Mechanism of Nozzle Position Affecting Coalbed Methane Mining in High-Pressure Air Blasting

Abstract

1. Introduction

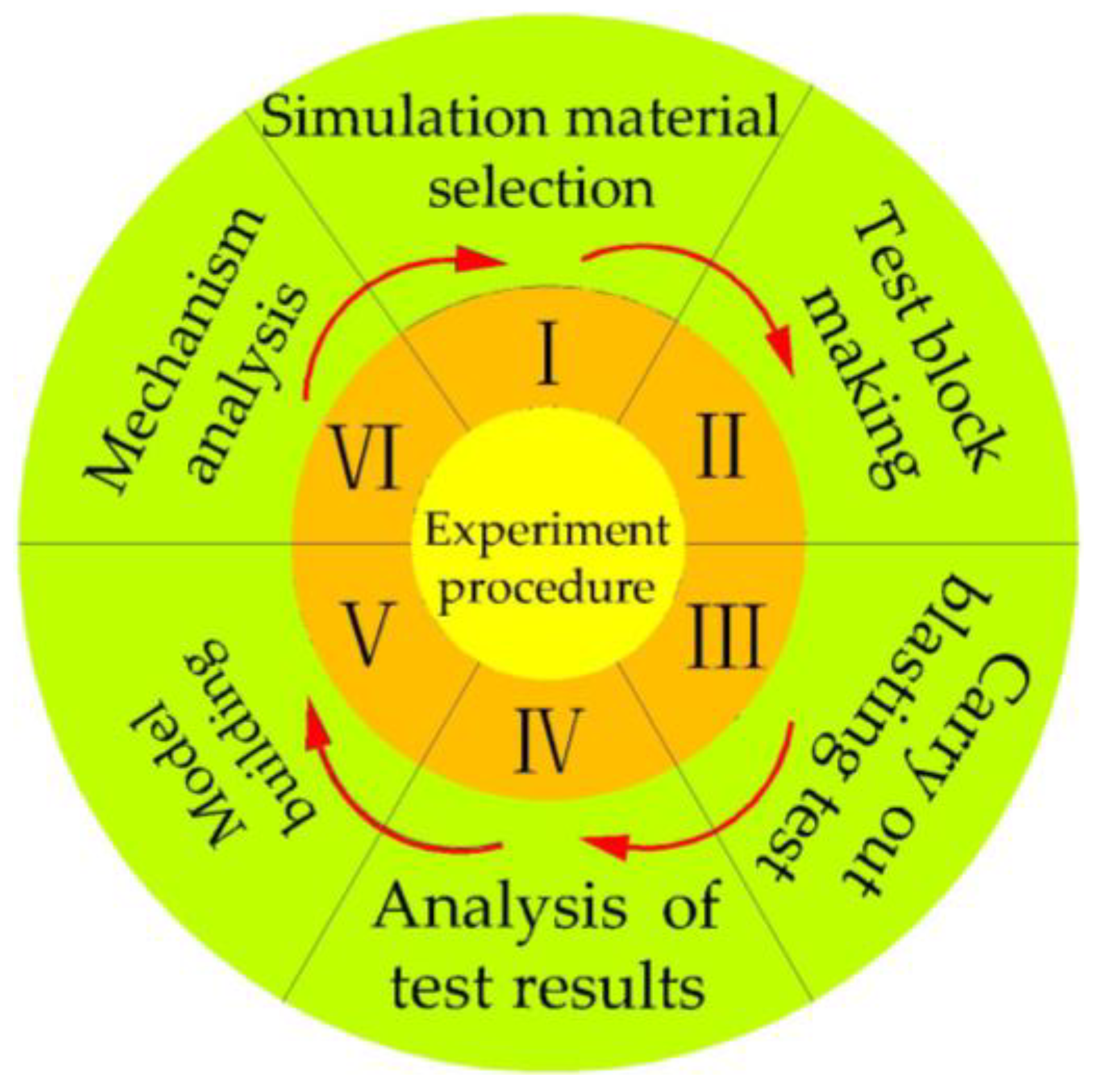

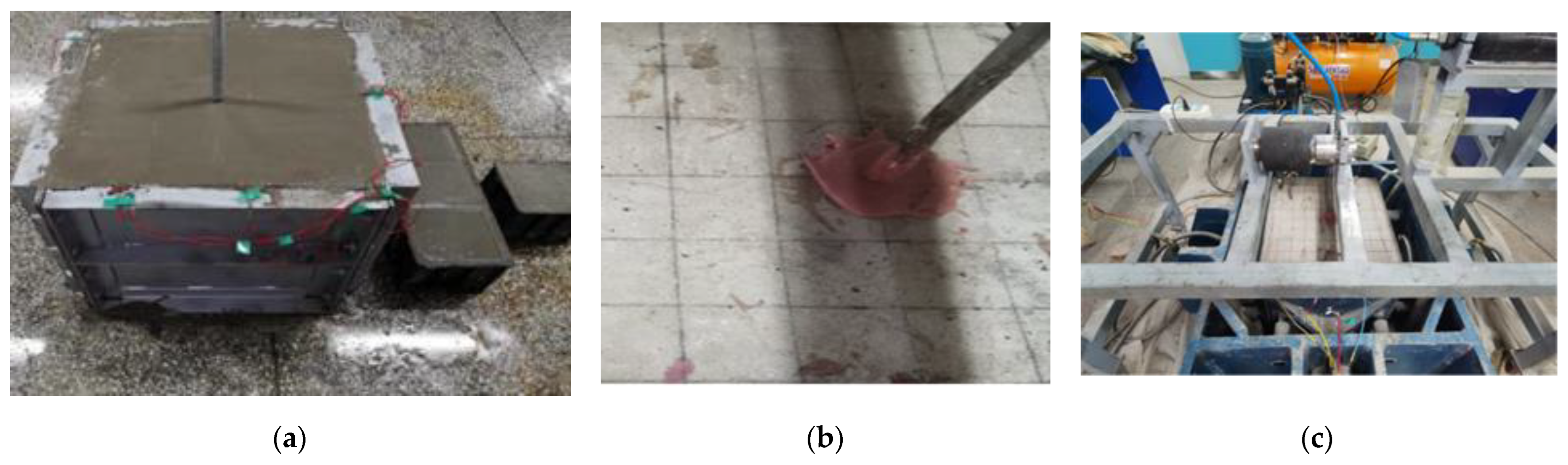

2. Materials and Methods

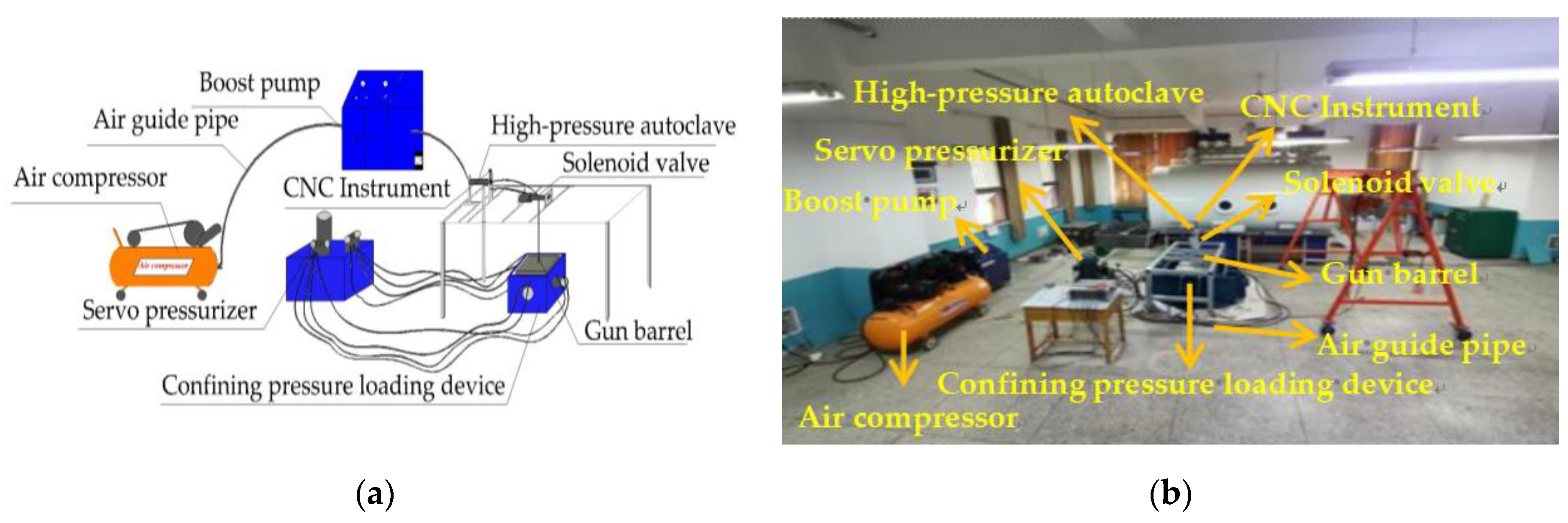

2.1. A Brief Introduction to the Test Equipment

2.2. Experimental Protocol

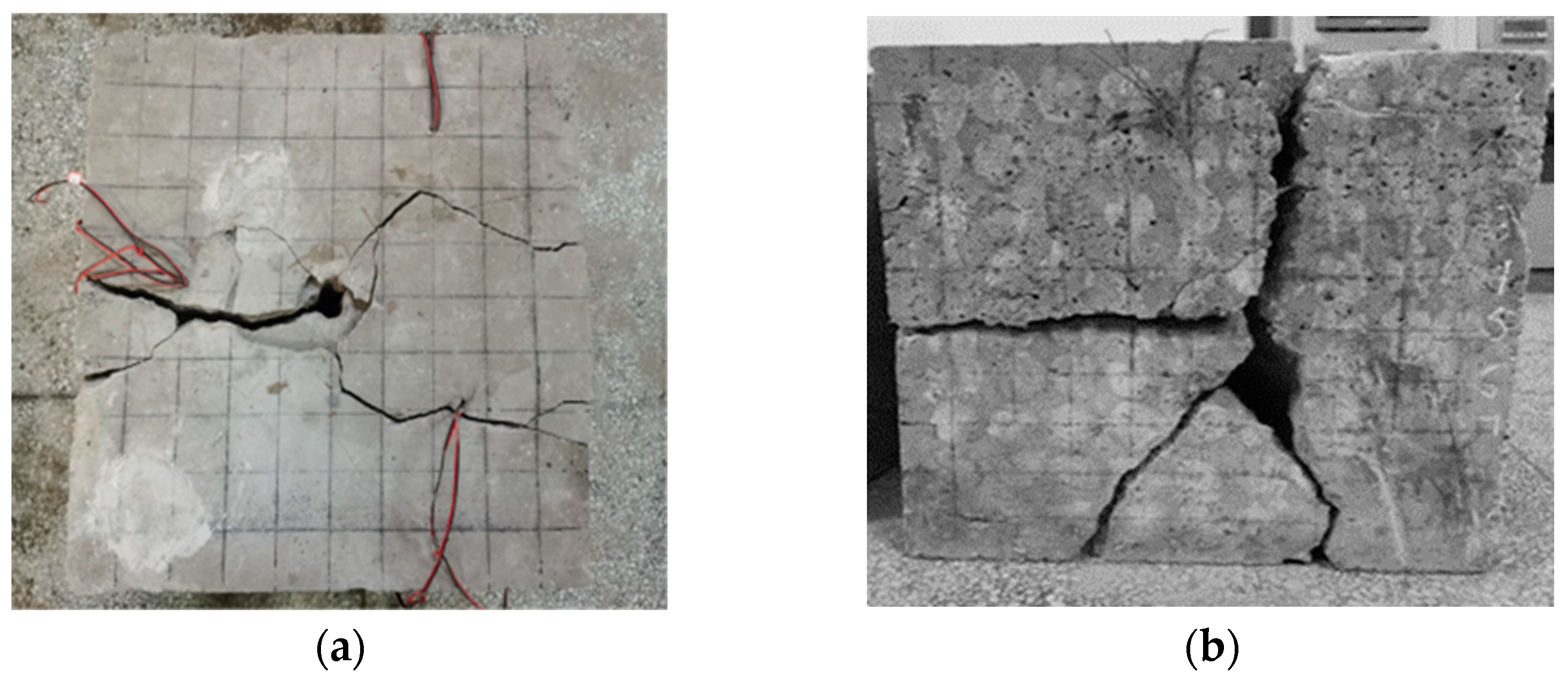

3. Results and Discussion

4. Damage Fracture Process and Mechanism of Blasting Coal Caused by Different Positions of Nozzles

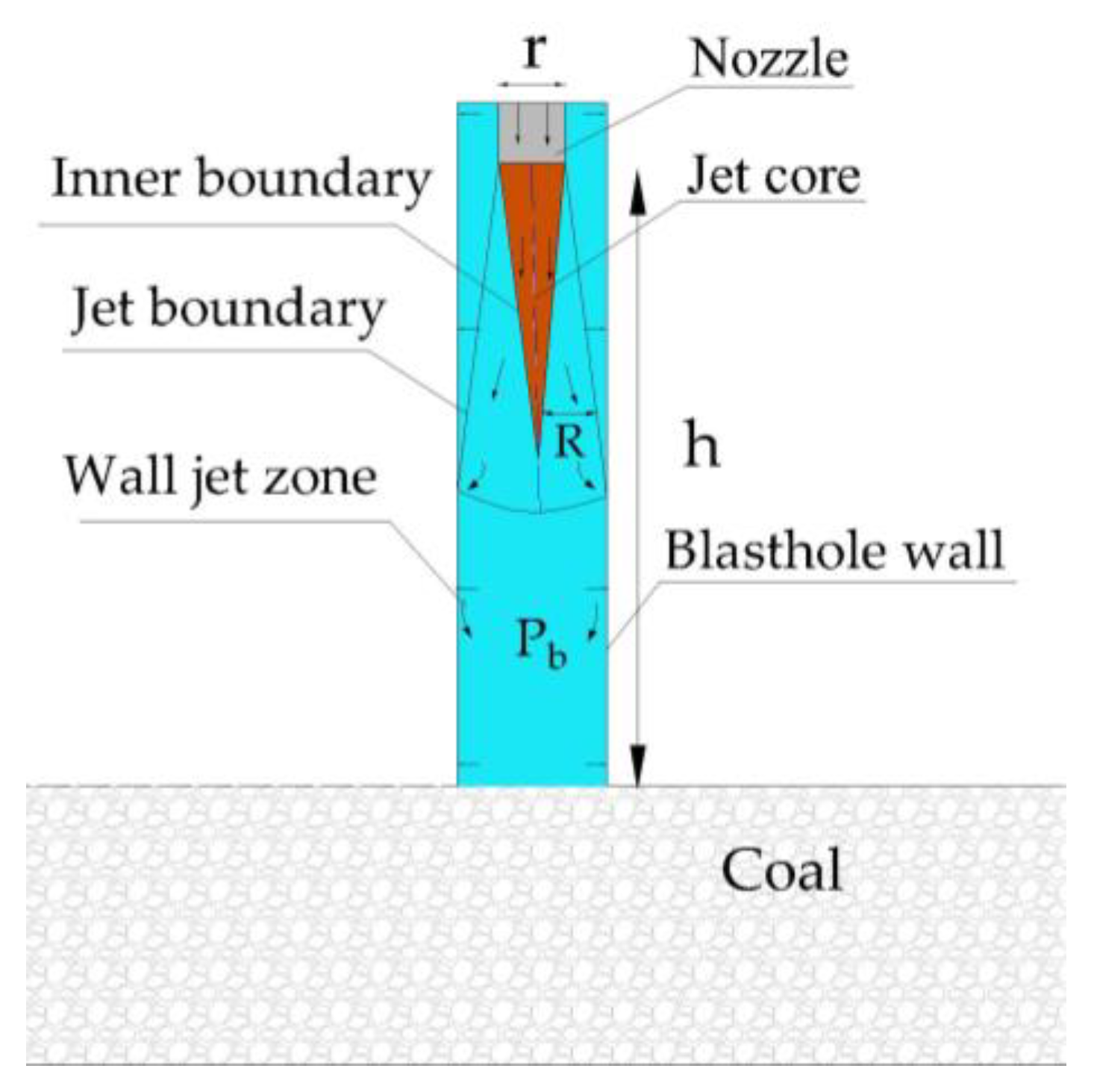

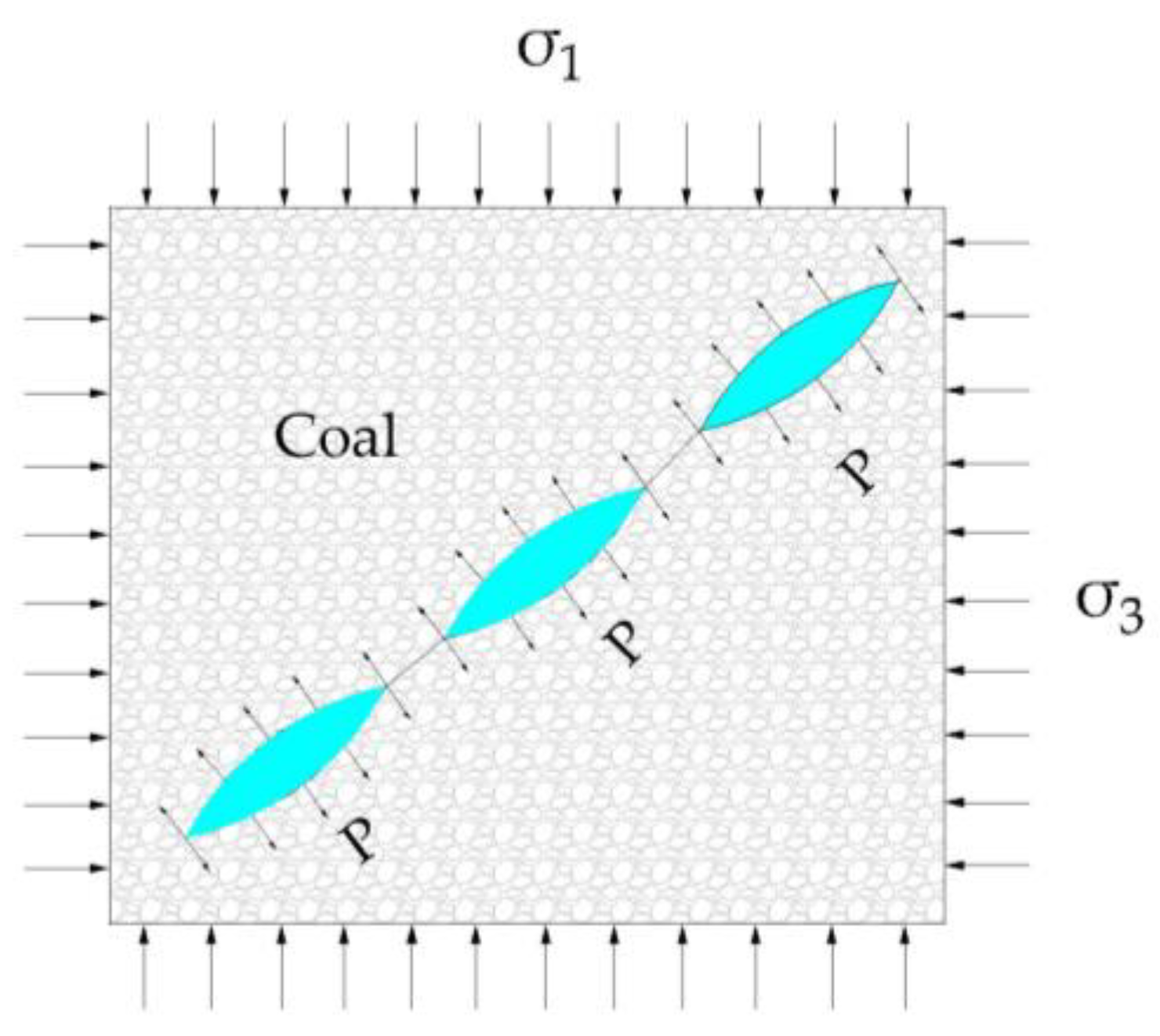

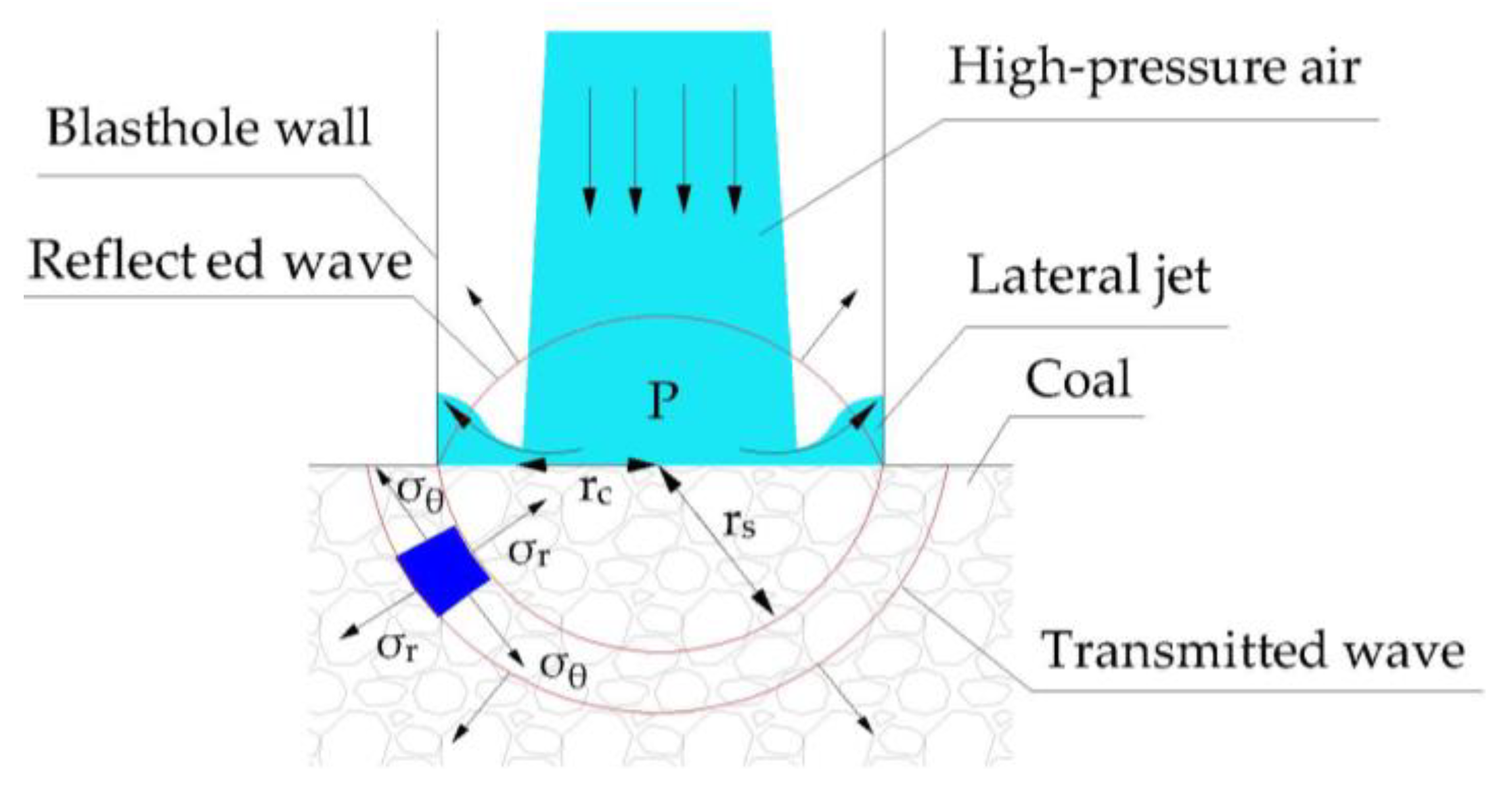

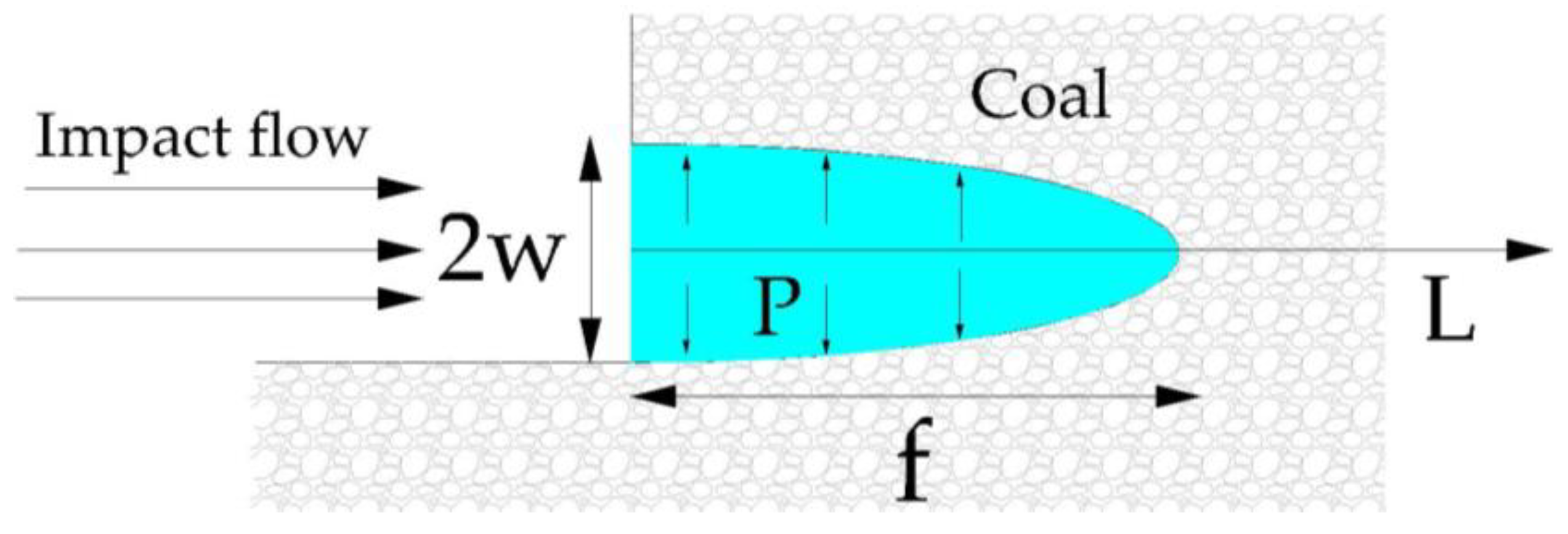

4.1. Damage Fracture Model of Coal with the Nozzle Located in the Middle-Upper Part

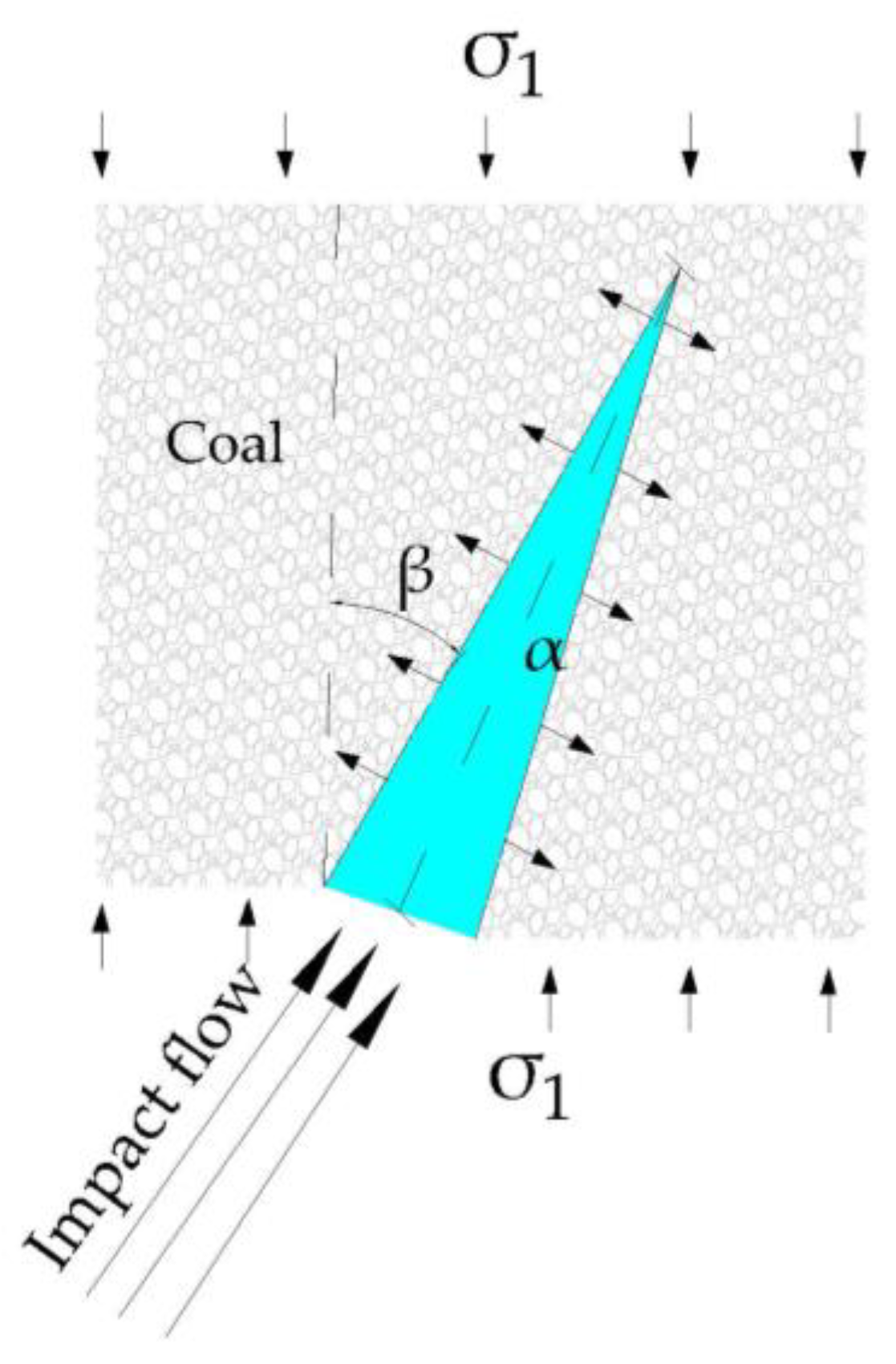

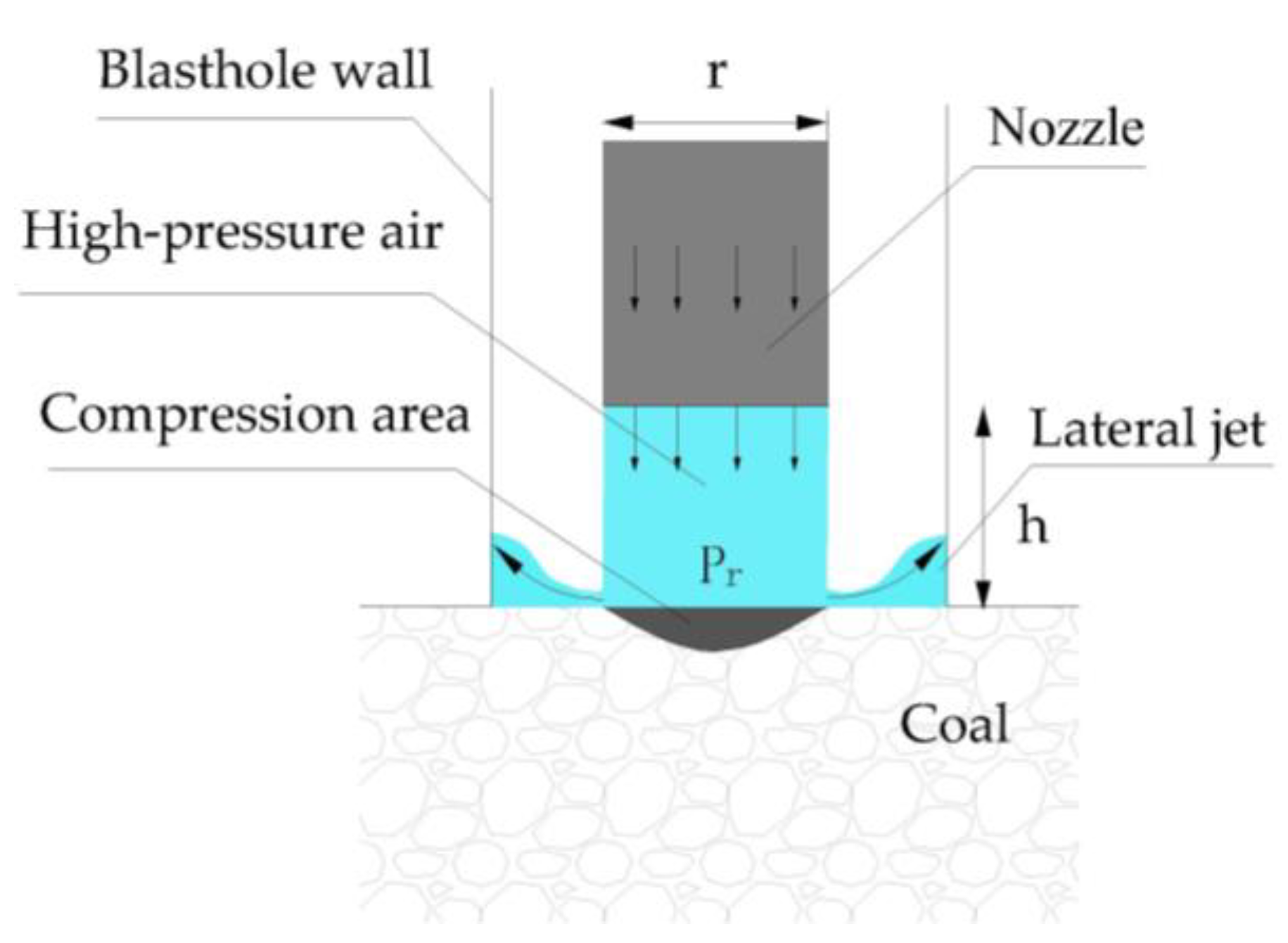

4.2. Damage Fracture Model with the Nozzle Located in the Middle-Lower Part

5. Conclusions

- When the nozzle is located in the upper part of the blasthole, longitudinal cracks penetrating the coal are formed at the upper and lower parts of the hole bottom. The crack slice depth is deeper. Meanwhile, under the action of the stress wave, many short and narrow secondary cracks in different directions are formed, and coal crack density increases. The increase in cutting depth and crack density improves the permeability of the coal seam, which is more conducive to the production of coalbed methane.

- When the nozzle is located in the middle-lower part of the blasthole, the bottom and top of the hole form a horizontal crack run through the coal under the superposition of stress concentration and tensile stress. Longitudinal cracks are only formed within the depth range of the blasthole. The crack density is small, and the cutting depth is limited to the upper part of the hole bottom. The permeability of the coal in the lower part of the hole bottom is not improved. The coal bed methane extraction volume is not as good as the nozzle located in the middle-upper part.

- When the nozzle position is close to the bottom of the hole, the enormous impact load will cause the bottom of the hole to be crushed and destroyed. This causes energy dissipation and weakens the ability of crack propagation, making the density and tangential depth of crack propagation in coal far less than the above two positions. Coalbed methane extraction is the lowest.

- By comparing the results, it was found that when the nozzle is located in the middle-upper part of the blasthole, the crack grid formed by the coal is more complex. When the nozzle is in the middle-lower part of the blasthole, horizontal cracks are easy to form at the bottom and top of the hole, and the crack propagation direction is single, so a three-dimensional crack grid cannot be formed. Therefore, the production of coalbed methane extracted from nozzles located in different positions is in the order from high to low: the middle-upper part, the middle-lower part, and the bottom part.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Zhang, S.; Shu, L. Coalbed methane migration mechanism under adsorption-desorption condition in coal. Coal Geol. Explor. 2019, 47, 12–18. [Google Scholar] [CrossRef]

- Hu, L.; Feng, Z.; Zhou, D.; Wang, X.; Shi, J.; Shen, Y.; Zhao, D. Numerical simulation study and engineering practice of in-situ heat injection mining of coalbed methane. J. China Coal Soc. 2023, 1–14. [Google Scholar] [CrossRef]

- Chu, H.B.; Wang, C.; Yang, X.L.; Yan, S.Y.; Ren, Y.Q.; Chen, Z.; Zhu, S.Y. A simulation experimental study on high-pressure air blasting of coal. J. Vib. Shock 2022, 41, 54–60+157. [Google Scholar] [CrossRef]

- Sun, H.T.; Shu, L.Y.; Jiang, Z.B.; Hu, J. Progress and trend of key technologies of CBM development and utilization in China coal mine areas. Coal Sci. Technol. 2022, 50, 1–13. [Google Scholar] [CrossRef]

- Yang, R.; Cong, R.; Liu, H.; Huang, Z.; Wen, H.; Hong, C. Pore-scale analysis of coal structure and mechanical properties evolution through liquid nitrogen thermal shock. Nat. Gas Ind. 2021, 41, 82–92. [Google Scholar] [CrossRef]

- Gao, J.L.; Guan, C.H.; Zhang, B. China’s CH4 emissions from coal mining: A review of current bottom-up inventories. Sci. Total Environ. 2020, 725, 2–7. [Google Scholar] [CrossRef]

- Liu, S.Q.; Wang, H.; Sang, S.X.; Hu, Q.J.; Jia, H.M.; Mao, C.H. Phase change and mass transfer process of coalbed water in anthracite res-ervoir and its engineering inspiration for coalbed methane development. J. China Coal Soc. 2023, 1–14. [Google Scholar] [CrossRef]

- Chu, H.B.; Yiao, X.L.; Wang, C.; Liang, W. Study on the Coal damage fracture Mechanism under Multiple Actions of Blasting Stress Wave. Arab. J. Sci. Eng. 2021, 46, 10847–10854. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, M.Y.; Gao, X.H. Study on the technology of enhancing permeability by deep hole presplitting blasting in Sanyuan coal mine. Sci. Rep. 2021, 11, 20353. [Google Scholar] [CrossRef]

- Ti, Z.; Zhang, F.; Pan, J.; Ma, X.; Shang, Z. Permeability enhancement of deep hole pre-splitting blasting in the low permeability coal seam of the Nanting coal mine. PLoS ONE 2018, 13, e0199835. [Google Scholar] [CrossRef]

- Shipovskii, I.; Odintsev, V. Numerical simulation of the stress-strain state of a coal seam caused by an explosion of a blast-hole charge with an annular gap. EPJ Web Conf. 2019, 221, 01053. [Google Scholar] [CrossRef]

- Hu, Q.T.; Liu, L.; Li, Q.G.; Wu, Y.Q.; Wang, X.G.; Jiang, Z.Z.; Yan, F.Z.; Xu, Y.C.; Wu, X.B. Experimental investigation on crack competitive extension during hydraulic fracturing in coal measures strata. Fuel 2020, 265, 117003. [Google Scholar] [CrossRef]

- Xu, J.Z.; Zhai, C.; Pathegama, G.R.; Sang, S.X.; Sun, Y.; Cong, Y.Z.; Tang, W.; Zheng, Y.F. Investigation of the mechanical damage of low rank coals under the impacts of cyclical liquid CO2 for coalbed methane recovery. Energy 2022, 239, 122145. [Google Scholar] [CrossRef]

- Sampath, K.H.S.M.; Perera, M.S.A.; Ranjith, P.G.; Matthai, S.K.; Li, D. Qualitative and quantitative evaluation of the alteration of micro-fracture characteristics of supercritical CO2-interacted coal. J. Supercrit. Fluids 2019, 147, 90–101. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, X.; Zhang, J.; Guo, S.; Meng, B. Characteristics and formation mechanisms of microstructures incoal treated with CO2 phase transition fracturing. Coal Geol. Explor. 2023, 51, 137–145. [Google Scholar] [CrossRef]

- Trofimov, V.A.; Shipovskii, I.E. Computer modeling of coal seam blasting. J. Min. Sci. 2020, 56, 741–752. [Google Scholar] [CrossRef]

- Huang, Z.W.; Li, G.F.; Yang, R.Y.; Li, G.S. Review and development trends of coalbed methane exploitation technology in China. J. China Coal Soc. 2022, 47, 3212–3238. [Google Scholar] [CrossRef]

- Zhang, S.A.; Liu, X.Z.; Wen, Q.Z.; Xiao, Z.; Wei, Z.; Yu, Y. Development situation and trend of stimulation and reforming technology of coalbed methane. Acta Pet. Sin. 2021, 42, 105–118. [Google Scholar]

- Chen, H.H.; Fan, H.F.; Guo, J.P.; He, X. Analysis and prospect on hydraulic fracturing fluid used in coalbed methane well. Coal Geol. Explor. 2017, 45, 33–40. [Google Scholar] [CrossRef]

- Xu, F.Y.; Yan, X.; Lin, Z.P.; Li, S.; Xiong, X.; Yan, D.; Mei, Y. Research progress and development direction of key technologies for efficient coalbed methane development in China. Coal Geol. Explor. 2022, 50, 1–15. [Google Scholar]

- Yan, S.Y.; Yang, X.L.; Chu, H.B.; Wang, C. Experimental Study on the Dynamic Response and Pore Structure Evolution of Coal under High-Pressure Air Blasting. ACS Omega 2022, 7, 24475–24480. [Google Scholar] [CrossRef]

- Li, S.G. Key technology and equipment research and development of improving coal seam permeability by high-pressure air blasting. Coal Sci. Technol. 2015, 43, 92–95. [Google Scholar] [CrossRef]

- Yang, X.L.; Wang, C.; Chu, H.B.; Yan, S.Y.; Wei, H.X.; Yu, M.F. Study on the Stress Field and Crack Propagation of Coal Mass Induced by High-Pressure Air Blasting. Mianerals 2022, 12, 300. [Google Scholar] [CrossRef]

- Saeed, A.; Najm, H.M.; Hassan, A.; Sabri, M.M.S.; Qaidi, S.; Mashaan, N.S.; Ansari, K. Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties. Materials 2022, 15, 8250. [Google Scholar] [CrossRef]

- Chen, M.; Huang, H.J.; Wang, D.Y.; Lee, S.; Chen, Y. PIV tests for flow characteristics of impinging jet in a semi-closed circular pipe. J. Vib. Shock 2021, 40, 91–97. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Yin, G.Z.; Wang, D.K. A coupled elastoplastic damage model for gas-saturated coal. Chin. Rock Mechan. Eng. 2009, 28, 993–999. [Google Scholar]

- Gou, Y.G.; Shi, X.Z.; Qiu, X.Y.; Zhou, J.; Chen, H.; Huo, X. Propagation Characteristics of Blast-Induced Vibration in Parallel Jointed Rock Mass. ASVE 2019, 19, 14. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Kou, S.Q.; Lindqvist, P.A.; Yu, Y. The relationship between the fracture toughness and tensile strength of rock. In Strength Theories: Applications, Development & Prospects for 21st Century; Science Press: Beijing, China, 1998; pp. 215–219. [Google Scholar]

- Chu, H.; Yu, M.; Sun, B.; Yan, S.; Wei, H.; Zhang, G.; Wang, D.; Xu, J. Experimental Study on Damage Fracture Law of Coal from Solid-Propellant Blasting. Energies 2022, 15, 8104. [Google Scholar] [CrossRef]

- Murakami, Y. Stress Intensity Factors Handbook; Pergamon Press: Oxford, UK, 1987. [Google Scholar]

- Yang, X.; Wang, S. Meso-mechanism of damage and fracture on rock blasting. Explos. Shock Waves 2000, 20, 247–252. [Google Scholar]

- Zhang, D.M.; Bai, X.; Yin, G.Z.; Li, S.J.; Rao, Z.; He, Q.B. Mechanism of breaking and fracture expansion of liquid CO2 phase change jet fracturing in low-permeability coal seam. J. China Coal Soc. 2018, 43, 3154–3168. [Google Scholar] [CrossRef]

- Peng, S.N.; Zhou, Y.H. Discussion On Models for Gas Leakage And Diffusion. Gas Heat 2008, 28, 39–42. [Google Scholar]

- Liu, S.; Du, C.; Jiang, H. Mechanical-Water Jet Combined Rock Breaking and Its Application in Mining Machinery; Science Press: Beijing, China, 2017. [Google Scholar]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Density (g·cm−3) | 1.4–1.6 | P wave velocity (m·s−1) | 1800–2000 |

| Compressive strength (MPa) | 12–18 | Elastic modulus (GPa) | 2.3–3.2 |

| Tensile strength (MPa) | 0.8–2 | Poisson’s ratio | 0.2–0.3 |

| Material | Quantity (kg) | Material | Quantity (kg) | Material | Quantity (kg) |

|---|---|---|---|---|---|

| Sand | 6.500 | Gypsum | 0.333 | Perlite | 0.045 |

| Cement | 2.333 | Foaming agent | 0.080 | ||

| Water | 1.000 | Crushed mica | 0.047 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Density (g·cm−3) | 1.62 | P wave velocity (m·s−1) | 2046 |

| Compressive strength (MPa) | 13.46 | Elastic modulus (GPa) | 2.70 |

| Tensile strength (MPa) | 1.39 | Poisson’s ratio | 0.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, H.; Wang, D.; Yang, X.; Yu, M.; Sun, B.; Yan, S.; Zhang, G.; Xu, J. Mechanism of Nozzle Position Affecting Coalbed Methane Mining in High-Pressure Air Blasting. Sustainability 2023, 15, 11171. https://doi.org/10.3390/su151411171

Chu H, Wang D, Yang X, Yu M, Sun B, Yan S, Zhang G, Xu J. Mechanism of Nozzle Position Affecting Coalbed Methane Mining in High-Pressure Air Blasting. Sustainability. 2023; 15(14):11171. https://doi.org/10.3390/su151411171

Chicago/Turabian StyleChu, Huaibao, Donghui Wang, Xiaolin Yang, Mengfei Yu, Bo Sun, Shaoyang Yan, Guangran Zhang, and Jie Xu. 2023. "Mechanism of Nozzle Position Affecting Coalbed Methane Mining in High-Pressure Air Blasting" Sustainability 15, no. 14: 11171. https://doi.org/10.3390/su151411171

APA StyleChu, H., Wang, D., Yang, X., Yu, M., Sun, B., Yan, S., Zhang, G., & Xu, J. (2023). Mechanism of Nozzle Position Affecting Coalbed Methane Mining in High-Pressure Air Blasting. Sustainability, 15(14), 11171. https://doi.org/10.3390/su151411171