A Feature Fusion Method for Driving Fatigue of Shield Machine Drivers Based on Multiple Physiological Signals and Auto-Encoder

Abstract

1. Introduction

2. Analysis of Driving Fatigue Generation Mechanism of Shield Drivers

2.1. Perceptual Information

2.2. Judgment and Strategy

2.3. Operation Task

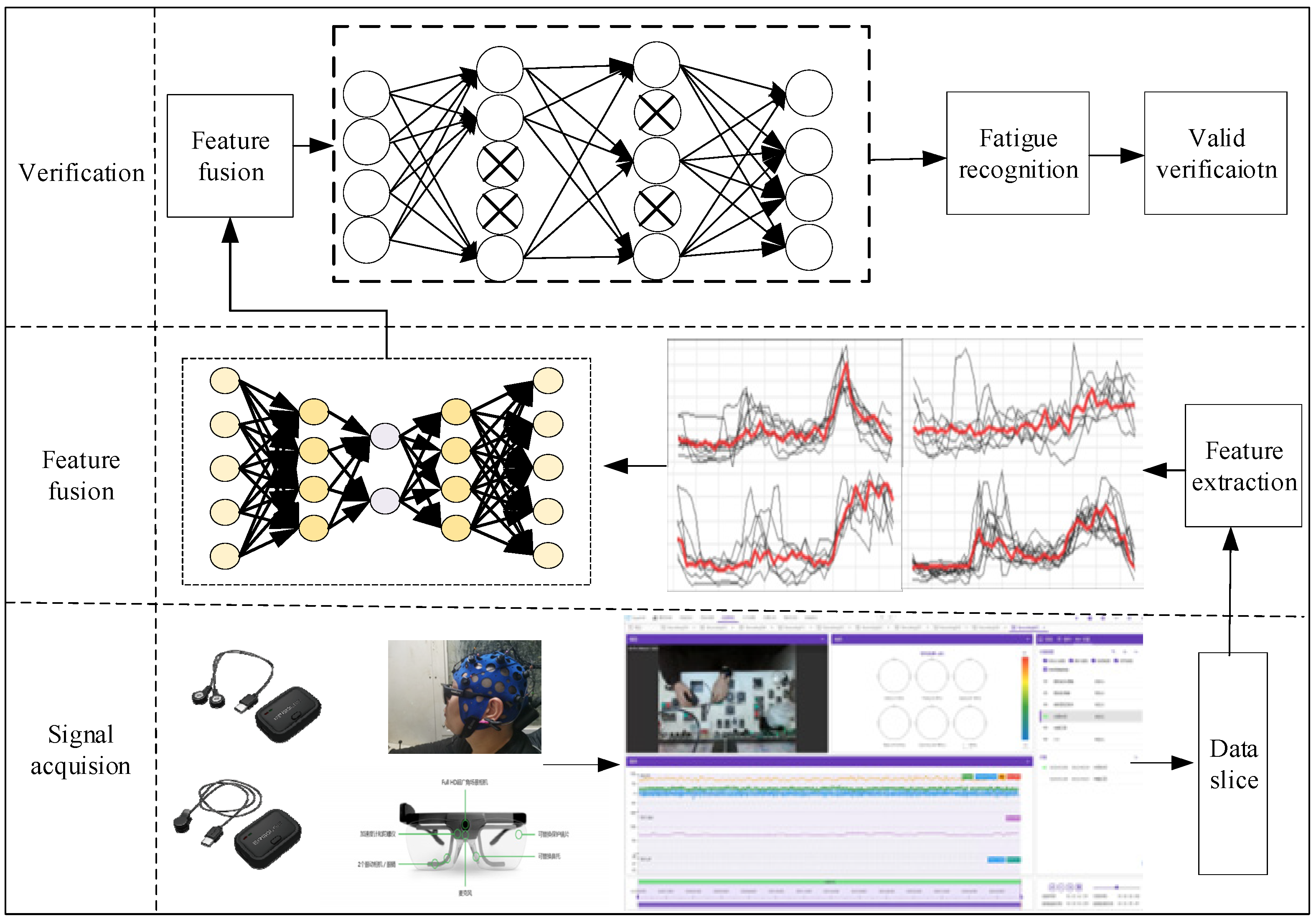

3. Feature Extraction Method for Multi-Physiological Signals of Shield Drivers

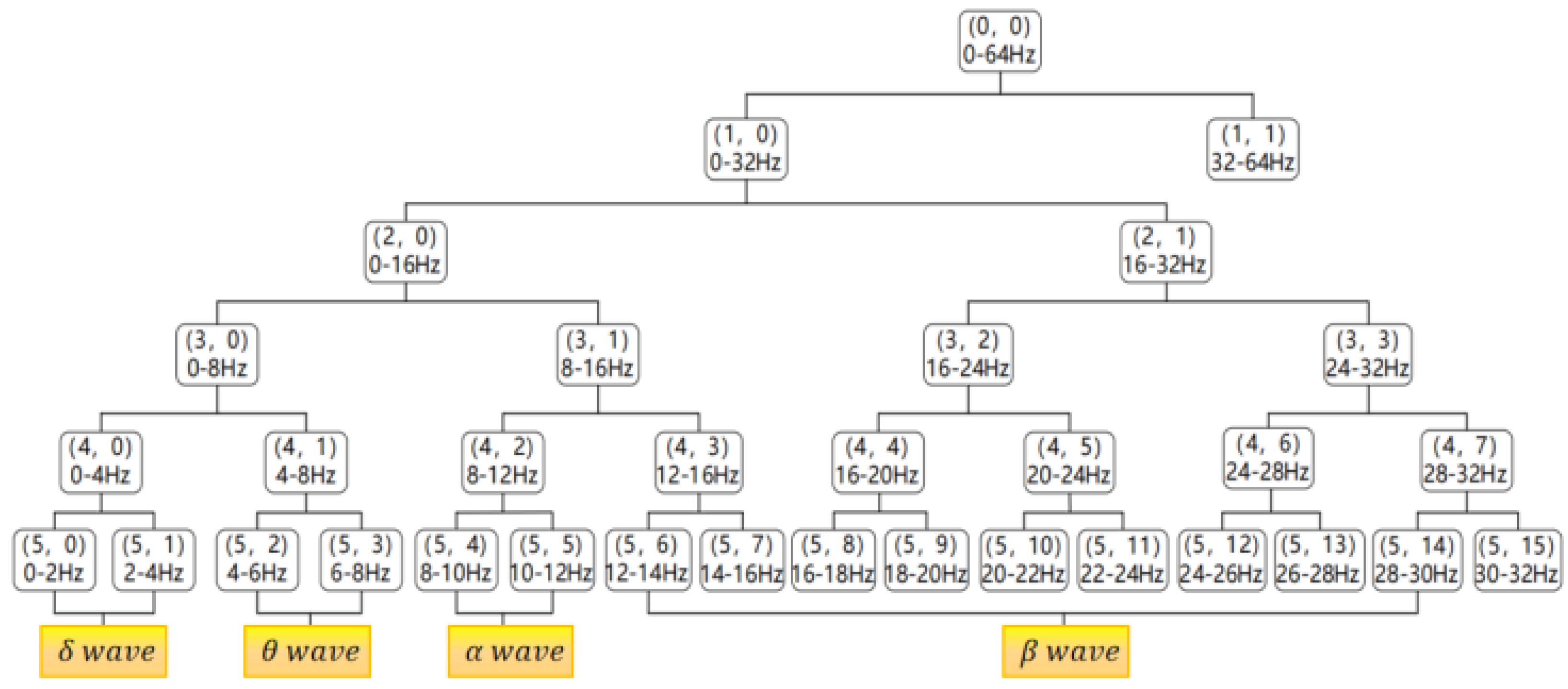

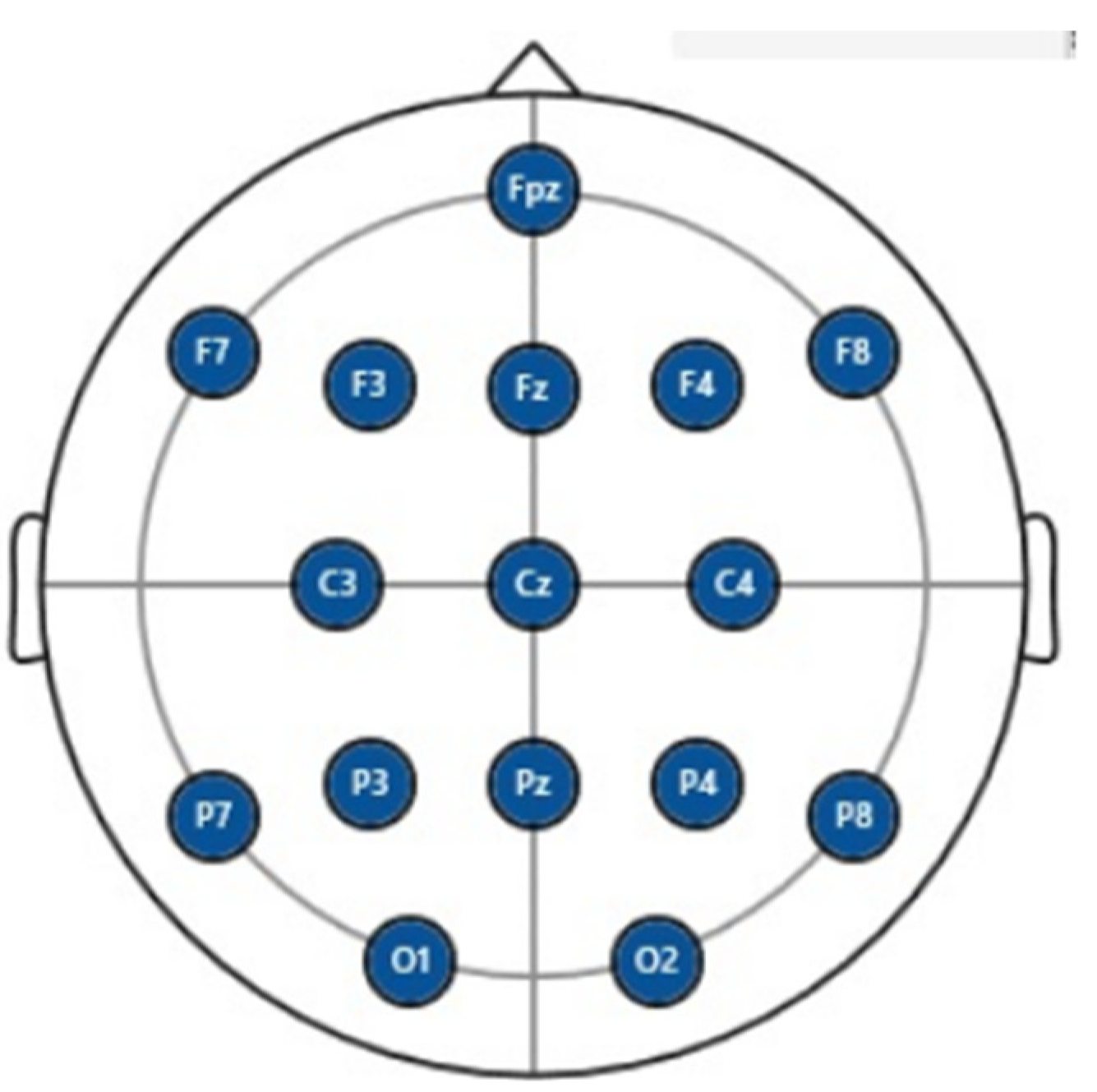

3.1. WPT-Based EEG Signal Feature Extraction for Shield Drivers

3.1.1. Analysis of EEG Signal Characteristics of Shield Drivers

3.1.2. WPT-Based EEG Feature Extraction Method for Shield Drivers

3.2. Feature Extraction from ECG of Shield Machine Drivers Based on Time–Frequency-Domain Analysis

3.2.1. HRV Time-Domain Index

3.2.2. HRV Frequency-Domain Index

4. Shield Machine Driver Multi-Modal Physiological Characteristics Fusion Method Based on Auto-Encoder of L2 Regularization

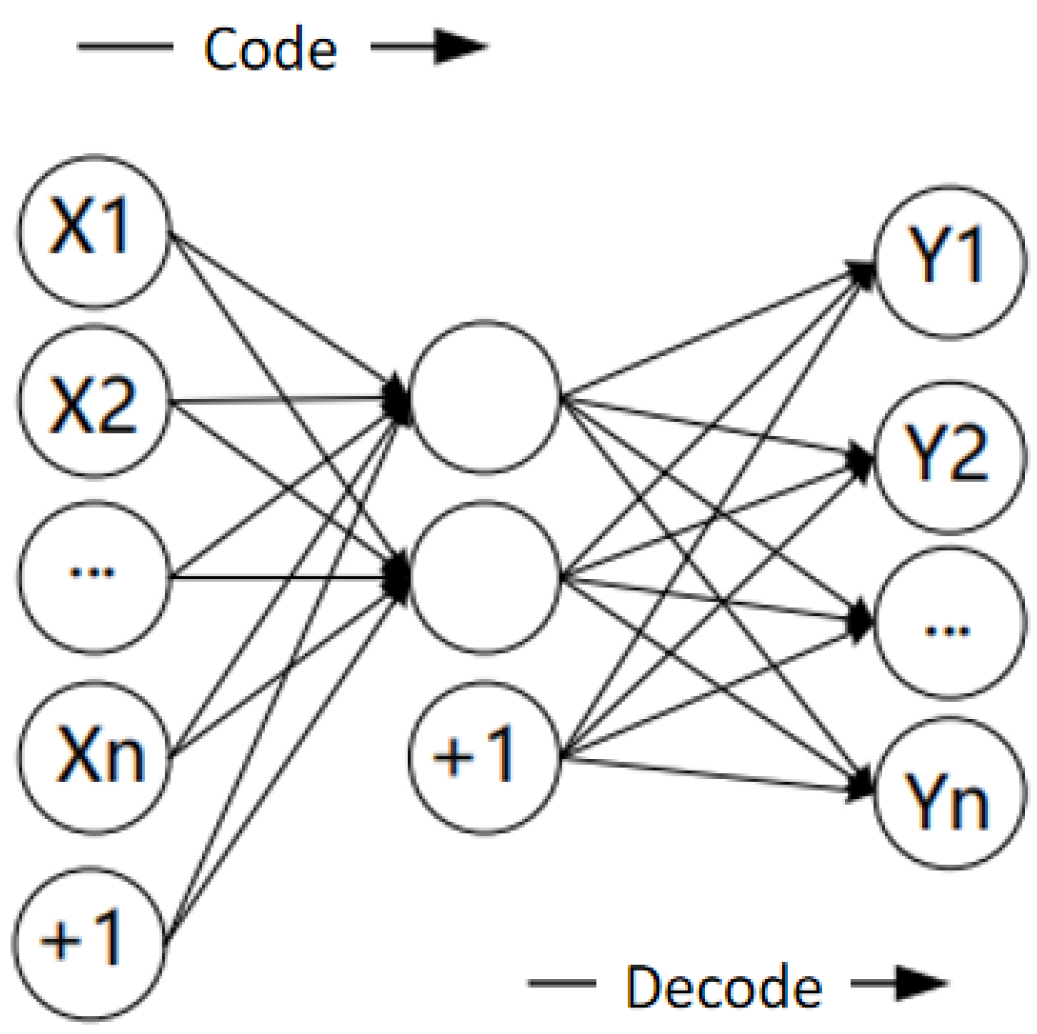

4.1. Auto-Encoder

4.2. L2 Regularization

4.3. Sigmoid Function

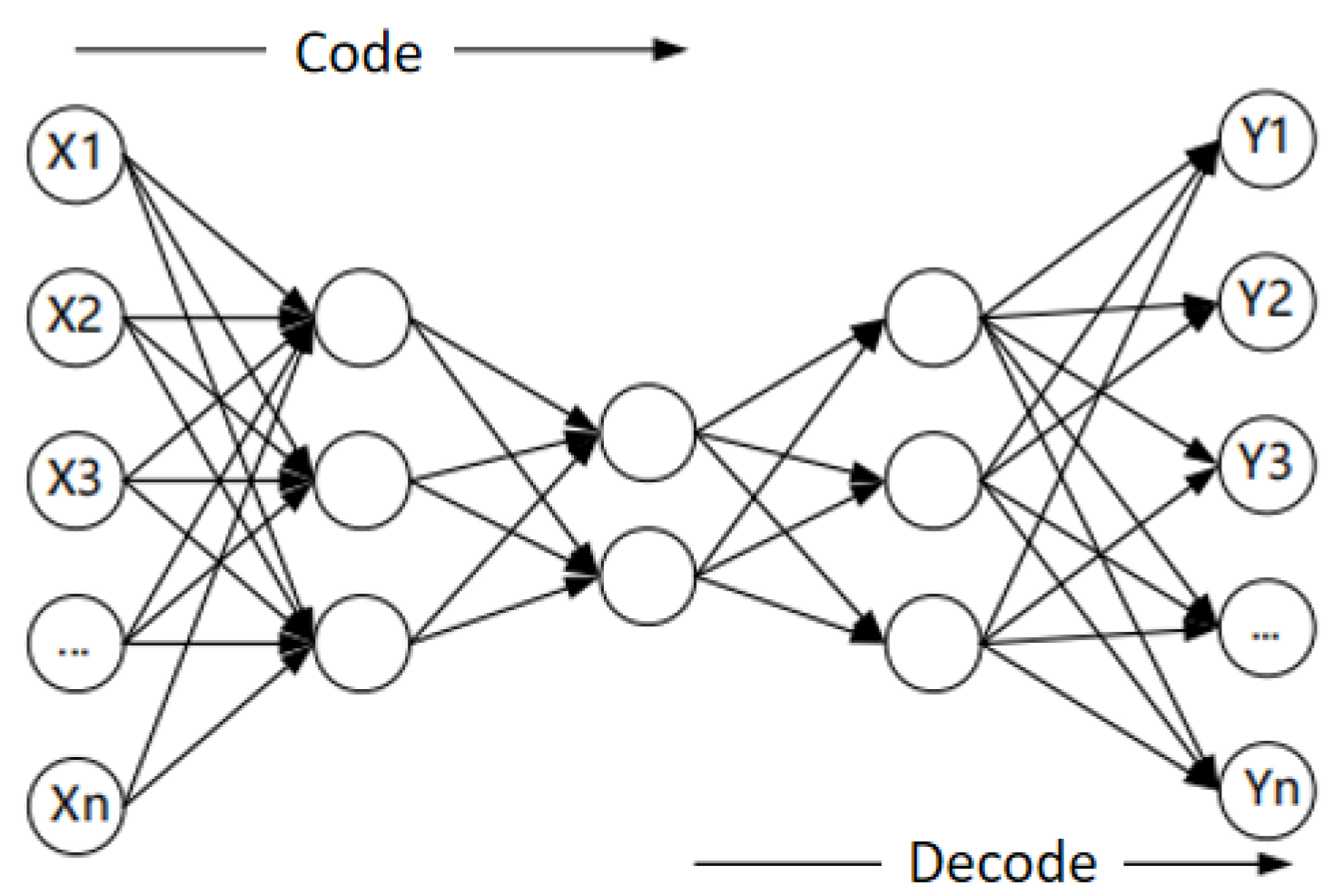

4.4. Stacked Auto-Encoder

4.5. Softmax Classifier

4.6. Fusion Method of Driving Fatigue Characteristics of Shield Drivers Based on L2-SAE

5. Experiment

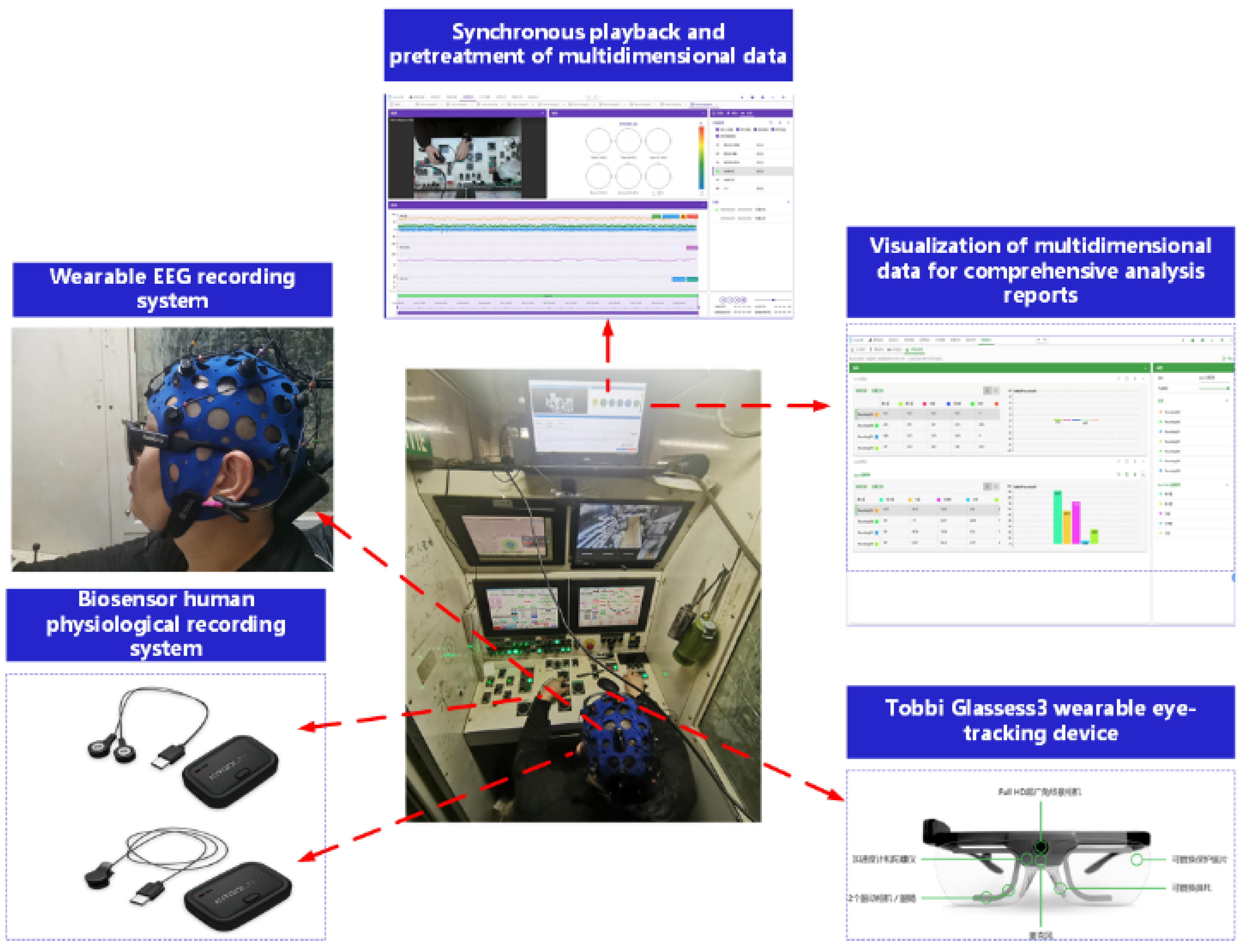

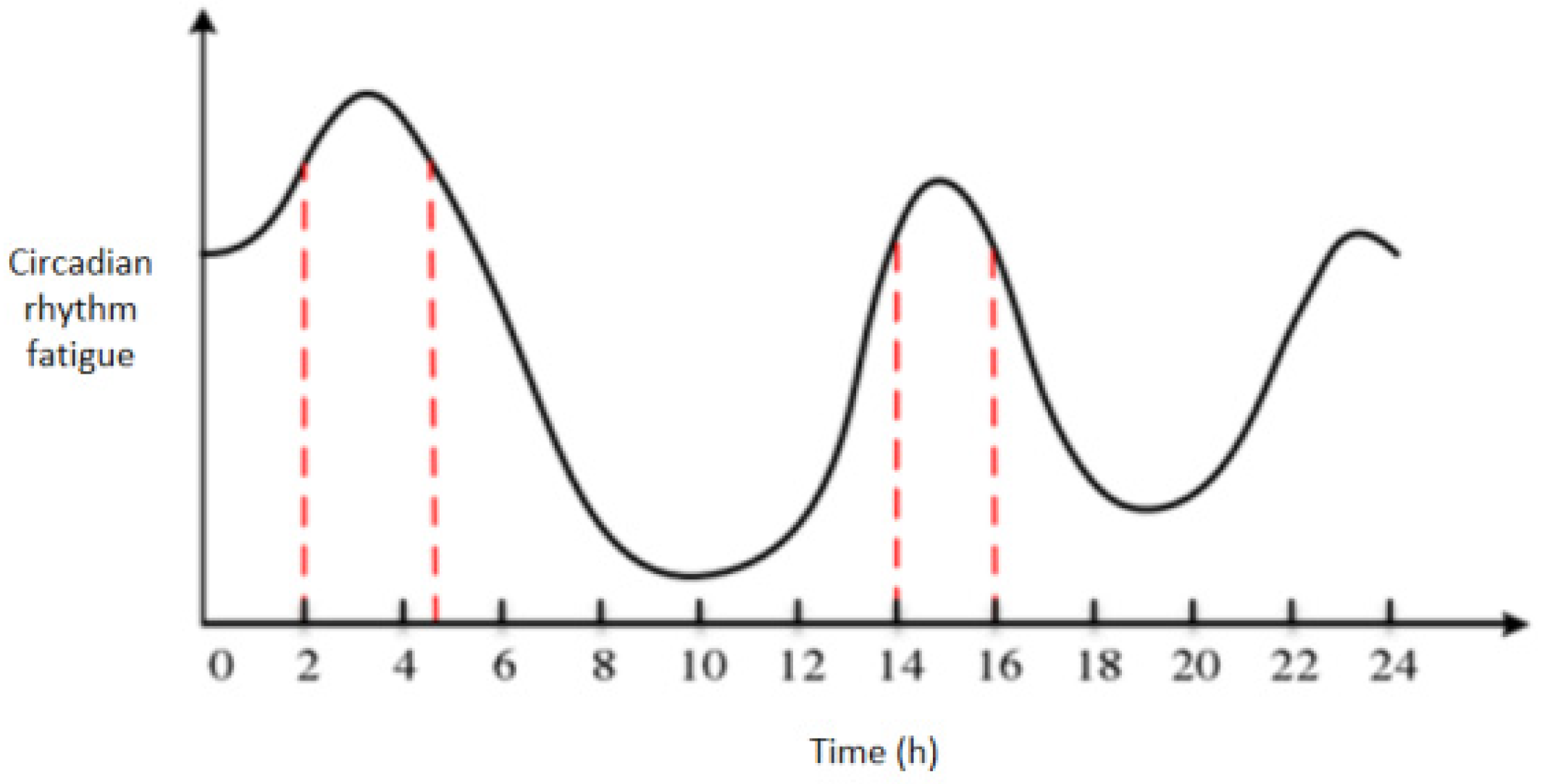

5.1. Experimental Conditions

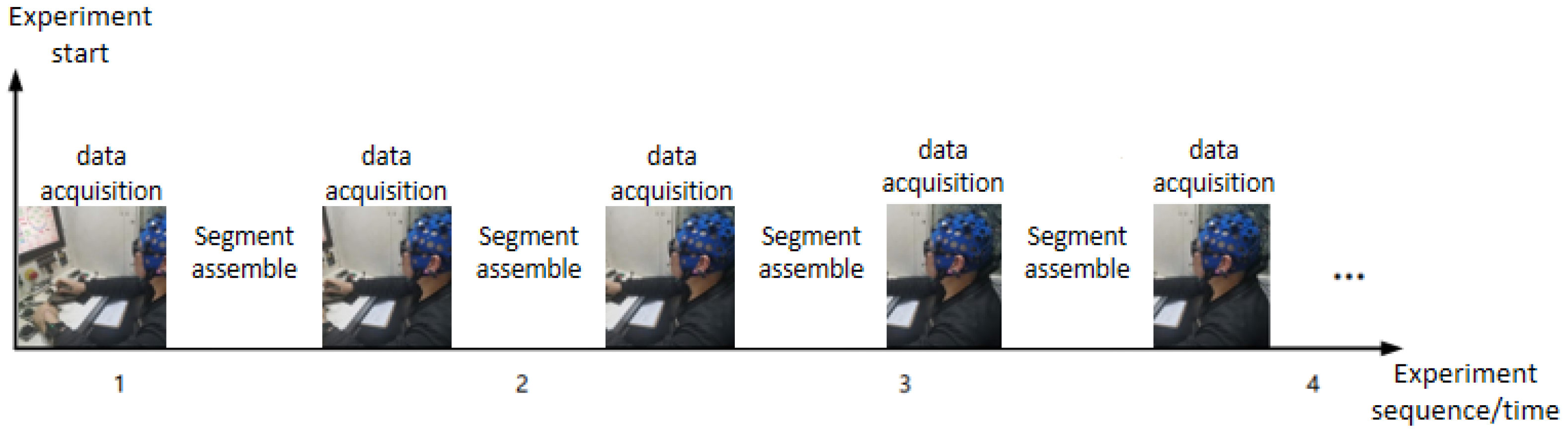

5.2. Experimental Process Design

- Debug the cloud platform to the working state to ensure that all modules are correctly connected.

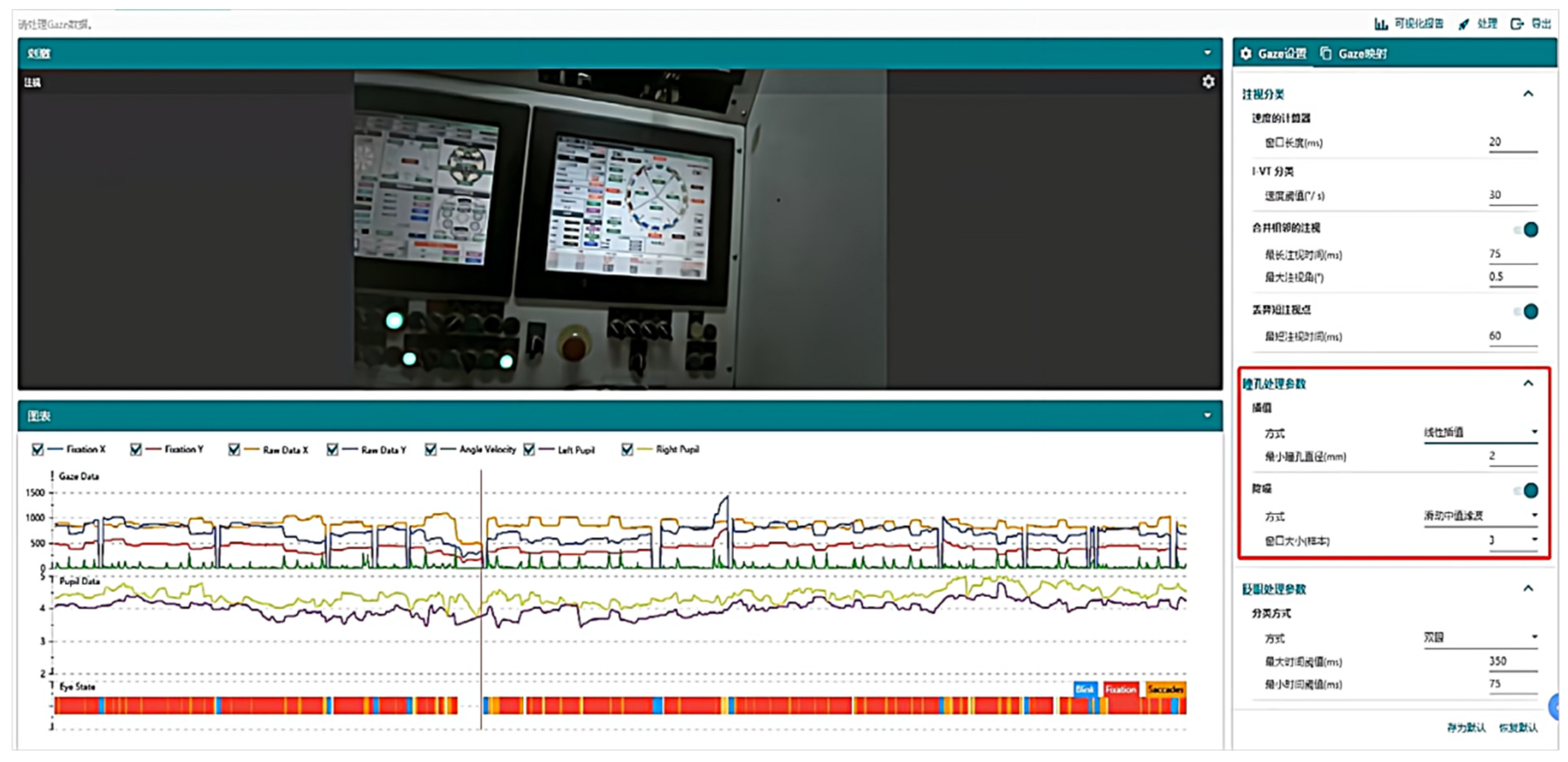

- Before they drive, have the subjects wear EEG caps, wearable eye movement meters and ECG sensors, and begin to collect relevant data (including personal data) after working for a few minutes.

- Ensure that the subjects complete the driving operation according to the normal work flow; read the stimulation information on the monitoring and control display; and perform the key, knob and other operations on the operating console. At the same time, record the subjects’ eye movement, EEG, pulse and skin electrical data.

- Remove the equipment.

- Repeat steps (2) and (3).

- Experiment complete; save the relevant data.

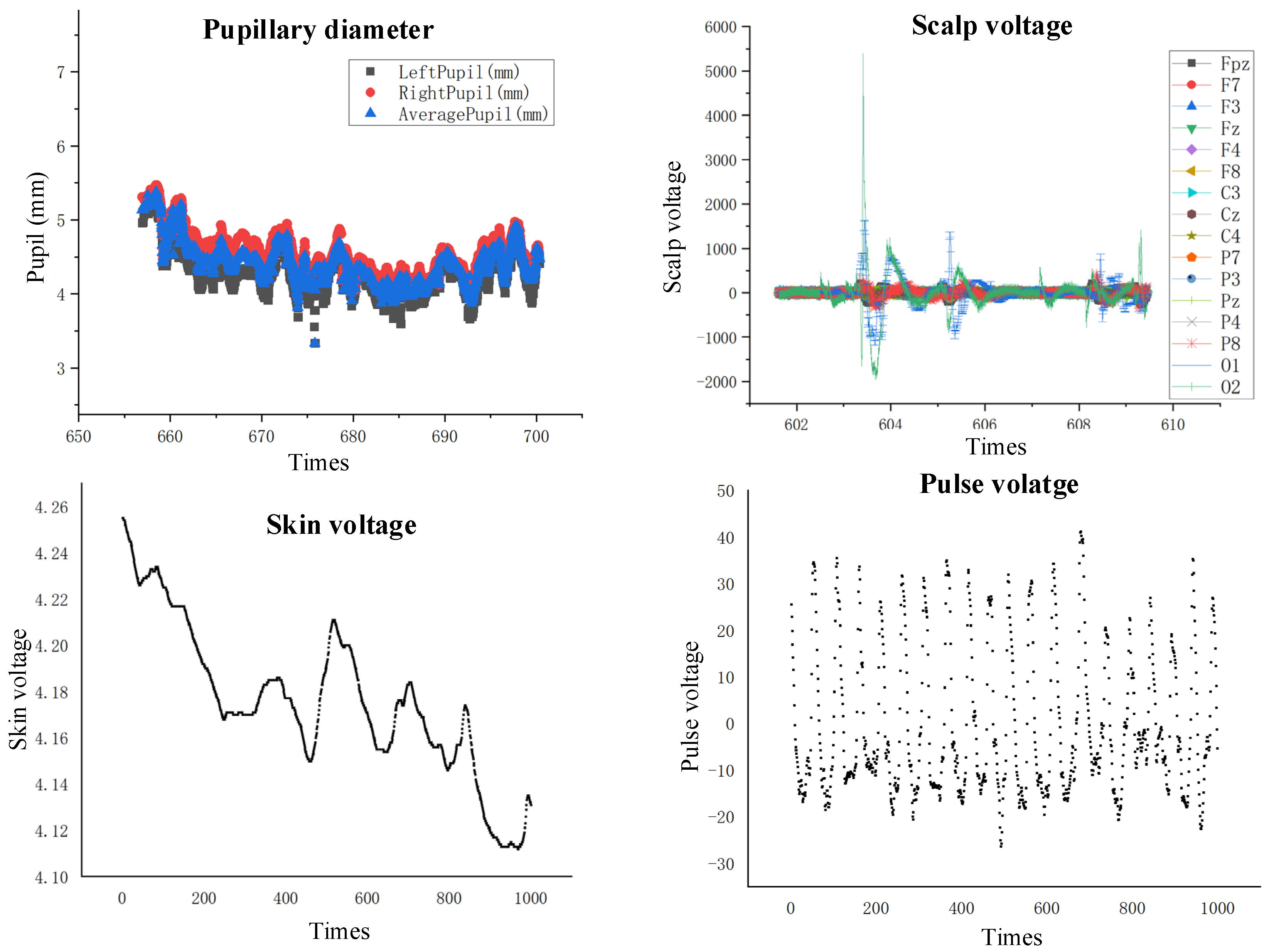

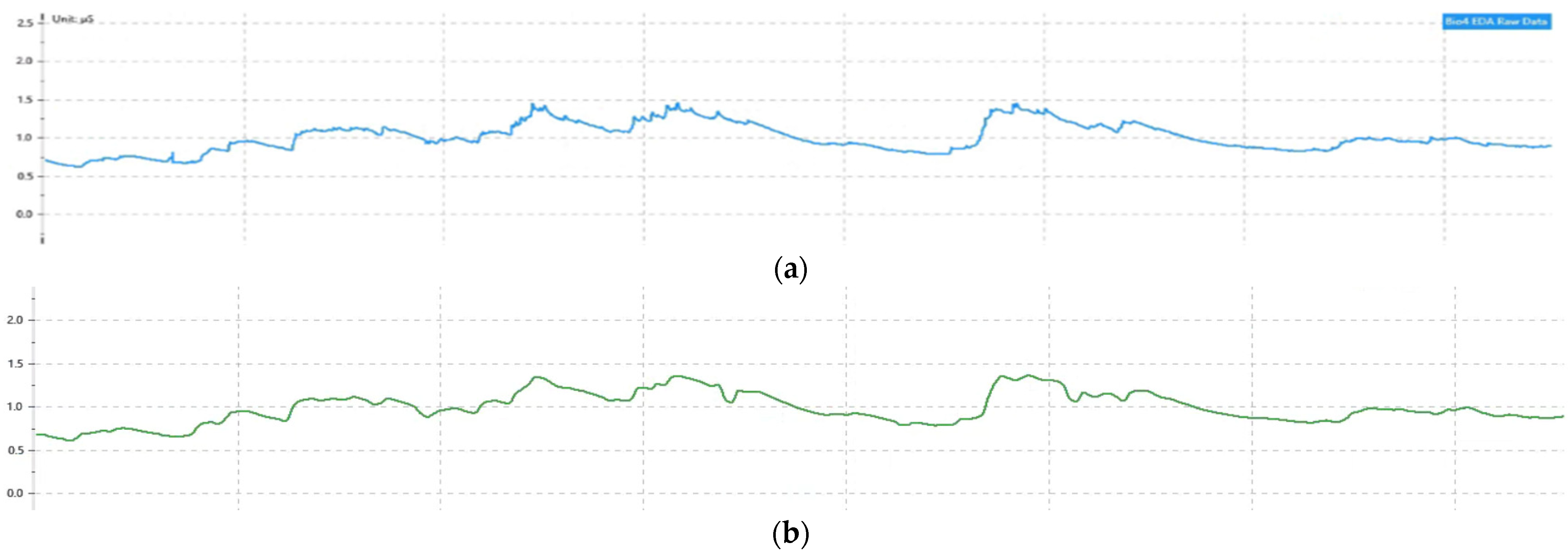

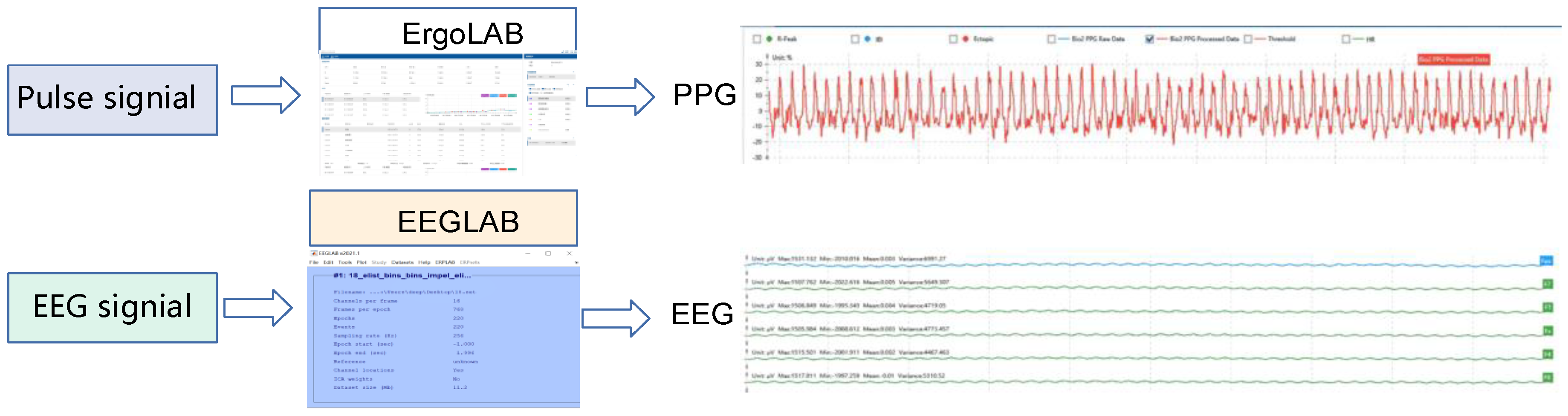

- The collected raw data are shown in Figure 9.

5.3. Data Analysis

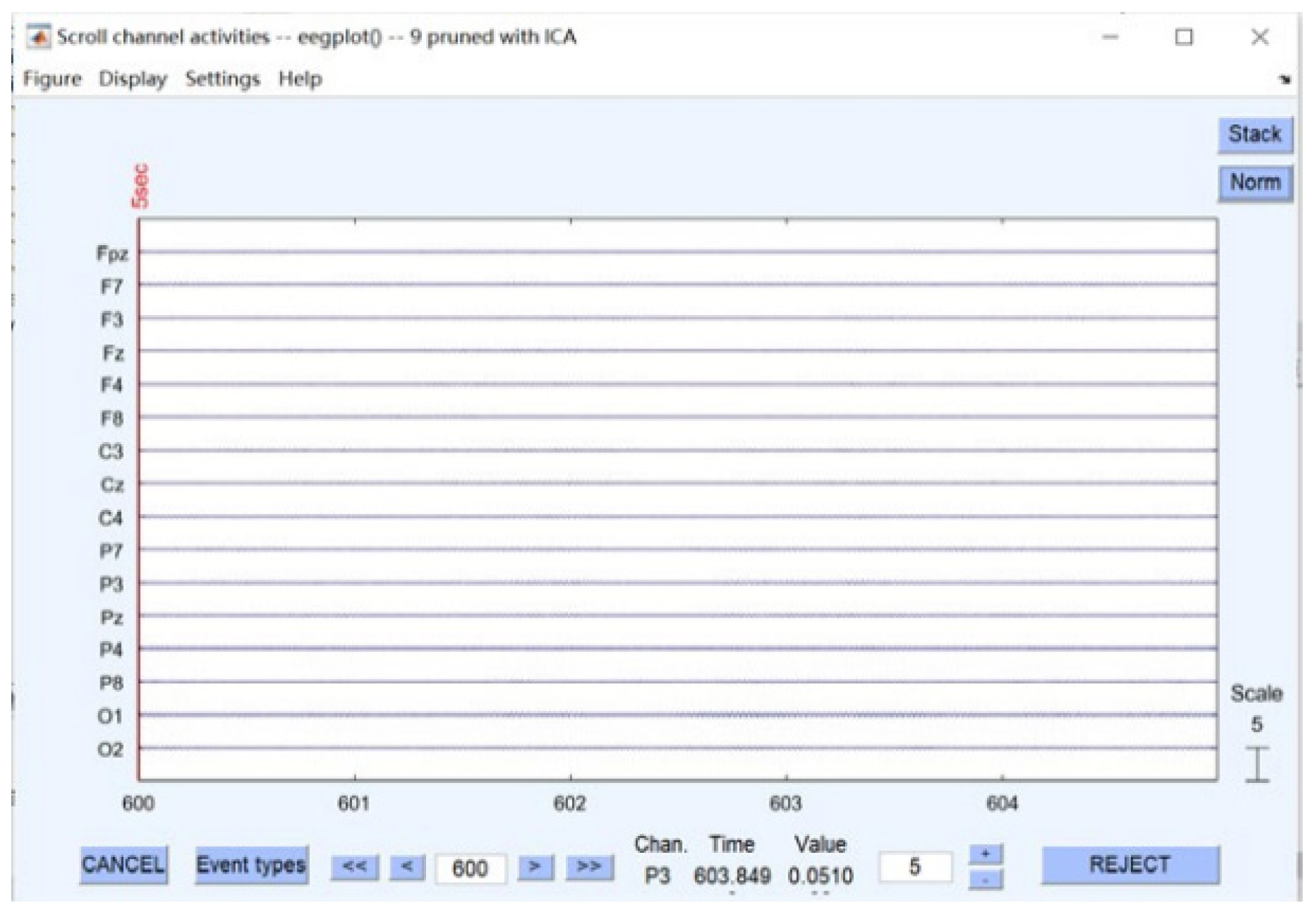

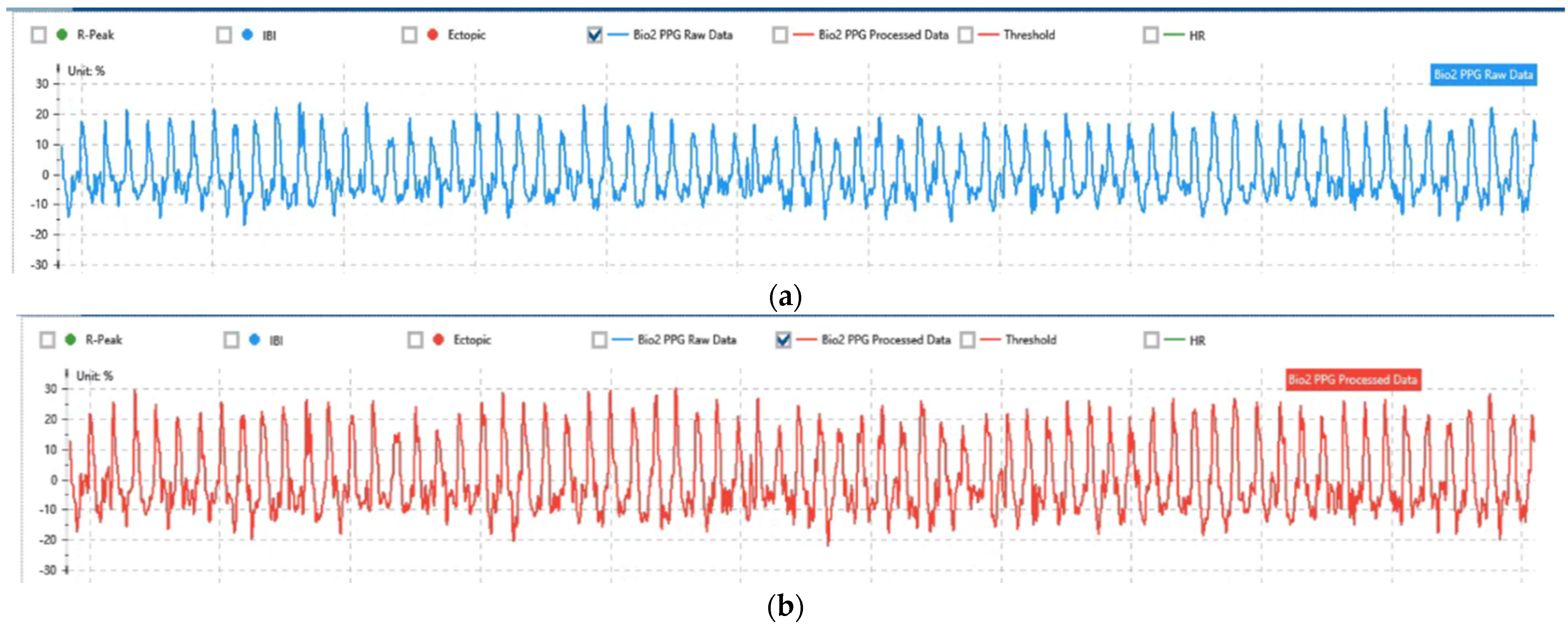

5.3.1. Data Preprocessing

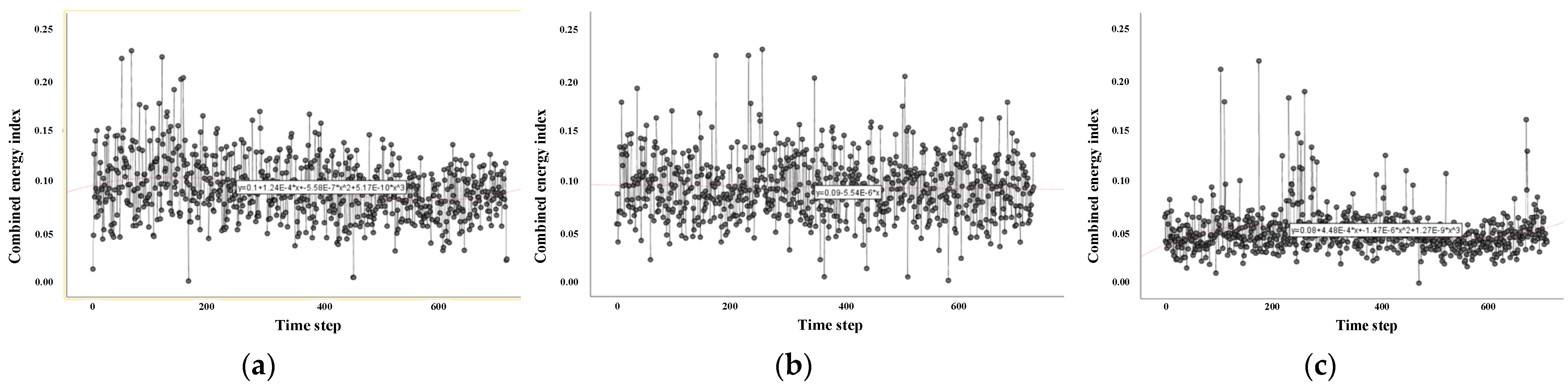

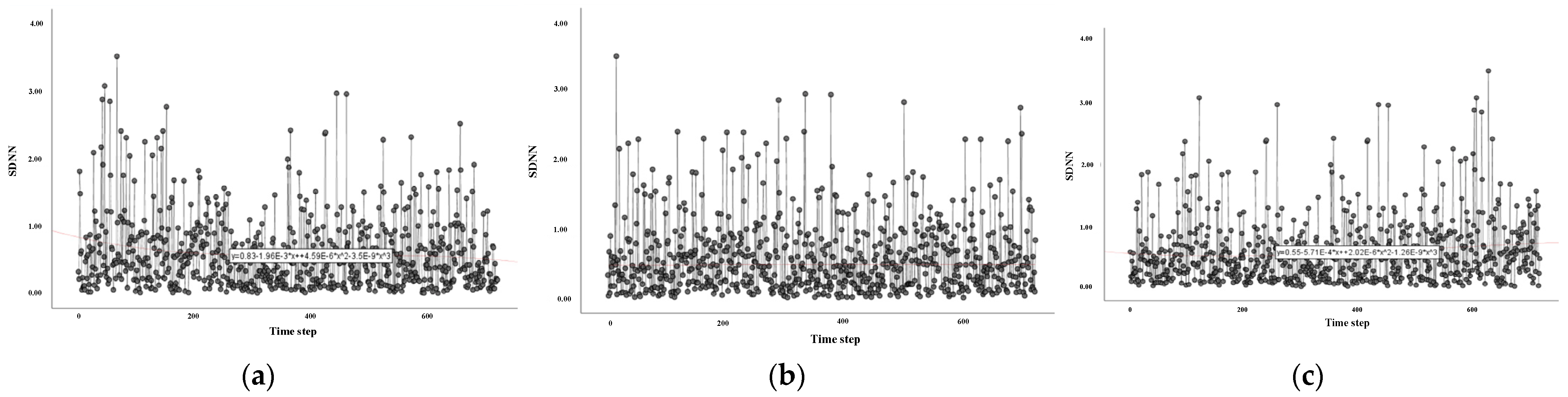

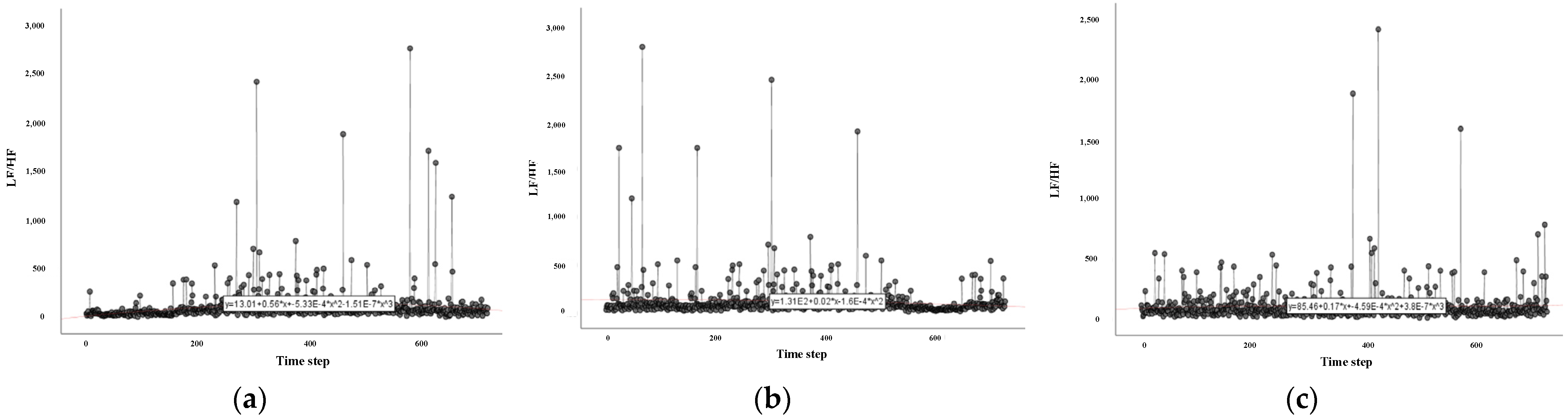

5.3.2. Feature Extraction

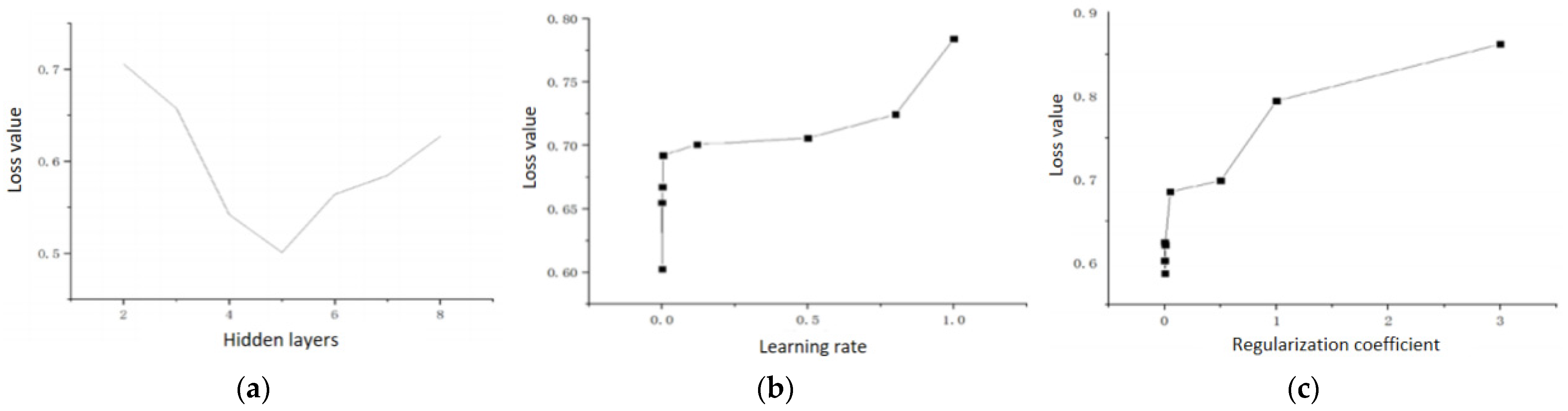

5.4. Feature Fusion Experiment

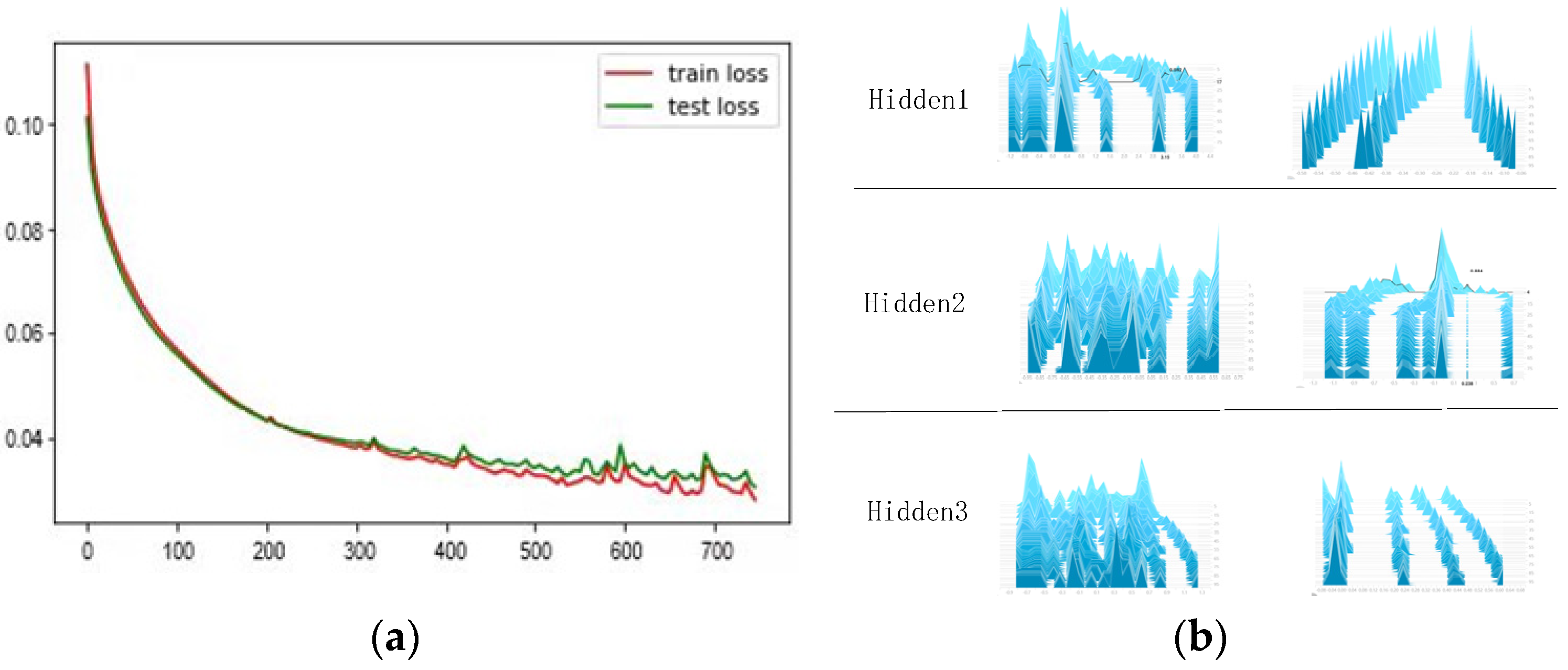

5.4.1. Fusion Process

5.4.2. Experimental Verification

5.4.3. Result Analysis

6. Conclusions and Prospect

6.1. Conclusions

6.2. Prospect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiang, Y.; Tian, G.; Liu, Y.; Li, Z. Energy-Efficiency Models of Sustainable Urban Transportation Structure Optimization. IEEE Access 2018, 6, 18192–18199. [Google Scholar] [CrossRef]

- Tian, G.; Jia, H.; Li, Z. Fuzzy random cost-profit tradeoff location model for a vehicle inspection station with regional constraints. IEEJ Trans. Electr. Electron. Eng. 2016, 11, 796–803. [Google Scholar] [CrossRef]

- Tian, G.; Liu, Y. Energy-Efficient Models of Sustainable Location for a Vehicle Inspection Station With Emission Constraints. IEEE Trans. Autom. Sci. Eng. 2015, 12, 238–243. [Google Scholar] [CrossRef]

- Tian, G.D.; Qiang, T.G.; Chu, J.W.; Qiao, G.M. Condensation DrippingWater Detection and Its Control Method from Exhaust Pipe of Gasohol Vehicle under Low Environmental Temperature Conditions: A Case Study in Harbin, China. Adv. Mech. Eng. 2012, 4, 627131. [Google Scholar] [CrossRef]

- Tian, G.; Zhou, M.; Chu, J.; Qiang, T.; Hu, H. Stochastic Cost-Profit Tradeoff Model for Locating an Automotive Service Enterprise. IEEE Trans. Autom. Sci. Eng. 2015, 12, 580–587. [Google Scholar] [CrossRef]

- Tian, G.; Zhou, M.; Li, P.; Zhang, C.; Jia, H. Multiobjective Optimization Models for Locating Vehicle Inspection Stations Subject to Stochastic Demand, Varying Velocity and Regional Constraints. IEEE Trans. Intell. Transp. Syst. 2016, 17, 1978–1987. [Google Scholar] [CrossRef]

- Zhang, H.; Peng, Y.; Hou, L.; Wang, D.; Tian, G.; Li, Z. Multistage Impact Energy Distribution for Whole Vehicles in High-Speed Train Collisions: Modeling and Solution Methodology. IEEE Trans. Ind. Inform. 2020, 16, 2486–2499. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, C.; Zhang, H.; Zhou, W.; Li, X.; Zhang, Q. Extraction of optimal fatigue-driving steering indicators considering individual differences. IET Intell. Transp. Syst. 2021, 15, 606–618. [Google Scholar] [CrossRef]

- Zou, S.; Qiu, T.; Huang, P.; Luo, H.; Bai, X. The functional brain network based on the combination of shortest path tree and its application in fatigue driving state recognition and analysis of the neural mechanism of fatigue driving. Biomed. Signal Process. Control. 2020, 62, 102129. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, X.; Wang, J.; He, J.; Peeta, S. Blink Number Forecasting Based on Improved Bayesian Fusion Algorithm for Fatigue Driving Detection. Math. Probl. Eng. 2015, 2015, 832621. [Google Scholar] [CrossRef]

- Harvy, J.; Bezerianos, A.; Li, J.H. Reliability of EEG Measures in Driving Fatigue. IEEE Trans. Neural Syst. Rehabil. Eng. 2022, 30, 2743–2753. [Google Scholar] [CrossRef]

- Wang, F.; Wu, S.; Ping, J.; Xu, Z.; Chu, H. EEG Driving Fatigue Detection With PDC-Based Brain Functional Network. IEEE Sens. J. 2021, 21, 10811–10823. [Google Scholar] [CrossRef]

- Wang, F.; Wang, H.; Zhou, X.; Fu, R. A Driving Fatigue Feature Detection Method Based on Multifractal Theory. IEEE Sens. J. 2022, 22, 19046–19059. [Google Scholar] [CrossRef]

- Gao, Z.; Li, S.; Cai, Q.; Dang, W.; Yang, Y.; Mu, C.; Hui, P. Relative Wavelet Entropy Complex Network for Improving EEG-Based Fatigue Driving Classification. IEEE Trans. Instrum. Meas. 2019, 68, 2491–2497. [Google Scholar] [CrossRef]

- Kong, W.; Zhou, Z.; Jiang, B.; Babiloni, F.; Borghini, G. Assessment of driving fatigue based on intra/inter-region phase synchronization. Neurocomputing 2017, 219, 474–482. [Google Scholar] [CrossRef]

- Du, G.; Li, T.; Li, C.; Liu, P.X.; Li, D. Vision-Based Fatigue Driving Recognition Method Integrating Heart Rate and Facial Features. IEEE Trans. Intell. Transp. Syst. 2021, 22, 3089–3100. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, W.; Jiang, X.; Hou, S.; Qin, Y. Assessment of Driver Mental Fatigue Using Facial Landmarks. IEEE Access 2019, 7, 150423–150434. [Google Scholar] [CrossRef]

- Yan, R.; Wu, C.; Wang, Y. Exploration and evaluation of individual difference to driving fatigue for high-speed railway: A parametric SVM model based on multidimensional visual cue. IET Intell. Transp. Syst. 2018, 12, 504–512. [Google Scholar] [CrossRef]

- Li, Z.; Yang, Q.; Chen, S.; Zhou, W.; Chen, L.; Song, L. A fuzzy recurrent neural network for driver fatigue detection based on steering-wheel angle sensor data. Int. J. Distrib. Sens. Netw. 2019, 15, 1550147719872452. [Google Scholar] [CrossRef]

- Mousavi, Z.; Rezaii, T.Y.; Sheykhivand, S.; Farzamnia, A.; Razavi, S. Deep convolutional neural network for classification of sleep stages from single-channel EEG signals. J. Neurosci. Methods 2019, 324, 108312. [Google Scholar] [CrossRef]

- Qi, M.S.; Xie, P.; Zhang, Y.Y.; Yang, W.J.; Liu, Z.J.; Cheng, S.C. Ieee In Driver fatigue Assessment Based on the Feature Fusion and Transfer Learning of EEG and EMG. In Proceedings of the Chinese Automation Congress (CAC), Xian, China, 30 November–2 December 2018; pp. 1314–1317. [Google Scholar]

- Gharagozlou, F.; Saraji, G.N.; Mazloumi, A.; Nahvi, A.; Nasrabadi, A.M.; Foroushani, A.R.; Kheradmand, A.A.; Ashouri, M.; Samavati, M. Detecting Driver Mental Fatigue Based on EEG Alpha Power Changes during Simulated Driving. Iran. J. Public Health 2015, 44, 1693–1700. [Google Scholar]

- Wang, H.; Wu, C.; Li, T.; He, Y.; Chen, P.; Bezerianos, A. Driving Fatigue Classification Based on Fusion Entropy Analysis Combining EOG and EEG. IEEE Access 2019, 7, 61975–61986. [Google Scholar] [CrossRef]

- Wang, F.; Wu, S.; Zhang, W.; Xu, Z.; Zhang, Y.; Chu, H. Multiple nonlinear features fusion based driving fatigue detection. Biomed. Signal Process. Control. 2020, 62, 102075. [Google Scholar] [CrossRef]

- Li, X.; Hong, L.; Wang, J.; Liu, X. Fatigue driving detection model based on multi-feature fusion and semi-supervised active learning. IET Intell. Transp. Syst. 2019, 13, 1401–1409. [Google Scholar] [CrossRef]

- Hussain, I.; Park, S.J. Big-ECG: Cardiographic Predictive Cyber-Physical System for Stroke Management. IEEE Access 2021, 9, 123146–123164. [Google Scholar] [CrossRef]

- Islam, M.S.; Hussain, I.; Rahman, M.; Park, S.J.; Hossain, A. Explainable Artificial Intelligence Model for Stroke Prediction Using EEG Signal. Sensors 2022, 22, 9859. [Google Scholar] [CrossRef]

- Hussain, I.; Park, S.J. HealthSOS: Real-Time Health Monitoring System for Stroke Prognostics. IEEE Access 2020, 8, 213574–213586. [Google Scholar] [CrossRef]

- Hussain, I.; Park, S.-J. Quantitative Evaluation of Task-Induced Neurological Outcome after Stroke. Brain Sci. 2021, 11, 900. [Google Scholar] [CrossRef]

- Hussain, I.; Young, S.; Park, S.-J. Driving-Induced Neurological Biomarkers in an Advanced Driver-Assistance System. Sensors 2021, 21, 6985. [Google Scholar] [CrossRef]

- Hussain, I.; Hossain, A.; Jany, R.; Bari, A.; Uddin, M.; Kamal, A.R.M.; Ku, Y.; Kim, J.-S. Quantitative Evaluation of EEG-Biomarkers for Prediction of Sleep Stages. Sensors 2022, 22, 3079. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, J. Fast Recognition Algorithm for Human Motion Posture Using Multimodal Bioinformation Fusion. Math. Probl. Eng. 2022, 2022, 9538295. [Google Scholar] [CrossRef]

- Peters, C.H.L.; Vullings, R.; Rooijakkers, M.J.; Bergmans, J.W.M.; Oei, S.G.; Wijn, P.F.F. A continuous wavelet transform-based method for time-frequency analysis of artefact-corrected heart rate variability data. Physiol. Meas. 2011, 32, 1517–1527. [Google Scholar] [CrossRef] [PubMed]

- Hittle, B.M.; Gillespie, G.L. Identifying shift worker chronotype: Implications for health. Ind. Health 2018, 56, 512–523. [Google Scholar] [CrossRef] [PubMed]

| Shift | Experiment Number | Start Time | End Time |

|---|---|---|---|

| Day shift | First test | 07:00 | After tunneling three rings |

| Second test | 10:00–14:00 | After tunneling three rings (including rest time) | |

| Third test | The last three tunneling instances on the day shift | After tunneling three rings | |

| Night shift | First test | 19:00 | After tunneling three rings |

| Second test | 00:00–02:00 | After tunneling three rings (including rest time) | |

| Third test | The last three tunneling instances on the night shift | Tunneling three rings | |

| Non-working state | First test | 10:00–14:00 | 20 min after the start |

| Classification | Name | Configuration |

|---|---|---|

| Hardware | Processor CPU©te© Core(TM) i7–11800H CPU @2.30 GHz | |

| Running memory RAM | 16 GB | |

| Solid-state disk | IM2P33F8–512GD (512 GB) | |

| Graphics card | NVIDIA GeForce RTX 3060 Laptop GPU (6 GB/1D05) | |

| Operating system | Windows10 | |

| Software | In-depth learning framework | TensorFlow2.6 |

| Development environment | Jupyter Notebook | |

| Algorithmic language | Python | |

| Layer | Hidden1 | Hidden2 | Hidden3 | Dense2 |

|---|---|---|---|---|

| Parameter | 16 | 1 | 16 | 3 |

| Hyper-Parameter Name | Parameter Code | Numerical Value |

|---|---|---|

| Hidden layers | h | 3 |

| Nodes in each layer | n | 3-16-1-16-3 |

| Learning rate | Learning_rate | 1 × 10−3 |

| Regularization factor | λ | 3 × 10−3 |

| Feature Fusion Method | Training Accuracy (%) | Test Accuracy (%) | Training Time (s) |

|---|---|---|---|

| PCA | 76.5 | 72.1 | 416 |

| D-S syndrome | 79.4 | 78.9 | 395 |

| Bayesian estimation | 78.3 | 76.9 | 413 |

| L2-SAE | 81.9 | 81.5 | 369 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Feng, G.; Jiang, X.; Zhao, W.; Tian, Z.; Zhao, R.; Bi, K. A Feature Fusion Method for Driving Fatigue of Shield Machine Drivers Based on Multiple Physiological Signals and Auto-Encoder. Sustainability 2023, 15, 9405. https://doi.org/10.3390/su15129405

Liu K, Feng G, Jiang X, Zhao W, Tian Z, Zhao R, Bi K. A Feature Fusion Method for Driving Fatigue of Shield Machine Drivers Based on Multiple Physiological Signals and Auto-Encoder. Sustainability. 2023; 15(12):9405. https://doi.org/10.3390/su15129405

Chicago/Turabian StyleLiu, Kun, Guoqi Feng, Xingyu Jiang, Wenpeng Zhao, Zhiqiang Tian, Rizheng Zhao, and Kaihang Bi. 2023. "A Feature Fusion Method for Driving Fatigue of Shield Machine Drivers Based on Multiple Physiological Signals and Auto-Encoder" Sustainability 15, no. 12: 9405. https://doi.org/10.3390/su15129405

APA StyleLiu, K., Feng, G., Jiang, X., Zhao, W., Tian, Z., Zhao, R., & Bi, K. (2023). A Feature Fusion Method for Driving Fatigue of Shield Machine Drivers Based on Multiple Physiological Signals and Auto-Encoder. Sustainability, 15(12), 9405. https://doi.org/10.3390/su15129405