Analysis of Carbon Emission Reduction at the Port of Integrated Logistics: The Port of Shanghai Case Study

Abstract

1. Introduction

2. Literature Review

2.1. Research on Port Carbon Emission

2.2. Research on Carbon Emission Analysis Method

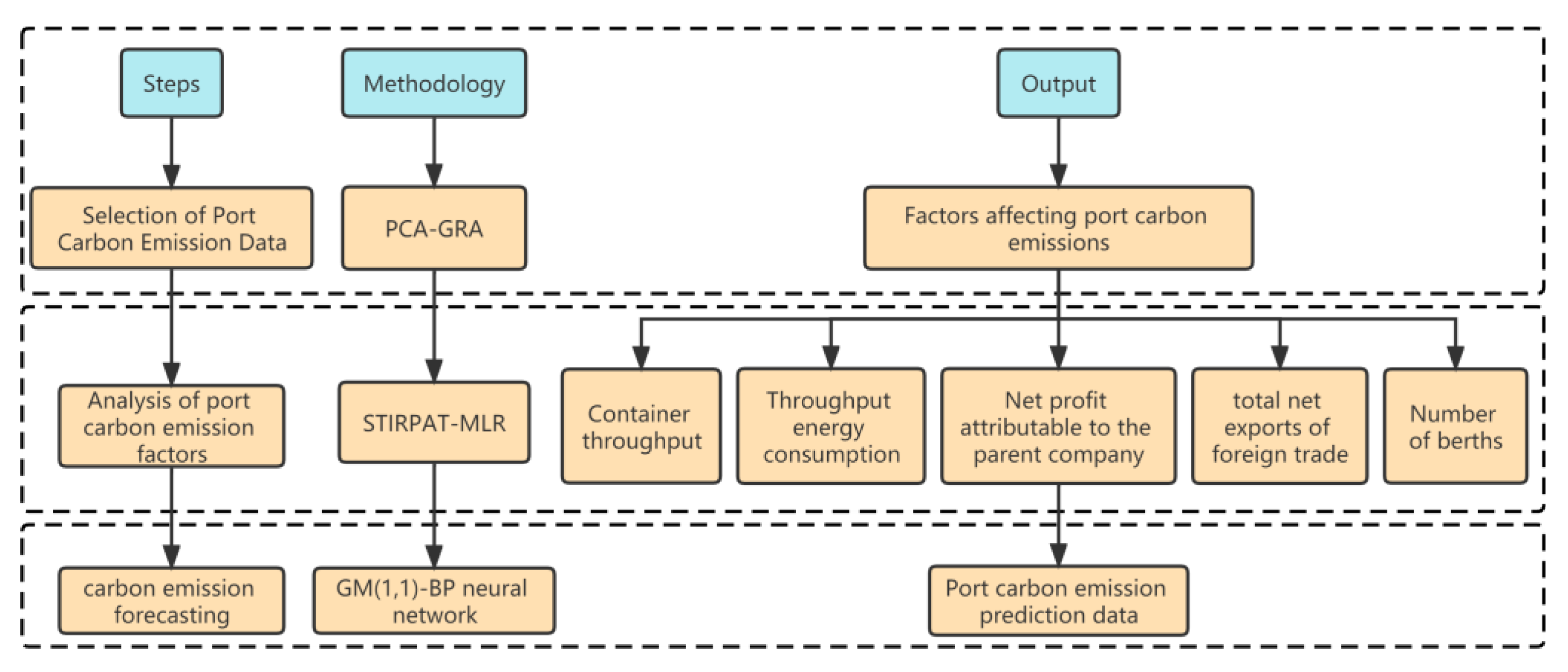

3. Methodology

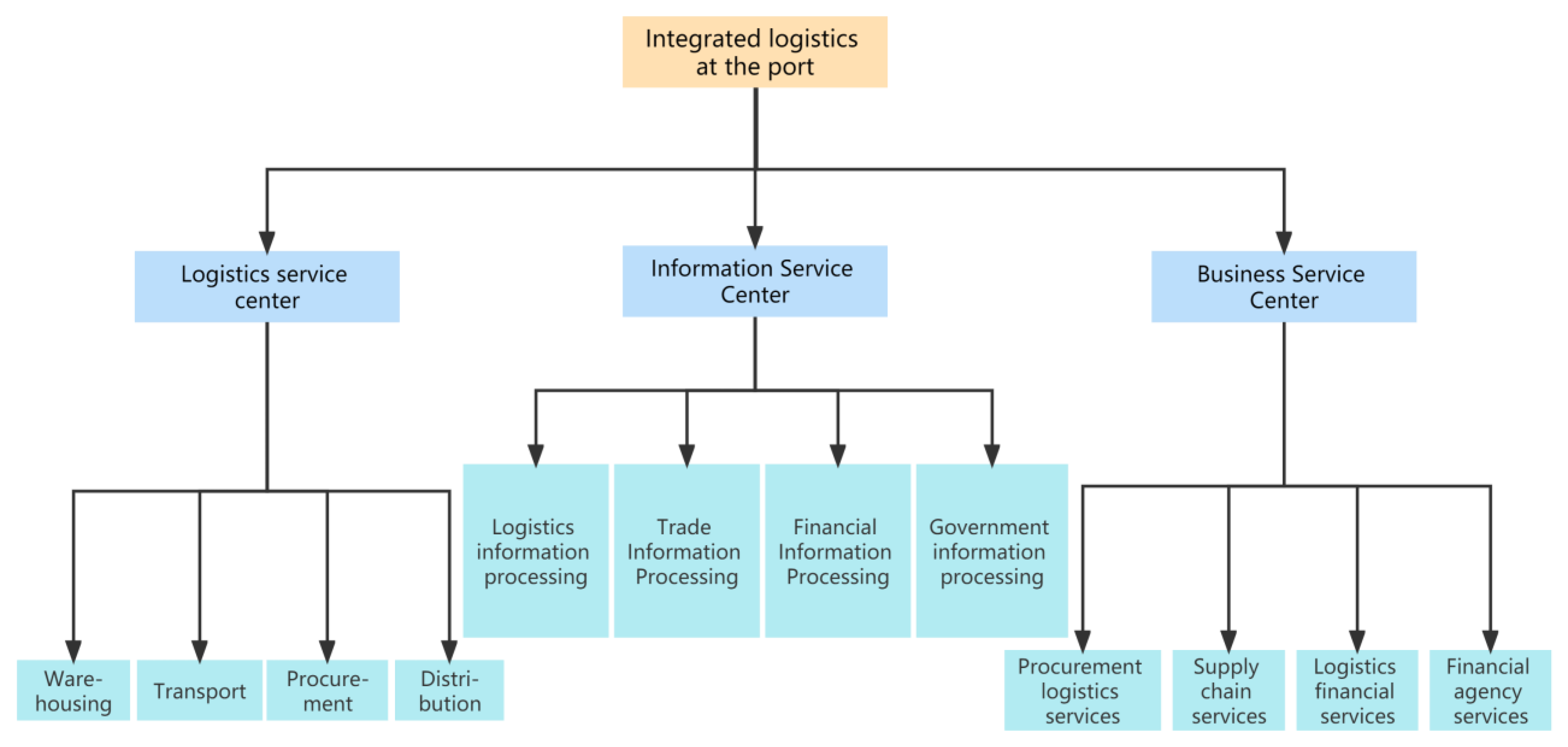

3.1. Research on Port Integrated Logistics

3.2. PCA-GRA

3.3. STIRPAT and MLR

3.4. GM (1,1)-BP Neural Network Model

3.5. Index Selection

4. Empirical Analysis

4.1. Introduction of Port of Shanghai

4.2. Analysis of Carbon Emission Sources in Port Integrated Logistics System

4.2.1. Carbon Emissions Source Analysis in Port Facilities

4.2.2. Carbon Emissions Source Analysis in Transportation

4.2.3. Analysis of Carbon Emission Sources in Material Consumption

4.3. Data Sources and Calculation Methods

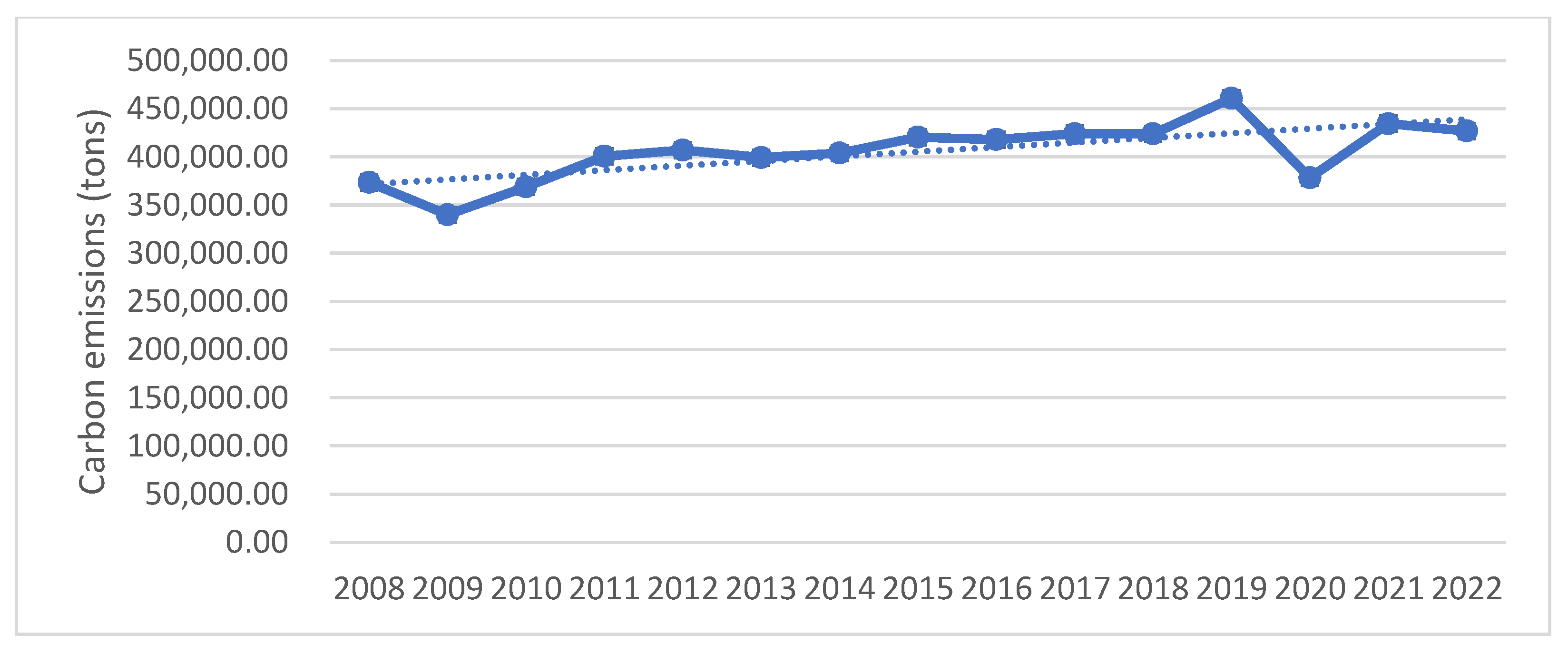

4.4. Analysis of Carbon Emissions in Shanghai Port over the Years

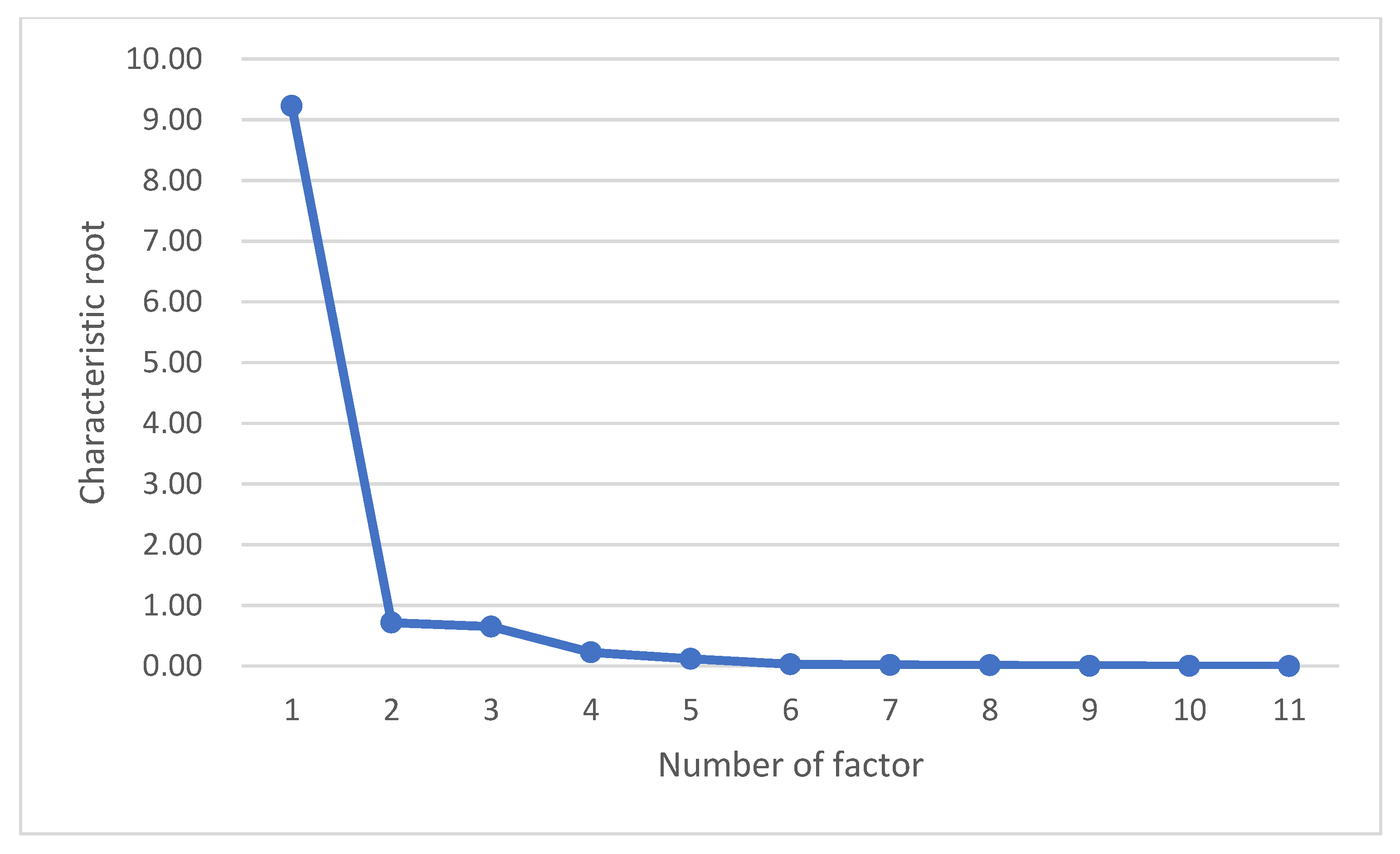

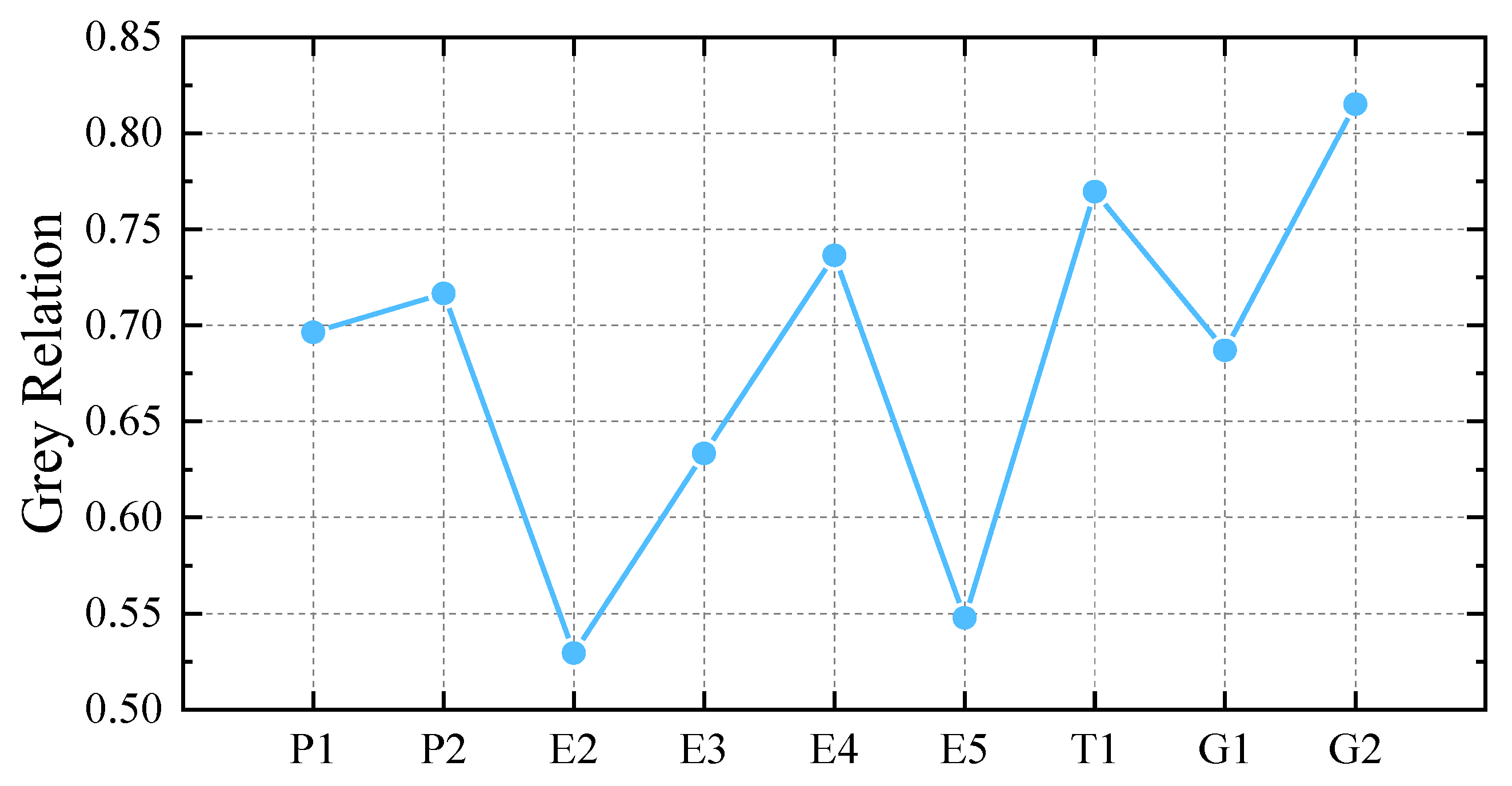

4.5. Identification of Carbon Emission Influencing Factors Based on PCA-GRA

4.6. Analysis of Improved STIRPAT Model

4.7. Ridge Regression Results and Discussion

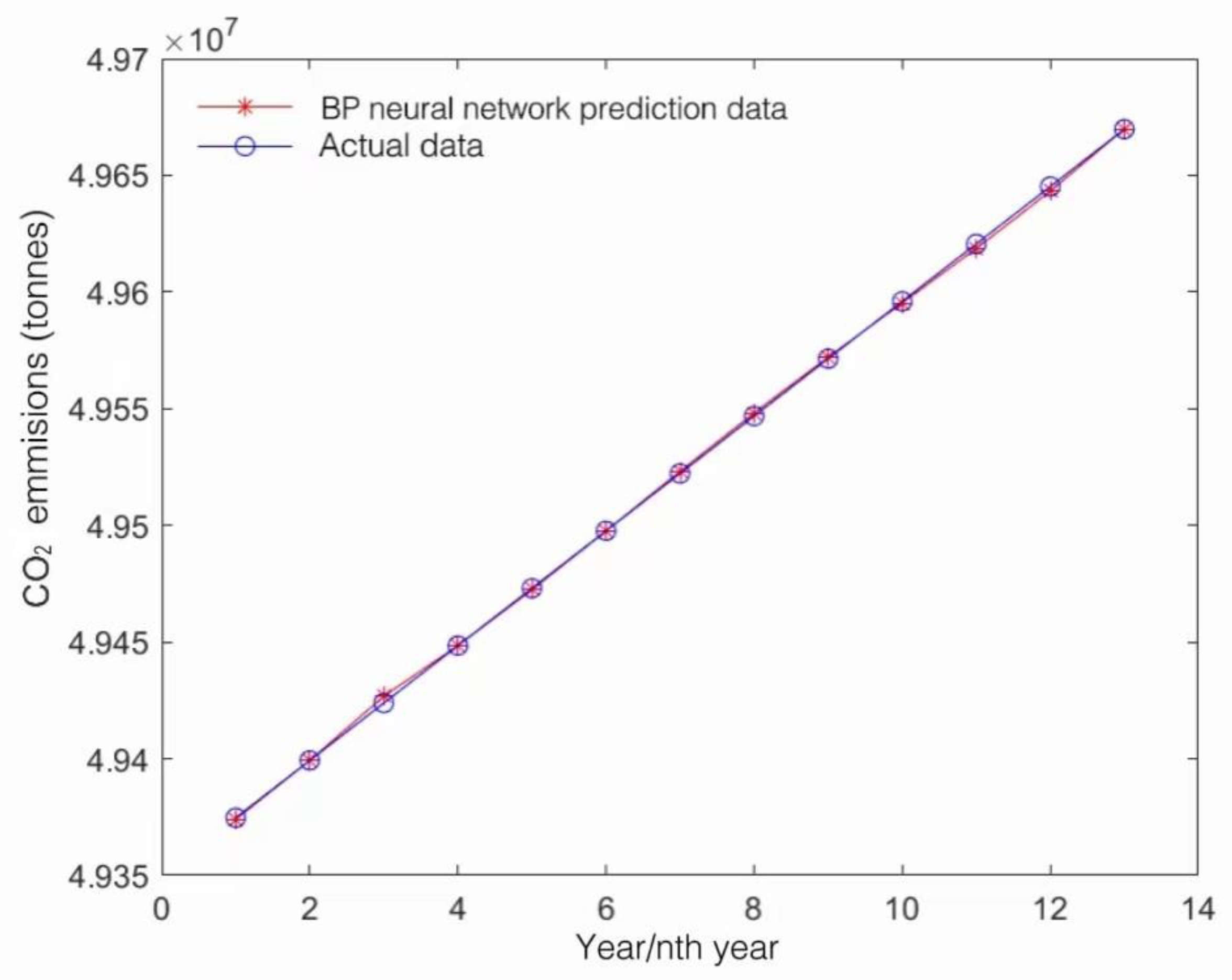

4.8. Prediction and Analysis of Carbon Emissions in Shanghai Port Integrated Logistics System

5. Strategies for Reducing Carbon Emissions in Port

5.1. Establish an Energy Forecasting and Early Warning Mechanism and an Emergency Response Mechanism to Meet the Needs of Trade Fluctuations

5.2. Vigorously Promote the Construction of Green Ports and Improve Energy Efficiency

5.3. Optimize Port Operation Management

5.4. Improve Berth Utilization and Reduce Loading and Unloading Time

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, J.; Kuang, H.; Yu, F. Study on Port Carbon Footprint Measurement and Drive Factors from the Perspective of Energy Consumption. Manag. Rev. 2020, 32, 40–51. [Google Scholar]

- Ircha, M.C. Social License for Ports; Canadian Sailing: Rivière-Beaudette, QC, Canada, 2012; pp. 17–22. [Google Scholar]

- Yan, W.; Yi, S. The Influencing Factors of Energy Conservation and Emission Reduction Efficiency in China from the Per-spective of Green Development—An Empirical Study Based on Super-efficiency DEA and Tobit Models. Manag. Rev. 2020, 32, 59–71. [Google Scholar]

- Misra, A.; Panchabikesan, K.; Gowrishankar, S.K.; Ayyasamy, E.; Ramalingam, V. GHG emission accounting and mitigation strategies to reduce the carbon footprint in conventional port activities—A case of the Port of Chennai. Carbon Manag. 2017, 8, 45–56. [Google Scholar] [CrossRef]

- Masson-Delmotte, V.; Intergovernmental Panel on Climate Change. Global Warming of 1.5 °C: An IPCC Special Report on Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Contex of Strengthening the Global Response to the Thereat of Blimate Change, Sustainable Development, and Efforts to Eradicate Poverty; Cambridge University Press: Cambridge, UK, 2018; pp. 43–50. [Google Scholar]

- Song, S. Ship emissions inventory, social cost and eco-efficiency in Shanghai Yangshan port. Atmospheric Environ. 2014, 82, 288–297. [Google Scholar] [CrossRef]

- Wang, J.J.; Slack, B. Regional governance of port development in China: A case study of Shanghai International Shipping Center. Marit. Policy Manag. 2004, 31, 357–373. [Google Scholar] [CrossRef]

- Wei, H.; Li, L.; Nian, M. China’s Urbanization Strategy and Policy During the 14th Five-Year Plan Period. Chin. J. Urban Environ. Stud. 2021, 9, 2150002. [Google Scholar] [CrossRef]

- Wang, S.; Luo, Y.; Liu, Z.; Lu, B. Analysis on Energy Conservation and Emission Reduction Efficiency and Influencing Factors for Ports around Bohai in China under the Low Carbon Target. Sustainability 2022, 14, 14765. [Google Scholar] [CrossRef]

- Sun, L.; Ding, P.; Xiong, Y.; Liu, W.; Hu, Z. Carbon emission reduction of shore power from power energy structure in China. Front. Mar. Sci. 2022, 9, 1077289. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Q.; Wang, L.; Chen, Y.; Wang, J. A review of the port carbon emission sources and related emission reduction technical measures. Environ. Pollut. 2023, 320, 121000. [Google Scholar] [CrossRef]

- Yu, Y.; Sun, R.; Sun, Y.; Shu, Y. Integrated Carbon Emission Estimation Method and Energy Conservation Analysis: The Port of Los Angles Case Study. J. Mar. Sci. Eng. 2022, 10, 717. [Google Scholar] [CrossRef]

- Meng, L.; Liu, K.; He, J.; Han, C.; Liu, P. Carbon emission reduction behavior strategies in the shipping industry under government regulation: A tripartite evolutionary game analysis. J. Clean. Prod. 2022, 378, 134556. [Google Scholar] [CrossRef]

- Wang, L.; Peng, C.; Shi, W.; Zhu, M. Carbon dioxide emissions from port container distribution: Spatial characteristics and driving factors. Transp. Res. Part D Transp. Environ. 2020, 82, 102318. [Google Scholar] [CrossRef]

- Yang, L.; Cai, Y.; Zhong, X.; Shi, Y.; Zhang, Z. A Carbon Emission Evaluation for an Integrated Logistics System—A Case Study of the Port of Shenzhen. Sustainability 2017, 9, 462. [Google Scholar] [CrossRef]

- Na, J.-H.; Choi, A.-Y.; Ji, J.; Zhang, D. Environmental efficiency analysis of Chinese container ports with CO 2 emissions: An inseparable input-output SBM model. J. Transp. Geogr. 2017, 65, 13–24. [Google Scholar] [CrossRef]

- Guo, X.; He, J.; Lan, M.; Yu, H.; Yan, W. Modeling carbon emission estimation for hinterland-based container intermodal network. J. Clean. Prod. 2022, 378, 134593. [Google Scholar] [CrossRef]

- Yu, Y.; Sun, R.; Sun, Y.; Wu, J.; Zhu, W. China’s Port Carbon Emission Reduction: A Study of Emission-Driven Factors. Atmosphere 2022, 13, 550. [Google Scholar] [CrossRef]

- Pinto, J.T.; Diemer, A. Supply chain integration strategies and circularity in the European steel industry. Resour. Conserv. Recycl. 2019, 153, 104517. [Google Scholar] [CrossRef]

- Kao, S.-L.; Chung, W.-H.; Chen, C.-W. AIS-Based Scenario Simulation for the Control and Improvement of Ship Emissions in Ports. J. Mar. Sci. Eng. 2022, 10, 129. [Google Scholar] [CrossRef]

- Tsao, Y.-C.; Linh, V.T. Seaport-dry port network design considering multimodal transport and carbon emissions. J. Clean. Prod. 2018, 199, 481–492. [Google Scholar] [CrossRef]

- Tai, H.-H.; Chang, Y.-H. Reducing pollutant emissions from vessel maneuvering in port areas. Marit. Econ. Logist. 2022, 24, 651–671. [Google Scholar] [CrossRef]

- Shang, J.R. Lanshan Port Environmental Protection Countermeasure Research—Based on the Sustainable Development. Adv. Mater. Res. 2013, 726–731, 3961–3967. [Google Scholar] [CrossRef]

- Bengtsson, S.; Fridell, E.; Andersson, K. Environmental assessment of two pathways towards the use of biofuels in shipping. Energy Policy 2012, 44, 451–463. [Google Scholar] [CrossRef]

- Acciaro, M.; Ghiara, H.; Cusano, M.I. Energy management in seaports: A new role for port authorities. Energy Policy 2014, 71, 4–12. [Google Scholar] [CrossRef]

- Ankathi, S.; Lu, Z.; Zaimes, G.G.; Hawkins, T.; Gan, Y.; Wang, M. Greenhouse gas emissions from the global transportation of crude oil: Current status and mitigation potential. J. Ind. Ecol. 2022, 26, 2045–2056. [Google Scholar] [CrossRef]

- Tao, X.; Wu, Q. Energy consumption and CO2 emissions in hinterland container transport. J. Clean. Prod. 2020, 279, 123394. [Google Scholar] [CrossRef]

- York, R.; Rosa, E.A.; Dietz, T. STIRPAT, IPAT and ImPACT: Analytic tools for unpacking the driving forces of environmental impacts. Ecol. Econ. 2003, 46, 351–365. [Google Scholar] [CrossRef]

- Waggoner, P.E.; Ausubel, J.H. A framework for sustainability science: A renovated IPAT identity. Proc. Natl. Acad. Sci. USA 2002, 99, 7860–7865. [Google Scholar] [CrossRef]

- Fan, Y.; Liu, L.-C.; Wu, G.; Wei, Y.-M. Analyzing impact factors of CO2 emissions using the STIRPAT model. Environ. Impact Assess. Rev. 2006, 26, 377–395. [Google Scholar] [CrossRef]

- Lin, S.; Zhen, L.; Wang, W.; Tan, Z. Green berth and yard space allocation under carbon tax policy in tidal ports. Marit. Policy Manag. 2022, 1–22. [Google Scholar] [CrossRef]

- Zhao, J. Models and Policies of Port Carbon Emission Reduction: A Case Study of the Port of Dalian. Master’s Thesis, World Maritime University, Malmö, Sweden, 2017. Available online: https://commons.wmu.se/all_dissertations/1532 (accessed on 28 May 2023).

- Xiao, G.; Wang, T.; Luo, Y.; Yang, D. Analysis of port pollutant emission characteristics in United States based on multiscale geographically weighted regression. Front. Mar. Sci. 2023, 10, 1131948. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Ma, D.; Lu, J.; Luo, W.; Fu, Y.; Li, S.; Feng, J.; Huang, C.; Ge, W.; et al. Port-Related Emissions, Environmental Impacts and Their Implication on Green Traffic Policy in Shanghai. Sustainability 2020, 12, 4162. [Google Scholar] [CrossRef]

- Xu, L.; Yang, Z.; Chen, J.; Zou, Z. Impacts of the COVID-19 epidemic on carbon emissions from international shipping. Mar. Pollut. Bull. 2023, 189, 114730. [Google Scholar] [CrossRef]

- Maćkiewicz, A.; Ratajczak, W. Principal components analysis (PCA). Comput. Geosci. 1993, 19, 303–342. [Google Scholar] [CrossRef]

- Liu, S.; Yang, Y.; Cao, Y.; Xie, N. A summary on the research of GRA models. Grey Syst. Theory Appl. 2013, 3, 7–15. [Google Scholar] [CrossRef]

- Liu, H.-F.; Ren, C.; Zheng, Z.-T.; Liang, Y.-J.; Lu, X.-J. Study of a Gray Genetic BP Neural Network Model in Fault Monitoring and a Diagnosis System for Dam Safety. ISPRS Int. J. Geo-Inf. 2017, 7, 4. [Google Scholar] [CrossRef]

- Li, J.-B.; Oh, Y.-S. A Research on Competition and Cooperation Between Shanghai Port and Ningbo-Zhoushan Port. Asian J. Shipp. Logist. 2010, 26, 67–91. [Google Scholar] [CrossRef]

- Zhao, R. Carbon emissions and carbon peak time calculation methods of container port. J. Dalian Marit. Univ. 2021, 4, 56–64. [Google Scholar] [CrossRef]

- Lu, J.; Wu, X.; Wu, Y. The Construction and Application of Dual-Objective Optimal Speed Model of Liners in a Changing Climate: Taking Yang Ming Route as an Example. J. Mar. Sci. Eng. 2023, 11, 157. [Google Scholar] [CrossRef]

- Roweis, S. EM algorithms for PCA and SPCA. Adv. Neural Inf. Process. Syst. 1997, 10, 626–632. [Google Scholar]

- McDonald, G.C. Ridge regression. WIREs Comput. Stat. 2009, 1, 93–100. [Google Scholar] [CrossRef]

- Cwiek, A.; Rajtmajer, S.M.; Wyble, B.; Honavar, V.; Grossner, E.; Hillary, F.G. Feeding the machine: Challenges to reproducible predictive modeling in resting-state connectomics. Netw. Neurosci. 2022, 6, 29–48. [Google Scholar] [CrossRef] [PubMed]

- Jin, W.; Li, Z.J.; Wei, L.S.; Zhen, H. The improvements of BP neural network learning algorithm. In Proceedings of the WCC 2000—ICSP 2000, 2000 5th International Conference on Signal Processing Proceedings, 16th World Computer Congress 2000, Institute of Electrical and Electronics Engineers (IEEE), Rotorua, New Zealand, 21–25 August 2002; Volume 3, pp. 1647–1649. [Google Scholar]

- Xiao, G.; Lu, Q.; Ni, A.; Zhang, C. Research on carbon emissions of public bikes based on the life cycle theory. Transp. Lett. 2023, 15, 278–295. [Google Scholar]

- Dai, Q.; Yang, J.; Li, D. Modeling a Three-Mode Hybrid Port-Hinterland Freight Intermodal Distribution Network with Environmental Consideration: The Case of the Yangtze River Economic Belt in China. Sustainability 2018, 10, 3081. [Google Scholar] [CrossRef]

- Zhen, L.; Zhuge, D.; Murong, L.; Yan, R.; Wang, S. Operation management of green ports and shipping networks: Overview and research opportunities. Front. Eng. Manag. 2019, 6, 152–162. [Google Scholar] [CrossRef]

- Khan, N.; Abas, N. Comparative study of energy saving light sources. Renew. Sustain. Energy Rev. 2011, 15, 296–309. [Google Scholar] [CrossRef]

- Yang, L.; Cai, Y.; Wei, Y.; Huang, S. Choice of technology for emission control in port areas: A supply chain perspective. J. Clean. Prod. 2019, 240, 118105. [Google Scholar] [CrossRef]

- Martínez-Moya, J.; Vazquez-Paja, B.; Maldonado, J.A.G. Energy efficiency and CO2 emissions of port container terminal equipment: Evidence from the Port of Valencia. Energy Policy 2019, 131, 312–319. [Google Scholar] [CrossRef]

- Talley, W.K. An Economic Theory of the Port. Res. Transp. Econ. 2006, 16, 43–65. [Google Scholar] [CrossRef]

| First-Level Indicators | Secondary Indicators | Variable | Unit |

|---|---|---|---|

| Port Factor | Container Cargo Throughput | P1 | million TEU |

| Number of berths | P2 | individual | |

| Coastal Pier Length | P3 | million meters | |

| Economic Factors | Operating costs | E1 | 100 million yuan |

| Total assets | E2 | 100 million yuan | |

| Total import and export of foreign trade | E3 | One hundred million U.S. dollars | |

| Net profit attributable to parent company | E4 | 100 million yuan | |

| Gross Product of the Region | E5 | 100 million yuan | |

| Technical Factor | Throughput energy consumption | T1 | tons/10,000 tons |

| Other Factor | Number of employees | G1 | individual |

| Transhipment | G2 | none |

| KMO and Bartlett’s Test | ||

|---|---|---|

| Kaiser-Meyer-Olkin Measure of Sampling Adequacy | 0.751 | |

| Bartlett’s Test of Sphericity | Approx. Chi-square | 335.464 |

| df | 55 | |

| Sig | 0.000 *** | |

| Variable | Non-Standardized Coefficient | Standardization Coefficient | t | p | VIF | R2 | Adjust R2 | F | |

|---|---|---|---|---|---|---|---|---|---|

| B | Standard Error | Beta | |||||||

| Regression equation constant term | 0.9 | 0 | - | 12,402,841,551.451 | 0.000 *** | - | 1 | 1 | F = 9.636633925398487 × 1022 p = 0.000 *** |

| lnP1 | 1 | 0 | 2.238 | 120,138,107,535.799 | 0.000 *** | 200.715 | |||

| lnT1 | 1 | 0 | 1.493 | 177,883,342,981.064 | 0.000 *** | 40.748 | |||

| lnE4 | 0 | 0 | 0 | 0.05 | 0.961 | 28.495 | |||

| lnP2 | 0 | 0 | 0 | 0.076 | 0.942 | 4.204 | |||

| lnE3 | 0 | 0 | 0 | −0.096 | 0.926 | 14.966 | |||

| lnG2 | 0 | 0 | 0 | 0.022 | 0.983 | 7.405 | |||

| Due to variables: CO2 emissions (ton) | |||||||||

| K = 0.172 | Non-Standardized Coefficient | Standardization Coefficient | t | p | R2 | Adjust R2 | F | |

|---|---|---|---|---|---|---|---|---|

| B | Standard Error | Beta | ||||||

| regression equation constant term | 10.478 | 0.45 | - | 23.269 | 0.000 *** | 0.938 | 0.904 | 27.41 (0.000 ***) |

| lnP1 | 0.084 | 0.016 | 0.187 | 5.099 | 0.001 *** | |||

| lnT1 | 0.183 | 0.054 | 0.273 | 3.372 | 0.008 *** | |||

| lnE4 | 0.095 | 0.016 | 0.495 | 5.816 | 0.000 *** | |||

| lnE3 | 0.108 | 0.035 | 0.266 | 3.08 | 0.013 ** | |||

| lnP2 | 0.123 | 0.053 | 0.208 | 2.343 | 0.044 ** | |||

| Due to variables: CO2 emissions (ton) | ||||||||

| Years | Carbon Emissions (ton) |

|---|---|

| 2021 | 49,698,654.85 |

| 2022 | 49,728,648.53 |

| 2023 | 49,758,281.33 |

| 2024 | 49,785,596.70 |

| 2025 | 49,808,899.45 |

| 2026 | 49,827,299.75 |

| 2027 | 49,840,884.41 |

| 2028 | 49,850,429.03 |

| 2029 | 49,856,907.70 |

| 2030 | 49,861,152.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Y.; Yuan, X.; Hou, B. Analysis of Carbon Emission Reduction at the Port of Integrated Logistics: The Port of Shanghai Case Study. Sustainability 2023, 15, 10914. https://doi.org/10.3390/su151410914

Zeng Y, Yuan X, Hou B. Analysis of Carbon Emission Reduction at the Port of Integrated Logistics: The Port of Shanghai Case Study. Sustainability. 2023; 15(14):10914. https://doi.org/10.3390/su151410914

Chicago/Turabian StyleZeng, Yilin, Xiang Yuan, and Bing Hou. 2023. "Analysis of Carbon Emission Reduction at the Port of Integrated Logistics: The Port of Shanghai Case Study" Sustainability 15, no. 14: 10914. https://doi.org/10.3390/su151410914

APA StyleZeng, Y., Yuan, X., & Hou, B. (2023). Analysis of Carbon Emission Reduction at the Port of Integrated Logistics: The Port of Shanghai Case Study. Sustainability, 15(14), 10914. https://doi.org/10.3390/su151410914