LCA Case Study of Ceramic Tableware: Ecodesign Aspects of Ceramics Production from Ancient Technology to Present Factory

Abstract

1. Introduction

2. Materials and Methods

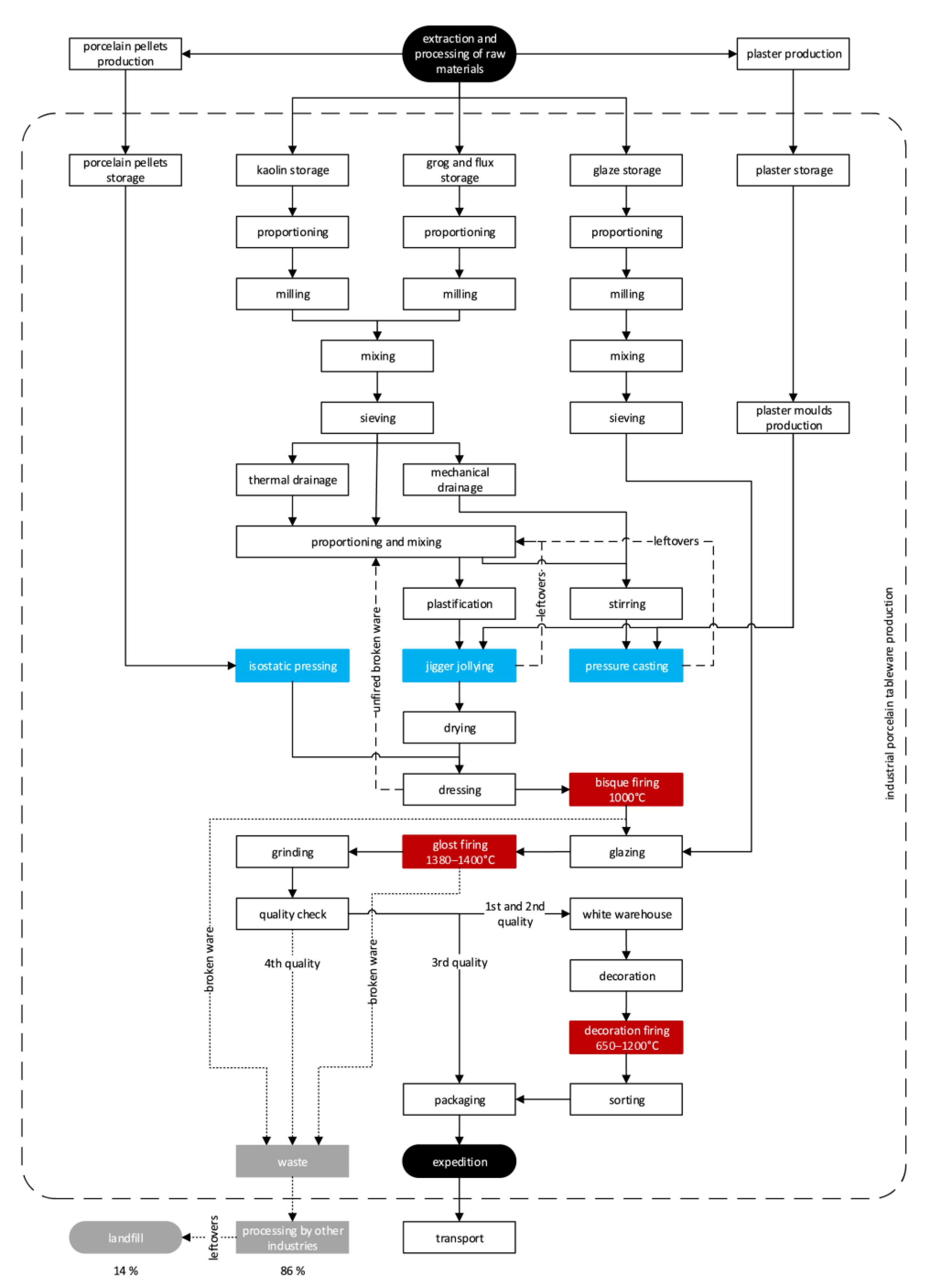

2.1. Mass Production of Tableware in Automatized Factory

2.2. Manufactory Production Using Slip Casting

2.3. Manufacture Production Using a Pottery Wheel

2.4. Experimental Production Using High Energy Rate Forming Technique

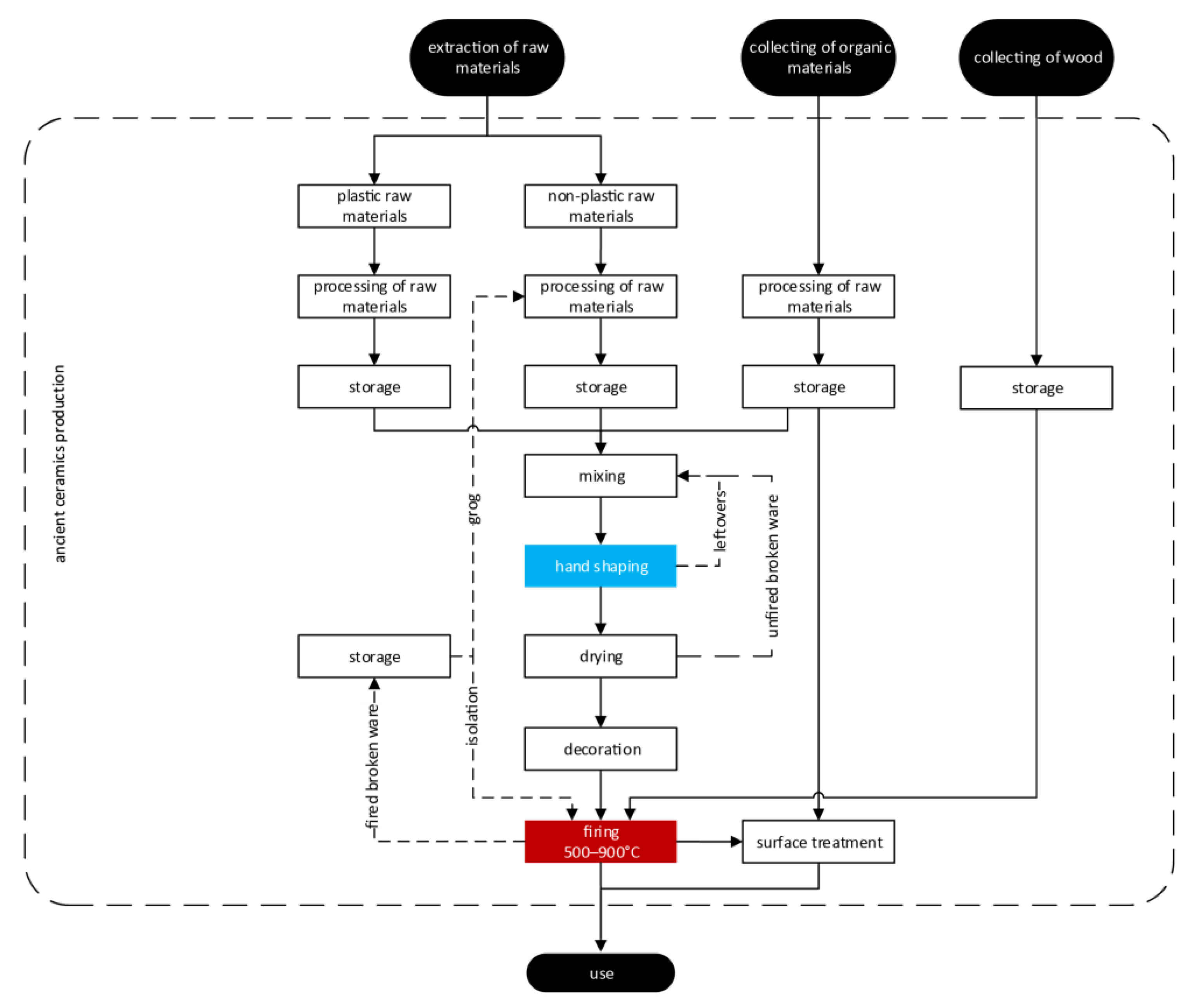

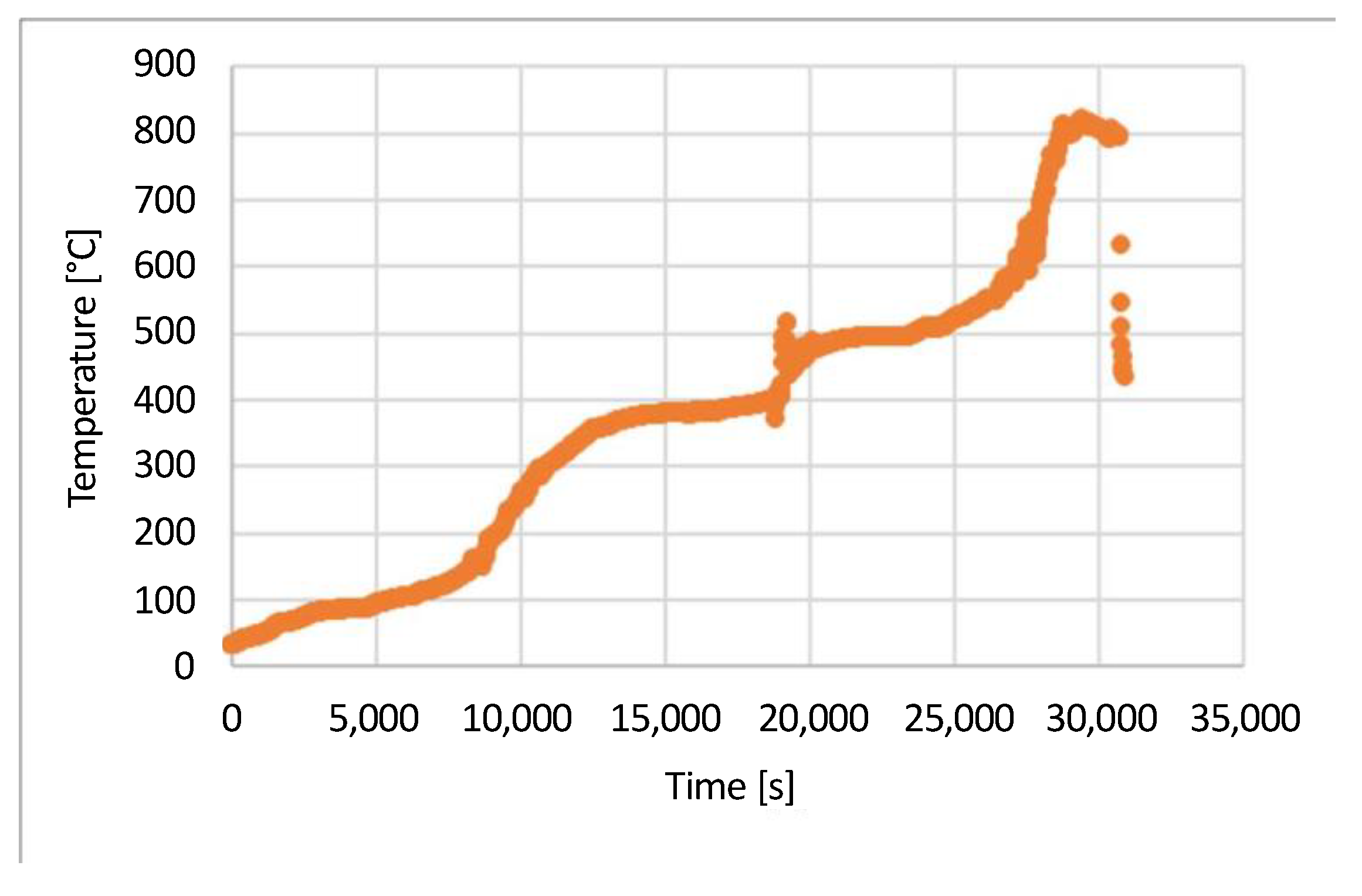

2.5. Experimental Production Using Reconstruction of the Ancient Technique

2.6. Life Cycle Assessment

2.7. Assumption Accepted in the Study

- Material and energy inventories were based on specific data of producers related to the year 2019. The inventory for the ANC scenario is based on one batch of ceramic products fired during the replication of the ancient approach.

- To model emissions from open-pit burning of wood, the generic process from the Gabi database was used (Process name: GLO: Open biomass burning—garbage burning of 1 kg dry matter, 40% C).

- The general composition of the dry mixture for glazing was considered in scenarios PW, PSC, and HERF. The considered percentage of kaolin, quartz, and feldspar was 50%, 25%, and 25%, respectively.

- In the PSC scenario, the consumption of gypsum was measured as 180 kg per year. However, the waste flow of gypsum was estimated to be 90 kg, because the producer stated that the life expectancy of the gypsum forms will last longer than one year.

- Packaging materials for ceramic products were excluded from the inventories and the phase of transport of the product to a customer was also not considered.

- Environmental impacts are allocated to 1 kg of fired ceramic without considering the volume or design of the vessel.

3. Results

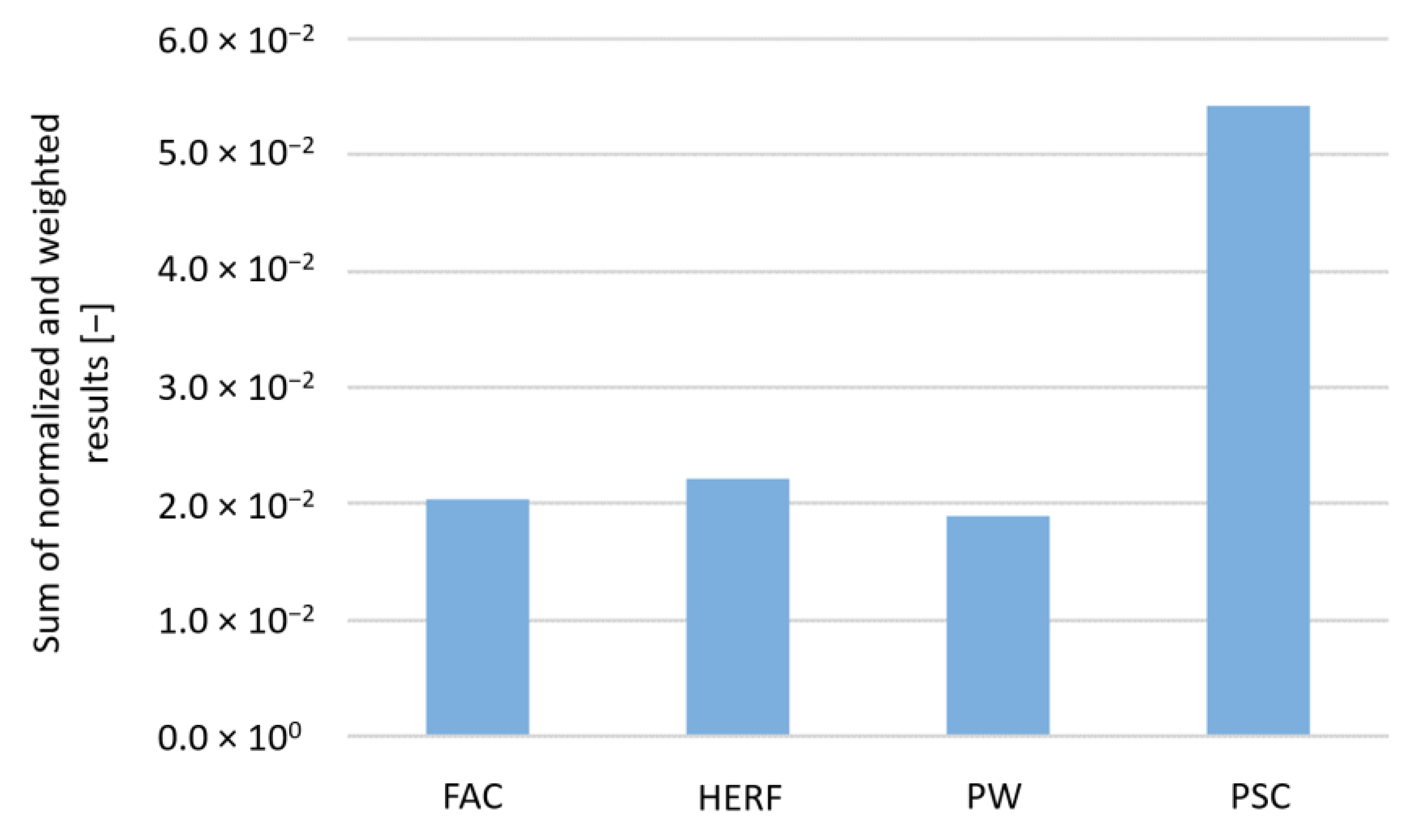

Normalisation and Weighting

4. Discussion

4.1. Material Efficiency

4.2. Energy Efficiency

4.3. Demanded Quality of a Product and Scrap Rate

4.4. Limitation of the Inventory Analysis

4.5. Limitation of LCA Study

4.6. Alternative Production of Ceramic Tableware

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Guinee, J. Handbook on Life Cycle Assessment—Operational Guide to the ISO Standards. Int. J. Life Cycle Assess. 2001, 6, 255. [Google Scholar] [CrossRef]

- Martins, F.F.; Castro, H. Raw Material Depletion and Scenario Assessment in European Union—A Circular Economy Approach. Energy Rep. 2020, 6, 417–422. [Google Scholar] [CrossRef]

- Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability. Available online: https://ec.europa.eu/docsroom/documents/42849 (accessed on 7 January 2021).

- Gomez, P.; Elduque, D.; Claveria, I.; Pina, C.; Javierre, C. Influence of the Material Composition on the Environmental Impact of Ceramic Glasses. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 431–442. [Google Scholar] [CrossRef]

- Khorassani, S.M.; Siligardi, C.; Mugoni, C.; Pini, M.; Cappucci, G.M.; Ferrari, A.M. Life Cycle Assessment of a Ceramic Glaze Containing Copper Slags and Its Application on Ceramic Tile. Int. J. Appl. Ceram. Technol. 2020, 17, 42–54. [Google Scholar] [CrossRef]

- Sappa, G.; Iacurto, S.; Ponzi, A.; Tatti, F.; Torretta, V.; Viotti, P. The LCA Methodology for Ceramic Tiles Production by Addition of MSWI BA. Resources 2019, 8, 93. [Google Scholar] [CrossRef]

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the Ceramics Industry: A Systematic and Critical Review of Policy Options, Developments and Sociotechnical Systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar] [CrossRef]

- Ceramic Manufacturing Industry|Eippcb. Available online: https://eippcb.jrc.ec.europa.eu/reference/ceramic-manufacturing-industry (accessed on 12 April 2023).

- Kallipoliti, L. History of Ecological Design. Oxf. Res. Encycl. Environ. Sci. 2018, 2. [Google Scholar] [CrossRef]

- Wimmer, W.; Züst, R.; Lee, K.M. ECODESIGN Implementation; Springer: Dodrecht, The Netherlands, 2004; ISBN 1-4020-3070-3. [Google Scholar]

- Quinteiro, P.; Araújo, A.; Oliveira, B.; Dias, A.C.; Arroja, L. The Carbon Footprint and Energy Consumption of a Commercially Produced Earthenware Ceramic Piece. J. Eur. Ceram. Soc. 2012, 32, 2087–2094. [Google Scholar] [CrossRef]

- Aραβωσης, K.A.; Camocho, D.J. Innovation and Ecodesign in Ceramic Industry an Overview of Knowledge Needs in Portugal, Spain and Greece. In Proceedings of the XXI Century, LeNS Conference, Bangalore, India, 29 September–1 October 2010. [Google Scholar]

- ISO Environmental Management—Life Cycle Assessment—Principles and Framework (ISO 14040:2006). Available online: https://www.iso.org/standard/37456.html (accessed on 1 October 2020).

- ISO Environmental Management—Life Cycle Assessment—Requirements and Guidelines (ISO 14044:2006). Available online: https://www.iso.org/standard/38498.html (accessed on 1 October 2020).

- Life Cycle Assessment LCA Software for Experts(Gabi Software). Available online: https://sphera.com/life-cycle-assessment-lca-software/ (accessed on 1 June 2023).

- Ecoinvent Database. Available online: https://www.ecoinvent.org/ (accessed on 1 October 2022).

- Wu, X.; Zhang, C.; Goldberg, P.; Cohen, D.; Pan, Y.; Arpin, T.; Bar-Yosef, O. Early Pottery at 20,000 Years Ago in Xianrendong Cave, China. Science 2012, 336, 1696–1700. [Google Scholar] [CrossRef] [PubMed]

- Boaretto, E.; Wu, X.; Yuan, J.; Bar-Yosef, O.; Chu, V.; Pan, Y.; Liu, K.; Cohen, D.; Jiao, T.; Li, S.; et al. Radiocarbon Dating of Charcoal and Bone Collagen Associated with Early Pottery at Yuchanyan Cave, Hunan Province, China. Proc. Natl. Acad. Sci. USA 2009, 106, 9595–9600. [Google Scholar] [CrossRef] [PubMed]

- Hanykýř, V. Technologie Keramiky; Vyd. 2., v Silikátovém Svazu 1.; Silikátový Svaz: Hrdlořezy, Česko, 2008; ISBN 978-80-86821-48-1. [Google Scholar]

- Bhaduri, A. High-Energy Rate Forming. In Metal Forming; Springer Series in Materials Science; Springer: Singapore, 2018; pp. 721–736. ISBN 978-981-10-7208-6. [Google Scholar]

- Ther, R. Ceramic Technology. How to Reconstruct and Describe Pottery-Forming Practices. Archaeol. Anthropol. Sci. 2020, 12, 172. [Google Scholar] [CrossRef]

- Ther, R.; Kallistova, A.; Svoboda, Z.; Kvetina, P.; Lisa, L.; Burgert, P.; Bajer, A. How Was Neolithic Pottery Fired? An Exploration of the Effects of Firing Dynamics on Ceramic Products. J. Archaeol. Method Theory 2019, 26, 1143–1175. [Google Scholar] [CrossRef]

- Ther, R. Identification of Pottery Firing Structures Using the Thermal Characteristics of Firing. Archaeometry 2014, 56, 78–99. [Google Scholar] [CrossRef]

- Heijungs, R.; Guineév, J.B. An Overview of the Life Cycle Assessment Method—Past, Present, and Future. In Life Cycle Assessment Handbook; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 15–41. ISBN 978-1-118-52837-2. [Google Scholar]

- Kupfer, T.; Baitz, M.; Colodel, C.M.; Kokborg, M.; Schöll, S.; Rudolf, M.; Bos, U.; Bosch, F.; Gonzalez, M.; Schuller, O.; et al. GaBi Database and Modelling Principles. Available online: http://www.gabi-software.com/fileadmin/gabi/Modelling_Principles/Modeling_Principles_-_GaBi_Databases_2020_2.pdf (accessed on 1 December 2020).

- Environmental Footprint 3.0. Available online: https://eplca.jrc.ec.europa.eu//EnvironmentalFootprint.html (accessed on 1 October 2022).

- He, B.; Shao, Y.W.; Wang, S.; Gu, Z.C.; Bai, K.J. Product Environmental Footprints Assessment for Product Life Cycle. J. Clean. Prod. 2019, 233, 446–460. [Google Scholar] [CrossRef]

- Sangwan, K.S.; Choudhary, K.; Batra, C. Environmental Impact Assessment of a Ceramic Tile Supply Chain—A Case Study. Int. J. Sustain. Eng. 2018, 11, 211–216. [Google Scholar] [CrossRef]

- Moreno, A. Ceramics for the Circular Economy. Int. J. Appl. Ceram. Technol. 2020, 17, 11. [Google Scholar] [CrossRef]

- Ceramic Industry Roadmap: Paving the Way to 2050|Cerame-Unie—The European Ceramic Industry Association. Available online: https://cerameunie.eu/topics/cerame-unie-sectors/cerame-unie/ceramic-industry-roadmap-paving-the-way-to-2050/ (accessed on 12 April 2023).

- Takada, J.; Ito, Y.; Yoshikawa, M.; Ishida, H. Ecodesign for Ceramic Tiles and Sanitary Ware. In Proceedings of the First International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Proceedings, Tokyo, Japan, 1–3 February 1999; pp. 131–135. [Google Scholar]

- Síla, D. Alternative Processes and Materials in Ceramics and Porcelain Production. Master’s Thesis, University of Jan Evangelista Purkyně in Ústí nad Labem, Faculty of Art and Design Ústí nad Labem, Ústí nad Labem, Czechia, 2021. [Google Scholar]

- ISO Ceramic Ware, Glass-Ceramic Ware and Glass Dinnerware in Contact with Food—Release of Lead and Cadmium—Part 2: Permissible Limits (ISO 6486-2:1999). Available online: https://www.iso.org/standard/27281.html (accessed on 24 May 2023).

- Ceramic World Review 151/2023. Available online: https://ceramicworldweb.com/en/magazines/ceramic-world-review-1512023 (accessed on 24 May 2023).

- Lorfing, D.; Olives, R.; Falcoz, Q.; Guillot, E.; Le Men, C.; Ahmadi, A. Design and Performance of a New Type of Boiler Using Concentrated Solar Flux. Energy Convers. Manag. 2021, 249, 114835. [Google Scholar] [CrossRef]

- Rasul, A. Thousand KW High-Temperature Solar Furnace in Parkent (Uzbekistan)—Energetical Characteristics. In A Guide to Small-Scale Energy Harvesting Techniques; IntechOpen: London, UK, 2019; ISBN 978-1-78923-910-2. [Google Scholar]

- Directive (EU) 2022/2464 of the European Parliament and of the Council of 14 December 2022 Amending Regulation (EU) No 537/2014, Directive 2004/109/EC, Directive 2006/43/EC and Directive 2013/34/EU, as Regards Corporate Sustainability Reporting (Text with EEA Relevance). 2022, Volume 322. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32022L2464 (accessed on 27 April 2023).

- Commission Notice Technical Guidance on the Application of ‘Do No Significant Harm’ under the Recovery and Resilience Facility Regulation. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52021XC0218(01) (accessed on 24 May 2023).

- Záhorková, L. Tak to Bylo. Available online: http://www.zahorkovalenka.com/prace/domu/ (accessed on 24 May 2023).

| Life Cycle Stage | Inputs and Outputs | FAC | PSC | PW | HERF | ANC |

|---|---|---|---|---|---|---|

| Production | Products, total (kg) | 3.0 × 106 | 180 | 5.0 × 103 | 113 | 9 |

| Secondary products | 8.3 × 105 | 0 | 0 | 0 | 0 | |

| Ceramic waste (kg) | 1.4 × 105 | 5 | 60 | 4 | 0.4 | |

| Loss (%) | 4.5 | 2.8 | 1.2 | 3.5 | 4.0 | |

| Porcelain + Glaze | Kaolin (kg) | 3.3 × 106 | 91 | 3.0 × 103 | 59 | 10 |

| Spar (kg) | 2.3 × 105 | 48 | 1.0 × 103 | 31 | 0 | |

| Dolomite | 5.4 × 104 | 1 | 8 | 0 | 0 | |

| Silica (kg) | 3.6 × 105 | 48 | 1.0 × 103 | 31 | 0 | |

| Gypsum (kg) | 4.6 × 104 | 180 | 80 | 4 | 0 | |

| Water (L) | 2.6 × 107 | 49 | 3.5 × 104 | 20 | 0 | |

| Titanium dioxide (kg) | 0 | 0 | 3.75 | 0 | 0 | |

| Specials | Aluminium (g) | 0 | 0 | 0 | 340 | 0 |

| Perchlorate (g) | 0 | 0 | 0 | 225 | 0 | |

| Copper (g) | 0 | 0 | 0 | 85 | 0 | |

| Kaolinite (kg) | 0 | 0 | 150 | 0 | 0 | |

| Firing | Wood (m3) | 0 | 0 | 0 | 0 | 91 |

| Straw (kg) | 0 | 0 | 0 | 0 | 45 | |

| Natural gas (m3) | 2.9 × 106 | 0 | 0 | 60 | 0 | |

| Electricity (kWh) | 4.5 × 106 | 2.5 × 103 | 2.2 × 104 | 180 | 0 | |

| Transport | Oil fuel (L) | 4.1 × 104 | 13 | 277 | 46 | 0 |

| LPG (L) | 2.5 × 103 | 0 | 0 | 0 | 0 | |

| Gasoline (L) | 1.2 × 104 | 0 | 0 | 0 | 0 | |

| Waste | Gypsum (kg) | 4.6 × 104 | 90 | 80 | 4 | 0 |

| Polypropylene packaging(kg) | 3.5 × 103 | 5 | 10 | 0 | 0 | |

| Inert (kg) | 1.4 × 105 | 5 | 60 | 4 | 0 |

| Indicator | FAC | HERF | ANC | PW | PSC |

|---|---|---|---|---|---|

| Acidification [Mole of H+ eq.] | 3.71 × 10−3 | 6.03 × 10−3 | 1.24 × 10−1 | 6.95 × 10−3 | 2.08 × 10−2 |

| Climate Change—total [kg CO2 eq.] | 3.64 | 3.78 | 4.03 | 3.1 | 8.93 |

| Climate Change, biogenic [kg CO2 eq.] | 1.60 × 10−2 | 1.66 × 10−2 | 1.85 × 100 | 1.94 × 10−2 | 5.77 × 10−2 |

| Climate Change, fossil [kg CO2 eq.] | 3.63 | 3.75 | 2.17 | 3.08 | 8.87 |

| Climate Change, land use and land use change [kg CO2 eq.] | 5.48 × 10−4 | 8.54 × 10−3 | 8.01 × 10−3 | 1.61 × 10−3 | 2.94 × 10−3 |

| Ecotoxicity, freshwater—total [CTUe] | 6.72 | 22.7 | 31.8 | 17.9 | 52.8 |

| Ecotoxicity, freshwater inorganics [CTUe] | 3.39 | 14.9 | 7.18 | 8.81 | 24.4 |

| Ecotoxicity, freshwater metals [CTUe] | 3.3 | 7.67 | 0.87 | 9.07 | 28.3 |

| Ecotoxicity, freshwater organics [CTUe] | 2.48 × 10−2 | 1.72 × 10−1 | 2.37 × 101 | 4.97 × 10−2 | 1.15 × 10−1 |

| Eutrophication, freshwater [kg P eq.] | 3.96 × 10−6 | 1.43 × 10−5 | 0.000241 | 7.76 × 10−6 | 2.24 × 10−5 |

| Eutrophication, marine [kg N eq.] | 1.08 × 10−3 | 1.92 × 10−3 | 0.0406 | 1.45 × 10−3 | 0.00412 |

| Eutrophication, terrestrial [Mole of N eq.] | 1.16 × 10−2 | 2.12 × 10−2 | 5.95 × 10−1 | 1.53 × 10−2 | 4.31 × 10−2 |

| Human toxicity, cancer—total [CTUh] | 4.83 × 10−10 | 5.84 × 10−10 | 1.21 × 10−7 | 3.55 × 10−10 | 9.87 × 10−10 |

| Human toxicity, cancer inorganics [CTUh] | 5.44 × 10−21 | 2.04 × 10−20 | 1.55 × 10−20 | 6.93 × 10−21 | 1.01 × 10−20 |

| Human toxicity, cancer metals [CTUh] | 2.90 × 10−10 | 4.22 × 10−10 | 3.12 × 10−10 | 1.58 × 10−10 | 4.14 × 10−10 |

| Human toxicity, cancer organics [CTUh] | 1.93 × 10−10 | 1.63 × 10−10 | 1.21 × 10−7 | 1.97 × 10−10 | 5.73 × 10−10 |

| Human toxicity, non-cancer—total [CTUh] | 3.68 × 10−8 | 3.83 × 10−8 | 7.43 × 10−7 | 2.54 × 10−8 | 7.31 × 10−8 |

| Human toxicity, non-cancer inorganics [CTUh] | 4.47 × 10−9 | 7.05 × 10−9 | 6.26 × 10−7 | 1.10 × 10−8 | 3.33 × 10−8 |

| Human toxicity, non-cancer metals [CTUh] | 3.23 × 10−8 | 3.12 × 10−8 | 3.36 × 10−8 | 1.44 × 10−8 | 3.97 × 10−8 |

| Human toxicity, non-cancer organics [CTUh] | 2.89 × 10−10 | 2.99 × 10−10 | 8.40 × 10−8 | 2.11 × 10−10 | 6.02 × 10−10 |

| Ionising radiation, human health [kBq U235 eq.] | 1.46 × 10−1 | 1.67 × 10−1 | 1.60 × 10−2 | 4.10 × 10−1 | 1.28 |

| Land Use [Pt] | 5.26 | 12.3 | 932 | 14.5 | 43.3 |

| Ozone depletion [kg CFC-11 eq.] | 5.18 × 10−11 | 6.67 × 10−10 | 2.32 × 10−12 | 2.90 × 10−11 | 7.16 × 10−11 |

| Particulate matter [Disease incidences] | 4.23 × 10−8 | 4.97 × 10−8 | 3.51 × 10−5 | 6.02 × 10−8 | 1.76 × 10−7 |

| Photochemical ozone formation, human health [kg NMVOC eq.] | 3.07 × 10−3 | 4.71 × 10−3 | 3.94 × 10−1 | 3.94 × 10−3 | 1.13 × 10−2 |

| Resource use, fossils [MJ] | 6.07 × 101 | 5.80 × 101 | 1.44 × 101 | 4.86 × 101 | 1.40 × 102 |

| Resource use, mineral and metals [kg Sb eq.] | 3.56 × 10−7 | 3.67 × 10−6 | 1.03 × 10−6 | 3.55 × 10−7 | 1.01 × 10−6 |

| Water use [m3 world equiv.] | 4.00 × 10−1 | 6.90 × 10−2 | 5.16 × 10−2 | 3.51 × 10−1 | 1.48 × 10−1 |

| Indicator | FAC | HERF | ANC | PW | PSC |

|---|---|---|---|---|---|

| Acidification | 4.14 × 10−4 | 6.73 × 10−4 | 1.39 × 10−2 | 7.76 × 10−4 | 2.32 × 10−3 |

| Climate Change—total | 9.48 × 10−3 | 9.82 × 10−3 | 1.05 × 10−2 | 8.06 × 10−3 | 2.32 × 10−2 |

| Ecotoxicity, freshwater—total | 3.02 × 10−4 | 1.02 × 10−3 | 1.43 × 10−3 | 8.07 × 10−4 | 2.37 × 10−3 |

| Eutrophication, freshwater | 6.91 × 10−6 | 2.50 × 10−5 | 4.19 × 10−4 | 1.35 × 10−5 | 3.91 × 10−5 |

| Eutrophication, marine | 1.64 × 10−4 | 2.91 × 10−4 | 6.15 × 10−3 | 2.20 × 10−4 | 6.24 × 10−4 |

| Eutrophication, terrestrial | 2.44 × 10−4 | 4.46 × 10−4 | 1.25 × 10−2 | 3.20 × 10−4 | 9.04 × 10−4 |

| Human toxicity, cancer—total | 6.08 × 10−5 | 7.37 × 10−5 | 1.53 × 10−2 | 4.47 × 10−5 | 1.24 × 10−4 |

| Human toxicity, non-cancer—total | 2.95 × 10−4 | 3.07 × 10−4 | 5.96 × 10−3 | 2.04 × 10−4 | 5.86 × 10−4 |

| Ionising radiation, human health | 1.73 × 10−4 | 1.98 × 10−4 | 1.90 × 10−5 | 4.86 × 10−4 | 1.51 × 10−3 |

| Land Use | 5.09 × 10−5 | 1.19 × 10−4 | 9.03 × 10−3 | 1.41 × 10−4 | 4.19 × 10−4 |

| Ozone depletion | 6.10 × 10−9 | 7.85 × 10−8 | 2.73 × 10−10 | 3.41 × 10−9 | 8.42 × 10−9 |

| Particulate matter | 6.37 × 10−4 | 7.47 × 10−4 | 5.28 × 10−1 | 9.06 × 10−4 | 2.64 × 10−3 |

| Photochemical ozone formation, human health | 3.62 × 10−4 | 5.55 × 10−4 | 4.64 × 10−2 | 4.64 × 10−4 | 1.34 × 10−3 |

| Resource use, fossils | 7.76 × 10−3 | 7.42 × 10−3 | 1.84 × 10−3 | 6.22 × 10−3 | 1.80 × 10−2 |

| Resource use, mineral and metals | 4.22 × 10−5 | 4.35 × 10−4 | 1.22 × 10−4 | 4.21 × 10−5 | 1.20 × 10−4 |

| Water use | 2.97 × 10−4 | 5.12 × 10−5 | 3.83 × 10−5 | 2.60 × 10−4 | 1.10 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Železný, A.; Kulhánek, J.; Pešta, J.; Kočí, V. LCA Case Study of Ceramic Tableware: Ecodesign Aspects of Ceramics Production from Ancient Technology to Present Factory. Sustainability 2023, 15, 9097. https://doi.org/10.3390/su15119097

Železný A, Kulhánek J, Pešta J, Kočí V. LCA Case Study of Ceramic Tableware: Ecodesign Aspects of Ceramics Production from Ancient Technology to Present Factory. Sustainability. 2023; 15(11):9097. https://doi.org/10.3390/su15119097

Chicago/Turabian StyleŽelezný, Adam, Jan Kulhánek, Jan Pešta, and Vladimír Kočí. 2023. "LCA Case Study of Ceramic Tableware: Ecodesign Aspects of Ceramics Production from Ancient Technology to Present Factory" Sustainability 15, no. 11: 9097. https://doi.org/10.3390/su15119097

APA StyleŽelezný, A., Kulhánek, J., Pešta, J., & Kočí, V. (2023). LCA Case Study of Ceramic Tableware: Ecodesign Aspects of Ceramics Production from Ancient Technology to Present Factory. Sustainability, 15(11), 9097. https://doi.org/10.3390/su15119097