Sustainable Irrigation Requirement Prediction Using Internet of Things and Transfer Learning

Abstract

1. Introduction

- Data gathering and transmission: in the first layer of an effective irrigation system, the layer collects all the information using sensors and transmits it using networking devices [5].

- Data processing and intelligence layer: in the second layer, intelligence techniques are used for processing and decision-making.

- Application layers: the third layer performs planning, optimization and implementations using the second layers’ decision [6].

- i.

- The irrigation system must be fully automated from the end-to-end process.

- ii.

- The integrations of different functionalities of irrigation systems cannot be interconnected from data collection to processing.

- iii.

- The real environment inputs (rain, soil moisture and atmosphere inputs) are not interconnected.

- iv.

- The current- and future-requirements prediction is still one of the main research gaps in smart irrigation systems.

- v.

- The predicted features and requirements are not shared with the neighbour farmers.

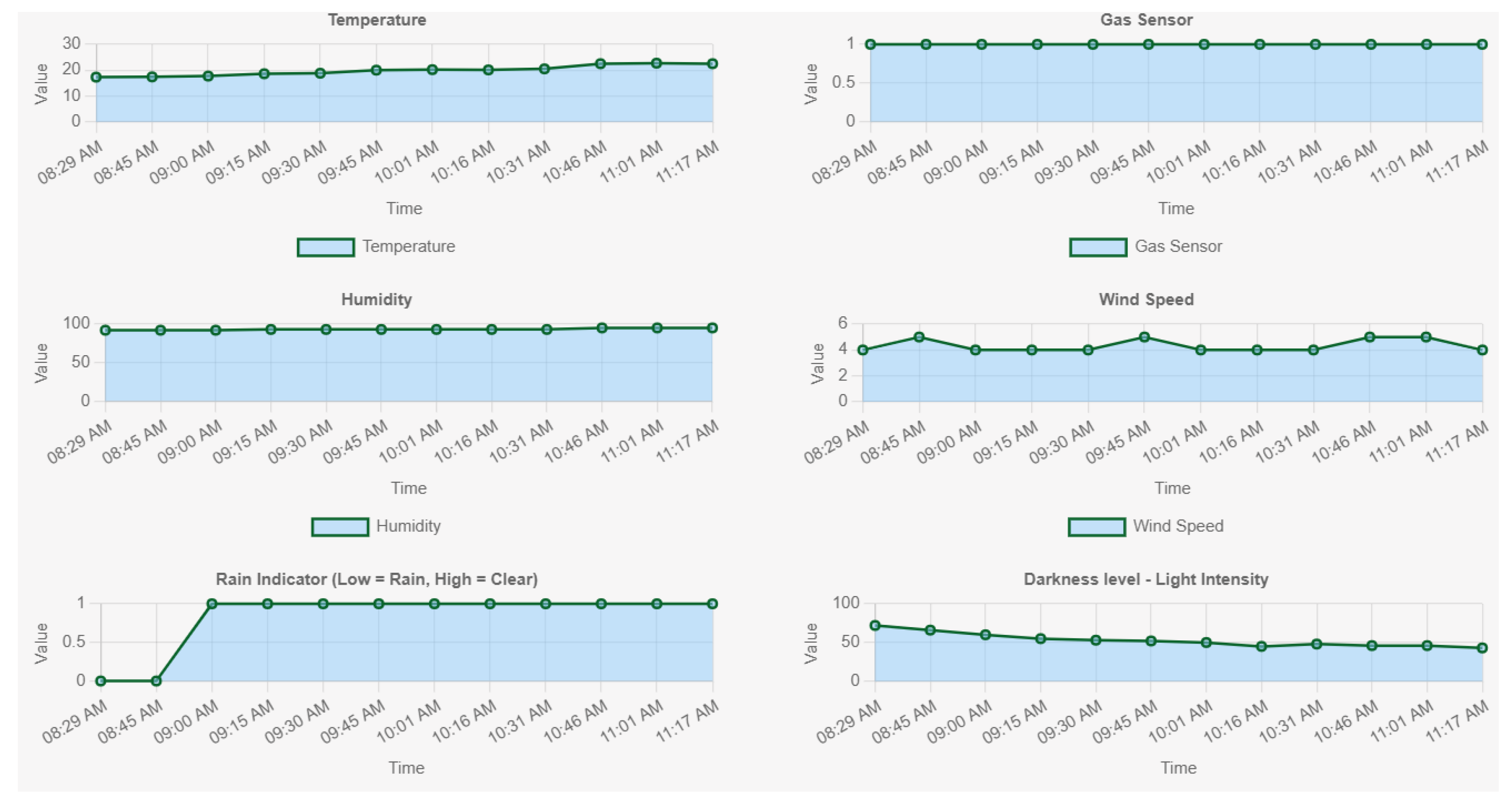

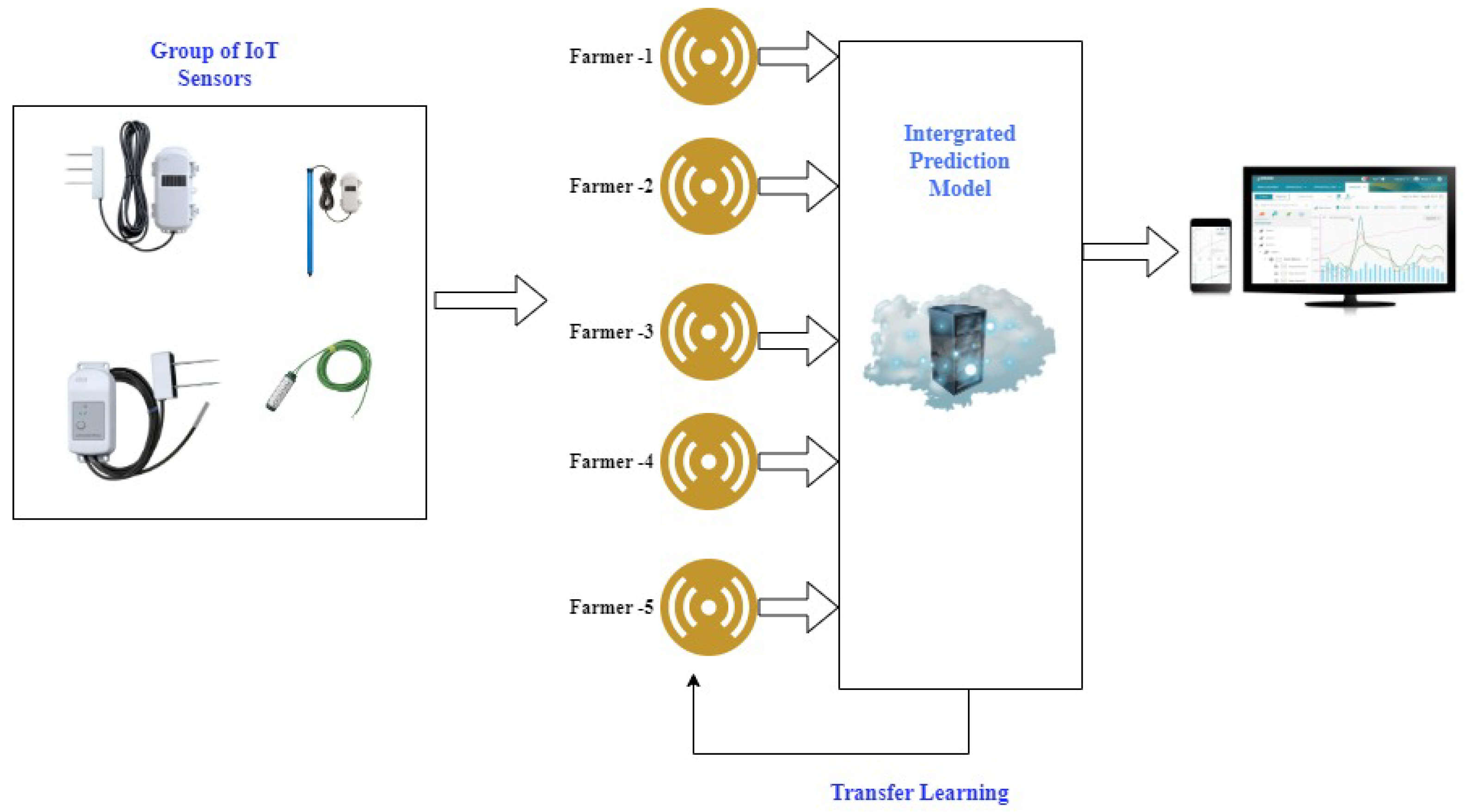

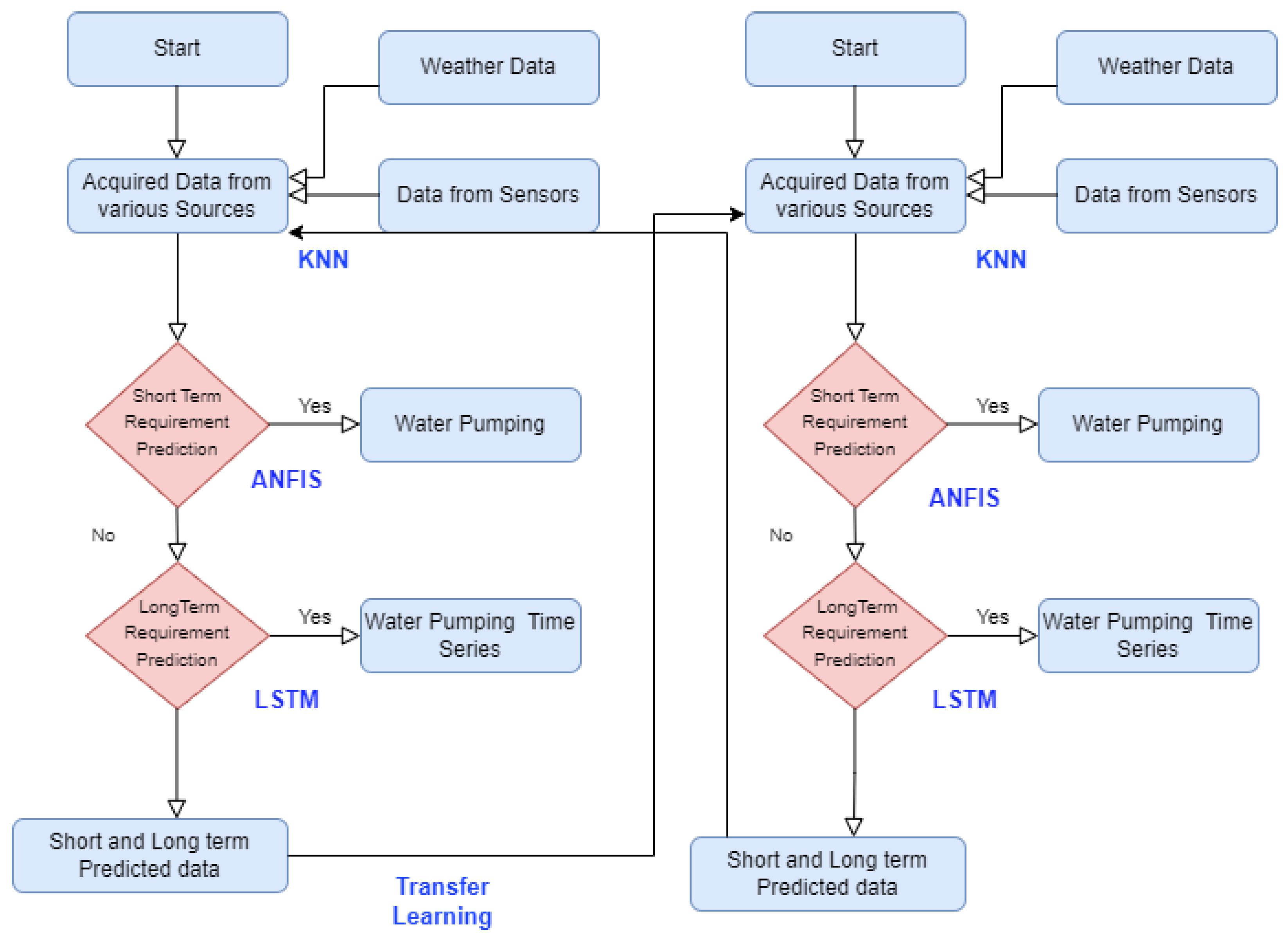

- In this work, IoT sensors and k-nearest neighbours are used to sense and collect the requirements.

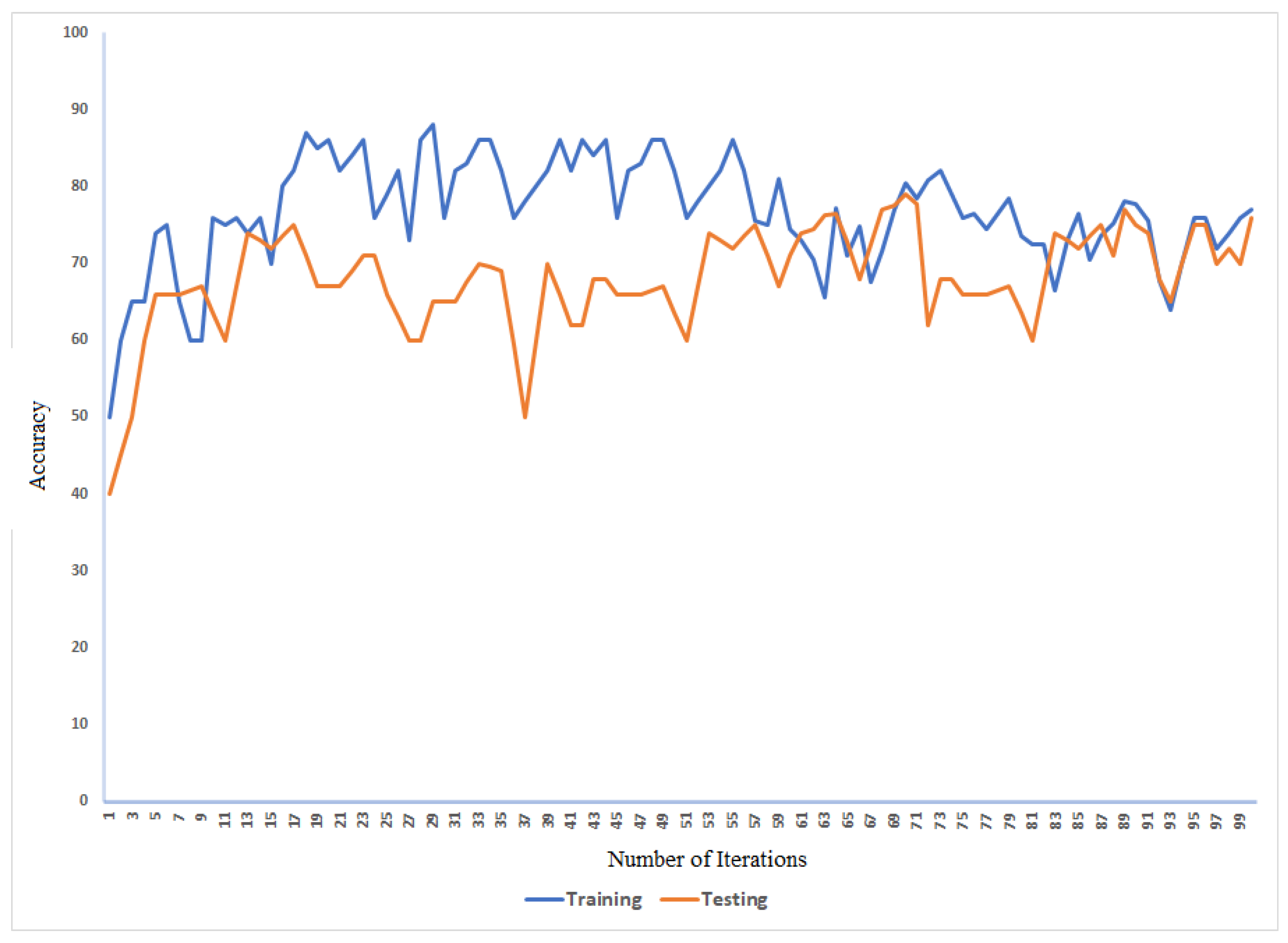

- We also propose a system to predict the short- and long-term sustainable prediction requirements of the irrigation system using ANFIS and LSTM techniques.

- The proposed model shares the sustainable requirements of the prediction using the cloud environment and shares the features with the nearest farmers for better requirements prediction using transfer learning.

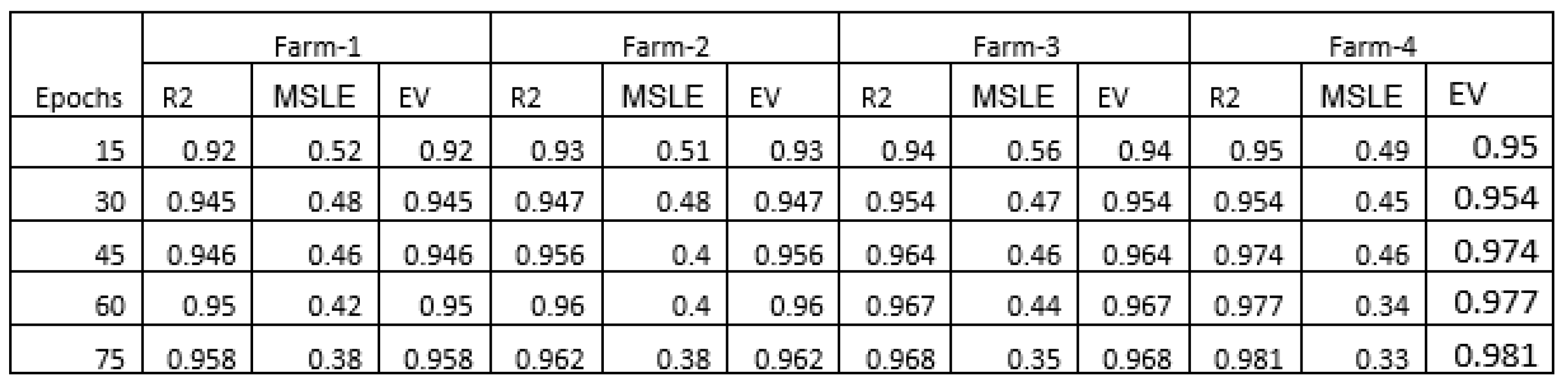

- The proposed model reduces and optimizes the sustainable irrigation requirements of the crops. It reduces by 42% to 50% the freshwater requirements compared to the previous traditional methods. The proposed work reduces water usage because the short- and long-term usage of irrigation requirements are calculated using the sensors, weather and history. Compared to the previous methods, the coefficient of determination (R2) is better (0.955), and mean squared logarithmic error (MSLE) is less (0.439).

- Compared to previous methodologies, this work is the first to introduce transfer learning to an irrigation system and forecast irrigation requirements using transfer learning to predict one farm from another. Compared to the previous method of irrigation requirements prediction [8], our method of LSTM and ANFIS with transfer learning reduces by 30.24% the water requirements in the single node of a banana tree in the implementations. Our method was tuned to consume 1.16% less water in a single banana-tree node than in ref. [8].

2. Related Work

2.1. Irrigation Techniques

2.2. Transfer Learning for Agriculture and Irrigation System

3. Materials and Method

3.1. Materials

3.2. Method

3.2.1. KNN Algorithm

3.2.2. ANFIS

3.2.3. Long Short-Term Memory

3.2.4. Transfer Learning

3.3. Working Principle

| Algorithm 1 Requirement Prediction and Features Transfer |

Input: Xm: Data Collection Using Sensors (Moisture); Xw: Weather details; TT: Temperature; X1, X2, X3, and X4: Farms Prediction Details Output: Short- and Long-term Prediction Details (Sp, Lp) Generating algorithm Begin: Moisture (Xm), Weather details (Xw), Temperature (TT) > 0 X1, X2, X3, and X4 > 0 Calculate (Xm), (Xw), (TT); { if Xm, Xw TT >0 Predict of Each Farm Requirements Details N = C (Prediction of Nearest features with respect to weights and time) D = Prediction of distance features between two terminals Sp = Tp -AP // Short- term prediction Lp = Tp -AP // Long- term prediction } End of Each Farm Prediction Share the month-wise history data Y = X1 (End prediction of single Farm) Share X1 to X2 T = [Y, f(.)] //Start Transfer Learning if X1 > X2 / X2 >X1 State Share the Y values if Xw = Rainy Stop // Stop sharing, Sensors in Sleep Mode end |

4. Result and Discussion

Comparison with Other Methods of Estimation and Transfer of Learning

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Managing Water Sustainably Is Key to the Future of Food and Agriculture. Available online: https://www.oecd.org/agriculture/topics/water-and-agriculture/ (accessed on 8 May 2023).

- Samjstria, A.G. Efficiencies of Florida Agricultural Irrigation Systems; University of Florida: Gainesville, FL, USA, 1988. [Google Scholar]

- The Current Water Crisis and the Need for Alternative Farming Solutions. Available online: https://www.edengreen.com/blog-collection/water-crisis-drought (accessed on 8 May 2023).

- Abioye, E.A.; Hensel, O.; Esau, T.J.; Elijah, O.; Abidin, M.S.Z.; Ayobami, A.S.; Yerima, O.; Nasirahmadi, A. Precision Irrigation Management Using Machine Learning and Digital Farming Solutions. AgriEngineering 2022, 3, 70–103. [Google Scholar] [CrossRef]

- Samian, M.; Mahdei, K.N.; Saadi, H.; Movahedi, R. Identifying factors affecting optimal management of agricultural water. J. Saudi Soc. Agric. Sci. 2015, 14, 11–18. [Google Scholar] [CrossRef]

- Ahansal, Y.; Bouziani, M.; Yaagoubi, R.; Sebari, I.; Sebari, K.; Kenny, L. Towards smart irrigation: A literature review on the use of geospatial technologies and machine learning in the management of water resources in arboriculture. Agronomy 2022, 12, 297. [Google Scholar] [CrossRef]

- Blessy, J.A.; Kumar, A. Smart Irrigation System Techniques using Artificial Intelligence and IoT. In Proceedings of the 2021 Third International Conference on Intelligent Communication Technologies and Virtual Mobile Networks (ICICV), Tirunelveli, India, 4–6 February 2021; pp. 1355–1359. [Google Scholar] [CrossRef]

- Vianny, D.M.M.; John, A.; Mohan, S.K.; Sarlan, A.; Ahmadian, A. Water optimization technique for precision irrigation system using IoT and machine learning. Sustain. Energy Technol. Assess. 2022, 52, 102307. [Google Scholar]

- Evans, R.G.; LaRue, J.; Stone, K.C.; King, B.A. Adoption of site-specific variable rate sprinkler irrigation systems. Irrig. Sci. 2013, 31, 871–887. [Google Scholar] [CrossRef]

- Kamienski, C.; Soininen, J.-P.; Taumberger, M.; Dantas, R.; Toscano, A. Smart water management platform: IoT-based precision irrigation for agriculture. Sensors 2019, 19, 276. [Google Scholar] [CrossRef]

- Messaoud, S.; Ben Ahmed, O.; Bradai, A.; Atri, M. Machine learning modelling-powered IoT systems for smart applications. In IoT-Based Intelligent Modelling for Environmental and Ecological Engineering; Springer: Cham, Swizterland, 2021; pp. 185–212. [Google Scholar]

- Abba, S.; Wadumi Namkusong, J.; Lee, J.A.; Liz Crespo, M. Design and performance evaluation of a low-cost autonomous sensor interface for a smart IoT-based irrigation monitoring and control system. Sensors 2019, 19, 3643. [Google Scholar] [CrossRef]

- Evett, S.R.; Colaizzi, P.D.; Lamm, F.R.; O’Shaughnessy, S.A. Past, present, and future of irrigation on the US Great Plains. Trans. ASABE 2020, 63, 703–729. [Google Scholar] [CrossRef]

- Mukherjee, D.; Nandy, S.; Mohan, S.; Al-Otaibi, Y.D.; Alnumay, W.S. Sustainable task scheduling strategy in cloudlets. Sustain. Comput. Inform. Syst. 2021, 30, 100513. [Google Scholar] [CrossRef]

- Schoups, G.; Addams, C.L.; Minjares, J.L.; Gorelick, S.M. Sustainable conjunctive water management in irrigated agriculture: Model formulation and application to the Yaqui Valley, Mexico. Water Resour. Res. 2006, 42, 1–19. [Google Scholar] [CrossRef]

- Durrant, A.; Markovic, M.; Matthews, D.; May, D.; Enright, J.; Leontidis, G. The role of cross-silo federated learning in facilitating data sharing in the agri-food sector. Comput. Electron. Agric. 2022, 193, 106648. [Google Scholar] [CrossRef]

- Mahato, S.; Rakshit, P.; Santra, A.; Dan, S.; Tiglao, N.C.; Bose, A. A GNSS-enabled multi-sensor for agricultural applications. J. Inf. Optim. Sci. 2019, 40, 1763–1772. [Google Scholar] [CrossRef]

- John, A.; Sugumaran, M.; Rajesh, R.S. Performance Analysis of the Past, Present and Future Indexing Methods for Spatio-Temporal Data. In 2017 2nd International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 19–20 October 2017; pp. 645–649. [Google Scholar]

- Abioye, E.A.; Abidin, M.S.; Mahmud, M.S.; Buyamin, S.; Ishak, M.H.; Abd Rahman, M.K.; Otuoze, A.O.; Onotu, P.; Ramli, M.S. A review on monitoring and advanced control strategies for precision irrigation. Comput. Electron. Agric. 2020, 173, 105441. [Google Scholar] [CrossRef]

- López-Morales, J.A.; Martínez, J.A.; Skarmeta, A.F. Improving Energy Efficiency of Irrigation Wells by Using an IoT-Based Platform. Electronics 2021, 10, 250. [Google Scholar] [CrossRef]

- Sánchez-Sutil, F.; Cano-Ortega, A. Smart Control and Energy Efficiency in Irrigation Systems Using Lo-RaWAN. Sensors 2021, 21, 7041. [Google Scholar] [CrossRef]

- Whig, P.; Kouser, S.; Velu, A.; Nadikattu, R.R. Fog-IoT-Assisted-Based Smart Agriculture Application. In Demystifying Federated Learning for Blockchain and Industrial Internet of Things; IGI Global: Hershey, PA, USA, 2022; pp. 74–93. [Google Scholar]

- Mahmoudi, N.; Majidi, A.; Jamei, M.; Jalali, M.; Maroufpoor, S. Mutating fuzzy logic model with various rigorous meta-heuristic algorithms for soil moisture content estimation. Agric. Water Manag. 2022, 261, 107342. [Google Scholar] [CrossRef]

- Shekhar, Y.; Dagur, E.; Mishra, S.; Sankaranarayanan, S. Intelligent IoT-based automated irrigation system. Int. J. Appl. Eng. Res. 2017, 12, 7306–7320. [Google Scholar]

- Saranya, T.; Deisy, C.; Sridevi, S.; Anbananthen, K.S.M. A comparative study of deep learning and Internet of Things for precision agriculture. Eng. Appl. Artif. Intell. 2023, 122, 106034. [Google Scholar] [CrossRef]

- Khamparia, S.; Jabade, S.; Kulkarni, S.; Nakade, P.; Bhatkhande, D. IoT for Water Management: A Sustainable Solution. In Internet of Things: Applications for Sustainable Development; Chapman and Hall/CRC: London, UK, 2023; Volume 109. [Google Scholar]

- Campos, N.G.S.; Rocha, A.R.; Gondim, R.; Coelho da Silva, T.L.; Gomes, D.G. Smart & green: An internet-of-things framework for smart irrigation. Sensors 2019, 20, 190. [Google Scholar]

- Goap, A.; Sharma, D.; Shukla, A.K.; Krishna, C.R. An IoT-based smart irrigation management system using Machine learning and open source technologies. Comput. Electron. Agric. 2018, 155, 41–49. [Google Scholar] [CrossRef]

- Sangeetha, B.P.; Kumar, N.; Ambalgi, A.P.; Haleem, S.L.A.; Thilagam, K.; Vijayakumar, P. IOT-based smart irrigation management system for environmental sustainability in India. Sustain. Energy Technol. Assess. 2020, 52, 101973. [Google Scholar]

- Adeyemi, O.; Grove, I.; Peets, S.; Norton, T. Advanced monitoring and management systems for improving sustainability in precision irrigation. Sustainability 2017, 9, 353. [Google Scholar] [CrossRef]

- Al Sahili, Z.; Mariette, A. The power of transfer learning in agricultural applications: AgriNet. Convolutional Neural Netw. Deep Learn. Crop. Improv. Prod. 2023, 195, 16648714. [Google Scholar] [CrossRef]

- Bosilj, P.; Aptoula, E.; Duckett, T.; Cielniak, G. Transfer learning between crop types for semantic segmentation of crops versus weeds in precision agriculture. J. Field Robot. 2020, 37, 7–19. [Google Scholar] [CrossRef]

- Hu, Y.; Zeng, H.; Tian, F.; Zhang, M.; Wu, B. An interannual transfer learning approach for crop classification in the Hetao Irrigation district, China. Remote Sens. 2022, 14, 1208. [Google Scholar] [CrossRef]

- Espejo-Garcia, B.; Mylonas, N.; Athanasakos, L.; Fountas, S.; Vasilakoglou, I. Towards weeds identification assistance through transfer learning. Comput. Electron. Agric. 2020, 171, 105306. [Google Scholar] [CrossRef]

- Vo, A.H.; Minh, T.V.; Tuong, L. A novel framework for trash classification using deep transfer learning. IEEE Access 2019, 7, 178631–178639. [Google Scholar] [CrossRef]

- Zhao, W.; Yamada, W.; Li, T.; Digman, M.; Runge, T. Augmenting crop detection for precision agriculture with deep visual transfer learning—A case study of bale detection. Remote Sens. 2020, 13, 23. [Google Scholar] [CrossRef]

- Thenmozhi, K.; Srinivasulu Reddy, U. Crop pest classification based on deep convolutional neural network and transfer learning. Comput. Electron. Agric. 2019, 164, 104906. [Google Scholar] [CrossRef]

- Bazzi, H.; Ienco, D.; Baghdadi, N.; Zribi, M.; Demarez, V. Distilling before refine: Spatio-temporal transfer learning for mapping irrigated areas using Sentinel-1 time series. IEEE Geosci. Remote. Sens. Lett. 2020, 17, 1909–1913. [Google Scholar] [CrossRef]

- Risheh, A.; Amirmohammad, J.; Ehsan, N. Smart Irrigation IoT solution using transfer learning for neural networks. In Proceedings of the 2020 10th International Conference on Computer and Knowledge Engineering (ICCKE), Mashhad, Iran, 29–30 October 2020. [Google Scholar]

- BANANA. Available online: https://nhb.gov.in/report_files/banana/BANANA.htm (accessed on 8 May 2023).

- Senthilkumar, M. Weather data analysis using Hadoop. Int. J. Pharm. Technol. 2016, 8, 21827–21834. [Google Scholar]

- Altman, N.S. An introduction to kernel and nearest-neighbour nonparametric regression. Am. Stat. 1992, 46, 175–185. [Google Scholar]

- Friedman, J.H. Stochastic gradient boosting. Comput. Stat. Data Anal. 2002, 38, 367–378. [Google Scholar] [CrossRef]

- Karaboga, D.; Ebubekir, K. Adaptive network-based fuzzy inference system (ANFIS) training approaches: A comprehensive survey. Artif. Intell. Rev. 2019, 52, 2263–2293. [Google Scholar] [CrossRef]

- Dehghani, M.; Akram, S.; Hossien, R.-M. Novel forecasting models for immediate-short-term to long-term influent flow prediction by combining ANFIS and grey wolf optimisation. J. Hydrol. 2019, 576, 698–725. [Google Scholar] [CrossRef]

- Adedeji, P.A.; Akinlabi, S.; Madushele, N.; Olatunji, O.O. Wind turbine power output very short-term forecast: A comparative study of data clustering techniques in a PSO-ANFIS model. J. Clean. Prod. 2020, 254, 120135. [Google Scholar] [CrossRef]

- Hua, Y.; Zhao, Z.; Li, R.; Chen, X.; Liu, Z.; Zhang, H. Deep learning with long short-term memory for time series prediction. IEEE Commun. Mag. 2019, 57, 114–119. [Google Scholar] [CrossRef]

- Chang, Y.-S.; Chiao, H.-T.; Abimannan, S.; Huang, Y.-P. Tsai, Y.-T.; Lin, K.-M. An LSTM-based aggregated model for air pollution forecasting. Atmos. Pollut. Res. 2020, 11, 1451–1463. [Google Scholar] [CrossRef]

- Zhuang, F.; Qi, Z.; Duan, K.; Xi, D.; Zhu, Y.; Zhu, H.; Xiong, H.; He, Q. A comprehensive survey on transfer learning. Proc. IEEE 2020, 109, 43–76. [Google Scholar] [CrossRef]

- Nowakowski, A.; Mrziglod, J.; Spiller, D.; Bonifacio, R.; Ferrari, I.; Mathieu, P.P.; Garcia-Herranz, M.; Kim, D.-H. Crop type mapping by using transfer learning. Int. J. Appl. Earth Obs. Geoinf. 2021, 98, 102313. [Google Scholar] [CrossRef]

- Olariu, E.M.; Tolas, R.; Portase, R.; Dinsoreanu, M.; Potolea, R. Modern approaches to preprocessing industrial data. In Proceedings of the 2020 IEEE 16th International Conference on Intelligent Computer Communication and Processing (ICCP), Cluj-Napoca, Romania, 3–5 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 221–226. [Google Scholar]

| Previous Models | Advantages | Limitations |

|---|---|---|

| IoT framework [5,8,9,16,23] | The site-specific variable-rate sprinkler irrigation [9] (SS-VRT) used crop and soil conditions for irrigation, KMO [23] is used to analyse the factors of irrigations, SWAMP [5] architecture provides better scalability, Federated learning [16] is used for irrigation without sharing the data, using machine learning. | SS-VRT does not support long-term application, KMO is not considered as a real factor affecting the irrigation, SWAMP is not considered as one of the the multiple features for irrigation and the Federated learning [8]. |

| Irrigation models [6,10,11,24,30] | A sprinkler–solid, centre pivot, travelling irrigator, and micro-spray are used for spatial-based irrigation. Automatic sensors and evaporation-based models are used to predict the requirements. | The spatial-based irrigation model is only supported at particular locations. Central data storage, irrigation scheduling, and root moisture are not considered for processing an effective system. |

| Recommendation system for irrigation [13] | Irrigation performed based on climate change, water availability, and a policy of productivity. | Considers area-wise irrigation and not irrigation technology, makes way for better decision-making. |

| Optimization and machine-learning algorithms [4,5,9,11,12,22,23,24] | Genetic algorithm, KNN, logical regression, SVM and decision-tree algorithms are considered for irrigation requirement predictions. | Effective sensor data and data on weather should be combined for effective predictions. |

| S. No | Components | Usages |

|---|---|---|

| 1 | HPT675 | Used to measure water level. |

| 2 | FC-28 | Used to sense soil moisture. |

| 3 | HTM2500LF | Used to measure the humidity and water vapour. |

| 4 | THERM200 | Used to sense soil temperature. |

| 5 | SHT11 | Used to measure root moisture. |

| 6 | WSN | Used to surveil and manage the transmission of data and monitoring. |

| 7 | Digital inclinometer | Measures the gradient and slope of the land |

| 8 | M2M (ZigBee) | Personal communication network |

| S. No | Month | Water Req Lit/Interval/Plant |

|---|---|---|

| 1 | February | 3–4 |

| 2 | March | 4–5 |

| 3 | April | 5–6 |

| 4 | May | 6–8 |

| 5 | June | 10–12 |

| 6 | July | 8–10 |

| 7 | August | 6–8 |

| 8 | September | 10–12 |

| 9 | October | 12–14 |

| 10 | November | 16–18 |

| S. No | Parameters and Requirements | Values |

|---|---|---|

| 1 | Number of farms | 4 |

| 2 | Number of trees in each farm | 300 |

| 3 | Maximum requirement of water per month | 50 L |

| 4 | Irrigation interval | Feb to November |

| 5 | Minimum temperature | 0 °C |

| 6 | Maximum temperature | 37 °C |

| 7 | Interval of irrigation | 7 Days |

| 8 | Average requirement of water per month | 36 L |

| S. No | Hyperparameters of LSTM | Values |

|---|---|---|

| 1 | Number of layers | 2 Layers |

| 2 | Units | 96 (64 + 32) |

| 3 | Feature points | 10 |

| 4 | Activation function | Sigmoid |

| 5 | Time steps | 20 |

| 6 | Loss function | Binary cross entropy |

| 7 | Total parameters | 34,242 |

| S. No | Hyperparameters of ANFIS | Values |

|---|---|---|

| 1 | Hidden layer size | 2 Layers |

| 2 | Input layer size | 10 |

| 3 | Activation function | Sigmoid |

| 4 | Time steps | 20 |

| 5 | Range of influence | 0.7 |

| 6 | Acceptance ratio | 0.5 |

| 7 | Number of maximum iterations | 100 |

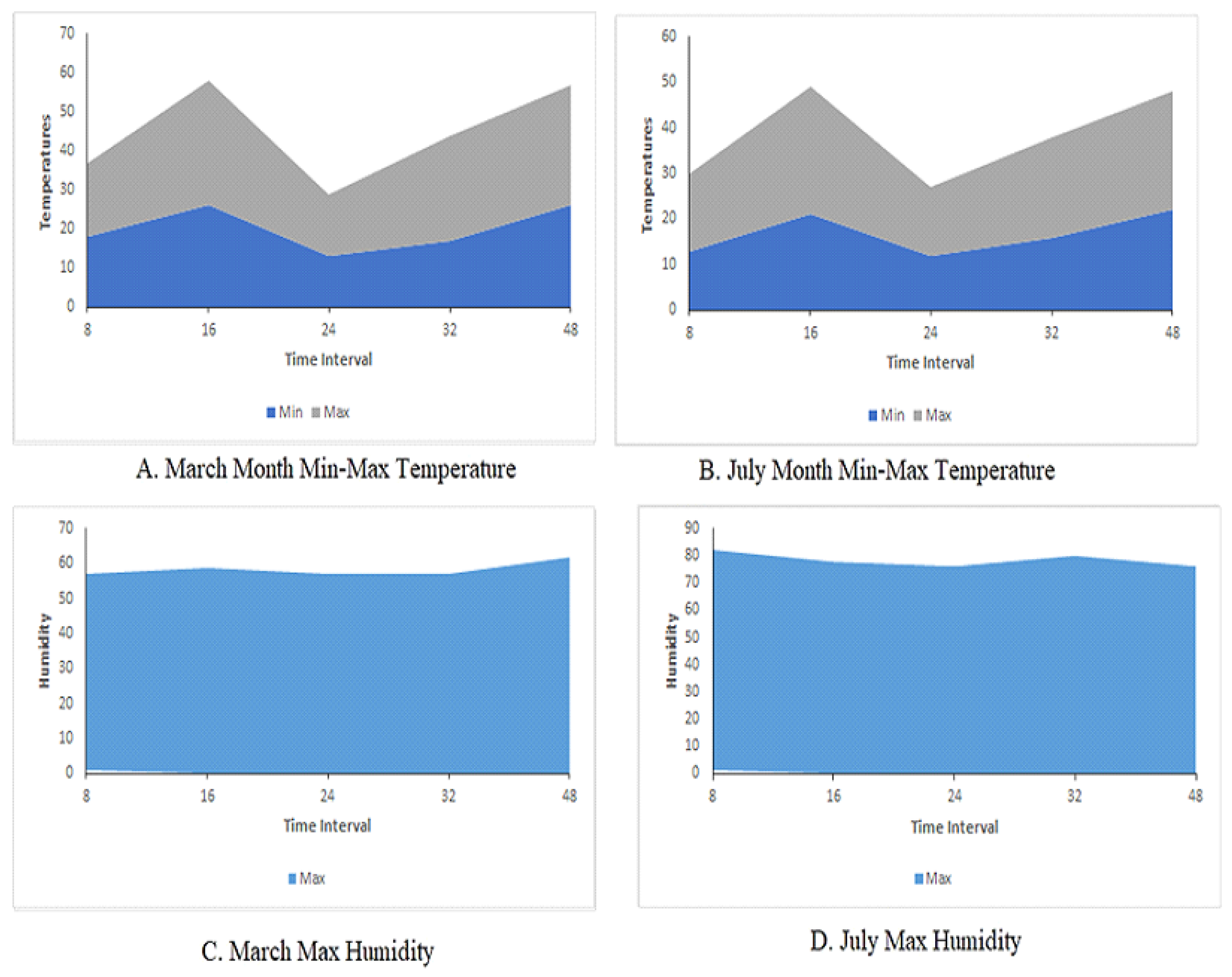

| Months | Min and Max/Time Interval | 8 | 16 | 24 | 32 | 48 |

|---|---|---|---|---|---|---|

| March | Min (Litres) | 8 | 3 | 1 | 2 | 3 |

| July | Min (Litres) | 0 | 1 | 1 | 3 | 1 |

| March | Max (Litres) | 3 | 4 | 2 | 3 | 4 |

| July | Max (Litres) | 1 | 2 | 2 | 1 | 2 |

| Months | Min and Max/Time Interval | 24 | 48 | 72 | 96 |

|---|---|---|---|---|---|

| March | Min (Litres) | 2 | 3 | 1 | 2 |

| July | Min (Litres) | 0 | 1 | 1 | 0 |

| March | Max (Litres) | 3 | 4 | 2 | 3 |

| July | Max (Litres) | 1 | 2 | 2 | 1 |

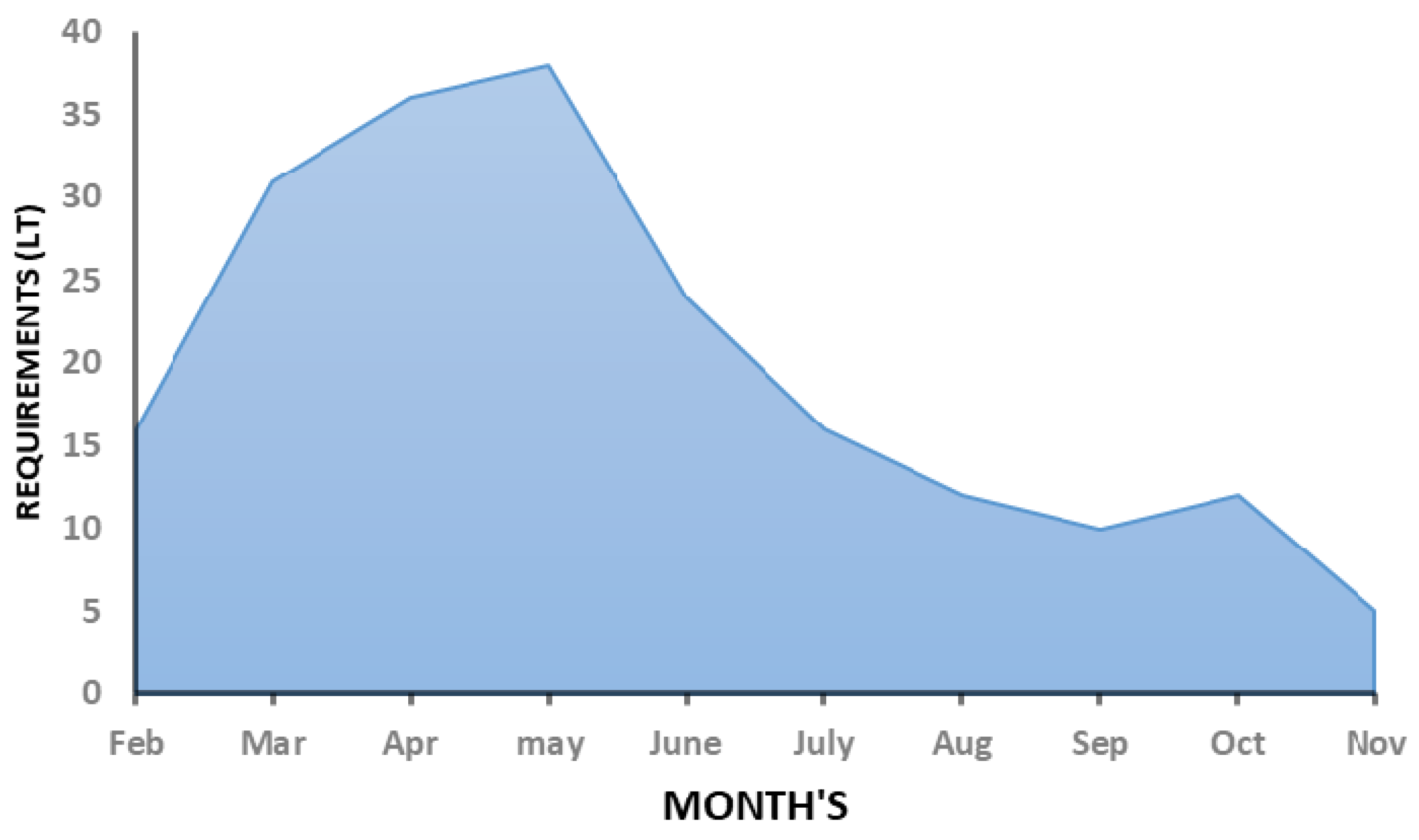

| Months | March/July Dates Interval | 4/2 | 8/6 | 12/10 | 16/15 | 20/18/ | 24/22 | 28/26 | Total Requirements |

|---|---|---|---|---|---|---|---|---|---|

| March | Min (Litres) | 2 | 4 | 5 | 4 | 4 | 5 | 4 | 28 |

| March | Max (Litres) | 3 | 5 | 6 | 5 | 5 | 5 | 5 | 34 |

| July | Min (Litres) | 0 | 1 | 1 | 0 | 1 | 2 | 2 | 7 |

| July | Max (Litres) | 1 | 2 | 2 | 1 | 3 | 3 | 3 | 16 |

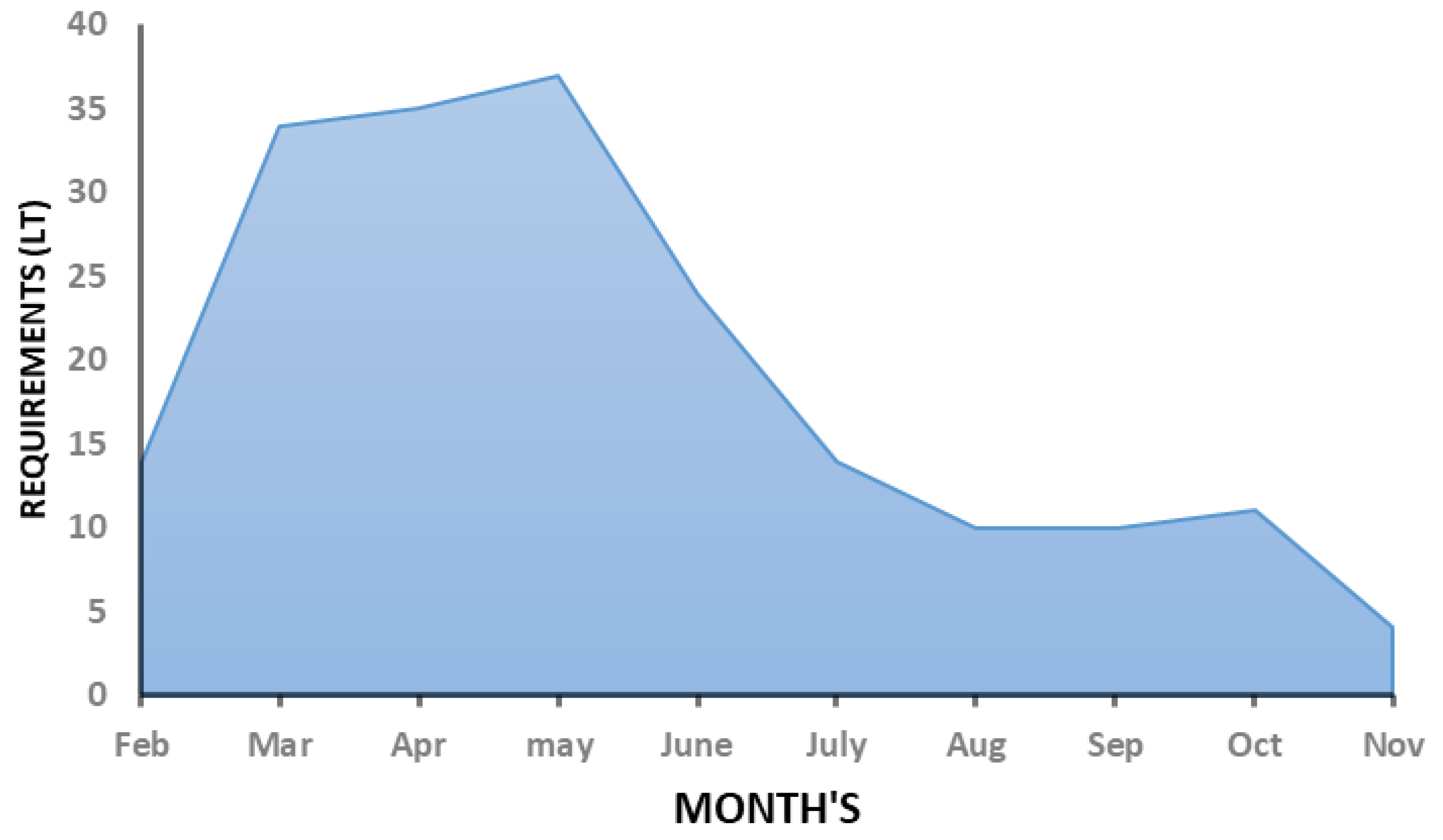

| Months | March/July Dates Interval | 4/2 | 8/6 | 12/10 | 16/15 | 20/18/ | 24/22 | 28/26 | Total Requirements |

|---|---|---|---|---|---|---|---|---|---|

| March | Min (Litres) | 2 | 3 | 3 | 4 | 4 | 3 | 4 | 23 |

| March | Max (Litres) | 3 | 4 | 4 | 5 | 5 | 5 | 5 | 31 |

| July | Min (Litres) | 0 | 1 | 1 | 0 | 2 | 3 | 2 | 9 |

| July | Max (Litres) | 1 | 2 | 2 | 1 | 3 | 4 | 3 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blessy, A.; Kumar, A.; Prabagaran A; Quadir Md, A.; Alharbi, A.I.; Almusharraf, A.; Khan, S.B. Sustainable Irrigation Requirement Prediction Using Internet of Things and Transfer Learning. Sustainability 2023, 15, 8260. https://doi.org/10.3390/su15108260

Blessy A, Kumar A, Prabagaran A, Quadir Md A, Alharbi AI, Almusharraf A, Khan SB. Sustainable Irrigation Requirement Prediction Using Internet of Things and Transfer Learning. Sustainability. 2023; 15(10):8260. https://doi.org/10.3390/su15108260

Chicago/Turabian StyleBlessy, Angelin, Avneesh Kumar, Prabagaran A, Abdul Quadir Md, Abdullah I. Alharbi, Ahlam Almusharraf, and Surbhi B. Khan. 2023. "Sustainable Irrigation Requirement Prediction Using Internet of Things and Transfer Learning" Sustainability 15, no. 10: 8260. https://doi.org/10.3390/su15108260

APA StyleBlessy, A., Kumar, A., Prabagaran A, Quadir Md, A., Alharbi, A. I., Almusharraf, A., & Khan, S. B. (2023). Sustainable Irrigation Requirement Prediction Using Internet of Things and Transfer Learning. Sustainability, 15(10), 8260. https://doi.org/10.3390/su15108260