Sustainability Score Comparison of Welding Strategies for the Manufacturing of Electric Transportation Components

Abstract

:1. Introduction

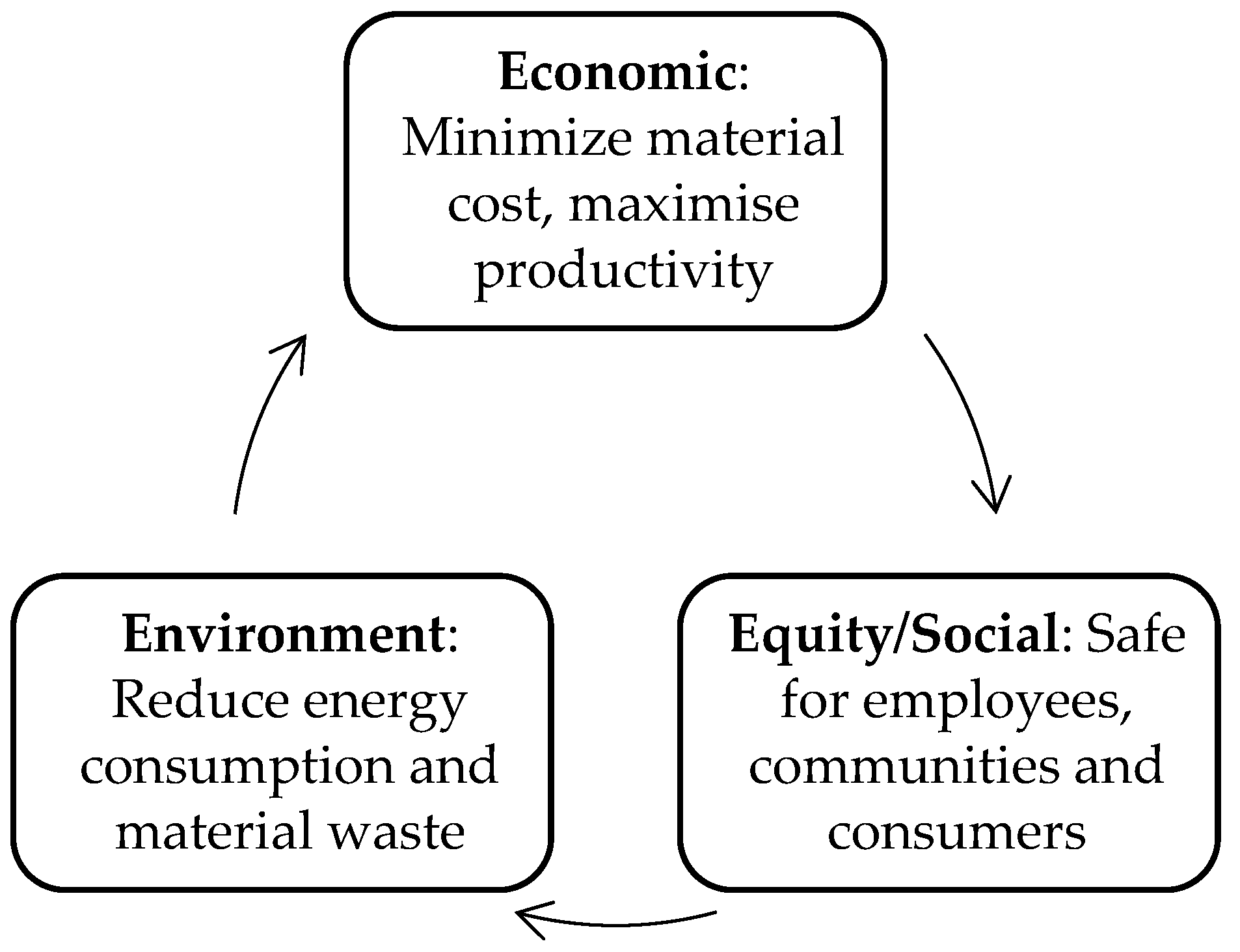

2. Preliminary Concepts and Proposed Work

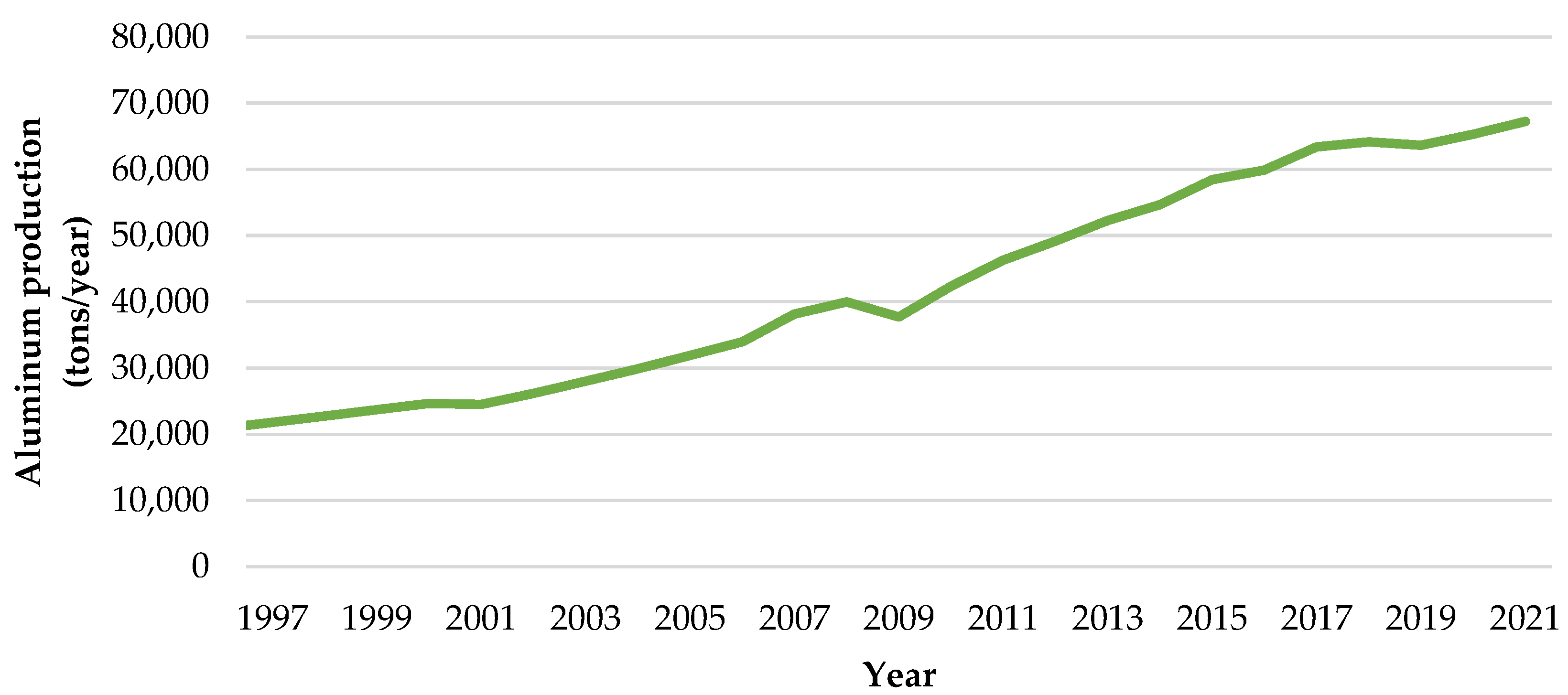

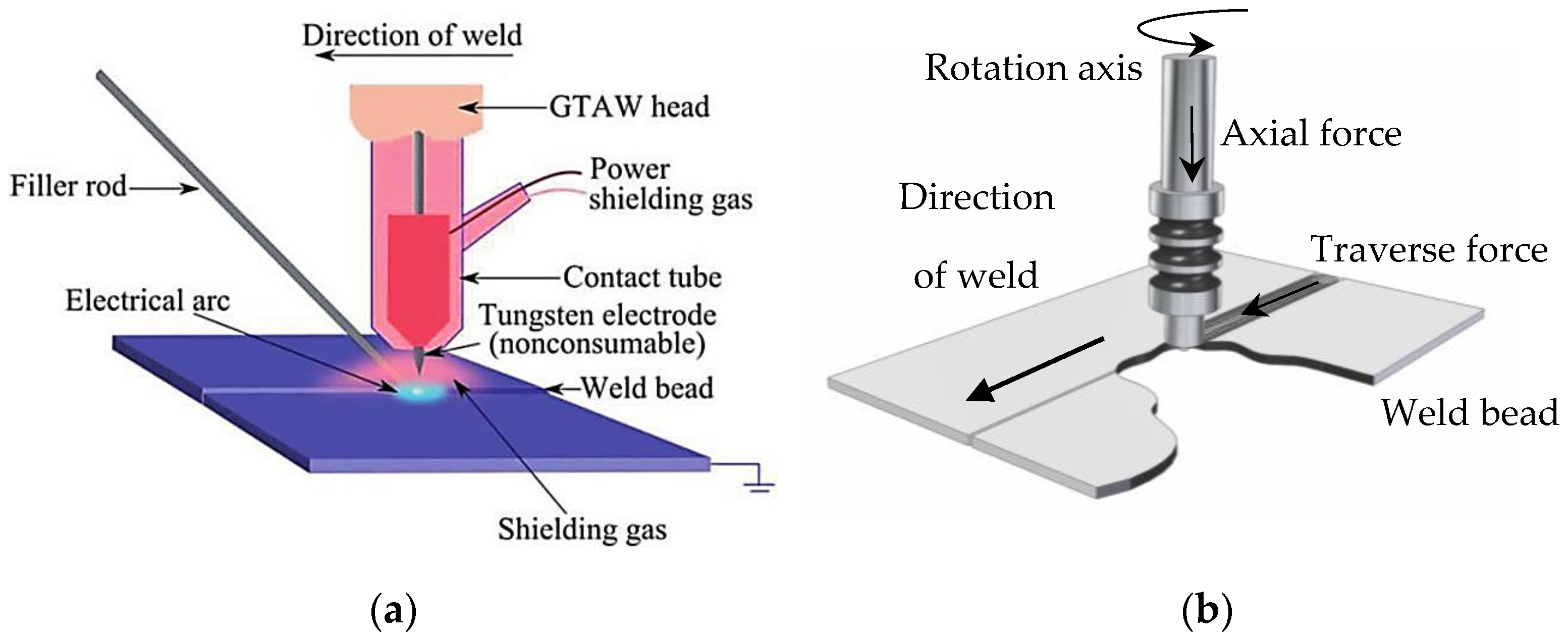

2.1. Aluminium Welding

2.2. Selection of a Welding Process

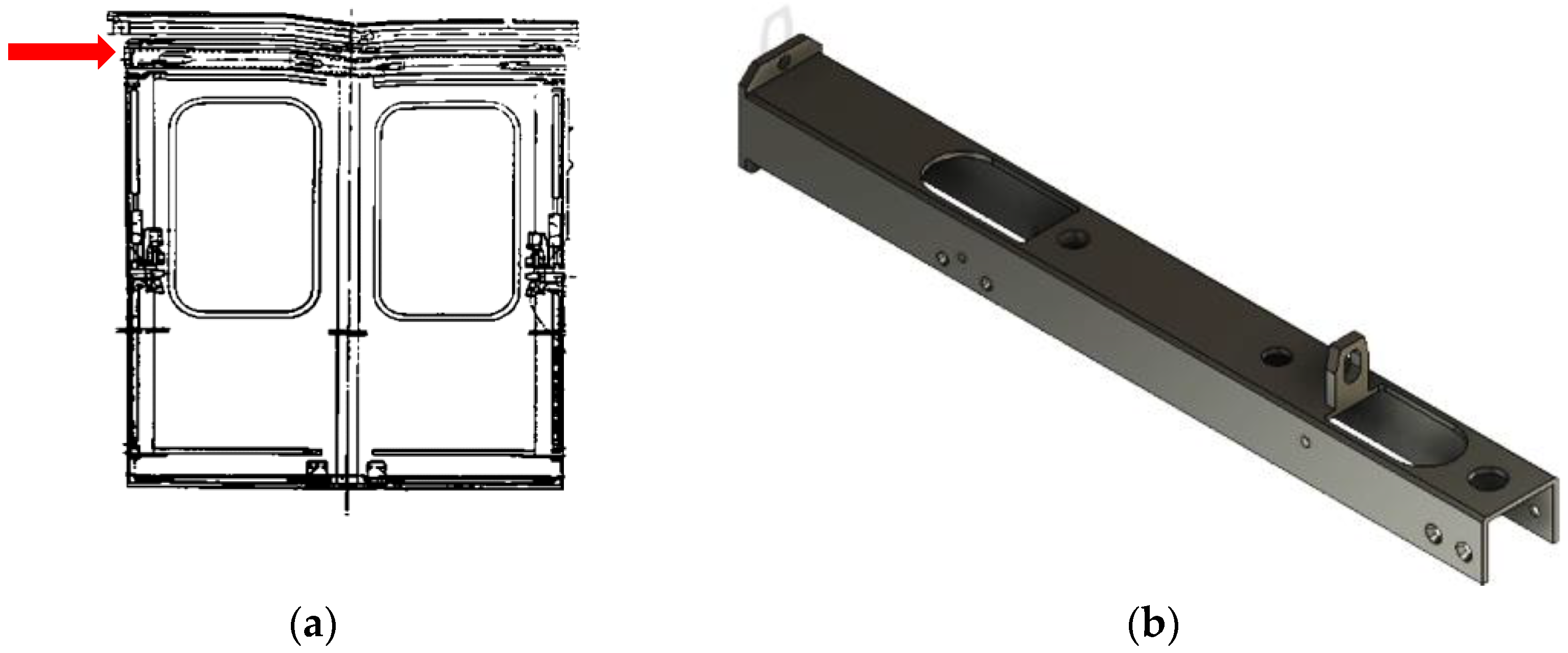

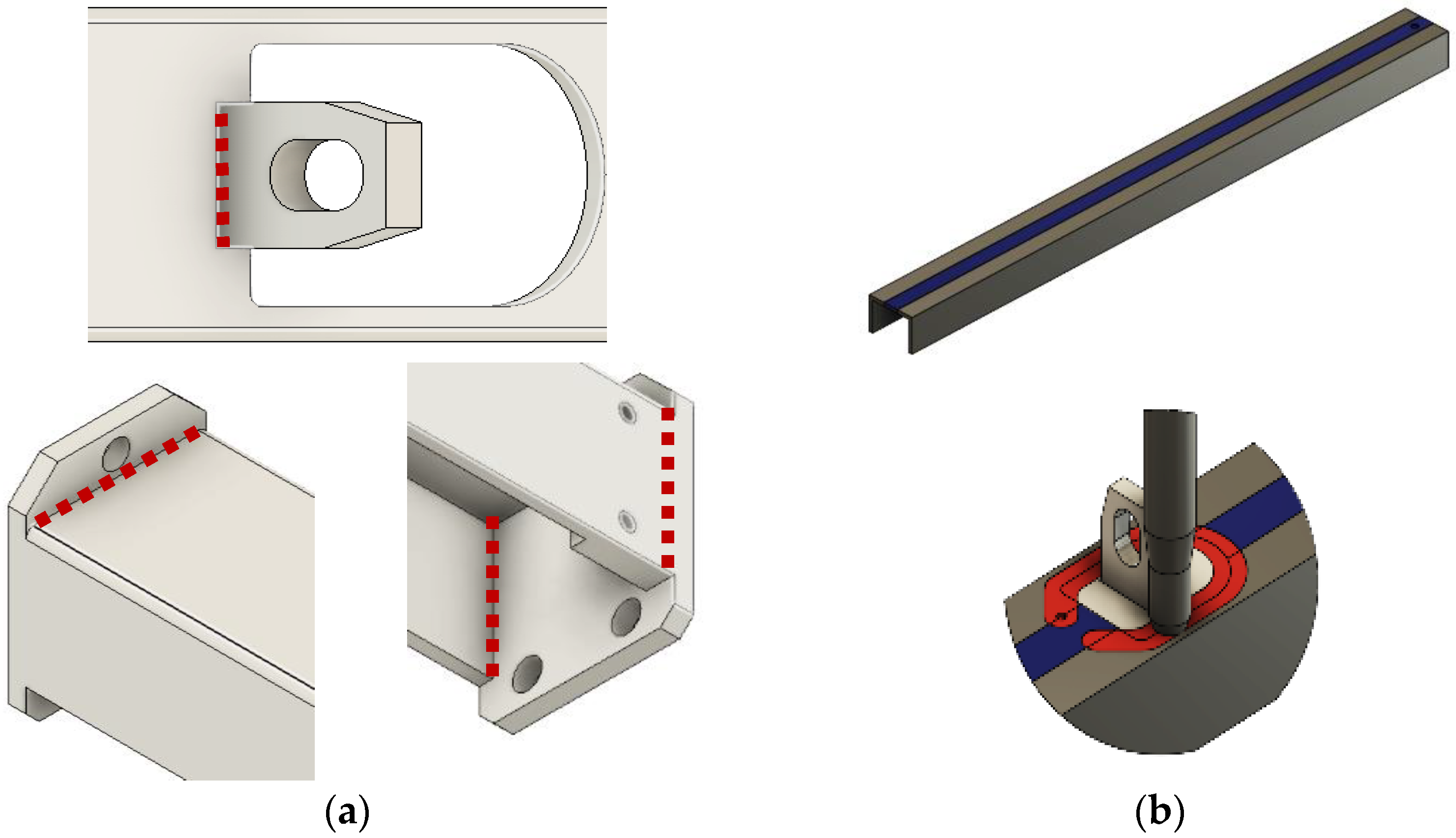

2.3. Case Study Description

3. Methodology for Calculating Sustainability Scores

3.1. Physical Impact

3.2. Environmental Impact

3.3. Economic Impact

3.4. Social Impact

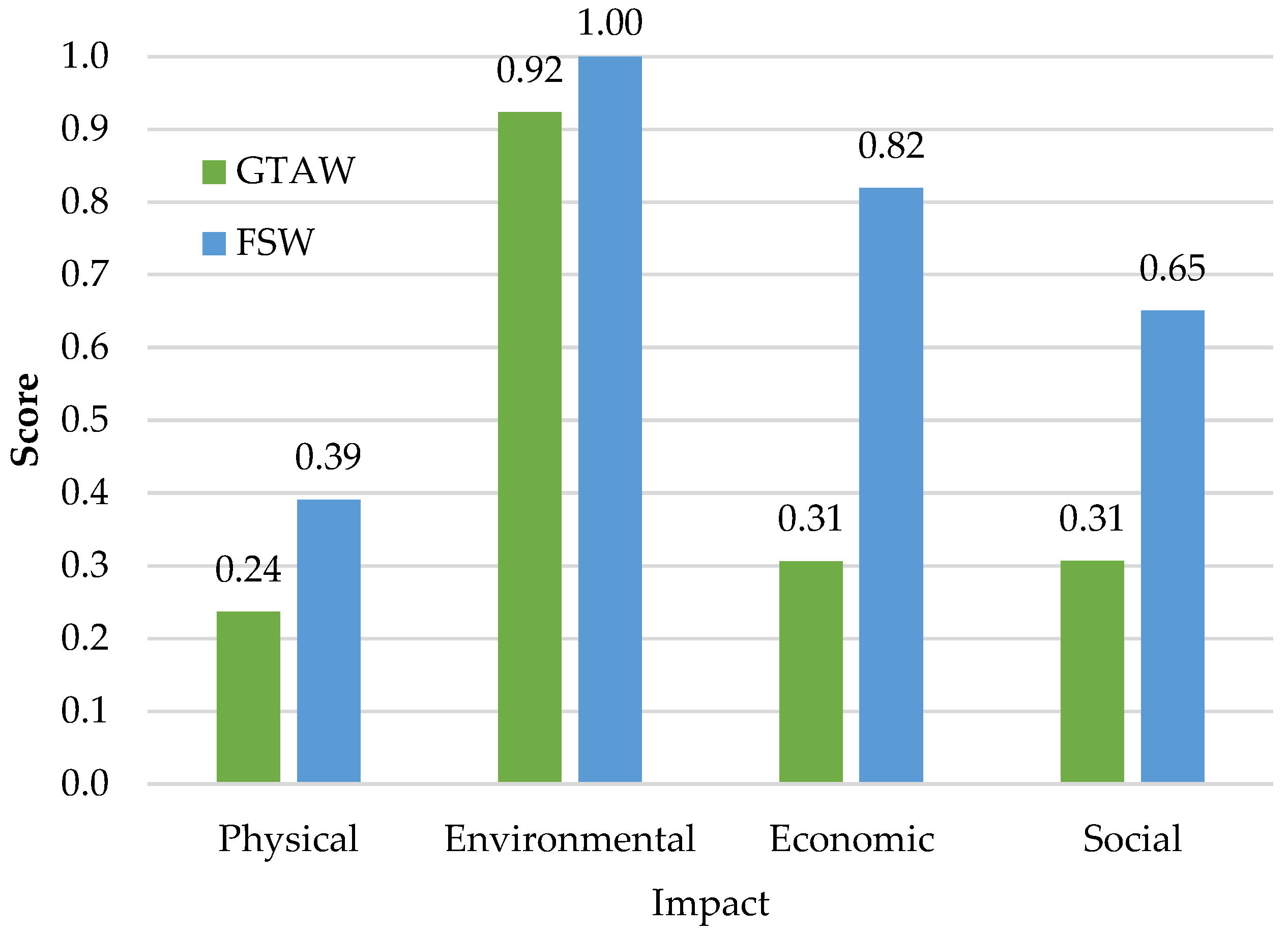

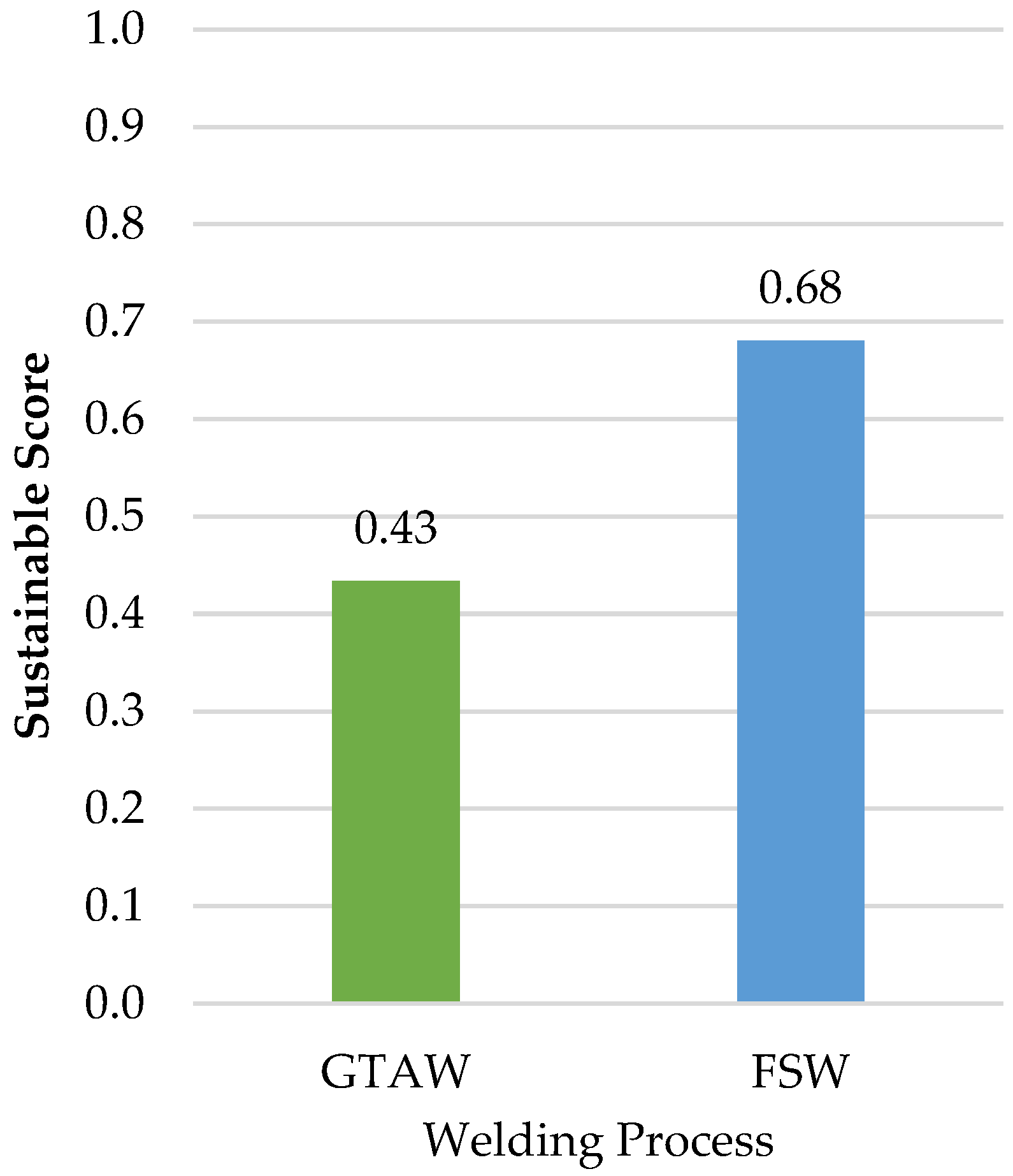

4. Results Analysis

4.1. Sustainability Scores as a Tool for the Selection of Manufacturing Strategies

4.2. Approach to Sustainability Scores in Battery Trays for the EV Industry

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Energy Balances—Energy—Eurostat. Available online: https://ec.europa.eu/eurostat/web/energy/data/energy-balances (accessed on 13 September 2022).

- Eslami, Y.; Dassisti, M.; Lezoche, M.; Panetto, H. A survey on sustainability in manufacturing organisations: Dimensions and future insights. Int. J. Prod. Res. 2019, 57, 5194–5214. [Google Scholar] [CrossRef]

- Herrmann, C.; Schmidt, C.; Kurle, D.; Blume, S.; Thiede, S. Sustainability in manufacturing and factories of the future. Int. J. Precis. Eng. Manuf.—Green Technol. 2014, 1, 283–292. [Google Scholar] [CrossRef]

- Guitouni, A.; Martel, J.-M. Tentative guidelines to help choosing an appropriate MCDA method. Eur. J. Oper. Res. 1997, 109, 501–521. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R.; Cross, J.; Garza-Reyes, J.A.; Antony, J.; Yadav, V. Integrating Green Lean Six Sigma and industry 4.0: A conceptual framework. J. Manuf. Technol. Manag. 2023, 34, 87–121. [Google Scholar] [CrossRef]

- Portney, K.E. Sustainability; MIT Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Tamang, S.K.; Chandrasekaran, M.; Sahoo, A.K. Sustainable machining: An experimental investigation and optimization of machining Inconel 825 with dry and MQL approach. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 374. [Google Scholar] [CrossRef]

- Bastas, A. Sustainable manufacturing technologies: A systematic review of latest trends and themes. Sustainability 2021, 13, 4271. [Google Scholar] [CrossRef]

- Chang, Y.J.; Sproesser, G.; Neugebauer, S.; Wolf, K.; Scheumann, R.; Pittner, A.; Rethmeier, M.; Finkbeiner, M. Environmental and Social Life Cycle Assessment of Welding Technologies. Procedia CIRP 2015, 26, 293–298. [Google Scholar] [CrossRef]

- Singh, V.; Chandrasekaran, M.; Samanta, S.; Devarasiddappa, D.; Arunachalam, R. Sustainability Assessment of Gas Metal Arc Welding Process of AISI 201LN using AHP-TLBO Integrated Optimization Methodology. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 68. [Google Scholar] [CrossRef]

- Giret, A.; Trentesaux, D.; Prabhu, V. Sustainability in manufacturing operations scheduling: A state of the art review. J. Manuf. Syst. 2015, 37, 126–140. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Li, F.; Meng, Q.; Li, J.; Xu, X. Energy consumption model and energy efficiency of machine tools: A comprehensive literature review. J. Clean. Prod. 2016, 112, 3721–3734. [Google Scholar] [CrossRef]

- Springer Nature Switzerland. Innovations in Manufacturing for Sustainability. 2019. Available online: http://www.springer.com/series/11181 (accessed on 10 November 2022).

- Venkat Ramana, G.; Yelamasetti, B.; Vishnu Vardhan, T. Study on weldability and effect of post heat treatment on mechanical and metallurgical properties of dissimilar AA 2025, AA 5083 and AA7075 GTAW weld joints. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; pp. 878–882. [Google Scholar] [CrossRef]

- Li, Y.; Zou, W.; Lee, B.; Babkin, A.; Chang, Y. Research progress of aluminum alloy welding technology. Int. J. Adv. Manuf. Technol. 2020, 109, 1207–1218. [Google Scholar] [CrossRef]

- International Aluminium Institute. Primary Aluminium Production. 2022. Available online: https://international-aluminium.org/statistics/primary-aluminium-production/ (accessed on 12 September 2022).

- The Aluminum Association. The Environmental Footprint of Semi-Fabricated Aluminum Products in North America; The Aluminium Association: Arlington, VA, USA, 2022. [Google Scholar]

- The Welding Institude (TWI). What Is Tungsten Inert Gas (GTAW or TIG) Welding?—TWI. Available online: https://www.twi-global.com/technical-knowledge/job-knowledge/tungsten-inert-gas-tig-or-gta-welding-006 (accessed on 2 November 2022).

- TWI. Friction Stir Welding: Tool and Technology Developments—TWI. 2003. Available online: https://www.twi-global.com/technical-knowledge/published-papers/friction-stir-welding-recent-developments-in-tool-and-process-technologies-july-2003 (accessed on 29 September 2022).

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 31. [Google Scholar] [CrossRef]

- Hoyos, E.; Serna, M.C. Basic tool design guidelines for friction stir welding of aluminum alloys. Metals 2021, 11, 2024. [Google Scholar] [CrossRef]

- TWI. What Materials Can I Join with Friction Stir Welding? 2023. Available online: https://www.twi-global.com/technical-knowledge/faqs/faq-what-materials-can-i-join-with-friction-stir-welding (accessed on 14 February 2023).

- Hojny, M. Thermo-mechanical model of a tig welding process for the aircraft industry. Arch. Metall. Mater. 2013, 58, 1125–1130. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Mahamood, R.M. Solid-State Welding: Friction and Friction Stir Welding Processes. 2020. Available online: http://www.springer.com/series/1161 (accessed on 15 January 2023).

- Lohwasser, D.; Chen, Z. Friction Stir Welding from Basics to Applications; Elsevier: Amsterdam, The Netherlands, 2009; Available online: https://www.elsevier.com/books/friction-stir-welding/lohwasser/978-1-84569-450-0 (accessed on 21 February 2023).

- Stepanov, A.; Laansoo, A. Improvement of Productivity in Al Welding. 2008. Available online: http://innomet.ttu.ee/daaam08/Online/Engineering%20Management/Stepanov.pdf (accessed on 10 January 2023).

- Li, H.; Hedmer, M.; Kåredal, M.; Björk, J.; Stockfelt, L.; Tinnerberg, H.; Albin, M.; Broberg, K. A Cross-Sectional Study of the Cardiovascular Effects of Welding Fumes. PLoS ONE 2015, 10, e01316482015. [Google Scholar] [CrossRef]

- Smolkova, P.; Nakladalova, M. The etiology of occupational pulmonary aluminosis-the past and the present. Biomed. Pap. Med. Fac. Univ. Palacky Olomouc. Czech Repub. 2014, 158, 535–538. [Google Scholar] [CrossRef] [PubMed]

- Herberts, P.; Kadefors, R.; Hogfors, C.; Sigholm, G. Shoulder Pain and Heavy Manual Labor. Clin. Orthop. Relat. Res. 1984, 50, 166–178. [Google Scholar] [CrossRef]

- Wanjari, M.; Radhikabai, S. Occupational Hazards Associated with Welding Work That Influence Health Status of Welders. Int. J. Cur. Res. Rev. 2020, 12, 51–55. [Google Scholar] [CrossRef]

- Mendes, N.; Neto, P.; Loureiro, A.; Moreira, A.P. Machines and control systems for friction stir welding: A review. Mater. Des. 2016, 90, 256–265. [Google Scholar] [CrossRef]

- Majeed, T.; Wahid, M.A.; Alam, M.N.; Mehta, Y.; Siddiquee, A.N. Friction stir welding: A sustainable manufacturing process. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; pp. 6558–6563. [Google Scholar] [CrossRef]

- de Medellín, M. Historia. 2021. Available online: https://www.metrodemedellin.gov.co/quiénessomos/historia (accessed on 14 February 2022).

- de Medellín, M. Metro de Medellín: Sistema Integrado de Transporte Masivo. 2022. Available online: https://www.metrodemedellin.gov.co/viaje-con-nosotros/sistema-integrado (accessed on 10 January 2023).

- Matweb. Aluminum 6063-T6. 2022. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=333b3a557aeb49b2b17266558e5d0dc0&ckck=1 (accessed on 2 November 2022).

- Heidari, A.; Ghassemi, A.; Atrian, A. Numerical and experimental investigation of forming limit diagrams of 6063 aluminum alloy sheets using ayada ductile fracture criterion and the second derivative of large strain criterion at increased temperatures. Lat. Am. J. Solids Struct. 2018, 15, 3–6. [Google Scholar] [CrossRef]

- Jamal, J.; Darras, B.; Kishawy, H. A study on sustainability assessment of welding processes. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2020, 234, 501–512. [Google Scholar] [CrossRef]

- Jamal, J. Sustainability Assessment of Welding Processes. Master’s Thesis, American University of Sharjah, Sharjah, United Arab Emirates, 2017. [Google Scholar]

- Itoh, K.; Andersen, H.B.; Seki, M. Track maintenance train operators? attitudes to job, organisation and management, and their correlation with accident/incident rate. Cogn. Technol. Work. 2004, 6, 63–78. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Spalanzani, A. Sustainability of manufacturing and services: Investigations for research and applications. Int. J. Prod. Econ. 2012, 140, 35–47. [Google Scholar] [CrossRef]

- Fasecolda. Sistema General de Riesgos Laborales. 2022. Available online: https://sistemas.fasecolda.com/rldatos/ (accessed on 8 December 2022).

- Fahimpour, V.; Sadrnezhaad, S.K.; Karimzadeh, F. Microstructure and mechanical property change during FSW and GTAW of Al6061 alloy. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2013, 44, 2187–2195. [Google Scholar] [CrossRef]

- En Colombia Factor de Emisión de CO2 por Generación Eléctrica del Sistema Interconectado: 164.38 gramos de CO2 por Kilovatio Hora. 2020. Available online: https://www.xm.com.co/noticias/en-colombia-factor-de-emision-de-co2-por-generacion-electrica-del-sistema-interconectado (accessed on 14 December 2022).

- Arter, C.A.; Buonocore, J.; Chang, C.; Arunachalam, S. Mortality-based damages per ton due to the on-road mobile sector in the Northeastern and Mid-Atlantic U.S. By region, vehicle class and precursor. Environ. Res. Lett. 2021, 16, 065008. [Google Scholar] [CrossRef]

- Patel, V.; De Backer, J.; Hindsefelt, H.; Igestrand, M.; Azimi, S.; Andersson, J.; Säll, J. High speed friction stir welding of AA6063-T6 alloy in lightweight battery trays for EV industry: Influence of tool rotation speeds. Mater. Lett 2022, 318, 132135. [Google Scholar] [CrossRef]

- Manufacturing Statistics in Great Britain, 2022. 2022. Available online: https://www.hse.gov.uk/statistics/industry/manufacturing.pdf (accessed on 21 February 2023).

- gov.uk. Energy Price Guarantee. 2022. Available online: https://www.gov.uk/government/publications/energy-bills-support/energy-bills-support-factsheet-8-september-2022 (accessed on 21 February 2023).

- talent.com. Cost Engineer Average Salary in United Kingdom. 2023. Available online: https://uk.indeed.com/career/cost-engineer/salaries (accessed on 21 February 2023).

| Environmental | Social | Economical |

|---|---|---|

| Free of consumables, shielding gases, fumes, smoke, or radiation [24] | Zero-emission of smoke or ultraviolet, X-ray, or infrared radiation [25] | Lower energy requirements compared to fusion processes [24] |

| Elimination of the use of solvents [24] | Fully mechanized process, safer for the operator [25] | Increase in productivity [26] |

| Decrease in the number of problems associated with shielding gases, fumes, smoke, and radiation [27] | ||

| Cardiovascular and lung diseases caused by welding fumes and metal dust from post-weld grinding operations [28] | ||

| Musculoskeletal disorder caused by repetitive manual welding [29] | ||

| Lower accident rates (eyes and skin burn) associated with exposure to intense light and radiation [30] |

| Properties | Value |

|---|---|

| Yield Strength [35] | 214 MPa |

| Toughness [36] | 25.8 J |

| GTAW | FSW |

|---|---|

| Filler material: ER4043 | Rotation Speed: 600 RPM |

| Current: 175 A | Welding Speed: 600 mm/min |

| Voltage: 18 V | Tilt angle: 0° |

| Shoulder with scroll | |

| Shoulder diameter: 16 mm | |

| Pin diameter: 8 mm |

| Physical Performance | Environmental Impact | Economic Impact | Social Impact | ||||

|---|---|---|---|---|---|---|---|

| Weld Yield Strength (MPa) | 60.0 | Weld emissions (kg) | 0.08 | Consumable cost (USD) | 26.05 | Incident rate (Days away from work/100 employees) 2019 | 13.95 |

| Weld Toughness (J) | 1.08 | Auxiliary material usage (g) | 186,666.67 | Labour cost (USD/min) | 0.12 | Maximum incident rate (Days away from work/100 employees) 2019 | 160 |

| Material auxiliary limit (g) | 816,666.67 | Weld time (min) | 16.67 | Incident rate (Days away from work/100 employees) 2020 | 105 | ||

| Wastage (g) | 0 | Energy consumption (kW) | 3.15 | Maximum incident rate (Days away from work/100 employees) 2020 | 165 | ||

| Weld mass (g) | 3303.63 | Energy cost (USD/kWh) | 0.05 | Incident rate (Days away from work/100 employees) 2021 | 131.91 | ||

| Carbon footprint limit (kg) | 986.28 | Equipment cost (USD) | 0.03 | Maximum incident rate (Days away from work/100 employees) 2021 | 170 | ||

| Carbon footprint (kg) | 0.14 | Weld part cost (USD) | 246.38 | ||||

| Metal particulate ratio (non-dimensional) | 0 | ||||||

| Physical Performance | Environmental Impact | Economic Impact | Social Impact | ||||

|---|---|---|---|---|---|---|---|

| Weld Yield Strength (Mpa) | 102.9 | Weld emissions (kg) | 0 | Consumable cost (USD) | 0.60 | Incident rate (Days away from work/100 employees) 2019 | 6.50 |

| Weld Toughness (J) | 1.86 | Auxiliary material usage (g) | 0 | Labour cost (USD/min) | 0.12 | Maximum incident rate (Days away from work/100 employees) 2019 | 76.49 |

| Material auxiliary limit (g) | 0 | Weld time (min) | 1.67 | Incident rate (Days away from work/100 employees) 2020 | 6.39 | ||

| Wastage (g) | 0 | Energy consumption (kW) | 4.80 | Maximum incident rate (Days away from work/100 employees) 2020 | 36.71 | ||

| Weld mass (g) | 3282 | Energy cost (USD/kWh) | 0.07 | Incident rate (Days away from work/100 employees) 2021 | 5.89 | ||

| Carbon footprint limit (kg) | 986.28 | Equipment cost (USD) | 0.02 | Maximum incident rate (Days away from work/100 employees) 2021 | 90.99 | ||

| Carbon footprint (kg) | 0.03 | Weld part cost (USD) | 246.38 | ||||

| Metal particulate ratio (non-dimensional) | 0 | ||||||

| Aspect | GTAW | FSW |

|---|---|---|

| Physical performance | 0.24 | 0.39 |

| Environmental Impact | 0.96 | 1.00 |

| Economic Impact | 0.89 | 1.00 |

| Social Impact | 0.80 | 0.89 |

| Sustainability Score | 0.69 | 0.78 |

| Physical Performance | Environmental Impact | Economic Impact | Social Impact | ||||

|---|---|---|---|---|---|---|---|

| Weld Yield Strength (Mpa) | 60 | Weld emissions (kg) | 0.08 | Consumable cost (USD) | 52.10 | Incident rate (Days away from work/10,000 employees) 2019 | 4536 |

| Weld Toughness (J) | 1.08 | Auxiliary material usage (g) | 3,360,000 | Labour cost (USD/min) | 0.35 | Maximum incident rate (Days away from work/10,000 employees) 2019 | 4536 |

| Material auxiliary limit (g) | 14,700,000 | Weld time (min) | 300 | Incident rate (Days away from work/10,000 employees) 2020 | 4158 | ||

| Wastage (g) | 0 | Energy consumption (kW) | 3.15 | Maximum incident rate (Days away from work/10,000 employees) 2020 | 4158 | ||

| Weld mass (g) | 3671.42 | Energy cost (USD/kWh) | 4.99 | Incident rate (Days away from work/10,000 employees) 2021 | 3780 | ||

| Carbon footprint limit (kg) | 986.28 | Equipment cost (USD) | 0.28 | Maximum incident rate (Days away from work/10,000 employees) 2021 | 3780 | ||

| Carbon footprint (kg) | 2.59 | Weld part cost (USD) | 246.38 | ||||

| Metal particulate ratio (non-dimensional) | 0 | ||||||

| Physical Performance | Environmental Impact | Economic Impact | Social Impact | ||||

|---|---|---|---|---|---|---|---|

| Weld Yield Strength (Mpa) | 102.9 | Weld emissions (kg) | 0 | Consumable cost (USD) | 3.60 | Incident rate (Days away from work/10,000 employees) 2019 | 2086.56 |

| Weld Toughness (J) | 1.86 | Auxiliary material usage (g) | 0 | Labour cost (USD/min) | 0.35 | Maximum incident rate (Days away from work/10,000 employees) 2019 | 4536 |

| Material auxiliary limit (g) | 0 | Weld time (min) | 18 | Incident rate (Days away from work/10,000 employees) 2020 | 1912.68 | ||

| Wastage (g) | 0 | Energy consumption (kW) | 20 | Maximum incident rate (Days away from work/10,000 employees) 2020 | 4158 | ||

| Weld mass (g) | 16,200 | Energy cost (USD/kWh) | 1.70 | Incident rate (Days away from work/10,000 employees) 2021 | 1738.80 | ||

| Carbon footprint limit (kg) | 11,130 | Equipment cost (USD) | 0.50 | Maximum incident rate (Days away from work/10,000 employees) 2021 | 3780 | ||

| Carbon footprint (kg) | 2.23 | Weld part cost (USD) | 246.38 | ||||

| Metal particulate ratio (non-dimensional) | 0 | ||||||

| Aspect | GTAW | FSW |

|---|---|---|

| Physical performance | 0.24 | 0.39 |

| Environmental Impact | 0.92 | 1.00 |

| Economic Impact | 0.31 | 0.82 |

| Social Impact | 0.31 | 0.65 |

| Sustainability Score | 0.43 | 0.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoyos, E.; Serna, M.C.; De Backer, J.; Martin, J. Sustainability Score Comparison of Welding Strategies for the Manufacturing of Electric Transportation Components. Sustainability 2023, 15, 8650. https://doi.org/10.3390/su15118650

Hoyos E, Serna MC, De Backer J, Martin J. Sustainability Score Comparison of Welding Strategies for the Manufacturing of Electric Transportation Components. Sustainability. 2023; 15(11):8650. https://doi.org/10.3390/su15118650

Chicago/Turabian StyleHoyos, Elizabeth, María Camila Serna, Jeroen De Backer, and Jonathan Martin. 2023. "Sustainability Score Comparison of Welding Strategies for the Manufacturing of Electric Transportation Components" Sustainability 15, no. 11: 8650. https://doi.org/10.3390/su15118650

APA StyleHoyos, E., Serna, M. C., De Backer, J., & Martin, J. (2023). Sustainability Score Comparison of Welding Strategies for the Manufacturing of Electric Transportation Components. Sustainability, 15(11), 8650. https://doi.org/10.3390/su15118650