Influence of Dry-Wet Cycles on the Structure and Shear Strength of Loess

Abstract

1. Introduction

- (1)

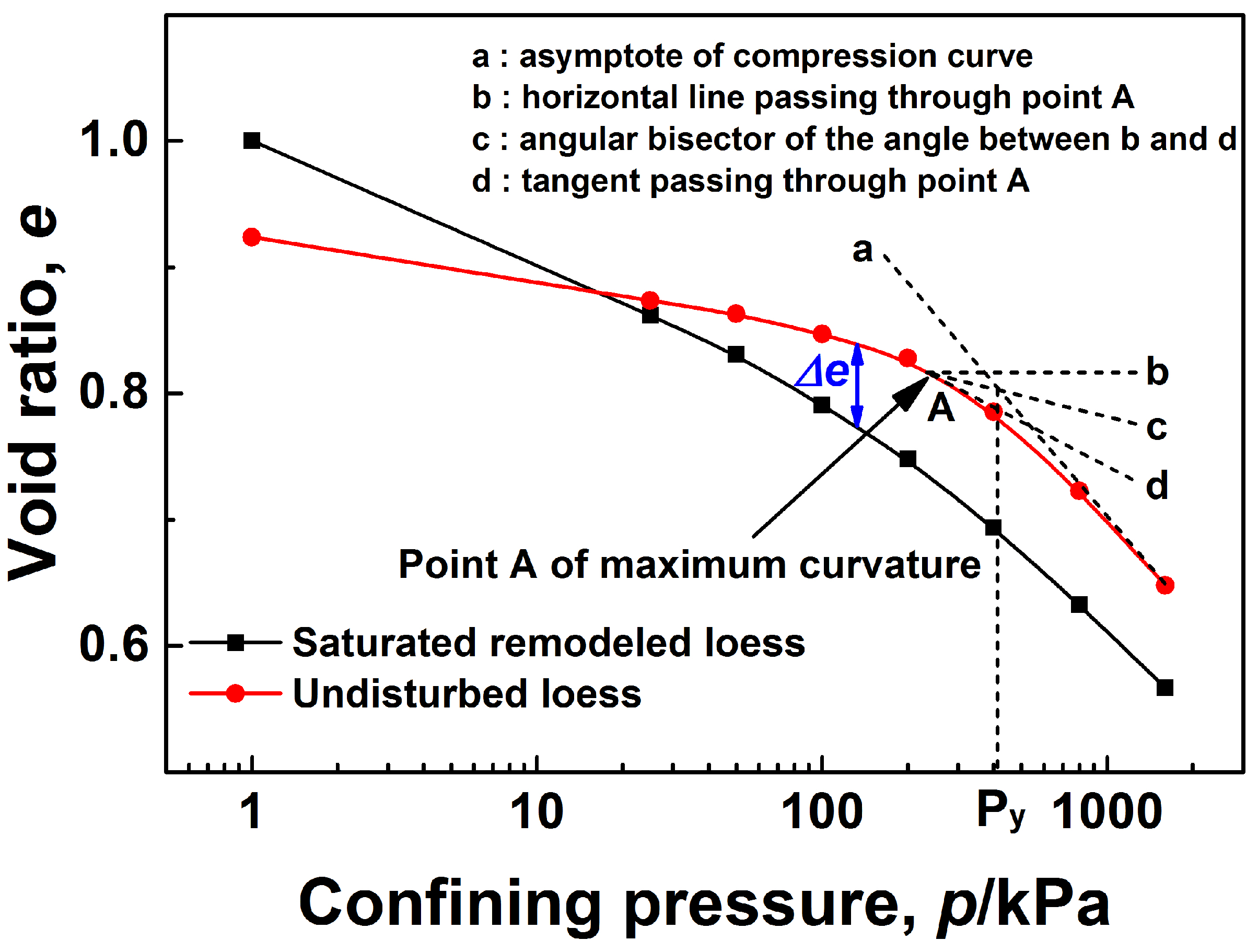

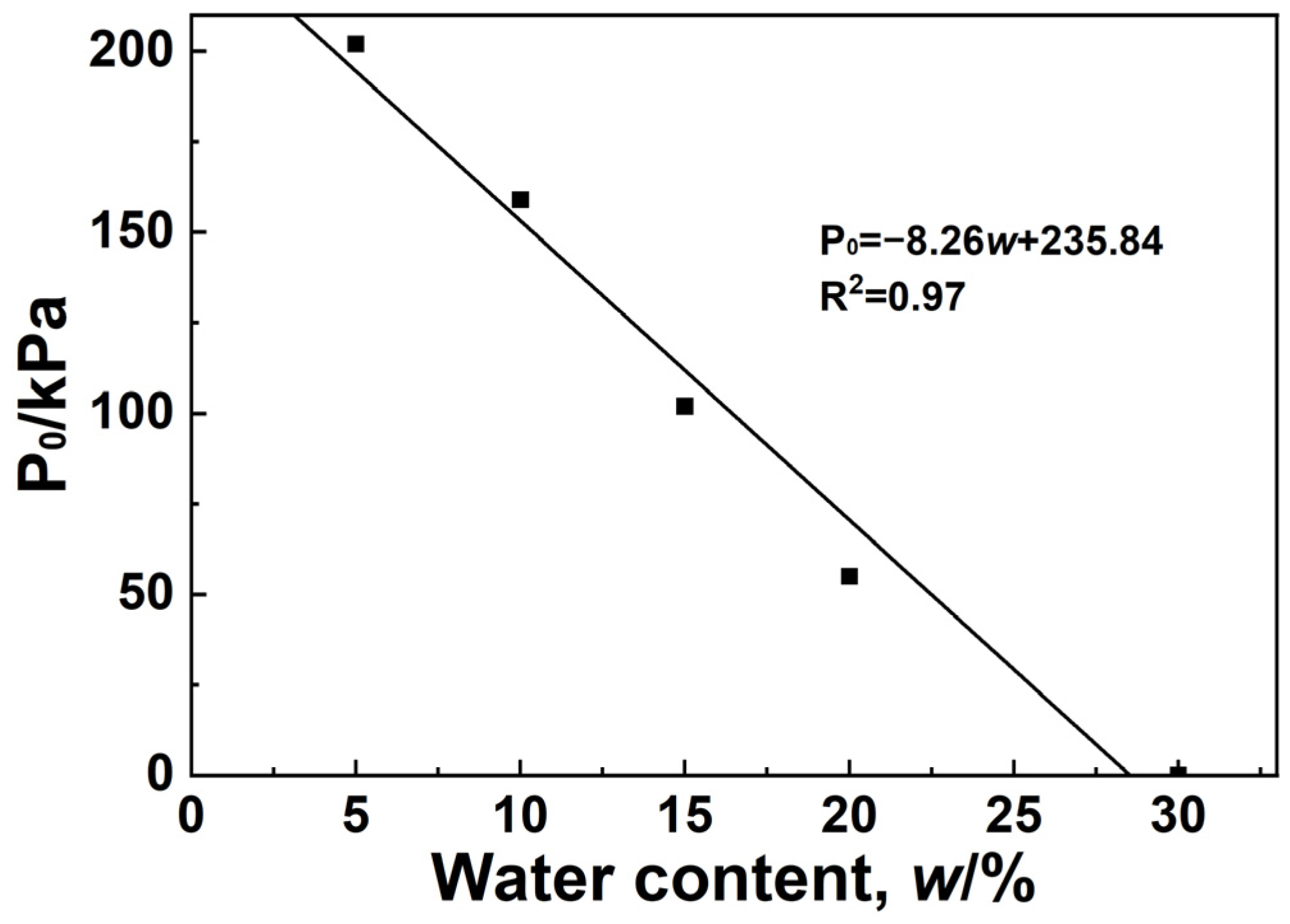

- Undisturbed loess has structure. The relationship curves between void ratio (e) and confining pressure (p) are different for the isotropic compression tests of undisturbed loess and saturated remolded loess, as shown in Figure 1. The compression curves of undisturbed loess are higher than those of saturated remolded loess. Under the same confining pressure, the undisturbed loess has an additional void ratio (Δe). There is a yield stress in undisturbed loess. Before yield stress, undisturbed loess maintains its intact structure, and only elastic deformation occurs as the stress increases. When the stress exceeds the yield stress, with the increase in stress, the structure of undisturbed loess is rapidly destroyed, elastic–plastic deformation occurs, and the additional void ratio decreases gradually. Finally, the compression curve of the undisturbed loess tends to be the same as that of the remolded soil. The yield stress is the maximum stress that the intact structure can bear, so the yield stress is called the structural strength Py of undisturbed loess. There is a significant relationship between Py and the water content w of loess.

- (2)

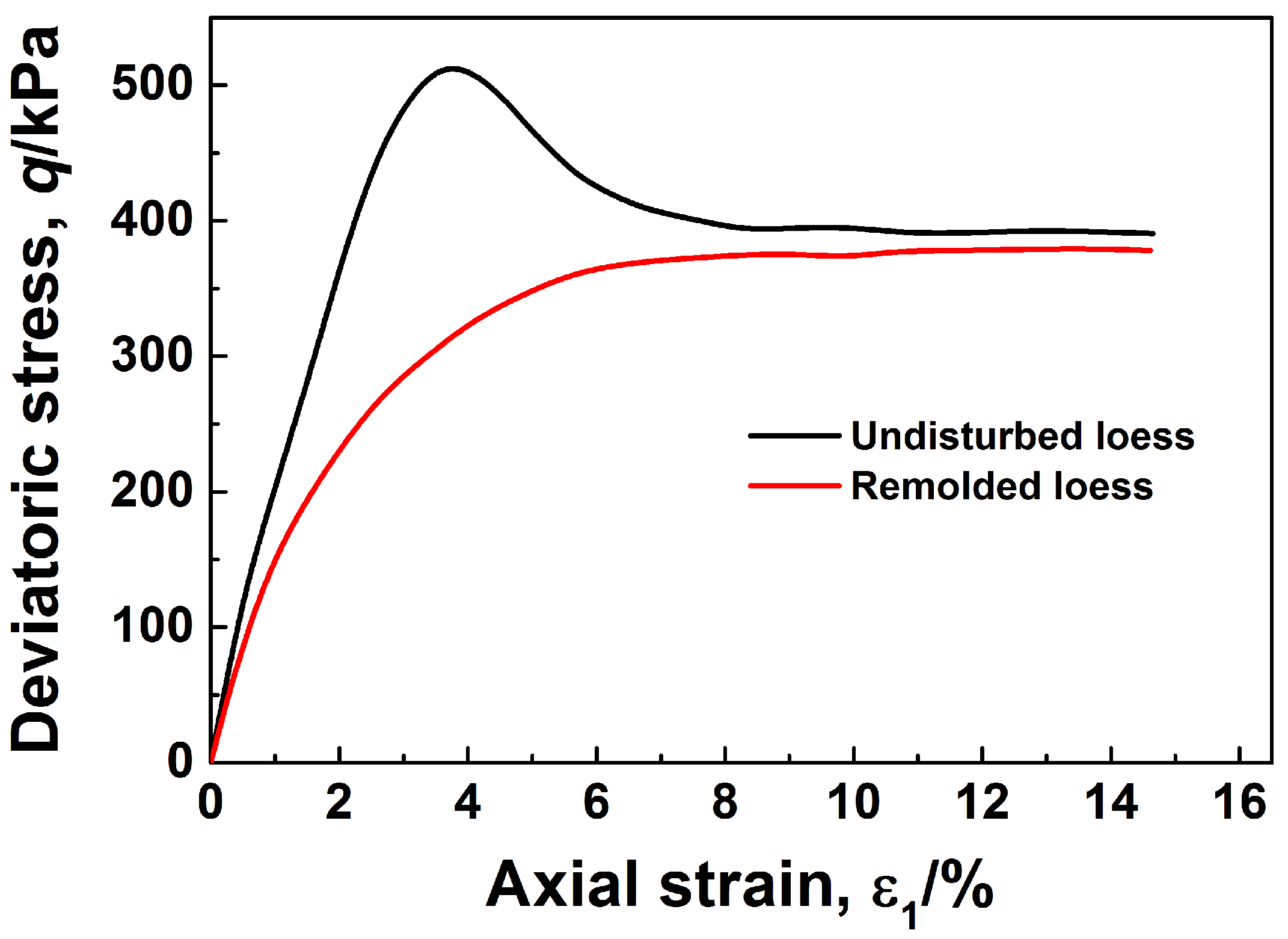

- Due to the influence of structure, the stress–strain curves of undisturbed loess and remolded loess are obviously different in triaxial tests, as shown in Figure 2. The typical stress–strain curve of undisturbed loess is higher than that of remolded loess, and the stress decreases after reaching the peak value. With the development of shear strain, the stress–strain curves of the two kinds of loess samples tend to be the same [45,46].

2. Materials and Methods

2.1. Materials and Preparation of Samples

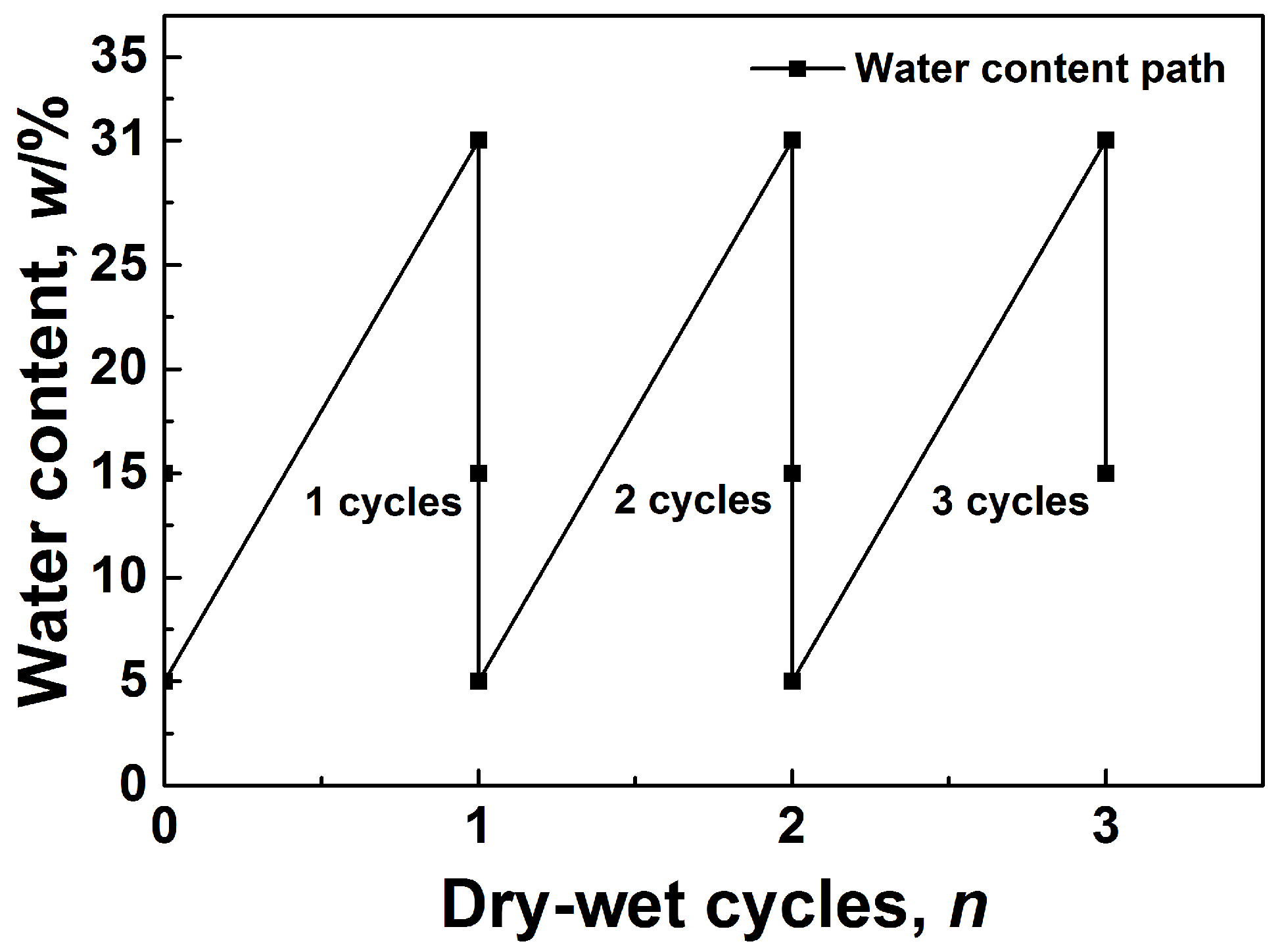

2.2. Experimental Methods

2.2.1. Isotropic Compression Test

2.2.2. Triaxial Shear Test

3. Results and Discussion

3.1. Analysis of Isotropic Compression Test

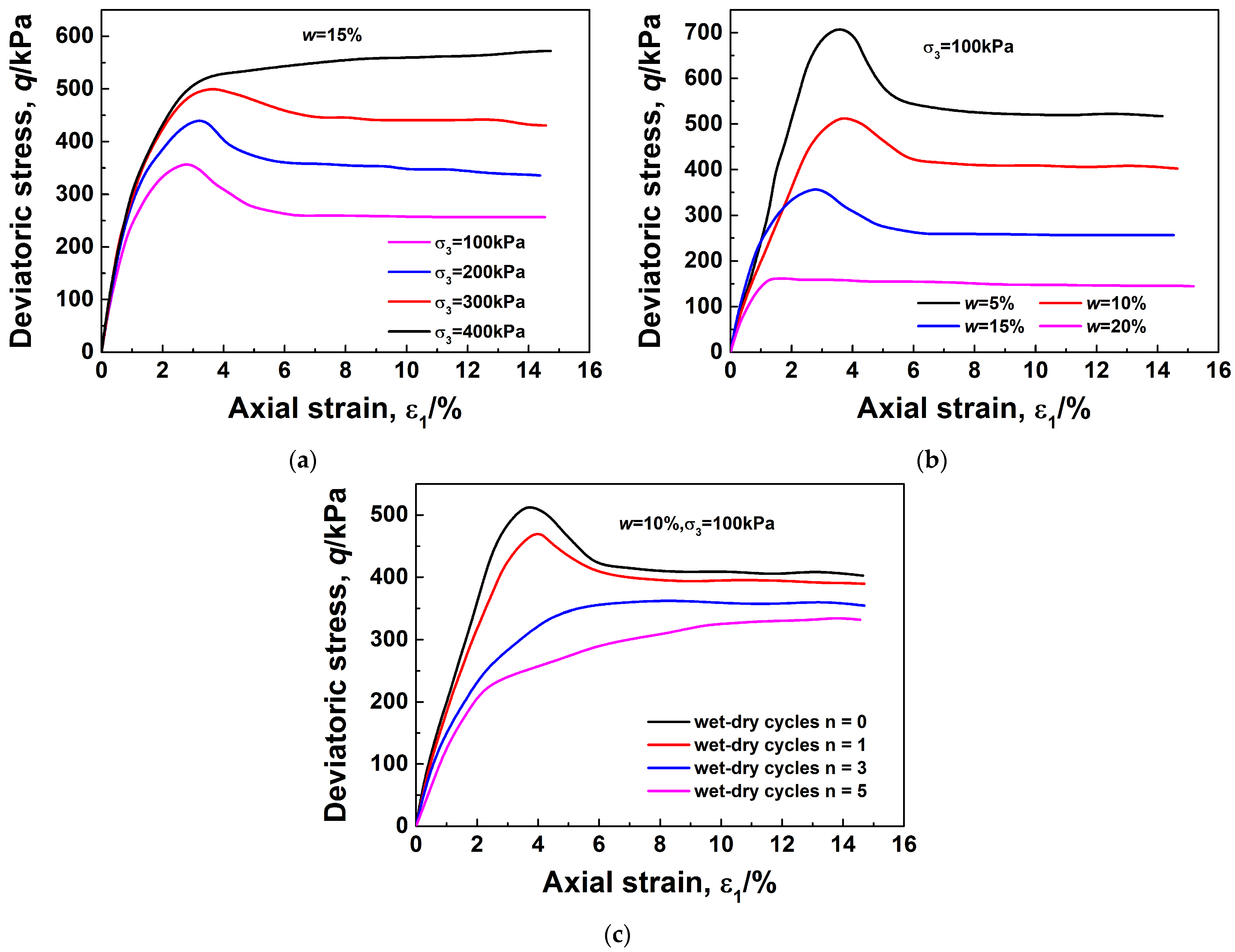

3.2. Analysis of Shear Strength of Loess under Dry-Wet Cycles

3.3. Analysis of Structural Parameters of Loess under Dry-Wet Cycles

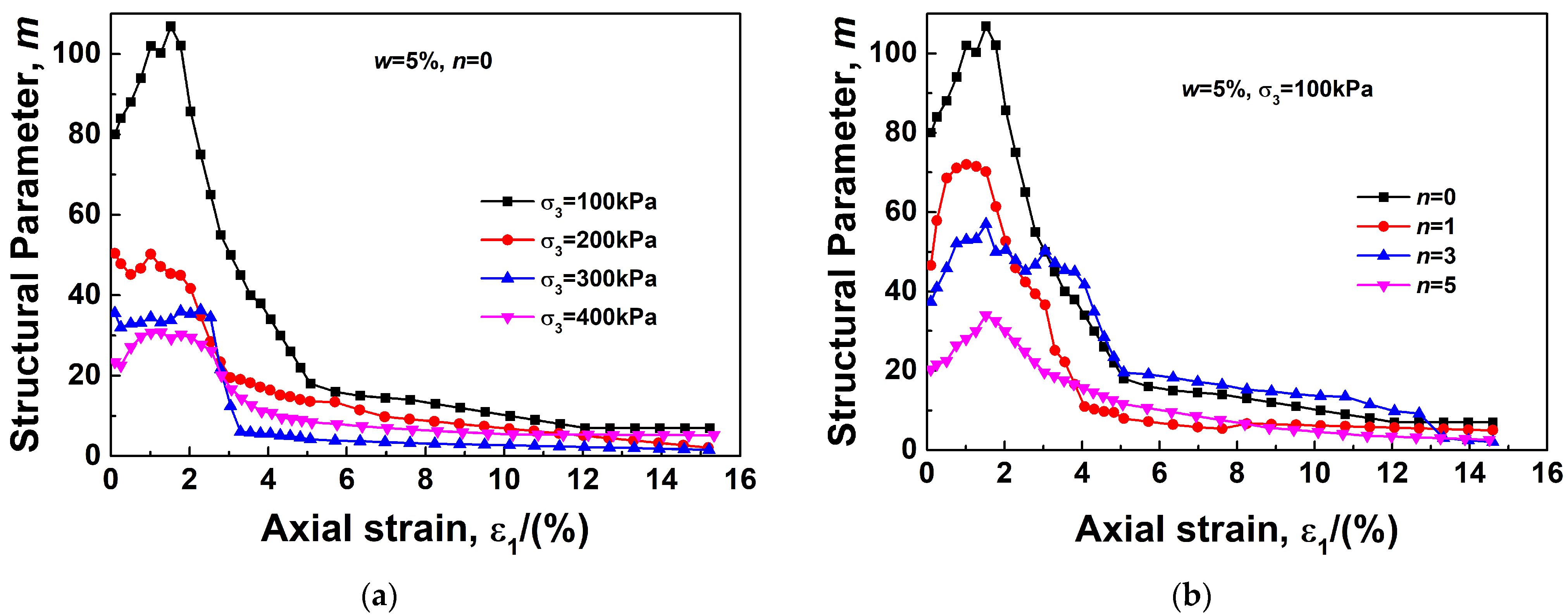

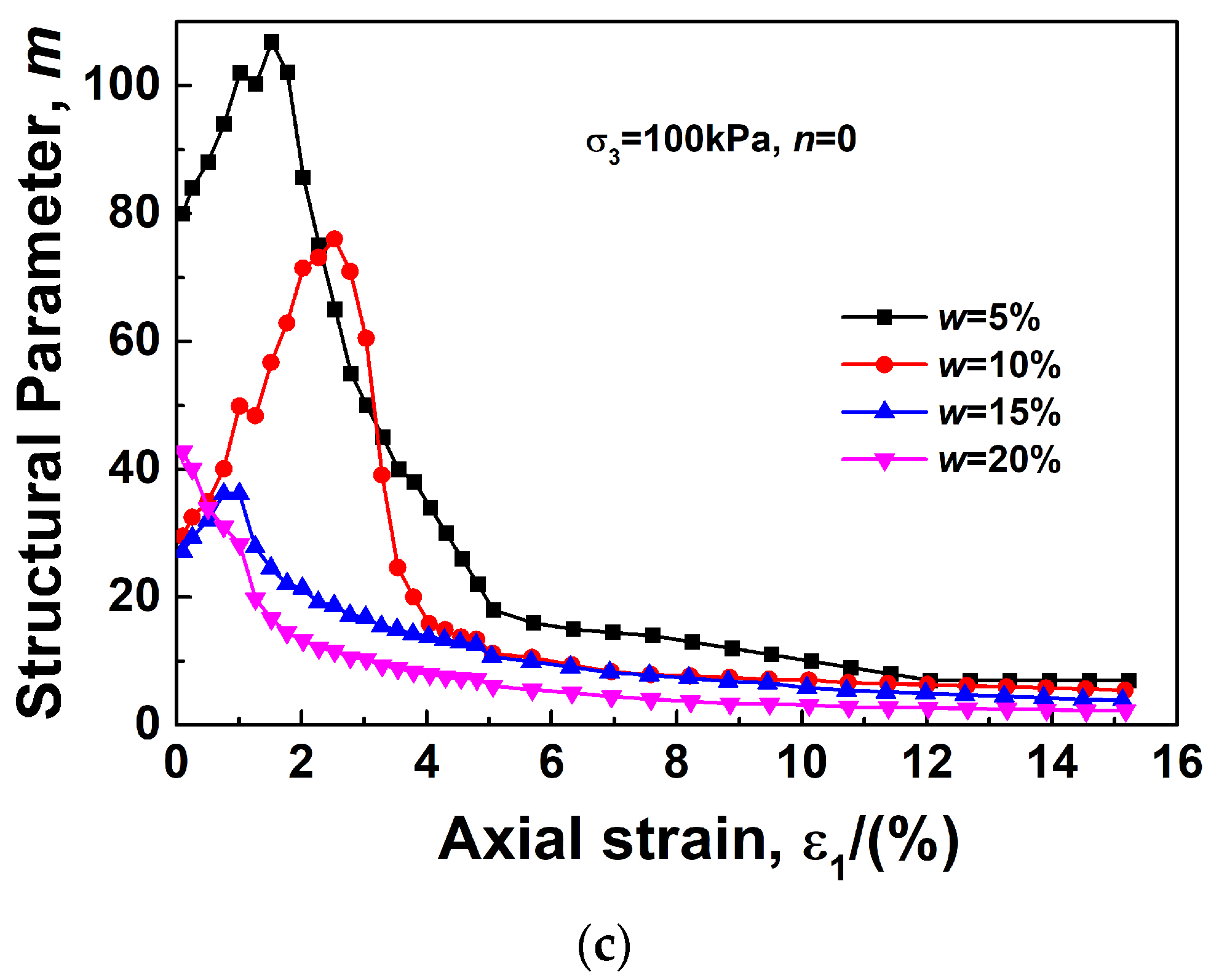

3.3.1. Description of Loess Structure

3.3.2. Change Rule of Loess Structure

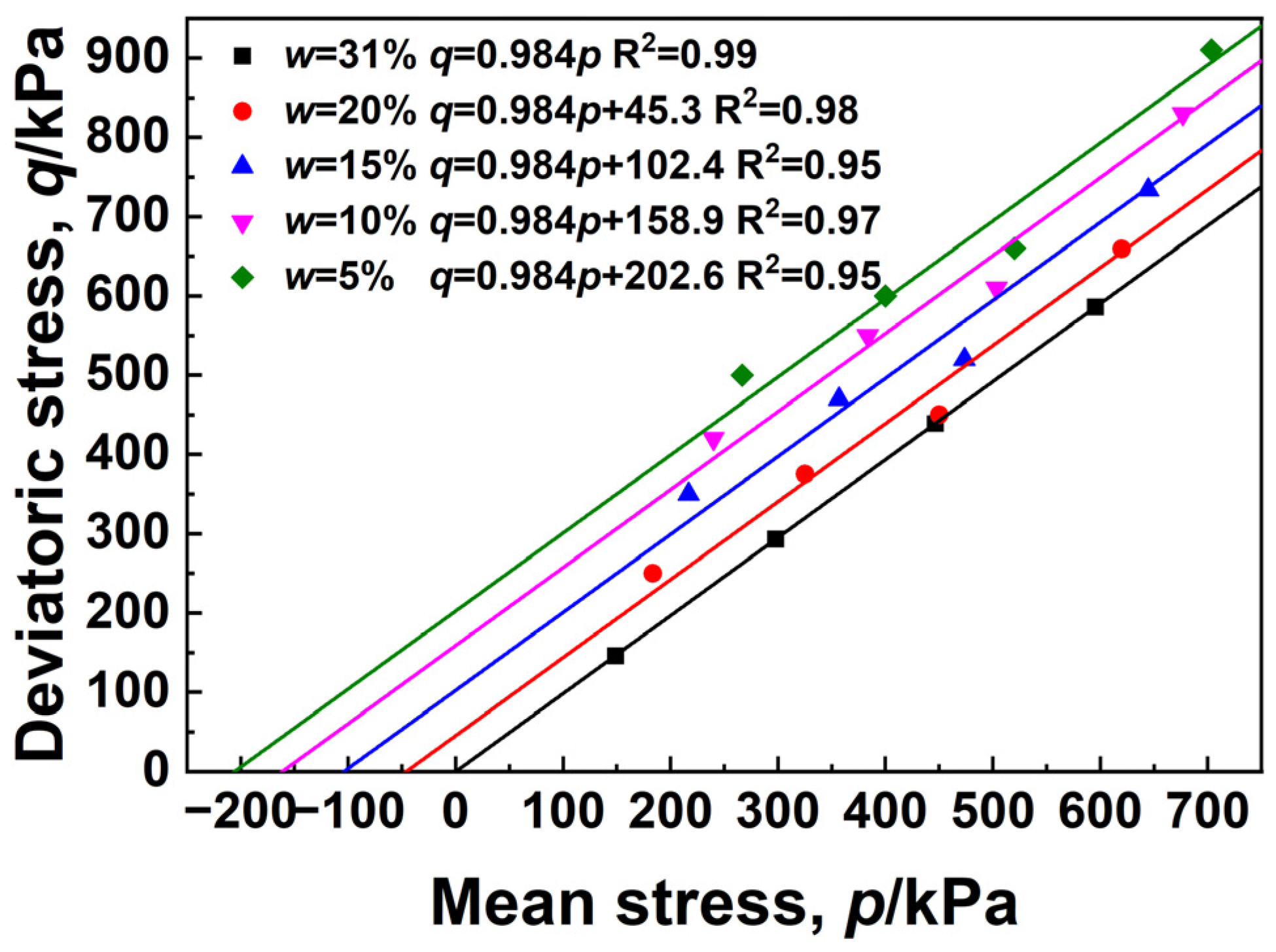

3.4. Initial Yield Characteristics of Loess

3.5. Limitations of Tests and Analysis Methods

4. Relationship between Structure and Shear Strength of Loess

5. Applications of Study Results

6. Conclusions

- (1)

- The dry-wet cycle reduces the cohesion c of loess, and the decrease degree is the greatest after the first dry-wet cycle, while the effect on the internal friction angle φ is negligible. In the case of low water content, the dry-wet cycle effect is obvious, but with the increase in water content, the effect weakens.

- (2)

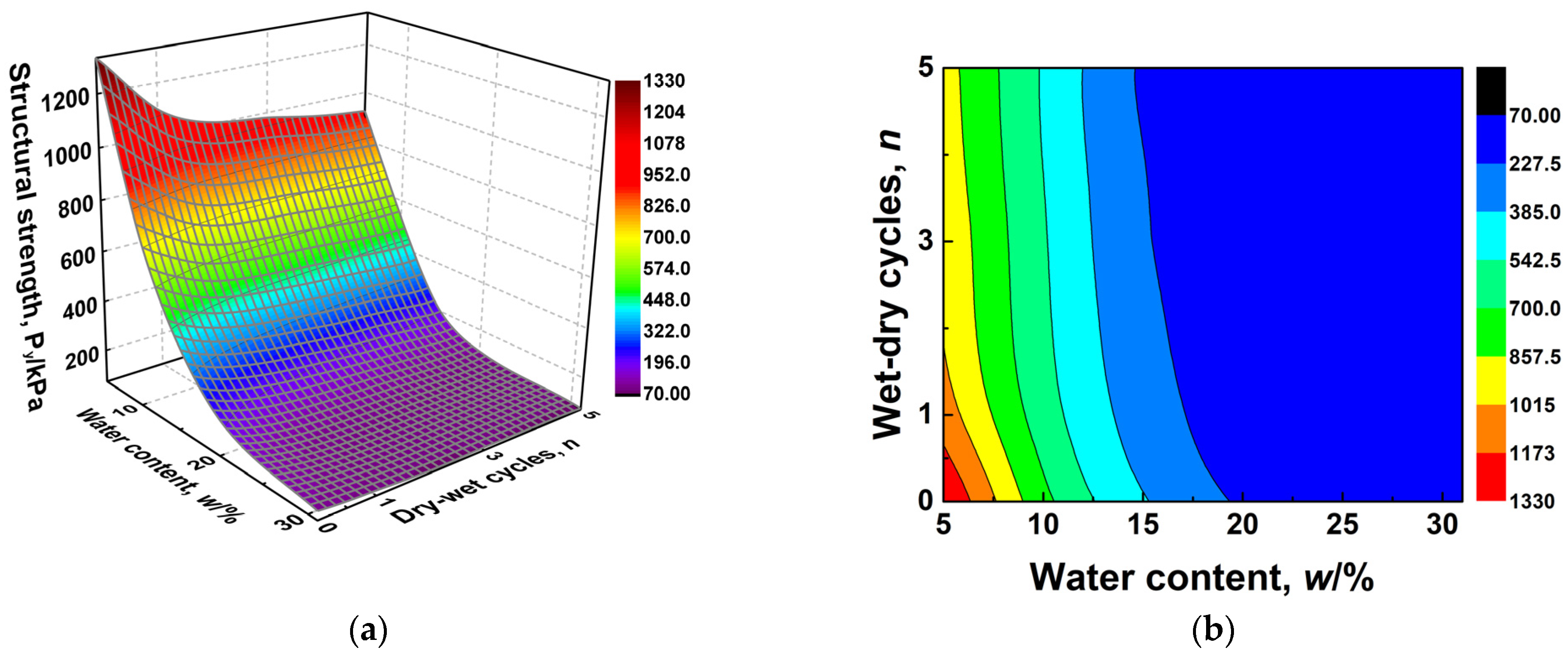

- The structural strength Py and structural parameter m can represent the structure of loess well; both decrease with increasing water content and dry-wet cycles.

- (3)

- In a p-q coordinate system, the initial yield surface of loess can be approximated by an ellipse, and the position and size of the ellipse vary with the water content and dry-wet cycles.

- (4)

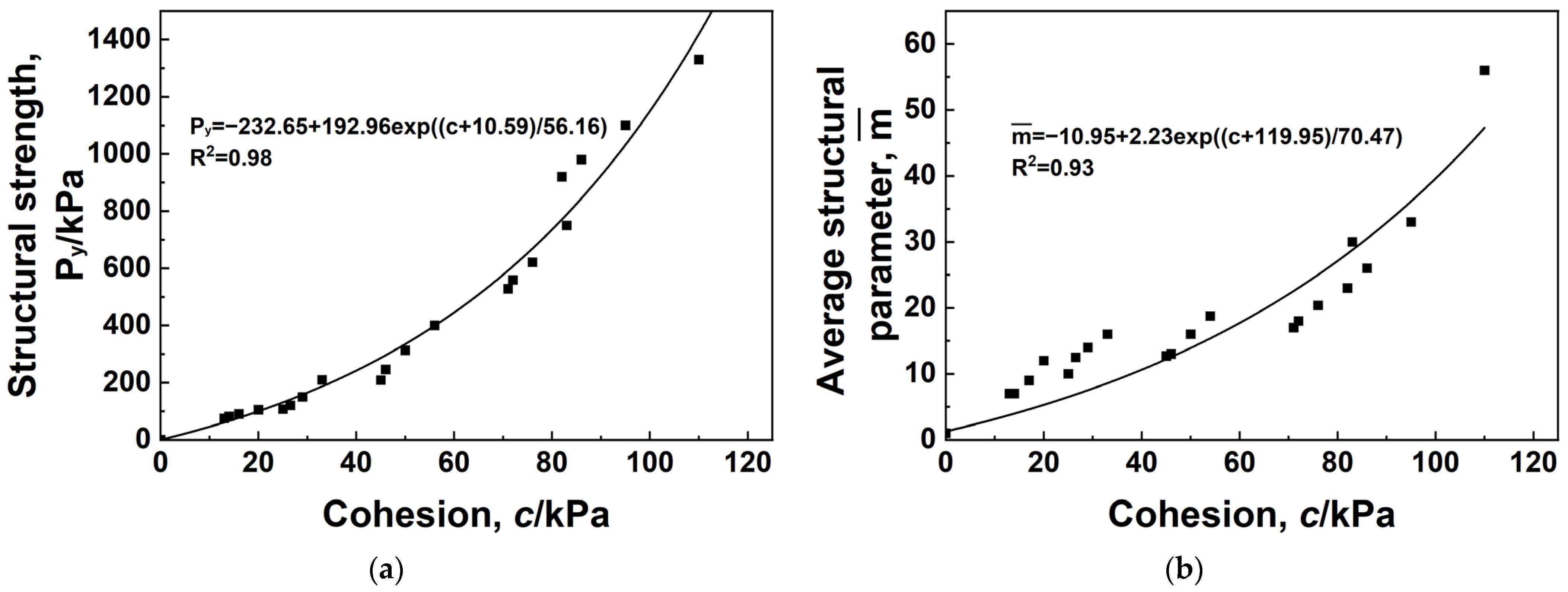

- The cohesion c of loess has similar variation rules with the structural strength Py and the average structural parameter . Py and increase with cohesion, according to an exponential function relationship.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Terzaghi, K.T. Theoretical Soil Mechanics; Wiley: New York, NY, USA, 1943. [Google Scholar] [CrossRef]

- Burland, J.B. On the compressibility and shear strength of natural clays. Géotechnique 1990, 40, 329–378. [Google Scholar] [CrossRef]

- Leroueil, S.; Vaughan, P.R. The general and congruent effects of structure in natural soils and weak rocks. Géotechnique 1990, 40, 467–488. [Google Scholar] [CrossRef]

- Cotecchia, F.; Cafaro, F.; Aresta, B. Structure and mechanical response of sub-Apennine Blue Clays in relation to their geological and recent loading history. Géotechnique 2007, 57, 167–180. [Google Scholar] [CrossRef]

- Haeri, S.M.; Khosravi, A.; Garakani, A.A.; Ghazizadeh, S. Effect of Soil Structure and Disturbance on Hydromechanical Behavior of Collapsible Loessial Soils. Int. J. Geomech. 2017, 17, 04016021. [Google Scholar] [CrossRef]

- Xu, Y.L.; Guo, P.P.; Zhu, C.G.; Lei, G.; Cheng, K. Experimental Investigation into Compressive Behaviour and Preconsolidation Pressure of Structured Loess at Different Moisture Contents. Geofluids 2021, 2021, 5585392. [Google Scholar] [CrossRef]

- Roscoe, K.H.; Schofield, A.N.; Wroth, C.P. On yielding of soils. Géotechnique 1958, 8, 22–53. [Google Scholar] [CrossRef]

- Novello, E.A.; Johnston, L.W. Geotechnical Materials and the Critical State. Géotechnique 1995, 45, 223–235. [Google Scholar] [CrossRef]

- Hachey, J.; Been, K.; Jefferies, M.G. The critical state of sands. Géotechnique 1991, 41, 365–381. [Google Scholar] [CrossRef]

- Newson, T.A. Validation of A Non-associated Critical State Model. Comput. Geotech. 1998, 23, 277–287. [Google Scholar] [CrossRef]

- Shen, Z.J. Mathematical model of soil structure—The core issue of soil mechanics in the 21st century. Chin. J. Geotech. Eng. 1996, 18, 95–97. [Google Scholar]

- DESAI, C.S. A consistent finite element technique for work softening behavior. In Proceedings of the International Conference on Computer Methods in Nonlinear Mechanics, Austin, TX, USA, 12 September 1974; University of Texas Press: Austin, TX, USA, 1974; pp. 403–418. [Google Scholar]

- Desai, C.S.; Ma, Y. Modeling of joints and interfaces using the disturbed state concept. Int. J. Numer. Anal. Methods Geomech. 1992, 16, 623–653. [Google Scholar] [CrossRef]

- Armaleh, S.H.; Desai, C.S. Modeling and testing of cohesion-less material using disturbed state concept. J. Mech. Behav. Mater. 1994, 50, 279–295. [Google Scholar] [CrossRef]

- Pal, S.; Wathugala, G.W. Disturbed state model for sand-geosynthetic interfaces and application to pull-out tests. Int. J. Numer. Anal. Methods Geomech. 1999, 23, 1873–1892. [Google Scholar] [CrossRef]

- Katti, D.R.; Desai, C.S. Modeling and Testing of Cohesive Soil Using Disturbed-State Concept. J. Eng. Mech. 1995, 121, 648–658. [Google Scholar] [CrossRef]

- Wang, G.X.; Xiao, S.F.; Huang, H.W.; Wu, C.Y. Study of Constitutive Model of Structural Clay based on the Disturbed State Concept. Chin. J. Solid Mech. 2004, 25, 191–197. [Google Scholar]

- Jin, X.; Zhao, C.G.; Chen, T.L. Study on Constitutive Model for Unsaturated Structural Loess. J. Eng. Geol. 2010, 18, 548–553. [Google Scholar]

- Shao, S.; Chu, F.; Shao, S.J. Experimental study on constitutive model of structural Q3 loess based on disturbed state concept. Chin. J. Rock Mech. Eng. 2016, 35, 1494–1500. [Google Scholar]

- Shen, Z.J.; Zhang, W.M. Application of damage mechanics in soil mechanics. In Proceedings of the 3th Conference of Numerical Analysis and Analytic Method on Rock and Soil Mechanics in China, Zhuhai, China, 1 November 1988; pp. 595–609. [Google Scholar]

- Shen, Z.J. A masonry model for structured clays. Rock Soil Mech. 2000, 21, 1–4. [Google Scholar]

- Shen, Z.J. An Elasto-plastic Damage Model for Cemented Clays. Chin. J. Geotech. Eng. 1993, 15, 21–28. [Google Scholar]

- Shen, Z.J. A nonlinear damage model for structured clay. Hydro-Sci. Eng. 1993, 3, 247–255. [Google Scholar]

- He, K.S.; Shen, Z.J. Elasto-viscoplastic damage model for structural clays. Hydro-Sci. Eng. 2002, 4, 7–13. [Google Scholar]

- Jin, X.; Zhao, C.G.; Liu, Y.; Cai, G.Q. An Elasto–Plastic Damage Constitutive Model of Unsaturated Natural Soils. J. Beijing Jiaotong Univ. 2010, 34, 78–82. [Google Scholar]

- Liu, M.D.; Carter, J.P. Virgin compression of structured soils. Géotechnique 1999, 49, 43–57. [Google Scholar] [CrossRef]

- Liu, M.D.; Carter, J.P. Modelling the destructuring of soils during virgin compression. Géotechnique 2000, 50, 479–483. [Google Scholar] [CrossRef]

- Liu, M.D.; Carter, J.P. A structured Cam Clay model. Can. Geotech. J. 2002, 39, 1313–1332. [Google Scholar] [CrossRef]

- Carter, J.P.; Liu, M.D. Review of the Structure Cam Clay model. Geotech. Spec. Publ. 2005, 128, 99–132. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Liu, M.D.; Liyanapathirana, D.S.; Suebsuk, J. Behaviour of cemented clay simulated via the theoretical framework of Structured Cam Clay model. Comput. Geotech. 2010, 37, 1–9. [Google Scholar] [CrossRef]

- Li, W.G.; Yang, G.; Liu, W.H.; Sun, X.L. Study of constitutive model for soils based on structural parameter. J. Dalian Univ. Technol. 2021, 61, 84–91. [Google Scholar]

- Li, W.G.; Yang, Q.; Liu, W.H.; Yang, G.; Sun, X.L. Structured quantitative characterization and elastoplastic constitutive model of clay. Chin. J. Geotech. Eng. 2022, 44, 678–686. [Google Scholar]

- Hou, L.L.; Weng, X.L.; Li, L.; Zhou, R.M. A critical state model for structural loess considering water content. Rock Soil Mech. 2022, 43, 737–748. [Google Scholar]

- Suebsuk, J.; Horpibulsuk, S.; Liu, M.D. Modified Structured Cam Clay: A generalised critical state model for destructured, naturally structured and artificially structured clays. Comput. Geotech. 2010, 37, 956–968. [Google Scholar] [CrossRef]

- Suebsuk, J.; Horpibulsuk, S.; Liu, M.D. A critical state model for overconsolidated structured clays. Comput. Geotech. 2011, 38, 648–658. [Google Scholar] [CrossRef]

- Xie, D.Y.; Qi, J.L. Soil structure characteristics and new approach in research on its quantitative parameter. Chin. J. Geotech. Eng. 1999, 21, 651–656. [Google Scholar]

- Xie, D.Y.; Qi, J.L.; Zhu, Y.L. Soil structure parameter and its relations to deformation and strength. J. Hydraul. Eng. 1999, 10, 1–6. [Google Scholar]

- Xie, D.Y.; Qi, J.L.; Zhang, Z.Z. A Constitutive Laws Considering Soil Structural Properties. China Civ. Eng. J. 2000, 33, 35–41. [Google Scholar]

- Shao, S.J.; Zhou, F.F.; Long, J.Y. Structural properties of loess and its quantitative parameter. Chin. J. Geotech. Eng. 2004, 26, 531–536. [Google Scholar]

- Luo, Y.S.; Xie, D.Y.; Shao, S.J. Structural parameter of soil under complex stress conditions. Chin. J. Rock Mech. Eng. 2004, 23, 4248–4251. [Google Scholar]

- Chen, C.L.; Hu, Z.Q.; Gao, P. Research on relationship between structure and deformation property of intact loess. Rock Soil Mech. 2006, 27, 1891–1896. [Google Scholar]

- Chen, C.L.; Hu, Z.Q.; Gao, P. Moistening deformation characteristic of loess and its relation to structure. Chin. J. Rock Mech. Eng. 2006, 25, 1352–1360. [Google Scholar]

- Chen, C.L.; Gao, P.; He, J.F. Equivalent linear model of intact loess considering structural effect. Chin. J. Geotech. Eng. 2007, 29, 1330–1336. [Google Scholar]

- Luo, Y.S.; Hu, Y.Z.; Zhang, A.J. Regularity of relation between structural parameter and strength indexes of unsaturated loess. Rock Soil Mech. 2009, 30, 943–948. [Google Scholar]

- Dang, J.Q.; Hao, Y.Q. Effect of water content on the structure strength of loess. J. Water Resour. Water Eng. 2000, 33, 35–41. [Google Scholar]

- Dang, J.Q.; Li, J. The structural strength and shear strength of unsaturated loess. J. Hydraul. Eng. 2001, 7, 79–83. [Google Scholar]

- Yuan, Z.H.; Ni, W.K.; Tang, C.; Hu, S.M.; Gan, J.J. Experimental study of structure strength and strength attenuation of loess under wetting-drying cycle. Rock Soil Mech. 2017, 38, 1894–1902. [Google Scholar]

- Delage, P.; Lefebvre, G. Study of the structure of a sensitive Champlain clay and evolution during consolidation. Can. Geotech. J. 1984, 21, 21–25. [Google Scholar] [CrossRef]

- Miao, T.D.; Wang, Z.G. Deformation Mechanism of Collapsible Loess Considering Microstructural Instability. Sci. Sin. (Chim.) 1990, 1, 86–96. [Google Scholar]

- Tovey, N.K. A digital computer technique for orientation analysis of micrographs of soil fabric. J. Microsc. 1992, 120, 303–315. [Google Scholar] [CrossRef]

- Kruyt, N.P.; Rothenburg, L. Micromechanical definition of the strain tensor for granular materials. J. Appl. Mech. 1996, 63, 706–711. [Google Scholar] [CrossRef]

- PAUL, G.J. Physical Basis and Validation of a Constitutive Model for Soil Shear Derived from Microstructural Changes. Int. J. Geomech. 2013, 13, 365–383. [Google Scholar] [CrossRef]

- Jiang, M.J.; Liu, J.D.; Sun, Y.G. Constitutive model for structured soils based on microscopic damage law. Chin. J. Geotech. Eng. 2013, 35, 1134–1139. [Google Scholar]

- Jiang, M.J.; Zhou, W.; Sun, Y.G. A constitutive model for anisotropic structured sandy soil based on micromechanical mechanism. Rock Soil Mech. 2016, 37, 3347–3355. [Google Scholar]

- Fang, H.L.; Zheng, H.; Zheng, J. Micromechanics-based Multimechanism Bounding Surface Model for Sands. Int. J. Plast. 2017, 90, 242–266. [Google Scholar] [CrossRef]

- Gao, G.R. A Structure Theory for Collapsing Deformation of Loess Soils. Chin. J. Geotech. Eng. 1990, 12, 1–10. [Google Scholar]

- Hu, Z.Q.; Shen, Z.J.; Xie, D.Y. Constitutive model of structural loess. Chin. J. Rock Mech. Eng. 2005, 24, 565–569. [Google Scholar]

- Shao, S.J.; Tao, H.; Xu, P. Discussion on research of mechanical characteristics of loess considering structural behavior and its application. Rock Soil Mech. 2011, 32, 42–50. [Google Scholar]

- Wang, F.; Li, G.Y.; Mu, Y.H.; Zhang, P.; Wu, Y.H.; Fan, S.Z. Experimental study of deformation characteristics of compacted loess subjected to drying-wetting cycle. Rock Soil Mech. 2016, 37, 2306–2320. [Google Scholar]

- Wu, J.H.; Yang, N.N.; Li, P.Y.; Yang, C.L. Influence of Moisture Content and Dry Density on the Compressibility of Disturbed Loess: A Case Study in Yan’an City, China. Sustainability 2023, 15, 6212. [Google Scholar] [CrossRef]

- Hu, C.M.; Yuan, Y.L.; Wang, X.Y.; Mei, Y.; Liu, Z. Experimental study on strength deterioration model of compacted loess under wetting-drying cycles. Chin. J. Rock Mech. Eng. 2018, 37, 2804–2818. [Google Scholar]

- Qin, Y.Y.; Li, G.Y.; Chen, X.J.; Fan, K.F. Study on shear strength and structure of Malan loess under wetting–drying cycles. Arabian J. Geosci. 2021, 14, 2854. [Google Scholar] [CrossRef]

- Ye, W.J.; Sai, Y.; Cui, C.Y.; Duan, X. Deterioration of the Internal Structure of Loess under Dry-Wet Cycles. Adv. Civ. Eng. 2020, 2020, 8881423. [Google Scholar] [CrossRef]

- Xu, X.T.; Shao, L.J.; Huang, J.B.; Xu, X.; Liu, D.Q.; Xian, Z.X.; Jian, W.B. Effect of wet-dry cycles on shear strength of residual soil. Soils Found. 2021, 61, 782–797. [Google Scholar] [CrossRef]

- Bai, Y.; Ye, W.J.; Wu, Y.T.; Chen, Y.Q. Multiscale Analysis of the Strength Deterioration of Loess under the Action of Drying and Wetting Cycles. Adv. Mater. Sci. Eng. 2021, 2021, 6654815. [Google Scholar] [CrossRef]

- Shi, G.M.; Li, X.Y.; Guo, Z.K.; Zhang, Z.Z.; Zhang, Y.Y. Effect of Mica Content on Shear Strength of the Yili Loess under the Dry-Wet Cycling Condition. Sustainability 2022, 14, 9569. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.P.; Chen, H.; Shao, L.T.; Zhou, X.G.; Wang, S.H. Influence of dry-wet cycles on the strength behavior of basalt-fiber reinforced loess. Eng. Geol. 2022, 302, 106645. [Google Scholar] [CrossRef]

- Wang, X.L. Research on the Effect of Shear Strength and Structural Property and Slope Stability of Loess Under Dry-Wet Cycle. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2017. [Google Scholar]

- Wei, Y.N.; Fan, W.; Ma, G.L. Characteristics of Microstructure and Collapsible Mechanism of Malan Loess in Loess Plateau, China. J. Earth Sci. Environ. 2022, 44, 581–592. [Google Scholar]

- Zheng, F.; Shao, S.J.; Wang, J.; Shao, S. Experimental Study on the Mechanical Behaviour of Natural Loess Based on Suction-Controlled True Triaxial Tests. KSCE J. Civ. Eng. 2020, 24, 2304–2321. [Google Scholar] [CrossRef]

- Ge, M.M.; He, X.; Gu, C.; Li, N.; Liu, N.F. Study on the Microstructure Evolution of a Compacted Loess along Compression, Wetting and Drying. J. Eng. Geol. 2023, 1–13. Available online: https://kns.cnki.net/kcms/detail/11.3249.p.20220829.1928.001.html (accessed on 9 May 2023).

| Dry Density, ρ/g·cm−3 | Water Content, w/% | Plastic Limit /% | Liquid Limit/% | Plasticity Index | Specific Gravity | Particle Composition/% | ||

| >0.075 mm | 0.075–0.005 mm | <0.005 mm | ||||||

| 1.41 | 12.1 | 22.11 | 32.46 | 10.35 | 2.72 | 1.2 | 85.44 | 13.36 |

| Water Content, w/% | Cycle Number, n | Confining Pressure, p/kPa | |

| Undisturbed samples | 5, 10, 15, 20, 31 | 0, 1, 3, 5 | 25, 50, 100, 200, 400, 800, 1600 |

| Saturated remolded samples | Saturated | 0 | 25, 50, 100, 200, 400, 800, 1600 |

| Water Content, w/% | Cycle Number, n | Confining Pressure, p/kPa | |

| Undisturbed samples | 5, 10, 15, 20, 31 | 0, 1, 3, 5 | 100, 200, 300, 400 |

| Saturated remolded samples | 5, 10, 15, 20, 31 | 0 | 100, 200, 300, 400 |

| Cycle Number | Water Content, w/% | ||||

| 5 | 10 | 15 | 20 | 31 | |

| Structural Strength, Py/kPa | |||||

| 0 | 1330 | 750 | 400 | 210 | 105 |

| 1 | 1100 | 621 | 313 | 150 | 90 |

| 3 | 980 | 559 | 246 | 120 | 82 |

| 5 | 920 | 528 | 209 | 107 | 75 |

| Water Content/% | Cycle Number, n | |||||||

| 0 | 1 | 3 | 5 | 0 | 1 | 3 | 5 | |

| Cohesion, c/kPa | Internal Friction Angle, φ/° | |||||||

| 5% | 110.61 | 95.46 | 86.10 | 82.19 | 28.47 | 25.75 | 25.28 | 25.15 |

| 10% | 83.23 | 76.57 | 72.93 | 71.43 | 27.43 | 25.32 | 24.60 | 24.55 |

| 15% | 56.51 | 50.31 | 46.04 | 45.80 | 25.50 | 24.50 | 24.80 | 24.56 |

| 20% | 33.22 | 29.79 | 26.50 | 25.25 | 25.10 | 24.50 | 24.80 | 24.56 |

| 31% | 20.89 | 16.64 | 14.63 | 13.31 | 24.90 | 25.10 | 24.50 | 24.70 |

| Parameters | ||||

| y0 | x0 | A | t | |

| Py | −232.65 | 10.59 | 192.96 | 56.16 |

| −10.95 | 119.95 | 2.23 | 70.47 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Li, H.; Zhong, Y.; Zhang, L.; Yang, X.; Han, X.; Hu, Z. Influence of Dry-Wet Cycles on the Structure and Shear Strength of Loess. Sustainability 2023, 15, 9280. https://doi.org/10.3390/su15129280

Wang X, Li H, Zhong Y, Zhang L, Yang X, Han X, Hu Z. Influence of Dry-Wet Cycles on the Structure and Shear Strength of Loess. Sustainability. 2023; 15(12):9280. https://doi.org/10.3390/su15129280

Chicago/Turabian StyleWang, Xiaoliang, Hongru Li, Yue Zhong, Longfei Zhang, Xi Yang, Xiaoning Han, and Zaiqiang Hu. 2023. "Influence of Dry-Wet Cycles on the Structure and Shear Strength of Loess" Sustainability 15, no. 12: 9280. https://doi.org/10.3390/su15129280

APA StyleWang, X., Li, H., Zhong, Y., Zhang, L., Yang, X., Han, X., & Hu, Z. (2023). Influence of Dry-Wet Cycles on the Structure and Shear Strength of Loess. Sustainability, 15(12), 9280. https://doi.org/10.3390/su15129280