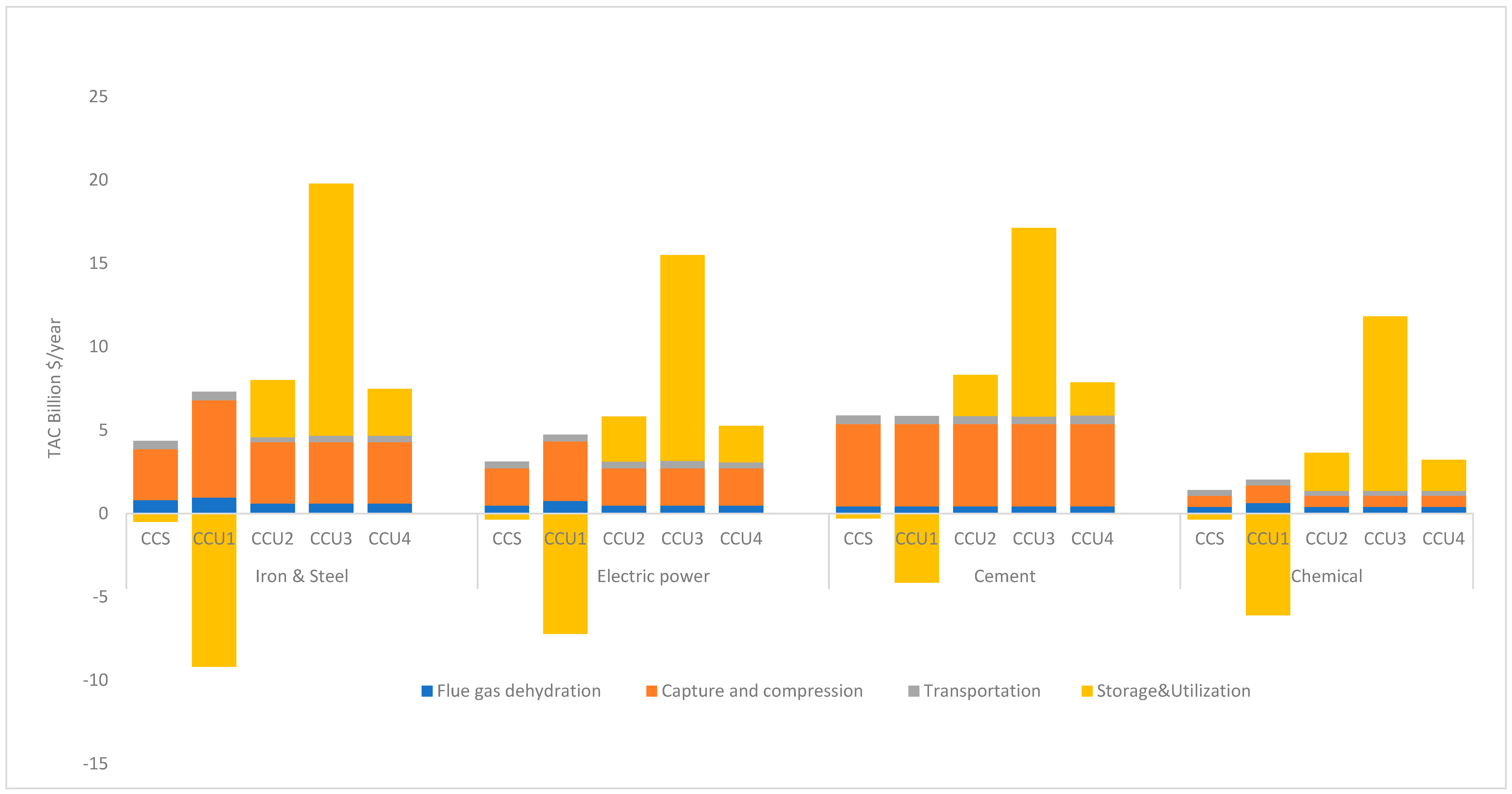

4.3. Comparison of CCS and CCU Optimization Results

5. Conclusions and Policy Suggestion

5.1. Conclusions

- (1)

- The lowest unit abatement cost was urea production compared to other utilization methods, ranging approximately from 71.86 USD/ton CO2 to 29.14 USD/ton CO2, and all four sectors achieved 50% of their abatement targets. Therefore, this utilization pathway is the primary choice for all industries.

- (2)

- CCS projects can also achieve helpful economic and environmental returns until other CO2 utilization technologies mature.

- (3)

- The costs of the CCU2, CCU3, and CCU4 systems are much higher than those of the CCS and CCU1 systems. It was also found that there is little difference between the cost of CCU4 and that of CCU2, and the CO2 utilization pathway of microalgae cultivation is most costly, which faces several challenges in terms of capital, technology, and land.

5.2. Policy Recommendations

- (1)

- Improve process equipment and explore new cutting-edge technologies in capture, such as negative emission technology of CCS/CCU coupled with new energy and new technology systems combined with hydrogen energy technology.

- (2)

- The CO2 utilization industry requires clear government guidance and industrial policy support. The government must set up a national industry-academia-research technology demonstration platform, increase scientific and technological research and financial support for CO2 utilization technology, and improve the CO2 utilization rate.

- (3)

- Further promotion of the CCUS projects integration demonstration is an important part of its scale development. The government should accelerate cluster infrastructure construction for CCUS and support the construction of CCUS industrial demonstration zones in high-carbon industries such as steel, cement, and chemical industries.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms | Distance from node g’ to g | ||

| CCUS | Carbon capture, utilization, and storage | Latitude of site g | |

| CCS | Carbon capture and storage | Longitude of site g | |

| CCU | Carbon capture and utilization | Terrain factor | |

| CO2-ECBM | CO2-enhanced coalbed methane recovery | Unit capture cost at source node i | |

| CO2-EOR | CO2-enhanced oil recovery | Variables | |

| GHG | Greenhouse gas | CO2 captured at the source node i | |

| 30.60 | Peak carbon emissions by 2030 and carbon neutrality by 2060 | Flow rate of CO2 transported from node g’ to node g | |

| Sets | CO2 flow rate at storage node j | ||

| I | Set of carbon dioxide emission sources | Carbon capture cost at source node i | |

| J | Set of carbon sink nodes | Pipeline capital costs between node g’ and node g | |

| T | Intermediate nodes | Pipeline operating costs between node g’ and node g | |

| G | Set of all the nodes (including I, J, and T) | Storage cost at storage node j | |

| Parameters | Variable unit cost at storage node j | ||

| Minimum reduction target (million tons per year) | Fixed cost at storage node j | ||

| Total CO2 emissions per source (million tons per year) | CO2 utilization benefit | ||

| Maximum capacity of storage or utilized nodes (million tons) | Dehydration cost at source node i | ||

| CCUS life cycle (years) | Amount of CO2 utilized or sequestered at node g | ||

| Pipeline operation and maintenance percentage factor for CO2 | CO2 captured at node g | ||

| 1 if CO2 is transported from g to g’, 0 otherwise |

References

- Wen, H.W.; Liang, W.T.; Lee, C.-C. China’s progress toward sustainable development in pursuit of carbon neutrality: Regional differences and dynamic evolution. Environ. Impact Assess. Rev. 2023, 98, 106959. [Google Scholar] [CrossRef]

- Van der Hoeven, M. CO2 Emissions from Fuel Combustion Highlights; International Energy Agency: Paris, France, 2014; pp. 1–134. [Google Scholar]

- IEA. CO2 Emissions from Fuel Combustion—Highlights; IEA: Paris, France, 2016. [Google Scholar]

- Li, Z.; Lin, B.; Luan, R. Impact assessment of clean air action on total factor energy productivity: A three-dimensional analysis. Environ. Impact Assess. Rev. 2022, 93, 106745. [Google Scholar] [CrossRef]

- Bu, Y.; Wang, E.; Qiu, Y.; Möst, D. Impact assessment of population migration on energy consumption and carbon emissions in China: A spatial econometric investigation. Environ. Impact Assess. Rev. 2022, 93, 106744. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, D.; Yin, J.; Zhou, X.; Li, Y.; Chi, P.; Han, Y.; Ansari, U.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-bearing Sediment in Northern South China Sea by Horizontal Wellbore: Evolution and Mechanism. Nat. Resour. Res. 2023, 32, 1595–1620. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, C.; Yang, Y.; Ansari, U.; Han, Y.; Li, X.; Cheng, Y. Preliminary experimental investigation on long-term fracture conductivity for evaluating the feasibility and efficiency of fracturing operation in offshore hydrate-bearing sediments. Ocean Eng. 2023, 281, 114949. [Google Scholar] [CrossRef]

- Sepehri, A.; Sarrafzadeh, M.H. Activity enhancement of ammonia-oxidizing bacteria and nitrite-oxidizing bacteria in activated sludge process: Metabolite reduction and CO2 mitigation intensification process. Appl. Water Sci. 2019, 9, 131. [Google Scholar] [CrossRef]

- IEA. Energy Technology Perspectives 2020; IEA: Paris, France, 2020. [Google Scholar]

- Huang, X.; Sun, Y.; Xu, Z.; Xue, Y.; Wang, Z.; Cai, H. Techno-economic Performance of Wind and Coal-fired Power with CCS Joint Planning. J. Energy Procedia 2017, 114, 6677–6684. [Google Scholar]

- Hong, W.Y. A techno-economic review on carbon capture, utilisation and storage systems for achieving a net-zero CO2 emissions future. Carbon Capture Sci. Technol. 2022, 3, 100044. [Google Scholar] [CrossRef]

- Lee, H.; Lee, J.; Koo, Y. Economic impacts of carbon capture and storage on the steel industry—A hybrid energy system model incorporating technological change. Appl. Energy 2022, 317, 119–208. [Google Scholar] [CrossRef]

- Bellotti, D.; Sorce, A.; Rivarolo, M.; Magistri, L. Techno-economic analysis for the integration of a power to fuel system with a CCS coal power plant. J. CO2 Util. 2019, 33, 262–272. [Google Scholar] [CrossRef]

- Aziz, E.A.; Alwi, S.R.W.; Lim, J.S.; Manan, Z.A.; Klemeš, J.J. An integrated Pinch Analysis framework for low CO2 emissions industrial site planning. J. Clean. Prod. 2017, 146, 125–138. [Google Scholar] [CrossRef]

- Tan, R.R.; Aviso, K.B.; Foo, D.C.Y. P-graph and Monte Carlo simulation approach to planning carbon management networks. Comput. Chem. Eng. 2017, 106, 872–882. [Google Scholar] [CrossRef]

- Leonzio, G.; Bogle, D.; Foscolo, P.U.; Zondervan, E. Optimization of CCUS supply chains in the UK: A strategic role for emissions reduction. Chem. Eng. Res. Des. 2020, 155, 211–228. [Google Scholar] [CrossRef]

- Zhang, S.; Zhuang, Y.; Tao, R.; Liu, L.; Zhang, L.; Du, J. Multi-objective optimization for the deployment of carbon capture utilization and storage supply chain considering economic and environmental performance. J. Clean. Prod. 2020, 270, 122481. [Google Scholar] [CrossRef]

- Chauvy, R.; Lepore, R.; Fortemps, P.; De Weireld, G. Comparison of multi-criteria decision-analysis methods for selecting carbon dioxide utilization products. Sustain. Prod. Consum. 2020, 24, 194–210. [Google Scholar] [CrossRef]

- Cui, X.; Zhuang, Y.; Dong, H.; Du, J. Multi-criteria screening of carbon dioxide utilization products combined with process optimization and evaluation. Fuel 2022, 328, 125319. [Google Scholar] [CrossRef]

- Lee, C.T.; Tsai, C.C.; Wu, P.J.; Yu, B.Y.; Lin, S.T. Screening of CO2 utilization routes from process simulation: Design, optimization, environmental and techno-economic analysis. J. CO2 Util. 2021, 53, 101722. [Google Scholar] [CrossRef]

- Do, T.N.; Chung, H.; Lee, Y.; Kim, C.; Kim, B.; Kim, J. Optimization-based framework for technical, economic, and environmental performance assessment of CO2 utilization strategies. IFAC-PapersOnLine 2022, 55, 412–417. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, W.; Wang, W.; Hu, S. The impact of carbon emission trading on green innovation of China’s power industry. Environ. Impact Assess. Rev. 2023, 99, 107040. [Google Scholar]

- Zhang, J.; Shen, J.; Xu, L.; Zhang, Q. The CO2 emission reduction path towards carbon neutrality in the Chinese steel industry: A review. Environ. Impact Assess. Rev. 2023, 99, 107017. [Google Scholar] [CrossRef]

- Yang, Q.; Sun, Y.Q.; Zhou, H.W.; Ling, C. Research review of carbon capture, utilization and storage technology in China’s typical industries. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2023, 51, 101–110+145. (In Chinese) [Google Scholar]

- Ravi, N.K.; Annaland MV, S.; Fransoo, J.C.; Grievink, J.; Zondervan, E. Development and implementation of supply chain optimization framework for CO2 capture and storage in The Netherlands. Comput. Chem. Eng. 2017, 102, 40–51. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, L.; Zhang, L.; Zhuang, Y.; Du, J. An optimization model for carbon capture utilization and storage supply chain: A case study in Northeastern China. Appl. Energy 2018, 231, 194–206. [Google Scholar] [CrossRef]

- Hasan, M.F.; First, E.L.; Boukouvala, F.; Floudas, C.A. A multi-scale framework for CO2 capture, utilization, and sequestration: CCUS and CCU. Comput. Chem. Eng. 2015, 81, 2–21. [Google Scholar] [CrossRef]

- Hasan, M.F.; Boukouvala, F.; First, E.L.; Floudas, C.A. Nationwide, Regional and Statewide CO2 Capture, Utilization and Sequestration Supply Chain Network Optimization. Ind. Eng. Chem. Res. 2014, 53, 7489–7506. [Google Scholar] [CrossRef]

- Ağralı, S.; Üçtuğ, F.G.; Türkmen, B.A. An optimization model for carbon capture & storage/utilization vs. carbon trading: A case study of fossil-fired power plants in Turkey. J. Environ. Manag. 2018, 215, 305–315. [Google Scholar]

- Simbeck, D.; Beecy, D. The CCS Paradox: The Much Higher CO2 Avoidance Costs of Existing versus New Fossil Fuel Power Plants. Energy Procedia 2011, 04, 1917–1924. [Google Scholar] [CrossRef][Green Version]

- GCCSI. Global Costs of Carbon Capture and Storage; Global CCS Institute: Melbourne, VIC, Australia, 2017. [Google Scholar]

- Serpa, J.; Morbee, J.; Tzimas, E. Technical and Economic Characteristics of a CO2 Transmission Pipeline Infrastructure; Publications Office of the European Union: Luxembourg, 2011. [Google Scholar]

- Broek, M.V.D.; Brederode, E.; Ramírez, A.; Kramers, L.; Kuip, M.V.D.; Wildenborg, T.; Turkenburg, W.; Faaij, A. Environmental modelling & software designing a cost-effective CO2 storage infrastructure using a GIS based linear optimization energy model. Environ. Modell. Softw. 2010, 25, 1754–1768. [Google Scholar]

- Dahowski, R.; Dooley, J.; Davidson, C.; Bachu, S.; Gupta, N. A CO2 Storage Supply Curve for North America.upta, N. In Proceedings of the 7 International Conference on Greenhouse Gas Control Technologies, Vancouver, BC, Canada, 5–9 September 2004. [Google Scholar]

- Knoope, M.M.J.; Ramírez, A.; Faaij, A.P.C. A state-of-the-art review of techno-economic models predicting the costs of CO2 pipeline transport. Int. J. Greenh. Gas Control 2013, 16, 241–270. [Google Scholar] [CrossRef]

- Wang, Z.; Luo, Y.Y.; Kuang, J.C.; Mao, Y.N. Source-sink matching and optimization of CCS for large coal-fired power plants in China. Ind. Eng. Manag. 2016, 21, 75–83+89. (In Chinese) [Google Scholar]

- Zero Emission Platform. The Costs of CO2 Capture, Transport and Storage; Post-Demonstration CCS in the EU; European Technology Platform for Zero Emission Fossil Fuel Power Plants: Brussels, Belgium, 2011. [Google Scholar]

- Patricio, J.; Angelis-Dimakis, A.; Castillo-Castillo, A.; Kalmykova, Y.; Rosado, L. Method to identify opportunities for CCU at regional level—Matching sources and receivers. J. CO2 Util. 2017, 22, 330–345. [Google Scholar] [CrossRef]

- Douskova, I.; Doucha, J.; Livansky, K.; Machat, J.; Novak, P.; Umysova, D.; Zachleder, V.; Vitova, M. Simultaneous flue gas bioremediation and reduction of microalgal biomass production costs. Environ. Biotechnol. 2009, 82, 179–185. [Google Scholar] [CrossRef] [PubMed]

- Hepburn, C.; Adlen, E.; Beddington, J.; Carter, E.A.; Fuss, S.; Mac Dowell, N.; Minx, J.C.; Smith, P.; Williams, C.K. The technological and economic prospects for CO2 utilization and removal. Nature 2019, 575, 87–97. [Google Scholar] [CrossRef] [PubMed]

- D’Amore, F.; Mocellin, P.; Vianello, C.; Maschio, G.; Bezzo, F. Economic optimisation of European supply chains for CO2 capture, transport and sequestration, including societal risk analysis and risk mitigation measures. Appl. Energy 2018, 223, 401–415. [Google Scholar] [CrossRef]

- Hou, L.; Niu, Y.; Wu, G.; Tian, J.; Zhang, Y.; Liu, J.; Zhang, X.; Jiang, J.; Cheng, S.; Pei, Z. Site Selection of Carbon Capture, Utilization and Storage Technology Application in Shanxi. Environ. Sustain. Dev. 2016, 41, 83–85. [Google Scholar]

- Zhang, B.; Liang, K.Q.; Wang, W.B.; Chen, L.L.; Wang, H. Evaluation of Effective CO2 Geological Sequestration Potential of Deep Saline Aquifer in Ordos Basin. Unconv. Oil Gas 2019, 6, 15–20. (In Chinese) [Google Scholar]

- Leonzio, G.; Foscolo, P.U.; Zondervan, E. Sustainable utilization and storage of carbon dioxide: Analysis and design of an innovative supply chain. Comput. Chem. Eng. 2019, 131, 106569. [Google Scholar] [CrossRef]

- Jarvis, S.M.; Samsatli, S. Technologies and infrastructures underpinning future CO2 value chains: A comprehensive review and comparative analysis. Renew. Sustain. Energy Rev. 2018, 85, 46–68. [Google Scholar] [CrossRef]

| Factory | Cost (USD/Ton CO2) |

|---|---|

| Power | 60 |

| Iron and steel | 74 |

| Cement | 129 |

| Fertilizer | 28 |

| Number | Type | Longitude | Latitude | Capacity (Million Tons) |

|---|---|---|---|---|

| 1 | CO2-ECBM | 112.45 | 39.07 | 164 |

| 2 | CO2-ECBM | 112.19 | 35.69 | 613 |

| 3 | Saline aquifer | 109.53 | 36.49 | 7883.24 |

| 4 | Saline aquifer | 110.85 | 39.52 | 3315.12 |

| Number | Type | Longitude | Latitude | Break-Even Cost (USD/Ton) |

|---|---|---|---|---|

| 1 | Urea | 111.25 | 36.31 | −99 |

| 2 | Methanol | 111.02 | 35.66 | 59 |

| 3 | Microalgae | 112 | 37.09 | 270 |

| 4 | Concrete curing | 112.55 | 37.78 | 48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Pan, L.; Mao, X. Optimization and Comparative Analysis of Different CCUS Systems in China: The Case of Shanxi Province. Sustainability 2023, 15, 13455. https://doi.org/10.3390/su151813455

Zhou W, Pan L, Mao X. Optimization and Comparative Analysis of Different CCUS Systems in China: The Case of Shanxi Province. Sustainability. 2023; 15(18):13455. https://doi.org/10.3390/su151813455

Chicago/Turabian StyleZhou, Wenyue, Lingying Pan, and Xiaohui Mao. 2023. "Optimization and Comparative Analysis of Different CCUS Systems in China: The Case of Shanxi Province" Sustainability 15, no. 18: 13455. https://doi.org/10.3390/su151813455

APA StyleZhou, W., Pan, L., & Mao, X. (2023). Optimization and Comparative Analysis of Different CCUS Systems in China: The Case of Shanxi Province. Sustainability, 15(18), 13455. https://doi.org/10.3390/su151813455