Criteria Clustering and Supplier Segmentation Based on Sustainable Shared Value Using BWM and PROMETHEE

Abstract

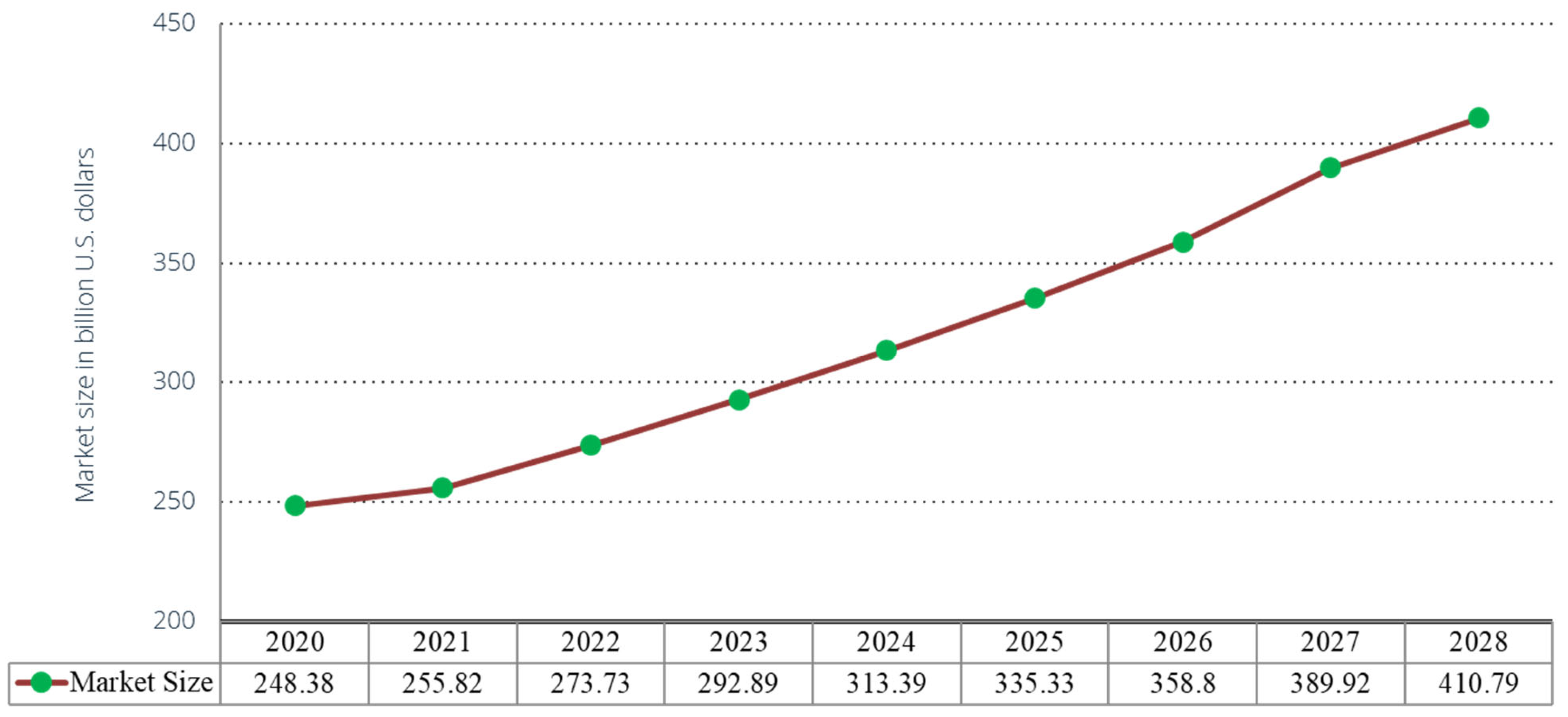

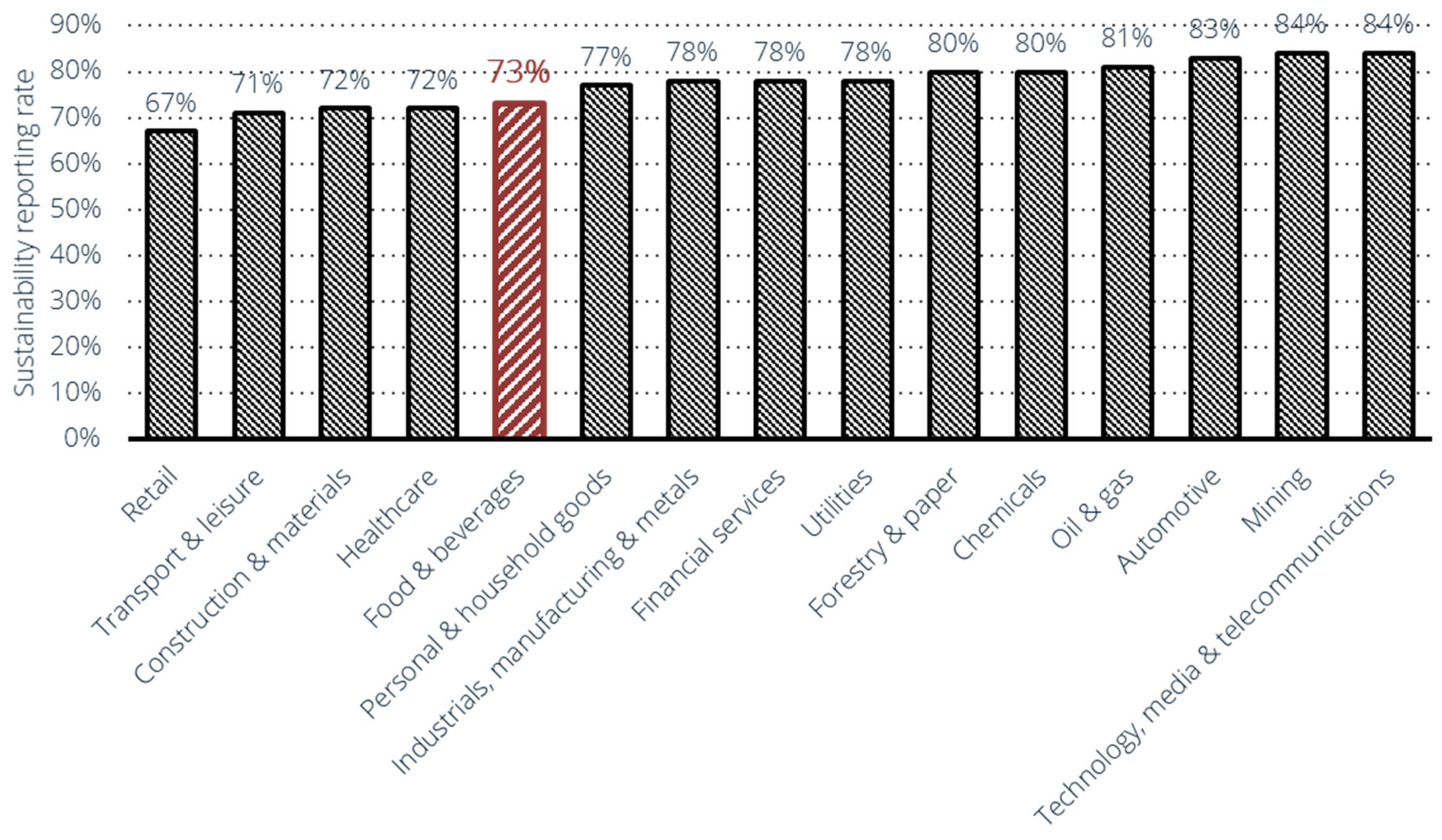

1. Introduction

2. Research Background

3. Models and Materials

PROMETHEE

4. Results

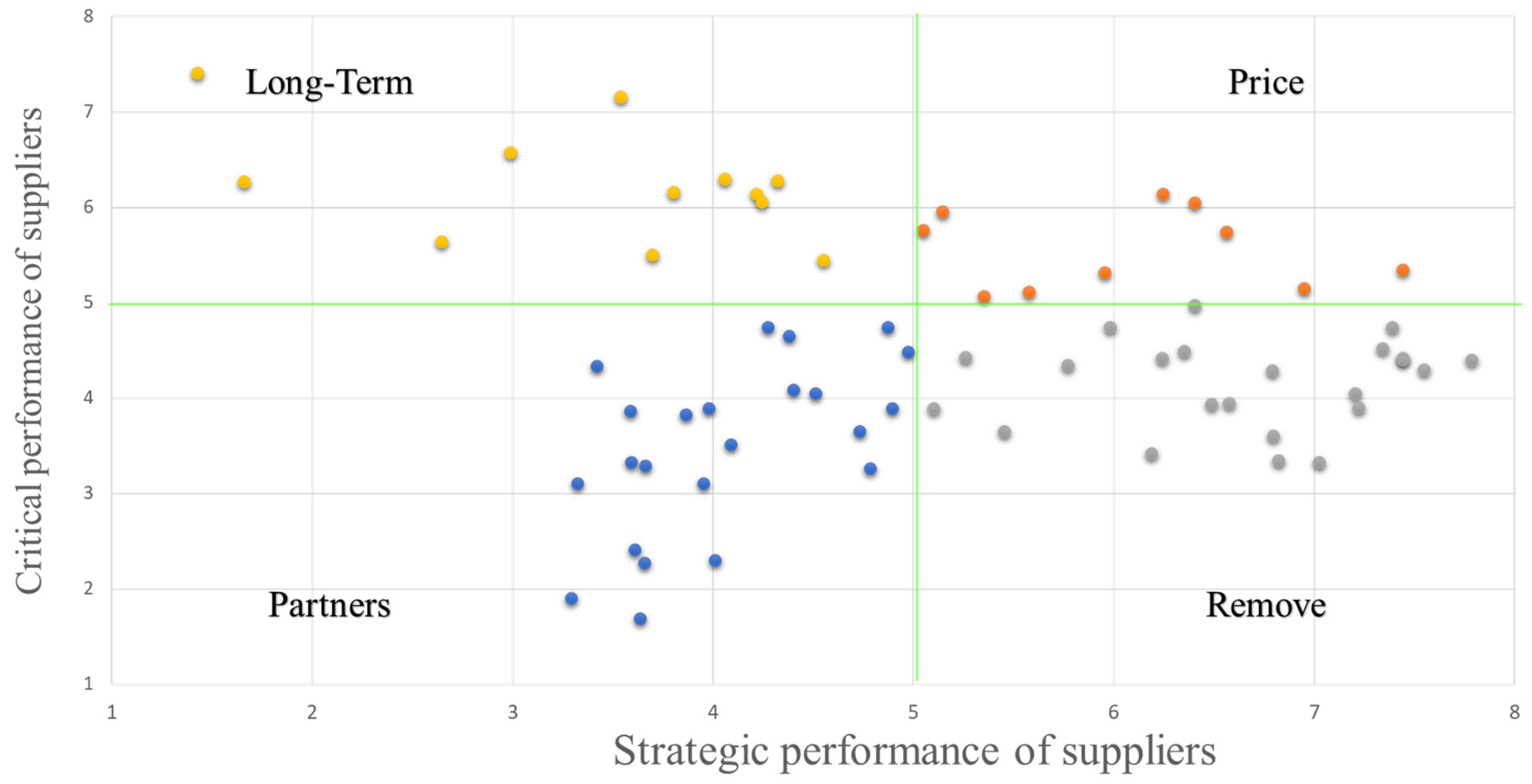

4.1. Supplier Segmentation

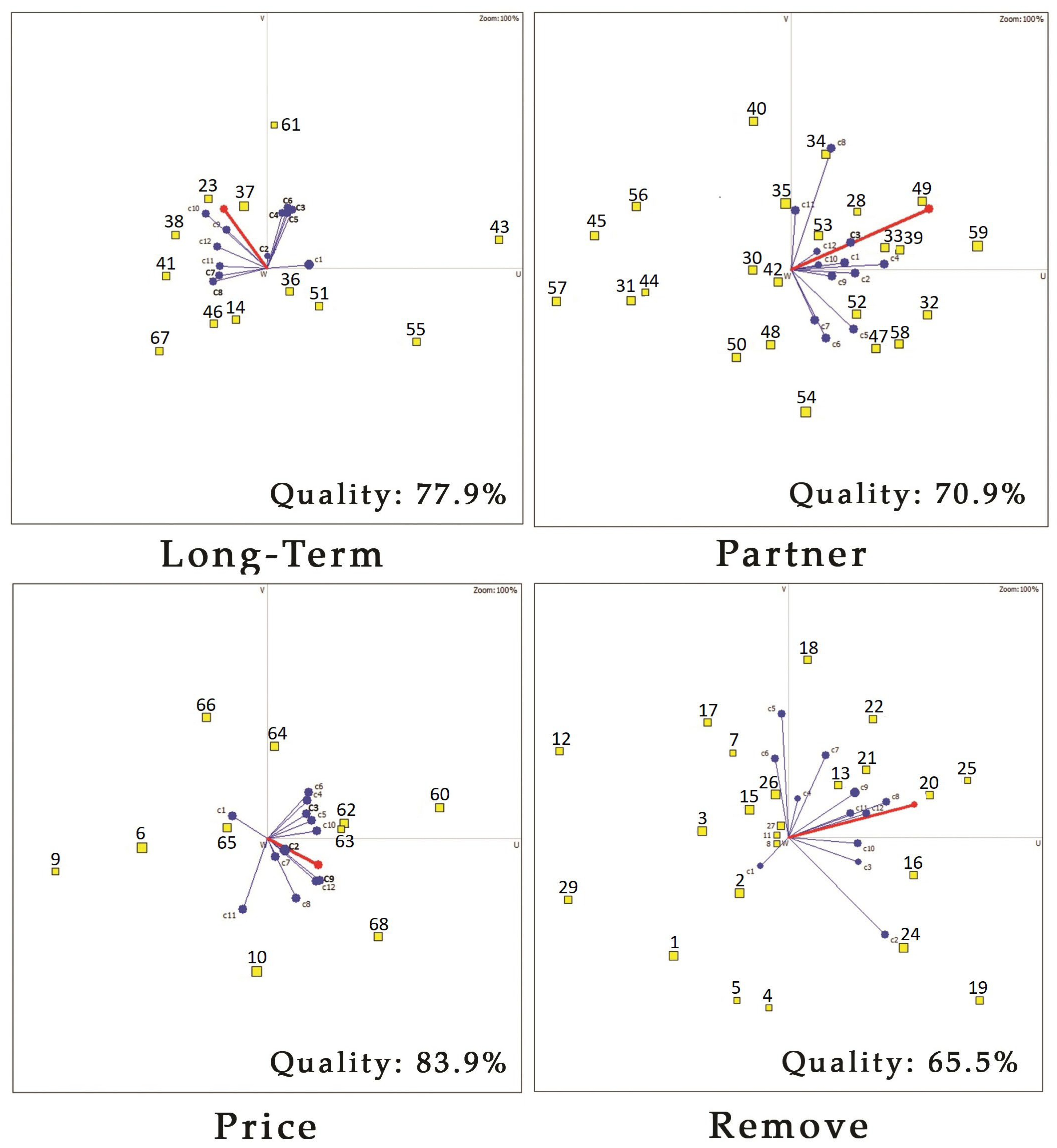

4.2. Analyzing the Properties of Each Cluster Using Visual PROMETHEE

5. Discussion

6. Limitations and Research Implications

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Taghipour, A.; Ramezani, M.; Khazaei, M.; Roohparvar, V.; Hassannayebi, E. Smart Transportation Behavior through the COVID-19 Pandemic: A Ride-Hailing System in Iran. Sustainability 2023, 15, 4178. [Google Scholar] [CrossRef]

- Merimi, M.; Taghipour, A. Accelerating the digitalization of the supply chain: An empirical research about COVID-19 crisis. In Digitalization of Decentralized Supply Chains During Global Crises; IGI Global: Pennsylvania, PA, USA, 2021; pp. 1–24. [Google Scholar]

- Segura, M.; Maroto, C. A multiple criteria supplier segmentation using outranking and value function methods. Expert Syst. Appl. 2017, 69, 87–100. [Google Scholar] [CrossRef]

- Mahfod, J.; Canel-Depitre, B.; Taghipour, A. Quality Function Deployment-ELECTRE in Supplier Evaluation. J. Adv. Manag. Sci. 2019, 7, 131–135. [Google Scholar] [CrossRef]

- Dutta, P.; Jaikumar, B.; Arora, M.S. Applications of data envelopment analysis in supplier selection between 2000 and 2020: A literature review. Ann. Oper. Res. 2021, 315, 1399–1454. [Google Scholar] [CrossRef]

- Loivet, W.; Taghipour, A.; Kang, D.S. The Rise of Green Supply Chain Management: Between Complexity and Necessity. J. Econ. Bus. Manag. 2020, 8, 1–7. [Google Scholar] [CrossRef]

- Xu, H.; Chen, L.; Li, Q.; Yang, J. A Multi-Attribute Decision Method under Uncertainty Environment Conditions—The Green Supplier Evaluation Perspective. Int. J. Environ. Res. Public Health 2021, 18, 344. [Google Scholar] [CrossRef]

- Joshi, R.; Banwet, D.; Shankar, R. A Delphi-AHP-TOPSIS based benchmarking framework for performance improvement of a cold chain. Expert Syst. Appl. 2011, 38, 10170–10182. [Google Scholar] [CrossRef]

- Govindan, K.; Dhingra Darbari, J.; Kaul, A.; Jha, P. Structural model for analysis of key performance indicators for sustainable manufacturer–supplier collaboration: A grey-decision-making trial and evaluation laboratory-based approach. Bus. Strategy Environ. 2021, 30, 1702–1722. [Google Scholar] [CrossRef]

- Vosooghidizaji, M.; Taghipour, A.; Canel-Depitre, B. Coordinating corporate social responsibility in a two-level supply chain under bilateral information asymmetry. J. Clean. Prod. 2022, 364, 132627. [Google Scholar] [CrossRef]

- Mosallanezhad, B.; Chouhan, V.K.; Paydar, M.M.; Hajiaghaei-Keshteli, M. Disaster relief supply chain design for personal protection equipment during the COVID-19 pandemic. Appl. Soft Comput. 2021, 112, 107809. [Google Scholar] [CrossRef]

- Taghipour, A.; Merimi, M. Digital Transformation of Supply Chains during Crisis: COVID-19. In Proceedings of the 11th Annual International Conference on Industrial Engineering and Operations Management, Singapore, 7–11 March 2021; pp. 7493–7501. [Google Scholar]

- Taghipour, A.; Glaa, B.; Zoghlami, N. Network coordination with minimum risk of information sharing. In Proceedings of the 2014 International Conference on Advanced Logistics and Transport (ICALT), Hammamet, Tunisia, 1–3 May 2014; pp. 184–188. [Google Scholar]

- Liu, L.; Song, W.; Liu, Y. Leveraging digital capabilities toward a circular economy: Reinforcing sustainable supply chain management with Industry 4.0 technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Wang, C.-N.; Tsai, H.-T.; Ho, T.-P.; Nguyen, V.-T.; Huang, Y.-F. Multi-Criteria Decision Making (MCDM) Model for Supplier Evaluation and Selection for Oil Production Projects in Vietnam. Processes 2020, 8, 134. [Google Scholar] [CrossRef]

- Ehsanifar, M.; Dekamini, F.; Spulbar, C.; Birau, R.; Khazaei, M.; Bărbăcioru, I.C. A Sustainable Pattern of Waste Management and Energy Efficiency in Smart Homes Using the Internet of Things (IoT). Sustainability 2023, 15, 5081. [Google Scholar] [CrossRef]

- Tavana, M.; Yazdani, M.; Di Caprio, D. An application of an integrated ANP–QFD framework for sustainable supplier selection. Int. J. Logist. Res. Appl. 2017, 20, 254–275. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Paydar, M.M.; Hajiaghaei-Keshteli, M. Recovery solutions for ecotourism centers during the Covid-19 pandemic: Utilizing Fuzzy DEMATEL and Fuzzy VIKOR methods. Expert Syst. Appl. 2021, 185, 115594. [Google Scholar] [CrossRef]

- Caniëls, M.; Gelderman, C.J. Purchasing strategies in the Kraljic matrix—A power and dependence perspective. J. Purch. Supply Manag. 2005, 11, 141–155. [Google Scholar] [CrossRef]

- Srhir, S.; Jaegler, A.; Montoya-Torres, J.R. Uncovering Industry 4.0 technology attributes in sustainable supply chain 4.0: A systematic literature review. Bus. Strategy Environ. 2023. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, D.; Li, Q.; Lev, B.; Ma, Y. Research on Sustainable Supplier Selection Based on the Rough DEMATEL and FVIKOR Methods. Sustainability 2021, 13, 88. [Google Scholar] [CrossRef]

- Taghipour, A.; Murat, S.; Huang, P. E-supply chain management: A review. Int. J. e-Educ. e-Bus. e-Manag. e-Learn. 2021, 11, 51–61. [Google Scholar] [CrossRef]

- Taghipour, A.; Abed, M.; Zoghlami, N. Design for remanufacturing respecting reverse logistics processes: A review. In Proceedings of the 2015 4th International Conference on Advanced Logistics and Transport (ICALT), Valenciennes, France, 20–22 May 2015; pp. 299–304. [Google Scholar]

- Taghipour, A.; Rouyendegh, B.D.; Ünal, A.; Piya, S. Selection of Suppliers for Speech Recognition Products in IT Projects by Combining Techniques with an Integrated Fuzzy MCDM. Sustainability 2022, 14, 1777. [Google Scholar] [CrossRef]

- Taghipour, A.; Frayret, J.-M. Supply Chain Coordination Planning: A Review; Work paper; École Polytechnique de Montréal: Montreal, QC, Canada, 2011. [Google Scholar]

- Reshad, A.I.; Biswas, T.; Agarwal, R.; Paul, S.K.; Azeem, A. Evaluating barriers and strategies to sustainable supply chain risk management in the context of an emerging economy. Bus. Strat. Environ. 2023. [Google Scholar] [CrossRef]

- Garjan, H.S.; Paydar, M.M.; Divsalar, A. A sustainable supply chain for a wellness tourism center considering discount and quality of service. Expert Syst. Appl. 2023, 211, 118682. [Google Scholar] [CrossRef]

- Taghipour, A.; Khazaei, M.; Azar, A.; Ghatari, A.R.; Hajiaghaei-Keshteli, M.; Ramezani, M. Creating Shared Value and Strategic Corporate Social Responsibility through Outsourcing within Supply Chain Management. Sustainability 2022, 14, 1940. [Google Scholar] [CrossRef]

- Nayeri, M.D.; Khazaei, M.; Abdolahbeigi, D. The drivers of success in new-service development: Rough set theory approach. Int. J. Serv. Oper. Manag. 2022, 43, 421. [Google Scholar] [CrossRef]

- Khazaei, M.; Ramezani, M.; Padash, A.; DeTombe, D. Creating shared value to redesigning IT-service products using SYRCS; Diagnosing and tackling complex problems. Inf. Syst. e-Bus. Manag. 2021, 19, 957–992. [Google Scholar] [CrossRef]

- Ramezani, M.; Azar, A.; Khazaei, M. Gap analysis through a hybrid method: Critical systems heuristics and best worst method. In Advances in Best-Worst Method: Proceedings of the Second International Workshop on Best-Worst Method (BWM2021); Springer: Berlin/Heidelberg, Germany, 2022; pp. 272–286. [Google Scholar]

- Khazaei, M.; Ramezani, M.; Padash, A.; DeTombe, D. The quantification role of BWM in problem structuring methods: SYRCS methodology. In Advances in Best-Worst Method: Proceedings of the Second International Workshop on Best-Worst Method (BWM2021); Springer: Berlin/Heidelberg, Germany, 2022; pp. 252–271. [Google Scholar]

- Vidal, N.G.; Spetic, W.; Croom, S.; Marshall, D. Supply chain stakeholder pressure for the adoption of sustainable supply chain practices: Examining the roles of entrepreneurial and sustainability orientations. Supply Chain Manag. Int. J. 2022, 28, 598–618. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Cheraghalipour, A.; Paydar, M.M.; Hajiaghaei-Keshteli, M. Applying a hybrid BWM-VIKOR approach to supplier selection: A case study in the Iranian agricultural implements industry. Int. J. Appl. Decis. Sci. 2018, 11, 274–301. [Google Scholar] [CrossRef]

- Hudnurkar, M.; Rathod, U.; Jakhar, S.K. Multi-criteria decision framework for supplier classification in collaborative supply chains: Buyer’s perspective. Int. J. Product. Perform. Manag. 2016, 65, 622–640. [Google Scholar] [CrossRef]

- Rezaei, J.; Lajimi, H.F. Segmenting supplies and suppliers: Bringing together the purchasing portfolio matrix and the supplier potential matrix. Int. J. Logist. Res. Appl. 2019, 22, 419–436. [Google Scholar] [CrossRef]

- Bianchini, A.; Benci, A.; Pellegrini, M.; Rossi, J. Supply chain redesign for lead-time reduction through Kraljic purchasing portfolio and AHP integration. Benchmarking Int. J. 2019, 26, 1194–1209. [Google Scholar] [CrossRef]

- Wang, G.; Jiang, Z.; Li, Z.; Liu, W. Supplier selection and order splitting in multiple-sourcing inventory systems. Front. Mech. Eng. China 2008, 3, 23–27. [Google Scholar] [CrossRef]

- Su, T.; Zhan, F. Supplier Selection and Evaluation System of Delphi Method and Analytic Hierarchy Process. IOP Conf. Ser. Mater. Sci. Eng. 2020, 768, 052107. [Google Scholar] [CrossRef]

- Fallahpour, A.; Nayeri, S.; Sheikhalishahi, M.; Wong, K.Y.; Tian, G.; Fathollahi-Fard, A.M. A hyper-hybrid fuzzy decision-making framework for the sustainable-resilient supplier selection problem: A case study of Malaysian Palm oil industry. Environ. Sci. Pollut. Res. 2021, 1–21. [Google Scholar] [CrossRef]

- Mirhosseini, S.S.; Ramezani, M.; Khazaei, M.; Azar, A. Exploring and analysing the risks and challenges of implementing ERP systems: Critical system thinking. Int. J. Inf. Syst. Change Manag. 2021, 12, 234–258. [Google Scholar] [CrossRef]

- Khazaei, M.; Dekamini, F.; Ehsanifar, M.; Spulbar, C.; Birau, R.; Ninulescu, P.V. shortcomings and challenges of creating shared value in management science: A critical review. Res. Sci. Today 2022, 24, 119. [Google Scholar] [CrossRef]

- Liu, G.; Fan, S.; Tu, Y.; Wang, G. Innovative Supplier Selection from Collaboration Perspective with a Hybrid MCDM Model: A Case Study Based on NEVs Manufacturer. Symmetry 2021, 13, 143. [Google Scholar] [CrossRef]

- Rezaei, J.; Wang, J.; Tavasszy, L. Linking supplier development to supplier segmentation using Best Worst Method. Expert Syst. Appl. 2015, 42, 9152–9164. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Demirtas, E.A.; Üstün, Ö. An integrated multiobjective decision making process for supplier selection and order allocation. Omega 2008, 36, 76–90. [Google Scholar] [CrossRef]

- Lee, A.H.; Chen, W.-C.; Chang, C.-J. A fuzzy AHP and BSC approach for evaluating performance of IT department in the manufacturing industry in Taiwan. Expert Syst. Appl. 2008, 34, 96–107. [Google Scholar] [CrossRef]

- Ha, S.H.; Krishnan, R. A hybrid approach to supplier selection for the maintenance of a competitive supply chain. Expert Syst. Appl. 2008, 34, 1303–1311. [Google Scholar] [CrossRef]

- Cakir, O.; Canbolat, M.S. A web-based decision support system for multi-criteria inventory classification using fuzzy AHP methodology. Expert Syst. Appl. 2008, 35, 1367–1378. [Google Scholar] [CrossRef]

- Yu, J.-R.; Tsai, C.-C. A decision framework for supplier rating and purchase allocation: A case in the semiconductor industry. Comput. Ind. Eng. 2008, 55, 634–646. [Google Scholar] [CrossRef]

- Levary, R.R. Using the analytic hierarchy process to rank foreign suppliers based on supply risks. Comput. Ind. Eng. 2008, 55, 535–542. [Google Scholar] [CrossRef]

- Kokangul, A.; Susuz, Z. Integrated analytical hierarch process and mathematical programming to supplier selection problem with quantity discount. Appl. Math. Model. 2009, 33, 1417–1429. [Google Scholar] [CrossRef]

- Gencer, C.; Gürpinar, D. Analytic network process in supplier selection: A case study in an electronic firm. Appl. Math. Model. 2007, 31, 2475–2486. [Google Scholar] [CrossRef]

- Jharkharia, S.; Shankar, R. Selection of logistics service provider: An analytic network process (ANP) approach. Omega 2007, 35, 274–289. [Google Scholar] [CrossRef]

- Wu, M. An alternative agent approach for managing materials purchasing. In Proceedings of the 2007 International Conference on Wireless Communications, Networking and Mobile Computing, Shanghai, China, 21–25 September 2007; pp. 6418–6420. [Google Scholar]

- Isik, S.; Vayvay, O. Selection of Strategic Suppliers for Partnership: A Model with Two Stages Approach. Int. J. Ind. Manuf. Eng. 2018, 12, 327–333. [Google Scholar]

- Abdullah, L.; Chan, W.; Afshari, A. Application of PROMETHEE method for green supplier selection: A comparative result based on preference functions. J. Ind. Eng. Int. 2019, 15, 271–285. [Google Scholar] [CrossRef]

- Brans, J.-P.; De Smet, Y. PROMETHEE methods. In Multiple Criteria Decision Analysis; Springer: Berlin/Heidelberg, Germany, 2016; pp. 187–219. [Google Scholar]

- Karande, P.; Chakraborty, S. Application of PROMETHEE-GAIA method for non-traditional machining processes selection. Manag. Sci. Lett. 2012, 2, 2049–2060. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, M.; Kannan, D. Supplier selection based on corporate social responsibility practices. Int. J. Prod. Econ. 2018, 200, 353–379. [Google Scholar] [CrossRef]

- Porter, M.E.; Kramer, M.R. Creating shared value. In Managing Sustainable Business; Springer: Berlin/Heidelberg, Germany, 2019; pp. 323–346. [Google Scholar]

| The Amount of Returned Shipments | Purchased Lot Size | Number of Suppliers | Factor Stopping Factory Production | Research and Development | Desire of the Supplier in the Availability of the Product | Annual Customer Demand | Trust and Two-Way Communication | Capability and Services of the Supplier Company | Market Risk | Risk of the Supplier Country | Quality of Communication with the Seller | Activities, Plans and Business Plans | Logistics Activity | Safety and Environmental Issues | Ethical Standards | Reliability | Company Profile | Services | Delivery time | Quality | Price | Criteria | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clusters | |||||||||||||||||||||||

| × | × | × | × | × | × | × | × | × | × | × | × | × | × | × | × | × | × | [9] | |||||

| × | × | × | × | × | × | × | × | × | × | × | × | × | × | × | × | [41] | |||||||

| × | × | × | × | × | × | × | × | × | × | × | × | × | × | × | [40] | ||||||||

| × | × | × | × | × | × | × | × | × | × | [15] | |||||||||||||

| × | × | × | × | × | × | × | × | × | × | [38] | |||||||||||||

| × | × | × | × | × | × | [37] | |||||||||||||||||

| × | × | × | × | [3] | |||||||||||||||||||

| × | × | × | × | × | × | × | × | × | × | × | × | × | × | [36] | |||||||||

| × | × | × | × | × | [45] | ||||||||||||||||||

| × | × | × | × | × | × | × | [46] | ||||||||||||||||

| × | × | × | × | × | × | × | × | [47] | |||||||||||||||

| × | × | × | × | × | × | × | × | × | × | × | × | × | × | [47] | |||||||||

| × | × | × | × | × | × | × | [48] | ||||||||||||||||

| × | × | × | × | × | × | × | × | [49] | |||||||||||||||

| × | × | × | × | × | [50] | ||||||||||||||||||

| × | × | × | × | × | × | × | × | × | × | [51] | |||||||||||||

| × | × | × | × | [52] | |||||||||||||||||||

| × | × | × | × | × | [39] | ||||||||||||||||||

| × | × | × | × | × | × | × | × | [53] | |||||||||||||||

| × | × | × | × | × | × | × | × | [54] | |||||||||||||||

| × | × | × | × | × | × | × | × | × | × | × | [55] | ||||||||||||

| × | × | × | × | × | [56] | ||||||||||||||||||

| S. No | Category | Practices |

|---|---|---|

| SC1 | Society | Generous financial donations |

| SC2 | Innovative giving | |

| SC3 | Support for education and job training programs | |

| SC4 | Direct involvement in community projects and affairs | |

| SC5 | Campaigning for environmental and social change | |

| SC6 | Disclosure of environmental and social performance | |

| E1 | Environment | Environmental policies, organization, and management |

| E2 | Materials policy of reduction, reuse, and recycling | |

| E3 | Monitoring and taking responsibility for releases to the environment | |

| E4 | Waste management | |

| E5 | Energy conservation | |

| E6 | Effective emergency response | |

| E7 | Product stewardship | |

| E8 | Environmental requirements for suppliers | |

| EM1 | Employees | Fair remuneration |

| EM2 | Effective communication | |

| EM3 | Learning and development opportunities | |

| EM4 | A healthy and safe work environment | |

| EM5 | Equal employment opportunities | |

| EM6 | Job security | |

| EM7 | Competent leadership | |

| EM8 | Community spirit | |

| C1 | Customers | Value for money |

| C2 | Truthful promotion | |

| C3 | Leadership in research and development | |

| C4 | Minimal packaging | |

| C5 | Rapid and respectful responses to customer comments/concerns | |

| S1 | Suppliers | Develop and maintain long-term purchasing relationships |

| S2 | Pay fair prices and settle bills according to terms agreed upon | |

| S3 | Encouragement to provide innovative suggestions | |

| S4 | Assist suppliers to improve their environmental/social performance | |

| S5 | Utilize local suppliers | |

| S6 | Inclusion of environmental/social criteria in the supplier selection | |

| SH1 | Shareholders | Good rate of long-term return for shareholders |

| SH2 | Disseminate comprehensive and clear information | |

| SH3 | Encourage staff ownership of shares | |

| SH4 | Develop and build relationships with shareholders | |

| SH5 | Clear dividend policy and payment of appropriate dividends |

| Criteria Categories | Code | Criteria | Weights |

|---|---|---|---|

| Critical | C1 | Performance Transparency | 17.50 |

| C2 | Social Empowerment | 10.00 | |

| C3 | Environmentally Friendly Products | 5.00 | |

| C4 | Environmentally Friendly Activities | 10.00 | |

| C5 | Resources Empowerment and Prosperity | 5.00 | |

| C6 | Fair Sourcing | 2.50 | |

| Strategic | C7 | Innovation Attention | 7.30 |

| C8 | Cost Effectiveness | 18.25 | |

| C9 | Sustainable Research and Development (R&D) | 4.38 | |

| C10 | Long-Term Relationship Potentiality | 10.95 | |

| C11 | Energy and Material Efficiency | 7.30 | |

| C12 | Openness and Communication | 1.82 | |

| Weights Summation | 100 |

| Rank | Supplier | Phi | Rank | Supplier | Phi | Rank | Supplier | Phi | Rank | Supplier | Phi |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 61 | 0.1467 | 8 | 51 | 0.0108 | 1 | 68 | 0.1574 | 7 | 66 | −0.0731 |

| 2 | 38 | 0.1324 | 9 | 46 | −0.0740 | 2 | 62 | 0.1421 | 8 | 64 | −0.1186 |

| 3 | 23 | 0.0964 | 10 | 43 | −0.0857 | 3 | 60 | 0.1282 | 9 | 6 | −0.1398 |

| 4 | 41 | 0.0867 | 11 | 36 | −0.2300 | 4 | 63 | 0.1111 | 10 | 9 | −0.1849 |

| 5 | 37 | 0.0802 | 12 | 55 | −0.2613 | 5 | 10 | 0.0446 | |||

| 6 | 14 | 0.0630 | 6 | 65 | −0.0669 | ||||||

| 7 | 67 | 0.0349 | LONG-TERM | 7 | 66 | −0.0731 | PRICE | ||||

| Rank | Supplier | Phi | Rank | Supplier | Phi | Rank | Supplier | Phi | Rank | Supplier | Phi |

| 1 | 59 | 0.3151 | 13 | 42 | −0.0046 | 1 | 19 | 0.1996 | 13 | 7 | −0.0288 |

| 2 | 49 | 0.2916 | 14 | 30 | −0.0096 | 2 | 25 | 0.1996 | 14 | 2 | −0.0530 |

| 3 | 32 | 0.2033 | 15 | 40 | −0.0265 | 3 | 21 | 0.1521 | 15 | 24 | −0.0590 |

| 4 | 58 | 0.1694 | 16 | 54 | −0.0636 | 4 | 18 | 0.1421 | 16 | 4 | −0.0624 |

| 5 | 33 | 0.1683 | 17 | 48 | −0.0993 | 5 | 16 | 0.1408 | 17 | 26 | −0.0728 |

| 6 | 34 | 0.1674 | 18 | 50 | −0.1739 | 6 | 22 | 0.1362 | 18 | 15 | −0.0737 |

| 7 | 39 | 0.1634 | 19 | 56 | −0.1813 | 7 | 8 | 0.0733 | 19 | 17 | −0.0787 |

| 8 | 28 | 0.1139 | 20 | 44 | −0.2488 | 8 | 13 | 0.0543 | 20 | 3 | −0.1652 |

| 9 | 53 | 0.1138 | 21 | 31 | −0.2512 | 9 | 20 | 0.0519 | 21 | 12 | −0.1749 |

| 10 | 35 | 0.0227 | 22 | 45 | −0.3223 | 10 | 27 | 0.0403 | 22 | 1 | −0.2269 |

| 11 | 47 | 0.0189 | 23 | 57 | −0.3676 | 11 | 5 | 0.0347 | 23 | 29 | −0.2550 |

| 12 | 52 | 0.0009 | PARTNERS | 12 | 11 | 0.0257 | REMOVE | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taghipour, A.; Fooladvand, A.; Khazaei, M.; Ramezani, M. Criteria Clustering and Supplier Segmentation Based on Sustainable Shared Value Using BWM and PROMETHEE. Sustainability 2023, 15, 8670. https://doi.org/10.3390/su15118670

Taghipour A, Fooladvand A, Khazaei M, Ramezani M. Criteria Clustering and Supplier Segmentation Based on Sustainable Shared Value Using BWM and PROMETHEE. Sustainability. 2023; 15(11):8670. https://doi.org/10.3390/su15118670

Chicago/Turabian StyleTaghipour, Atour, Arvin Fooladvand, Moein Khazaei, and Mohammad Ramezani. 2023. "Criteria Clustering and Supplier Segmentation Based on Sustainable Shared Value Using BWM and PROMETHEE" Sustainability 15, no. 11: 8670. https://doi.org/10.3390/su15118670

APA StyleTaghipour, A., Fooladvand, A., Khazaei, M., & Ramezani, M. (2023). Criteria Clustering and Supplier Segmentation Based on Sustainable Shared Value Using BWM and PROMETHEE. Sustainability, 15(11), 8670. https://doi.org/10.3390/su15118670