Abstract

Supply chains are increasingly vulnerable to disruptions due to the complex and interconnected nature of global business operations. Supply chain nervousness (SCN) leads to inefficiencies and disruptions in the flow of goods and services. Managing SCN is critical for sustaining the continuity of business operations in today’s dynamic and uncertain business environment. To address this issue, this study proposes a strategic framework that integrates key components of supply chain nervousness management and establishes a robust framework that prioritizes these factors based on their relative importance. By incorporating the fuzzy-ELECTRE methodology into the analysis, the proposed framework acknowledges the inherent uncertainties and imprecisions present in supply chain disruptions. It offers a systematic and comprehensive approach to prioritizing and managing SCN factors, considering both qualitative and quantitative assessments. To validate the effectiveness of the proposed framework, a case study is conducted in a real-world supply chain context. The results highlight demand variability as the factor with the greatest impact on SCN. Moreover, the results demonstrate the framework’s ability to effectively manage SCN by providing valuable insights for practitioners and researchers seeking to understand the causes of supply chain nervousness and mitigate its impact. The contributions of this research lie in providing decision-makers with a strategic framework for disruption management under fuzzy environments. The proposed approach enhances the understanding of SCN and enables proactive decision making to mitigate its negative consequences.

1. Introduction

In today’s rapidly changing interconnected world, supply chains become more complicated to be managed [1]. Due to this complexity, managers face several challenges that may affect their goal of designing sustainable and competitive supply chains [2,3]. One such challenge is supply chain nervousness (SCN). SCN can be defined as the disruptions or uncertainties that occur in supply chain systems due to several factors. These disruptions have extensively been studied in the literature without linking them to the nervousness of the supply chains, such as demand disruptions, supply disruptions, production disruptions, sudden disruptions, unforeseen events, environmental uncertainties, and many more [4].

Supply chain nervousness management (SCNM) is the practice of identifying, evaluating, and controlling nervousness in an organization’s supply chain [5]. Nervousness is any kind of inside or outside factor and effect that makes it uncertain whether and when a business will make decisions to achieve its goals. Using global SCNM strategies, a company can operate more efficiently, reduce costs, and enhance customer service. The supply chain is typically nervous about decisions that are vulnerable to activity, changes, and disruptions, whether inside or outside. SC instability is a state that both influences and is influenced by nervousness. Desirable or undesirable supply chain nervousness has an impact on industries, consumers, the economy, and organizations. Income and profit volatility raises unhappiness, dissatisfaction, and investment costs. Markets and economies are notorious for being uneasy. Inventory, planning, production, profit, and other uncertain and erratic outcomes are all heavily impacted by SCN. The COVID-19 crises draw attention to SC’s worries about nervousness, including its causes, cures, and safeguards. Nervousness management techniques preserve the product flow during crises while offering long-term economic advantages to individual producers, businesses, and other industries [6].

A nervousness assessment is the best way to identify internal nervousness, as well as external nervousness presented by SC allies who have a significant impact on a company’s ability to meet its commitments to produce and deliver quality products [7]. Nervousness identification is considered the most important activity of a nervousness assessment because a company cannot manage a nervousness it does not identify. There are two parts to nervousness: the consequences of an event and the associated likelihood of an event occurring. A supply chain nervousness assessment goal is to make sure that the company takes specific actions to better understand its nervousness and the potential effects that nervousness may have. The SCNM process includes three main stages: identifying, evaluating, and treatment of SCN; and three main components: SCNM elements, SCNM objectives, and SCNM main pillars.

The vulnerabilities connected to managing the global supply chain (GSC) have generated discussion amongst researchers and practitioners. This is demonstrated by the increasing business uncertainties in SCM that endanger the economy and the whole network flow. Action is necessary at all times, including before, during, and after a disruption event. But so is planning that action in a deliberate and methodical way [8]. Decision makers must be careful that the steps they take will restore stability; otherwise, the turmoil in the supply chain may spread as a result. SC mangers need access to trustworthy supply chain insights in order to make the right decisions and take the appropriate actions. Again, this is not simply a picture of the present; it is a comprehensive, accurate, and up-to-date view of operations and circumstances that is updated and analyzed frequently. The management of supply chain nervousness by executives must take that into consideration all the time and a cross the whole SC. Truly risk-free decisions will never exist. It is not a decision maker’s responsibility to completely remove nervousness; rather, they should be aware of its potential effects and strive to minimize it wherever they can [3].

There are few studies that have looked at nervousness in the supply chain. Previous research has looked at nervousness from specific aspects, such as changes in demand, inventory, and MRP systems, but has not examined the entire supply chain nervousness, its impact, and how it should be managed [9,10]. This research seeks to cover the gap and get it off the ground for researchers from academics and industry to see the aspects related to nervousness in terms of definition, evaluation, minimization of its impact, and management within a practical framework. Therefore, this research seeks to answer a number of questions, including: What are the components of nervousness management in the supply chain? How might we identify, evaluate, and minimize their impact and consequences? What are the objectives of nervousness management in the supply chain? How might we determine the goals of SCNM in an organization? And how can we identify, analyze, and shape SCNM pillars?

This research is distinctive in that it thoroughly analyzes the SCN and proposes a supply chain nervousness management framework. The SCNM frame discusses the process of identifying the factors that contribute to nervousness in the SCs, including the internal and external sources and causes of nervousness, assessing the qualitative and quantitative nervousness factors, and introducing the reactive and proactive methodology to reduce or mitigate the impact of nervousness factors. Additionally, it examines current supply chain developments and how they relate to nervousness. It looks at managerial strategies and how they impact supply chain nervousness. In light of the extraordinary advancements and transformations in business, economics, technology, and science, as well as the intense rivalry that surpassed all expectations, this research offers a framework for SCNM. Other contributions comprise the identification of a number of open research problems to be investigated further in the future. Furthermore, the paper offers a methodology for leveraging the fuzzy multi-criteria decision analysis (Fuzzy-MCDA), elimination and choice translating reality (ELECTRE) method to rank SCNM factors based on their importance and effect. Building SCNM is essential given the present high level of global competition and the advent of crises like the COVID-19 matter. To achieve this, the following objectives have been identified:

- Modeling SCNM elements by identifying, assessing, and mitigating SCN factors;

- Determining the SCNM goal and objectives for current and future SC resilience and sustainability;

- Analyzing the pillars of SCNM in terms of strategies, planning, measuring, and continuity;

- Propose a fuzzy-MCDA approach to prioritize SCNM factors;

- Assessing SCN in UAE using the proposed technique and framework, then evaluating and validating the results with the experts and concerned parties.

Considering that the United Arab Emirates enjoys a strong economy and a large group of supply chains that link it to the whole world, it is more vulnerable than others to nervousness [11]. Especially since this nervousness can be caused by natural, political, economic, or financial changes around the world and outside the control of companies and institutions within the Emirates. These sudden changes can be the result of crises such as diseases and epidemics, or human-made such as wars and social unrest [12]. In this research, the nervousness in the supply chains in the United Arab Emirates will be studied and evaluated in terms of its causes and how to mitigate and measure it, as well as analyzing its sources and how to treat and reduce its impact. So, a comprehensive SCNM framework for nervousness in the UAE supply chains is proposed. A fuzzy-MCDA approach will be used to evaluate SCNM factors and create priorities based on their importance. The results will be presented, discussed, and evaluated with the stakeholders and specialists.

The rest of the paper is arranged as follows: Section 2 reviews previous studies and clarifies the gaps; Section 3 presents the SCNM framework and discusses its main components; and Section 4 presents the analysis and evaluation of nervousness factors coupled with a numerical case study. Findings and discussion of results are provided in Section 5; Section 6 presents conclusions, recommendations, and limitations, and suggests future studies.

2. Related Work and Background

2.1. Supply Chain Nervousness

SCs face many challenges during crises like COVID-19. Crises and disruptions usually lead to SCN [9,12,13]. Nervousness identification, assessment, and mitigation are a significant concern for supply chain managers, and it has attracted attention from several supply chain segments. The management of nervousness associated with the supply chain becomes an urgent necessity to help decision makers in the SC to ensure competitiveness, stability, and increased SCs effectiveness [13]. In previous studies, researchers tend to use the concept of supply chain management (SCM) to ensure stability [14], effectiveness [14], resilience [15], and sustainability [16]. They defined the SCM as a systems-based method to control the whole flow of commodities inventories from the supplier to the final client in [17]. SCM involves managing the entire process from creating a product to disposing of it after the sale. It includes product creation, acquisition, planning, manufacturing, distribution, fulfillment, and post-sale support. It is crucial for the success of any organization [18]. Business performance is now heavily influenced by sustainable supply chain management. Understanding this relationship is crucial for managers to improve both environmental and financial performance [19]. Other researchers delve into business performance by focusing on the risks facing the supply chain and how to minimize these risks. This field of research is commonly known as SCRM (supply chain risk management) [20]. Risk management is crucial for the smooth running of supply chains as it helps to handle uncertainty. Also, the increased efficiency in the supply chain due to globalization and low inventories has resulted in new vulnerabilities, leading to disruptions in the economy’s stability. To address this, risk analysis and mitigation have become crucial to stabilize businesses. It is important to identify key assets in the supply chain and secure them against potential threats to ensure the continuity of the company [21]. The most significant long-term risks associated with supply disruption are human resource regulatory risks, workplace issues, inflation costs, safety violations, and social welfare violations. Those looking for suppliers in numerous areas should be aware of the high dangers there that can call for mitigation action [22].

SCRM employs risk management process tools, either independently or in partnership with supply chain partners, to address risks and uncertainties relating to logistics-related activities, product availability, or resources in the supply chain [23]. However, analysts often only consider their immediate surroundings, ignoring potential future issues [24]. Identifying risks and disruptions have been discussed in different fields and at different levels of the supply chain. For example, the authors of [25] examine six risks affecting the supply chain with a special focus on supplier selection. The investigated risks are supply and demand risks, manufacturing risks, logistics risks, information risks, and environmental risks. Other authors [26] study the same risks, except for the logistics risks in the SMEs of clothing retailers. The authors of [27] focus on the risks associated with SC with the aim of achieving resilience and sustainability, they classify the risks according to their sources; demand-related risks and supply-related risks. The demand-related risks include market disruption, demand spike, purchase behavior, and personal protective equipment (PPE) shortage. Supply-related risks or factors include demand plunge, production disruption, and failed networks. The supply-related risks gain more focus in the study of [28] by analyzing the dependent and independent disruptions among suppliers. This analysis can be done by examining the supply risks that affect specific suppliers and the environmental risks that affect many suppliers in the region. Other authors classify the disruptions as minor or major surprises according to the warning degree preceding their occurrence [29]. One of the major causes of environmental disruption is the COVID-19 pandemic, which affects the resilience and sustainability of the SCs [27]. Supply and demand disruptions brought on by the COVID-19 pandemic have reverberating impacts on supply chain management and operations, highlighting a need to increase flexibility to reduce epidemic and demand risks [30].

Developing SCRM strategies is extremely critical in minimizing the impact of disruptions during the COVID-19 pandemic and increasing the strength and ability to recover the supply chain. These strategies are critical in ensuring supply chain stability [31] and will lessen the effects of both natural and human-made disasters [32]. While Industry 4.0 has revolutionized many aspects of production engineering, the development of supply chains and supply chain management is still not as advanced [33]. The difficulty lies in figuring out how to apply supply chain management effectively [34]. So, many researchers develop strategies for building resilient, effective, stable, and sustainable SCs using Industry 4.0 technologies including artificial intelligence (AI), the Internet of things (IoT), block chains, and E-supply chains. Firms with these technologies can ensure that they can match up their information processing capabilities with the requirements, and this will lead to improving the SCRM capabilities and boosts supply chain resilience [35,36,37,38].

The significant consequences of COVID-19 have spurred scholars to develop creative and effective strategies that can mitigate the impact of disruptions of SCs and ensure the smooth functioning of operations. Researchers have taken different approaches to developing strategies. For example, the authors of [39] find that the most significant long-term risks associated with supply disruption are human resource regulatory risks, workplace issues, inflation costs, safety violations, and social welfare violations. Those looking for suppliers in numerous areas should be aware of the high dangers there that can call for mitigation action [22]. Other scholars develop financial strategies because of the big impact on a country’s economy and the financial performance of the companies [40]. Some scholars focus on resilience while developing strategies to ensure the ability to recover from disruptions [41]. Others derived their strategies from the concept of flexibility to emphasize responsiveness and adaptability when dealing with changing conditions [42]. Similarly, agility has been the focus for scholars who design strategies to enable effective responses to any unexpected events [43]. Moreover, sustainability has been the guiding principle of developing strategies for some scholars to ensure long-term efficient supply chains [44]. The most recent articles on developing strategies that mitigate the effects of disruptions, risks, and uncertainties are included in Table 1 below.

Table 1.

Adapted strategies to mitigate the effect of disruptions in supply chains.

Although the term nervousness has been used previously in some research studies, its use has been limited to some aspects such as those related to inventory management, MRP, and demand. The relationship between demand planning and the bullwhip effect can be defined by comparing planning accuracy across various demand-supply network echelons and identifying the areas of greatest nervousness [9]. Nervousness and volatility are common in a multifaceted planning system. There have been significant technology and market developments in SCM, which are then compared to the theory’s predicted adjustments [55]. Supply chain disruptions negatively affect the performance of participants in the supply chain, making it crucial to reduce risks and improve performance in the field of supply chain management [56].

2.2. Fuzzy-ELECTRE Method

To avoid vagueness in decision makers’ and experts’ expressions, fuzzy analysis is a technique used in many fields, including engineering, to solve problems involving uncertainty and ambiguity. It has been used in SCs, management, planning, and decision-making issues.

To assess the generated mitigation strategies and prioritize the risks and disruptions in the supply chain, different MCDA methods have been followed in previous studies. For example, the SCOR technique is used to map and categorize supply chain operations, the integrated methodologies (HOR) and analytic network process (ANP) with Pareto diagrams and method-based ratings, and evaluations based on the assessment of the FMEA technique, as well as risk events and risk agents are identified as proper approaches to assess supply chain risks [57]. The authors of [58] combine AHP, VIKOR, and simulation to evaluate the practices of GSCM. Others [59] use a hybrid fuzzy MCDA that combines the fuzzy decision-making trial and evaluation laboratory (DEMATEL) with ANP and fuzzy ANP to assess and evaluate the factors of their framework and rank the evaluation criteria. The authors of [60] integrate Delphi, the grey theory, fuzzy set, and Weighted Influence Non-linear Gauge System (WINGS) approaches to generate a useful policy for a sustainable supply chain.

A series of MCDA methods known as ÉLECTRE was developed in Europe in the middle of the 1960s. ÉLECTRE is an acronym for Élimination Et Choix Traduisant la Realité [61]. The fuzzy-ELECTRE method will be used to evaluate the factors affecting supply chain nervousness. The ELECTRE methods—elimination and choice translating reality—assemble a group of decision-making systems whose distinguishing characteristic is the partial aggregate based on the growth of relations of performance comparisons between each pair of solutions.

Typically, this type of decision making is referred to as an “outranking approach”. ELECTRE applied to the three key issues of selecting, ranking, and sorting. They are employed in the domains of business, growth, design, supplier selection, and development. An ELECTRE application has two primary components: first, the creation of one or more outranking relations, which tries to compare every pair of actions in depth; and second, an exploitation technique, which expands on the recommendations made in the first phase. The nature of the suggestions varies depending on the issue being handled: selecting, ranking or sorting. The importance coefficients and veto thresholds are two separate sets of criteria parameters used in ELECTRE procedures. The weights of the criteria cannot be determined using the ELECTRE approach. It can be used with other strategies like AHP and has been utilized in previous studies for supply chain analysis and to identify and rank barriers to GSCM implementation in the leather sector with the use of AHP-ELECTRE combination [62], in order to establish an environmental trade-off between energy consumption and product life cycle in the cold supply chain using the best-worst method and ELECTRE-I methodology [63]; establish the significance of dealership performance evaluation in a supply chain; take into account the DEMATEL and ELECTRE [64]; select the optimum strategy among available alternatives of hazards in the supply chain of a medical equipment maker company using a combined ANP-ELECTRE technique [65]; use a vague group framework selection for electronic supply chain management [66]; rank the factors influencing the green supply chain [67]; compare effective factor rankings in supply chain management using fuzzy-ELECTRE [68]; analyze and prioritize green health suppliers using fuzzy-ELECTRE [69]; and rank the green chain suppliers using a fuzzy TOPSIS and ELECTRE method [70].

Few studies have addressed nervousness management in the supply chain or the use of MCDA in the evaluation of SCNM factors, especially if the issue is related to the nervousness of the supply chain in an integrated manner and not a small part of it. There is also a rebuttal in studies that quantify nervousness to response based on its degree of impact and importance. This paper proposes a framework for nervousness management in the supply chain. The proposed framework aims to fill the gap in previous studies and provide decision makers with tools to assess and avoid supply chain nervousness in their organizations. The evaluation of SCNM factors will be done using the fuzzy-MCDA method to avoid uncertainty and ambiguity in decision making. This research serves as a resource for future supply chain management and decision making. The most recent articles on multi-criteria decision analysis methods, which primarily focus on supply chain nervousness, are included in Table 2 below.

Table 2.

Multi-criteria decision analysis (MCDA) methods for supply chain management.

Table 2 provides an overview of the various multi-criteria decision analysis methods employed in supply chain management. However, there is a noticeable gap in the current research when it comes to utilizing these approaches to specifically address the issue of managing and mitigating supply chain nervousness. This indicates a clear need for further investigation in this area, particularly studies that delve into how MCDM techniques can be used to assess factors pertaining to the management of supply chain nervousness.

3. Materials and Methods

The research methodology for studying supply chain nervousness management (SCNM), as depicted in Figure 1, comprises the following steps: Review of prior studies and literature review analysis; gathering of necessary data and information using surveys, interviews, and meetings including seminars and workshops with the presence of experts; and having SC executives, specialists, and managers from an expert team to help select the SCNM factors according to importance and sequence of application. The expert group helps evaluate the SCNM framework basics and validate the assessments process and results; defines SCNM elements cause, evaluation, and mitigation process; analyzes current supply chain nervousness pillars, strategies, planning, measures, and continuity phases; proposes a framework to model SCN management components; evaluates and prioritize SCNM factors using a fuzzy-ELECTRE technique; apply the proposed fuzzy-MCDM technique to a numerical case study; and discuss the results and present the findings.

Figure 1.

Research methodology.

3.1. The Study Tools

The study tools of this research were surveys, interviews, and workshops. The surveys were developed based on reviewing prior studies and conducting a literature review, gathering data to define the SCNM factors. Prior to this, the respondents were initially asked about their business type, their positions within their organizations, their years of experience, and the size of the company they work for. This information helped to ensure that the data collected would be relevant and meaningful to the research objectives.

3.2. Sample and Population

The study population consisted of all working experts in the supply chain and logistics field in the UAE. The study sample consisted of (7) experts in supply chain management within the leading companies in the UAE with diverse expertise, including CEOs, supply chain managers, logistics experts, and data analysts.

3.3. Analysis and Evaluation of Nervousness Factors Using Fuzzy-ELECTRE Technique

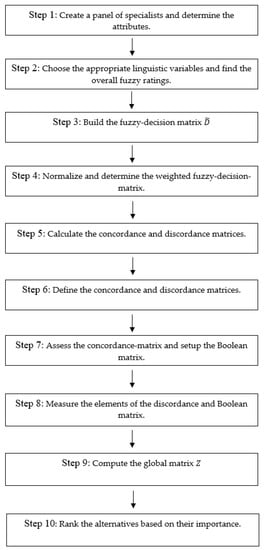

In this section, the fuzzy-ELECTRE I procedure is based on the approach proposed by [6,95,96,97,98,99,100]. The study uses a ten-step algorithm as shown in Figure 2.

Figure 2.

Fuzzy-ELECTRE hierarchy model.

Step 1: Create a panel of specialists and determine the attributes. Form a committee of experts. The fuzzy evaluation of each expert can be denoted as triangular fuzzy numbers (TFN) with relationship function . Then, define the alternatives and evaluation criteria.

Step 2: Choose the appropriate linguistic variables and find the overall fuzzy ratings. Select suitable linguistic variables to evaluate attributes and criteria. Determine the aggregate fuzzy rating defined by the experts , as , . Where

Consider the eth expert’s fuzzy rating and importance weights are , and , . Following that, the agreed-upon fuzzy rating of the alternatives for each criterion is as follows:

Then, each criterion’s aggregated fuzzy weights are determined as:

Step 3: Build the fuzzy decision matrix

where and for is attainable using positive triangular fuzzy numbers.

Step 4: Normalize and determine the weighted fuzzy decision matrix. Normalize the fuzzy decision matrix which can be obtained by

Next, calculate the weighted normalized decision matrix .

where denote the importance and weight of evaluation criteria .

Step 5: Calculate the concordance and discordance matrices. Utilize the weighted normalized fuzzy decision matrix and pairwise evaluation of the alternatives, to compute the concordance and discordance matrices. Consider these two possibilities, and the concordance set can be calculated using:

represent all the index criteria related to concordance coalition using the outranking relations .

The following Equation is used to compute the hamming distance between two fuzzy numbers .

when comparing two alternatives and for each evaluation criteria, the least upper bound is determined using . Next, the hamming distances are computed. , if .

Discordance can be calculated using:

represent all the index criteria related to discordance coalitions where is at least the same as . Similarly, when comparing two alternatives and for each criterion, the Hamming distances assume that if .

Step 6: Define the concordance and discordance matrices. Specify the concordance matrix for each pairwise comparison:

The concordance matrix’s components are calculated as the fuzzy aggregation of all the fuzzy weights assigned to the concordance sets criteria.

Then, express the discordance matrix D, where:

Step 7: Assess the concordance matrix and set up the Boolean matrix. To assess the concordance matrix members’ values, calculate the concordance level such as the average of the components in the concordance matrix is calculated using the following Equation.

After that, form the Boolean matrix B based on the minimum concordance level . Hamming distance is utilized to compare and . In the matrix alternative, g dominates alternative if .

Step 8: Measure the elements of the discordance and Boolean matrix. The measures are accomplished by stating the discordance-level as the average of constituents in the discordance matrix.

Then, measure the Boolean matrix by the least discordance level. The matrix’s elements measure the strength of the discordant coalition; therefore, if an element value exceeds a specific level, , the statement is no longer true. A discordant coalition never has any influence when , i.e., the matrix elements with values of 1 depict the dominance relationships amongst the possible solutions.

Step 9: Compute the global matrix using the peer multiplication of the components of the matrix and using the following Equation.

where the element in matrix is calculated using:

Step 10: Rank the alternatives based on their importance. Exploit outranking relation from matrix to determine the smallest collection of choices from which the best compromise option could be chosen.

4. Case Study

4.1. Supply Chain Management in UAE

The proposed framework was demonstrated using a numerical case study, which took place in the United Arab Emirates. The United Arab Emirates is more susceptible to anxiety than other countries because of its robust economy and extensive network of supply chains connecting it to the rest of the world [97], particularly given that these uncertainties may result from global ecological, political, economic, or financial shocks that are beyond the control of businesses and organizations inside the Emirates. These abrupt shifts may be brought on by natural disasters like disease outbreaks and epidemics, or by human-made events like wars and societal instability.

4.2. SCNM Framework

The SCNM framework aims to manage nervousness in the supply chain by going through six stages to identify, analyze, prioritize, treat, and monitor factors that cause nervousness. As shown in Figure 3, SCNM is a technique used by organizations to manage supply chain anxiety by identifying, evaluating, and mitigating risks. SCNM involves continuous assessment of risks to ensure the continuity of the supply chain and reduce its vulnerability.

Figure 3.

SCNM framework.

4.3. SCNM Elements

4.3.1. Identifying SCN Factors

The SCNM process starts by identifying the sources of nervousness in the supply chain. This includes both internal and external risks such as product design, staffing arrangements, external disruptions, and environmental concerns. Internal risks are the dangers that can be affected or controlled by the organization, while external risks are those that the organization has little to no control over [28].

The main factors that lead to SCN include demand variation, flows interruptions, SGE factors, unplanned events, business uncertainties, operations disruptions, and SC-ICT vulnerabilities, as described below.

- Demand variations. Client demand variability refers to the unpredictability of consumer demand, which can be driven by factors such as complexity and international differences. The main factors affecting demand variability are volatility, uncertainty, complexity, and ambiguity, and managing it can be a challenge for supply chain executives due to the cost and impact of the bullwhip effect [29].

- Flows interruptions. Supply chains are complex systems that need cooperation from all participants to function effectively. The main supply chain flows are product, negotiation, risk, information, and promotion. Disruptions to the supply chain can have serious consequences and can be caused by various events such as pandemics, conflicts, political instability, financial crises, social unrest, and natural disasters [29,31].

- SGEC factors. The supply chain can be influenced by various factors including social issues, government policies, economic conditions, and cultural attitudes. These factors can impact the growth, safety, and welfare of communities and human rights.

- Unplanned events. The supply chain can be disrupted by unexpected events such as sudden increases in demand, weaknesses in partners, economic shocks, cyberattacks, and natural disasters. The COVID-19 crisis highlights the potential impact of these events on supply and demand [6].

- Business uncertainties. Business uncertainty refers to the difficulty in predicting future outcomes due to changes in the economy, competition, and society. This can result from expanding into new markets, economic uncertainty, or competitors’ actions.

- Operations disruptions. The supply chain and its internal systems and processes are prone to operational issues that can cause disruptions in the manufacture, sale, or distribution of goods.

- SC-ICT vulnerabilities. Information and communication technologies (ICT) play a vital role in the supply chain process as they facilitate connections and improve management of time, cost, and quality. However, ICT also brings security risks, as hackers often target supply chain vendors to gain access to a corporation through a backdoor attack, causing potential harm to operations, finances, and reputation. This has caused concern among supply chain managers and partners, requiring immediate action to address these vulnerabilities.

4.3.2. Assessing SCN

The second part of the supply chain nervousness management process involves assessing the factors that cause nervousness in the supply chain. There are two main methods for assessing nervousness, quantitative and qualitative. A quantitative assessment relies on objective data, while a qualitative assessment uses knowledge and experience. The process of SCN assessment involves ten steps, including evaluating organization preparedness, quantifying probability, and impact, and updating decision systems. Organizations can manage their supply chain nervousness through four processes, including identifying and documenting nervousness, observing it, and conducting regular reviews. A supply chain nervousness assessment checklist is used to make sure the company takes specific actions to understand its nervousness and potential effects on the bottom line.

The supply chain nervousness assessment is a continuous monitoring and examination process to identify any potential weaknesses in current nervousness management procedures. It aims to enhance industry standards and raise awareness of exposures, threats, and vulnerabilities related to goods and services moving through the supply chain. Nervousness quantification gives a numerical representation of vulnerabilities and helps businesses prioritize problems. Nervousness factor scoring is a useful tool to quickly identify the most pressing issues and prioritize them based on their score.

4.3.3. Mitigate SCN

As shown in Figure 3, the third aspect of SCNM is the mitigation process, the process involves creating a strategy to manage, eliminate, or limit the hindrances causing nervousness. The four common methods of nervousness reduction are acceptance, transference, reduction, and avoidance, and organizations need to understand these methods to effectively reduce nervousness in their business [9]. The next step is to evaluate each source of nervousness based on its potential consequences. There are two main strategies for supply chain risk management: reactive and proactive. Reactive management focuses on minimizing the harm from potential threats and quickly recovering from them but assumes that interruptions will happen. Proactive management aims to predict and prevent problems before they occur, reducing both the likelihood of accidents and the time it takes to resolve them. This approach leads to stronger and more successful supply chains compared to reactive management [98].

4.4. SCNM Main Goals

The SCNM framework consists of four pillars: stability, competitiveness, resilience, and sustainability. Effective management of supply chain nervousness requires ongoing monitoring, planning, and execution. The four pillars of SCNM help minimize the effects of unexpected events and ensure smooth operations. The ultimate objective of SCNM is to be vulnerable to a range of problems that may result in higher prices, postponed deadlines, and faults in quality and delivery. To safeguard the company’s resources, it is essential to implement effective nervousness management.

4.5. Pillars of SCNM

As shown in Figure 3, there are four nervousness pillars to ensure efficient SCNM. These pillars include SCN strategy, planning, measuring, and continuity. Any SCNM system should thoroughly consider these pillars for the effective building of a model or framework to make sure SC nervousness is minimized [99,100].

4.5.1. SCN Strategy

SCNM helps organizations avoid negative consequences in the GSC by understanding and managing nervousness in the supply chain. The key to building a successful SCNM framework understands the appropriate strategies for managing nervousness. A comprehensive SCNM strategy can help the organization to operate efficiently, reduce costs, and improve customer satisfaction.

4.5.2. SCN Planning

A supply chain nervousness management plan is a strategy to minimize supply chain disruptions by identifying and managing sources of nervousness. The steps include understanding the sources, defining boundaries and responsibilities, managing trade-offs, and modeling nervousness. Organizational boundaries refer to the divisions within a company, such as departments, business units, and supply chain affiliations. The management level in charge of control is also important. The company plans to strengthen relationships with government and corporate entities through outreach and involvement, and exchange information with supply chain partners about threats and mitigation strategies. Supply chain responsibility means managing partnerships in a socially and environmentally responsible manner. Supply chain (SC) decision making can lead to improvements in key metrics if trade-offs are understood and decisions are made with model risk management in mind to control negative impacts and ensure accurate modeling.

4.5.3. SCN Measuring

To measure SCN several steps are designated for quantifying nervousness in the supply chain. The recommended steps include forming a scale, defining nervousness boundaries, quantifying SCN, outlining nervousness levels, categorizing nervousness levels, and calculating the aggregated SCN factors score. There are different methods to quantify supply chain nervousness (SCN) factors, including financial impact assessment, process mapping, and group approach. The supply chain management process has three levels—strategic, tactical, and operational—while the SCN management levels include managerial, commercial process, and system levels.

4.5.4. SCN Continuity

The SCM continuity strategy is a comprehensive plan for managing disasters and ensuring the uninterrupted flow of information, goods, and services. It includes six phases: regular review, risk assessment, impact analysis, plan development, maintenance and testing, and communication. This plan is essential for protecting the organization’s operations and preserving the interests of all parties involved. The plan should be reviewed annually by an outside specialist and updated to reflect changes in the environment. Communication with internal and external parties is crucial to keep everyone informed about events and updates.

5. Results and Discussion

The article discusses the importance of revisiting global supply chain strategy in the current high competition and crisis such as COVID-19. It highlights the need to determine nervousness elements in the supply chain and establish a framework for decision making. The research approach includes a review of past studies, SCNM strategies, and the impact of nervousness on the supply chain. The proposed framework connects the main SCNM elements for analysis, improvement, and responsiveness, allowing decision makers to support future flexibility and competitiveness. The article also presents methods and techniques for dealing with SCNM factors and offers recommendations for an innovative solution for the global supply chain.

To our knowledge, the limited previous research has considered SC nervousness management and determined the SCNM process in terms of identifying, assessing, and effective handling. Particularly with the interruptions created by crises such as the COVID-19 pandemic, which has a unique and exceptional impact that has resulted in a great deal of SC instability and an increase in the expenses of maintaining the supply chain and its relationships. An investigation of the objectives of SCNM and potential solutions is offered in this research. A questionnaire was developed to explore and evaluate the nervousness of the UAE-SCNM factors, and F-ELECTRE was used to analyze the SCNM factors and prioritize the factors that are most important in supply chain nervousness management.

A questionnaire was sent out to businesses and organizations to gather information on the factors affecting supply chain nervousness as a first step in the research. A team of experts was then formed to evaluate the supply chain concerns and determine the weight of the evaluation criteria. The experts evaluated the alternatives based on the criteria and identified the most significant variables and alternatives related to nervousness.

This research paper evaluates and arranges factors related to supply chain nervousness and its impact on the supply chain network. It identifies factors from the literature and uses a questionnaire to gather data from companies and organizations. A group of experts in supply chain and logistics was formed to conduct assessments and determine the most important factors and alternatives related to nervousness, as well as evaluate alternatives according to the chosen criteria.

To complete the assessment, the experts identified five factors and five evaluation criteria from among the previously discussed factors. Factors include demand variation (DV), flow interruptions (FI), SGE factors (SF), unplanned events (UE), and business uncertainties (BU). The evaluation criteria compromise is supply chain resilience (Re), total SC cost (Co), customer satisfaction (Sc), SC visibility (Vi), and the SC integration and partners collaboration (Ic). The proposed fuzzy-ELECTRE method and steps described previously in Section 2.2 are used to prioritize the influence of factors on supply chain nervousness.

First, the specialist group includes seven experts (E1–E7). The experts define the five factors (A1–A5) and the five evaluation criteria (C1–C5) as discussed in the previous paragraph. Then, the linguistic expressions for the importance weights of the evaluation criteria and the performance rating for the alternative factors are determined. Table 3 shows the linguistics variables and their corresponding TFN values.

Table 3.

The linguistic variables for the weights of the criteria and performance rating.

The decision makers assess the importance weights for each evaluation criterion using linguistic terms. Subsequently, the TFN weights of each criterion are aggregated using Equations (3) and (4). Table 4 shows the criteria linguistic important weights and their equivalent aggregated fuzzy weights.

Table 4.

The important weights and aggregated fuzzy weights of criteria.

Equations (3) and (4) are used to combine the fuzzy ratings of options for each criterion. Table 5 provides an example of the linguistics assessment values of the seven experts for alternative DV with respect to criterion Co and Sc and their aggregated fuzzy values. Table 6 displays the combined fuzzy ratings of the alternatives for each criterion with the fuzzy decision matrix.

Table 5.

Sample calculations of the aggregated linguistics values.

Table 6.

Fuzzy decision matrix.

Using Equations (8) and (9), Table 7 shows the normalized fuzzy decision matrix. Table 8 presents the weighted normalized fuzzy decision matrix using Equation (11).

Table 7.

Normalized fuzzy decision matrix.

Table 8.

Weighted normalized fuzzy decision matrix.

The distance between two alternatives and is calculated using the Hamming distance Equation (13). Table 9 presents the concordance matrix using Equation (16). The last row in the table indicates the minimum concordance level. The concordance level is calculated using Equation (19).

Table 9.

Concordance matrix.

The discordance matrix is calculated by using Equation (18), as shown in Table 10. The last row in the table indicates the minimum discordance level. The discordance level is calculated using Equation (22).

Table 10.

Discordance matrix.

Based on the concordance matrix and by using Equation (21), the Boolean matrix is calculated based on the minimum concordance level . Table 11 shows the Boolean concordance matrix.

Table 11.

The concordance index matrix.

Based on the discordance matrix and by using Equation (24), the Boolean matrix is calculated based on the minimum discordance level . Table 12 shows the Boolean discordance matrix.

Table 12.

The discordance index matrix.

Equations (25) and (26) are used to calculate the global matrix by compeer multiplication of the matrices and ’s entries are shown in Table 13.

Table 13.

Global matrix.

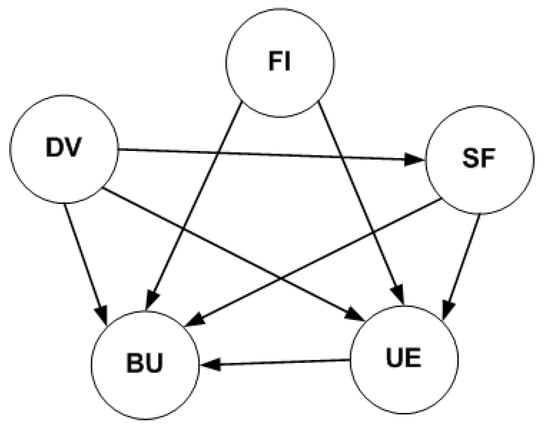

From the global matrix and according to Figure 4, it is clear that: (DV > SF, DV > UE, DV > BU), (FI > UE, FI > BU), (SF > UE, SF > BU), and (UE > BU) which indicate that the ranks based on their importance are DV > FI > SF > UE > BU. FI and SF have the same importance and could be interchangeable.

Figure 4.

The resulting diagram of the ranking.

This rank is compatible with the survey and experts rank results of the alternatives based on their important DV > FI > UE > SF > BU. The only difference is that the experts rank alternative UE before alternative SF. Demand variations (DV) are designated as the factor that has the most effect on the supply chain nervousness. Demand fluctuation can cause disruptions in the supply chain, so it is important to plan for supply chain resilience to reduce the impact of these disruptions. Supply chain resilience involves resistance and recovery capabilities to mitigate these disruptions.

6. Conclusions, Implications, Limitations, and Future Work

6.1. Summary of Findings

The purpose of this research was to create a holistic framework that allows companies to attain a long-lasting competitive advantage in their supply chain operations by proficiently managing and mitigating nervousness. In order to fulfill this aim, the investigation examined the concept of supply chain nervousness within the United Arab Emirates and put forward a comprehensive framework that considered the essential sources, objectives, and pillars involved in effectively managing supply chain nervousness. The research employed the fuzzy-ELECTRE technique to assess and prioritize the importance and influence of different factors associated with supply chain nervousness. The evaluation findings indicated that supply chain nervousness is primarily influenced by demand variations. Additionally, interruptions in flows, supplier-generated events, unplanned events, and business-related events were identified as other significant factors affecting the supply chain. The experts and survey respondents agreed with this ranking, with the only difference being that the experts rated un-planned events higher than the alternative SGE factors. Organizations can enhance their ability to manage supply chain nervousness by identifying and giving priority to these critical factors. This recognition allows them to allocate resources effectively and develop strategies aimed at minimizing the impact of uncertainty in the supply chain. Moreover, businesses can channel their efforts toward managing risks more efficiently by adopting appropriate measures based on this framework. This study emphasizes the significance of efficiently mitigating uncertainties in demand to improve competitiveness.

6.2. Interpretation and Implications

The results offer a significant understanding of the factors that give rise to supply chain nervousness. The most influential factor found was fluctuations in demand, which have the capacity to cause severe disruptions throughout the entire supply chain system. This indicates that it is critical for organizations to engage in robust resilience planning within their supply chains so as to effectively respond and adapt to unexpected shifts or increases in demand. By doing so, they will be better equipped with higher levels of resistance, recovery, and mitigation capabilities necessary for reducing the negative impacts caused by disturbances. In addition, the research highlights the crucial responsibility of decision makers to effectively implement strategies that not only improve overall performance but also foster resilience and sustainability within the supply chain. Developing such a holistic approach not only enhances the effectiveness of the supply chain but also holds substantial importance in establishing a sustainable competitive advantage in the industry.

6.3. Limitations

While the study offers valuable insights into strategies for supply chain resilience, it is crucial to acknowledge certain limitations. One such limitation pertains to the study’s small sample size of participating experts and its focus exclusively on a select number of companies in the United Arab Emirates. Consequently, this limited sample size may impede the generalizability of findings and restrict their application to a broader population. Another potential limitation pertains specifically to the geographic scope of this investigation as it solely focuses on UAE-based organizations. Hence, these conclusions may not comprehensively capture or represent a diverse range of supply chain practices and contexts prevalent across various countries worldwide.

6.4. Recommendations for Future Research

Future studies could expand the scope of this research to include international companies along the supply chain. The study can also be applied to specific areas of the supply chain such as supply chains related to industries, food, pharmaceuticals, clothing, and others. This would help to validate and refine the framework and could potentially reveal additional factors that contribute to supply chain nervousness. Furthermore, different assessment methods such as F-PROMETHEE, F-ANP, F-VIKOR, F-TOSIS, or a combination of any of two or more MCDM techniques can also be used to provide a more comprehensive evaluation of SCNM factors.

6.5. Management Insight

In light of globalization, automation, the fourth industrial revolution, virtual reality and augmented reality, and digital transformation, a framework is offered to explain the SCNM and examine its impact on the global supply chain’s competitiveness. The proposed supply chain nervousness management (SCNM) framework identifies the primary sources of supply chain nervousness, sets objectives for resilience and sustainability, and establishes strategies for planning, measurement, and continuity. It also provides insights into mitigating risks associated with uncertainties in operations, improving customer satisfaction, and reducing costs related to inventory management. These insights highlight the need for managers to adopt the SCNM framework to effectively manage supply chain nervousness. The research introduces a method for ranking SCNM components based on their significance and impact, using the fuzzy-ELECTRE approach. This approach is particularly useful for managers as it helps in evaluating causal relationships and prioritizing elements, which is crucial for achieving a sustainable competitive advantage. The framework is also designed to respond to rapid transformations in business, economics, technology, and science, as well as intense competition. This is making it a valuable tool for managers and decision makers to effectively navigate the complexities of supply chain operations.

Author Contributions

Conceptualization, M.Z.M. and G.M.M.; data curation, M.Z.M. and G.M.M.; formal analysis, M.Z.M. and G.M.M.; investigation, M.Z.M. and G.M.M.; methodology, G.M.M.; project administration, M.Z.M.; resources, M.Z.M. and G.M.M.; software, M.Z.M.; supervision, M.Z.M.; validation, M.Z.M. and G.M.M.; visualization, M.Z.M. and G.M.M.; writing—original draft, M.Z.M.; writing—review and editing, M.Z.M. and G.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the research unit at Liwa College, UAE.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ayan, B.; Güner, E.; Son-Turan, S. Blockchain Technology and Sustainability in Supply Chains and a Closer Look at Different Industries: A Mixed Method Approach. Logistics 2022, 6, 85. [Google Scholar] [CrossRef]

- Mensah, P.; Merkuryev, Y. Developing a resilient supply chain. Procedia Soc. Behav. Sci. 2014, 110, 309–319. [Google Scholar] [CrossRef]

- Antonio, F.; Atayde, J.; Yamzon, M.; Sy, C. An optimization model for the design of supply chains considering disruptions from pandemic uncertainty and infection trends. Clean. Eng. Technol. 2022, 11, 100577. [Google Scholar] [CrossRef]

- Magableh, G.M.; Mistarihi, M. Supply Chain Nervousness Strategies. Available online: https://ssrn.com/abstract=4415220 (accessed on 7 June 2023).

- Ali, S.M.; Rahman, M.H.; Tumpa, T.J.; Rifat, A.A.M.; Paul, S.K. Examining price and service competition among retailers in a supply chain under potential demand disruption. J. Retail. Consum. Serv. 2018, 40, 40–47. [Google Scholar] [CrossRef]

- Raj, A.; Mukherjee, A.A.; de Sousa Jabbour, A.B.L.; Srivastava, S.K. Supply chain management during and post-COVID-19 pandemic: Mitigation strategies and practical lessons learned. J. Bus. Res. 2022, 142, 1125–1139. [Google Scholar] [CrossRef]

- Dohale, V.; Ambilkar, P.; Gunasekaran, A.; Verma, P. Supply chain risk mitigation strategies during COVID-19: Exploratory cases of “make-to-order” handloom saree apparel industries. Int. J. Phys. Distrib. Logist. Manag. 2022, 52, 109–129. [Google Scholar] [CrossRef]

- Hernandez, M.C.; Alvarez, A.N.R.; Anguiano, F.I.S. Project management and supply chain 4.0 improvement: The case of infant formulas in the face of the challenge of COVID-19. Procedia Comput. Sci. 2023, 217, 278–285. [Google Scholar] [CrossRef] [PubMed]

- Kaipia, R.; Korhonen, H.; Hartiala, H. Planning nervousness in a demand supply network: An empirical study. Int. J. Logist. Manag. 2006, 17, 95–113. [Google Scholar] [CrossRef]

- Atadeniz, S.N.; Sridharan, S.V. Effectiveness of nervousness reduction policies when capacity is constrained. Int. J. Prod. Res. 2020, 58, 4121–4137. [Google Scholar] [CrossRef]

- Pooya, A.; Fakhlaei, N.; Alizadeh-Zoeram, A. Designing a dynamic model to evaluate lot-sizing policies in different scenarios of demand and lead times in order to reduce the nervousness of the MRP system. J. Ind. Prod. Eng. 2021, 38, 122–136. [Google Scholar] [CrossRef]

- Magableh, G.M.; Mistarihi, M.Z. Causes and effects of supply chain nervousness: Mena case study. Acta Logist. 2022, 9, 223–235. [Google Scholar] [CrossRef]

- Gobind, J. Transport anxiety and work performance. SA J. Hum. Resour. Manag. 2018, 16, 1–7. [Google Scholar] [CrossRef]

- Liu, B.; Ju, T.; Chan, H.K. The diverse impact of heterogeneous customer characteristics on supply chain finance: Empirical evidence from Chinese factoring. Int. J. Prod. Econ. 2022, 243, 108321. [Google Scholar] [CrossRef]

- Wieland, A.; Durach, C.F. Two perspectives on supply chain resilience. J. Bus. Logist. 2021, 42, 315–322. [Google Scholar] [CrossRef]

- Park, A.; Li, H. The effect of blockchain technology on supply chain sustainability performances. Sustainability 2021, 13, 1726. [Google Scholar] [CrossRef]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining supply chain management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Lu, X.; Swaminathan, J.M. Supply chain management. In International Encyclopedia of the Social Behavioral Sciences, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 709–713. [Google Scholar]

- Cousins, P.D.; Lawson, B.; Petersen, K.J.; Fugate, B. Investigating green supply chain management practices and performance: The moderating roles of supply chain ecocentricity and traceability. Int. J. Oper. Prod. Manag. 2019, 39, 767–786. [Google Scholar] [CrossRef]

- Ho, W.; Zheng, T.; Yildiz, H.; Talluri, S. Supply chain risk management: A literature review. Int. J. Prod. Res. 2015, 53, 5031–5069. [Google Scholar] [CrossRef]

- Pai, R.R. Supply Chain Risk Mitigation. International Series in Operations Research & Management Science. 2022. Available online: https://www.semanticscholar.org/paper/Supply-Chain-Risk-Mitigation-Pai/dcd303a905c6a0ddad477db4ac9a91d9debfcf9b (accessed on 5 May 2022).

- Handfield, R.; Sun, H.; Rothenberg, L. Assessing supply chain risk for apparel production in low cost countries using newsfeed analysis. Supply Chain Manag. Int. J. 2020, 25, 803–821. [Google Scholar] [CrossRef]

- Helmold, M.; Yılmaz, A.K.; Dathe, T.; Flouris, T.G. Supply Chain Risk Management. Manag. Prof. 2022, 20, 113879. [Google Scholar]

- Thomas, C.; Chermack, T. Using Scenario Planning to Supplement Supply Chain Risk Assessments. In Revisiting Supply Chain Risk; Springer: Cham, Switzerland, 2019; pp. 37–51. [Google Scholar]

- Shang, Z.; Yang, X.; Barnes, D.; Wu, C. Supplier selection in sustainable supply chains: Using the integrated BWM, fuzzy Shannon entropy, and fuzzy MULTIMOORA methods. Expert Syst. Appl. 2022, 195, 116567. [Google Scholar] [CrossRef]

- Mamun, M. Supply Chain Risk Management in a Digital Era: Evidence from SMEs of Clothing Retailers in Australia. J. Risk Financ. Manag. 2023, 16, 242. [Google Scholar] [CrossRef]

- Moosavi, J.; Fathollahi-Fard, A.M.; Dulebenets, M.A. Supply chain disruption during the COVID-19 pandemic: Recognizing potential disruption management strategies. Int. J. Disaster Risk Reduct. 2022, 75, 102983. [Google Scholar] [CrossRef] [PubMed]

- Kamalahmadi, M.; Parast, M.M. An assessment of supply chain disruption mitigation strategies. Int. J. Prod. Econ. 2017, 184, 210–230. [Google Scholar] [CrossRef]

- Azadegan, A.; Modi, S.; Lucianetti, L. Surprising supply chain disruptions: Mitigation effects of operational slack and supply redundancy. Int. J. Prod. Econ. 2021, 240, 108218. [Google Scholar] [CrossRef]

- McMaster, M.; Nettleton, C.; Tom, C.; Xu, B.; Cao, C.; Qiao, P. Risk management: Rethinking fashion supply chain management for multinational corporations in light of the COVID-19 outbreak. J. Risk Financ. Manag. 2020, 13, 173. [Google Scholar] [CrossRef]

- El Baz, J.; Ruel, S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int. J. Prod. Econ. 2021, 233, 107972. [Google Scholar] [CrossRef]

- Gurtu, A.; Johny, J. Supply chain risk management: Literature review. Risks 2021, 9, 16. [Google Scholar] [CrossRef]

- Khan, M.D.; Schaefer, D.; Milisavljevic-Syed, J. Supply Chain Management 4.0: Looking Backward, Looking Forward. Procedia CIRP 2022, 107, 9–14. [Google Scholar] [CrossRef]

- Lambert, D.M.; Cooper, M.C.; Pagh, J.D. Supply chain management: Implementation issues and research opportunities. Int. J. Logist. Manag. 1998, 9, 1–20. [Google Scholar] [CrossRef]

- Yang, J.; Xie, H.; Yu, G.; Liu, M. Antecedents and consequences of supply chain risk management capabilities: An investigation in the post-coronavirus crisis. Int. J. Prod. Res. 2021, 59, 1573–1585. [Google Scholar] [CrossRef]

- Kurdi, B.; Alzoubi, H.; Alshurideh, M.; Alquqa, E.; Hamadneh, S. Impact of supply chain 4.0 and supply chain risk on organizational performance: Empirical evidence from the UAE food manufacturing industry. Uncertain Supply Chain Manag. 2023, 11, 111–118. [Google Scholar] [CrossRef]

- Alshurideh, M.; Alquqa, E.; Alzoubi, H.; Kurdi, B.; Hamadneh, S. The effect of information security on e-supply chain in the UAE logistics and distribution industry. Uncertain Supply Chain Manag. 2023, 11, 145–152. [Google Scholar] [CrossRef]

- Al-Ayed, S.; Al-Tit, A. The effect of supply chain risk management on supply chain resilience: The intervening part of Internet-of-Things. Uncertain Supply Chain Manag. 2023, 11, 179–186. [Google Scholar] [CrossRef]

- Sari, K. A novel multi-criteria decision framework for evaluating green supply chain management practices. Comput. Ind. Eng. 2017, 105, 338–347. [Google Scholar] [CrossRef]

- Guan, Z.; Mou, Y.; Sun, M. Hybrid robust and stochastic optimization for a capital-constrained fresh product supply chain integrating risk-aversion behavior and financial strategies. Comput. Ind. Eng. 2022, 169, 108224. [Google Scholar] [CrossRef]

- Badhotiya, G.K.; Soni, G.; Jain, V.; Joshi, R.; Mittal, S. Assessing supply chain resilience to the outbreak of COVID-19 in Indian manufacturing firms. Oper. Manag. Res. 2022, 15, 1161–1180. [Google Scholar] [CrossRef]

- Tang, C.; Tomlin, B. The power of flexibility for mitigating supply chain risks. Int. J. Prod. Econ. 2008, 116, 12–27. [Google Scholar] [CrossRef]

- Shen, B.; Li, Q. Market disruptions in supply chains: A review of operational models. Int. Trans. Oper. Res. 2017, 24, 697–711. [Google Scholar] [CrossRef]

- Zavala-Alcívar, A.; Verdecho, M.J.; Alfaro-Saiz, J.J. A conceptual framework to manage resilience and increase sustainability in the supply chain. Sustainability 2020, 12, 6300. [Google Scholar] [CrossRef]

- Haraguchi, M.; Neise, T.; She, W.; Taniguchi, M. Conversion strategy builds supply chain resilience during the COVID-19 pandemic: A typology and research directions. Prog. Disaster Sci. 2023, 17, 100276. [Google Scholar] [CrossRef]

- Rinaldi, M.; Bottani, E. How did COVID-19 affect logistics and supply chain processes? Immediate, short and medium-term evidence from some industrial fields of Italy. Int. J. Prod. Econ. 2023, 262, 108915. [Google Scholar] [CrossRef]

- Gurbuz, M.C.; Yurt, O.; Ozdemir, S.; Sena, V.; Yu, W. Global supply chains risks and COVID-19: Supply chain structure as a mitigating strategy for Small and Medium-Sized Enterprises. J. Bus. Res. 2023, 155, 113407. [Google Scholar] [CrossRef]

- Das, D. The impact of Sustainable Supply Chain Management practices on firm performance: Lessons from Indian organizations. J. Clean. Prod. 2018, 203, 179–196. [Google Scholar] [CrossRef]

- Zhou, H.; Li, L. The impact of supply chain practices and quality management on firm performance: Evidence from China’s small and medium manufacturing enterprises. Int. J. Prod. Econ. 2020, 230, 107816. [Google Scholar] [CrossRef]

- Patare, S.; Venkataraman, S.V. Strategies in supply chain competition: A game theoretic approach. Comput. Ind. Eng. 2023, 180, 109242. [Google Scholar] [CrossRef]

- Majumdar, A.; Sinha, S.K.; Govindan, K. Prioritising risk mitigation strategies for environmentally sustainable clothing supply chains: Insights from selected organisational theories. Sustain. Prod. Consum. 2021, 28, 543–555. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, S.L.P.; Shi, W.W.; Kanrak, M. Cruise supply chain risk mitigation strategies: An empirical study in Shanghai, China. Mar. Policy 2023, 153, 105600. [Google Scholar] [CrossRef]

- Suryadi, A.; Rau, H. Considering Region Risks and Mitigation Strategies in the Supplier Selection Process for Improving Supply Chain Resilience. Comput. Ind. Eng. 2023, 181, 109288. [Google Scholar] [CrossRef]

- Alghababsheh, M.; Butt, A.S.; Ali, S.M. The role of buyers’ justice in achieving socially sustainable global supply chains: A perspective of apparel suppliers and their workers. J. Purch. Supply Manag. 2023, 29, 100820. [Google Scholar] [CrossRef]

- Min, S.; Zacharia, Z.G.; Smith, C.D. Defining supply chain management: In the past, present, and future. J. Bus. Logist. 2019, 40, 44–55. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, X.; Feng, L.; Yang, W. Disruption risks in supply chain management: A literature review based on bibliometric analysis. Int. J. Prod. Res. 2020, 58, 3508–3526. [Google Scholar] [CrossRef]

- Ummi, N.; Ferdinant, P.F.; Irman, A.; Gunawan, A. Integration house of risk and analytical network process for supply chain risk mitigation of cassava opak chips industry. In MATEC Web of Conferences; EDP Sciences: Castanet-Tolosan, France, 2018; Volume 218, p. 04022. [Google Scholar]

- Sufiyan, M.; Haleem, A.; Khan, S.; Khan, M.I. Evaluating food supply chain performance using hybrid fuzzy MCDM technique. Sustain. Prod. Consum. 2019, 20, 40–57. [Google Scholar] [CrossRef]

- Lohmer, J.; Bugert, N.; Lasch, R. Analysis of resilience strategies and ripple effect in blockchain-coordinated supply chains: An agent-based simulation study. Int. J. Prod. Econ. 2020, 228, 107882. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, K. Improving Agricultural Green Supply Chain Management by a Novel Integrated Fuzzy-Delphi and Grey-WINGS Model. Agriculture 2022, 12, 1512. [Google Scholar] [CrossRef]

- Bernard, R. Classement et choix en présence de points de vue multiples (la méthode ELECTRE). Rev. D’Inform. Rech. Oper. RIRO 1968, 2, 57–75. [Google Scholar]

- Uddin, S.; Ali, S.M.; Kabir, G.; Suhi, S.A.; Enayet, R.; Haque, T. An AHP-ELECTRE framework to evaluate barriers to green supply chain management in the leather industry. Int. J. Sustain. Dev. World Ecol. 2019, 26, 732–751. [Google Scholar] [CrossRef]

- Kumar, N.; Tyagi, M.; Sachdeva, A. Estimation of best possible solutions for environmental trade-offs in cold supply chain using BWM based ELECTRE-I approach. Int. J. Six Sigma Compet. Advant. 2022, 14, 152–169. [Google Scholar] [CrossRef]

- Kabadayı, N. Dealership performance evaluation in supply chain with dematel and electre methods. Kabadayı, N.; Dağ, S.Dealership Performance Evaluation in Supply Chain with DEMATEL and ELECTRE Methods. Pamukkale Univ. J. Eng. Sci. 2020, 26, 241–253. [Google Scholar] [CrossRef]

- Farughi, H.; Mostafayi, S. A hybrid approach based on ANP, ELECTRE and SIMANP metaheuristic method for outsourcing manufacturing procedures according to supply chain risks-Case study: A medical equipment manufacturer company in Iran. Decis. Sci. Lett. 2017, 6, 77–94. [Google Scholar] [CrossRef]

- Zandi, F.; Tavana, M.; Martin, D. A fuzzy group Electre method for electronic supply chain management framework selection. Int. J. Logist. Res. Appl. 2011, 14, 35–60. [Google Scholar] [CrossRef]

- Bizhan, N.; Asia, M.H. Ranking the Factors Affecting the Green Supply Chain with Economics-Based Approach Using ELECTRE (Case Study: Waste Management In Shiraz). Int. J. Resist. Econ. 2016, 4, 28–43. [Google Scholar]

- Edalat Sarvestani, M.R.; Shahraki, M.R. Comparing affective factors Ranks in the supply chain Management by using Fuzzy ELECTRE (I) method and ackknife resampling method with an Interval Analysis. Emerg. Manag. 2016, 4, 107–117. [Google Scholar]

- Shojaie, A.A.; Babaie, S.; Sayah, E.; Mohammaditabar, D. Analysis and prioritization of green health suppliers using Fuzzy ELECTRE method with a case study. Glob. J. Flex. Syst. Manag. 2018, 19, 39–52. [Google Scholar] [CrossRef]

- Qu, G.; Zhang, Z.; Qu, W.; Xu, Z. Green supplier selection based on green practices evaluated using fuzzy approaches of TOPSIS and ELECTRE with a case study in a Chinese Internet company. Int. J. Environ. Res. Public Health 2020, 17, 3268. [Google Scholar] [CrossRef]

- Korucuk, S.; Tirkolaee, E.B.; Aytekin, A.; Karabasevic, D.; Karamaşa, Ç. Agile supply chain management based on critical success factors and most ideal risk reduction strategy in the era of industry 4.0: Application to plastic industry. Oper. Manag. Res. 2023, 1–22. [Google Scholar] [CrossRef]

- Stević, Ž.; Ulutaş, A.; Korucuk, S.; Memiş, S.; Demir, E.; Topal, A.; Karamaşa, Ç. Supply Chain Management (SCM) Breakdowns and SCM Strategy Selection during the COVID-19 Pandemic Using the Novel Rough MCDM Model. Complexity 2023, 2023, 3478719. [Google Scholar] [CrossRef]

- Tsai, J.F.; Shen, S.P.; Lin, M.H. Applying a Hybrid MCDM Model to Evaluate Green Supply Chain Management Practices. Sustainability 2023, 15, 2148. [Google Scholar] [CrossRef]

- Wei, Y. A Machine Learning Algorithm for Supplier Credit Risk Assessment Based on Supply Chain Management. Int. Trans. Electr. Energy Syst. 2022, 2022, 4766597. [Google Scholar] [CrossRef]

- Shyur, H.J.; Shih, H.S. A hybrid MCDM model for strategic vendor selection. Math. Comput. Model. 2006, 44, 749–761. [Google Scholar] [CrossRef]

- Tliche, Y.; Taghipour, A.; Mahfod-Leroux, J.; Vosooghidizaji, M. Collaborative Bullwhip Effect-Oriented Bi-Objective Optimization for Inference-Based Weighted Moving Average Forecasting in Decentralized Supply Chain. Int. J. Inf. Syst. Supply Chain. Manag. 2023, 16, 1–37. [Google Scholar] [CrossRef]

- Kao, J.C.; Wang, C.N.; Nguyen, V.T.; Husain, S.T. A Fuzzy MCDM Model of Supplier Selection in Supply Chain Management. Intell. Autom. Soft Comput. 2022, 31, 1451–1466. [Google Scholar] [CrossRef]

- Bairagi, B. A novel MCDM model for warehouse location selection in supply chain management. Decis. Mak. Appl. Manag. Eng. 2022, 5, 194–207. [Google Scholar] [CrossRef]

- Roy, S.; Paul, A.; Paul, A.; Kashyap, S.; Jana, A. Ranking barriers of supply chain management by MCDM method during disaster management: A case study of India. Int. J. Syst. Dyn. Appl. IJSDA 2021, 10, 1–16. [Google Scholar] [CrossRef]

- Riaz, M.; Akmal, K.; Almalki, Y.; Ahmad, D. Cubic intuitionistic fuzzy topology with application to uncertain supply chain management. Math. Probl. Eng. 2022, 2022, 9631579. [Google Scholar] [CrossRef]

- Singh, N.P. Managing environmental uncertainty for improved firm financial performance: The moderating role of supply chain risk management practices on managerial decision making. Int. J. Logist. Res. Appl. 2020, 23, 270–290. [Google Scholar] [CrossRef]

- Ganguly, A.; Kumar, C. Evaluating Supply Chain Resiliency Strategies in the Indian pharmaceutical sector: A fuzzy analytic hierarchy process (F-AHP) approach. Int. J. Anal. Hierarchy Process 2019, 11, 153–180. [Google Scholar] [CrossRef]

- Chand, M.; Bhatia, N.; Singh, R.K. ANP-MOORA-based approach for the analysis of selected issues of green supply chain management. Benchmarking Int. J. 2018, 25, 642–659. [Google Scholar] [CrossRef]

- Luqman, N.A.; Ahmad, S.Z.; Hussain, M. Effects of the degree of supply chain resilience capability in supply chain performance in the UAE energy industry. Supply Chain. Manag. Int. J. 2023; ahead-of-print. [Google Scholar]

- Misbauddin, S.M.; Alam, M.J.; Karmaker, C.L.; Nabi, M.N.U.; Hasan, M.M. Exploring the antecedents of supply chain viability in a pandemic context: An empirical study on the commercial flower supply chain of an emerging economy. Sustainability 2023, 15, 2146. [Google Scholar] [CrossRef]

- Wu, A.; Sun, Y.; Zhang, H.; Sun, L.; Wang, X.; Li, B. Research on Resilience Evaluation of Coal Industrial Chain and Supply Chain Based on Interval Type-2F-PT-TOPSIS. Processes 2023, 11, 566. [Google Scholar] [CrossRef]

- Liu, W.; He, Y.; Dong, J.; Cao, Y. Disruptive technologies for advancing supply chain resilience. Front. Eng. Manag. 2023, 10, 360–366. [Google Scholar] [CrossRef]

- Sharma, M.; Antony, R.; Tsagarakis, K. Green, resilient, agile, and sustainable fresh food supply chain enablers: Evidence from India. Ann. Oper. Res. 2023, 1–27. [Google Scholar] [CrossRef]

- Hsu, C.H.; Li, M.G.; Zhang, T.Y.; Chang, A.Y.; Shangguan, S.Z.; Liu, W.L. Deploying big data enablers to strengthen supply chain resilience to mitigate sustainable risks based on integrated HOQ-MCDM framework. Mathematics 2022, 10, 1233. [Google Scholar] [CrossRef]

- Sathyan, R.; Parthiban, P.; Dhanalakshmi, R.; Sachin, M.S. An integrated Fuzzy MCDM approach for modelling and prioritising the enablers of responsiveness in automotive supply chain using Fuzzy DEMATEL, Fuzzy AHP and Fuzzy TOPSIS. Soft Comput. 2023, 27, 257–277. [Google Scholar] [CrossRef]

- Hsu, C.H.; He, X.; Zhang, T.Y.; Chang, A.Y.; Liu, W.L.; Lin, Z.Q. Enhancing Supply Chain Agility with Industry 4.0 Enablers to Mitigate Ripple Effects Based on Integrated QFD-MCDM: An Empirical Study of New Energy Materials Manufacturers. Mathematics 2022, 10, 1635. [Google Scholar] [CrossRef]

- Khan, J.; Ishizaka, A.; Mangla, S.K. Assessing risk of supply chain disruption due to COVID-19 with fuzzy VIKORSort. Ann. Oper. Res. 2022, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Mabrouk, N. Green supplier selection using fuzzy Delphi method for developing sustainable supply chain. Decis. Sci. Lett. 2021, 10, 63–70. [Google Scholar] [CrossRef]

- Sumarliah, E.; Li, T.; Wang, B.; Indriya, I. An examination of halal fashion supply chain management risks based on the fuzzy best-worst approach. Inf. Resour. Manag. J. IRMJ 2021, 34, 69–92. [Google Scholar] [CrossRef]

- Aytac, E.; IŞIK, A.T.; Kundakci, N. Fuzzy ELECTRE I method for evaluating catering firm alternatives. Ege Acad. Rev. 2011, 11, 125–134. [Google Scholar]

- Hatami-Marbini, A.; Tavana, M. An extension of the Electre I method for group decision-making under a fuzzy environment. Omega 2011, 39, 373–386. [Google Scholar] [CrossRef]

- Shayah, M.H.; Qifeng, Y. Development of free zones in United Arab Emirates. Int. Rev. Res. Emerg. Mark. Glob. Econ. IRREM 2015, 1, 286–294. [Google Scholar]

- Kırılmaz, O.; Erol, S. A proactive approach to supply chain risk management: Shifting orders among suppliers to mitigate the supply side risks. J. Purch. Supply Manag. 2017, 23, 54–65. [Google Scholar] [CrossRef]

- Mistarihi, M.Z.; Magableh, G.M. Prioritization of Supply Chain Capabilities Using the FAHP Technique. Sustainability 2023, 15, 6308. [Google Scholar] [CrossRef]

- Mistarihi, M.Z.; Magableh, G.M. Supply Chain Nervousness Optimization Using the FuzzyELECTRE Technique. In Proceedings of the International Conference on Mechanical, Industrial and Production Engineering (ICMIPE-23), Suez, Egypt, 24–25 May 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).