Analysis of the Potential of Meeting the EU’s Sustainable Aviation Fuel Targets in 2030 and 2050

Abstract

1. Introduction

1.1. Sustainable Aviation Fuel

1.2. Policy Barriers in the Proposed Mandates

- Currently, there are no agreements on how to deal with international flights coming with or without SAF certification from another country. The same applies to flights between the UK and the EU. The mandates regulate only domestic flights or flights that start or end in the country or region where the mandate is in place. Therefore, a comprehensive framework with full cooperation on a global level is needed to maximize policy alignment and avoid the risk of carbon leakage in the case of supplying or producing SAF in different countries.

- How to deal with tankering is not yet clear. Tankering refers to flights that might be overfilled with normal jet fuel to avoid refilling the tank in the EU region. This practice is performed to avoid the additional cost of SAF in the EU, where the fuel might be more expensive compared to the conventional one or SAF in non-EU states. This will require clear procedures to avoid such practices; otherwise, this will compromise the aviation industry in the whole EU and make it less competitive compared to international flights that are fed with cheaper jet fuel.

- The mandates do not clearly state how to deal with the potential overlapping between the production of SAF and other green synthetic fuels, especially when similar feedstocks are required for both fuels.

- Policy framework for importing feedstocks from non-EU countries. Some of those feedstocks utilized in SAF production typically grow in East and South Asia. The unregulated and unsupervised cultivation and harvesting of such feedstocks could lead to deforestation, competition with food production, and other environmental problems, if not produced sustainably. Such practices will abuse the land and affect the local communities in such countries. Moreover, it will represent a source of carbon leakage.

1.3. Technical Barriers for Sustainable Aviation Fuel Deployment

1.4. Methodology

- One of the main challenges that limits the expansion of SAF production is feedstock availability. Therefore, the different types of bio-based feedstocks that could be used for SAF were quantified to determine their potential and supply limitations. This information will help determine if the EU has enough sustainable feedstocks that could be used for SAF production to meet the demands.

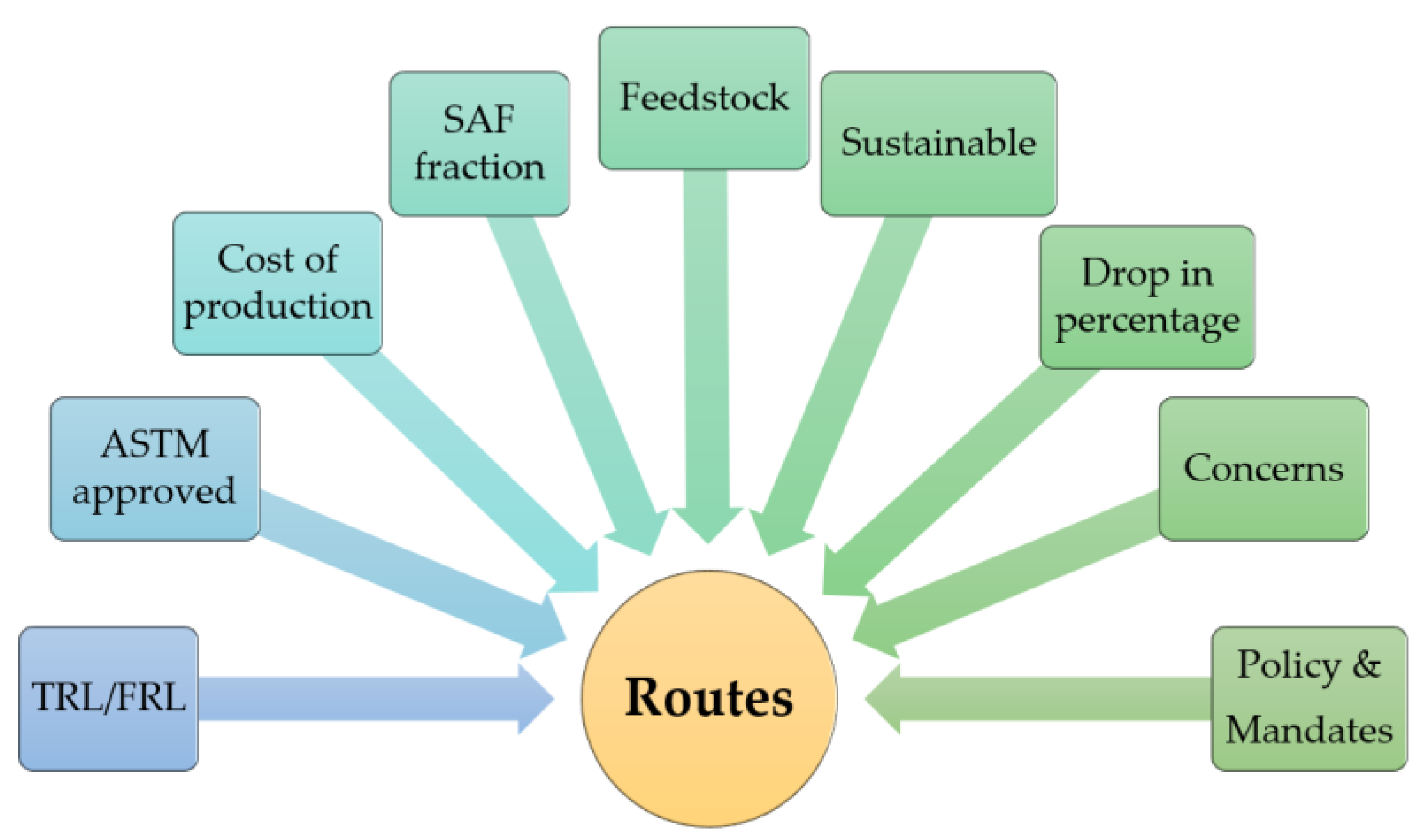

- Several pathways can be used to convert bio-feedstocks into SAF. These pathways have significant differences that arise from the utilization of diverse feedstocks and processes with varying levels of technological readiness. Therefore, the defined pathways by ASTM D7566 were comprehensively analyzed to determine the most promising and economically viable pathways that could be implemented in the short and medium term from the moment of issuing the mandate.

- By utilizing the optimal pathways and available feedstock quantities identified in the earlier steps, the capacity of SAF production in the EU was collected. The capacity in million tonnes (Mt) of SAF was calculated according to the following formula: SAF Capacity (Mt) = Feedstock quantity (Mt) × The yield percentage of liquid hydrocarbon × SAF fraction in the liquid hydrocarbon. The yield values can change depending on the pathway and the feedstock. Therefore, estimating the capacity of SAF production from each pathway shows which combination of feedstocks and pathways is capable of supplying enough SAF to meet the mandate targets.

- The accuracy of the yield values is crucial for this study as it represents the main source of uncertainty since the literature data was inconsistent. Therefore, a pathway was selected as a case study to validate the above-mentioned approach by performing a process simulation that corresponds to a large commercial production facility. The results of the simulation help to verify the literature data by providing reliable values for the process yield under different scenarios and configurations. Such information is essential to confirm the maximum possible capacity of SAF production from a particular pathway. The analysis helps to make informed decisions and prioritize the pathways that have the potential to meet the SAF targets using the current technologies and feedstocks.

2. SAF Feedstocks Availability and Quantification

2.1. Bio-Based Feedstocks

2.1.1. Waste Oil, Fats, and Grease

2.1.2. Vegetable Oils

2.1.3. Agricultural Residues

2.1.4. Lignocellulosic Cover Crops

2.1.5. Municipal Solid Waste

2.1.6. Primary and Secondary Forest Residual

2.2. Feedstock Quantification

- Sustainable.

- Easily available for collections.

- Considers the competing demand from other sectors.

- Affordable and logistically viable.

3. Analysis of SAF Pathways

3.1. Approved ASTM D7566 SAF Pathways

3.1.1. Fischer–Tropsch—Synthetic Paraffinic Kerosene

3.1.2. Fischer–Tropsch—Synthetic Paraffinic Kerosene with Added Aromatics

3.1.3. Hydroprocessed Esters Fatty Acids—Synthetic Paraffinic Kerosene

3.1.4. Hydroprocessing of Fermented Sugars—Synthetic Iso-Paraffinic Fuels

3.1.5. Alcohol-to-Jet Synthetic Paraffinic Kerosene

3.1.6. Co-Processing of Bio-Oils with Petroleum

3.1.7. Catalytic Hydrothermolysis Synthetic Kerosene

3.1.8. High Hydrogen Content Synthetic Paraffinic Kerosene

3.2. Comprehensive Analysis for SAF Pathways

- The feedstocks used in HEFA, such as vegetable oils and animal fats, do not require extensive processing, which reduces the capital investment required for the production facility. Therefore, only around 7–10% of the jet fuel’s cost comes from the capital cost. Different from HEFA, the capital cost represents the bulk of the jet fuel’s cost in other pathways, such as FT and ATJ.

- The HEFA process is a proven technology that has been used in the production of biodiesel for many years. The technology is well understood and can be easily adapted for the production of renewable aviation fuel.

- HEFA has a relatively high yield conversion compared to other pathways, which means that a relatively small amount of feedstock, when processed, will turn out to be around 90% liquid hydrocarbon. Therefore, this will reduce both the capital and operating costs.

- Side streams produce valuable co-products such as glycerol, which can be sold to offset the operating costs of the plant.

3.3. Most Promising and Economically Viable Pathways

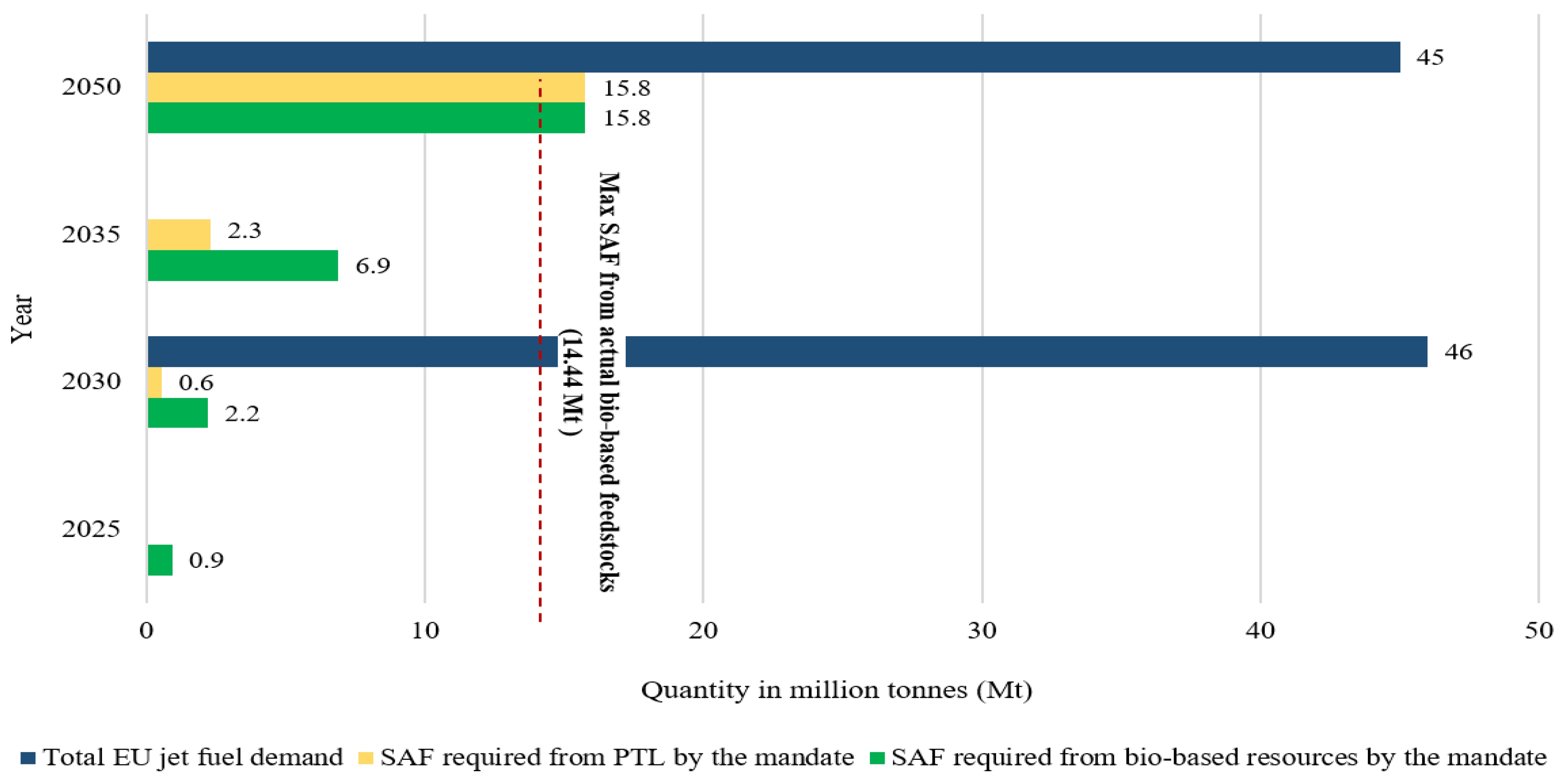

3.4. Jet Fuel Demand

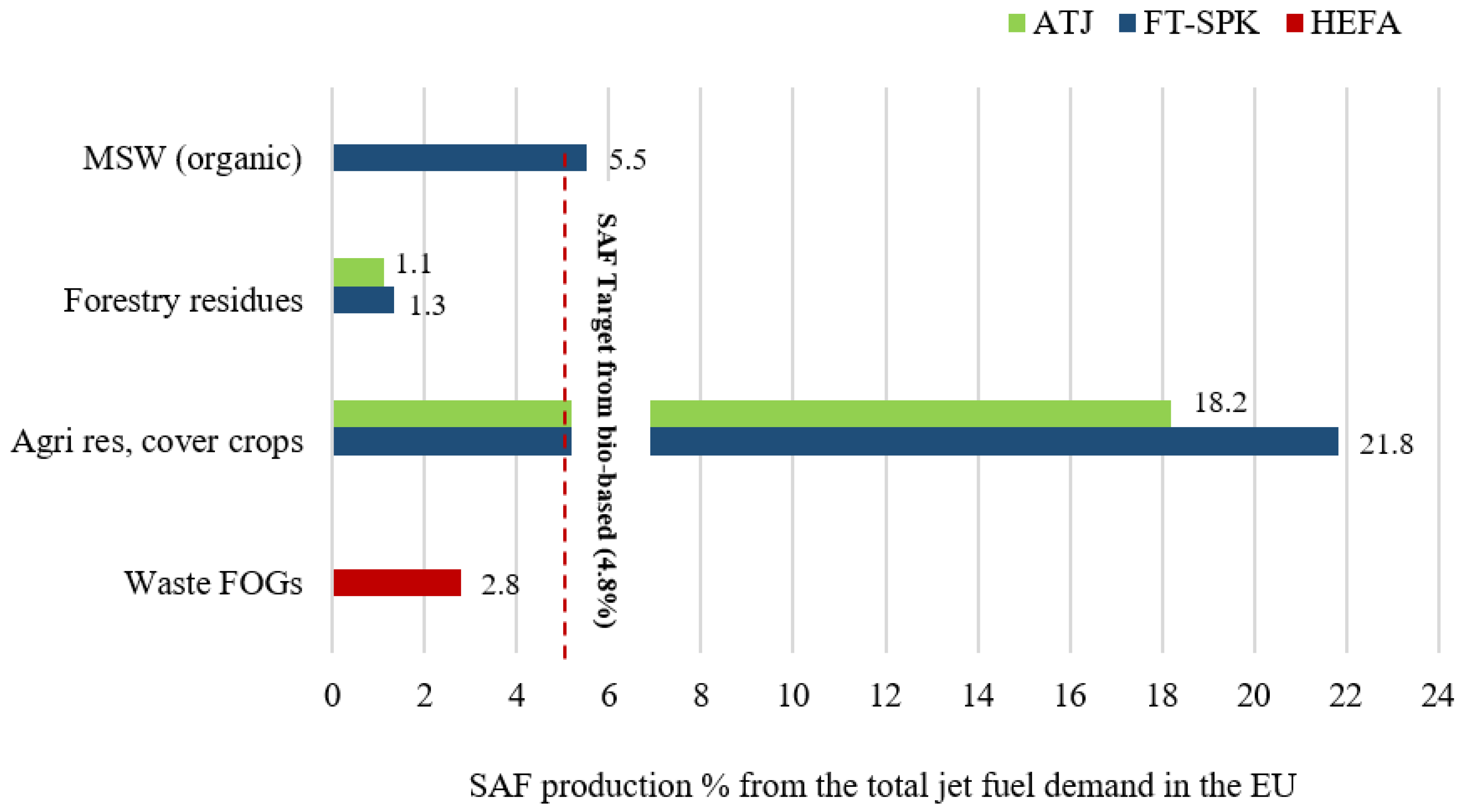

3.5. Capacity of SAF Production in the EU by 2030

3.6. Capacity of SAF Production in the EU in 2050

4. Validation by Process Simulation

- Changing the type of biomass to study the influence of the different compositions on the SAF yield. These dried biomasses were wood chips of high quality, wood chips of industrial quality, and wood pellets, with a moisture content of 11.24%, 10.76%, and 5.93%, respectively. This scenario helped to determine the most influential parameters in the biomass that impact SAF production.

- Two different types of gas loop designs were compared. An open loop where there is no recycle stream to the FT reactor vs. a closed loop FT.

- Changing the catalyst utilized in the FT reactor and its CO conversion rate by using catalysts from the literature.

5. Conclusions and Prospects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| SAF | Sustainable aviation fuel |

| HEFA | Hydroprocessed Esters Fatty Acids |

| Alcohol to Jet | ATJ |

| FT-SPK | Fischer-Tropsch Synthetic Paraffinic Kerosene |

| TRL | Technology readiness level |

| FRL | Fuel readiness level |

| GHG | Greenhouse gas emissions |

| IPCC | Intergovernmental Panel on Climate Change |

| CORSIA | Carbon Offsetting and Reduction Scheme for International Aviation |

| PTL | Power to liquid |

| Mt | Million tonnes |

| UCO | used cooking oil |

| MSW | Municipal Solid Waste |

| FOGs | Fats, oils, and greases |

| ASTM | American Society for Testing and Materials |

| FT-SPK/A | Fischer-Tropsch—Synthetic Paraffinic Kerosene with added aromatics |

| HFS-SIP | Hydroprocessing of Fermented Sugars—Synthetic Iso-Paraffinic fuels |

| CHJ-SK | Catalytic Hydrothermolysis Synthetic Kerosene |

| (HC-HEFA-SPK or HHC-SPK) | High Hydrogen Content Synthetic Paraffinic Kerosene |

| CAPEX | Total capital expenditure |

| OPEX | Operational expenditure |

| LCA | Life cycle assessment |

| WGS | Water gas shift reactor |

References

- Hasan, M.A.; Mamun, A.A.; Rahman, S.M.; Malik, K.; Al Amran, M.I.U.; Khondaker, A.N.; Reshi, O.; Tiwari, S.P.; Alismail, F.S. Climate Change Mitigation Pathways for the Aviation Sector. Sustainability 2021, 13, 3656. [Google Scholar] [CrossRef]

- Bergero, C.; Gosnell, G.; Gielen, D.; Kang, S.; Bazilian, M.; Davis, S.J. Pathways to net-zero emissions from aviation. Nat. Sustain. 2023, 6, 404–414. [Google Scholar] [CrossRef]

- Climate math: What a 1.5-Degree Pathway Would Take: Decarbonizing Global Business at Scale is Achievable, but the Math Is Daunting. McKinsey Quarterly, 15 March 2022. Available online: https://www.mckinsey.com/~/media/mckinsey/business%20functions/sustainability/our%20insights/climate%20math%20what%20a%201%20point%205%20degree%20pathway%20would%20take/climate-math-what-a-1-point-5-degree-pathway-would-take-final.pdf (accessed on 5 June 2023).

- International Civil Aviation Organization. Agenda Item 16: Environmental Protection—International Aviation and Climate Change—Policy and Standardization. 2019. Available online: https://www.icao.int/Meetings/a39/Documents/WP/wp_461_en.pdf (accessed on 18 November 2022).

- Air Transport Action Group. Balancing Growth in Connectivity with a Comprehensive Global Air Transport Response to the Climate Emergency. 2020. Available online: https://aviationbenefits.org/media/167187/w2050_full.pdf (accessed on 8 March 2023).

- Undavalli, V.; Gbadamosi Olatunde, O.B.; Boylu, R.; Wei, C.; Haeker, J.; Hamilton, J.; Khandelwal, B. Recent advancements in sustainable aviation fuels. Prog. Aerosp. Sci. 2023, 136, 100876. [Google Scholar] [CrossRef]

- Kurzawska, P. Overview of Sustainable Aviation Fuels including emission of particulate matter and harmful gaseous exhaust gas compounds. Transp. Res. Procedia 2021, 59, 38–45. [Google Scholar] [CrossRef]

- Larsson, J.; Elofsson, A.; Sterner, T.; Åkerman, J. International and national climate policies for aviation: A review. Clim. Policy 2019, 19, 787–799. [Google Scholar] [CrossRef]

- Fageda, X.; Teixidó, J.J. Pricing carbon in the aviation sector: Evidence from the European emissions trading system. J. Environ. Econ. Manag. 2022, 111, 102591. [Google Scholar] [CrossRef]

- Department for Transport. Sustainable Aviation Fuels Mandate: Summary of Consultation Responses and Government Response. 2022. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1060601/sustainable-aviation-fuels-mandate-consultation-summary-of-responses.pdf (accessed on 2 December 2022).

- European Commission. ReFuelEU Aviation initiative: Sustainable Aviation Fuels and the ‘fit for 55′ Package. 2022. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2022/698900/EPRS_BRI(2022)698900_EN.pdf (accessed on 7 March 2023).

- Chiaramonti, D. Sustainable Aviation Fuels: The challenge of decarbonization. Energy Procedia 2019, 158, 1202–1207. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Sustainable Aviation Fuel: Review of Technical Pathways. 2020. Available online: https://www.energy.gov/sites/prod/files/2020/09/f78/beto-sust-aviation-fuel-sep-2020.pdf (accessed on 5 February 2023).

- Cabrera, E.; de Sousa, J.M.M. Use of Sustainable Fuels in Aviation—A Review. Energies 2022, 15, 2440. [Google Scholar] [CrossRef]

- Steve Csonka. Sustainable Aviation Fuels Are not all the Same and Regular Commercial Use of 100% SAF is More Complex. Online. 2022. Available online: https://www.greenairnews.com/?p=2460 (accessed on 13 March 2023).

- European Union. DIRECTIVE (EU) 2018/2001 of the European Parliament and of the Council: On the Promotion of the Use of Energy from Renewable Sources. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001 (accessed on 5 October 2022).

- International Civil Aviation Organization. CORSIA Sustainability Criteria for Corsia Eligible Fuels. 2022. Available online: https://www.icao.int/environmental-protection/CORSIA/Documents/CORSIA_Eligible_Fuels/ICAO%20document%2005%20-%20Sustainability%20Criteria%20-%20November%202022.pdf (accessed on 20 January 2023).

- US Department of Agriculture, und USDA Foreign Agricultural Service. Consumption of Vegetable Oils Worldwide from 2013/14 to 2022/2023, by Oil Type (in Million Metric Tons). Available online: https://www.statista.com/statistics/263937/vegetable-oils-global-consumption/ (accessed on 21 May 2023).

- Karan, S.K.; Hamelin, L. Towards local bioeconomy: A stepwise framework for high-resolution spatial quantification of forestry residues. Renew. Sustain. Energy Rev. 2020, 134, 110350. [Google Scholar] [CrossRef]

- Titus, B.D.; Brown, K.; Helmisaari, H.-S.; Vanguelova, E.; Stupak, I.; Evans, A.; Clarke, N.; Guidi, C.; Bruckman, V.J.; Varnagiryte-Kabasinskiene, I.; et al. Sustainable forest biomass: A review of current residue harvesting guidelines. Energ Sustain. Soc. 2021, 11, 10. [Google Scholar] [CrossRef]

- Panoutsou, K.C. Maniatis. Sustainable Biomass Availability in the EU, to 2050. 2021. Available online: https://www.concawe.eu/wp-content/uploads/Sustainable-Biomass-Availability-in-the-EU-Part-I-and-II-final-version.pdf (accessed on 22 November 2022).

- Prussi, M.; Panoutsou, C.; Chiaramonti, D. Assessment of the Feedstock Availability for Covering EU Alternative Fuels Demand. Appl. Sci. 2022, 12, 740. [Google Scholar] [CrossRef]

- O’Malley, J.; Pavlenko, N.; Searle, S. Estimating Sustainable Aviation Fuel Feedstock Availability to Meet Growing European Union Demand; Working Paper 2021-13; ICCT: Washington, DC, USA, 2021. [Google Scholar]

- Carraro, C.; Searle, S.; Baldino, C. Waste and Residue Availability for Advanced Biofuel Production in the European Union and the United Kingdom 2021-39, 202100. Available online: https://trid.trb.org/view/1894362 (accessed on 26 January 2023).

- EU. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on waste. 2018. Available online: https://www.eea.europa.eu/publications/reaching-2030s-residual-municipal-waste (accessed on 2 December 2022).

- IEA Bioenergy. Progress in Commercialization of Biojet/Sustainable Aviation Fuels (SAF): Technologies, Potential and Challenges; IEA Bioenergy: 2021. Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/06/IEA-Bioenergy-Task-39-Progress-in-the-commercialisation-of-biojet-fuels-May-2021-1.pdf (accessed on 2 August 2022).

- European Union Aviation Safety Agency. European Aviation Environmental Report. 2022. Available online: https://www.easa.europa.eu/eco/sites/default/files/2023-02/230217_EASA%20EAER%202022.pdf (accessed on 24 March 2023).

- Aghbashlo, M.; Hosseinzadeh-Bandbafha, H.; Shahbeik, H.; Tabatabaei, M. The role of sustainability assessment tools in realizing bioenergy and bioproduct systems. Biofuel Res. J. 2022, 9, 1697–1706. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Khounani, Z.; Hosseinzadeh-Bandbafha, H.; Gupta, V.K.; Amiri, H.; Lam, S.S.; Morosuk, T.; Tabatabaei, M. Exergoenvironmental analysis of bioenergy systems: A comprehensive review. Renew. Sustain. Energy Rev. 2021, 149, 111399. [Google Scholar] [CrossRef]

- Prussi, M.; Lee, U.; Wang, M.; Malina, R.; Valin, H.; Taheripour, F.; Velarde, C.; Staples, M.D.; Lonza, L.; Hileman, J.I. CORSIA: The first internationally adopted approach to calculate life-cycle GHG emissions for aviation fuels. Renew. Sustain. Energy Rev. 2021, 150, 111398. [Google Scholar] [CrossRef]

- World Economic Forum—McKinsey & Company. Clean Skies for Tomorrow Sustainable Aviation Fuels as a Pathway to Net-Zero Aviation. 2020. Available online: https://www.mckinsey.com/~/media/mckinsey/industries/travel%20transport%20and%20logistics/our%20insights/scaling%20sustainable%20aviation%20fuel%20today%20for%20clean%20skies%20tomorrow/clean-skies-for-tomorrow.pdf (accessed on 26 August 2022).

- Pavlenko, N.; Searle, S. Fueling flight: Assessing the Sustainability Implications of Alternative Aviation Fuels; International Council on Clean Transportation (ICCT): Washington, DC, USA, 2021. [Google Scholar]

- Pavlenko, N. An Assessment of the Policy Options for Driving Sustainable Aviation Fuels in the European Union; International Council on Clean Transportation (ICCT): Washington, DC, USA, 2021. [Google Scholar]

- Yáñez, É.; Meerman, H.; Ramírez, A.; Castillo, É.; Faaij, A. Assessing bio-oil co-processing routes as CO2 mitigation strategies in oil refineries. Biofuels Bioprod. Bioref. 2021, 15, 305–333. [Google Scholar] [CrossRef]

- Breuer, J.; Scholten, J.; Koj, J.; Schorn, F.; Fiebrandt, M.; Samsun, R.; Albus, R.; Görner, K.; Stolten, D.; Peters, R. An Overview of Promising Alternative Fuels for Road, Rail, Air, and Inland Waterway Transport in Germany. Energies 2022, 15, 1443. [Google Scholar] [CrossRef]

- ktalley. Implementing NATO’s Strategic Concept on China. Atlantic Council, 2 March 2023. Available online: https://www.atlanticcouncil.org/in-depth-research-reports/report/implementing-natos-strategic-concept-on-china/ (accessed on 22 April 2023).

- Transport & Environment. Briefing—Food not Fuel: Part Two: Vegetable Oils Are Being Burned in Cars Despite Empty Supermarket Shelves And Skyrocketing Prices. 2022. Available online: https://www.transportenvironment.org/wp-content/uploads/2022/06/Food-vs-Fuel_-Part-2_Vegetable-oils-in-biofuels.pdf (accessed on 1 April 2023).

- Transport & Environment. Briefing—10 Years of EU Fuels Policy Increased EU’s Reliance on Unsustainable Biofuel. 2021. Available online: https://www.transportenvironment.org/wp-content/uploads/2021/08/Biofuels-briefing-072021.pdf (accessed on 19 April 2023).

- Gupta, S.K. (Ed.) Breeding Oilseed Crops for Sustainable Production: Opportunities and Constraints; Academic Press: Amsterdam, The Netherlands, 2015; ISBN 978-0-12-801309-0. [Google Scholar]

- Havrysh, V.; Kalinichenko, A.; Pysarenko, P.; Samojlik, M. Sunflower Residues-Based Biorefinery: Circular Economy Indicators. Processes 2023, 11, 630. [Google Scholar] [CrossRef]

- Shams Esfandabadi, Z.; Ranjbari, M.; Scagnelli, S.D. The imbalance of food and biofuel markets amid Ukraine-Russia crisis: A systems thinking perspective. Biofuel Res. J. 2022, 9, 1640–1647. [Google Scholar] [CrossRef]

- International Civil Aviation Organization. Report on the Updated Long Term Traffic Forecasts. A40-WP/20. 2019. Available online: www.icao.int/Meetings/a40/Documents/WP/wp_020_en.pdf (accessed on 15 March 2023).

- European Enviornmental Agency. Municipal Waste Management in the Western Balkan countries. 2022. Available online: https://www.eea.europa.eu/publications/municipal-waste-management-in-western (accessed on 21 May 2023).

- König, D.H.; Baucks, N.; Dietrich, R.-U.; Wörner, A. Simulation and evaluation of a process concept for the generation of synthetic fuel from CO2 and H2. Energy 2015, 91, 833–841. [Google Scholar] [CrossRef]

- Almena, A.; Thornley, P.; Chong, K.; Röder, M. Carbon dioxide removal potential from decentralised bioenergy with carbon capture and storage (BECCS) and the relevance of operational choices. Biomass Bioenergy 2022, 159, 106406. [Google Scholar] [CrossRef]

- Larson, E.D.; Kreutz, T.G.; Greig, C.; Williams, R.H.; Rooney, T.; Gray, E.; Elsido, C.; Martelli, E.; Meerman, J.C. Design and analysis of a low-carbon lignite/biomass-to-jet fuel demonstration project. Appl. Energy 2020, 260, 114209. [Google Scholar] [CrossRef]

- Shehab, M.; Stratulat, C.; Ozcan, K.; Boztepe, A.; Isleyen, A.; Zondervan, E.; Moshammer, K. A Comprehensive Analysis of the Risks Associated with the Determination of Biofuels’ Calorific Value by Bomb Calorimetry. Energies 2022, 15, 2771. [Google Scholar] [CrossRef]

- Freire Ordóñez, D.; Halfdanarson, T.; Ganzer, C.; Shah, N.; Dowell, N.M.; Guillén-Gosálbez, G. Evaluation of the potential use of e-fuels in the European aviation sector: A comprehensive economic and environmental assessment including externalities. Sustain. Energy Fuels 2022, 6, 4749–4764. [Google Scholar] [CrossRef] [PubMed]

| Feedstock Type | Theoretical Available 2030 (Mt) | Theoretical Available 2050 (Mt) | Actual Available 2030 (Mt) |

|---|---|---|---|

| Waste oil and fats | 5.3 | 9.9 | 2.4 |

| Organic fraction in MSW | 44–80 | 33–61 | 21.2 |

| Agriculture residual | 45–65 | 65–71 | 87.7 |

| Cover crops | 36–108 | 42–127 | |

| Primary forest residual Secondary forest residual | 41–68 | 45–75 | 5.1 |

| 89–126 | 93–139 |

| Routes | ASTM Approved | Supported by Mandates | Max Drop In % | TRL | FRL | Cost of Production (§) | Sustainability gCO2e/MJ | Feedstock | SAF Fraction % | Geopolitical/Geographical Concerns | References | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SAF Cost Dollar/Tonne | CAPEX % | OPEX % | Type | Availability (§§) | Cost Range (§§§) | ||||||||||

| FT-SPK | 2009 | Yes | 50% | 6–8 | 7–8 | 1866–2250 | 68–83 | 14–17% | 7.7–12.2 | Waste and biomass residues | High | Low | 40–70% | NO | [26,30,31,32,33] |

| FT-SPK/A | 2015 | 50–100% | |||||||||||||

| HEFA-SPK | 2011 | Only until 2030 | 50% | 7–9 | 9 | 1100–1550 | 7–10 | 10–14% | 13.9–60 | Bio-oils, animal fat, Vegetable oils, UCO | Low | Med-High | 20–55% | YES | [26,30,31,32,33] |

| HFS-SIP | 2014 | Yes | 10% | 5–7 | 5–7 | 2100–2900 | N/A | N/A | 32.4–32.8 | Sugarcane, sugar beet | Med | Med-High | 90–100% | Yes | [26,30,31,32,33] |

| ATJ- SPK | 2016 | Yes | 50% | 4–7 | 7 | 2100–2900 | 41–56 | 31–45% | 23.8–65.7 | Sugarcane sugar beet sawdust lignocellulosic residues (straw) | Med | Low | 60–77% | Yes | [26,30,31,32,33] |

| Co-Processing Bio-Oils in Petroleum | 2018 | Yes | 5% | N/A | N/A | N/A | N/A | N/A | N/A | Fats, oils, and greases (FOG) | Low | Med-High | N/A | YES | [26,34] |

| CHJ-SKA | 2020 | Yes | 50–100% | 6–7 | 6 | N/A | N/A | N/A | N/A | Triglycerides such oils as soybean, jatropha and camelina Oil | Low | Med-High | 33% | YES | [35] |

| HC- HEFA-SPK | 2020 | Yes | 10% | 4 | 6 | N/A | N/A | N/A | N/A | Algae | N/A | Med-High | N/A | NO | [35] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shehab, M.; Moshammer, K.; Franke, M.; Zondervan, E. Analysis of the Potential of Meeting the EU’s Sustainable Aviation Fuel Targets in 2030 and 2050. Sustainability 2023, 15, 9266. https://doi.org/10.3390/su15129266

Shehab M, Moshammer K, Franke M, Zondervan E. Analysis of the Potential of Meeting the EU’s Sustainable Aviation Fuel Targets in 2030 and 2050. Sustainability. 2023; 15(12):9266. https://doi.org/10.3390/su15129266

Chicago/Turabian StyleShehab, Moaaz, Kai Moshammer, Meik Franke, and Edwin Zondervan. 2023. "Analysis of the Potential of Meeting the EU’s Sustainable Aviation Fuel Targets in 2030 and 2050" Sustainability 15, no. 12: 9266. https://doi.org/10.3390/su15129266

APA StyleShehab, M., Moshammer, K., Franke, M., & Zondervan, E. (2023). Analysis of the Potential of Meeting the EU’s Sustainable Aviation Fuel Targets in 2030 and 2050. Sustainability, 15(12), 9266. https://doi.org/10.3390/su15129266