Characterization of Sustainable Asphalt Binders Modified with Styrene–Isoprene–Styrene (SIS) and Processed Oil

Abstract

1. Introduction

2. Research Methodology

2.1. Components

2.2. Preparation Process

2.2.1. Fundamental Attribute Assessments

2.2.2. Data Analysis

3. Results and Discussion

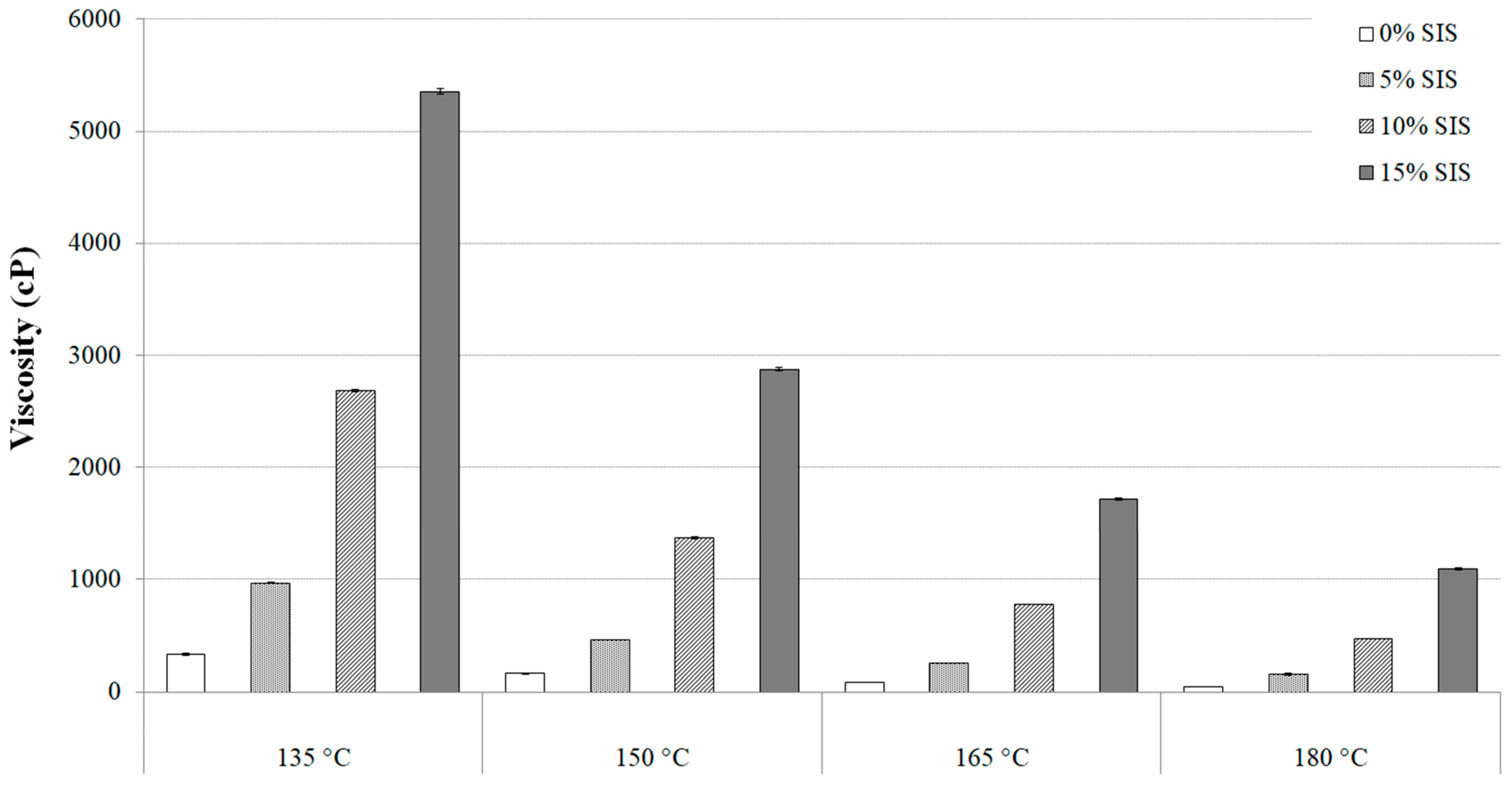

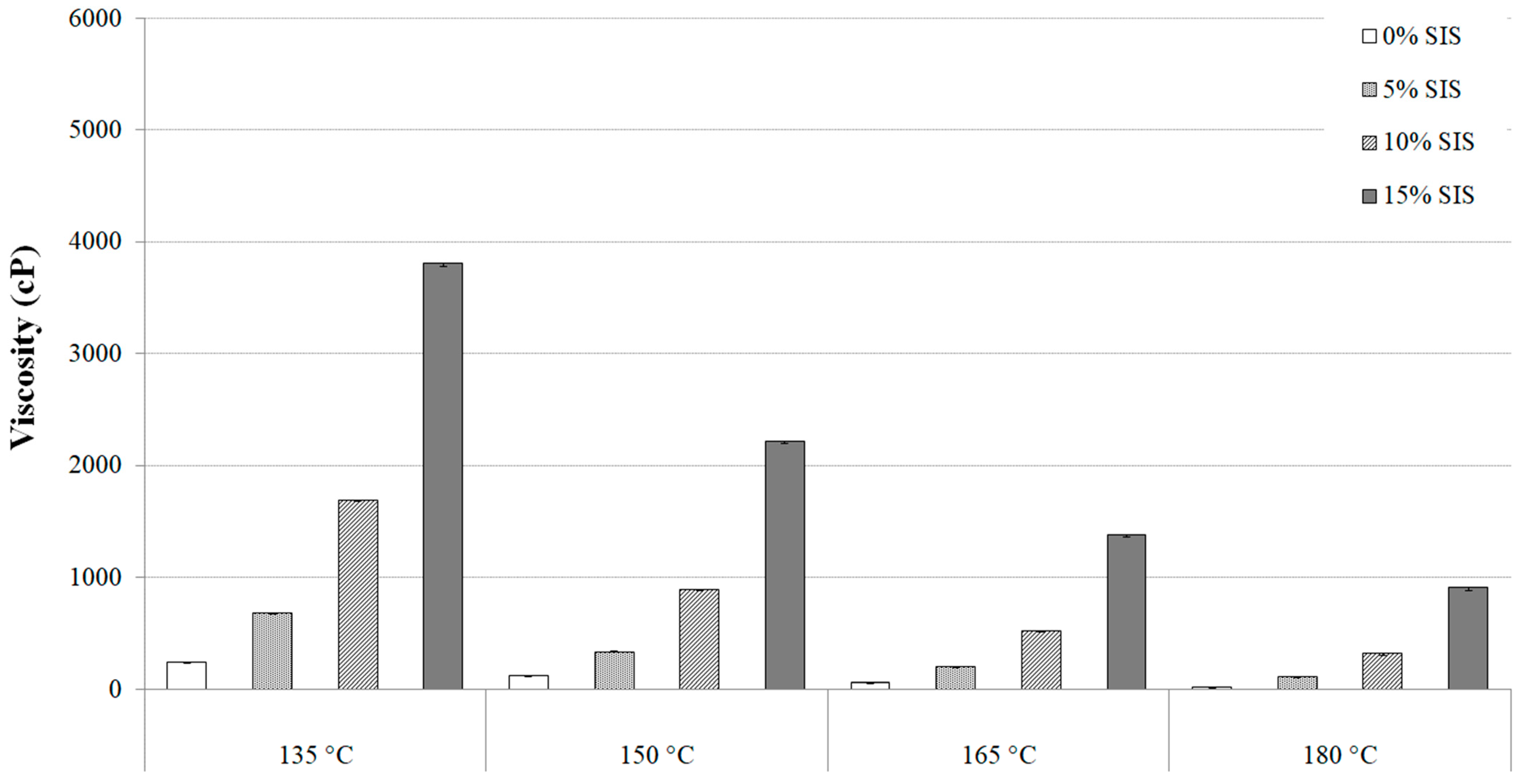

3.1. Viscosity

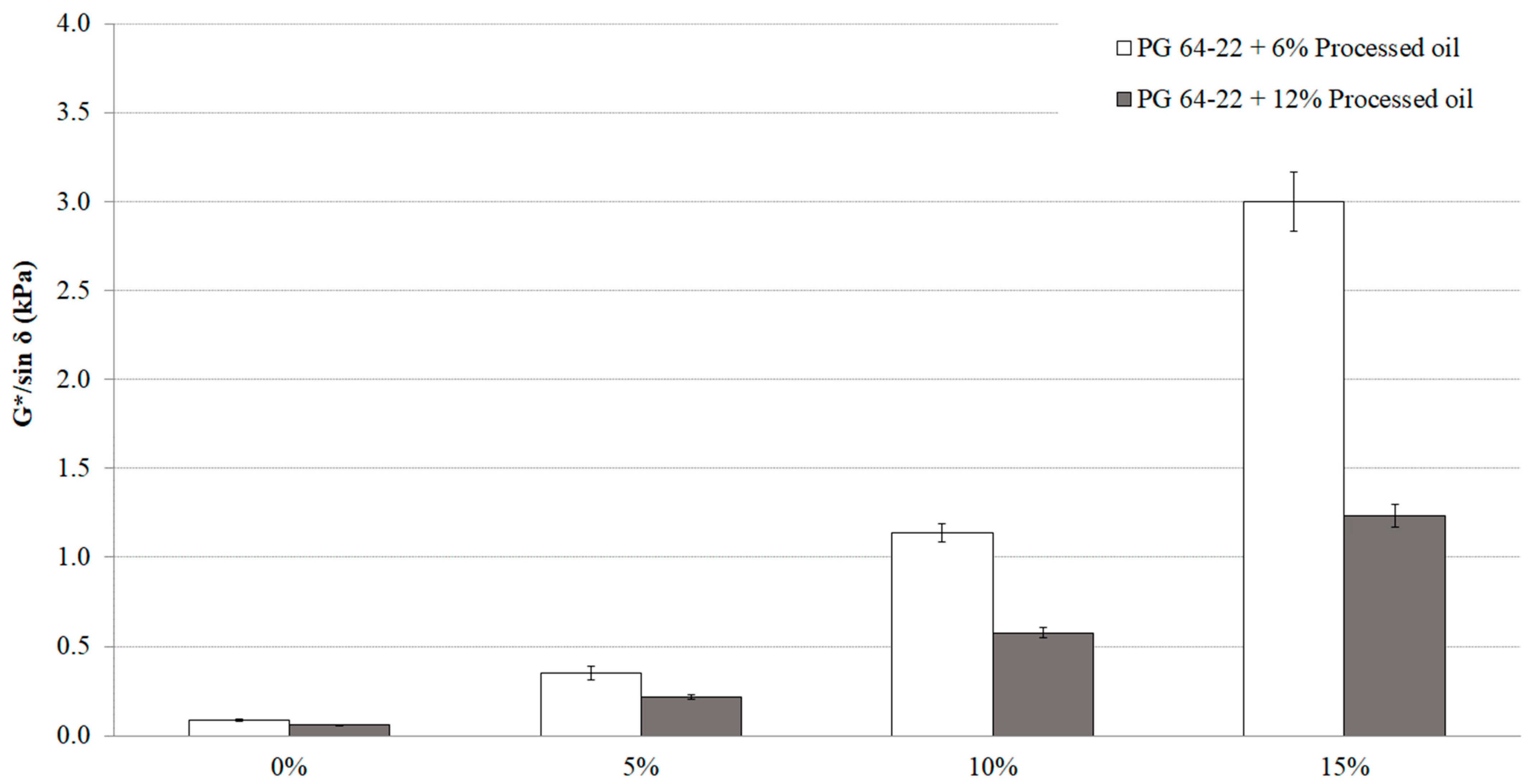

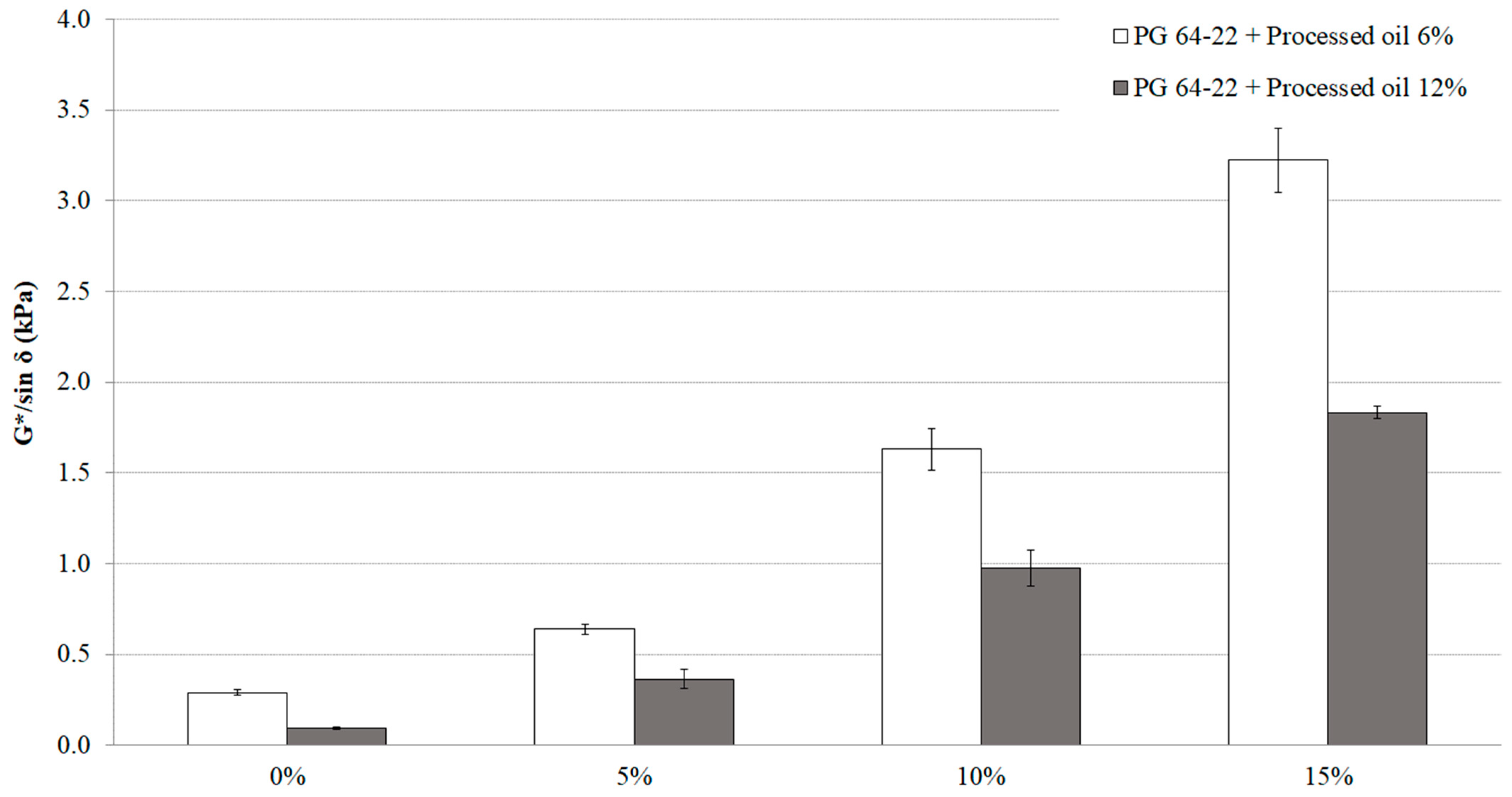

3.2. Rutting Properties

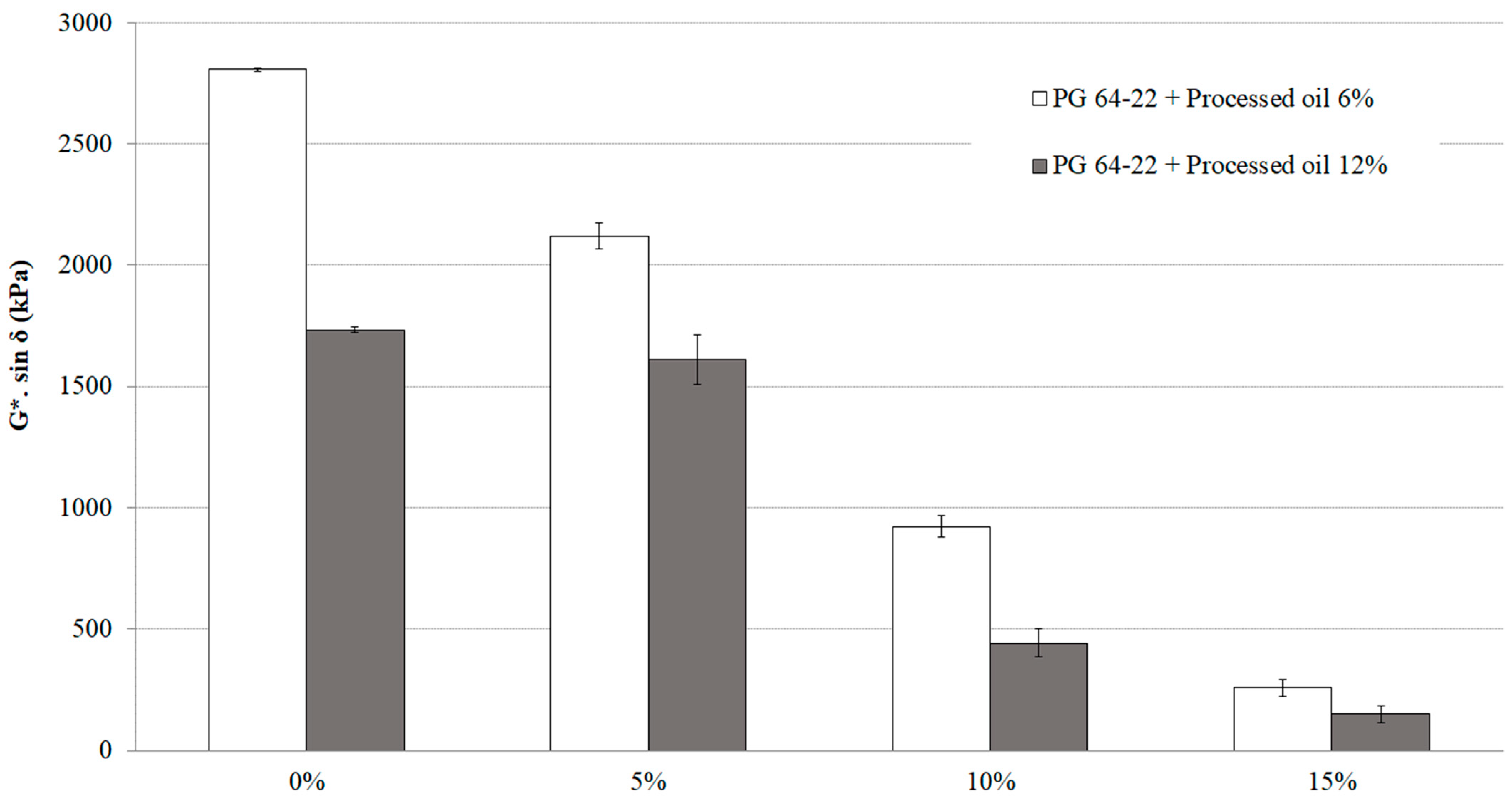

3.3. Fatigue Cracking

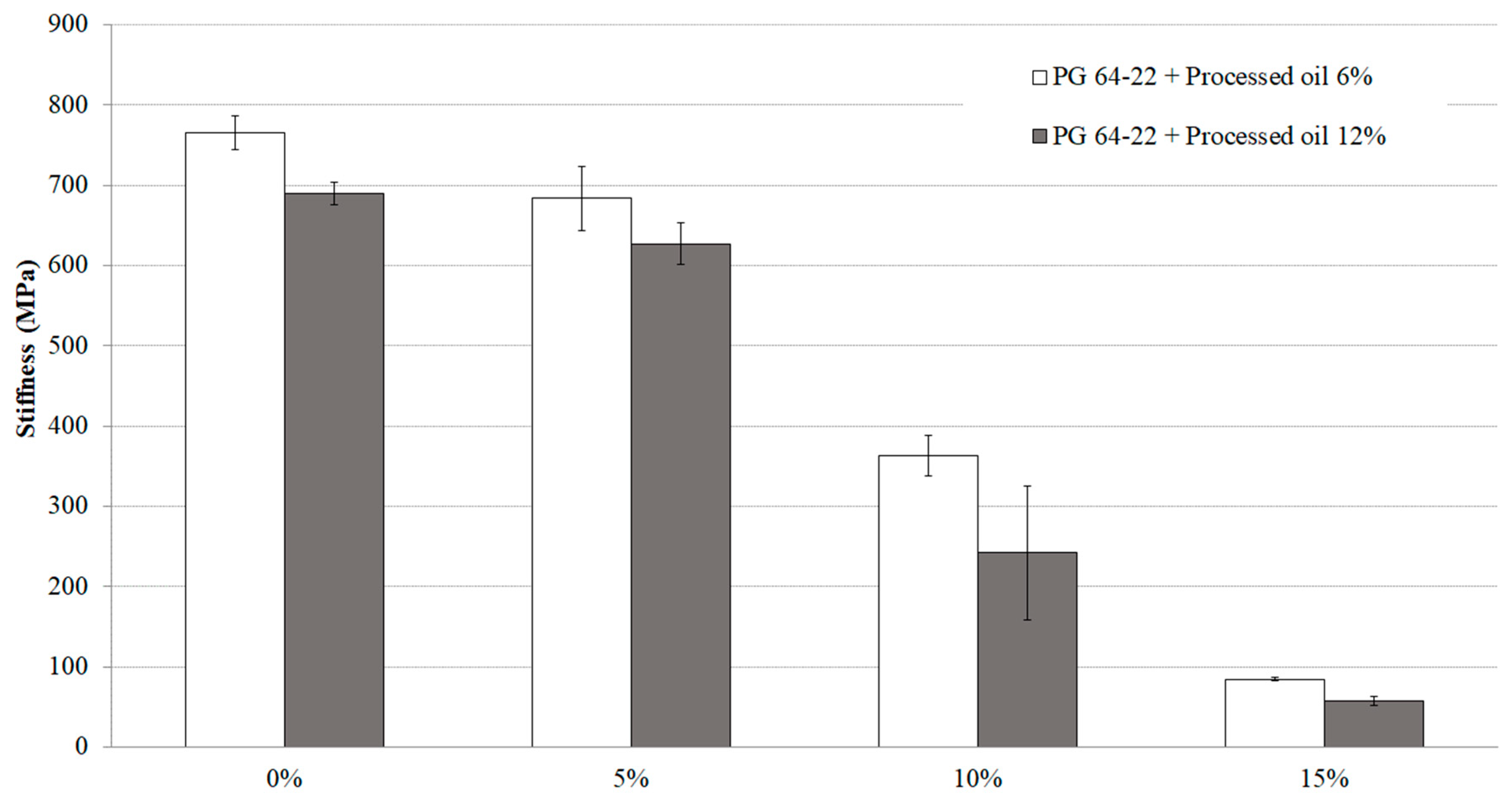

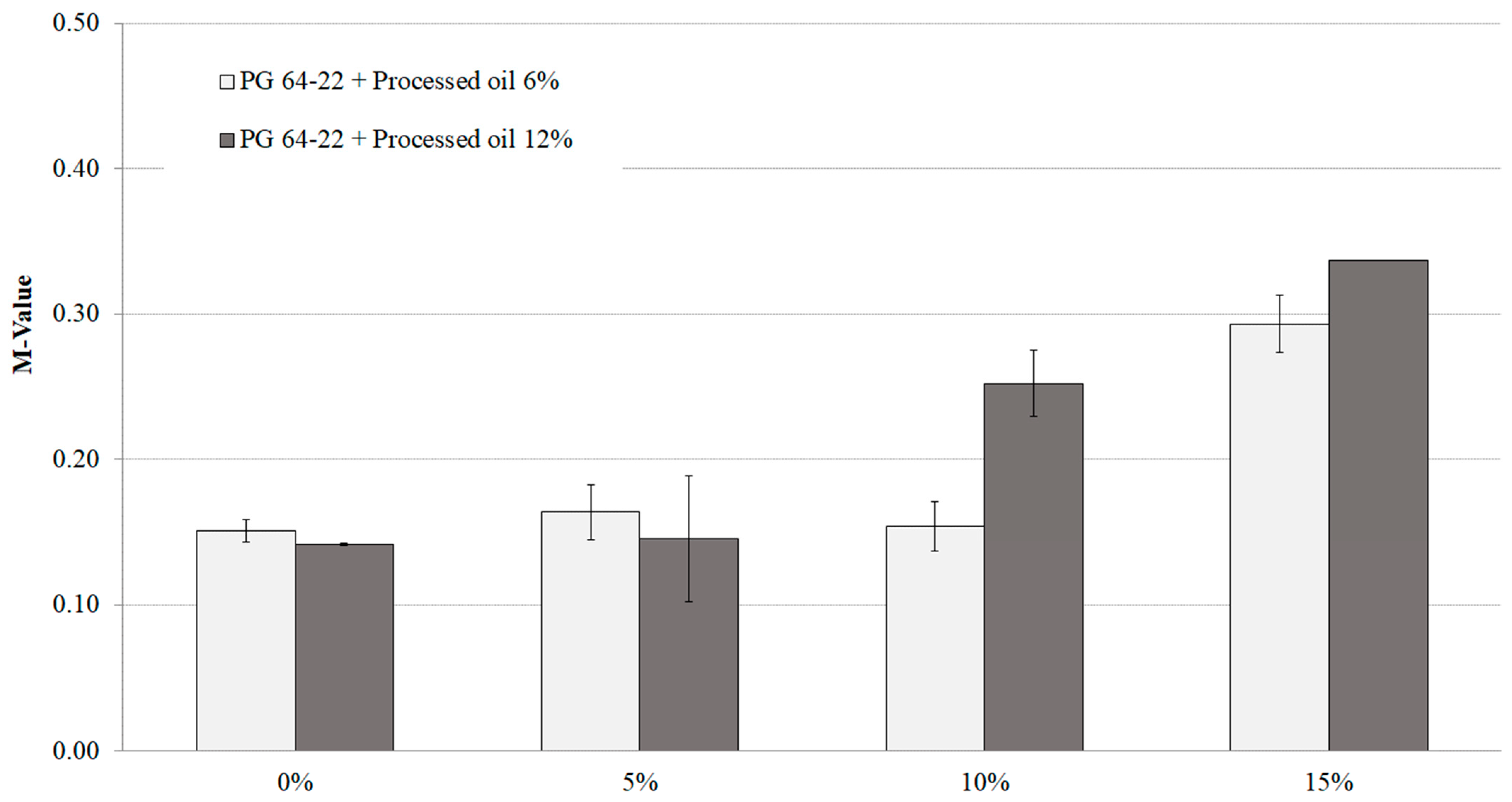

3.4. Thermal Cracking Resistance and Characteristics

4. Conclusions

- Although the addition of SIS increases viscosity, the presence of processed oil as a co-modifier leads to a substantial improvement in viscosity values. The modified asphalt binders containing 12% processed oil exhibit a more considerable reduction in viscosity for all SIS contents (5%, 10%, and 15%) when contrasted with the 6% processed oil modification.

- DSR testing revealed that the inclusion of processed oil mitigates the negative impact of SIS and enhances both viscosity and rutting performance at high temperatures. A decrease in G*/sin δ values was observed in modified asphalt binders at original and short-term (RTFO) aging states, which provides evidence of the positive effects of co-modification using processed oil and SIS.

- Values extracted from DSR, and evaluation of fatigue cracking tests showed a significant decrease due to addition of processed oil and SIS. The addition of processed oil had a positive effect on the viscosity and viscoelasticity of long-term-aged asphalt and its rejuvenating. Therefore, the application of processed oil along with SIS showed effectiveness in improving the resistance against fatigue cracking.

- The results of the BBR test indicated that the incorporation of processed oil and SIS caused a significant reduction in stiffness of asphalt binder modified with different contents of processed oil and SIS, while the same positive effect of this conjugation was observed in m-values. These results show the important role of processed oil in viscoelasticity of asphalt binders.

- Simultaneous application of processed oil and SIS had a positive effect on the resistance of asphalt binders at high and low temperatures, which shows how processed oil can be effective as a co-modifier in mixture design. It is desirable to study the impact of processed oil in conjunction with other modifiers such as SBS, CRM, SBR, and other common ones.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kriz, P.; Stastna, J.; Zanzotto, L. Glass transition and phase stability in asphalt binders. Road Mater. Pavement Des. 2008, 9 (Suppl. S1), 37–65. [Google Scholar] [CrossRef]

- Wang, J.; Sun, J.; Luo, S.; Li, Q. Laboratory and Field Performance Evaluation of High-Workability Ultra-Thin Asphalt Overlays. Materials 2022, 15, 2123. [Google Scholar] [CrossRef] [PubMed]

- Tabatabaee, H.A.; Velasquez, R.; Bahia, H.U. Predicting low temperature physical hardening in asphalt binders. Constr. Build. Mater. 2012, 34, 162–169. [Google Scholar] [CrossRef]

- Corbett, L.W.; Schweyer, H.E. Composition and Rheology Considerations in Age Hardening of Bitumen. Available online: https://trid.trb.org/view/725873 (accessed on 13 March 2023).

- Ou, L.; Zhu, H.; Xu, Y.; Chen, R.; Yang, X. Gray correlation entropy analysis of zero shear viscosity and high-temperature rheological parameters of phosphogypsum-modified asphalt. Case Stud. Constr. Mater. 2022, 17, e01448. [Google Scholar] [CrossRef]

- Hemmati, N.; Vigneswaran, S.; Mazumder, M.; Lee, M.S.; Lee, S.J. Laboratory Assessment of Modified Asphalt Binders Using Crumb Rubber Modifier (CRM) and Processed Oil. Constr. Mater. 2023, 3, 93–109. [Google Scholar] [CrossRef]

- Diab, A.; You, L.; Saboo, N.; Li, X. Appraising bitumen coverage, workability, and production temperatures of warm asphalt-aggregate blends. Road Mater. Pavement Des. 2022, 24, 1793–1819. [Google Scholar] [CrossRef]

- Hemmati, N.; Vigneswaran, S.; Kim, H.H.; Lee, M.S.; Lee, S.J. Laboratory Evaluation of Asphalt Binders Containing Styrene-Butadiene-Styrene (SBS) and Processed Oil. Materials 2023, 16, 1235. [Google Scholar] [CrossRef] [PubMed]

- Ameri, M.; Abdipour, S.V.; Yengejeh, A.R.; Shahsavari, M.; Yousefi, A.A. Evaluation of rubberised asphalt mixture including natural Zeolite as a warm mix asphalt (WMA) additive. Int. J. Pavement Eng. 2022, 1–12. [Google Scholar] [CrossRef]

- Ji, B.; Lee, S.J.; Mazumder, M.; Lee, M.S.; Kim, H.H. Deep regression prediction of rheological properties of SIS-modified asphalt binders. Materials 2020, 13, 5738. [Google Scholar] [CrossRef] [PubMed]

- Mazumder, M.; Siddique, A.; Ahmed, R.; Lee, S.J.; Lee, M.S. Rheological and Morphological Characterization of Styrene-Isoprene-Styrene (SIS) Modified Asphalt Binder. Adv. Civ. Eng. 2020, 2020, 8877371. [Google Scholar] [CrossRef]

- Zhao, R.; Jing, F.; Li, C.; Wang, R.; Xi, Z.; Cai, J.; Wang, Q.; Xie, H. Viscosity-curing time behavior, viscoelastic properties, and phase separation of graphene oxide/epoxy asphalt composites. Polym. Compos. 2022, 43, 5454–5464. [Google Scholar] [CrossRef]

- Halle, M.; Rukavina, T.; Domitrovic, J. Influence of temperature on asphalt stiffness modulus. In Proceedings of the 5th Eurasphalt Eurobitume Congress, Istanbul, Turkey, 13–15 June 2012; pp. 13–15. [Google Scholar]

- Yan, S.; Dong, Q.; Chen, X.; Zhou, C.; Dong, S.; Gu, X. Application of waste oil in asphalt rejuvenation and modification: A comprehensive review. Constr. Build. Mater. 2022, 340, 127784. [Google Scholar] [CrossRef]

- Borhan, M.N.; Suja, F.; Ismail, A.; Rahmat RA, O.K. The effects of used cylinder oil on asphalt mixes. Eur. J. Sci. Res. 2009, 28, 398–411. Available online: http://www.eurojournals.com/ejsr.htm (accessed on 1 January 2009).

- Woszuk, A.; Wróbel, M.; Franus, W. Influence of waste engine oil addition on the properties of zeolite-foamed asphalt. Materials 2019, 12, 2265. [Google Scholar] [CrossRef] [PubMed]

- Sonibare, K.; Rucker, G.; Zhang, L. Molecular dynamics simulation on vegetable oil modified model asphalt. Constr. Build. Mater. 2021, 270, 121687. [Google Scholar] [CrossRef]

- Shoukat, T.; Yoo, P.J. Rheology of asphalt binder modified with 5W30 viscosity grade waste engine oil. Appl. Sci. 2018, 8, 1194. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, K. Review on performance of asphalt and asphalt mixture with waste cooking oil. Materials 2023, 16, 1341. [Google Scholar] [CrossRef] [PubMed]

- Asphalt Institute. Individual Asphalt Binder Tests; Asphalt Institute: Lexington, KY, USA, 2003; Available online: https://interstatetesting.com/binder-lab/ (accessed on 19 November 2021).

| Aging States | Test Properties | Test Condition | PG 64-22 |

|---|---|---|---|

| Original | Viscosity (cP) | At 135 °C | 538 |

| G*/sin δ (kPa) | At 64 °C | 2.20 | |

| Short-term-aged residual RTFO | G*/sin δ (kPa) | At 64 °C | 3.40 |

| Long-term-aged residual RTFO+PAV | G*sin δ (kPa) | At 25 °C | 4400 |

| Stiffness (MPa) | At −12 °C | 187 | |

| m-value | At −12 °C | 0.32 |

| Parameter | Unit | Value |

|---|---|---|

| Styrene Grade | 4113 A/4113 N | |

| Polymer Structure | Linear | |

| Styrene | wt% | 15.0 |

| Melt Flow | g/10 min (200 °C/5 kg) | 11.0 |

| Viscosity | mPa-s | 1240.0 |

| Ash Content | wt% | 0.3 |

| Volatiles | wt% | 0.2 |

| Specific Gravity | 0.92 | |

| Tensile Strength | psi (MPa) | 3600 (25) |

| Elongation | % | 1250.0 |

| Hardness, Shore A | 33.0 |

| Test | Test Condition | Unit | Value | Specification |

|---|---|---|---|---|

| Relative Density | At 15 °C | 1.0049 | D4052 | |

| Flash Point | Cleveland Open Cup | °C | 228.0 | D92 |

| Kinematic Viscosity | At 98.9 °C | cm2/minute | 13.554 | D 445 |

| At 100 °C | cm2/minute | 12.918 | D 445 | |

| Pour Point | °C | +15 | D 97 | |

| Viscosity Gravity Constant | 0.9555 | D 2140 | ||

| Hydrocarbon Type | Aromatic | % | 41.9 | D 2140 |

| Naphtenic | % | 26.2 | D 2140 | |

| Paraffinic | % | 31.9 | D 2140 |

| Viscosity | 135 °C | 150 °C | 165 °C | 180 °C | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SIS% | 0 | 5 | 10 | 15 | 0 | 5 | 10 | 15 | 0 | 5 | 10 | 15 | 0 | 5 | 10 | 15 | |

| 135 °C | 0 | - | S | S | S | S | S | S | S | S | N | S | S | S | S | S | S |

| 5 | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| 10 | - | S | S | S | S | S | S | S | S | S | S | S | S | S | |||

| 15 | - | S | S | S | S | S | S | S | S | S | S | S | S | ||||

| 150 °C | 0 | - | S | S | S | S | S | S | S | S | N | S | S | ||||

| 5 | - | S | S | S | S | S | S | S | S | N | S | ||||||

| 10 | - | S | S | S | S | S | S | S | S | S | |||||||

| 15 | - | S | S | S | S | S | S | S | S | ||||||||

| 165 °C | 0 | - | S | S | S | S | S | S | S | ||||||||

| 5 | - | S | S | S | S | S | S | ||||||||||

| 10 | - | S | S | S | S | S | |||||||||||

| 15 | - | S | S | S | S | ||||||||||||

| 180 °C | 0 | - | S | S | S | ||||||||||||

| 5 | - | S | S | ||||||||||||||

| 10 | - | S | |||||||||||||||

| 15 | - | ||||||||||||||||

| Viscosity | 135 °C | 150 °C | 165 °C | 180 °C | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SIS% | 0 | 5 | 10 | 15 | 0 | 5 | 10 | 15 | 0 | 5 | 10 | 15 | 0 | 5 | 10 | 15 | |

| 135 °C | 0 | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S |

| 5 | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | ||

| 10 | - | S | S | S | S | S | S | S | S | S | S | S | S | S | |||

| 15 | - | S | S | S | S | S | S | S | S | S | S | S | S | ||||

| 150 °C | 0 | - | S | S | S | S | S | S | S | S | N | S | S | ||||

| 5 | - | S | S | S | S | S | S | S | S | N | S | ||||||

| 10 | - | S | S | S | S | S | S | S | S | N | |||||||

| 15 | - | S | S | S | S | S | S | S | S | ||||||||

| 165 °C | 0 | - | S | S | S | S | S | S | S | ||||||||

| 5 | - | S | S | S | S | S | S | ||||||||||

| 10 | - | S | S | S | S | S | |||||||||||

| 15 | - | S | S | S | S | ||||||||||||

| 180 °C | 0 | - | S | S | S | ||||||||||||

| 5 | - | S | S | ||||||||||||||

| 10 | - | S | |||||||||||||||

| 15 | - | ||||||||||||||||

| G*/sin δ | SIS % | 0 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| PG 64-22 and Processed Oil 6% | 0 | - | N | N | S |

| 5 | - | N | S | ||

| 10 | - | S | |||

| 15 | - | ||||

| PG 64-22 and Processed Oil 12% | 0 | - | N | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - |

| G*/sin δ | SIS % | 0 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| PG 64-22 and Processed Oil 6% | 0 | - | S | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - | ||||

| PG 64-22 and Processed Oil 12% | 0 | - | S | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - |

| G*sin δ | SIS % | 0 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| PG 64-22 and Processed Oil 6% | 0 | - | S | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - | ||||

| PG 64-22 and Processed Oil 12% | 0 | - | S | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - |

| Stiffness | SIS % | 0 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| PG 64-22 and Processed Oil 6% | 0 | - | S | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - | ||||

| PG 64-22 and Processed Oil 12% | 0 | - | S | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - |

| Stiffness | SIS % | 0 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| PG 64-22 + Processed Oil 6% | 0 | - | S | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - | ||||

| PG 64-22 + Processed Oil 12% | 0 | - | N | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - |

| m-Value | SIS % | 0 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| PG 64-22 and Processed Oil 6% | 0 | - | N | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - | ||||

| PG 64-22 and Processed Oil 12% | 0 | - | N | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - |

| m-Value | SIS % | 0 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| PG 64-22 and Processed Oil 6% | 0 | - | N | N | S |

| 5 | - | N | S | ||

| 10 | - | S | |||

| 15 | - | ||||

| PG 64-22 and Processed Oil 12% | 0 | - | N | S | S |

| 5 | - | S | S | ||

| 10 | - | S | |||

| 15 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hemmati, N.; Yun, J.; Mazumder, M.; Lee, M.-S.; Lee, S.-J. Characterization of Sustainable Asphalt Binders Modified with Styrene–Isoprene–Styrene (SIS) and Processed Oil. Sustainability 2023, 15, 9464. https://doi.org/10.3390/su15129464

Hemmati N, Yun J, Mazumder M, Lee M-S, Lee S-J. Characterization of Sustainable Asphalt Binders Modified with Styrene–Isoprene–Styrene (SIS) and Processed Oil. Sustainability. 2023; 15(12):9464. https://doi.org/10.3390/su15129464

Chicago/Turabian StyleHemmati, Navid, Jihyeon Yun, Mithil Mazumder, Moon-Sup Lee, and Soon-Jae Lee. 2023. "Characterization of Sustainable Asphalt Binders Modified with Styrene–Isoprene–Styrene (SIS) and Processed Oil" Sustainability 15, no. 12: 9464. https://doi.org/10.3390/su15129464

APA StyleHemmati, N., Yun, J., Mazumder, M., Lee, M.-S., & Lee, S.-J. (2023). Characterization of Sustainable Asphalt Binders Modified with Styrene–Isoprene–Styrene (SIS) and Processed Oil. Sustainability, 15(12), 9464. https://doi.org/10.3390/su15129464