Identifying Loss and Waste Hotspots and Data Gaps throughout the Wheat and Bread Lifecycle in the Fars Province of Iran through Value Stream Mapping

Abstract

1. Introduction

1.1. Problem Statement and Objectives of the Study

1.2. The Background and Implications of Value Stream Mapping

2. Materials and Methods

2.1. Sampling Strategy and Survey Development

2.2. Data Analysis

3. Results and Discussion

3.1. Overview

3.2. Wheat and Bread Lifecycle

“Until 12 years ago, AREEO used to produce certified seeds. Nowadays, AREEO focuses only on research and producing nucleus breeds and delegates the rest of the breeding program to private companies…. We recently received breed 2, from which we produced 60 kg of breed 3 and, finally, 200 kg of the maternal line. Certified seeds are produced by [propagating] maternal seeds.” (Farmer 1)

“We plant certified seeds supplied by AREEO. We purchase the seeds from the local AREEO subsidiary.” (Farmer 4)

“The seed-producing companies sign contracts with some farmers. They give maternal seeds to farmers, and farmers produce certified seeds. The certified seed is used to produce bread wheat.” (Co-op CEO)

“We produce two types of wheat: one for seed using the hybrid cultivars supplied by breeding companies and another for consumption produced from certified seeds.… The price of the seeds is normally 20–25% more than bread wheat” (Farmer 1)

“The cultivation for seed production is executed more carefully compared to bread wheat. For example, AREEO requires farmers to test the soil for efficient fertilization.” (Co-op CEO)

“If the seeds produced by farmers contain high soil and weed dockage or too many broken grains, the companies or AREEO reject them, and farmers sell them as normal wheat.” (GCCS inspector)

“I purchase the certified seeds distributed by the rural cooperative. My father used to reuse the good wheat grains as seeds for the next year’s cultivation. Or if a neighboring farmer had good seeds worth more than bread wheat, my father used to make a deal with them to replace their good batch with bread wheat and get their good seeds for cultivation. The other farmer was selling the bread wheat batch at a normal price, and my father would pay them the difference. The good grains were sprayed with a certain pesticide and stored to be used as seeds in the following year. I do not do that.” (Baker 3)

“I could also produce seeds, but they [breeding companies or AREEO] do not buy them because they [the seeds] include too much soil and weed impurities.” (Farmer 3)

“Farmers usually do not irrigate the field if it rains about 30–40 mm after sowing.” (Co-op CEO)

“We harvest [wheat] in June or July.” (Farmer 3)

“We sell our [wheat] products to the cooperative, and they send them to silos.” (Farmer 2)

“We sell the product directly to silos. Sometimes we sell to the cooperative.” (Farmer 3)

“We deliver the yield to the cooperative.” (Farmer 4)

“The wheat is delivered to the cooperative’s purchasing center. It is weighted here, and the amount is recorded in the online system under the farmer’s name. The online system is connected to the Keshavarzi Bank (Bank of Agriculture), GCCS, and the Ministry of Industry, Mine, and Trade.” (Co-op CEO)

“The cooperative records the yield. They also assess the besatz content to determine the price based on their tables. They give us a receipt with all the details and record everything on a computer.” (Farmer 4)

“Our cooperative has 2000 members (shareholders) from 14 surrounding villages.” (Co-op CEO)

“From the moment producers deliver wheat to us, we are responsible for storing and safekeeping the wheat and later loading trucks and sending it to its designated destiny, which GCCS of Fars [province] determines. The destinations can be a milling factory or a silo…. GCCS uses an online system to tell us where to distribute wheat.” (Co-op CEO)

“The payment takes around two months. I sold my last batch at the end of June 2018. The payment took two to three months.” (Farmer 3)

“Not all the wheat the farmers produce is purchased by the cooperative. Some private buyers pay a negotiated price to the farmers…. These buyers either sell to the milling factories or the silos.” (Co-op CEO)

“Some intermediaries buy [bread] wheat to sell to the livestock feed-producing factories or directly to livestock farms. They normally have storage and weighing facilities.” (Farmer 2)

“They [intermediaries] normally pay less than the government, but they pay right away.” (Co-op CEO)

“[With intermediaries,] there is no waiting time to weigh farmers’ products, and the payment is instant, although at a bit lower price.” (Farmer 2)

“[Currently,] intermediaries pay more than cooperatives or silos…. They sell the wheat for livestock feed at a slightly higher price.” (Farmer 3)

“Normally, farmers sell wheat to silos or the cooperative right after harvest. They also store part of their harvest, which they later sell to intermediaries for livestock feed. Some farmers build a storage room, usually made of cement and isolated with tiles from the inside.” (Farmer 3)

“Almost 90% of the farmers are not able to store their yield. Therefore, they need to sell their product as soon as possible to gain some revenue to compensate for their costs for at least nine months.” (Co-op CEO)

“The advantage of selling to silos or cooperatives is receiving subsidized seeds, fertilizers, and pesticides. Moreover, our personal storage room is limited.” (Farmer 3)

“It is sometimes better to sell to the cooperative [or to silos] because we can buy fertilizer and pesticides with a discount for the next year in proportion to our current harvest amount.” (Farmer 2)

“[Currently,] supplying wheat outside the governmental supply chain is against the law, even to individuals.” (GCCS inspector)

“We receive wheat starting from June 10 until around July 1. We store the wheat (about 6000–8000 tonnes) here, usually around 20–30 days. In rare cases, we store wheat here for up to three months.” (Co-op CEO)

“Wheat remains in silos and will be distributed based on demands throughout the year. The silos are organized by the government.” (Co-op CEO)

“The GCCS of Fars uses the online system to tell us how to distribute wheat. For example, the GCCS of Fars would give us transportation permission for shipping 2000 tonnes of wheat to [company’s name] milling factory.” (Co-op CEO)

“The grains in silos are not threshed and include soil and weed residues or broken grains.” (Farmer 1)

“Milling factories separate the bran from the grains and grade them based on the existing standards. These factories distribute wheat flour to local or industrial bakeries based on quotas designated by GCCS Fars province and the union of bakers.” (Farmer 2)

“The government controls the distribution through an online platform, and bakers receive wheat flour based on their quota.… Our baking factory produces up to one thousand bread pieces per day. This amount is produced from our wheat flour quota.” (Baker 4)

“We order online based on our quota. The milling companies ship flour to each bakery based on online orders. We also pay transportation costs and store flour here.” (Baker 3)

“We order wheat flour via a website. Each bakery has a quota for each month. We store the flour here and prepare the dough, and then bake the bread.” (Baker 1)

“The milling factories supply wheat flour either to the free market via whole sellers or directly to bakers.” (Baker 4)

“The nomadic families and households in small villages also have flour quotas to bake their own bread.” (Farmer 2)

“Our buyers are supermarkets, household consumers, and fast food stores…. We sell bread to supermarkets in dated plastic packs…. Household consumers and fast foods buy fresh bread daily.” (Baker 4)

“We have a contract with an industrial bakery. The bread comes daily in box packs of 40 pieces.” (Foodservice 1)

“We buy our bread from a local bakery…. We use the fresh bread for the day and store the surplus in a freezer.” (Foodservice 2)

3.3. Loss and Waste Hotspots and Data Gaps

“The loss in the cooperative’s purchasing center is minimal. I am personally liable for any loss that may happen here…. Silos have a minimal amount of loss. For example, the nearby Silo in Sivand has a capacity of 70,000 tonnes. When the silo is fully loaded, it can preserve between 69,500 and 69,700 tonnes [about 0.07% loss]. The rest could rot or absorb too much moisture, which is insignificant.” (Co-op CEO)

“Once wheat enters milling factories, there is no loss. All parts of the wheat will be sold. For example, the wheat bran separated to produce white flour for confectioneries will be sold for animal feed.” (Farmer 1)

“The highest loss in storage can happen due to high water content, and because wheat has low water content in Iran, this loss is limited.” (Agri. Mins. Officer)

“Transport loss is limited unless the trucks are not sealed well, which does not happen often.” (Farmer 4)

“We do not experience any flour loss, and we are able to sell all the bread we produce. However, if the dough is ruined, we have to convert it into dried bread and sell it to intermediaries who eventually sell it to livestock farms.” (Baker 1)

“We usually sell 100% of our white bread production, although other bread types may experience some loss. During certain conditions, such as heavy rain or cold weather when we have fewer customers, we may not sell 100% of our production. Consequently, we end up with some unsold bread which we typically dry and sell as breadcrumbs.” (Baker 4)

“The main reasons for bread loss in supermarkets are expiration date and stale bread. Supermarkets typically sell their bread waste to bread waste recyclers, who in turn sell it as livestock feed.” (Baker 4)

“The on-farm loss is due to seed overuse, pests and harvesting.” (Seed producer)

“Bread waste happens in restaurants due to consumers having leftovers or passing expiration dates and staling.” (Baker 4)

“The highest bread waste amount is in households because the consumers do not manage their grocery shopping appropriately.” (Baker 4)

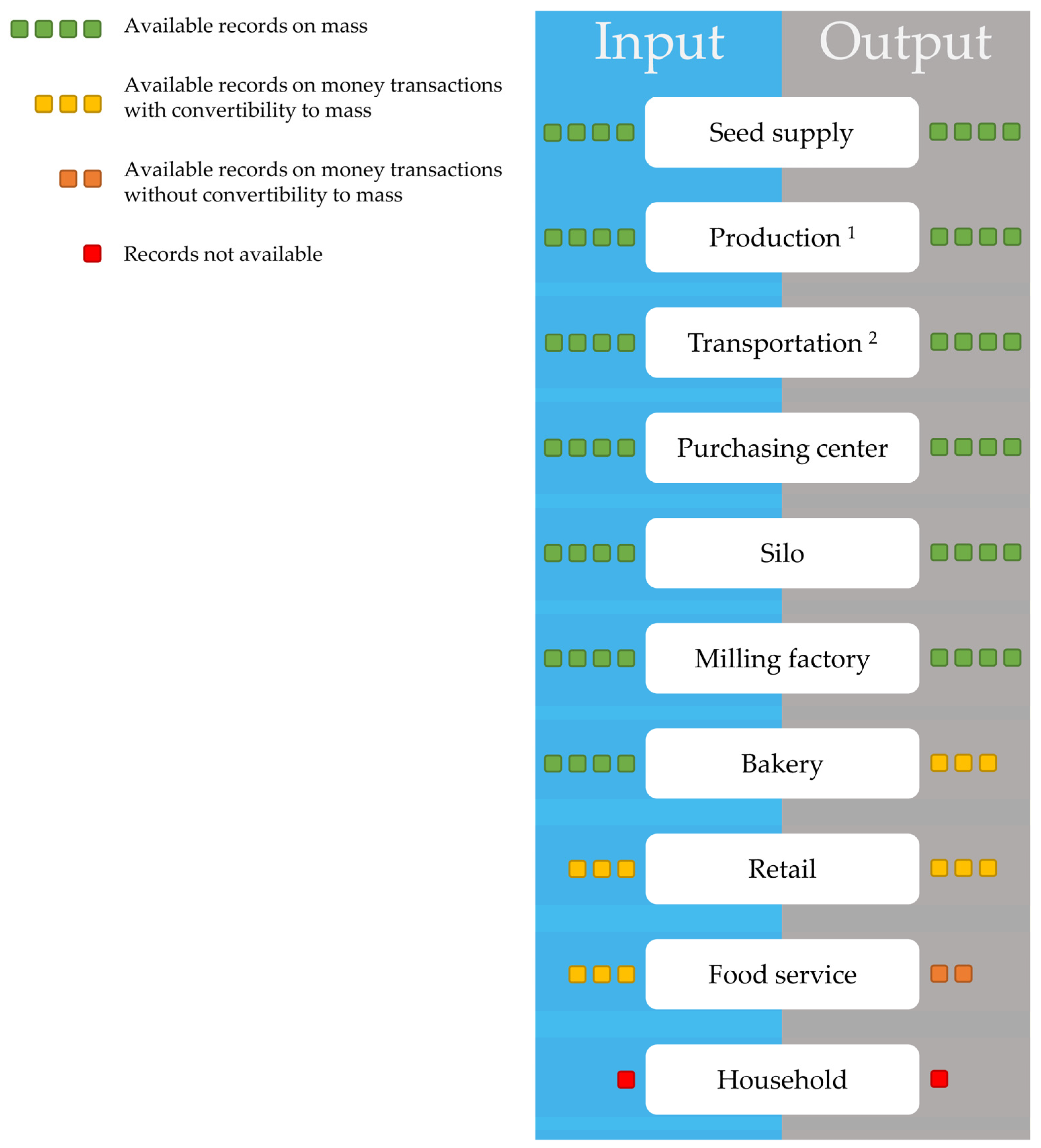

3.4. Material Flow Inventory along the Wheat and Bread Lifecycle

“We sell expired or stalled bread to intermediaries who sell them to animal farms as feed. We also record the amount we sell to them.” (Baker 2)

“We record what we sell to bread recyclers for internal accounting.” (Baker 3)

“We sell bread leftover to bread recyclers. They measure the amount and pay us accordingly.” (Foodservice 1)

The input and output of this purchasing center are accurately recorded. There is weight loss, which is due to losing moisture. We record moisture content both at purchasing time and later at loading time. [In the last measurement], the average moisture content of 12 random samples was 8.9%. The average at the time of loading was 8.1%, which means a 0.8% mass reduction was expected. (Co-op CEO)

3.5. Limitations of the Study and Future Research Directions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. The State of Food and Agriculture 2019: Moving Forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019. [Google Scholar]

- Shafiee-Jood, M.; Cai, X. Reducing Food Loss and Waste to Enhance Food Security and Environmental Sustainability. Environ. Sci. Technol. 2016, 50, 8432–8443. [Google Scholar] [CrossRef]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food Waste within Food Supply Chains: Quantification and Potential for Change to 2050. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef]

- Lemaire, A.; Limbourg, S. How Can Food Loss and Waste Management Achieve Sustainable Development Goals? J. Clean. Prod. 2019, 234, 1221–1234. [Google Scholar] [CrossRef]

- Abbas, A.; Zhao, C.; Waseem, M.; Ahmed Khan, K.; Ahmad, R. Analysis of Energy Input–Output of Farms and Assessment of Greenhouse Gas Emissions: A Case Study of Cotton Growers. Front. Environ. Sci. 2022, 9, 725. [Google Scholar] [CrossRef]

- Abbas, A.; Zhao, C.; Ullah, W.; Ahmad, R.; Waseem, M.; Zhu, J. Towards Sustainable Farm Production System: A Case Study of Corn Farming. Sustainability 2021, 13, 9243. [Google Scholar] [CrossRef]

- Elahi, E.; Khalid, Z. Estimating Smart Energy Inputs Packages Using Hybrid Optimisation Technique to Mitigate Environmental Emissions of Commercial Fish Farms. Appl. Energy 2022, 326, 119602. [Google Scholar] [CrossRef]

- Elahi, E.; Khalid, Z.; Tauni, M.Z.; Zhang, H.; Lirong, X. Extreme Weather Events Risk to Crop-Production and the Adaptation of Innovative Management Strategies to Mitigate the Risk: A Retrospective Survey of Rural Punjab, Pakistan. Technovation 2022, 117, 102255. [Google Scholar] [CrossRef]

- Ranhotra, G.S. Wheat: Contribution to World Food Supply and Human Nutrition. In Wheat; Bushuk, W., Rasper, V.F., Eds.; Springer: Boston, MA, USA, 1994; pp. 12–24. [Google Scholar]

- Shewry, P.R.; Hey, S.J. The Contribution of Wheat to Human Diet and Health. Food Energy Secur. 2015, 4, 178–202. [Google Scholar] [CrossRef]

- Karizaki, V.M. Ethnic and Traditional Iranian Breads: Different Types, and Historical and Cultural Aspects. J. Ethn. Foods 2017, 4, 8–14. [Google Scholar] [CrossRef]

- Igrejas, G.; Branlard, G. The Importance of Wheat. In Wheat Quality for Improving Processing and Human Health; Igrejas, G., Ikeda, T., Guzmán, C., Eds.; Springer International Publishing: Cham, Germany, 2020; pp. 1–7. ISBN 9783030341633. [Google Scholar]

- FAO. World Food and Agriculture—Statistical Yearbook 2022; FAO: Rome, Italy, 2022. [Google Scholar]

- Fortune Business Insights. Wheat Flour Market Size, Share & COVID-19 Impact Analysis, by Type (Whole and Refined), Application (Bread, Bakery Products, Noodles & Pasta, and Others), and Regional Forecast, 2021–2028; Fortune Business Insights: Maharashtra, India, 2022. [Google Scholar]

- Safa, M.; Samarasinghe, S. CO2 Emissions from Farm Inputs “Case Study of Wheat Production in Canterbury, New Zealand”. Environ. Pollut. 2012, 171, 126–132. [Google Scholar] [CrossRef]

- Bux, C.; Lombardi, M.; Varese, E.; Amicarelli, V. Economic and Environmental Assessment of Conventional versus Organic Durum Wheat Production in Southern Italy. Sustainability 2022, 14, 9143. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Monforti, F. Energy Flows and Greenhouses Gases of EU (European Union) National Breads Using an LCA (Life Cycle Assessment) Approach. J. Clean. Prod. 2017, 140, 455–469. [Google Scholar] [CrossRef]

- Chiriacò, M.V.; Grossi, G.; Castaldi, S.; Valentini, R. The Contribution to Climate Change of the Organic versus Conventional Wheat Farming: A Case Study on the Carbon Footprint of Wholemeal Bread Production in Italy. J. Clean. Prod. 2017, 153, 309–319. [Google Scholar] [CrossRef]

- Statistical Centre of Iran. Summary of the Agricultural Statistics—2021/2022 (1400); Statistical Centre of Iran: Tehran, Iran, 2022. [Google Scholar]

- Khoshroo, A. Energy Use Pattern and Greenhouse Gas Emission of Wheat Production: A Case Study in Iran. Agric. Commun. 2014, 2, 9–14. [Google Scholar]

- Esmaeilzadeh, S.; Asgharipour, M.R.; Bazrgar, A.B.; Soufizadeh, S.; Karandish, F. Assessing the Carbon Footprint of Irrigated and Dryland Wheat with a Life Cycle Approach in Bojnourd. Environ. Prog. Sustain. Energy 2019, 38, 13134. [Google Scholar] [CrossRef]

- FAO. Food Wastage Footprint—Impacts on Natural Resources—Summary Report; FAO: Rome, Italy, 2013. [Google Scholar]

- Xue, L.; Liu, G.; Parfitt, J.; Liu, X.; Van Herpen, E.; Stenmarck, Å.; O’Connor, C.; Östergren, K.; Cheng, S. Missing Food, Missing Data? A Critical Review of Global Food Losses and Food Waste Data. Environ. Sci. Technol. 2017, 51, 6618–6633. [Google Scholar] [CrossRef]

- UNEP. Food Waste Index Report 2021; UNEP: Nairobi, Kenya, 2021. [Google Scholar]

- Galaktionova, E.A.; Kok, M.; Bos-Brouwers, H. Ways to Monitor FLW: Review and Recommendations on Data Collection and Reporting for the Russian Context. Russ. J. Econ. 2022, 8, 81–94. [Google Scholar] [CrossRef]

- Nicastro, R.; Carillo, P. Food Loss and Waste Prevention Strategies from Farm to Fork. Sustainability 2021, 13, 5443. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; de Hooge, I.; Amani, P.; Bech-Larsen, T.; Oostindjer, M. Consumer-Related Food Waste: Causes and Potential for Action. Sustainability 2015, 7, 6457–6477. [Google Scholar] [CrossRef]

- Chalak, A.; Abou-Daher, C.; Abiad, M.G. Generation of Food Waste in the Hospitality and Food Retail and Wholesale Sectors: Lessons from Developed Economies. Food Secur. 2018, 10, 1279–1290. [Google Scholar] [CrossRef]

- Hines, P.; Rich, N.; Bicheno, J.; Brunt, D.; Taylor, D.; Butterworth, C.; Sullivan, J. Value Stream Management. Int. J. Logist. Manag. 1998, 9, 25–42. [Google Scholar] [CrossRef]

- Cudney, E.; Elrod, C. A Comparative Analysis of Integrating Lean Concepts into Supply Chain Management in Manufacturing and Service Industries. Int. J. Lean Six Sigma 2011, 2, 5–22. [Google Scholar] [CrossRef]

- Forno, A.J.D.; Pereira, F.A.; Forcellini, F.A.; Kipper, L.M. Value Stream Mapping: A Study about the Problems and Challenges Found in the Literature from the Past 15 Years about Application of Lean Tools. Int. J. Adv. Manuf. Technol. 2014, 72, 779–790. [Google Scholar] [CrossRef]

- Vinodh, S.; Ben Ruben, R.; Asokan, P. Life Cycle Assessment Integrated Value Stream Mapping Framework to Ensure Sustainable Manufacturing: A Case Study. Clean Technol. Environ. Policy 2016, 18, 279–295. [Google Scholar] [CrossRef]

- Hartini, S.; Ciptomulyono, U.; Anityasari, M. Life Cycle—Value Stream Mapping: Evaluating Sustainability Using Lean Manufacturing Tools in the Life Cycle Perspective. AIP Conf. Proc. 2019, 2114, 030024. [Google Scholar] [CrossRef]

- Salvador, R.; Barros, M.V.; dos Santos, G.E.T.; van Mierlo, K.G.; Piekarski, C.M.; de Francisco, A.C. Towards a Green and Fast Production System: Integrating Life Cycle Assessment and Value Stream Mapping for Decision Making. Environ. Impact. Assess. Rev. 2021, 87, 106519. [Google Scholar] [CrossRef]

- Hellweg, S.; Canals, L.M.I. Emerging Approaches, Challenges and Opportunities in Life Cycle Assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef]

- Faulkner, W.; Badurdeen, F. Sustainable Value Stream Mapping (Sus-VSM): Methodology to Visualize and Assess Manufacturing Sustainability Performance. J. Clean. Prod. 2014, 85, 8–18. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Hernandez Marquina, M.V.; Zwolinski, P.; Mangione, F. Application of Value Stream Mapping Tool to Improve Circular Systems. Clean Eng. Technol. 2021, 5, 100270. [Google Scholar] [CrossRef]

- Galvão, G.D.A.; Homrich, A.S.; Geissdoerfer, M.; Evans, S.; Ferrer, P.S.S.; Carvalho, M.M. Towards a Value Stream Perspective of Circular Business Models. Resour. Conserv. Recycl. 2020, 162, 105060. [Google Scholar] [CrossRef]

- Mangers, J.; Plapper, P. Analysis of Supply-Chains in the Circular Economy by Means of VSM; Schriftenreihe der Wissenschaftlichen Gesellschaft für Arbeits- und Betriebsorganisation (WGAB) e.V.; GITO-Verlag: Berlin, Germany, 2021; pp. 261–278. [Google Scholar] [CrossRef]

- Diaz-Ruiz, R.; Costa-Font, M.; López-i-Gelats, F.; Gil, J.M. Food Waste Prevention along the Food Supply Chain: A Multi-Actor Approach to Identify Effective Solutions. Resour. Conserv. Recycl. 2019, 149, 249–260. [Google Scholar] [CrossRef]

- Matzembacher, D.E.; Vieira, L.M.; de Barcellos, M.D. An Analysis of Multi-Stakeholder Initiatives to Reduce Food Loss and Waste in an Emerging Country—Brazil. Ind. Mark. Manag. 2021, 93, 591–604. [Google Scholar] [CrossRef]

- De Steur, H.; Wesana, J.; Dora, M.K.; Pearce, D.; Gellynck, X. Applying Value Stream Mapping to Reduce Food Losses and Wastes in Supply Chains: A Systematic Review. Waste Manag. 2016, 58, 359–368. [Google Scholar] [CrossRef]

- Bait, S.; Di Pietro, A.; Schiraldi, M.M. Waste Reduction in Production Processes through Simulation and VSM. Sustainability 2020, 12, 3291. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ekinci, E.; Ozen, Y.D.O.; Pala, M.O. Reducing Food Waste Through Lean and Sustainable Operations: A Case Study from The Poultry Industry. Rev. Adm. Empresas 2021, 61, e2020-0226. [Google Scholar] [CrossRef]

- Goriwondo, W.M.; Mhlanga, S.; Marecha, A. Use of the Value Stream Mapping Tool for Waste Reduction in Manufacturing. Case Study for Bread Manufacturing in Zimbabwe. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 22–24 January 2011. [Google Scholar]

- Hines, P.; Rich, N. The Seven Value Stream Mapping Tools. Int. J. Oper. Prod. Manag. 1997, 17, 46–64. [Google Scholar] [CrossRef]

- Flanagan, K.; Robertson, K.; Hanson, C. Reducing Food Loss and Waste: Setting a Global Action Agenda; WRI (World Resources Institute): Washington, DC, USA, 2019. [Google Scholar]

- Fabi, C.; Cachia, F.; Conforti, P.; English, A.; Rosero Moncayo, J. Improving Data on Food Losses and Waste: From Theory to Practice. Food Policy 2021, 98, 101934. [Google Scholar] [CrossRef]

- Curtis, J.J. Judgmental Sampling. Transplantation 2011, 91, 1320. [Google Scholar] [CrossRef]

- Iranian National Standards Organization (INSO). Traditional Bread-Specifications and Test Methods (Code: 2628); INSO: Tehran, Iran, 2014. [Google Scholar]

- Iranian National Standards Organization (INSO). Bulk Bread-Specifications and Test Methods (Code: 2338); INSO: Tehran, Iran, 2017. [Google Scholar]

- Ghaziani, S.; Ghodsi, D.; Schweikert, K.; Dehbozorgi, G.; Rasekhi, H.; Faghih, S.; Doluschitz, R. The Need for Consumer-Focused Household Food Waste Reduction Policies Using Dietary Patterns and Socioeconomic Status as Predictors: A Study on Wheat Bread Waste in Shiraz, Iran. Foods 2022, 11, 2886. [Google Scholar] [CrossRef]

- Pretty, J.N.; Guijt, I.; Thompson, J.; Scoones, I. A Trainer’s Guide for Participatory Learning and Action; International Institute for Environment and Development: London, UK, 1995; ISBN 9781899825004. [Google Scholar]

- Fielding, J.; Fielding, N.; Hughes, G. Opening up Open-Ended Survey Data Using Qualitative Software. Qual. Quant. 2012, 47, 3261–3276. [Google Scholar] [CrossRef]

- VERBI. Software MAXQDA Analytics Pro 2022; VERBI Software: Berlin, Germany, 2022. [Google Scholar]

- AREEO. AREEO Organizational Chart. Available online: https://en.areeo.ac.ir/organization (accessed on 24 December 2022).

- Seed and Plant Certification and Registration Institute Certified Seeds Production. Available online: https://spcri.ir/page-Main/fa/0/form/pId1558 (accessed on 26 December 2022).

- Miri, M. The General Seed Certification Program Model, from the Modification of a New Variety to Its Utilization by by Farmers; Agriculture and Natural Resources Research and Education Center of Fars Province: Shiraz, Iran, 2016. [Google Scholar]

- Ali, A.; Rahut, D.B.; Behera, B.; Imtiaz, M. Farmers’ Access to Certified Wheat Seed and Its Effect on Poverty Reduction in Pakistan. J. Crop. Improv. 2015, 29, 247–265. [Google Scholar] [CrossRef]

- Key, N.; Runsten, D. Contract Farming, Smallholders, and Rural Development in Latin America: The Organization of Agroprocessing Firms and the Scale of Outgrower Production. World Dev. 1999, 27, 381–401. [Google Scholar] [CrossRef]

- Ceccarelli, S.; Grando, S. Participatory Plant Breeding. In Cereals; Carena, M.J., Ed.; Springer: New York, NY, USA, 2009; pp. 395–414. ISBN 978-0-387-72294-8. [Google Scholar]

- Almekinders, C.J.M.; Thiele, G.; Danial, D.L. Can Cultivars from Participatory Plant Breeding Improve Seed Provision to Small-Scale Farmers? Euphytica 2006, 153, 363–372. [Google Scholar] [CrossRef]

- Witcombe, J.R.; Joshi, K.D.; Gyawali, S.; Musa, A.M.; Johansen, C.; Virk, D.S.; Sthapit, B.R. Participatory Plant Breeding Is Better Described as Highly Client-Oriented Plant Breeding. I. Four Indicators of Client-Orientation in Plant Breeding. Exp. Agric. 2005, 41, 299–319. [Google Scholar] [CrossRef]

- Ashby, J.A. The Impact of Participatory Plant Breeding. In Plant Breeding and Farmer Participation; Ceccarelli, S., Guimarães, E.P., Weltzien, E., Eds.; FAO: Rome, Italy, 2009; pp. 649–671. [Google Scholar]

- Swain, B.B. Determinants of Farmers’ Participation in Contract Farming: The Cases of Gherkin and Paddy Seed in Andhra Pradesh, India. Millenn. Asia 2012, 3, 169–185. [Google Scholar] [CrossRef]

- International Association for Cereal Science and Technology (ICC). Standard No. 102/1; Determination of Besatz of Wheat; ICC: Hamburg, Germany, 1964. [Google Scholar]

- Iranian Center of Cereal Research. Guideline for Quality Valuation of Domestically Produced Wheat-2018; Government Trading Corporation of Iran: Tehran, Iran, 2018.

- Iranian Center of Cereal Research. Guideline for Quality Valuation of Domestically Produced Wheat-2022; Government Trading Corporation of Iran: Tehran, Iran, 2022.

- Aktar, W.; Sengupta, D.; Chowdhury, A. Impact of Pesticides Use in Agriculture: Their Benefits and Hazards. Interdiscip Toxicol 2009, 2, 1–12. [Google Scholar] [CrossRef]

- Abebe, G.K.; Bijman, J.; Royer, A. Are Middlemen Facilitators or Barriers to Improve Smallholders’ Welfare in Rural Economies? Empirical Evidence from Ethiopia. J. Rural Stud. 2016, 43, 203–213. [Google Scholar] [CrossRef]

- Abate, G.T.; Bernard, T.; de Brauw, A.; Minot, N. The Impact of the Use of New Technologies on Farmers’ Wheat Yield in Ethiopia: Evidence from a Randomized Control Trial. Agric. Econ. 2018, 49, 409–421. [Google Scholar] [CrossRef]

- Yan, J.; Xue, Y.; Quan, C.; Wang, B.; Zhang, Y. Oligopoly in Grain Production and Consumption: An Empirical Study on Soybean International Trade in China. Econ. Res. 2023, 36, 2142818. [Google Scholar] [CrossRef]

- Gafarova, G.; Perekhozhuk, O.; Glauben, T. Analysis of Oligopolistic Behaviour of Kazakh and Russian Exporters in the South Caucasus Wheat Market. In Proceedings of the 2017 International Congress, European Association of Agricultural Economists, Parma, Italy, 28 August 2017. [Google Scholar]

- Finch-Savage, W.E.; Leubner-Metzger, G. Seed Dormancy and the Control of Germination. New Phytol. 2006, 171, 501–523. [Google Scholar] [CrossRef]

- Souza, J.L.B.; Antonangelo, J.A.; de Oliveira Silva, A.; Reed, V.; Arnall, B. Recovery of Grain Yield and Protein with Fertilizer Application Post Nitrogen Stress in Winter Wheat (Triticum aestivum L.). Agronomy 2022, 12, 2024. [Google Scholar] [CrossRef]

- Critchley, B.R. Literature Review of Sunn Pest Eurygaster integriceps Put. (Hemiptera, Scutelleridae). Crop Prot. 1998, 17, 271–287. [Google Scholar] [CrossRef]

- Dizlek, H.; Özer, M.S. The Effects of Sunn Pest (Eurygaster integriceps) Damage Ratios on Bread Making Quality of Wheat with and without Additives. Qual. Assur. Saf. Crops Foods 2016, 9, 79–91. [Google Scholar] [CrossRef]

- The Council of Pricing and Implementation of Supportive Policies for Basic Agricultural Products. Purity Table of the Procurement Price for Domestic Wheat—2022; The Ministry of Agriculture Jihad: Tehran, Iran, 2022.

- Saini, S.; Gulati, A. Price Distortions in Indian Agriculture; International Bank for Reconstruction and Development/The World Bank: Washington, DC, USA, 2017. [Google Scholar]

- Elasraag, Y.H.; Alarcón, S. Efficiency of Wheat Production in Egypt. New Medit. 2015, 14, 19–27. [Google Scholar]

- Khan, R.E.A.; Gill, A.R. Determinants of Inflation: A Case of Pakistan (1970–2007). J. Econ. 2017, 1, 45–51. [Google Scholar] [CrossRef]

- Aditya, K.S.; Subash, S.P.; Praveen, K.V.; Nithyashree, M.L.; Bhuvana, N.; Sharma, A. Awareness about Minimum Support Price and Its Impact on Diversification Decision of Farmers in India. Asia Pac. Policy Stud. 2017, 4, 514–526. [Google Scholar] [CrossRef]

- Chintapalli, P.; Tang, C.S. The Value and Cost of Crop Minimum Support Price: Farmer and Consumer Welfare and Implementation Cost. Manag. Sci. 2020, 67, 6839–6861. [Google Scholar] [CrossRef]

- Das, R.C. Does Minimum Support Price Have Long-Run Associations and Short-Run Interplays with Yield Rates and Quantities of Outputs? A Study on Food and Non-Food Grains in India. Rev. Mark. Integr. 2022, 13, 42–65. [Google Scholar] [CrossRef]

- Petersson, S.; Schnurer, J. Biocontrol of Mold Growth in High-Moisture Wheat Stored under Airtight Conditions by Pichia Anomala, Pichia Guilliermondii, and Saccharomyces Cerevisiae. Appl. Environ. Microbiol. 1995, 61, 1032. [Google Scholar] [CrossRef]

- Wiersma, J.J.; Ransom, J.K. The Small Grains Field Guide; University of Minnesota Extension Service: St. Paul, MN, USA, 2005. [Google Scholar]

- Igrejas, G.; Ikeda, T.M.; Guzmán, C. Wheat Quality for Improving Processing and Human Health; Springer International Publishing: New York, NY, USA, 2020; ISBN 9783030341633. [Google Scholar]

- Chand, R. Challenges to Ensuring Food Security through Wheat. CAB Rev. 2009, 4, 1–13. [Google Scholar] [CrossRef]

- Van Zanten, H.H.E.; Mollenhorst, H.; de Vries, J.W.; van Middelaar, C.E.; van Kernebeek, H.R.J.; de Boer, I.J.M. Assessing Environmental Consequences of Using Co-Products in Animal Feed. Int. J. Life Cycle Assess. 2014, 19, 79–88. [Google Scholar] [CrossRef]

- Baek, J.; Koo, W.W. Analyzing Factors Affecting U. S. Food Price Inflation. Can. J. Agric. Econ. 2010, 58, 303–320. [Google Scholar] [CrossRef]

- Pixton, S.W.; Hyde, M.B.; Ayerst, G. Long-Term Storage of Wheat. J. Sci. Food Agric. 1964, 15, 152–161. [Google Scholar] [CrossRef]

- Kumar, C.; Ram, C.L.; Jha, S.N.; Vishwakarma, R.K. Warehouse Storage Management of Wheat and Their Role in Food Security. Front. Sustain. Food Syst. 2021, 5, 1–14. [Google Scholar] [CrossRef]

- Halverson, J.; Zeleny, L. Criteria of Wheat Quality. In Wheat: Chemistry and Technology; Pomeranz, Y., Ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 1988; Volume I, pp. 15–45. ISBN 9780913250655. [Google Scholar]

- Demartini, M.; Pinna, C.; Tonelli, F.; Terzi, S.; Sansone, C.; Testa, C. Food Industry Digitalization: From Challenges and Trends to Opportunities and Solutions. IFAC PapersOnLine 2018, 51, 1371–1378. [Google Scholar] [CrossRef]

- Jagtap, S.; Rahimifard, S. The Digitisation of Food Manufacturing to Reduce Waste—Case Study of a Ready Meal Factory. Waste Manag. 2019, 87, 387–397. [Google Scholar] [CrossRef]

- Yan, H.; Song, M.-J.; Lee, H.-Y. A Systematic Review of Factors Affecting Food Loss and Waste and Sustainable Mitigation Strategies: A Logistics Service Providers’ Perspective. Sustainability 2021, 13, 11374. [Google Scholar] [CrossRef]

- Kumar, D.; Kalita, P. Reducing Postharvest Losses during Storage of Grain Crops to Strengthen Food Security in Developing Countries. Foods 2017, 6, 8. [Google Scholar] [CrossRef]

- Melese, B.; Satheesh, N.; Workneh Fanta, S.; Bishaw, Z. Quantitative and Qualitative Post-Harvest Loss of Emmer Wheat in Selected Value Chain in Bale Zone, Ethiopia. Cogent. Food Agric. 2022, 8, 1–25. [Google Scholar] [CrossRef]

- FAO. Postharvest Loss Assessment of Maize, Wheat, Sorghum and Haricot Bean; FAO: Rome, Italy, 2017. [Google Scholar]

- Łaba, S.; Cacak-Pietrzak, G.; Łaba, R.; Sułek, A.; Szczepański, K. Food Losses in Consumer Cereal Production in Poland in the Context of Food Security and Environmental Impact. Agriculture 2022, 12, 665. [Google Scholar] [CrossRef]

- Kumar, V.; Brancoli, P.; Narisetty, V.; Wallace, S.; Charalampopoulos, D.; Kumar Dubey, B.; Kumar, G.; Bhatnagar, A.; Kant Bhatia, S.; J.Taherzadeh, M. Bread Waste—A Potential Feedstock for Sustainable Circular Biorefineries. Bioresour. Technol. 2023, 369, 128449. [Google Scholar] [CrossRef]

- Ellis, W.O.; Smith, J.P.; Simpson, B.K.; Oldham, J.H.; Scott, P.M. Aflatoxins in Food: Occurrence, Biosynthesis, Effects on Organisms, Detection, and Methods of Control. Crit. Rev. Food Sci. Nutr. 2009, 30, 403–439. [Google Scholar] [CrossRef]

- Payne, G.A.; Brown, M.P. Genetics and Physiology of Aflatoxin Biosynthesis. Annu. Rev. Phytopathol. 1998, 36, 329–362. [Google Scholar] [CrossRef]

- Reiss, J. Comparison of the Ability of Three Aspergillus Strains to Form Aflatoxins on Bakery Products and on Nutrient Agar. Mycopathologia 1982, 77, 99–102. [Google Scholar] [CrossRef]

- Pardakhti, A.; Maleki, S. Risk Assessment of Aflatoxin M1 Contamination of Milk in Iran. Int. J. Environ. Res. 2019, 13, 265–271. [Google Scholar] [CrossRef]

- Fakhri, Y.; Ghorbani, R.; Taghavi, M.; Keramati, H.; Amanidaz, N.; Moradi, B.; Nazari, S.H.; Shariatifar, N.; Khaneghah, A.M. Concentration and Prevalence of Aflatoxin M1 in Human Breast Milk in Iran: Systematic Review, Meta-Analysis, and Carcinogenic Risk Assessment: A Review. J. Food Prot. 2019, 82, 785–795. [Google Scholar] [CrossRef]

- Mokhtari, S.A.; Nemati, A.; Fazlzadeh, M.; Moradi-Asl, E.; Ardabili, V.T.; Seddigh, A. Aflatoxin M1 in Distributed Milks in Northwestern Iran: Occurrence, Seasonal Variation, and Risk Assessment. Environ. Sci. Pollut. Res. 2022, 29, 41429–41438. [Google Scholar] [CrossRef]

- Mahato, D.K.; Lee, K.E.; Kamle, M.; Devi, S.; Dewangan, K.N.; Kumar, P.; Kang, S.G. Aflatoxins in Food and Feed: An Overview on Prevalence, Detection and Control Strategies. Front. Microbiol. 2019, 10, 2266. [Google Scholar] [CrossRef]

- Robens, J.F.; Richard, J.L. Aflatoxins in Animal and Human Health. Rev. Environ. Contam. Toxicol. 1992, 127, 69–94. [Google Scholar] [CrossRef]

- Negash, D. A Review of Aflatoxin: Occurrence, Prevention, and Gaps in Both Food and Feed Safety. J. Nutr. Health Food Eng. 2018, 8, 190–197. [Google Scholar] [CrossRef]

- Mesterházy, ákos; Oláh, J.; Popp, J. Losses in the Grain Supply Chain: Causes and Solutions. Sustainability 2020, 12, 2342. [Google Scholar] [CrossRef]

- FAO. Global Food Losses and Food Waste—Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2011. [Google Scholar]

- Papargyropoulou, E.; Steinberger, J.K.; Wright, N.; Lozano, R.; Padfield, R.; Ujang, Z. Patterns and Causes of Food Waste in the Hospitality and Food Service Sector: Food Waste Prevention Insights from Malaysia. Sustainability 2019, 11, 6016. [Google Scholar] [CrossRef]

- Schanes, K.; Dobernig, K.; Gözet, B. Food Waste Matters—A Systematic Review of Household Food Waste Practices and Their Policy Implications. J. Clean. Prod. 2018, 182, 978–991. [Google Scholar] [CrossRef]

- Williams, H.; Wikström, F.; Otterbring, T.; Löfgren, M.; Gustafsson, A. Reasons for Household Food Waste with Special Attention to Packaging. J. Clean. Prod. 2012, 24, 141–148. [Google Scholar] [CrossRef]

- Graham-Rowe, E.; Jessop, D.C.; Sparks, P. Predicting Household Food Waste Reduction Using an Extended Theory of Planned Behaviour. Resour. Conserv. Recycl. 2015, 101, 194–202. [Google Scholar] [CrossRef]

- De Boni, A.; Pasqualone, A.; Roma, R.; Acciani, C. Traditions, Health and Environment as Bread Purchase Drivers: A Choice Experiment on High-Quality Artisanal Italian Bread. J. Clean. Prod. 2019, 221, 249–260. [Google Scholar] [CrossRef]

- Carroll, N.; Wallace, A.; Jewell, K.; Darlington, G.; Ma, D.W.L.; Duncan, A.M.; Parizeau, K.; von Massow, M.; Haines, J. Association between Diet Quality and Food Waste in Canadian Families: A Cross-Sectional Study. Nutr. J. 2020, 19, 54. [Google Scholar] [CrossRef]

- Conrad, Z.; Niles, M.T.; Neher, D.A.; Roy, E.D.; Tichenor, N.E.; Jahns, L. Relationship between Food Waste, Diet Quality, and Environmental Sustainability. PLoS ONE 2018, 13, e0195405. [Google Scholar] [CrossRef]

- Ghaziani, S.; Ghodsi, D.; Dehbozorgi, G.; Faghih, S.; Ranjbar, Y.R.; Doluschitz, R. Comparing Lab-Measured and Surveyed Bread Waste Data: A Possible Hybrid Approach to Correct the Underestimation of Household Food Waste Self-Assessment Surveys. Sustainability 2021, 13, 3472. [Google Scholar] [CrossRef]

- Lipinski, B. The Complex Picture of On-Farm Loss. In The Circular Economy to Food Security, Proceedings of the Crawford Fund 2016 Annual Conference: WASTE NOT, WANT NOT, Canberra, Australia, 29–30 August 2016; Milligan, A., Ed.; The Crawford Fund: Canberra, Australia, 2016; pp. 17–22. [Google Scholar]

- Dennett, A.L.; Trethowan, R.M. Milling Efficiency of Triticale Grain for Commercial Flour Production. J. Cereal Sci. 2013, 57, 527–530. [Google Scholar] [CrossRef]

- Johnson, L.K.; Dunning, R.D.; Bloom, J.D.; Gunter, C.C.; Boyette, M.D.; Creamer, N.G. Estimating On-Farm Food Loss at the Field Level: A Methodology and Applied Case Study on a North Carolina Farm. Resour. Conserv. Recycl. 2018, 137, 243–250. [Google Scholar] [CrossRef]

- Baker, G.A.; Gray, L.C.; Harwood, M.J.; Osland, T.J.; Tooley, J.B.C. On-Farm Food Loss in Northern and Central California: Results of Field Survey Measurements. Resour. Conserv. Recycl. 2019, 149, 541–549. [Google Scholar] [CrossRef]

- Yu, Y.; Jaenicke, E.C. Estimating Food Waste as Household Production Inefficiency. Am. J. Agric. Econ. 2020, 102, 525–547. [Google Scholar] [CrossRef]

- Ghaziani, S.; Ghodsi, D.; Schweikert, K.; Dehbozorgi, G.; Faghih, S.; Mohabati, S.; Doluschitz, R. Household Food Waste Quantification and Cross-Examining the Official Figures: A Study on Household Wheat Bread Waste in Shiraz, Iran. Foods 2022, 11, 1188. [Google Scholar] [CrossRef]

- Elimelech, E.; Ert, E.; Ayalon, O. Bridging the Gap between Self-Assessments and Measured Household Food Waste: A Hybrid Valuaion Approach. Waste Manag. 2019, 95, 259–270. [Google Scholar] [CrossRef]

- Quested, T.E.; Palmer, G.; Moreno, L.C.; McDermott, C.; Schumacher, K. Comparing Diaries and Waste Compositional Analysis for Measuring Food Waste in the Home. J. Clean. Prod. 2020, 262, 121263. [Google Scholar] [CrossRef]

- Delley, M.; Brunner, T.A. Household Food Waste Quantification: Comparison of Two Methods. Br. Food J. 2018, 120, 1504–1515. [Google Scholar] [CrossRef]

- Elimelech, E.; Ayalon, O.; Ert, E. What Gets Measured Gets Managed: A New Method of Measuring Household Food Waste. Waste Manag. 2018, 76, 68–81. [Google Scholar] [CrossRef]

- Withanage, S.V.; Dias, G.M.; Habib, K. Review of Household Food Waste Quantification Methods: Focus on Composition Analysis. J. Clean. Prod. 2021, 279, 123722. [Google Scholar] [CrossRef]

- Mirfakhrayi, F.; Ghafarpour, M.; Naghibi, A.; Mirbagheri, E.; Seyedan, N.; Darbandi, M. Investigating the Amount of and the Factors Affecting Bread Waste in Households and Bakeries in Tehran; National Nutrition and Food Technology Research Institute: Tehran, Iran, 1991. (In Persian) [Google Scholar]

- Irani, P.; Ayeeneh, G.; Farzaneh, F.; Rezaee, P.; Dorouki, E. Subproject: Investigating the Reasons and the Amount of Wheat Flour and Bread Loss and Waste; Project: Loss and Waste Reduction in Wheat Production and Consumption; National Scientific Research Council (Agriculture Commission): Tehran, Iran, 2005. (In Persian) [Google Scholar]

- Patton, M.Q. Qualitative Research & Evaluation Methods: Integrating Theory and Practice, 4th ed.; SAGE Publications Inc.: London, UK, 2015; ISBN 978-1-4129-7212-3. [Google Scholar]

- Kumar, R. Research Methodology A Step-By-Step Guide for Beginners, 3rd ed.; SAGE Publications Ltd.: London, UK, 2011. [Google Scholar]

- Fiedler, K. Beware of Samples! A Cognitive-Ecological Sampling Approach to Judgment Biases. Psychol. Rev. 2000, 107, 659–676. [Google Scholar] [CrossRef]

- Perla, R.J.; Provost, L.P. Judgment Sampling: A Health Care Improvement Perspective. Qual. Manag. Health Care 2012, 21, 169–175. [Google Scholar] [CrossRef]

- Amicarelli, V.; Lombardi, M.; Varese, E.; Bux, C. Material Flow and Economic Cost Analysis of the Italian Artisan Bread Production before and during the Russia–Ukraine Conflict. Environ. Impact. Assess. Rev. 2023, 101, 107101. [Google Scholar] [CrossRef]

- Rahbari, M.; Arshadi Khamseh, A.; Sadati-Keneti, Y. Resilience Strategies in Coping to Disruptions of Wheat Supply Chain Caused by the Russia–Ukraine War Crisis: Case Study from an Emerging Economy. Kybernetes, 2023; ahead-of-print. [Google Scholar] [CrossRef]

- MORSE, J.M. Approaches to Qualitative-Quantitative Methodological Triangulation. Nurs. Res. 1991, 40, 120–123. [Google Scholar] [CrossRef]

- Charmaz, K. Constructing Grounded Theory: A Practical Guide through Qualitative Analysis; SAGE Publications Ltd.: London, UK, 2006; ISBN 10 0-7619-7352-4. [Google Scholar]

| Participant’s ID | Role |

|---|---|

| Seed producer | The owner of a plant breeding and seed production company. |

| Farmer 1 | A farmer with large-sized (over 70 ha) land. |

| Farmer 2 | A farmer with small-sized (10 ha) land. |

| Farmer 3 | A farmer with small-sized (10 ha) land. |

| Farmer 4 | A farmer with small-sized (20 ha) land. |

| Co-op CEO | The chief executive officer (CEO) at a local agricultural cooperative and a farmer with medium-sized (50 ha) land. |

| GCCS inspector | The technical inspector of Grain Company and Commercial Services (GCCS) of Fars province. |

| Agri. Mins. Officer | A high-ranking officer at the Ministry of Agriculture. |

| Foodservice 1 | The owner of a fast-food restaurant. |

| Foodservice 2 | The head chef at a hotel. |

| Baker 1 | The manager of a traditional bread (sangak) bakery. |

| Baker 2 | The manager of a traditional bread (lavash) bakery. |

| Baker 3 | The manager of a traditional bread (sangak) bakery. |

| Baker 4 | The owner of a non-traditional bread bakery. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghaziani, S.; Dehbozorgi, G.; Bakhshoodeh, M.; Doluschitz, R. Identifying Loss and Waste Hotspots and Data Gaps throughout the Wheat and Bread Lifecycle in the Fars Province of Iran through Value Stream Mapping. Sustainability 2023, 15, 8404. https://doi.org/10.3390/su15108404

Ghaziani S, Dehbozorgi G, Bakhshoodeh M, Doluschitz R. Identifying Loss and Waste Hotspots and Data Gaps throughout the Wheat and Bread Lifecycle in the Fars Province of Iran through Value Stream Mapping. Sustainability. 2023; 15(10):8404. https://doi.org/10.3390/su15108404

Chicago/Turabian StyleGhaziani, Shahin, Gholamreza Dehbozorgi, Mohammad Bakhshoodeh, and Reiner Doluschitz. 2023. "Identifying Loss and Waste Hotspots and Data Gaps throughout the Wheat and Bread Lifecycle in the Fars Province of Iran through Value Stream Mapping" Sustainability 15, no. 10: 8404. https://doi.org/10.3390/su15108404

APA StyleGhaziani, S., Dehbozorgi, G., Bakhshoodeh, M., & Doluschitz, R. (2023). Identifying Loss and Waste Hotspots and Data Gaps throughout the Wheat and Bread Lifecycle in the Fars Province of Iran through Value Stream Mapping. Sustainability, 15(10), 8404. https://doi.org/10.3390/su15108404