Responsibility Allocation of Provincial Industry Emission Reduction from the Perspective of Industrial Linkages—A Case Study of Shanxi Province

Abstract

1. Introduction

2. Research Methodology and Data

2.1. Design of Carbon Emissions Reduction Responsibility Allocation Indicator System from Industry Perspective

2.2. Design of Carbon Emissions Reduction Responsibility Allocation Indicator System from Industrial Linkages Perspective

2.2.1. Design of the Equity Principle Indicator System from Industrial Linkages Perspective

2.2.2. Design of the Efficiency Principle Indicator System from Industrial Linkages Perspective

2.3. A Provincial Inter-Industry Model for Emissions Reduction Responsibility Allocation

2.4. Data Source and Processing

3. Research Results and Discussion

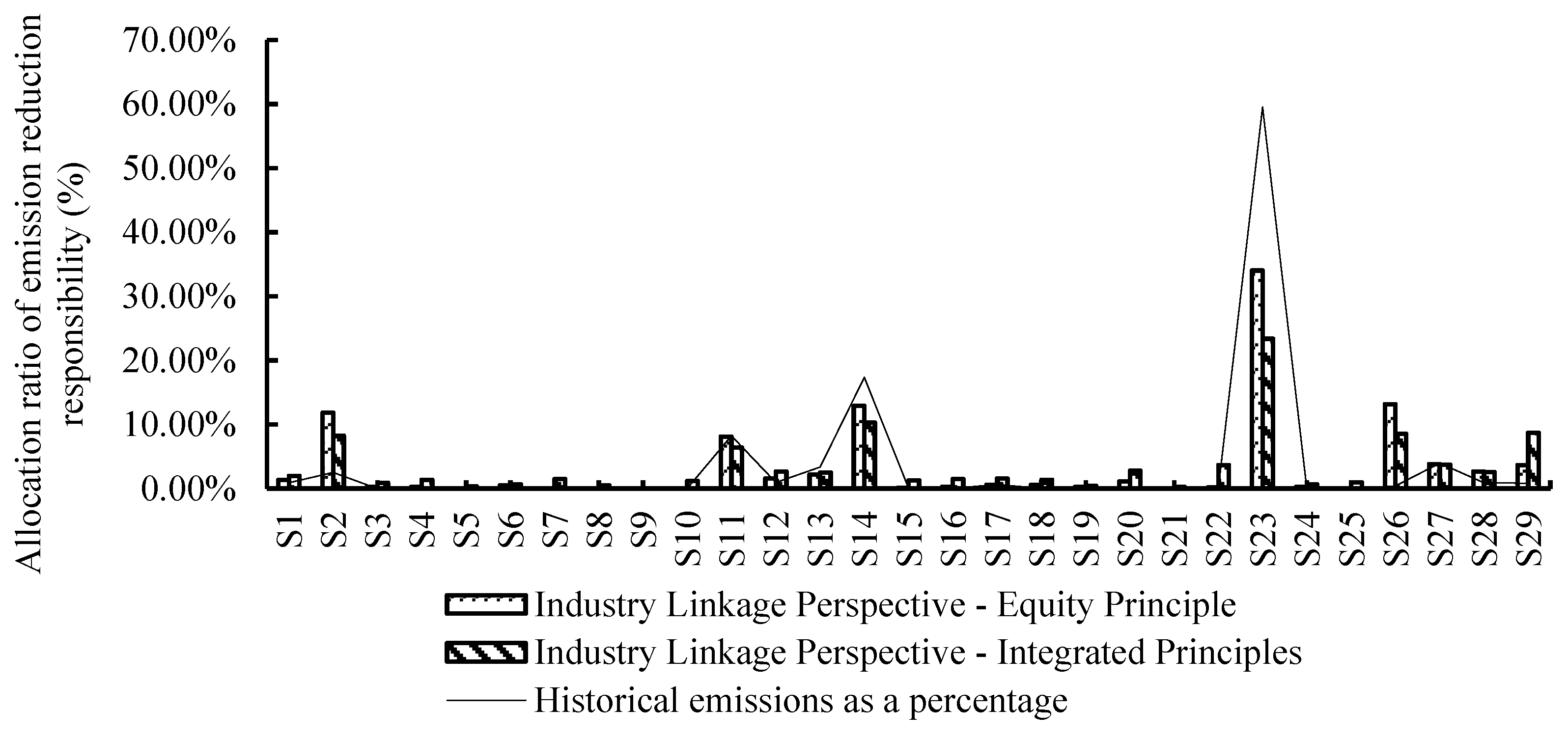

3.1. Allocation Results of Carbon Emissions Reduction Responsibility from Industrial Linkages Perspective

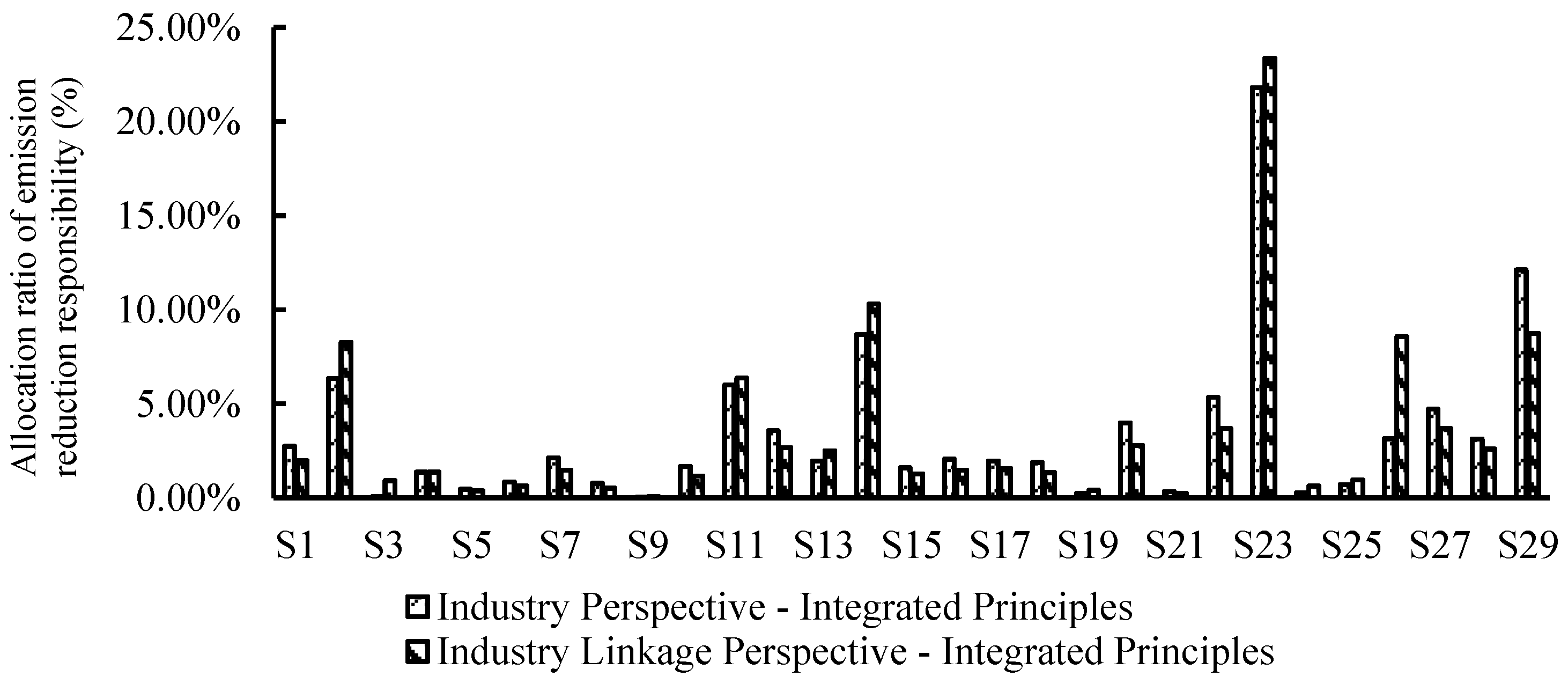

3.2. Differences and Links of Each Industry’s Emissions Reduction Responsibility from Different Perspectives

4. Policy Recommendations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Deng, Z.; He, G.; Wang, H.; Zhang, X.; Lin, J.; Qi, Y.; Liang, X. Challenges and opportunities for carbon neutrality in China. Nat. Rev. Earth Environ. 2021, 3, 141–155. [Google Scholar] [CrossRef]

- Zhang, L.; Ling, J.; Lin, M. Carbon neutrality: A comprehensive bibliometric analysis. Environ. Sci. Pollut. Res. 2023, 30, 45498–45514. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Liu, Q.Q.; Cai, W.G.; Liu, Y.; Yu, Y.H.; Zhang, Y.H. Echelon peaking path of China’s provincial building carbon emissions: Considering peak and time constraints. Energy 2023, 271, 127003. [Google Scholar] [CrossRef]

- Zhou, A.S.; Zhou, J.S.; Si, J.J.; Wang, G.Y. Study on Embodied CO2 Emissions and Transfer Pathways of Chinese Industries. Sustainability 2023, 15, 2215. [Google Scholar] [CrossRef]

- Ran, C.Y.; Xu, X.L.; Zhang, S.Z. Embodied carbon emissions transfers via inter-regional trade: Evidence from value-added extended decomposition model in China. Heliyon 2022, 8, e10521. [Google Scholar] [CrossRef] [PubMed]

- Hsiao, C.M. Economic Growth, CO2 Emissions Quota and Optimal Allocation under Uncertainty. Sustainability 2022, 14, 8706. [Google Scholar] [CrossRef]

- Zhao, S.W.; Shi, Y.; Xu, J.P. Carbon emissions quota allocation based equilibrium strategy toward carbon reduction and economic benefits in China’s building materials industry. J. Clean. Prod. 2018, 189, 307–325. [Google Scholar] [CrossRef]

- Han, R.; Yu, B.Y.; Tang, B.J.; Liao, H.; Wei, Y.M. Carbon emissions quotas in the Chinese road transport sector: A carbon trading perspective. Energy Policy 2017, 106, 298–309. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Hao, J.-F. Carbon emission quota allocation among China’s industrial sectors based on the equity and efficiency principles. Ann. Oper. Res. 2017, 255, 117–140. [Google Scholar] [CrossRef]

- Hou, H.M.; Bai, H.T.; Ji, Y.J.; Wang, Y.; Xu, H. A historical time series for inter-industrial embodied carbon transfers within China. J. Clean. Prod. 2020, 264, 121738. [Google Scholar] [CrossRef]

- Sato, M.; Rafaty, R.; Calel, R.; Grubb, M. Allocation, allocation, allocation! The political economy of the development of the European Union Emissions Trading System. Wiley Interdiscip. Rev. Clim. Chang. 2022, 13, e796. [Google Scholar] [CrossRef]

- Qin, Q.D.; Liu, Y.; Li, X.; Li, H.A. A multi-criteria decision analysis model for carbon emission quota allocation in China’s east coastal areas: Efficiency and equity. J. Clean. Prod. 2017, 168, 410–419. [Google Scholar] [CrossRef]

- Duan, F.M.; Wang, Y.; Wang, Y.; Zhao, H. Estimation of marginal abatement costs of CO2 in Chinese provinces under 2020 carbon emission rights allocation: 2005–2020. Environ. Sci. Pollut. Res. 2018, 25, 24445–24468. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, R.C.; Heitzig, J. Carbon leakage: Grandfathering as an incentive device to avert firm relocation. J. Environ. Econ. Manag. 2014, 67, 209–223. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, L.Y.; Xie, P.J.; Pan, X.Y. Allocation and optimization of carbon emission permits considering fairness and efficiency under the dual-carbon background. Front. Environ. Sci. 2022, 10, 1036771. [Google Scholar] [CrossRef]

- Lin, Z.W.; Wang, P.; Ren, S.Y.; Zhao, D.Q. Economic and environmental impacts of EVs promotion under the 2060 carbon neutrality target-A CGE based study in Shaanxi Province of China. Appl. Energy 2023, 332, 120501. [Google Scholar] [CrossRef]

- Zhang, N.; Wei, X. Dynamic total factor carbon emissions performance changes in the Chinese transportation industry. Appl. Energy 2015, 146, 409–420. [Google Scholar] [CrossRef]

- Sajid, M.J.; Li, X.C.; Cao, Q.R. Demand and supply-side carbon linkages of Turkish economy using hypothetical extraction method. J. Clean. Prod. 2019, 228, 264–275. [Google Scholar] [CrossRef]

- Dong, F.; Hua, Y.F.; Yu, B.L. Peak Carbon Emissions in China: Status, Key Factors and Countermeasures-A Literature Review. Sustainability 2018, 10, 2895. [Google Scholar] [CrossRef]

- Zhang, Z.; Cao, L.B.; Dong, H.J.; Cai, B.F.; Geng, Y.; Pang, L.Y.; Tang, Y.Q. Allocating China’s 2025 CO2 emission burden shares to 340 prefecture cities: Methods and findings. Environ. Sci. Pollut. Res. 2022, 29, 90671–90685. [Google Scholar] [CrossRef]

- Li, Z.Y.; Chen, H.D.; Wang, J.; Zhao, T. Optimal allocation of CO2 emission quotas at the city level in Bohai Rim Economic Circle based on multi-objective decision approach. Environ. Sci. Pollut. Res. 2021, 28, 60798–60817. [Google Scholar] [CrossRef]

- He, F.; Yang, Y.; Liu, X.; Wang, D.; Ji, J.P.; Yi, Z.B. Input-Output Analysis of China’s CO2 Emissions in 2017 Based on Data of 149 Sectors. Sustainability 2021, 13, 4172. [Google Scholar] [CrossRef]

- Zhang, J.X.; Jin, W.X.; Yang, G.L.; Li, H.; Ke, Y.J.; Philbin, S.P. Optimizing regional allocation of CO2 emissions considering output under overall efficiency. Socio-Econ. Plan. Sci. 2021, 77, 13. [Google Scholar] [CrossRef]

- Pang, J.; Timilsina, G. How would an emissions trading scheme affect provincial economies in China: Insights from a computable general equilibrium model. Renew. Sust. Energ. Rev. 2021, 145, 111304. [Google Scholar] [CrossRef]

- Zhang, H.L.; Shen, L.; Zhong, S.; Elshkaki, A. Economic Structure Transformation and Low-Carbon Development in Energy-Rich Cities: The Case of the Contiguous Area of Shanxi and Shaanxi Provinces, and Inner Mongolia Autonomous Region of China. Sustainability 2020, 12, 1875. [Google Scholar] [CrossRef]

- Pan, X.Z.; den Elzen, M.; Hoehne, N.; Teng, F.; Wang, L.N. Exploring fair and ambitious mitigation contributions under the Paris Agreement goals. Environ. Sci. Policy 2017, 74, 49–56. [Google Scholar] [CrossRef]

- Gao, P.; Yue, S.J.; Chen, H.T. Carbon emission efficiency of China’s industry sectors: From the perspective of embodied carbon emissions. J. Clean. Prod. 2021, 283, 9. [Google Scholar] [CrossRef]

- Zhang, Y.G. Provincial responsibility for carbon emissions in China under different principles. Energy Policy 2015, 86, 142–153. [Google Scholar] [CrossRef]

- Pang, Q.H.; Dong, X.W.; Peng, S.; Zhang, L.N. Sector linkages and driving forces of Chinese household CO2 emissions based on semi-closed input-output model. Environ. Sci. Pollut. Res. 2022, 29, 35408–35421. [Google Scholar] [CrossRef]

- Li, Z.Y.; Zhao, T.; Wang, J.; Cui, X.Y. Two-step allocation of CO2 emission quotas in China based on multi-principles: Going regional to provincial. J. Clean. Prod. 2021, 305, 127173. [Google Scholar] [CrossRef]

- Gopalakrishnan, S.; Granot, D.; Granot, F.; Sosic, G.; Cui, H.L. Incentives and Emission Responsibility Allocation in Supply Chains. Manag. Sci. 2021, 67, 4172–4190. [Google Scholar] [CrossRef]

- Wu, J.J.; Guo, Q.H.; Yuan, J.H.; Lin, J.Y.; Xiao, L.S.; Yang, D.W. An integrated approach for allocating carbon emission quotas in China’s emissions trading system. Resour. Conserv. Recycl. 2019, 143, 291–298. [Google Scholar] [CrossRef]

- Tian, M.H.; Hu, Y.J.; Wang, H.L.; Li, C.J. Regional allowance allocation in China based on equity and efficiency towards achieving the carbon neutrality target: A composite indicator approach. J. Clean. Prod. 2022, 342, 130914. [Google Scholar] [CrossRef]

- Song, J.K.; Chen, R.; Ma, X.P. Provincial Allocation of Energy Consumption, Air Pollutant and CO2 Emission Quotas in China: Based on a Weighted Environment ZSG-DEA Model. Sustainability 2022, 14, 2243. [Google Scholar] [CrossRef]

- Ma, C.Q.; Ren, Y.S.; Zhang, Y.J.; Sharp, B. The allocation of carbon emission quotas to five major power generation corporations in China. J. Clean. Prod. 2018, 189, 1–12. [Google Scholar] [CrossRef]

- Liao, Z.L.; Zhu, X.L.; Shi, J.R. Case study on initial allocation of Shanghai carbon emission trading based on Shapley value. J. Clean. Prod. 2015, 103, 338–344. [Google Scholar] [CrossRef]

- Kong, Y.C.; Zhao, T.; Yuan, R.; Chen, C. Allocation of carbon emission quotas in Chinese provinces based on equality and efficiency principles. J. Clean. Prod. 2019, 211, 222–232. [Google Scholar] [CrossRef]

- Wei, Y.M.; Wang, L.; Liao, H.; Wang, K.; Murty, T.; Yan, J.Y. Responsibility accounting in carbon allocation: A global perspective. Appl. Energy 2014, 130, 122–133. [Google Scholar] [CrossRef]

- Bathrinath, S.; Saravana Kumar, P.; Venkadesh, S.; Suprriyan, S.S.; Koppiahraj, K.; Bhalaji, R.K.A. A fuzzy COPRAS approach for analysing the factors affecting sustainability in ship ports. Mater. Today Proc. 2022, 50, 1017–1021. [Google Scholar] [CrossRef]

- Wang, L.H.; Wang, Z.; Ma, Y.T. Does environmental regulation promote the high-quality development of manufacturing? A quasi-natural experiment based on China’s carbon emission trading pilot scheme. Socio-Econ. Plan. Sci. 2022, 81, 101216. [Google Scholar] [CrossRef]

- Zhang, P.F.; Cai, W.Q.; Yao, M.T.; Wang, Z.Y.; Yang, L.Z.; Wei, W.D. Urban carbon emissions associated with electricity consumption in Beijing and the driving factors. Appl. Energy 2020, 275, 115425. [Google Scholar] [CrossRef]

- Hung, C.C.W.; Hsu, S.C.; Cheng, K.L. Quantifying city-scale carbon emissions of the construction sector based on multi-regional input-output analysis. Resour. Conserv. Recycl. 2019, 149, 75–85. [Google Scholar] [CrossRef]

- Zhou, J.G.; Jin, B.L. Carbon Allowance Allocation on Chinese Industrial Sectors in 2030 under Multiple Indicators. Pol. J. Environ. Stud. 2019, 28, 1981–1997. [Google Scholar] [CrossRef] [PubMed]

| Perspective | Industry Perspective | Industrial Linkages Perspective |

|---|---|---|

| Equity principle | Historical carbon emissions | Historical carbon emissions Embodied carbon emissions |

| Efficiency principle | Added value Industrial actual carbon intensity/advanced level of industrial carbon intensity | Added value Industrial actual carbon intensity/advanced level of industrial carbon intensity Carbon diffusion coefficient Carbon-inducing coefficient |

| Industry Code | Industry Name | Equity Principle | Efficiency Principle | ||||

|---|---|---|---|---|---|---|---|

| Actual Carbon Emissions (Million Tons) | Embodied Carbon Emissions (Million Tons) | Value Added (Billions of Dollars) | Carbon Emissions Intensity /Advanced Level | Influence Coefficient | Sensitivity Coefficient | ||

| S1 | Agriculture, forestry, and fisheries | 437.47 | 780.10 | 764.06 | 4.57 | 0.33 | 0.20 |

| S2 | Coal mining and washing industry | 1229.99 | 8738.52 | 2290.20 | 0.65 | 0.89 | 0.57 |

| S3 | Oil and gas extraction industry | 0.32 | 148.80 | 28.89 | 0.06 | 1.42 | 0.00 |

| S4 | Metal mining industry | 46.17 | 149.70 | 89.07 | 3.90 | 1.60 | 0.04 |

| S5 | Non-metallic and other mineral mining industry | 0.20 | 3.61 | 1.37 | 1.39 | 0.50 | 0.00 |

| S6 | Food processing and tobacco manufacturing | 16.85 | 306.29 | 256.11 | 1.19 | 0.25 | 0.02 |

| S7 | Textile industry | 2.28 | 37.24 | 6.69 | 6.27 | 0.76 | 0.01 |

| S8 | Textile, apparel, and leather manufacturing | 0.40 | 9.66 | 8.29 | 2.27 | 0.20 | 0.00 |

| S9 | Wood processing and furniture manufacturing | 0.04 | 18.63 | 13.50 | 0.09 | 0.30 | 0.00 |

| S10 | Paper, printing, and education and sports manufacturing | 12.11 | 31.85 | 17.99 | 4.88 | 0.69 | 0.02 |

| S11 | Petroleum processing, coking, and nuclear fuel processing industry | 4041.23 | 4269.20 | 389.89 | 13.29 | 2.08 | 2.42 |

| S12 | Chemical industry | 473.95 | 926.84 | 352.23 | 10.18 | 1.16 | 0.28 |

| S13 | Non-metallic mineral products industry | 1653.72 | 768.68 | 171.42 | 2.85 | 2.48 | 0.96 |

| S14 | Metal smelting and rolling processing industry | 8524.56 | 5526.48 | 829.56 | 3.09 | 3.36 | 5.77 |

| S15 | Metal products industry | 28.53 | 74.89 | 97.56 | 4.57 | 1.18 | 0.02 |

| S16 | General equipment manufacturing | 18.48 | 176.08 | 54.01 | 6.04 | 0.92 | 0.02 |

| S17 | Specialized equipment manufacturing | 319.85 | 285.12 | 70.62 | 5.59 | 1.17 | 0.33 |

| S18 | Transportation equipment manufacturing | 18.84 | 342.89 | 92.43 | 5.48 | 0.66 | 0.03 |

| S19 | Electrical machinery and equipment manufacturing | 0.67 | 166.26 | 65.08 | 0.44 | 0.65 | 0.00 |

| S20 | Communications equipment, computers, and other electronic equipment manufacturing | 21.58 | 688.10 | 203.35 | 12.14 | 0.53 | 0.02 |

| S21 | Instrument manufacturing | 0.12 | 19.68 | 8.53 | 1.02 | 0.30 | 0.00 |

| S22 | Scrap waste, equipment repair, and other manufacturing | 31.06 | 111.63 | 53.13 | 17.22 | 0.66 | 0.02 |

| S23 | Electricity, heat production, and supply industry | 29,277.15 | 8936.69 | 572.50 | 3.13 | 8.61 | 17.09 |

| S24 | Gas production and supply industry | 0.21 | 175.25 | 87.32 | 0.07 | 0.97 | 0.00 |

| S25 | Water production and supply industry | 0.24 | 11.92 | 11.49 | 2.03 | 1.34 | 0.00 |

| S26 | Construction | 207.88 | 10,640.78 | 1019.84 | 3.54 | 0.97 | 0.19 |

| S27 | Wholesale, retail trade and accommodation, and catering | 1946.39 | 1940.10 | 1480.31 | 2.45 | 0.51 | 0.69 |

| S28 | Transportation, storage, and postal industry | 451.77 | 1620.16 | 1052.14 | 2.23 | 0.60 | 0.19 |

| S29 | Other Services | 411.85 | 2268.74 | 5440.85 | 3.48 | 0.30 | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, F.; Li, J. Responsibility Allocation of Provincial Industry Emission Reduction from the Perspective of Industrial Linkages—A Case Study of Shanxi Province. Sustainability 2023, 15, 9330. https://doi.org/10.3390/su15129330

Wan F, Li J. Responsibility Allocation of Provincial Industry Emission Reduction from the Perspective of Industrial Linkages—A Case Study of Shanxi Province. Sustainability. 2023; 15(12):9330. https://doi.org/10.3390/su15129330

Chicago/Turabian StyleWan, Fang, and Jizu Li. 2023. "Responsibility Allocation of Provincial Industry Emission Reduction from the Perspective of Industrial Linkages—A Case Study of Shanxi Province" Sustainability 15, no. 12: 9330. https://doi.org/10.3390/su15129330

APA StyleWan, F., & Li, J. (2023). Responsibility Allocation of Provincial Industry Emission Reduction from the Perspective of Industrial Linkages—A Case Study of Shanxi Province. Sustainability, 15(12), 9330. https://doi.org/10.3390/su15129330