Experimental Study on Expansive Soil Improved by Lignin and Its Derivatives

Abstract

1. Introduction

2. Materials and Methods

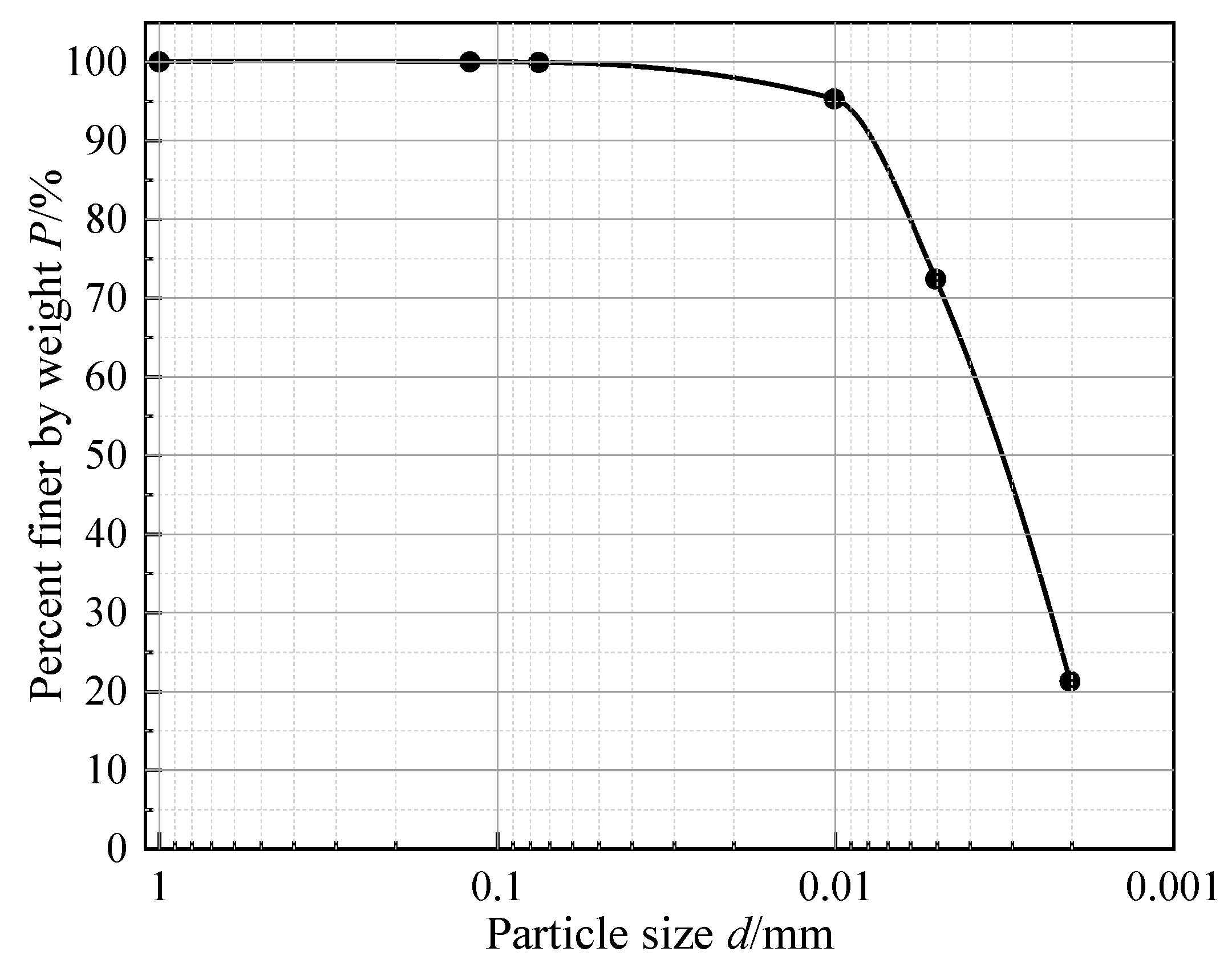

2.1. Testing Material

2.2. Test Scheme and Test Method

2.2.1. Test Scheme

2.2.2. Test Method

3. Test Result Analysis

3.1. Changes in the Physical Properties

3.1.1. Atterberg Limit

3.1.2. Free Expansion Rate Test

3.2. Changes of in the Mechanical Properties of Expansive Soil Modified by Single Addition of Calcium Lignosulfonate

3.2.1. Direct Shear Test

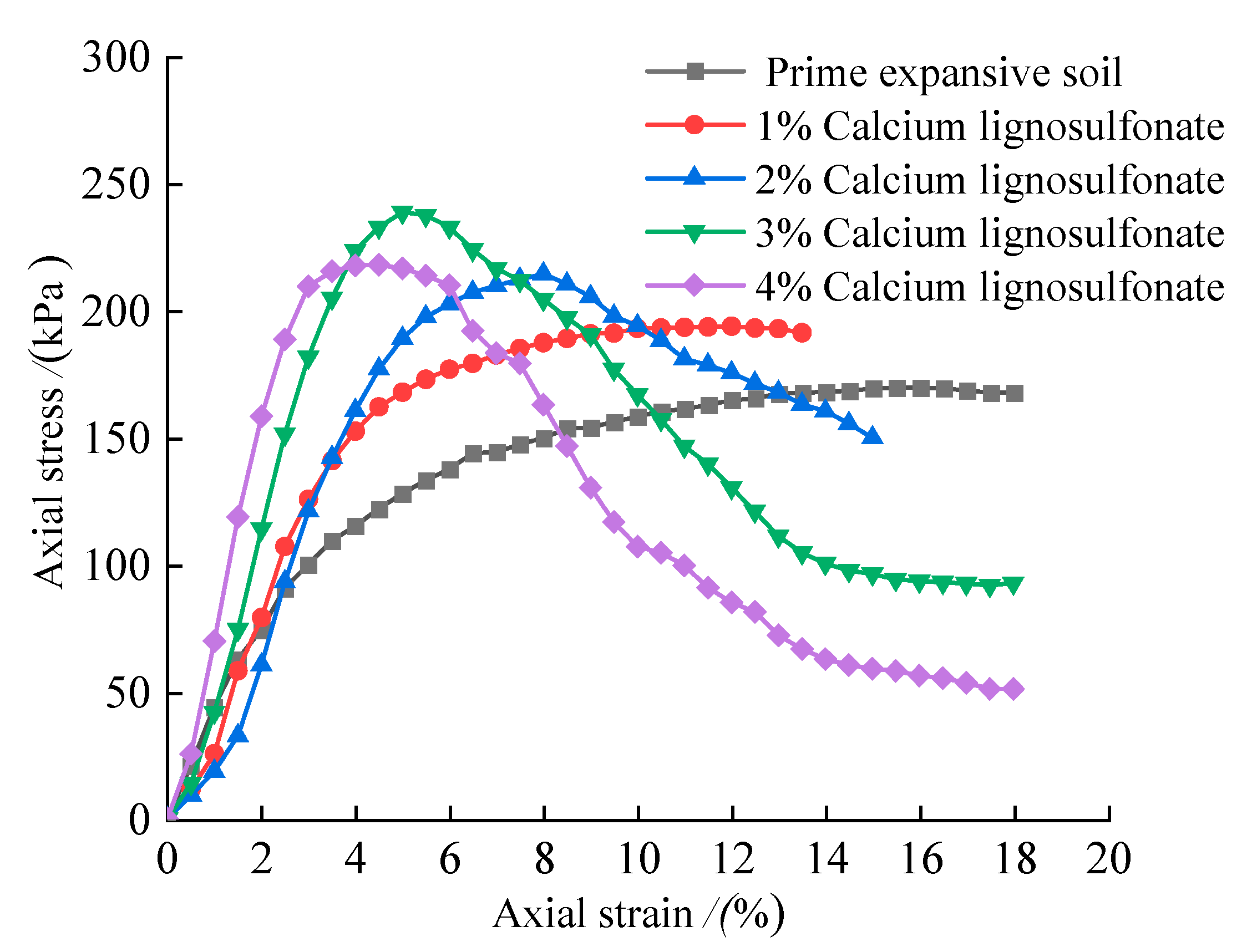

3.2.2. Unconfined Compressive Strength Test

3.3. Changes in the Mechanical Properties of Expansive Soil Modified by Calcium Lignosulfonate-Lignin Fiber Composite

3.3.1. Direct Shear Test

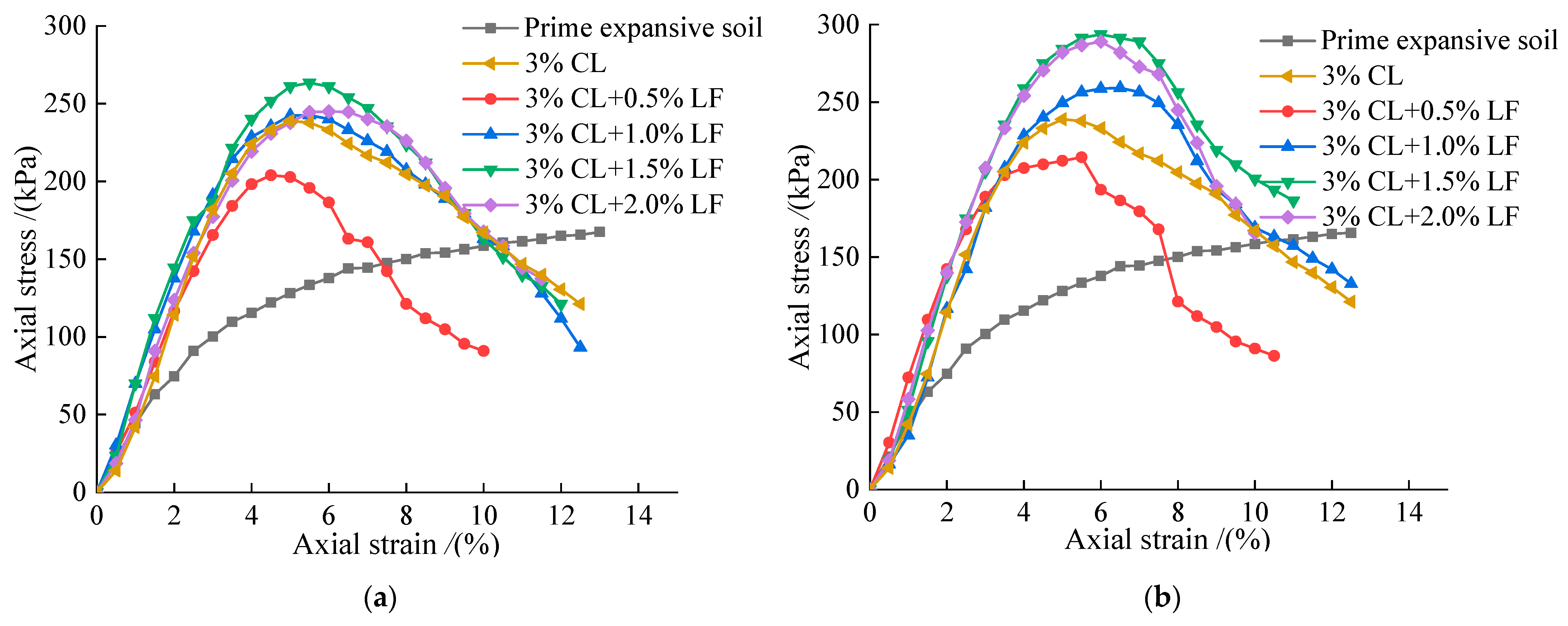

3.3.2. Unconfined Compressive Strength Test

3.4. Failure Characteristics of the Improved Soil Samples

3.5. Water Stability Test

4. Composite Improved Micro-Mechanism Analysis

5. Conclusions

- Upon adding calcium lignosulfonate, the improved soil’s liquid limit and plasticity index decreased, the lowest results were 28.72 and 5.18, with a decrease of 46.82% and 83.52%;

- Following the addition of calcium lignosulfonate, the combination of hydrophilic minerals and water in the soil decreased, achieving the effect of weakening the expansion; thus, the expansion rate of the improved soil was reduced, and the free expansion rate dropped to 38.4%, which can be identified as non-expansive soil. When carrying out the free expansion rate test, the expansion rate increased slightly with the continuous addition of calcium lignosulfonate;

- The shear strength of the modified soil mixed only with calcium lignosulfonate increased significantly under low-stress conditions, especially in terms of cohesion, by up to 72.897 kPa. The change of the internal friction angle was slightly smaller than that of the prime expansive soil, which fluctuated internally in the range of 24.2~46.6%. The 3% dosage of calcium lignosulfonate was determined to be the best, but its strength would have been reduced if too much had been added. When the composite lignin fiber was mixed with the 3% dosage of calcium lignosulfonate, the shear strength of the improved soil was further improved, the cohesion increased by 5.2–21.1%, and the internal friction angle increased by a maximum of 20%. This result could be used as the theoretical basis for shallow landslide prevention;

- The unconfined compressive strength of the improved soil mixed with calcium lignosulfonate increased first and then decreased. It was 1.14–1.41 times higher than that of the prime expansive soil sample. The unconfined compressive strength of the improved soil reached its maximum when the content of calcium lignosulfonate was 3%, which is 238.96 kPa. The unconfined compressive strength of composite lignin fiber-improved soil increased by 1.08–1.23 times based on single mixing, and the strength of 3% calcium lignosulfonate + 1.5% lignin fiber composite-improved soil was the highest, which was 293.72 kPa. This improvement method is a physical improvement, no hydration product was formed, and the effect of increasing the curing time did not improve the soil’s strength;

- Upon adding lignin and its derivatives, the internal connection effect of the improved soil was better, and the degree of particle aggregation was increased. The mechanical properties of the composite-improved sample were further enhanced based on the improvement of calcium lignosulfonate, manifested as a plastic bulging failure. Incorporating lignin and its derivatives inhibited the development and extension of tiny pores and cracks, reduced water penetration, and enhanced the water stability of the sample. Three percent calcium lignosulfonate + 1.5% lignin fiber has been determined to be the best ratio for compound improvement;

- Lignin and its derivatives are non-polluting to the environment, and the improvement process does not produce new chemical substances. Improper materials are cheap and easy to obtain, which is not in line with the concept of sustainable development. Combined with the low-stress direct shear test set up in this paper, the shallow surface condition makes the application of the test results more feasible in terms of treatment depth and can be applied to expansive soil shallow slopes or in projects with low-overlying loads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leng, T.; Tang, C.S.; Xu, D.; Li, Y.S.; Zhang, Y.; Wang, K.; Shi, B. Advance on the engineering geological characteristics of expansive soil. J. Eng. Geol. 2018, 26, 112–128. [Google Scholar]

- Bao, C.G. On slope stability of expansive soil canal of Middle Route Project of S-N Water Transfer and counter measures. J. Yangtze River 2003, 34, 4–5. [Google Scholar]

- Huang, Z.; Wei, B.X.; Zhang, L.J.; Chen, W.; Peng, Z.M. Surface crack development rules and shear strength of compacted expansive soil due to dry–wet cycles. J. Geotech. Geol. Eng. 2019, 37, 2647–2657. [Google Scholar] [CrossRef]

- Yang, H.P.; Wang, J.; Zhan, W.T. Study of treatment technology and design scheme of expansive soil subgrade for Nanning outer ring expressway. J. Rock Soil Mech. 2011, 32 (Suppl. S2), 359–365. [Google Scholar]

- Shi, B.; Jiang, H.T.; Liu, Z.B.; Fang, H.Y. Engineering geological characteristics of expansive soils in China. J. Eng. Geol. 2002, 67, 63–71. [Google Scholar] [CrossRef]

- Hu, X.H.; Zhang, K.Y.; Nie, M.J.; Pan, R.Y. Effect of experimental conditions on strength indexes of expansive soil during wet−dry cycles. J. Cent. South Univ. Sci. Technol. 2022, 53, 269–279. [Google Scholar]

- Vipulanandan, C.; Mohammed, A.S. Characterizing the Index Properties, Free Swelling, Stress–Strain Relationship, Strength and Compacted Properties of Polymer Treated Expansive CH Clay Soil Using Vipulanandan Models. J. Geotech. Geol. Eng. 2020, 38, 5589–5602. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Mohammed, A.S. 3-dimension stresses and new failure model to predict behavior of clay soils in various liquid limit ranges. Arab. J. Geosci. 2021, 14, 160. [Google Scholar] [CrossRef]

- Mawlood, Y.; Mohammed, A.; Hummadi, R.; Hasan, A.; Ibrahim, H. Modeling and statistical evaluations of unconfined compressive strength and compression index of the clay soils at various ranges of liquid limit. J. Test. Eval. 2021, 50, 1148. [Google Scholar] [CrossRef]

- Mohammed, A.; Vipulanandan, C. Testing and modeling the short-term behavior of lime and fly ash treated sulfate contaminated CL soil. J. Geotech. Geol. Eng. 2015, 33, 1099–1114. [Google Scholar] [CrossRef]

- Mohammed, A.; Hummadi, R.A.; Mawlood, Y.I. Predicting the chemical and mechanical properties of gypseous soils using different simulation technics. J. Acta Geotech. 2022, 17, 1111–1127. [Google Scholar] [CrossRef]

- Gao, X.B.; Ruan, B.; Tian, X.T.; Lv, Y.Y.; Li, S.Q.; Tang, B.B. Experimental Study on unconfined compressive strength of lime stabilized expansive soil in Guizhou province. J. Railw. Sci. Eng. 2011, 11, 68–71. [Google Scholar]

- Zhao, H.; Chu, C.F.; Guo, K.L.; Ye, H. Experimental analysis of the basic engineering properties of expansive soils improved by iron tailings sand. J. Civ. Environ. Eng. 2017, 39, 98–104. [Google Scholar]

- Hao, J.B.; Zhang, H.; Li, G.C.; Liu, Z.Y.; Huang, J.X.; Jiang, Z.W. Strength and cracking characteristics of expansive soil improved by fly ash and sisal fiber. J. Railw. Sci. Eng. 2022, 19, 2620–2628. [Google Scholar]

- Fu, X.S.; Wang, Q.; Yang, Z.B.; Li, X.; Wang, S.J. Experimental analysis on effect manufactured sand and water glass on unconfined compressive strength and shear strength of weak expansive soil. J. Civ. Environ. Eng. 2022, 44, 60–67. [Google Scholar]

- Alazigha, D.P.; Indraratna, B.; Vinod, J.S.; Ezeajugh, L.M. The swelling behaviour of lignosulfonate-treated expansive soil. J. Proc. Inst. Civ. Eng.-Ground Improv. 2016, 169, 182–193. [Google Scholar] [CrossRef]

- Alazigha, D.P.; Indraratna, B.; Vinod, J.S.; Heitor, A. Mechanisms of stabilization of expansive soil with lignosulfonate admixture. J. Transp. Geotech. 2018, 14, 81–92. [Google Scholar] [CrossRef]

- Wu, D.J.; She, W.; Wei, L.S.; Zuo, W.Q.; Hu, X.Y.; Hong, J.X.; Miao, C.W. Stabilization mechanism of calcium lignosulphonate used in expansion sensitive soil. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2020, 35, 847–855. [Google Scholar] [CrossRef]

- Liu, S.Y.; Zhang, T.; Cai, G.J.; Li, J.H.; Jie, D.B. Research progress of soil stabilization with lignin from Bio-energy By-products. J. Chin. J. Highw. Transp. 2014, 27, 1–10. (In Chinese) [Google Scholar]

- Ta’negonbadi, B.; Noorzad, R. Physical and geotechnical long-term properties of lignosulfonate-stabilized clay: An experimental investigation. J. Transp. Geotech. 2018, 17, 41–50. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.J.; Liu, S.Y. Assessment of mechanical properties in recycled lignin-stabilized silty soil as base fill material. J. Clean. Prod. 2018, 172, 1788–1799. [Google Scholar] [CrossRef]

- Jiang, T.D. Lignin; Chemical Industry Press: Beijing, China, 2008; pp. 1–3. [Google Scholar]

- Wolter, K.E. Lignins: Occurrence, Formation, Structure, and Reactions. J. For. Sci. 1973, 19, 160. [Google Scholar]

- Kong, L.B.; Hasanbeigi, A.; Price, L.; Liu, H.B. Energy conservation and CO2 mitigation potentials in the Chinese pulp and paper industry. J. Resour. Conserv. Recycl. 2017, 117, 74–84. [Google Scholar] [CrossRef]

- Furszyfer, D.R.D.D.; Sovacool, B.K.; Griffiths, S.; Bazilian, M.; Kim, J.; Foley, A.M.; Rooney, D. Decarbonizing the pulp and paper industry: A critical and systematic review of sociotechnical developments and policy options. J. Renew. Sustain. Energy Rev. 2022, 167, 112706. [Google Scholar] [CrossRef]

- Alazigha, D.P. Potential use of lignosulfonate for expansive soil stabilisation. J. Environ. Geotech. 2018, 6, 480–488. [Google Scholar] [CrossRef]

- Ijaz, N.; Dai, F.C.; Meng, L.C.; Rehman, Z.; Zhang, H.Q. Integrating lignosulphonate and hydrated lime for the amelioration of expansive soil: A sustainable waste solution. J. Clean. Prod. 2020, 254, 119985. [Google Scholar] [CrossRef]

- Chen, Y.H.; Cai, Y.; Ou, M.X. Experimental study on lignin fiber-high calcium fly ash composite improved expansive soil. J/OL J. Saf. Environ. [CrossRef]

- Xiao, J.; Yang, H.P.; Li, H.F.; Tang, X.Y. Shear strength test of Nanning expansive soil with Various Dry Densities and low stress. China J. Highw. Transp. 2013, 26, 15–21+37. [Google Scholar]

- GB 50112-2013; Technical Code for Buildings in Expansive Soil Regions. Architecture & Building Press: Beijing, China, 2013.

- Fan, K.W.; Yan, J.; Liu, L.J.; Pei, Q.Y.; Zou, W.L. Study on strength characteristics and microstructure of expansive soil treated with lignin fibers in seasonal frozen area. J. Cent. South Univ. Nat. Sci. Ed. 2022, 53, 326–334. [Google Scholar]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Water Resources of the People’s Republic of China. China Planning Press: Beijing, China, 2019.

- Wang, H.; Cao, S.J.; Cao, Y.K.; Qiu, A.B. Engineering Characteristics and Microscopic Mechanism of Lignin Ameliorating Expansive Soil. J/OL J. Civil Eng. Environ. Eng. 2022. Available online: http://kns.cnki.net/kcms/detail/50.1218.TU.20221019.1809.002.html (accessed on 10 April 2023).

- Zhou, S.Q.; Shi, M.J.; Li, J.W.; Li, D.W. Experimental study on improvement of expansive soil by cationic compound. J. Undergr. Space Eng. 2022, 18, 901–909+924. [Google Scholar]

- Ma, S.K.; Ma, M.; Huang, Z.; Hu, Y.; Shao, Y. Research on the improvement of rainfall infiltration behavior of expansive soil slope by the protection of polymer waterproof coating. J. Soils Found. 2023, 63, 101299. [Google Scholar] [CrossRef]

- Zhang, R.; Tang, P.; Lan, T.; Liu, Z.; Ling, S.G. Resilient and Sustainability Analysis of Flexible Supporting Structure of Expansive Soil Slope. Sustainability 2022, 14, 12813. [Google Scholar] [CrossRef]

- Chavali, R.V.P.; Reshmarani, B. Characterization of expansive soils treated with lignosulfonate. J. Int. J. Geo-Eng. 2020, 11, 11–21. [Google Scholar] [CrossRef]

- Viswanadham, B.V.S.; Phanikumar, B.R.; Mukherjee, R.V. Effect of polypropylene tape fibre reinforcement on swelling behaviour of an expansive soil. J. Geosynth. Int. 2009, 16, 393–401. [Google Scholar] [CrossRef]

- Wang, Y.X.; Guo, P.P.; Shan, S.B.; Yuan, H.P.; Yuan, B.X. Study on Strength Influence Mechanism of Fiber-Reinforced Expansive Soil Using Jute. J. Geotech. Geol. Eng. 2016, 34, 1079–1088. [Google Scholar]

- Phanikumar, B.R.; Singla, R. Swell-consolidation characteristics of fiber-reinforced expansive soils. J. Soils Found. 2016, 56, 138–143. [Google Scholar] [CrossRef]

| Liquid Limit (%) | Plastic Limit (%) | Plasticity Index | Maximum Dry Density (g/cm3) | Optimal Moisture Content (%) | Free Swelling Ratio (%) |

|---|---|---|---|---|---|

| 54.01 | 22.58 | 31.43 | 1.65 | 19.03 | 50.0 |

| Sample Name | Calcium Lignosulfonate Content/% | Lignin Fiber/% |

|---|---|---|

| Prime expansive soil | / | / |

| Calcium lignosulfonate-improved soil | 1.0/2.0/3.0/4.0 | / |

| Composite-improved soil | Optimal Calcium lignosulfonate content | 0.5 |

| 1.0 | ||

| 1.5 | ||

| 2.0 |

| Calcium Lignosulfonate Content % | C/kPa | φ/(°) | R2 |

|---|---|---|---|

| 0 | 37.702 | 30.689 | 0.9803 |

| 1 | 68.158 | 30.575 | 0.9407 |

| 2 | 56.799 | 42.323 | 0.9644 |

| 3 | 65.924 | 44.991 | 0.9016 |

| 4 | 72.897 | 23.258 | 0.9138 |

| Lignin Fiber Content % | C/kPa | φ/(°) | R2 |

|---|---|---|---|

| Prime expansive soil | 37.702 | 30.689 | 0.9803 |

| 0 | 65.924 | 44.991 | 0.9016 |

| 0.5 | 76.181 | 35.990 | 0.9367 |

| 1.0 | 69.351 | 45.210 | 0.9379 |

| 1.5 | 75.041 | 45.635 | 0.9887 |

| 2.0 | 79.837 | 41.324 | 0.9460 |

| Sample Name | Beginning of the Soaking in Water Process (within 30 min) | Soaking Process (48 h) | Final Result (96 h) |

|---|---|---|---|

| Prime expansive soil | There are many tiny gaps on the sample’s surface, accompanied by bubbles. | The cracks in the sample begin to develop, gradually extending to both ends of the sample, and there are small cracks at the ends. | The cracks in the sample gradually increase, running through the entire sample, the end cracks are fully developed, and the crack width increases. |

| Three percent calcium lignosulfonate+1.5% lignin fiber composite samples | There is no noticeable change in the overall sample, a small amount of air bubbles are generated on the surface, and no cracks are formed. | Some “foaming” particles appear in the sample, and the overall sample increases slightly. | Cracks appear on the edge of the sample and start to peel off, but no shots are formed in the middle, and the integrity can still be maintained. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Y.; Ou, M. Experimental Study on Expansive Soil Improved by Lignin and Its Derivatives. Sustainability 2023, 15, 8764. https://doi.org/10.3390/su15118764

Cai Y, Ou M. Experimental Study on Expansive Soil Improved by Lignin and Its Derivatives. Sustainability. 2023; 15(11):8764. https://doi.org/10.3390/su15118764

Chicago/Turabian StyleCai, Yi, and Mingxi Ou. 2023. "Experimental Study on Expansive Soil Improved by Lignin and Its Derivatives" Sustainability 15, no. 11: 8764. https://doi.org/10.3390/su15118764

APA StyleCai, Y., & Ou, M. (2023). Experimental Study on Expansive Soil Improved by Lignin and Its Derivatives. Sustainability, 15(11), 8764. https://doi.org/10.3390/su15118764