1. Introduction

In recent years, global warming has attracted a lot of attention from many scholars. Carbon emissions from the massive consumption of fossil energy are considered to be a major cause of global warming [

1]. Statistical Review of World Energy (71st edition), which was published by BP, shows that global energy consumption grew by 5.8% in 2021 due to accelerating economic activity. Therefore, a global consensus has been reached regarding vigorously promoting clean energy, improving energy efficiency, and reducing carbon emissions [

2]. As a major emitter of carbon, China has fulfilled its obligations under the Paris Agreement and assumed its responsibilities as a major country. It has set a clearly defined goal, which is to reach its carbon peak in 2030 and carbon neutrality in 2060 [

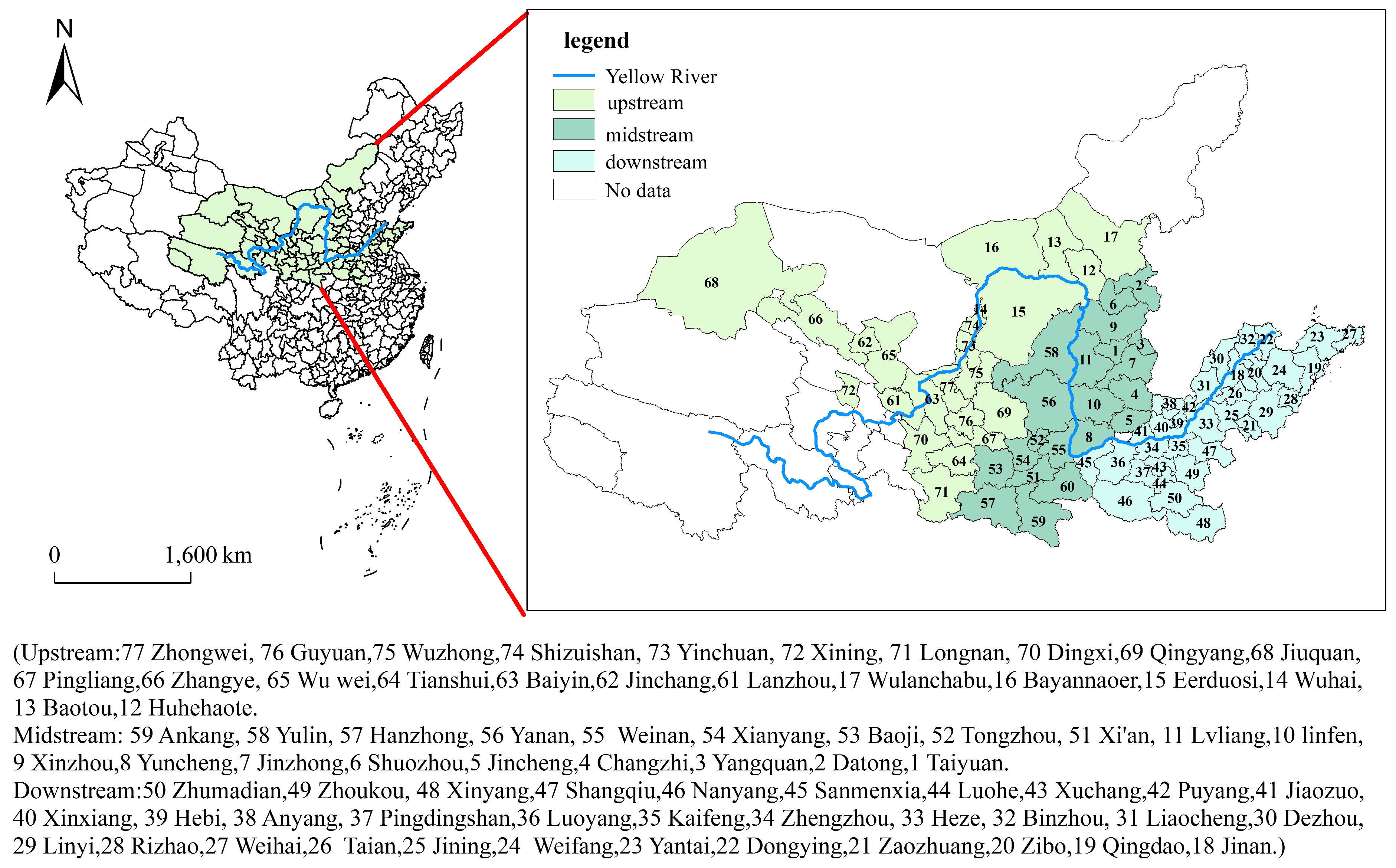

3]. As a significant ecological security barrier and economic development region [

4], the low-carbon economic development of the Yellow River Basin is of vital importance to the achievement of China’s dual carbon goal. The low development level, high proportion of high energy-consuming industries and unreasonable spatial layout constrain high-quality regional development [

5]. The Yellow River Basin consumed 35.1% of the country’s fossil energy in 2019 and produced 40.5% of the country’s total carbon emissions. As an important energy base and industrial agglomeration area in China, it has a good manufacturing foundation and a well-developed system. The manufacturing industry occupies a dominant position in driving the regional development of basin, but the arbitrary structure of the manufacturing industry, insufficient innovation and R&D capabilities, and insufficient attention to technology introduction and transformation have constrained the low carbon development of the manufacturing industry [

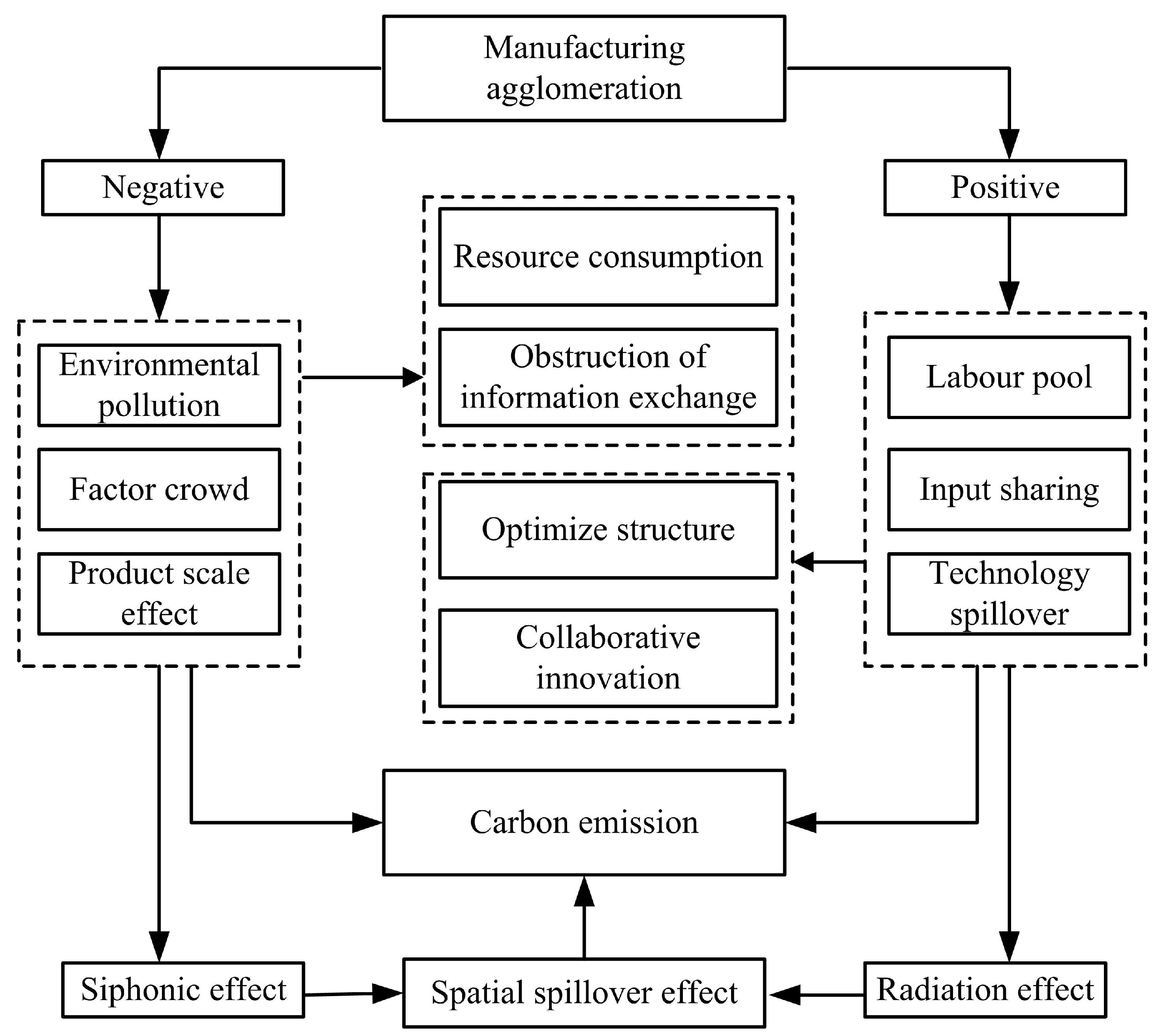

6]. Relevant studies suggest that manufacturing agglomeration characterized by technological innovation can promote the collaborative innovation of enterprises, strengthen resource utilization, and thus reduce carbon emissions. However, resource and energy endowments attract the spatial agglomeration of polluting industries, with no technological progress, knowledge spillover or optimization of resource allocation, which may intensify the competition for resources and factors in the agglomeration area and expand energy consumption to some extent. Therefore, it is important to study the effect of manufacturing agglomeration on carbon emissions in the Yellow River Basin to clarify the connection between manufacturing agglomeration and carbon emissions, and to promote the low-carbon transformation of the manufacturing industry.

The carbon dioxide content generated by energy consumption is the highest in greenhouse gas emissions, so carbon dioxide emissions are used as an index to measure greenhouse gas emissions and are referred to as carbon emissions. In addition to the total carbon emissions in the standard sense, for convenience, indicators such as carbon productivity and carbon emission intensity are also introduced [

7,

8,

9]. Carbon emission measurements are calculated mainly by IPCC methods, input–output methods, MEIC models, etc. Among them, the IPCC method is widely used [

10,

11,

12,

13]. Many scholars have calculated the carbon emissions of different industries and sectors, such as industry, agriculture, tourism, and transportation. Studies on carbon emissions from land use [

14], carbon emissions from energy consumption [

15], and embodied carbon emissions from trade [

16] have also gradually increased. Regarding the influencing factors of carbon emissions, related research focuses on urbanization [

17], technological innovation [

18], energy consumption scale [

19], and industrial agglomeration [

20], these studies use the LMDI model [

21], spatial econometric model [

22] and threshold effect to conduct in-depth research. According to IPCC (2019) data, China’s carbon emissions from manufacturing accounted for 53.27% of the country’s total carbon emissions in 2017. Manufacturing agglomeration is an important factor affecting carbon emissions. There are three main views on the relationship.

The first view is that manufacturing agglomeration will increase carbon emissions. This phenomenon generally appears in the early stage of manufacturing agglomeration. On the one hand, competing regions blindly pursue economic development and may lower environmental standards to attract industrial agglomeration [

23]. Hence, the technical level of enterprises is not high, the production efficiency and energy utilization efficiency are low, and the massive expansion of production capacity is accompanied by severe pollution. On the other hand, agglomeration causes a shortage of land, labor, energy and other resources, illogical resource allocation, and vicious competition between enterprises. The negative externality effect of industrial agglomeration begins to become prominent, and the industry is characterized by “low efficiency and high energy consumption”, resulting in a “crowding effect” [

24], thus increasing carbon emissions. At the same time, in most manufacturing agglomeration areas, the centralized treatment of pollutants has not been realized, and the rate of pollutant treatment is low, further aggravating pollution [

25].

The second view is that manufacturing agglomeration will reduce carbon emissions. This phenomenon generally appears in the later period of manufacturing agglomeration. On the one hand, manufacturing agglomeration can improve regional labor productivity and increase residents’ income and fiscal revenue. Residents have a higher demand for a better environment, forcing the government to adopt stricter environmental policies to protect the environment [

26,

27]. Strict environmental regulations will bring “innovation compensation” to companies, further encouraging them to develop clean technologies. On the other hand, through the mechanism of sharing, matching, and learning, agglomeration promotes technological innovation, improves labor productivity, and strengthens the exchange and interaction of knowledge, technology, and capital among enterprises [

28,

29], resulting in an agglomeration spillover effect. In addition, the agglomeration of upstream and downstream industries in a geographical space facilitates the centralized production of products and the centralized treatment of pollutants [

30] and achieves improvement of energy infrastructure, thus reducing carbon emissions [

31].

The third view is that there is an upside-down U-shaped relation between manufacturing agglomeration and carbon emissions [

32]. As the degree of manufacturing agglomeration increases, carbon emissions first increase and then decrease. In the early stage of manufacturing agglomeration, the structure of industry tends to be “pollution intensive,” and carbon emissions increase with the expansion of the production scale of enterprises. In the middle and later stages of manufacturing agglomeration, the industrial structure is gradually optimized, and energy consumption decreases in the region. Overall, the effect of manufacturing agglomeration on carbon emissions is not a single linear relationship but results from the combined effect of the agglomeration effect and crowding effect [

33]. As the level of manufacturing agglomeration increases, the positive effects, such as knowledge and technology spillover and cooperative competition brought by agglomeration, gradually outweigh the negative effects, such as congestion effect and energy consumption caused by excessive competition, and carbon emissions are reduced; otherwise, carbon emissions will be increased. There are also regional differences in the relationship between manufacturing agglomeration and carbon emissions, but they do not show a certain regularity. The main reason is that there are many factors affecting the relationship between manufacturing agglomeration and carbon emission, such as city size, economic development level, industrial structure, etc., all of which directly or indirectly affect the relationship between the two, making it difficult to sort out and summarize a general rule. The specialization of manufacturing agglomeration is significant in small cities, while the diversification of manufacturing agglomeration is more significant in large and medium-sized cities [

34]. In developed countries such as Japan and the United States [

35,

36], manufacturing can form industrial clusters with other industries, promote information sharing and technological innovation, and reduce carbon emissions. The economic foundation of Western China is weak, the technological innovation ability is poor, the positive externalities generated by agglomeration are small, and the crowding effect is obvious. On the other hand, the Yangtze River Delta region of China has a solid economic foundation, a large number of scientific research talents, strong positive externalities brought by agglomeration, and less carbon emissions.

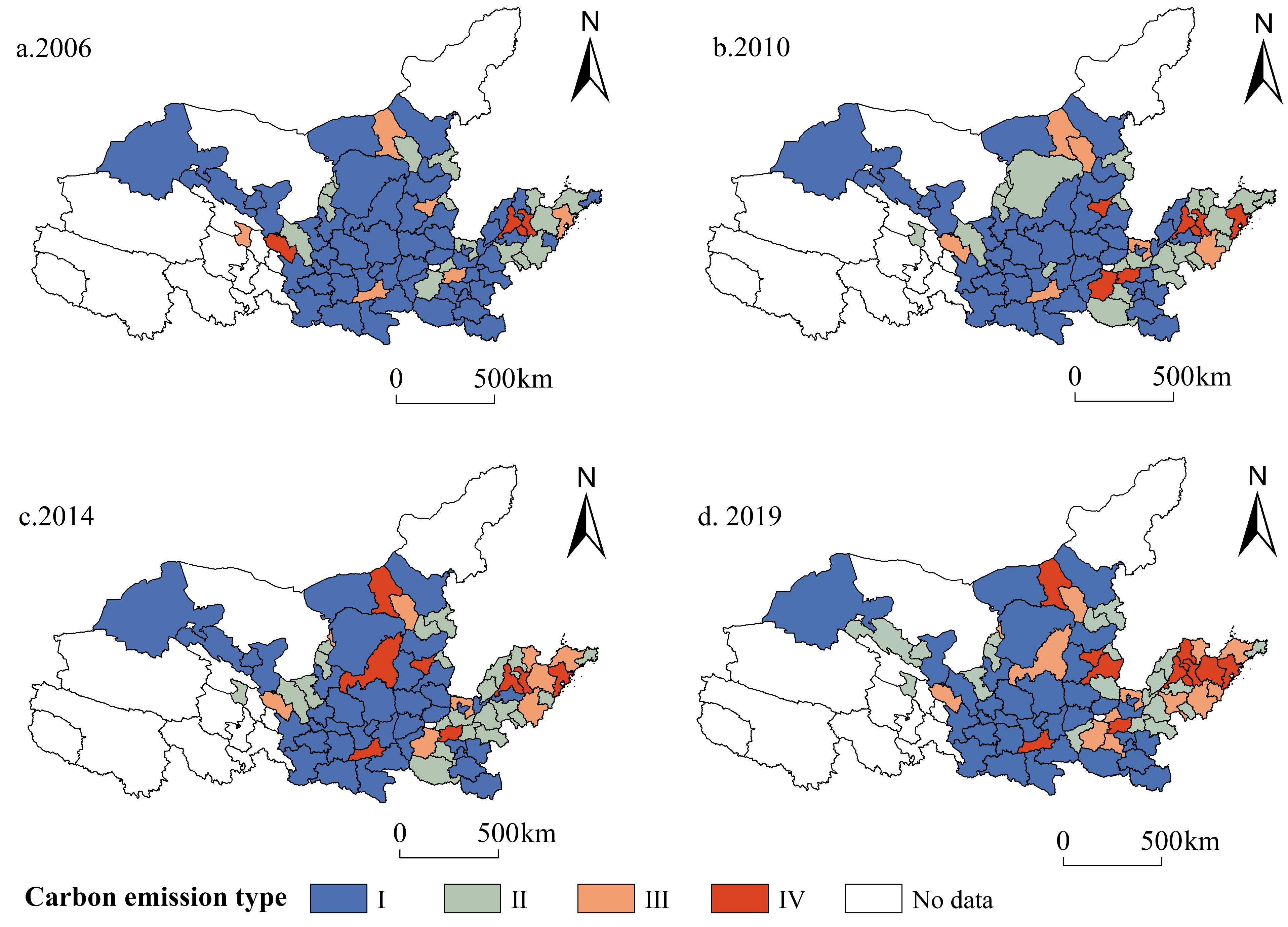

In general, the research on manufacturing agglomeration and carbon emissions in the relevant literature at home and abroad has made progress, but there are still various debates on the connection between manufacturing agglomeration and carbon emissions, and the conclusions vary by region and time scale. At the same time, there are relatively few studies on the effect of manufacturing agglomeration on carbon emissions in the Yellow River Basin. The literature that covers regional heterogeneity analysis is also relatively scarce. In this paper, the Markov transition matrix was used to study the transfer characteristics of carbon emission types, and the SDM model was constructed to empirically analyze the effect of manufacturing agglomeration on carbon emission and the spatial spillover effect and to study the regional heterogeneity of manufacturing agglomeration on carbon emission. This paper intends to make contributions from three aspects: (1) It considers regional differences in carbon emissions from the perspective of prefecture-level cities and enriches the research framework of the carbon emissions of prefecture-level cities. (2) We further elucidate the spatial spillover effect and regional heterogeneity of manufacturing agglomeration on carbon emissions in the Yellow River Basin. (3) The Markov transition matrix was used to analyze the transfer rules of carbon emission types in different regions of the Yellow River Basin, providing countermeasures for carbon emission reduction.

The remaining paper is organized as follows: the second section is the data and methods, the third section is the empirical analysis, the fourth section is the discussion, and the fifth section is the conclusion and countermeasures.

4. Discussion

Carbon reduction in manufacturing is an important path to achieving the dual carbon goal. The study of the impact of manufacturing agglomeration on carbon emissions can provide a basis for carbon emission reduction. By establishing the spatial Dubin model, we found that from the perspective of the whole Yellow River Basin, manufacturing agglomeration will increase the local carbon emissions, which is similar to the conclusion of Zhang et al. [

49,

50] but will reduce the carbon emissions of neighboring regions. This is mainly related to the stage of manufacturing agglomeration in the Yellow River Basin. The manufacturing agglomeration in the Yellow River Basin is in the early stage, and the labor reservoir effect and intermediate input sharing brought by agglomeration are weak, while the crowding effect is dominant, which will increase carbon emissions in the region [

51]. The spatial spillover effect on neighboring areas is mainly negative, mainly because the polarization effect is greater than the radiation effect, attracting capital, talent, technology and other factors in neighboring areas, hindering the information exchange and knowledge spillover between enterprises in neighboring areas, and reducing carbon emissions (

Figure 4).

In addition, we tried to study the relationship between manufacturing agglomeration and carbon emissions from different reaches of the Yellow River basin, which is also an innovation point of this paper. We found that the middle and upper reaches of the Yellow River Basin, like the whole basin, are still in the early stage of manufacturing agglomeration, but the lower reaches are in the transition stage of manufacturing agglomeration from the early stage to the late stage due to a relatively developed economy, and the spatial spillover effect on neighboring areas is mainly positive. The radiation effect is greater than the polarization effect; advanced technology and production processes spread to the surrounding areas, reduce the production cost of enterprises, increase the investment in research and development technology, promote the collaborative innovation and technological progress of enterprises in the neighboring areas, optimize and upgrade the industrial structure, and reduce the carbon emissions in the neighboring areas. The manufacturing industry in the Yellow River Basin faces great pressure of carbon emission reduction, so green transformation is very necessary. The manufacturing industry in the Yellow River Basin faces great pressure of carbon emission reduction, so green transformation is very necessary. In particular, the upstream region undertakes energy-intensive industries from the downstream region, which to some extent leads to the “pollution refuge” effect. Therefore, it is necessary to design the optimal agglomeration mode and build a modern manufacturing system according to the characteristics of the manufacturing industry [

52].

Existing studies mostly focus on the relationship between industrial agglomeration and environmental pollution. For example, Fang et al. [

28] believe that manufacturing agglomeration will reduce haze pollution in local and surrounding areas. This paper explores the relationship between manufacturing agglomeration and carbon emissions, further considers regional heterogeneity, and compares the similarities and differences between manufacturing agglomeration and carbon emissions in different river reaches of the basin, which is innovative to a certain extent. Due to limited data sources and research time, there are still some limitations. In the future, research on the impact and spillover effect of manufacturing agglomeration on carbon emissions at the county scale or in typical case areas can be further strengthened.